Abstract

A bacterium Stenotrophomonas sp. TRMK2 capable of utilizing cinnamic acid was isolated from agro-industrial waste by enrichment culture technique. This strain completely utilizes 5 mM cinnamic acid within 18 h of incubation. The different metabolites formed during the degradation of cinnamic acid were characterized by GC-HRMS. The involvement of various enzymes, namely cinnamate reductase, 3-phenylpropionic acid hydroxylase, p-hydroxybenzoic acid hydroxylase and protocatechuate 3,4-dioxygenase in cinnamic acid degradation was demonstrated. A catabolic pathway for cinnamic acid in Stenotrophomonas sp. TRMK2 is as follows: Cinnamic acid; 3-Phenylpropionic acid; 3-(4-Hydroxyphenyl) propionic acid; 4-Hydroxy benzoic acid and Protocatechuic acid. Further, this strain is capable of utilizing various phenolic compounds.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Aromatic compounds are abundant within the biosphere as naturally occurring and man-made ecological contaminants. Various types of pesticides, insecticides, herbicides and aromatic compounds are the contaminants, many of which are recalcitrant, toxic and accumulate in sediments. These compounds are phenolic derivatives of a general phenylpropane or benzyl structure (Sleat and Robinson 1984). At certain level of concentrations, phenolic compounds contribute toxicity to the respective aquatic or soil systems unless they are transformed or removed accordingly. Industrial effluents that contain a significant phenolic fraction include those from olive oil mills, wine distilleries and paper-pulping mills (Andreozzi et al. 1995; Di Gioia et al. 2001; Isidori et al. 2004). Cinnamic acid and its derivatives are very well known as allelochemicals. These are released into the environment in considerable amount through root exudation, leaching, decomposition of plant materials and accumulated in many agricultural fields (Ding et al. 2007; Singh et al. 2013). The presence of phenolic allelochemicals in soil is an important factor for crop decline in terms of growth, yield and quality leading to tremendous agricultural losses (Chen et al. 2011a, b). Toxicity of phenolic compounds for microorganisms is largely an issue of concentration, where large amounts of aromatics can accumulate in and disrupt cell membranes (Díaz et al. 2001). The presence of caffeic, coumaric, ferulic, or vanillic acids at concentration of above 0.1 mM affects nitrogen-fixing bacteria and also inhibits the ruminal bacterial growth at concentration of above 1 mM (Hartley and Whitehead 1985; Akin et al. 1993). Phenolic allelochemicals are utilized by many microorganisms as energy sources, detoxify or mineralize these compounds and catalyse their oxidation and polymerization reactions (Chen et al. 2011a; Zhang et al. 2010).

Phenylpropionoid compounds (cinnamic, phenylpropionic, p-coumaric and ferulic acids) are derived from the degradation of lignin and other aromatic constituents of plants (Subba Rao et al. 1971; Kawakami 1980). Bacterial catabolism of these compounds is an important element in the carbon cycle by which both natural aromatics and many industrial pollutants are degraded. As early as 1959, Coulson and Evans (1959) reported the reduction of the cinnamic acid side chain in Pseudomonas. Such reduction of the double bond in the side chain of cinnamic acid, p-hydroxycinnamic acid and 3,4-dihydroxycinnamic acid was also observed in Lactobacillus pastorianus subsp. quinicus (Whiting and Carr 1959). Blakley and Simpson (1964) suggested that the whole cells of a Pseudomonas sp. metabolised cinnamic acid to 2,3-dihydroxyphenylpropionic acid via phenylpropionic acid and m-hydroxyphenylpropionic acid based on the principle of sequential induction. Dagley et al. (1965) showed the appearance of 2-hydroxy 3-phenylpropionate and 2,3-dihydroxy 3-phenylpropionate in the growth medium when Achrobacter species was grown on phenylpropionate as a carbon source.

In the present investigation, cinnamic acid degrading bacterium was isolated from agro-industrial waste and a degradation pathway for cinnamic acid in Stenotrophomonas sp. TRMK2 has been proposed. Further, the utilization of various phenolic compounds by the isolated strain has been demonstrated.

