Abstract

This work aimed to isolate and characterize organisms able to store polyhydroxyalkanoates (PHAs), from a mixed microbial culture (MMC) selected under feast and famine conditions, using hardwood sulfite spent liquor (HSSL), a by-product of the pulp and paper industry, as the carbon source. The MMC was able to accumulate PHA from the different HSSL carbon components (acetic acid, xylose and lignosulfonates) with a PHA storage content during the reactor operation of 54.2 ± 10.6 % PHB. In order to clarify the MMC composition, isolation was performed from the MMC, using HSSL or its main components. Three isolates were identified: Rhodococcus spp., Pseudomonas spp. and Klebsiella spp. All isolates were able to grow and accumulate PHAs in harsh conditions of HSSL using xylose, the second most abundant sugar in nature. Rhodococcus and Pseudomonas isolates were able to accumulate a homopolymer PHB, whereas Klebsiella accumulated the copolymer P(HB-co-HV), with a composition of 96 % HB and 4 % HV. 16S rDNA clonal analysis was performed to identify the unculturable fraction of the MMC, and members of Novosphingobium spp., Sphingobium spp. and Pleomorphomonas spp., were found to be related to PHA production. The capability of the isolated bacteria to simultaneously consume xylose and accumulate PHAs offers a possibility for further studies and routes for the valorization of xylose-rich by-products.

Similar content being viewed by others

Introduction

Polyhydroxyalkanoates (PHAs) are polymers produced biologically, with similar properties to synthetic plastics. PHAs are biodegradable, biocompatible and may be produced from renewable sources, thus offering a solution to the environmental hazards of conventional plastics (Gumel et al. 2013). In the last few years, the interest in polyhydroxyalkanoates production by mixed microbial cultures (MMC), such as activated sludge from wastewater treatment plants, has been growing, since their use does not require sterile conditions, thus saving energy and equipment costs (Serafim et al. 2008; Villano et al. 2010). In this way, overall production costs can be further decreased. The selection of substrate is an important factor to optimize PHAs production since it affects the final cell content, composition and properties of the polymer. Moreover, raw materials can account for 40 % of the total operating costs of PHAs production, and more than 70 % of these costs are related to the carbon source (Reis et al. 2003). Consequently, the use of cheap carbon substrates is attracting considerable interest (Serafim et al. 2008; Akaraonye et al. 2010). Recently, Queirós et al. (2014) successfully selected a MMC, which under feast and famine conditions was able to store PHAs from hardwood sulfite spent liquor (HSSL), a by-product of the pulp and paper industry.

Despite the growing importance of PHAs production by MMCs, numerous researchers have been attempting to isolate PHAs-producing microorganisms from different sources aiming to discover and identify robust and novel species with high storage capacity (Sangkharak and Prasertsan 2012). The isolation of PHAs-accumulating bacteria from activated sludge has been the object of several studies (Liu et al. 2000; Wong et al. 2002; Kourmentza et al. 2009; Reddy and Mohan 2012). The search for strains able to resist and metabolize inhibitory compounds present in sugarcane bagasse hydrolysates was performed by Lopes et al. (2014). Burkholderia sp. F24 reached values of biomass of 25 g L−1, with a content of 49 % polyhydroxybutyrate (PHB) in 44 h, corresponding to a volumetric productivity of 0.28 g L−1 h−1 (Lopes et al. 2014).

Therefore, the present paper aims to study the microbial population selected by Queirós et al. (2014) in order to improve the use of HSSL as a substrate in the biorefinery concept. The isolation and characterization of organisms from the MMC was performed to obtain PHAs-accumulating bacteria able to grow under harsh conditions brought by complex substrates, such as HSSL, and to use xylose as carbon source. Additionally, a 16S rRNA gene clonal analysis was carried out in order to identify the uncultivable PHAs-accumulating bacteria present in the MMC.

Materials and methods

Culture

Microorganisms isolated in this work were obtained from a PHAs-storing MMC selected in a sequencing batch reactor (SBR) under aerobic dynamic feeding (ADF) with HSSL as substrate. The operation of SBR was described by Queirós et al. (2014); however, it was not fully optimized, showing evidence of a more stable behavior by the end of the operation. Briefly, the SBR was inoculated with activated sludge obtained from the aerobic tank of the municipal wastewater treatment plant, Aveiro Norte (SIMRia). The SBR, with a working volume of 1.5 L, was operated under ADF conditions, during which alternating feast and famine phases were imposed. The SBR worked in cycles of 12 h that comprised 10.5 h of aerobiosis, with fresh medium supplied during the first 15 min, 1 h of settling (with agitation and aeration switched off) and 0.5 h of withdrawing. The hydraulic retention time (HRT) and sludge retention time (SRT) were 1 and 5 days, respectively.

