Abstract

Commercial cellulase production has increased in recent years and consistent research has been carried out to improve levels of β-glucosidase. Bioprocesses have been successfully adapted to produce this enzyme, with solid-state fermentations as the best-suited technique involving fungi. The aim of this study was to use leaves of tarbush (Flourensia cernua), an abundant shrub of the Chihuahuan Desert, as a carbon source for β-glucosidase production by Aspergillus niger. During the solid bioprocess, this enzyme reached its peak production at 36 h of culture with 3876.6 U/L. There is a particular interest in the substrate composition because of the possibility of phenolic glycosides having an important role in β-glucosidase production. HPLC–MS analyses showed that glycosides were present with the highest accumulation at 36 h of fungal culture. Luteolin and apigenin glycosides [1.8 and 2.4 absorbance units, respectively] were also detected and showed their highest point of detection alongside the highest β-glucosidase activity. No apparent changes in cellulose were observed, while hemicellulose content decreased, which could be related to production and activity of β-glucosidase. This study shows that leaves of F. cernua are an important raw material for β-glucosidase production and give a source of compounds of added value which also may have an important role for β-glucosidase production.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Lignocellulose is the most abundant polymer in nature and it has received wide attention for its sustainable exploitation (Wang et al. 2013). Its components are cellulose, hemicellulose, and lignin, emphasizing the polysaccharides which serve as raw material for high added-value compounds extraction or production (Phitsuwan et al. 2013). In addition, phenolic compounds are secondary metabolites produced by a great variety of plants and consist of a variety of structures classified into a number of major groups including phenolic acids, flavonoids, lignans, and stilbenes, among others (Celep et al. 2014). Kris-Etherton et al. (2002) mentioned that they are natural constituents present in small amounts in plants and food products. It has also been reported that this shrub contains a large number of compounds capable of displaying bioactive actions (de Rodríguez et al. 2012), such as antimicrobial, insecticidal, cytotoxicity, and antioxidant activity (De León-Zapata et al. 2016). Biotechnological processes, such as fungal fermentation, have been proposed to use natural resources that are widely available. In this case, tarbush (Flourensia cernua) is a promising source for obtaining compounds of high added-value (El-Bakry et al. 2015; De León-Zapata et al. 2016), and it has been previously studied for this purpose (Ventura et al. 2008). Interest in the development of bioprocesses for the production or extraction of bioactive compounds from natural sources has increased in recent years due to the potential applications of these compounds in the food, chemical, and pharmaceutical industries (Martins et al. 2011). In this context, solid-state fermentation (SSF) has received great attention, because this bioprocess can convert inexpensive agroindustrial residues, as well as unpalatable forage plants, in a great variety of valuable compounds, including bioactive phenolic compounds (Sukumaran et al. 2009; Buck et al. 2015; El-Bakry et al. 2015). As SSF involves the growth of microorganisms on moist solid substrates in the absence of free-flowing water, it is suitable for a process of such characteristics and offers some advantages like the simulation of the natural habitat of the microorganisms, leading to higher enzymatic productivity (Hölker et al. 2004). In addition, the enzymes produced using SSF are less susceptible to inhibition by the substrate, and are more stable in terms of the effects of temperature and pH, compared to submerged fermentation processes (Thomas et al. 2013; Hansen et al. 2015). There are a great number of enzymes that can be used for the target of interest. Cellulase plays a key role in hydrolyzing β-1,4 glycosidic linkage in cellulose, a dominant component of plant cell wall (Singhania et al. 2010; Yoon et al. 2014). The three components of this enzyme pool: endoglucanase, exoglucanase, and β-glucosidase, efficiently depolymerize the cellulose chains in the lignocellulosic substrate to produce smaller sugar units that consist of cellobiose and glucose. Fungi are the most suitable cellulase producers due to its ability to produce a complete cellulase system. The mechanism is as follows: cellobiohydrolases, also known as exoglucanases, attack the crystalline ends of cellulose producing cellobiose (Phitsuwan et al. 2013). Endoglucanases split glycosidic bonds within the amorphous part of the substrate (Yoon et al. 2014). Finally, the released cellobiose is cleaved by β-glucosidases into glucose monomers (Liu et al. 2012; Wang et al. 2013; Behera and Ray 2015). The majority of microorganisms employed in cellulase production in SSF are fungi, bacteria, and to a lesser extent actinomycetes, which act under specific (aerobic and anaerobic) conditions (Behera and Ray 2015). The β-glucosidase production by solid-state fermentation depends on several factors such as substrate type, composition, temperature, moisture content, and pH of the medium. According to Pandey et al. (2000), the difficulty of monitoring and controlling fermentation variables in SSF is perhaps the main drawback of this process. Variations of pH during the fermentation process are due to the metabolic activity of the microorganisms and may be increased or decreased according to the by-products released or the nutrients consumed during the process. The advantage of SSF to achieve goals is the low-tech fermentation system required plus the possibility of carrying out the process on farms (Graminha et al. 2008). For this study, a solid-state culture was carried out to explore the β-glucosidase production while correlating phytochemicals available for the fungal growth. This is the first stage in a project that aims to understand the relationship between phenolic glycosides and β-glucosidase production by Aspergillus niger.

