Abstract

Designing and building an ideal catalyst for organic reactions is needed to increase the efficiency, reaction conditions, and to reduce its environmental impacts. The growth of nanotechnology is realized in the production of various nano-level catalysts for different applications. The as-synthesized nanocatalysts are easily manipulated to a desired shape and size with a high surface area to volume ratio, which is their critical property of the interaction of the nanomaterials with the substrates. These days, a vast array of catalysts (nanocatalysts) such as metals, metal oxides, magnetic, and alloyed/mixed nanocatalysts are applied in organic reactions to synthesize important chemicals in industries and pharmaceutical sectors with a high yield, selectivity, and reusability via reduction/hydrogenation, oxidation, condensation, C–C coupling, cyclization, and more. Consequently, this present review highlights the application of various nanocatalysts in organic reactions by combining certain proposed reaction mechanisms that have shown the impact of nanoparticles on the reactions. The factors influencing nanocatalyst performances are also discussed. Finally, the conclusion and future prospects are conveyed.

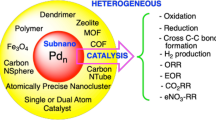

Graphic abstract

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

The continuous advancements in chemical transformation in recent decades have contributed vastly to chemical processing efficiencies using cost-effective precursors and catalysts to contribute some aspects of greenness (Varma 2016). In this regard, catalyst plays a central role where various chemical industries transform organic substrates into useful fine chemicals, pharmaceutical drugs, agrochemicals, cosmetics, and more (Amirmahani et al. 2020; Gao et al. 2021). Importantly, the continuous growth of nanotechnology has paramount importance in improving efficiency as the size of the catalytic particle plays a strong influence on the activity of the heterogeneous and homogeneous catalysis routes. Therefore, the concept of nanocatalyst is a hot issue for researchers due to its efficiency and selectivity, along with the environmental friendly synthetic approach, easily recycle and inexpensive material (Beletskaya and Tyurin 2010; Das 2016).

Nanomaterials in various forms possess distinct and unique physicochemical properties in relation to the bulk materials from which they are manufactured. This is due to the corollaries of their sizes, shapes, and synergistic effects (Holade et al. 2015). Recently, the synthesis of metals, metal oxides, magnetic and hybrid nanomaterials has undergone extensive nanotechnology studies for various applications. For instance, palladium nanoparticle (NPs), the most versatile element is used in organic reaction via alloying, decorating, or assisted with organic stabilizers, dendrimers, polymers, and iron having the advantage of magnetically recoverable and recyclable nanocatalysts. The development and innovation of novel nanocatalysts for organic synthesis are not only to increase the efficiency of the catalytic activity, but also to reduce the risks of environmental pollution (Kann 2010; Varma 2014; Tanna et al. 2016; Basavegowda et al. 2017; Mohammadparast et al. 2019; Dong et al. 2021). The nano-level materials may be designed in the form of NPs, nanocomposites, polymer-encapsulated NPs, nanorods, nanotubes, nanotemplates, nanowires, quantum dots, nanoflowers, etc. should be designed from the green chemistry point of view, free of phosphine, suitable for green solvents such as ionic liquids (ILs), supercritical fluids, water, fluorous phases, etc. and from the green chemistry principle (atom saving, dematerialization, energy-saving, raw material diversification and more) (Nacci and Cioffi 2011). Separation of the catalyst from the reaction medium is another important event; however, in some cases, their appearance in nanoscale is difficult for their recovery. The nanocatalyst separation from the reaction mixture via filtration, extraction, or centrifugation strategies is tedious and time-consuming, or sometimes impossible. In recent times, the nanocatalysts are acting as a bridge between heterogeneous and homogeneous catalysts which provides a large surface area for an increased rate of reaction and ease of their recovery from the reaction mixtures (Fig. 1). Particular attention is given to the heterogeneous magnetic nanocatalysts (MNCs) because of their insoluble and paramagnetic nature, which can be recovered by an external magnet without time-consuming procedures (Gross et al. 2015; Abu-dief and Abdel-fatah 2017; Ghobadi et al. 2021).