Culture medium

HSSL was supplied by Caima–Indústria de Celulose (Constância, Portugal) and was obtained from a magnesium-based acidic sulfite pulping of Eucalyptus globulus and pre-treated as previously described (Xavier et al. 2010; Queirós et al. 2014. The HSSL composition was fully characterized by Marques et al. (2009).

Two different culture media were used to isolate the different microorganisms responsible for the uptake of different substrates. The first culture medium had the same composition of the one fed to the selected MMC in the SBR: pre-treated HSSL and mineral solution (Queirós et al. 2014). The second one consisted of synthetic mineral, salts and vitamins medium (MSV), prepared with the major carbon sources [sodium acetate (CH3COONa) – 0.172 g L−1 and xylose (C5H10O5) – 0.360 g L−1] present in HSSL (Table 1). The MSV medium was also composed by (per liter of MilliQ water): 85 mg KH2PO4, 110 mg K2HPO4, 100 mg MgSO4°7H2O, 80 mg CaCl2°2H2O, 2 mg FeCl3∙H2O, 3 mg Na∙EDTA and 500 mg (NH4)2SO4. An amount of 1 mL L−1 of vitamin solution, composed by (per liter of MilliQ water): 20 mg Biotin, 20 mg Folic acid, 100 mg Pyridoxine, 50 mg Thiamine, 50 mg Riboflavin, 50 mg Nicotinic acid, 50 mg Pantothenic acid, 2 mg Vitamin B12, and 50 mg 4-Aminobenzoic acid, was added to the growth medium. Agar was used to a concentration of 15 g L−1.

Bacterial isolation

In order to isolate PHAs-accumulating bacteria from the selected MMC, solid culture medium was prepared, for each media described above. Despite SBR being operated without temperature control, the temperature remained around 20 °C. Therefore, a volume of 50 μL of MMC were spread onto agar growth medium and incubated at 20 °C for 48 h. Pure cultures of PHAs-storing bacteria were isolated after repeated streaking of isolated colonies. The PHAs-accumulating capacity of the isolates was evaluated through their inoculation on 50-mL Erlenmeyer flasks with culture medium of 0.5 g L−1 of acetic acid or xylose, at 20 °C for 48 h followed by Nile blue staining of samples.

Kinetic tests

A 400-mL Erlenmeyer flask was inoculated with 50 mL of actively growing cells on culture medium plus the carbon source with the same concentration as in SBR feeding: 0.172 g L−1 of sodium acetate or 0.360 g L−1 of xylose. Kinetic tests were performed at 20 °C, 90 rpm for 24 h, in triplicate. Samples were taken during tests to evaluate the culture growth and substrate consumption through chemical oxygen demand (COD) analysis. Nile blue staining procedure was performed in order to evaluate PHAs accumulation.

Microscopic visualizations

Gram-staining was performed according to the procedure described by Jenkins et al. (1986). Nile blue staining was applied to fresh samples collected as described by Rees et al. (1992), with the goal of monitoring the PHAs accumulating capacity of the isolates during the incubations.

Fluorescence in situ hybridization (FISH) was performed on paraformaldehyde-fixed biomass samples (Amann et al. 1995). Several oligonucleotide probes were applied. All the hybridizations with group-specific probes were carried out simultaneously with probes EUB338, EUB338-II and EUB338-III combined in a mixture (EUB338mix) for the detection of most bacteria, and with DAPI staining for quantifying the total number of cells. All the probes were synthesized with 50-FITC and -Cy3 labels and purchased from MWG Biotech (Germany). Samples were visualized using an epifluorescence microscope, Olympus BX51, equipped with an Olympus XM10 camera (Cell-F software).

Analytical methods

Overall substrate consumption was determined based on COD evolution, using Spectroquant® photometric kit (Merck), according to the manufacturer’s instructions.

The amount of biomass was accounted as cell dry weight. A sample of 50 mL was filtered using previously dried and weighed membranes (cellulose acetate filter, 0.2 μm pore size; Sartorius). Then, the membranes were placed in an oven at 105 °C for 72 h. After cooling and weighing, the biomass concentration was determined in g L−1 of suspended solids (SS).

PHA concentration was determined by gas chromatography following the method described by Lemos et al. (2006).

Genomic DNA extraction and PCR amplification of 16S rRNA gene

DNA was extracted from 2 mL of the MMC sample following the protocol reported in Rossetti et al. (2003). The concentration and purity of the genomic DNA were determined by NanoDrop 2000c spectrophotometer (Thermo Scientific, USA).