Materials and methods

Plant material

Leaves, petioles, and stems of F. cernua were collected in the South of Saltillo, Coahuila Mexico (25°15′07.39″N, 101°04′40.66″W) during August 2015. This material was dried at 60 °C in a drying oven and stored in an obscure bag at room temperature until its processing. For this study, only the leaves were used.

Strain, maintenance, and inoculum preparation

For spores propagation, A. niger strain GH1 belonging to the DIA-UAdeC Culture Collection, Saltillo, Mexico was used; it was maintained in a cryoprotected system of glycerol and skim milk at −20 °C. 250 ml of a PDA medium enriched with 0.5 g/L of soybean meal as an additional N source was sterilized in ten Erlenmeyer flasks. Subsequently, an aliquot of 40 μL of a spore suspension of A. niger GH1 was added and incubated at 30 °C for 48 h. Then, the spores were recovered using 0.1% Tween 80 and spores per mL were calculated by counting them in a Neubauer chamber.

Solid substrate and preparation of fermentation media

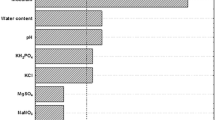

15 g of tarbush leaves were placed in aluminum tray reactors (12.5 cm diameter × 3 cm). A mineral medium with pH adjusted to 5.5 was prepared. It was autoclaved at 121 °C for 15 min. The media content (g/L) were: 2.0 (NaNO3), 0.5 (KH2PO4), 0.25 (KCl), and 0.25 (MgSO4). Subsequently, 45 mL (=75% humidity) of medium was added to the trays containing the leaves. Then, 3 × 108 spores of A. niger per g of substrate were added. Fermentation was then carried out in an incubator at 30 °C for 48 h. Recovery of the enzymatic extract was carried out by the addition of 15 mL of 10 mM citrate buffer at a pH of 4.6. Samples were recovered using filter paper by a vacuum pump.

Analytical methods

Estimation of β-glucosidase activity of A. niger GH1

Eight hundred microliters of 0.1 M citrate buffer pH 4.6 were placed in test tubes. Subsequently, 100 μL of p-nitrophenyl-β-d-glucopyranoside (pNPG) 0.009 M were added as indicated by Vattem and Shetty (2003). The tubes were incubated at 50 °C and 100 µL of diluted 1:10 enzyme extract were added. After 10 min, 100 µL of 0.1 M Na2CO3 were added to stop the reaction. The released p-nitrophenol was measured by the absorbance registered in a spectrophotometer at 400 nm. One unit of β-glucosidase (U/L) was defined as the amount of enzyme required to release one micromole of p-nitrophenol per min, under the assay conditions. To carry out the measurement of the activity of interest, enzyme and substrate blanks and a reaction mixture were prepared.

Determination of hydrolyzable phenolic compounds

The measurement was carried out according to Wong-Paz et al. (2015). 800 μL of the sample were mixed with 800 μL of Folin–Ciocalteu reagent (Sigma-Aldrich), shaken and left for 5 min. Then, 800 μL of Na2CO3 (0.01 M) were added and shaked, and left for 5 min again. Finally, the solution was diluted with 5 mL of distilled water and the absorbance was measured at 750 nm in a spectrophotometer (Helios Epsilon, Thermo Spectronic). Hydrolyzable phenolic compounds were expressed as gallic acid equivalents per gram of vegetal material (mg GAE/g).

