Abstract

Organosolv is an effective pretreatment strategy for increasing digestibility of lignocellulosic materials owing to selectivity of solvents on separating biopolymeric constituents of plant biomass. In the present work, a novel low-temperature alkali-catalyzed organosolv pretreatment of rice straw was studied. The effects of alkaline catalysts (i.e., NaOH, ammonia, and tri-ethylamine) and solvent types (i.e., acetone, ethanol, and water) were carried out. Addition of alkalis led to increasing sugar from enzymatic hydrolysis while acetone was found to be superior to ethanol and water on selectivity towards cellulose preservation. The optimal alkaline-catalyzed pretreatment reaction contained 5% (w/v) NaOH in an aqueous-acetone mixture (1:4) at 80 °C for 5 min. A glucose yield of 913 mg/g of pretreated biomass was achieved, equivalent to a maximal glucose recovery of 93.0% from glucan in the native biomass. Scanning electron microscope revealed efficient removal of non-cellulosic components, resulting in exposed cellulose microfibers with a reduced crystallite size as determined by X-ray diffraction. With potential on obtaining high-quality lignin, the work demonstrated potential of the novel low-temperature alkaline-catalyzed acetone-based organosolv process for pretreatment of lignocellulosic materials in biorefineries.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Lignocellulosic plant biomass is the most abundant organic carbon resource on earth and is a promising renewable starting material for production of fuels and chemicals in the biorefinery industry. With the carbon-neutral nature of lignocelluloses, establishment of feasible biomass industry is expected to mitigate the global warming crisis from exploitation of fossil resources. However, the recalcitrance of lignocellulose to chemical and enzymatic digestion hinders its efficient conversion to sugars, the key intermediates in biorefinery. An effective pretreatment step is thus a prerequisite to achieve practical sugar yields from plant biomass for further processing. Pretreatment leads to solubilization of the amorphous hemicellulose and the protective lignin shield, reduction on degree of polymerization, and destruction of the cellulose crystalline structures. These effects altogether increase the overall accessibility of saccharifying enzymes to cellulose fibers (Viikari et al. 2012; Alvira et al. 2010).

Pretreatment of lignocelluloses with organic solvents (organosolv) is a promising alternative method in biorefineries (Amiri et al. 2014; Koo et al. 2011). Organosolv is versatile with respect to the types of raw materials that can be processed, and has been applied for the pretreatment of hardwoods, softwoods, agricultural residues, and grasses (Zhao et al. 2009; Maurya et al. 2015). Advantages of organosolv in comparison with other pretreatment methods include reduction of viscosity in the reaction mixture, greater efficiency of lignin removal, and reduced lignin recondensation on the biomass surface with a less destructive effect on the cellulose fibers (Zhang et al. 2016). The processes also allow recovery of a high-quality lignin, which is primarily un-altered in terms of chemical structure compared with Kraft lignin and can be used for various applications with higher value (Mesa et al. 2011). Ethanol and methanol are among the primary solvents used in organosolv pretreatment mixtures; however, alternative solvents with varying boiling point, polarity and selectivity for extraction of specific biopolymers have been reported. These include organic bases, ketones, and esters, as well as high boiling point solvents such as glycerol, ethylene, and propylene glycol in addition to 1,4-butanediol, butanol, and ethanolamine (Zhang et al. 2016). Organic acids such as formic acid, acetic acid and peroxyformic acid have also been used as solvent systems with a variety of lignocellulosic feedstock (Sindhu et al. 2010).