16S rRNA genes of the isolates and genomic DNA were amplified using primers 27 F and 1492R for the Bacteria domain using the TaKaRa Ex TaqTM kit (Japan) as previously described (Rossetti et al. 2003). T7f and U19r (or M13r), which are specific plasmid primers, were used for the screening of clones from the 16S rDNA clone library (Table 2). PCR products were purified using the QIAquick® PCR purification kit (Qiagen, Milan, Italy). 16S rRNA gene sequences of the clone inserts were obtained using the following primers: 530f, 926f, 907r and 519r (Table 2).

Cloning of 16S rRNA gene

Cloning of PCR products was carried out using pGEM-T Easy Vector System (Promega, USA) into Escherichia coli JM109 competent cells (Promega) according to the manufacturer’s instructions. Positive inserts were amplified from recombinant plasmids obtained from white colonies by PCR using the sequencing primers T7f and M13r following the PCR protocol previously described.

Nucleotide sequences accession numbers

The nucleotide sequences identified in this study were deposited in the GenBank database under accession numbers KM873626, KM873627 and KM873628, for the isolates AF1, AF2 and DS1, respectively. For the clones FA1, FA2, FA3, FA4, FA5 and FA6, the accession numbers were KM873629, KM873630, KM873631, KM873632, KM873633 and KM873634, respectively.

Results and discussion

SBR operation

The MMC used in this study was selected by operating a SBR under ADF conditions with HSSL as substrate, with an organic loading rate (OLR) of 4.2 g COD L−1 day−1, during 67 days without any interruptions. The SBR was inoculated with activated sludge obtained from the aerobic tank of the municipal wastewater treatment plant, Aveiro Norte (SIMRia). The SBR worked in cycles of 12 h, with a hydraulic retention time (HRT) of 1 day and a sludge retention time (SRT) of 5 days (Queirós et al. 2014). Queirós et al. (2014) described the SBR operation in more detail and the evolution of the microbial community. They observed that Alphaproteobacteria was clearly the dominant class (Fig. 1) at the end of the reactor operation, when the SBR reached a pseudo-steady state. This observation was based on the stabilization of polymer accumulation in the last 20 days of operation, 53.25 ± 3.25 % PHA. For the same period, a stable microbial populations was observed with minor fluctuations of Alphaproteobacteria, 75.33 ± 2.44 % of the total bacteria. To a minor extent, cells belonging to Betaproteobacteria and Gammaproteobacteria were also detected by FISH analysis. The MMC showed a quite high PHA storage capacity with an average value of storage content of 54.2 ± 10.6 % PHB (Queirós et al. 2014). Hence, the isolation of microorganisms able to consume xylose, accumulate PHA and survive in such harsh conditions was important to understand the community dynamics and establish a starting point to a possible process of PHA production. As xylose is the second most abundant sugar in nature, it is important to indicate microorganisms able to convert it into other value-added products. Moreover, with the increasing research in using lignocellulosic biomass as substrate for several biological processes, those microorganisms are gaining importance.

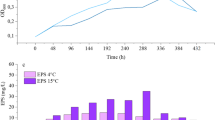

During the SBR cycles, the concentrations of main carbon sources of HSSL decreased along with ammonium. The MMC revealed a preference towards acetic acid, being completely consumed after 4 h of reaction at a rate of 0.110 g L−1 h−1. The ammonium uptake rate was faster before the acetic acid exhaustion, 0.177 g L−1 h−1 decreasing to 0.074 g L−1 h−1. Xylose was consumed along with acetic acid but at a slower rate, around 0.030 g L−1 h−1, but never depleted, remaining around 70 % at the end of each cycle. Concerning the lignosulfonates, there was not a clear tendency in any of the cycles, but it was consumed at a rate of 0.098 g L−1 h−1 (Queirós et al. 2014). Figure 2 shows an example of an SBR cycle, in which the accumulation reached 19.5 %, with an YPHA/S of 0.44 g PHA g substrate−1 (S). Considering only acetic acid as the main precursor for PHA production, the YPHA/Acet increased to 1.04, suggesting that this substrate was not the only one involved in PHA accumulation. This was confirmed by Queirós et al. (2014) during batch tests with acetic acid and xylose fed separately. In these tests, the MCC was able to accumulate PHA from both carbon sources, reaching storage contents of 63.4 and 31.5 %, respectively (Queirós et al. 2014).