Determination of soluble protein

Soluble protein content was determined according to the method of Lowry et al. (1951). The absorbance was measured in a spectrophotometer at 660 nm wavelength and the soluble protein concentration was estimated by interpolation to the bovine serum albumin standard curve.

Lignocellulosic composition

Neutral detergent fiber (NDF), acid detergent fiber (ADF), cellulose, and hemicellulose in the fermented material were determined according to the methodology of Van Soest et al. (1991). The difference between NDF and ADF values gave the hemicellulose content of the fermented sample.

Profile of phytochemicals by HPLC–MS

Prior to injection, the samples were filtered through a 0.45 µm nylon membrane. The compounds were detected by HPLC (Varian ProStar) using an autosampler, a ternary pump, and a photodiode array detector at 320 nm. The column used for separation was carried out with a Denali C18 column (3.1 µm; 150 × 4.6 mm, Grace, USA) at 30 °C. Mobile phases were ethanol as wash phase (solvent A), acetonitrile (solvent B), and 0.2% formic acid (solvent C) in gradients, at a flow of 1 ml min−1 with an injection volume of 10 µm. The gradients were applied as follows: initial 3% B; 5–15 min, 16% B linear; 15–45 min, 50% B linear. Then, the column was washed and reconditioned. For mass spectrometry analysis, a Varian 500/MS equipment with an ion trap, electrospray ionization (ESI), negative mode (M-H−), capillary voltage 90 V, and mass range 100–2000 m/z was used (Ascacio-Valdés et al. 2016).

Results and discussion

β-glucosidase activity and phenolic contents

The maximum activity of β-glucosidase was detected at 36 h (3876.6 U/L) under the present culture conditions (Fig. 1). It was also observed that from 0 to 24 h, no enzymatic activity was detected. This activity was detected at 30 h of culture with a value of 2109.06 U/L. Like most desert plants, F. cernua has a wide array of complex chemical compounds, which employs to deter herbivory, to survive in harsh environments and defend against microbial attack. The levels of these compounds in leaves vary over years, seasons, development stage, and the location of the plant (Estell et al. 2013). This could be related to the immediate non-detection of enzyme activity during the first few hours of the solid culture. Within this group of complex compounds are the phenolic compounds and are usually conjugated or linked with sugars and glycosides (Vattem and Shetty 2003). This could represent a challenge for the microorganism to metabolize them immediately; however, the strain of A. niger used seems to be capable of degrading these compounds. These results are in line with findings of Ascacio-Valdés et al. (2016). There are other reports on this enzymatic activity where different strains of fungi were used in different solid substrates and the maximum production times were quite prolonged (Table 1).

In chromatographic and spectrometric analysis, several glycosylated compounds were detected (Fig. 3) and it was possible to partially identify some of them (Veitch and Grayer 2008) in the fermented samples (Fig. 2; Table 2). These compounds have been previously detected by De León-Zapata et al. (2016) in leaves of F. cernua under different treatment conditions. The main flavones found in this study were luteolin and apigenin. These detections reached their maximum peak at 36 h (Fig. 2) coinciding with the maximum enzymatic activity of β-glucosidase. After that time, both showed a significant decrease in the enzymatic activity and in the accumulation of the compounds afore mentioned. Considering its nature (glycosyl hydrolase), it is possible that β-glucosidase might be responsible for catalyzing the glycosidic bonds between the phenolics compounds to release sugar molecules and their aglycones. In addition to this enzyme, it is possible that other enzymes exerted their activity by degrading cellular structures that led to the accumulation of the observed compounds. Within the bioprocess, a probable effect of the enzyme of interest was expressed when the caffeic acid-4-o-glucoside was subsequently detected by the HPLC as the sole molecule of caffeic acid (Fig. 4). The β-glucosidase activity has been reported to have an effect on this type of molecules (Dey and Kuhad 2014). Cui et al. (2016) documented the ability of this enzyme to disrupt the bond present in naringin to later release an aglycone in a process where fungal enzymes are used. Ascacio-Valdés et al. (2014) observed that the presence of β-glucosidase was obtained during the solid fungal fermentation of pomegranate polyphenols. This can be associated with the work of Vattem and Shetty (2003) who attributed the degradation of a type of glycosylated polyphenols to a β-glucosidase. Thus, it is possible that degradation of this type of glycosides is due to the effect of β-glucosidase or some other type of glycosidase (Aguilar-Zárate 2016).