Acetone is an excellent solvent for lignin and lignin-derived products (Hasegawa et al. 2004). It is more effective for solubilizing lignin than ethanol owing to its lower polarity (log P acetone = −0.042; log P ethanol = −0.18) with a δ value of 9.9, similar to that of acetic acid (Pan and Sano 1999). Its low boiling point also allows simple separation and recycling by evaporation (Zhang et al. 2007). Acetone-based organosolv pretreatments of lignocellulosic materials have been demonstrated in only a limited number of studies both in the auto-catalyzed and acid-catalyzed processes (Araque et al. 2008; Sannigrahi et al. 2010). However, the reported acetone-based and most of other organosolv processes were generally performed at relatively high temperatures (160–230 °C) and considered energy intensive. Alkalis are efficient catalysts for delignification of lignocellulosic materials in aqueous systems. However, the application of alkaline catalysts in organosolv pretreatments has been rather limited (Mesa et al. 2011) compared to the extensive studies on the use of acid catalysts in various organic media (Sannigrahi et al. 2010) while there has been no report on their effects in ketone solvents. Given the known benefits of acetone and the delignification effect of alkalis, their combined effect may lead to a more efficient organosolv pretreatment strategy.

In this study, the uses of organic and inorganic alkaline catalysts on pretreatment of rice straw in an aqueous-acetone system were studied compared with those in water and ethanol. Physicochemical characteristics of the cellulose-enriched pulp after processing were analyzed. The results demonstrated the effects of alkalis on promoting efficiency and selectivity of the organosolv pretreatment processes with advantages over the conventional aqueous-based and ethanol-based reactions. With potential on obtaining high quality lignin, the work provides a potential novel low-temperature organosolv pretreatment for efficient processing of lignocellulosic materials for subsequent conversion to biorefinery products.

Materials and methods

Materials

Rice straw (RS) was collected from a local field in Pathumthani province, Thailand. It was physically processed using a cutting mill (Retsch ZM2000, Haan, Germany) and sieved to retain particles 250–420 µm in diameter. The processed biomass was then used as a starting material for experimental studies. According to the standard NREL analysis (Sluiter et al. 2008), the RS contains 35.80 wt% cellulose, 21.50 wt% hemicelluloses, 24.40 wt% lignin, and 15.0 wt% ash. Analytical grade organic solvents and chemicals were purchased from major chemical suppliers i.e., Sigma-Aldrich, Merck, and Fluka.

Organosolv pretreatment

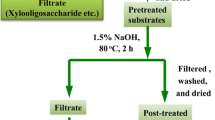

Organosolv pretreatment of RS was performed in a 600 mL stainless steel high-pressure reactor installed with a thermocouple for internal temperature measurement with a mixing system (Parr Reactor 4560, Parr instrument, Moline, IL, USA). The initial reaction mixture contained 2% (w/v) of RS in 200 mL of the reaction medium containing organic solvent (acetone or ethanol) in the presence or absence of alkaline catalysts: 5% (w/v) NaOH (40 mL of 25% w/v of NaOH/160 mL of solvent), 5% (v/v) NH4OH (40 mL of 25% NH4OH solution/160 mL of solvent), and 5% (v/v) tri-ethylamine (TEA) (10 mL of TEA/190 mL of solvent) and heated at 80–100 °C for 30 min at 20 bars as purged by nitrogen gas with stirring at 250 rpm. The reaction was then quenched in a water bath. The solid and liquid fractions after pretreatment were separated by vacuum filtration using 20–25 μm paper filter (No.4). The solid fraction was washed by deionized water until pH equaled 7 and then the residue was dried in an oven at 60 °C overnight. Control reactions using selected alkalis in water were conducted for comparison.

The pretreatment reaction in acetone using NaOH as a catalyst was further studied by varying the final concentration of NaOH (5–10% w/v), solid loading (2–8% w/v), and reaction time (0–60 min) at a fixed temperature of 80 °C. The reaction time was defined as the residence time at the respective temperature.