Materials and methods

Isolation, media and growth conditions

Selective enrichment technique was opted for the isolation of a bacterium capable of utilizing cinnamic acid as the only source of carbon and energy. Media and growth conditions for isolation of the microorganism was carried out according to Monisha et al. (2017), where cinnamic acid was supplied as a sole source of carbon and energy. The purity of the culture was checked by plating on Luria–Bertani (LB) agar plate.

16S rDNA sequencing

The 16S rDNA of the strain TRMK2 was isolated and amplified by PCR using the universal primer pair F27, 5′-AGAGTTTGATCMTGGCTCAG-3′ and R1492 5′-TACGGYTACCTTGTTACGACTT-3′ (Lane 1991). The sequence analysis was then performed by BLAST network services at NCBI.

Utilization of cinnamic acid

Utilization of cinnamic acid was performed by inoculating Stenotrophomonas sp. TRMK2 into 50 ml MS1 medium supplemented with 5 and 10 mM cinnamic acid into 250 ml flasks. The flasks were incubated in a temperature-controlled orbital shaker at 180 rpm and 30 °C. The utilization of cinnamic acid was monitored by determining the residual cinnamic acid at different time intervals. At regular time intervals, the culture broth was centrifuged and the resulting supernatant was filtered. The residual concentration of cinnamic acid in the spent medium was determined by HPLC.

Cinnamic acid % utilization, ή at different periods of incubation was defined by the following expression:

where S0 denotes initial concentration of cinnamic acid (%) prior to utilization, and S1 denotes residual concentration (%) after the utilization.

Extraction and analysis of metabolites

The extraction of metabolites was carried out as described previously (Monisha et al. 2017). The extract was treated with N-methyl-N-trimethylsilyl-trifluoroacetamide (MSTFA) for the preparation of TMS derivatives. The method involves the addition of 50 µl of MSTFA to 200 µl of metabolite extract in a small reaction vial with a constant agitation for 12 h at 30 °C to form TMS-esters and ethers (Sepic et al. 1998). The trimethylsilyl (TMS) derivatized sample was analysed by GC-HRMS (ACCU TOF GCv from Jeol Asia Ltd.).

Preparation of cell free extract and enzyme assays

Stenotrophomonas sp. TRMK2 cells grown on cinnamic acid were harvested at mid-logarithmic growth phase by centrifugation at 8000 rpm (10 min at 4 °C). The cell pellet was washed twice with 25 mM potassium phosphate buffer of pH 7.0 and resuspended in the same buffer. The cell suspension was disrupted four times using Vibra cell ultrasonicator (model 375, USA) at nominal power of 70 W for 30 s periods, each of 30 s duration, followed by 1 min off-cycle during which the disrupted cells and oscillator probe were cooled in ice. Unbroken cells and cell debris were removed by centrifugation at 12,000 rpm (30 min at 4 °C). This cell-free supernatant was used for different enzymatic assays (Santoshkumar et al. 2011).

For cinnamate reductase, 1 ml of reaction mixture contains phosphate buffer (100 mM, pH 7.0), 1 mM NADH, 1 mM cinnamic acid and an appropriate amount of crude enzyme. The activity was measured spectrophotometrically by measuring the decrease in the absorbance at 340 nm. 3-Phenylpropionic acid hydroxylase and p-hydroxybenzoic acid hydroxylase assays were carried out as reported previously (Suarez et al. 1995) with slight modifications. Protocatechuate 3,4-dioxygenase activity was assayed according to MacDonald et al. (1954). Specific activities of above mentioned enzymes were expressed as micromoles of substrate-oxidized or product formed per milligram of protein. The protein concentration was determined by Lowry’s method using BSA as a standard (Lowry et al. 1951).

Utilization of various phenolic compounds

Stenotrophomonas sp. TRMK2 was inoculated into different conical flasks containing 50 ml MS1 medium. Each flask was supplied with 3-phenylpropionic acid (15 mM), 3-(4-hydroxy phenyl) propionic acid (15 mM), p-coumaric acid (10 mM), ferulic acid (10 mM), caffeic acid (10 mM), p-hydroxybenzoic acid (25 mM), vanillic acid (5 mM), protocatechuic acid (25 mM), p-hydroxy benzaldehyde (5 mM) or vanillin (5 mM) as a sole source of carbon and energy individually. All these flasks were incubated in a rotary incubator at 180 rpm and at 30 °C. Culture was withdrawn at regular intervals, centrifuged at 8000 rpm for 10 min. Residual concentration of phenolic compounds was analysed as mentioned elsewhere.