Today, the catalytic activity of the nanocatalyst represents a driving force and rich resource for chemical processes, used in both industries and in academia (Gawande et al. 2016). The NPs ranging from 1 to 100 nm are highly interesting and attracting researchers to use them in a wide range of technological applications (Gebre and Sendeku 2019). The catalytic efficiency, high yield, conversion, reusability, easily separated, and selectivity of the nanocatalyst is due to the small size, high surface area, shape, composition, the arrangement of the nanocatalyst as well as their interaction with the supporting materials. The nanostructured materials are designed by introducing inorganic or organic supporting materials to prevent agglomeration, modify their functional groups, improving the recyclability of the nanocatalyst, retain their magnetism and stability during the synthesis. For instance, free Au cannot be recycled as well as its catalytic activity depends on its size and morphology; therefore, size and morphology control synthesis of Au NPs applying appropriate supporting materials is a prime interest (Sharma et al. 2016a; Qin et al. 2019; Astruc 2020). In another case, MNCs such as Fe3O4 and γ-Fe2O3 can lose their magnetism due to fast oxidation in air and coating their surface via biopolymers/ILs like polyvinylpyrrolidone (PVP), polyethylene glycol (PEG), polyvinyl alcohol (PVA), dextran, cellulose, amino acids, etc. keep them magnetized. The coating of MNCs with large molecules which are sterically crowed, charged and functional polymers can also protect the agglomeration and improve their stability in aqueous media (Rossi et al. 2014; Díaz-hernández et al. 2018; Chen et al. 2020; Escoda-torroella et al. 2021; Gebre 2021). Indeed, the attached ligands have multiple functions which offered additional benefit such as increasing activity at the core of the metal, synergistic effect, and their binding ability towards the metal is crucial for the long-term stability of the nanocatalyst. For example, carboxyl and hydroxyl groups have a strong binding affinity for iron oxide NPs, while thiols have a high affinity for gold-bearing surfaces (Heuer-jungemann et al. 2019). A weak bond between the supporters and the metal core leads to sintering and leaching of the metal during applications. Therefore, the use of magnetically recyclable nanocatalysts in an aqueous medium is a prime choice for chemists due to its availability, safe, economically feasible, environmentally benign, and easily handle with better product yields (Gawande et al. 2013). It should be noted here that most of the MNCs are superior to the other in terms of their stability (negligible leaching), less catalyst load required, and ease of separation (Sharma et al. 2016b). Nanocatalyst with a large surface area plays a major role in various organic reactions such as hydrogenation, reduction, oxidation, carbon–carbon (C–C), nitrogen–nitrogen (N–N), and carbon–nitrogen (C–N) coupling reactions, cyclization, condensation, and more as demonstrated in Fig. 2 (Chng et al. 2013). The increased surface area provides the advantage of increasing the reaction rate (Govan and Gun’ko 2014). Immobilization of a homogeneous metal complex on solid supports is a common method for producing heterogeneous molecular catalysts. Among various types of solid catalysts, transition metal complexes supported on metal–organic frameworks (M@MOFs) represent one of the most important groups, owing to their advantages such as high surface area, defined pore size, and tunable structure in their framework (Alamgholiloo et al. 2019, 2020). It has been confirmed that, the high surface area exhibited to increase the catalytic activity (yield and conversion) while modifying or blocking some part of the catalytic site or increasing the surface crowdedness binds the complex reactant molecule to the specific site without competing for other reaction pathways lead to increase the selectivity and specificity of the reaction (Jin et al. 2017).

Given the growing interest in research and promising potential applications in their catalytic properties, it is ideal and timely to offer a comprehensive overview of the latest developments of nanocatalysts. In this review, the potential application of the nanocatalyst in the coupling, oxidation, reduction, condensation, heterocyclic synthesis, and dehalogenation reactions is summarized based on their efficiency, recyclability, yield, stability, and environmental concerns. Finally, the major challenges are highlighted and the conclusion is offered based on the latest developments in the field of the catalyst. I hope this review will provide guidance for researchers to rationally design various noncatalytic structures with unique morphologies and sizes for organic synthesis. Meantime, excellent articles from (Sharma et al. 2015; Zhang et al. 2019b; Bhaskaruni et al. 2020) were published on the basis of different aspects of the synthesis and applications of nanocatalysts. Despite the availability of literature reviews, they specifically focus on the synthesis approaches, or specific to MNCs for heterocyclic scaffolds, none of the recent reviews compiles broad applications of the nanomaterials. This review is exhaustive on a variety of nanocatalysts for various organic responses with their efficiency, stability, and recyclability. It is specifically aimed at compiling, discussing, and summarizing the recent trends on the nanocatalyst applications in organic reactions by addressing mechanistic aspects and characterizations. I hope this paper is an updated literature review on the varieties of nanomaterials for organic reaction applications.