Enzymatic hydrolysis

The enzymatic hydrolysis reaction (1 mL total volume) contained 5% (w/v) pretreated RS with 20 FPU/g Accellerase® 1500 (Dupont, Rochester, USA) in 50 mM of sodium citrate buffer (pH 4.8) and 0.25% (w/v) sodium azide. The reaction was incubated at 50 °C for 72 h with vertical rotation at 30 rpm. Enzymatic hydrolysis experiments were performed in triplicate. The amount of liberated reducing sugars was measured using 3,5-dinitrosalicylic acid (DNS) method (Miller 1959). The fermentable sugar profile was analyzed on a high performance liquid chromatograph (SPD-M10A DAD, Shimadzu, Japan) equipped with a refractive index (RI) detector and a Bio-rad Aminex HPX-87H column (Bio-rad, Hercules, CA, USA). A 5 mM solution of H2SO4 was used as a mobile phase at a flow rate 0.5 mL/min with the column temperature of 65 °C. The sugar yield was reported based on the amount of sugars based on the pretreated substrate on a weight basis. Glucose recovery was calculated as the percentage of glucose obtained based on the percent cellulose (×1.11) in the native RS on a dried weight basis.

Analytical method

Scanning electron microscopy

The structure and morphology of the native and pretreated rice straw at optimal condition was analyzed by scanning electron microscope (SEM) using a S-3400 N Type II SEM (Hitachi, Tokyo, Japan). The samples were dried and coated with gold. An electron beam energy of 5 kV was used for analysis.

X-ray diffraction analysis

The crystallinity of samples was determined by X-ray diffraction (XRD) using an X’Pert PRO diffractometer (PANalytical, Almelo, The Netherlands). The samples were scanned at a speed of 0.5°/min in a range of 2θ = 5–40° with a step size of 0.02° at 40 kV, 30 mA and radiation at Cu Kα (λ = 1.5418 Å). The average size of crystallites was calculated from the Scherrer equation with the method based on the width of the diffraction patterns obtained from the highest intensity for the crystalline portion of biomass (I 002). The crystallinity index (CrI) and the crystallite size (D hkl) were calculated according to the following Eqs. 1 and 2, respectively (Sun et al. 2015),

where CrI is the crystallinity index of sample (%); I 002 is the highest intensity for the crystalline portion of biomass (i.e., cellulose) at 2θ = 22.03 and I am is the peak for the amorphous portion (i.e., cellulose, hemicellulose, and lignin) at 2θ = 18.19.

where D hkl is the average size of the crystallite (nm); K is the Scherrer constant (0.94); λ is X-ray wavelength (Cu, 0.15418 nm); β is the full-width at half-maximum of the crystalline portion (radian, π), and 2θ which is the corresponding Bragg angle.

Results and discussion

Effects of alkaline catalysts

The effect of different alkalis (NaOH, NH4OH and TEA) on pretreatment efficiency in acetone or ethanol was studied initially using RS at 2% w/v solid loading at varying temperatures (Fig. 1). The native biomass was recalcitrant to enzymatic hydrolysis, resulting in 130 mg/g-pretreated rice straw of released total sugar yield. The biomass also showed low digestibility after pretreating in the absence of the catalysts in both solvents, resulting in total sugar yield of <145 mg/g-pretreated substrate under all temperatures tested. Enzymatic digestibility of the cellulose-rich fraction was enhanced to varying degrees by the addition of alkali using both solvent systems. According to two-way ANOVA, there was a significant interaction effect between temperature and alkaline catalysts factors on increasing the total sugar yield (P value <0.05). Addition of alkaline catalysts showed stronger effects on the sugar yield than the operational temperature under the experimental conditions. NaOH addition gave the greatest increase in the total sugar yield to 865 mg/g from RS pretreated at 100 °C in acetone, equivalent to a 5.9-fold increase compared with the respective no catalyst control, while a slightly lower yield (856 mg/g) was obtained at 80 °C (Fig. 1a). Glucose constituted the majority of fermentable sugars under all conditions (>96%) in the hydrolysate with the maximal glucose yield of 834 mg/g at 80 °C, while xylose and arabinose represented the minor sugars with the yield of 20 and 2 mg/g, respectively. Organic alkaline catalysts (NH4OH and TEA) were less efficient on enhancing biomass digestibility, resulting in a marginal (less than twofold) increase in the sugar yield compared with controls. Increase in temperature led to no significant enhancement (<1.1%) on the total sugar yield under the pretreatment conditions catalyzed by all alkaline catalysts under the experimental conditions.