Analytical methods

Growth of the bacterial strain TRMK2 and different enzyme activities were monitored by UV–Vis spectrophotometer (Specord 50, Analytikjena). The residual concentration of different phenolic compounds was analysed by HPLC. The analysis was performed using HPLC (Waters, model number 2489) armed with dual beam wavelength UV–Vis detector and C18 column; mobile phase used was acetonitrile:water:acetic acid (30:69.5:0.5, v/v) at a flow rate of 1 ml min−1 (Chamkha et al. 2001). The trimethylsilyl (TMS) derivatized extract was analysed by GC-HRMS equipped with HP5 column with the ionization voltage of 70 eV and the mobile gas was helium.

Statistical analysis

The data were subjected to analysis of variance using SPSS21.0 software. The significance of differences between the treatments was judged by F test, while the treatment means were compared by Least Significant Difference (LSD-Fisher’s test) and Honestly Significant Difference (HSD-Tukey’s test) at P < 0.05. The results are taken from HSD only because of multiple variable comparison and least chances of type 1 error.

Results and discussion

Identification of a bacterium

The selective enrichment culture technique was used to isolate the cinnamic acid degrading bacterium. The strain TRMK2 has the ability to grow in MS1 medium supplied with cinnamic acid as a sole source of carbon and energy. The isolated strain is gram-negative, motile, straight or slightly curved bacilli. On cinnamic acid-MS1 agar medium, the strain TRMK2 formed sticky circular colonies. The 16S rDNA sequence of the Stenotrophomonas sp. TRMK2 was deposited in Gen Bank under the accession number KU522144. It was aligned with reference sequences obtained from Gen Bank database.

Utilization of cinnamic acid

Stenotrophomonas sp. TRMK2 utilized supplemented cinnamic acid completely within 24 h of incubation. When 5 mM cinnamic acid was provided, the strain TRMK2 showed the maximum growth (A600nm 1.02) within 18 h of incubation with 99% utilization. At 10 mM cinnamic acid, the strain exhibited maximum growth (A600nm 1.15) with 82% utilization within 24 h of incubation (Fig. 1).

Identification of metabolic intermediates of cinnamic acid

The metabolic intermediates of cinnamic acid degradation were characterized by GC-HRMS analysis (Table 1). The mass spectrum of the metabolic intermediates was given in Fig. 2. The GC-HRMS of metabolite I (3-phenylpropanoic acid) gave a molecular ion (M+) at m/z 222 subsequently at 207 (M+–CH3), 191 (M+–CH3–O), 161 (M+–3CH3–O), 133, 118, 105, 91 and 77. Mass spectrum of metabolite II (3-(4-hydroxyphenyl) propanoic acid) exhibited molecular ion fragment at m/z 310 (M+) and successive fragments at 295 (M+–CH3), 265 (M+–3CH3), 237 (M+–TMS), 207, 192, 176, 164, 148, 134, 120, 106 and 92. The fragmentation of metabolite III (4-hydroxybenzoic acid) gave the molecular ion peak at m/z 282 (M+) and fragment ions at 267 (M+–CH3), 237 (M+–3CH3), 222 (M+–4CH3), 206, 191, 163, 136, 104, 89, 64 and 51. The GC-HRMS of metabolite IV (protocatechuic acid) revealed the molecular ion peak at m/z 355 (M+–CH3) with the loss of one CH3 and consecutive fragments at 340 (M+–CH3–CH3), 325 (M+–CH3–2CH3), 310 (M+–CH3–3CH3), 295, 119, 281, 162, 134, 119 and 75.