Characterization of the isolates and PHAs storage

The isolation attempts of PHAs-accumulating bacteria able to survive in harsh conditions were first performed on solid medium containing the same composition of that supplied to the SBR. From two different Petri dishes inoculated with the MMC, five isolated colonies from around 150 grown were selected randomly, continuously streaked onto solid medium and named AF1 to AF5. Additionally, synthetic mineral medium, MSV, containing sodium acetate or xylose, the main carbon components of HSSL, was tested. Colonies only grew with xylose as the sole carbon source. After several replating cycles, a pure culture was obtained, and called DS1.

Partial sequencing of 16S rRNA genes of AF1 and AF3 isolates showed 100 % similarity with Rhodococcus spp. while isolates AF2, AF4 and AF5 had 100 % similarity with Pseudomonas spp. The complete sequencing of each representative of isolates belonging to Rhodococcus spp. (AF1) and to Pseudomonas spp. (AF2) was performed, and hereafter experiments were performed only using AF1 and AF2 isolates. Near-full-length 16S rRNA gene sequence of AF1 showed that this isolate was closely related to Rhodococcus qingshengii strain djl-6, with 100 % of sequence similarity (Xu et al. 2007). The AF2 isolate had 99 % sequence similarity to Pseudomonas libanensis strain CIP 105460 (Dabboussi et al. 1999). The complete sequencing of 16S rRNA genes of DS1 isolate allowed for its identification as Klebsiella spp., sharing 99 % similarity with an uncultured Klebsiella sp. clone JXS1-28 (Peng et al. 2012).

The PHAs accumulating ability of the isolates was evaluated after their inoculation on mineral base medium with sodium acetate at a concentration of 0.5 g L−1 followed by Nile blue staining of samples. This specific staining for PHAs inclusions confirmed that the isolates were PHAs-accumulating bacteria. The presence of inclusion bodies of PHAs was easily observed by the presence of bright dots in the cells after the Nile blue staining procedure under epifluorescence microscopy (Fig. 3).

Kinetic tests were performed in order to characterize isolates AF1, AF2 and DS1 and evaluate growth on different carbon sources and PHAs-accumulating behavior, namely on HSSL and xylose, the main component of HSSL and a carbon source with limited use among microorganisms (Lopes et al. 2009). The results of the kinetic parameters obtained are summarized in Table 3. Growth and substrate consumption in the three different media, for AF1and AF2, are shown in Figs. 4 and 5, respectively. Diversely from isolates AF1 and AF2, acetate did not sustain the growth of DS1, which only grew on xylose as sole carbon source (Fig. 6). Members of Klebsiella were described as able to grow on xylose and to store PHAs and are often found in activated sludge systems (Lopes et al. 2009).

Isolate AF1 showed a preference for medium containing HSSL or xylose, since it began to grow right after inoculation with an undetectable lag phase in both media. With acetic acid as sole carbon source, the isolate presented a lag phase of around 2 h. A higher biomass concentration, of 0.510 ± 0.0966 g VSS L−1, was obtained in the assay with HSSL (Fig. 4). This value was 6 times higher than the biomass concentration obtained using xylose as sole carbon source, 0.0867 ± 0.0538 g VSS L−1, and 17 times higher than using acetic acid, 0.0308 ± 0.00247 g VSS L−1. One reason for the differences observed in biomass amount may be the lower concentration of substrate in media with acetic acid and xylose, since the amount of carbon sources were determined in order to be approximately the same as in HSSL but other carbon compounds are missing; sugars like mannose, galactose, arabinose and phenolic components such as pyrogallol and galic acids that could be metabolized by the organisms. However, xylose and acetic acid were still present at the end of the kinetic tests, with acetic acid at much lower concentration (0.0467 g COD L−1) than xylose (0.124 g COD L−1), with cells already in the death phase, showing that other nutrients besides carbon were missing. The lack of other components present in HSSL needed for microbial growth could be supported by the value of specific growth rate of isolate AF1 when grown in liquid medium with HSSL, 0.212 ± 0.0219 h−1, which was the highest showed by this isolate. With acetic acid as sole carbon source, AF1 presented a maximum growth rate (μmax) of 0.153 ± 0.0252 h−1 and in xylose a μmax of 0.188 ± 0.0238 h−1. Growth and PHAs accumulation by Rhodococcus strains using acetate as carbon source has already been reported, but the authors only quantified PHAs accumulation content and monomeric composition, without information about growth (Haywood et al. 1990; Hori et al. 2009). However, the effect of acetate concentration on cell growth of a Rhodococcus strain, R. rhodochrous, has been previously discussed (Honda et al. 1998). According to Honda et al. (1998), cell growth was significantly inhibited at concentrations of acetate above 3 g L−1. Below 2.5 g L−1, the growth rate was in a range of 0.15 to 0.16 h−1, which confirmed the results obtained with isolate AF1. The fact that AF1 was able to metabolize xylose was a very interesting finding, since no reports on utilization of this sugar by wild-type strains belonging to genus Rhodococcus have thus far been found.