Effects of alkaline catalysts on enzymatic digestibility of rice straw. The reaction contained 2% (w/v) rice straw in a 200 mL of reaction mixture with the final alkali concentration of 5% (40 mL of 25% w/v of NaOH/160 mL of solvent; 40 mL of 25% v/v NH4OH solution/160 mL of solvent, or 10 mL of TEA/190 mL of solvent) and heated at varying temperatures for 30 min. The reaction in the absence of alkaline catalysts was used as a control a acetone; b ethanol. The data represent an average from a triplicate experiment and the standard deviation is within ±5%

Similar enhancing effects of alkaline catalysts on sugar yields were observed when ethanol was used as the solvent (Fig. 1b). However, the total sugar yield obtained in ethanol-based organosolv reaction in the presence of either strong or weak alkalis (126–856 mg/g) was lower than that in acetone. This was corresponded to the significantly lower glucose yield and the higher fraction of pentoses in the hydrolysates under all NaOH-catalyzed reaction in ethanol (P value <0.05 according to Fisher’s test; odd ratio = 0.332 and 3.094 for glucose and xylose, respectively). The results thus suggested lower selectivity towards cellulose and lower pretreatment efficiency of the ethanol-based reaction compared to that performed in acetone.

Comparison of sugar recoveries from the available glucan in the native biomass using the organic solvents and water as the reaction medium in the presence of different alkaline catalysts at 80 °C is shown in Fig. 2. Acetone was shown to be superior in term of glucose recovery (76.0%) compared to ethanol (71.0%) and water (71.0%) when NaOH was used as the catalyst which also corresponded to the lower weight loss in the acetone-based reaction. Markedly lower glucose recovery was found using weak alkalis as the catalysts in all solvent systems. However, water was found as a preferred medium to organic solvents when organic alkalis were used as the catalysts as shown by the slightly higher glucose recoveries in the aqueous system compared with those in acetone or ethanol in the presence of ammonia or TEA. These data suggested the NaOH-catalyzed reaction in acetone as the most selective and effective process for cellulose pretreatment.

Comparison of glucose recovery from alkaline-catalyzed pretreatment of rice straw in water and organic solvents. The reaction contained 2% (w/v) rice straw in a 200 mL of reaction mixture with the final alkali concentration of 5% and heated at 80 °C for 30 min. The data represent an average from a triplicate experiment and the standard deviation is within ±5%

Effects of reaction parameters in acetone system

The effects of alkali concentration and pretreatment conditions were further studied for the NaOH–acetone system. A one-to-one variation of the individual parameters to digestibility of the pretreated solid was studied based on the initial reaction conditions (i.e., 2% w/v biomass loading, 5% w/v NaOH at 80 °C for 30 min). Slight increases in the total sugar and glucose yields to 916- and 877 mg/g-pretreated RS were achieved with the NaOH dosage of 7.5% w/v; however, no significant increase in the sugar yield was found when the catalyst concentration was further increased. When taking weight loss of the biomass during the pretreatment step into account, the maximum theoretical glucose recovery of 80.0% from the native rice straw was obtained at the NaOH concentration of 10%, which was slightly higher than that obtained at a lower catalyst concentration (76.0%). Xylose contamination was minimal under all conditions (20–38 mg/g) (Fig. 3). The NaOH loading under the optimized conditions was in the same range compared to previous works on alkaline pretreatment in water and ethanosolv systems (Iberahim et al. 2013; Sahin 2003).