Applications of nanocatalyst in organic reactions

Carbon–carbon coupling reactions

Cross-coupling reactions are some of the most studied reactions in modern chemistry using metal catalysts in recent decades (Prechtl et al. 2010; Niakan et al. 2021). Very important compounds for pharmaceuticals, agrochemicals, polymers, biologically active natural products, intermediates, fine chemicals, and high-technology materials, etc. can be obtained by the C–C, C–N, S–S, C–O linkage reactions (Hong et al. 2020; Sharma et al. 2020; Sun et al. 2020). Palladium-catalyzed C–C coupling reactions of aryl halides, such as Suzuki cross-coupling reactions also called Suzuki–Miyaura, Stille, Heck cross-coupling or refereed as Mizoroki–Heck reactions, Ullmann reactions, etc. (Fig. 3b), are powerful reactions for joining of biaryl or coupling of unsaturated and saturated alkyl structures into organic reactions (Narayanan 2010; Chen et al. 2015). The oxidizing addition of the organic electrophile leads to the formation of the unsaturated metal nanocatalyst complex. The reduction elimination terminates the coupling products with the regeneration of the nanocatalyst for further reuse as shown in Fig. 3a. The application of bulk metals for C–C coupling is not common except for some metals such as bulk Pd due to their low catalytic activity, non-recyclable, and environmentally unfavorable activity. However, metals at the nano-level are highly efficient and active for the C–C coupling reaction in aqueous solutions with highly selective, recyclability, and take place under normal conditions (Holz et al. 2019; Jani and Bahrami 2020). In the coupling reaction, both the electron-rich and electron-deficient aryl halides are coupled to produce moderate efficiency, high selectivity, and conversion. Less reactive aryl halides were performed at higher temperatures to meet the conversion. The yield of the product depends on the presence of electron-withdrawing and releasing groups in the aromatic derivatives (Goonesinghe et al. 2020). Ayad et al. (2019) engineered green and water-soluble Pd NPs supported on phosphonic acids for the Suzuki Miyaura, Sonogashira, and Heck cross-coupling reactions. The NP prepared environmentally friendly showed promising catalytic activity with high turnover frequencies (TOF) reached with low Pd NP load without any addition of toxic solvents.

Venkatesan and Santhanalakshmi (2010) developed Au/Ag/Pd trimetallic nanoparticle (TNP)-based catalysts for Sonogashira coupling reactions between phenylacetylene and iodobenzene. Thus, the trimetallic NPs was highly active and catalyzed the reaction with a small amount of dose [0.5 mol% of Au–Ag–Pd (1:1:1)] to achieve 99.5% of 1,2-diphenylethyne yield and conversion; however, the Pd and Au–Pd NP yield 94% and 96%, respectively, under the same reaction condition (dimethylformamide (DMF))-H2O solvent, K2CO3, 120 °C reaction temperature, and 2 h). Cu NP was used for the synthesis of chromene derivatives using aromatic aldehydes, 4-hydroxy coumarins, and malononitrile reactants mixed together and allowed to stir on a magnetic stirrer at the 70 °C upon adding the Cu NPs. The reaction progression was controlled using thin-layer chromatography (TLC) using n-hexane: ethyl acetate (8:2) as an eluent. The catalyst was removed by adding ethanol, heating it, and then filtering it out of the reaction mix. The products were elucidated using Proton Nuclear Magnetic Resonance (1H NMR), Fourier Transform Infrared (FTIR), Mass Spectrometry (MS), and the melting point of the product was compared with authentic samples from the literature (Tanna et al. 2016). In addition, the catalyst did not lose its catalytic activity even after five consecutive cycles, indicating the stability and proper reuse of the nanocatalyst in the reaction model. The attachment of Cl, Br, and CN substituents at the para position of the aldehyde (benzaldehyde) increases the yield of the chromene derivatives to 90, 93, and 95% yields, respectively, in 65–70-min reaction time (Balou et al. 2019). In another study, Chitosan functionalized Fe3O4 NPs was used for 2-amino-4H-chromene synthesis using a one-pot strategy (Fig. 4). The MNCs was designed to produce a 99% yield of the product under ultrasound irradiation in a short time (20 min). Furthermore, the MNCs were recovered using a magnet and reused five times without noticeable loss. Only a 2% yield was decreased in the fourth run (Safari and Javadian 2015).