Isolate AF2 identified as Pseudomonas sp. showed a similar behavior to AF1, since it also grew in the three media, obtaining higher biomass concentrations when grown in HSSL. However, the biomass concentrations obtained were lower than those obtained with AF1. In HSSL, the biomass concentration obtained for AF2, 0.174 ± 0.0297 g VSS L−1, was three times lower than for AF1 in the same medium. The biomass concentration achieved in HSSL was about three times higher than in the assays using acetic acid or xylose as sole carbon sources, which were 0.0536 ± 0.0121 g VSS L−1 and 0.0642 ± 0.0124 g VSS L−1, respectively. Table 3 shows the preference of both isolates for growing in medium with HSSL: a higher μmax in the essays with HSSL, 0.212 ± 0.0219 h−1 and 0.251 ± 0.0526 h−1, and yield biomass on substrate (Y(X/S)), 0.454 g X g S−1 and 0.747 g X g S−1, were obtained by AF1 and AF2, respectively. On the other hand, AF1 (Rhodococcus spp.) showed a preference in consuming xylose and AF2 (Pseudomonas spp.) in acetic acid, as they presented a higher specific substrate consumption rates (qs) of 0.572 g COD g VSS−1 h−1 and 0.430 g COD g VSS−1 h−1, respectively, compared to those with the two other substrates. In future studies, quantification of other components of HSSL over time should be performed for a better understanding of the growth and consumption behavior of both isolates.

A qualitative evaluation of the PHAs-accumulating capability of isolates, AF1 and AF2 in liquid medium with three different carbon sources analyzed (HSSL, acetic acid and xylose) was performed (Figs. 4, 5). Samples taken during the kinetics tests were observed under phase contrast and after Nile blue staining. PHAs accumulation by AF1 and AF2 increased during the incubation period reaching a maximum at the late exponential stage of the growth curve. For both isolates, in HSSL and xylose assays, intracellular PHAs inclusions were clearly observed. In acetic acid assay, cells were completely fluorescent, which meant that they were completely full of PHAs. As PHAs accumulation increased and reached the maximum PHAs content, some cells of AF1 and AF2 were completely fluorescent in all tests. Nevertheless, the fluorescence intensity was always higher in assays with acetic acid, meaning that cells of isolates AF1 and AF2 were completely full of PHAs. This finding was somehow expected when acetic acid was the substrate, since volatile fatty acids are the preferred substrates by MMCs for PHAs production (Gumel et al. 2013). In addition, in assays with HSSL, a higher intensity of fluorescence was clearly observed for AF1 than for AF2, which indicates a higher content of PHAs produced by the former. Regarding DS1, this isolate was grown on xylose (Fig. 6). This isolate was also able to produce PHAs and the increase of inclusion bodies during the growth was clearly observed by Nile blue staining.

The identification of PHAs accumulated was performed by GC analysis. The results showed that isolates AF1 and AF2 accumulated a homopolymer PHB, and DS1 accumulated a copolymer poly(hydroxybutyrate-co-hydroxyvalerate) [P(HB-co-HV)], with 4 % of HV. A large number of different hydroxy-fatty acids may be converted into polymers, but only if suitable carbon sources are provided as precursor substrates. Some substrates lead to monomer formation of equal carbon chain length. This behavior could explain the copolymer accumulation of the isolate DS1 from an unrelated carbon source as xylose. Starting from related substrates, the synthesis pathway is closely connected to the fatty-acid β-oxidation cycle (Babel et al. 2001). In some bacteria, the copolymers P(HB-co-HV) are synthesized from sugars by methyl-malonyl-CoA. Succinyl-CoA is decarboxylated via methyl-malonyl-CoA to propionyl-CoA as the precursor of 3-hydroxyvaleryl-CoA (Valentin and Dennis 1996).

The isolation of AF1, AF2 and DS1 can contribute to the development of bioprocesses using xylose as substrate. This sugar is the second most abundant in nature, especially in vegetable biomass, but only a few papers have focused on its valorization and even fewer when it comes to PHA production. As xylose is one of the most abundant sugars in nature, it is important to find microorganisms with the capacity to metabolize it and, consequently, convert it into products of interest.