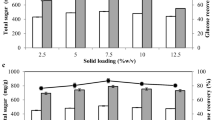

Increasing initial solid loading of the biomass from 2 to 8% (w/v) in the pretreatment reaction led to changes in the pretreatment efficiency at 5% NaOH concentration (Fig. 4). The highest total sugar and glucose yields of 948- and 911 mg/g-pretreated RS were found at the initial solid loading of 4% (w/v). Further increase in solid loading of the biomass led to a respective decrease in sugar yields. However, weight recovery of the solid fraction increased with increasing solid loading. The maximal glucose recovery of 88.2% from the native biomass was found at the solid loading of 4% (w/v).

The effect of residence time in the pretreatment step was studied at 4% solid loading (Fig. 5). A slight increase in glucose yield was observed after 5 min, but longer residence times showed no further increase in glucose yield. The total sugar and glucose yields increased from 873 to 953 mg/g- and 832 to 919 mg/g-pretreated RS, respectively, when increased the reaction time from 0 to 60 min. However, the increase in sugar yield was offset by the greater weight loss with longer residence time owing to increasing cellulose decomposition. The maximum recovery of glucose recovery of 93.0% was achieved using the residence time of 5 min.

Physical characterization of pretreated rice straw

The structural changes of RS pretreated under the optimal condition (i.e., 4% (w/v) solid with 5% (w/v) NaOH concentration in acetone at 80 °C for 5 min) were examined by SEM compared with the untreated RS (Fig. 6). The native RS showed an intact wax-coated surface and physical structure with no cavities or cracks. The alkaline-catalyzed pretreatment led to structural alteration on the biomass surface due to destruction of the cuticle wax and silica layers. The pretreatment resulted in peeling of the surface lignin, and associated hemicelluloses allowing increasing accessibility to the inner cellulose microfibers in the biomass. The majority of micro-fibrous cellulose structures were highly preserved.

The crystallinity structure and average crystallite size of samples were analyzed by XRD (Table 1). The alkaline-catalyzed organosolv pretreatment led to an increase in crystallinity index of 55.13% compared with the native RS (44.11%). This could be due to removal of the amorphous lignin and hemicellulose fractions, which was consistent with the data from SEM analysis. Variation in the effects of organic solvent treatment on crystallinity of lignocellulosic materials has been reported depending on the solvent systems and reaction conditions. Increased crystallinity of organosolv-pretreated biomass was also shown by Chen et al. (2015) using different solvents such as ethanol, formic acid, and acetic acid on pretreatment of wheat straw in the presence or absence of sulfuric acid (Chen et al. 2015). However, this was in contrast to the decreased biomass crystallinity reported by Sannigrahi et al. (2010) using an aqueous-ethanol as the solvent system operated at 170 °C with H2SO4 as a catalyst (Sannigrahi et al. 2010). The average size of cellulose crystallite in the native biomass was 2.86 nm, which was reduced to 2.40 nm in the pretreated sample. The reduction in crystallite diameter after alkali-catalyzed pretreatment could explain the enhanced enzymatic digestibility of the substrate in the saccharification step (Sun et al. 2015).

Among the catalysts and solvents tested in our study, the NaOH-catalyzed reaction in aqueous-acetone mixture was shown to be a superior system for pretreatment of RS. Acetone has been demonstrated as a preferred solvent in terms of selectivity to cellulose and its enzymatic digestibility compared to ethanol and water under the experimental conditions used in this study. This could be related to its high efficiency on removals of lignin and lignin-derived degradation products from alkaline hydrolysis (Menon and Rao 2012), which is related to its polarity (log P acetone value = −0.042) (Zhao et al. 2009). Comparison of glucose yields achieved in our study and previous works including various auto- and acid- or alkali-catalyzed ethanol/acetone-based organosolv pretreatments is summarized in Table 2, showing a remarkably high sugar recovery in this study using the reaction operated at a relatively low temperature. This can be related to the combined effects of high lignin solubility in acetone and delignification enhancement by the alkaline catalysts.