Phenols accumulated as the fermentation time increased. It was observed that a significant concentration began to occur after the first 6 h of incubation, with the maximum accumulation registered at 36 h, with a content of only 2.54 ± 0.20 mg GAE/g. Hyder et al. (2005) reported higher production (81 mg/g). The levels of the phenolic content vary according to the type of plant used (Wong-Paz et al. 2015). In this study, it is believed that variation of phenol levels was due to the fermentation process to which the plant material was subjected. This increase can be explained by the fungal degradation of plant cell components with the corresponding release of phytochemicals present in foliar cells of F. cernua; that is, that the fungus could have polymerized and depolymerized phenolic monomers and could even carry out a dimerization and trimerization of these monomers, which could explain this accumulation (De León-Zapata et al. 2013). When measuring phenolic compounds, it is possible to record the variation of the amounts of these and to find a relationship between them, as well as the production of the enzyme of interest. Many of these compounds have glycosylation which can be degraded by β-glucosidase or other glycosylases (Fu et al. 2008).

As noted above, a significant accumulation of luteolin and apigenin glycosides occurred. Compared with data obtained by De León-Zapata et al. (2016) by means of a conventional extraction of F. cernua compounds, higher levels of these glycosides were detected in the present study, although quantification of them was not performed; the levels reported were approximately 0.08 and 0.14 μAU, whereas in the present investigation, 1.8 and 2.4 AU (area units) of luteolin and apigenin glycosides, respectively, were detected. Fu et al. (2008) reported that it is possible to obtain these molecules and their glycosides by extraction assisted by commercial hydrolytic enzymes.

Extracellular protein production

Table 3 shows that extracellular protein concentration was reached at 36 h of incubation with 3.16 ± 0.051 mg/g (mean ± SD) and the lowest concentration was 1.62 ± 0.273 mg/g at 48 h. With these values and the enzymatic activity of interest, β-glucosidase specific activity was determined as shown in Table 3. The amount of proteins determined could be due to the amount of depolymerizing enzymes produced during the fermentation period. There are many reports of the enormous potential of A. niger on its hydrolytic nature towards heterogeneous substrates. This strain is unable to use proteins or lipids as immediate carbon sources for its growth, because they are much more complex molecular structures than primary carbohydrates, which are easier to metabolize as the compounds mentioned previously (Lynd et al. 2002; Ventura et al. 2008).

Lignocellulosic composition after fermentation

The bulk of the lignocellulosic matter of a plant consists of cellulose (33–40%), hemicellulose (20–25%), and lignin (15–20%) (Rani et al. 2014). These values, in general, are higher than those found in the insoluble fraction of F. cernua after 48 h of fermentation by A. niger; 14–24% lignin, 16–23% cellulose, and 7–16% hemicellulose (Fig. 5). As it is well known (Cruz and Sánchez 2000), the difference between these types of fiber corresponds to the hemicellulose content. The clearest change was observed in the hemicellulose content as the bioprocess progressed. This assertion was supported by Student’s t test in which there is a statistically significant difference (t 0.05 = 1.8595 > t = −7.03), between the value of the mean of time 0 with (12.4%) respect to the value of the mean at time 48 (8.12%). The fungal strain used in the current trial produces enzymes for degrading hemicellulose as reported by Van Munster et al. (2014) and Grujic et al. (2015) using different strains of Aspergillus niger (N402 and ATCC, respectively). In this case, it is more likely that the glycosides are released in the course of the SSF process and induce or stimulate the production of β-glycosidase activity. This possible interaction between fiber-glycosides may also be linked to the activation of other enzymes and that the fungus is capable of producing glycohydrolases, carbohydrate esterases, endoxylanases, xylosidases, manases, mannosidases and arabinofuranosidases (Rani et al. 2014). Lu et al. (2010) reported the production of several hydrolytic enzymes from a bioprocess where xylose was the sole carbon source in the presence of an A. niger strain. Along with this knowledge, the mere presence of cellulose could induce β-glucosidase production, even though cellulose content apparently was unaffected.