16S rRNA gene clonal analysis

In order to identify the unculturable bacteria responsible for PHAs accumulation of the MMC, a 16S rRNA gene clonal analysis was performed on DNA extracted from the selected MMC. A total of 31 clones were obtained and 26 identified. Clones were closely related to nine different genera: Achromobacter spp., Comamonas spp., Clostridium spp., Methylobacillus spp., Novosphingobium spp., Pedobacter spp., Pleomorphomonas spp., Pseudomonas spp. and Sphingobium spp. (Table 4; Fig. 7). Some of the species highlighted by the clonal analysis have been reported as PHAs-accumulating bacteria and have been previously identified or isolated from activated sludge samples, such as Clostridium spp. (Emeruwa and Hawirko 1973), Comamonas spp. (Zakaria et al. 2010), Novosphingobium spp. (Addison et al. 2007), Pleomorphomonas spp. (Xie and Yokota 2005) and Sphingobium spp. (Liang and Lloyd-Jones 2010). Dai et al. (2015) also investigated the microbial community evolution when fed with poplar hydrolysates. They also observed enrichments in Alpha- and Betaproteobacteria and identified these classes as mainly responsible for PHB accumulation and suggested further isolation of microorganisms to use wood hydrolysates as substrate for PHA production.

Phylogenetic tree based on full-length nucleotide sequences of 16SrRNA gene of isolate AF1, AF2 and DS1 and clones FA1, FA2, FA3, FA4, FA5 and FA6 (in the tree preceded by a filled dot). The evolutionary history was inferred using the Neighbor-Joining method. Evolutionary analyses were conducted in MEGA6

Nearly all the identified bacteria belonging to the acclimatized MMC, both from isolation attempts and the 16S rRNA gene clonal analysis, were consistent with the findings of Queirós et al. (2014) after characterization, by FISH, of the acclimatized MMC. Alphaproteobacteria was the dominant group of the MMC, accounting for 72.7 ± 4.0 % of total bacteria, followed by Betaproteobacteria, 11.1 ± 0.37 % and Gammaproteobacteria, 10.3 ± 0.3 %. A minor presence of Deltaproteobacteria, Actinobacteria and Bacteroides was also detected (Queirós et al. 2014). Nevertheless, a complete characterization of all genera selected in the MMC for an optimum design and modeling of the bioreactor is necessary (Dai et al. 2015). This will allow maximum accumulation and productivity by the MMC.

Conclusion

Isolates belonging to four of the six groups of the microbial community identified previously were isolated and characterized. It was possible to successfully isolate Rhodococcus spp., Pseudomonas spp. and Klebsiella spp. The isolates were able to both grow and accumulate PHAs despite the harsh conditions brought about by complex substrates, such as HSSL, as well as to use xylose as the carbon source. Moreover, from the clonal analysis, the identification of Novosphingobium spp., Sphingobium spp. and Pleomorphomonas spp. were possible, they having been previously found to be related to PHA production.

This work constitutes a step forward towards the identification of the microorganisms responsible for the accumulation of PHAs in the MMC, and, consequently, to the valorization of HSSL as a complex substrate for biological processes. The isolation of microbial strains able to use xylose, the second most abundant sugar in nature, for PHAs production could be an important advance leading for the valorization of raw materials resulting from the bioprocessing of vegetable biomass.

References

Addison SL, Foote SM, Reid NM, Lloyd-Jones G (2007) Novosphingobium nitrogenifigens sp. nov., a polyhydroxyalkanoate-accumulating diazotroph isolated from a New Zealand pulp and paper wastewater. Int J Syst Evol Microbiol 57:2467–2471. doi:10.1099/ijs.0.64627-0

Akaraonye E, Keshavarz T, Roy I (2010) Production of polyhydroxyalkanoates: the future green materials of choice. J Chem Technol Biotechnol 85:732–743. doi:10.1002/jctb.2392

Amann RI, Ludwig W, Schleifer KH (1995) Phylogenetic identification and in situ detection of individual microbial cells without cultivation. Microbiol Rev 59:143–169

Babel W, Ackermann JU, Breuer U (2001) Physiology, regulation, and limits of the synthesis of poly(3HB). Adv Biochem Eng Biotechnol 71:125–157. doi:10.1007/3-540-40021-4_4

Dabboussi F, Hamze M, Elomari M, Verhille S, Baida N, Izard D, Leclerc H (1999) Pseudomonas libanensis sp. nov., a new specie isolated from Lebanese spring waters. Int J Syst Bacteriol 49:1091–1101. doi:10.1099/00207713-49-3-1091