Compared to acetone, short-chain alcohols, particularly ethanol, is a more common reaction medium in organosolv. Various auto-catalyzed and acid-catalyzed ethanosolv processes have been reported to efficiently separate lignin from biomass and resulted in pretreated cellulose-enriched solid with high enzymatic digestibility (Mesa et al. 2011; Wildschut et al. 2013). However, most ethanosolv processes were performed at a relatively high temperature range (120–220 °C) (Zhang et al. 2016) compared to the alkali-catalyzed reaction in acetone in our study. Only a very limited number of organosolv pretreatment using ketones as solvents have been reported. Most studies have been focused on the use of acetone-based processes on delignification of woody biomass in pulp industry (Hasegawa et al. 2004; Paszner and Chang 1983). An acid-catalyzed organosolv process was also reported by Paszner et al. (1985). The woody biomass was treated with hot water at 180 °C and further extracted by a flowing stream of aqueous acetone at 230 °C under pressurized conditions, leading to sequential separation of hemicellulose, lignin and cellulose fractions. Hasegawa et al. (2004) reported a one-step extraction of woody biomass in a 50% water/acetone solution at 200 °C using a batch reactor, which resulted in preparation of a cellulose fraction with high homogeneity (Hasegawa et al. 2004). This reflected the specificity of acetone on removal of non-cellulosic components while conserving the integrity of cellulose fibers.

So far only a few studies have demonstrated the efficiency of acetone as an alternative solvent in organosolv pretreatment aiming for improving susceptibility of the cellulose-enriched fraction for enzymatic hydrolysis. Araque et al. (2008) studied the organosolv pretreatment of Pinus radiata with a 50% aqueous-acetone mixture using 0.9% H2SO4 as a catalyst (Araque et al. 2008). Almost all hemicellulose was degraded under the optimal conditions, while 47% of lignin was recovered. The delignified biomass showed a modest glucose yield of 72% after enzymatic hydrolysis. Huijgen et al. (2010)has reported an auto-catalyzed acetone-based organosolv (Huijgen et al. 2010). The optimized process was performed at 205 °C in a 50:50% w/w acetone–water mixture. This led to 82% hemicellulose hydrolysis, 79% lignin removal, and 93% cellulose recovery with good enzymatic digestibility, resulting in 87% glucose yield.

Incorporation of different alkalis into aqueous media and organic solvents led to a varying degree on enhancing selectivity of the reaction toward cellulose fractionation and on increasing enzymatic digestibility of the resultant solids. Alkaline pretreatment of lignocellulosic materials in aqueous media led to decreases in lignin and hemicellulose contents due to disruption of the lignin–carbohydrate complex which resulted in the respective increase in the cellulose content of the substrates, together with swelling of biomass resulting in increased accessible surface area of the substrates and reduction in the degree of cellulose polymerization (Menon and Rao 2012; Sridevi et al. 2015). Application of alkaline catalysts in organic solvent, particularly in ethanol, has been reported in only few studies, showing their higher potential on lignin extraction and greater recovery of high-quality lignin compared with reactions in aqueous media. Wang et al. (2012) reported that the addition of NaOH at 1% (w/w) in aqueous ethanol solution improved efficiency on hemicellulose solubilization in organosolv fractionation under mild reaction conditions compared with the use of formic acid and TEA (Wang et al. 2012). NaOH was also shown to improve the enzymatic digestibility of pretreated pitch pine with a reported 85.4% product yield after ethanosolv pretreatment at 210 °C for 20 min (Park et al. 2010). In addition, Li et al. (2013) reported that ethanosolv pretreatment of bamboo catalyzed by 10% (w/w) NaOH with 75% (v/v) ethanol at 180 °C for 30 min could increase the conversion yield of cellulose to glucose from 28.9 to 45.1% after enzymatic hydrolysis (Li et al. 2013). The effects of alkaline catalysts such as KOH and TEA were also demonstrated for their efficiency on solubilizing glucose and pentoses in organosolv pretreatment of Tamarix austromongolica using dimethyl sulphoxide or aqueous ethanol at relatively low temperature (75 °C) for 180 min (Sun et al. 2011). These works thus support the effectiveness of alkaline catalysts in organosolv pretreatment reactions using different solvent systems.