One-pot synthesis of 2-amino-4H-chromenes catalyzed by Fe3O4–chitosan nanoparticles under ultrasound irradiation at 50 °C (Safari and Javadian 2015)

Suramwar et al. (2016) synthesized Cu NPs (40–80 nm) using a reduction method applying sodium borohydride and starch as reducing and stabilizing agents. The as-synthesized NP was checked in the Ullman reaction for the synthesis of biphenyl from iodobenzene and the NPs has been performed a 92% yield of the product (biphenyl); however, the reaction taking place using normal copper powder yields only 40% of biphenyl at the same reaction conditions (Fig. 5a). In a recent study, phenanthroline-functionalized polyacrylonitrile fiber (PANF) with Pd(0) NPs was reported for the Heck reaction. The fiber-stabilized Pd(0) NPs (PANPhenF-Pd(0)) catalyst was used to synthesize cinnamic acid from iodobenzene and acrylic acid with excellent catalytic activity (Fig. 5b). The fiber-based catalyst was removed by a tweezer from the reaction and washed with ethyl acetate and dried. It was reused for six consecutive series and a slight decrease of yield from 96 to 87% was recorded in the sixth run (Xiao et al. 2021).

a Formation of biphenyl b Gram-scale experiment of Heck reaction catalyzed by PANPhenF-Pd(0) (Xiao et al. 2021)

Qiu et al. (2018) synthesized Pd NPs with narrow particle size distribution (1.8 ± 0.2 nm) for Suzuki–Miyaura coupling catalytic activity. The NP was prepared using organic molecular cages as a template to resist agglomeration and to control the size of the catalyst. The NPs exhibited greater catalytic activity than the normal Pd(PPh3)4 in the Suzuki–Miyaura coupling reaction with a yield greater than > 99% summarized in Table 1.

Kardanpour et al. (2014) synthesized highly disperse and reusable Pd NPs supported on amino-functionalized metal–organic framework for the Suzuki cross-coupling reaction. The Pd/UiO-66-NH2 NP was used in the Suzuki coupling reaction between an aryl halide and phenylboronic acid to give good yields of biphenyl derivatives as shown in Table 2 below. Furthermore, the NPs were filtered, washed with water and DMF, and dried at 60 °C, and further reused until the fifth cycle without significant loss of their initial activity.

In another study, Mallikarjuna et al. (2017) used a bioinspired method to synthesize Pd NPs using fenugreek tea extracts as a reducing and stabilizing agent. The PdNPs@FT catalyst was used in the Suzuki–Miyaura coupling reaction between bromobenzene and phenylboronic acid, and an excellent yield (96%) of the product was obtained as confirmed by the 1H NMR and UV–vis spectrum. Puthiaraj and Ahn (2015) studied Pd NPs immobilized on NH2-MIL-125 (Pd@NH2-MIL-125) for the purpose of Suzuki coupling between aryl chlorides and aryl boronic acids under K2CO3 (1.5 mmol), MeOH (3 mL), Pd@NH2-MIL-125 (0.9 mol% of Pd) for 22 h as summarized in Table 3 below.

A recently published study by Ahadi et al. (2019) revealed the synthesis of Pd containing bipyridium chloride (liquid ionic-based) periodic mesoporous organosilica (Pd@Bipy–PMO) as a hybrid catalyst for Suzuki–Miyaura cross-coupling reaction in water taking 4-bromoacetophenone with phenylboronic acid as a model of the reaction. Excellent result up to 98% isolated yield was obtained. The reusability of the catalyst has been checked up to the 6th run, the leaching of Pd was detected by a hot filtration test (HFT). Furthermore, the Field Emission Scanning Electron Microscope (FESEM) image confirms the intact morphology of nanocatalyst Pd@Bipy–PMO nanocatalyst used in the 6th run (Fig. 6a–c).

FESEM images of a Pd@Bipy–PMO b the corresponding FESEM image after 6th run c recyclability study of Pd@Bipy–PMO catalyst in Suzuki reaction (Ahadi et al. 2019)