Dai J, Gliniewicz K, Settles ML, Coats ER, McDonald AG (2015) Influence of organic loading rate and solid retention time on polyhydroxybutyrate production from hybrid poplar hydrolysates using mixed microbial cultures. Bioresour Technol 175:23–33. doi:10.1016/j.biortech.2014.10.049

Emeruwa AC, Hawirko RZ (1973) Poly-β-Hydroxybutyrate metabolism during growth and sporulation of Clostridium botulinum. J Bacteriol 116:989–993

Gumel AM, Annuar MSM, Chisti Y (2013) Recent advances in the production, recovery and applications of polyhydroxyalkanoates. J Polym Environ 21:580–605. doi:10.1007/s10924-012-0527-1

Haywood GW, Anderson AJ, Ewing DF, Dawes EA (1990) Accumulation of a polyhydroxyalkanoate containing primarily 3-Hydroxydecanoate from simple carbohydrate substrates by Pseudomonas sp. Strain NCIMB 40135. Appl Environ Microbiol 56:3354–3359

Honda H, Sugiyama H, Saito I, Kobayashi T (1998) High cell density culture of Rhodococcus rhodochrous by pH-stat feeding and dibenzothiophene degradation. J Ferment Bioeng 85:334–338. doi:10.1016/S0922-338X(97)85685-1

Hori K, Kobayashi A, Ikeda H, Unno H (2009) Rhodococcus aetherivorans IAR1, a new bacterial strain synthesizing poly(3-hydroxybutyrate-co-3-hydroxyvalerate) from toluene. J Biosci Bioeng 107:145–150. doi:10.1016/j.jbiosc.2008.10.005

Jenkins D, Richard MG, Daigger GT (1986) Manual on the causes and control of activated sludge bulking and foaming. Ridgeline, Lafayette

Kourmentza C, Ntaikou I, Kornaros M, Lyberatos G (2009) Production of PHAs from mixed and pure cultures of Pseudomonas sp. using short-chain fatty acids as carbon source under nitrogen limitation. Desalination 248:723–732. doi:10.1016/j.desal.2009.01.010

Lemos PC, Serafim LS, Reis MAM (2006) Synthesis of polyhydroxyalkanoates from different short-chain fatty acids by mixed cultures submitted to aerobic dynamic feeding. J Biotechnol 122:226–238. doi:10.1016/j.jbiotec.2005.09.006

Liang Q, Lloyd-Jones G (2010) Sphingobium scionense sp. nov., an aromatic hydrocarbon-degrading bacterium isolated from contaminated sawmill soil. Int J Syst Evol Microbiol 60:413–416. doi:10.1099/ijs.0.008144-0

Liu W-T, Mino T, Matsuo T, Nakamura K (2000) Isolation, characterization and identification of polyhydroxyalkanoate-accumulating bacteria from activated sludge. J Biosci Bioeng 90:494–500. doi:10.1016/S1389-1723(01)80029-3

Lopes M, Rocha R, Zanotto S, Gomez J, da Silva L (2009) Screening of bacteria to produce polyhydroxyalkanoates from xylose. World J Microbiol Biotechnol 25:1751–1756. doi:10.1007/s11274-009-0072-9

Lopes M, Gomez J, Taciro M, Mendoça T, Silva L (2014) Polyhydroxyalkanoate biosynthesis and simultaneous remotion of organic inhibitors from sugarcane bagasse hydrolysate by Burkholderia sp. J Ind Microbiol Biotechnol 41:1353–1363. doi:10.1007/s10295-014-1485-5

Marques AP, Evtuguin DV, Magina S, Amado FML, Prates A (2009) Chemical composition of spent liquors from acidic magnesium-based sulphite pulping of Eucalyptus globulus. J Wood Chem Technol 29:322–336. doi:10.1080/02773810903207754

Peng X, Zhang Z, Zhao Z, Jia X (2012) 16S ribosomal DNA clone libraries to reveal bacterial diversity in anaerobic reactor-degraded tetrabromobisphenol A. Bioresour Technol 112:75–82. doi:10.1016/j.biortech.2012.02.060

Queirós D, Rossetti S, Serafim LS (2014) PHA production by mixed cultures: a way to valorize wastes from pulp industry. Bioresour Technol 157:197–205. doi:10.1016/j.biortech.2014.01.099

Reddy MV, Mohan SV (2012) Effect of substrate load and nutrients concentration on the polyhydroxyalkanoates (PHA) production using mixed consortia through wastewater treatment. Bioresour Technol 114:573–582. doi:10.1016/j.biortech.2012.02.127