Enzyme assay

The enzymes involved in the degradation of cinnamic acid were detected in the cell-free extract of cells of strain TRMK2 grown on cinnamic acid. The cinnamate reductase exhibited less activity, whereas 3-phenylpropionic acid hydroxylase and p-hydroxybenzoic acid hydroxylase showed moderate activity. On the other hand, protocatechuate 3,4-dioxygenase showed good activity and is the key enzyme involved in the cleavage of terminal aromatic ring (Table 2).

Catabolic pathway of cinnamic acid

The possible pathways involved in the microbial degradation of phenyl propionic acid (C6–C3) proceeds by (1) di- hydroxylation of the benzene nucleus followed by ring fission leaving the side chain intact (Seidman et al. 1969); or (2) shortening of the side chain by a two-carbon fragment before ring fission (Cartwright and Smith 1967). The strain TRMK2 catabolises the cinnamic acid to 3-phenyl propionic acid by the reduction of aliphatic side chain catalysed by a reductase. Isolation and characterization of 3-phenylpropionic acid in culture broth and the presence of cinnamate reductase in the crude enzyme preparation shows the reduction of cinnamic acid to 3-phenylpropionic acid. Andreoni and Bestetti (1986) reported such conversion in Pseudomonas stutzeri CINNS, Pseudomonas putida CINNP and Pseudomonas putida CINNW growing on cinnamic acid. Coulson and Evans (1959) showed the side chain reduction of cinnamic acid in soil Pseudomonas species. Further, this type of reduction also has been observed in a strictly anaerobic Clostridium glycolicum, capable of transforming cinnamic acid to hydroxycinnamic acid and a wide range of other cinnamic acid derivaties to their corresponding 3-phenylpropionic acid by reducing the double bond of the side chain (Chamkha et al. 2001). However, Nali et al. (1985) reported anaerobic microbial conversion of three hydroxycinnamic acids, namely caffeic acid, ferulic acid and synaptic acid by a microbial consortium via the reduction of the double bond of the side chain, the replacement of the nuclear hydroxyl group in position 4 by hydrogen and the demolition of the side chain by the loss of a C1 unit. On the contrary, Stenotrophomonas sp. TRMK2 catabolises 3-phenylpropionic acid by the hydroxylation of benzene nucleus to form 3-(4-hydroxy phenyl) propionic acid. The formed 3-(4-hydroxy phenyl) propionic acid is detected in the spent medium which is then converted to 4-hydroxybenzoic acid. 4-hydroxybenzoic acid hydroxylase catalyses the conversion of 4-hydroxybenzoic acid to protocatechuic acid. The formed protocatechuic acid, a terminal aromatic metabolite undergoes ortho-cleavage leads the formation of β-carboxy cis, cis-muconic acid (Fig. 3). On the other hand, Whiting and Carr (1959) reported that Lactobacillus pastorianusis able to reduce the side chain of cinnamic acid, 4-hydroxycinnamic and 3,4-dihydroxy cinnamic acids. These metabolic products may then be decarboxylated to corresponding 4-ethylderivatives. Coulson and Evans (1959) also found that the accumulation of 2-hydroxy-l-phenylpropionate and 2,3-dihydroxy-2-phenylpropionate in Pseudomonas grown on cinnamic acid. Blakley and Simpson (1964) showed that Pseudomonas sp. metabolised cinnamic acid to 2,3-dihydroxyphenylpropionic acid via phenylpropionic acid and m-hydroxyphenylpropionic acid. Hilton and Cain (1990) reported that a soil Pseudomonad has the ability to catabolise cinnamic acid to acetophenone and 3-keto-3-phenylpropionic acid.