An important aspect of any process is the benefit of by-products such as the availability of nutrients from F. cernua for livestock (Estell et al. 2016). In this case, NDF retained a higher level with respect to ADF (data not shown), which is desirable in ruminant feeding (Cruz and Sánchez 2000). In an earlier study (unpublished results), Huerta (2015) found that the fungal fermentation of F. cernua leaves increased the protein content from 9.05 to 21.78%. This is considered an enormous improvement in the nutritional potential of this shrub for ruminant nutrition (Mellado et al. 2007). The microbial exploitation of lignocellulosic materials has become very important, because many agroindustrial residues are generated or there are renewable resources of a similar nature that can be subjected to microbial action or biotechnological processes (Villas-Bôas et al. 2002; Graminha et al. 2008).

Conclusions

In the present study, we investigated the ability of the A. niger GH1 strain to degrade components of leaves of F. cernua through the activity of the enzyme β-glucosidase. A high amount of the enzyme was detected at 36 h of fermentation. In addition, high values of extracellular protein and the main glycosylated compounds detected as the Apigenin arabinoside–glucoside and Luteolin-7-O-rutinoside detected by HPLC/MS reached their maximum concentration at this time. Therefore, β-glucosidase is a good candidate to be used in a series of biotechnological processes in solid-state fermentations due to its hydrolytic activity and, additionally, to the fact that in this system, fungal growth closely resembles the growth seen in a natural environment. Thus, in these processes, it is always desirable to produce enzymes at low cost using high amounts of solid substrates. This research is still underway with the aim of elucidating the interaction of polyphenols and lignocellulosic fibers of the plant used. It is likely that the glycosylated phenolic compounds function as inducers of the enzymatic activity of interest. It is feasible to use the biotechnological resources available in the arid zones of northern Mexico, such as the leaves of F. cernua to obtain fungal β-glucosidase and at the same time accumulate glycosides with high added value.

References

Aguilar-Zárate P (2016) Purification and characterization of an ellagitannase of Aspergillus niger GH1. Universidad Autónoma de Coahuila. Doctoral thesis

Ascacio-Valdés JA, Buenrostro J, De la Cruz R, Sepúlveda L, Aguilera A, Prado A, Contreras J, Rodríguez R, Aguilar CN (2014) Fungal biodegradation of pomegranate ellagitannins. J Basic Microbiol 54:28–34

Ascacio-Valdés J, Aguilera-Carbó AF, Buenrostro J, Prado-Barragán P, Rodríguez-Herrera R, Aguilar CN (2016) The complete biodegradation pathway of ellagitannins by Aspergillus niger in solid-state fermentation. J Basic Microbiol 56:329–336

Behera S, Ray R (2015) Solid state fermentation for production of microbial cellulases: recent advances and improvement strategies. Int J Biol Macromol 86:656–669

Buck A, Casciatori F, Thoméo J, Tsotsas E (2015) Model-based control of enzyme yield in solid-state fermentation. Procedia Eng 102:362–371

Celep GS, Rastmanesh R, Marotta F (2014) Microbial metabolism of polyphenols and health. In: Watson RR, Preedy VR, Zibadi S (eds) Polyphenols in human health and disease. Academic, San Diego, pp 577–589

Cruz M, Sánchez J (2000) La fibra en la alimentación del ganado lechero. Nutrición Anim Trop 6:39–74

Cui P, Li T, Ping L, Sun W (2016) Highly selective and efficient biotransformation of linarin to produce tilianin by naringinase. Biotechnol Lett 38:1367–1373

De León-Zapata MA, Sáenz A, Jasso-Cantú D, Rodríguez R, Pandey A, Aguilar CN (2013) Fermented Flourensia cernua extracts and their in vitro assay against Penicillium expansum and Fusarium oxysporum. Food Technol Biotechnol 51:233–239

De León-Zapata MA, Pastrana-Castro L, Rua-Rodríguez M, Alvarez-Pérez O, Rodríguez-Herrera R, Aguilar CN (2016) Experimental protocol for the recovery and evaluation of bioactive compounds of tarbush against postharvest fruit fungi. Food Chem 198:62–67

de Rodríguez DJ, Hernández D, Solís S, Rodríguez R, Rodríguez R (2012) Flourensia cernua D.C: a plant from Mexican semiarid regions with a broad spectrum of action for disease control, integrated pest management and pest control—current and future tactics. In Tech. doi:10.5772/1383