Rees GN, Vasiliadis G, May JW, Bayly RC (1992) Differentiation of polyphosphate and poly-β-hydroxybutyrate granules in an Acinetobacter sp. isolated from activated sludge. FEMS Microbiol Lett 94:171–173. doi:10.1111/j.1574-6968.1992.tb05309.x

Reis MAM, Serafim LS, Lemos PC, Ramos AM, Aguiar FR, van Loosdrecht MCM (2003) Production of polyhydroxyalkanoates by mixed microbial cultures. Bioprocess Biosyst Eng 25:377–385. doi:10.1007/s00449-003-0322-4

Rossetti S, Blackall LL, Majone M, Hugenholtz P, Plumb JJ, Tandoi V (2003) Kinetic and phylogenetic characterization of an anaerobic dechlorinating microbial community. Microbiology 149:459–469. doi:10.1099/mic.0.26018-0

Sangkharak K, Prasertsan P (2012) Screening and identification of polyhydroxyalkanoates producing bacteria and biochemical characterization of their possible application. J Gen Appl Microbiol 58:173–182. doi:10.2323/jgam.58.173

Serafim L, Lemos P, Albuquerque ME, Reis MM (2008) Strategies for PHA production by mixed cultures and renewable waste materials. Appl Microbiol Biotechnol 81:615–628. doi:10.1007/s00253-008-1757-y

Valentin HE, Dennis D (1996) Metabolic pathway for poly(3-hydroxybutyrate-co-3-hydroxyvalerate) formation in Nocardia corallina: Inactivation of mutB by chromosomal integration of a kanamycin resistance gene. Appl Environ Microbiol 62:372–379

Villano M, Beccari M, Dionisi D, Lampis S, Miccheli A, Vallini G, Majone M (2010) Effect of pH on the production of bacterial polyhydroxyalkanoates by mixed cultures enriched under periodic feeding. Process Biochem 45:714–723. doi:10.1016/j.procbio.2010.01.008

Wong PL, Chua H, Lo W, Lawford H, Yu P (2002) Production of specific copolymers of polyhydroxyalkanoates from industrial waste. Appl Biochem Biotechnol 98–100:655–662. doi:10.1385/ABAB:98-100:1-9:655

Xavier AMRB, Correia MF, Pereira SR, Evtuguin DV (2010) Second-generation bioethanol from eucalypt sulphite spent liquor. Bioresour Technol 101:2755–2761. doi:10.1016/j.biortech.2009.11.092

Xie CH, Yokota A (2005) Pleomorphomonas oryzae gen. nov., sp. nov., a nitrogen-fixing bacterium isolated from paddy soil of Oryza sativa. Int J Syst Evol Microbiol 55:1233–1237. doi:10.1099/ijs.0.63406-0

Xu JL, He J, Wang ZC, Wang K, Li WJ, Tang SK, Li SP (2007) Rhodococcus qingshengii sp. nov., a carbendazim-degrading bacterium. Int J Syst Evol Microbiol 57:2754–2757. doi:10.1099/ijs.0.65095-0

Zakaria MR, Ariffin H, Johar NAM, Abd-Aziz S, Nishida H, Shirai Y, Hassan MA (2010) Biosynthesis and characterization of poly(3-hydroxybutyrate-co-3-hydroxyvalerate) copolymer from wild-type Comamonas sp. EB172. Polym Degrad Stab 95:1382–1386. doi:10.1016/j.polymdegradstab.2010.01.020

Acknowledgments

This work was developed within the scope of the project CICECO-Aveiro Institute of Materials (Ref. FCT UID /CTM /50011/2013), financed by national funds through the FCT/MEC and when appropriate co-financed by FEDER under the PT2020 Partnership Agreement. Diogo Queirós thanks FCT for his PhD grant (SFRH/BD/87758/2012).

Authors’ Contributions

AMF participated in the design of the study, performed the experimental work and wrote the manuscript. DQ was responsible for the isolation of DS1 and its identification and kinetic tests. DQ was also responsible for phylogenetic tree construction and interpretation and the writing of the manuscript. MCG provided technical and scientific guidance. LSS and SR conceived the idea, were part of the design of the study and provided scientific guidance and constructive feedback during the draft of the manuscript. All authors read and approved the final manuscript.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Ferreira, A.M., Queirós, D., Gagliano, M.C. et al. Polyhydroxyalkanoates-accumulating bacteria isolated from activated sludge acclimatized to hardwood sulphite spent liquor. Ann Microbiol 66, 833–842 (2016). https://doi.org/10.1007/s13213-015-1169-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13213-015-1169-z