Conclusion

In conclusion, a novel low-temperature alkali-catalyzed organosolv pretreatment process in an aqueous-acetone mixture has been first reported in this study. This process provides a highly selective separation of the cellulose fraction with high enzymatic digestibility for conversion to fermentable glucose with minimal cross-contamination of pentoses and potential on obtaining high-quality lignin for subsequent utilization e.g., for conversion to phenolics. With the advantages on low energy demand and recyclable nature of the solvent, the work thus demonstrated potential of the developed process for efficient pretreatment of lignocellulosic biomass in integrated biorefinery producing multiple fuels and chemical products.

References

Alvira P, Tomás-Pejó E, Ballesteros M, Negro MJ (2010) Pretreatment technologies for an efficient bioethanol production process based on enzymatic hydrolysis: a review. Bioresour Technol 101(13):4851–4861

Amiri H, Karimi K, Zilouei H (2014) Organosolv pretreatment of rice straw for efficient acetone, butanol, and ethanol production. Bioresour Technol 152:450–456

Araque E, Parra C, Freer J, Contreras D, Rodríguez J, Mendonça R, Baeza J (2008) Evaluation of organosolv pretreatment for the conversion of Pinus radiata D.Don to ethanol. Enzyme Microb Technol 43(2):214–219

Chen H, Zhao J, Hu T, Zhao X, Liu D (2015) A comparison of several organosolv pretreatments for improving the enzymatic hydrolysis of wheat straw: substrate digestibility, fermentability and structural features. Appl Energy 150:224–232

Hasegawa I, Tabata K, Okuma O, Mae K (2004) New pretreatment methods combining a hot water treatment and water/acetone extraction for thermo-chemical conversion of biomass. Energy Fuels 18(3):755–760

Huijgen WJJ, Reith JH, den Uil H (2010) Pretreatment and fractionation of wheat straw by an acetone-based organosolv process. Ind Eng Chem Res 49(20):10132–10140

Iberahim NI, Jahim JM, Harun S, Nor MTM, Hassan O (2013) Sodium hydroxide pretreatment and enzymatic hydrolysis of oil palm mesocarp fiber. Inter J Chem Eng Appl 4(3):101

Koo B-W, Kim H-Y, Park N, Lee S-M, Yeo H, Choi I-G (2011) Organosolv pretreatment of Liriodendron tulipifera and simultaneous saccharification and fermentation for bioethanol production. Biomass Bioenerg 35(5):1833–1840

Li Z, Jiang Z, Fei B, Pan X, Cai Z, Liu X, Yu Y (2013) Ethanosolv with NaOH pretreatment of moso bamboo for efficient enzymatic saccharification. BioResources 8(3):4711–4721

Maurya DP, Singla A, Negi S (2015) An overview of key pretreatment processes for biological conversion of lignocellulosic biomass to bioethanol. Biotech 5(5):597–609

Menon V, Rao M (2012) Trends in bioconversion of lignocellulose: biofuels, platform chemicals & biorefinery concept. Prog Energy Combust Sci 38(4):522–550

Mesa L, González E, Cara C, González M, Castro E, Mussatto SI (2011) The effect of organosolv pretreatment variables on enzymatic hydrolysis of sugarcane bagasse. Chem Eng J 168(3):1157–1162

Miller GL (1959) Use of dinitrosalicylic acid reagent for determination of reducing sugar. Anal Chem 31(3):426–428

Pan X-J, Sano Y (1999) Acetic acid pulping of wheat straw under atmospheric pressure. J Wood Sci 45(4):319–325

Park N, Kim HY, Koo BW, Yeo H, Choi IG (2010) Organosolv pretreatment with various catalysts for enhancing enzymatic hydrolysis of pitch pine (Pinus rigida). Bioresour Technol 101(18):7057–7064