Utilization of various phenolic compounds

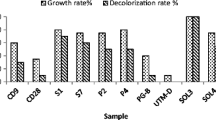

Stenotrophomonas sp. TRMK2 having the ability to utilize cinnamic acid was further checked for its capability to utilize various other phenolic compounds. The strain exhibited maximum utilization of p-hydroxybenzoic acid and protocatechuic acid. When the concentration of both of these phenolics was supplemented at 25 mM, the strain showed 99.9% utilization of p-hydroxybenzoic acid in 24 h and protocatechuic acid in 30 h. At 15 mM 3-phenylpropionic acid and 3-(4-hydroxyphenyl) propionic acid, the strain utilized these phenolics 84.6% and 100%, respectively, at 30 and 24 h of incubation. When 10 mM p-coumaric, ferulic and caffeic acids was supplied, the strain showed more than 98% utilization at 30 h of incubation. When 5 mM p-hydroxybenzaldehyde, vanillic acid and vanillin was provided, the strain utilized above 82% of these compounds at 24 h of incubation (Table 3). Levene test showed the homogeneity of variance with respect to the utilization of p-hydroxybenzoic acid and protocatechuic acid, when compared with the rest of the phenolic compounds’ utilization. Tukey test also showed no significant difference between the utilization pattern of 3-phenylpropionic acid, 3-(4-hydroxyphenyl) propionic acid, p-coumaric, ferulic and caffeic acids, p-hydroxybenzaldehyde, vanillic acid and vanillin by the strain TRMK2.

The current investigations revealed that the newly isolated Stenotrophomonas sp. TRMK2 is capable of utilizing cinnamic acid and various phenolic compounds. Based on the characterization of metabolic intermediates and the detection of different enzymes, a catabolic pathway for the degradation of cinnamic acid has been proposed in Stenotrophomonas sp. TRMK2.

References

Akin DE, Borneman WS, Rigsby LL, Martin AS (1993) Coumaroyl and feruloyl arabinoxylans from plant cell walls as substrates for ruminal bacteria. Appl Environ Microbiol 59:644–647

Andreoni V, Bestetti G (1986) Comparative analysis of different Pseudomonas strains that degrade cinnamic acid. Appl Environ Microbiol 52:930–934

Andreozzi R, Caprio V, D’Amore MG, Insola A (1995) Coumaric acid abatement by ozone in aqueous solution. Water Res 29:1–6

Blakley ER, Simpson FJ (1964) The microbial metabolism of cinnamic acid. Can J Microbiol 10:175–185

Cartwright NJ, Smith ARW (1967) Bacterial attack on phenolic ethers: An enzyme system demethylating vanillic acid. Biochem J 102:826–841

Chamkha M, Labat M, Bharat KCP, Garcia JL (2001) Isolation of a cinnamic acid metabolizing Clostridium glycolicum strain from oil mill wastewaters and emendation of the species description. Int J Syst Evol Microbiol 51:2049–2054

Chen LH, Yang XM, Raza W, Junhua L, Yanxia L, Meihua Q, Fengge Z, Qirong S (2011a) Trichoderma harzianum SQR-T037 rapidly degrades allelochemicals in rhizospheres of continuously cropped cucumbers. Appl Microbiol Biotechnol 89:1653–1663

Chen Y, Peng Y, Dai CC, Qun J (2011b) Biodegradation of 4-hydroxybenzoic acid by Phomopsis liquidambari. Appl Soil Ecol l51:102–110

Coulson CB, Evans WC (1959) Microbiological degradation of trans-cinnamic acid by soil Pseudomonas. Chem Ind 17:543–544

Dagley S, Chapman PJ, Gibson DT (1965) The metabolism of p-phenylpropionic acid by an Achromobacter. Biochem J 97:643–650

Di Gioia D, Bertin L, Fava F, Leonardo M (2001) Biodegradation of hydroxylated and methoxylated benzoic, phenylacetic and phenylpropionic acids present in olive mill wastewaters by two bacterial strains. Res Microbiol 152:83–93

Díaz E, Ferrández A, Prieto MA, José LG (2001) Biodegradation of Aromatic compounds by Escherichia coli. Appl Environ Microbiol 65:523–569

Ding J, Sun Y, Xiao CL, Kai S, Yan HZ, Jing QY (2007) Physiological basis of different allelopathic reactions of cucumber and fig leaf gourd plants to cinnamic acid. J Exp Bot 58:3765–3773

Hartley RD, Whitehead DC (1985) Phenolic acids in soils and their influence on plant growth and soil microbial processes. In: Vaughan D, Malcolm RE (eds) Soil organic matter and biological activity, developments in plant and soil sciences series, 16. Kluwer Academic Publishers, Dordrecht

Hilton MD, Cain WJ (1990) Bioconversion of cinnamic acid to acetophenone by a Pseudomonad: microbial production of a natural flavour compound. Appl Environ Microbiol 56:623–627