Dey T, Kuhad R (2014) Enhanced production and extraction of phenolic compounds from wheat by solid-state fermentation with Rhizopus oryzae RCK2012. Biotechnol Rep 4:120–127

El-Bakry M, Abraham J, Cerda A, Barrena R, Gea T, Sánchez A (2015) From wastes to high value added products: novel aspects of SSF in the production of enzymes. Crit Rev Environ Sci Tec 45:1999–2042

Estell RE, James DK, Fredrickson EL, Anderson DM (2013) Within-plant distribution of volatile compounds on the leaf surface of Flourensia cernua. Biochem Syst Ecol 48:144–150

Estell R, Anderson D, James D (2016) Defoliation of Flourensia cernua (tarbush) with high-density mixed-species stockings. J Arid Environ 130:62–67

Fu Y, Liu W, Zu Y, Tong M, Li S, Yan M, Efferth T, Luo H (2008) Enzyme assisted extraction of luteolin and apigenin from pigeonpea [Cajanus cajan (L.) Millsp.] leaves. Food Chem 111:508–512

Gómez-García R (2016) Study of recovery of enzymes industrial interest (cellulases, xylanases and invertases) using flexible-chain polymers. Universidad Autónoma de Coahuila. Bachelor science thesis

Graminha E, Goncalves A, Pirota R, Balsalobre M, Da Silva R, Gomez E (2008) Enzyme production by solid-state fermentation: application to animal nutrition. Anim Feed Sci Technol 144:1–22

Grujić M, Dojnov B, Potočnik I, Duduk B, Vujčić Z (2015) Spent mushroom compost as substrate for the production of industrially important hydrolytic enzymes by fungi Trichoderma spp. and Aspergillus niger in solid state fermentation. Int Biodeterior Biodegrad 104:290–298

Hansen G, Lübeck M, Frisvad J, Lübeck P, Andersen B (2015) Production of cellulolytic enzymes from ascomycetes: comparison of solid state and submerged fermentation. Process Biochem 50:1327–1341

Hölker U, Hofer M, Lenz J (2004) Biotechnological advantages of laboratory-scale solid-state fermentation with fungi. Appl Microbiol Biotechnol 64:175–186

Huerta I (2015) Chemical characterization and fungal fermentation of semidesert plants with animal feed potential. Mexico: Universidad Autónoma Agraria Antonio Narro. Dissertation

Hyder P, Fredrickson E, Estell R, Lucero M, Remmenga M (2005) Loss of phenolic compounds from leaf litter of creosotebush [Larrea tridentata (Sess. & Moc. ex DC.) Cov.] and tarbush (Flourensia cernua DC.). J Arid Environ 61:79–91

Kris-Etherton PM, Hecker KD, Bonanome A, Coval SM, Binkoski AE, Hilpert KF (2002) Bioactive compounds in foods: their role in the prevention of cardiovascular disease and cancer. Am J Med 113:71S–88S

Liu D, Zhang R, Yang X, Zhang Z, Song S, Miao Y, Shen Q (2012) Characterization of a thermostable β-glucosidase from Aspergillus fumigatus Z5, and its functional expression in Pichia pastoris X33. Microb Cell Fact 11:1–15

Lowry O, Rosebrough N, Farr A, Randall R (1951) Protein measurement with the Folin phenol reagent. J Biol Chem 193:265–275

Lu X, Sun J, Nimtz M, Wissing J, Zeng A, Rinas U (2010) The intra- and extracellular proteome of Aspergillus niger growing on defined medium with xylose or maltose as carbon substrate. Microb Cell Fact 9:1–13

Lynd L, Weimer P, Van Zyl W, Pretorius L (2002) Microbial cellulose utilization: fundamentals and biotechnology. Microbiol Molec Biol Rev 66:506–577

Martins S, Mussatto SI, Martínez-Avila G, Montañez-Saenz J, Aguilar CN, Teixeira JA (2011) Bioactive phenolic compounds: production and extraction by solid-state fermentation. A review. Biotechnol Adv 29(3):365–373

Mellado M, Olivares L, Pittroff W, Díaz H, López R, Villarreal JA (2007) Oral morphology and dietary choices of goats on rangeland. Small Rumin Res 71:194–199