Paszner L, Chang PC (1983) Organosolv delignification and saccharification process for lignocellulosic plant materials. US4409032 A

Paszner L, Quinde AA, M M (1985) ACOS—accelerated hydrolysis of wood by acid catalysed organosolv means. Paper presented at the International Symposium on Wood and Pulping Chemistry, Vancouver, Canada

Sahin HT (2003) Base-catalyzed organosolv pulping of jute. J Chem Technol Biotechnol 78(12):1267–1273

Sannigrahi P, Miller SJ, Ragauskas AJ (2010) Effects of organosolv pretreatment and enzymatic hydrolysis on cellulose structure and crystallinity in Loblolly pine. Carbohydr Res 345(7):965–970

Sindhu R, Binod P, Satyanagalakshmi K, Janu KU, Sajna KV, Kurien N, Sukumaran RK, Pandey A (2010) Formic acid as a potential pretreatment agent for the conversion of sugarcane bagasse to bioethanol. Appl Biochem Biotechnol 162(8):2313–2323

Sluiter A, Hames B, Ruiz R, Scarlata C, Sluiter J, Templeton D, Crocker D (2008) Determination of structural carbohydrates and lignin in biomass: Laboratory Analytical Procedure (LAP). NREL/TP-510-42618. National Renewable Energy Laboratory, Golden, Colorado

Sridevi A, Narasimha G, Ramanjaneyulu G, Dileepkumar K, Reddy BR, Devi PS (2015) Saccharification of pretreated sawdust by Aspergillus niger cellulase. Biotech 5(6):883–892

Sun Y-C, Wen J-L, Xu F, Sun R-C (2011) Structural and thermal characterization of hemicelluloses isolated by organic solvents and alkaline solutions from Tamarix austromongolica. Bioresour Technol 102(10):5947–5951

Sun FF, Wang L, Hong J, Ren J, Du F, Hu J, Zhang Z, Zhou B (2015) The impact of glycerol organosolv pretreatment on the chemistry and enzymatic hydrolyzability of wheat straw. Bioresour Technol 187:354–361

Viikari L, Vehmaanpera J, Koivula A (2012) Lignocellulosic ethanol: from science to industry. Biomass Bioenerg 46:13–24

Wang K, Yang H, Guo S, Tang Y, Jiang J, Xu F, Sun RC (2012) Organosolv fractionation process with various catalysts for improving bioconversion of triploid poplar. Proc Biochem 47(10):1503–1509

Wildschut J, Smit AT, Reith JH, Huijgen WJJ (2013) Ethanol-based organosolv fractionation of wheat straw for the production of lignin and enzymatically digestible cellulose. Bioresour Technol 135:58–66

Zhang YH, Ding SY, Mielenz JR, Cui JB, Elander RT, Laser M, Himmel ME, McMillan JR, Lynd LR (2007) Fractionating recalcitrant lignocellulose at modest reaction conditions. Biotechnol Bioeng 97(2):214–223

Zhang K, Pei Z, Wang D (2016) Organic solvent pretreatment of lignocellulosic biomass for biofuels and biochemicals: a review. Bioresour Technol 199:21–33

Zhao X, Cheng K, Liu D (2009) Organosolv pretreatment of lignocellulosic biomass for enzymatic hydrolysis. Appl Microbiol Biotechnol 82(5):815–827

Acknowledgements

Raita M. was supported by the Thailand Research Fund (TRG5980019). Laosiripojana N. was supported by the Thailand Research Fund (RTA5980006). Manuscript editing by Dr. Philip Shaw is appreciated.

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Marisa Raita and Naphatsaya Denchokepraguy are co-first authors.

Rights and permissions

About this article

Cite this article

Raita, M., Denchokepraguy, N., Champreda, V. et al. Effects of alkaline catalysts on acetone-based organosolv pretreatment of rice straw. 3 Biotech 7, 340 (2017). https://doi.org/10.1007/s13205-017-0969-1

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s13205-017-0969-1