Isidori M, Lavorgna M, Nardelli A, Parrella A (2004) Chemical and toxic evaluation of a biological treatment for olive-oil mill wastewater using commercial microbial formulations. Appl Microbiol Biotechnol 64:735–739

Kawakami H (1980) Degradation of lignin-related compounds by several Pseudomonads. In: Kirk TK, Higuchi T, Chang HM (eds) Lignin biodegradation: microbiology, chemistry, and potential applications, 2. CRC Press, Inc., Boca Raton, pp 103–125

Lane DJ (1991) Small subunit ribosomal RNA sequences and primers. Large subunit ribosomal RNA sequences and primers. In: Stackebrandt E, Goodfellow M (eds) Nucleic acid techniques in bacterial systematics, Wiley, Chichester, pp 148–175

Lowry OH, Rosebrough NJ, Farr AL (1951) Protein measurement with the folin phenol reagent. J Biol Chem 193:265–275

MacDonald DL, Stanier RY, Ingraham JL (1954) The enzymatic formation of β-carboxymuconic acid. J Biol Chem 210:809–820

Monisha TR, Mukram I, Kirankumar B, Pooja VR, Anand SN, Karegoudar TB (2017) Utilization of phenylpropionoids by newly isolated bacterium Pseudomonas sp. TRMK1. Appl Biochem Biotechnol 182:1240–1255

Nali M, Rindone B, Tollari S, Anderoni V, Treccani V (1985) Anaerobic microbial conversion of three hydroxycinnamic acids. Experientia 41:1351–1353

Santoshkumar M, Veeranagouda Y, Lee K, Karegoudar TB (2011) Utilization of aliphatic nitrile by Paracoccussp. SKG isolated from chemical waste samples. Int Biodeter Biodegr 65:153–159

Seidman MM, Toms A, Wood JM (1969) Influence of side-chain substituents on the position of cleavage of the benzene ring by Pseudomonas fuorescens. J Bacteriol 97:1192–1197

Sepic E, Bricelj M, Leskovsek H (1998) Degradation of fluoranthene by Pasteurella sp. IFA and Mycobacterium sp. PYR-1: isolation and identification of metabolites. J Appl Microbiol 85:746–754

Singh NB, Yadav K, Amist N (2013) Phytotoxic effects of cinnamic acid on cabbage (Brassica oleracea var. capitata). J Stress Physiol Biochem 92:307–317

Sleat R, Robinson JP (1984) The bacteriology of anaerobic degradation of aromatic compounds. J Appl Bacteriol 57:381–394

Suarez M, Martín M, Ferrer E (1995) Purification and characterization of 4-hydroxybenzoate 3-hydroxylase from a Klebsiella pneumoniae mutant strain. Arch Microbiol 164:70–77

Subba Rao PV, Nambudiri AMD, Bhat JV (1971) Microbial degradation of phenylpropionoids compounds. J Sci Ind Res 30:663–679

Whiting GC, Carr JG (1959) Metabolism of cinnamic acid and hydroxycinnamic acids by Lactobacillus pastorianusvar. quinicus. Nature 184:1427–1428

Zhang ZY, Pan LP, Li HH (2010) Isolation, identification and characterization of soil microbes which degrade phenolic allelochemicals. J Appl Microbiol 108:1839–1849

Acknowledgements

One of the authors Mr. Monisha T. R. would like to thank University Grants Commission (UGC), New Delhi, India for the financial assistance in the mode of BSR Fellowship. Dr. T. B Karegoudar is grateful to UGC for awarding UGC-BSR faculty fellowship. The financial support from UGC in the form of UGC-SAP programme [No.F.4–27/2015/DRS-II (SAP-II)] sanctioned to the department is highly acknowledged.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

Authors declare that the manuscript does not contain any conflict of interest.

Rights and permissions

About this article

Cite this article

Monisha, T.R., Ismailsab, M., Masarbo, R. et al. Degradation of cinnamic acid by a newly isolated bacterium Stenotrophomonas sp. TRMK2. 3 Biotech 8, 368 (2018). https://doi.org/10.1007/s13205-018-1390-0

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s13205-018-1390-0