Nava-Cruz NY, Contreras-Esquivel JC, Aguilar-González MA, Nuncio A, Rodríguez-Herrera R, Aguilar CN (2016) Agave atrovirens fibers as substrate and support for solid-state fermentation for cellulase production by Trichoderma asperellum. 3 Biotech 6:115

Pandey CR, Soccol D, Mitchell DA (2000) New developments in solid state fermentation: I-bioprocesses and products. Process Biochem 35:1153–1169

Phitsuwan P, Laohakunjit N, Kerdchoechuen O, Kyu K, Ratanakhanokchai K (2013) Present and potential applications of cellulases in agriculture, biotechnology, and bioenergy. Folia Microbiol 58:163–176

Rani V, Mohanram S, Tiwari R, Nain L, Arora A (2014) Beta-glucosidase: key enzyme in determining efficiency of cellulase and biomass hydrolysis. J Bioprocess Biotech 5:1–8

Singhania RR, Sukumaran RK, Patel AK, Larroche C, Pandey A (2010) Advancement and comparative profiles in the production technologies using solid-state and submerged fermentation for microbial cellulases. Enzyme Microb Technol 46:541–549

Sukumaran RK, Singhania RR, Mathew GM, Pandey A (2009) Cellulase production using biomass feed stock and its application in lignocellulose saccharification for bio-ethanol production. Renew Energy 34:421–424

Thomas L, Larroche C, Pandey A (2013) Current developments in solid-state fermentation. Biochem Eng J 81:146–161

Van Munster JM, Daly P, Delmas S, Pullan ST, Blythe MJ, Malla S, Kokolski M, Noltorp ECM, Wennberg K, Fetherston R, Beniston R, Yu X, Dupree P, Archer DB (2014) The role of carbon starvation in the induction of enzymes that degrade plant-derived carbohydrates in Aspergillus niger. Fungal Genet Biol 72:34–47

Van Soest PJ, Robertson JB, Lewis BA (1991) Polysaccharides in relation to animal nutrition. J Dairy Sci 74:3583–3597

Vattem DA, Shetty K (2003) Ellagic acid production and phenolic antioxidant activity in cranberry pomace (Vaccinium macrocarpon) mediated by Lentinus edodes using a solid-state system. Process Biochem 39:367–379

Veitch NC, Grayer RJ (2008) Flavonoids and their glycosides, including anthocyanins. Nat Prod Rep 25:555–611

Ventura J, Belmares R, Aguilera-Carbo A, Gutiérrez-Sanchez G, Rodríguez-Herrera R, Aguilar CN (2008) Fungal biodegradation of tannins from creosote bush (Larrea tridentata) and tar bush (Flourensia cernua) for gallic and ellagic acid production. Food Technol. Biotechnol. 46:213–217

Villas-Bôas SG, Esposito E, Mitchell DA (2002) Microbial conversion of lignocellulosic residues for production of animal feeds. Anim Feed Sci Technol 98:1–12

Wang M, Liu K, Dai L, Zhang J, Fang X (2013) The structural and biochemical basis for cellulose biodegradation. J Chem Technol Biotechnol 88:491–500

Wong-Paz J, Contreras-Esquivel J, Rodríguez-Herrera R, Carrillo M, López L, Nevárez V, Aguilar C (2015) Total phenolic content, in vitro antioxidant activity and chemical composition of plant extracts from semiarid Mexican region. Asian Pac J Trop Med 8:104–111

Yoon LW, Ang TN, Ngoh GC, Chua ASM (2014) Fungal solid-state fermentation and various methods of enhancement in cellulase production. Biomass Bioenerg 67:319–338

Acknowledgements

The authors would like to thank the National Council of Science and Technology (CONACyT) for providing a scholarship and financial support.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that there is no conflict of interest.

Rights and permissions

About this article

Cite this article

Lopez-Trujillo, J., Medina-Morales, M.A., Sanchez-Flores, A. et al. Solid bioprocess of tarbush (Flourensia cernua) leaves for β-glucosidase production by Aspergillus niger: initial approach to fiber–glycoside interaction for enzyme induction. 3 Biotech 7, 271 (2017). https://doi.org/10.1007/s13205-017-0883-6

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s13205-017-0883-6