Strongly cross-linked Pd-based NPs have been synthesized for Suzuki–Miyaura and Mizoroki–Heck cross-coupling reactions. The heterogeneous nanocatalyst was developed by immobilizing the Pd NPs with a polymer containing a ligand of 4′‐(4‐hydroxyphenyl)‐2,2′:6′,2″‐terpyridine (HPTPy) ligand. The cross-linkage of the polymer with trimethylolpropane triacrylate (TMPTA) units was synthesized by polymerization of itaconic acid-HPTPy (ITC-HPTPy) monomer [so-called cross-linked poly (ITC-HPTPy)]. The stabilized Pd-based nanocatalyst offers excellent efficiency of up to 98% and 213 h−1 TOF. The catalyst was separated by centrifugation to be used consecutively. The Scanning Electron Microscope (SEM) image of the sixth time reused nanocatalyst proved the stability without any change (Fig. 7a–d), while the energy-dispersive X-ray spectroscopy (EDX) spectrum of the recovered nanocatalyst showed little leaching of Pd into the solution over the multiple runs (Fig. 7e, f) (Targhan et al. 2020). In another recent study, Ahmadi et al. (2020) synthesized magnetic mesoporous silica nanocomposite (Fe3O4-MCM-41) functioned with palladium Schiff base complex which has been applied as an efficient catalyst for Suzuki–Miyaura. The Fe3O4@MCM-41-SB-Pd nanocomposite was able to produce a 98% yield of the substituted biphenyl derivatives in a short reaction time (0.16 h) using DMF as a solvent. The catalyst was recovered using an external magnet and reused five times without a noticeable change in its activity; FTIR analysis of the nanocomposite confirmed that the structure of the nanocomposite was not changed after five runs.

SEM images of a and b fresh, c and d recovered after 6th run, EDX pattern of e fresh and f recovered after 6th run of cross-linked poly (ITC-HPTPy)-Pd (Targhan et al. 2020)

A magnetically recovered and stable Pd@Fe3O4 nanocatalyst has been checked for the hydrogenation of nitroarenes and Suzuki–Miyaura reactions by taking 2 mmol of the substrates, 5 mL of ethanol, 50 mg load of the catalyst under 1 atm of hydrogen pressure, and the reaction progress was controlled by TLC and conversion was checked by Gas Chromatography (GC). On the other hand, 5 mL ethanol, 0.5 mmol of aryl chloride, 0.6 mmol of phenyl boric acid, and 1.5 mmol of K3PO4 were used for the Suzuki–Miyaura reactions. Over 99% conversion of hydrogenation of various substrates using Pd@Fe3O4 as a catalyst has been confirmed. Suzuki–Miyaura coupling reactions involving aryl chlorides, bromides, and iodides with phenyl boric acid have also shown > 90% yield of biphenyl when electron-withdrawing substituents are attached to the aryl halides than electron-releasing groups (Amali and Rana 2009).

Sawoo et al. (2009) studied the catalytic activity of Pd NPs for C–C coupling reactions. The NPs was synthesized in water and templated in a PEG stabilizer. Thus, the aqueous nano-sized Pd NPs were a highly efficient catalyst for Suzuki, Heck, Sonogashira, and Stille C–C coupling reactions where only water was used as a solvent in the reactions. A 95% yield of products was obtained from the Suzuki reaction after isolation and purification inside 3 h at room temperature. Similar activities of the NPs are observed in Heck, Sonogashira, and Stille C–C coupling reactions as summarized in Table 4.

Sulfur-containing (aryl sulfide) derivatives are important compounds in biological, pharmaceutical, and other materials. Thus, these compounds are synthesized using nanostructure catalysts such as CuO hollow nanostructures through Ullmann reactions. The reaction of iodobenzene with thiophenol using the charcoal (CuO/C) in DMF and 120 °C provided a low conversion rate and not selective to diphenyl thioether or diphenyl disulfide products (Fig. 8). Acetylene black (CuO/AB) was used to overcome the problems but till the low conversion of the reaction was observed but high selectivity among the products has been observed (Woo et al. 2013).

CuO/AB-catalyzed Ullmann coupling reaction with various substrates (Woo et al. 2013)

Similarly, Sengupta et al. (2017) used nickel NPs supported on reduced graphene oxide (Ni/RGO-40) for C–S cross-coupling reaction between an aryl halide and thiol using DMF solvent, K2CO3 as a base at 100 °C. The C–S coupling reactions between the iodoarene and aryl thiols with different groups such as OMe, F, COCH3, and NO2 were equally efficient in the coupling reaction to produce the unsymmetrical diary sulfides in the range of 88–93% yield products. Aliphatic thiols were also resulted in the coupling reaction in the formation of unsymmetrical aryl alkyl thioether with a relatively lower yield of 75–80%, indicating the aliphatic thiols are less reactive in the C–S coupling than the aromatic thiols. Finally, the Ni/RGO-40 nanocatalyst was recovered using a magnet, washed using excess ethanol, dried in a vacuum oven, and reused six times and a 91% yield of products was obtained in the sixth run. Selective sulfenylation of indole derivatives has been carried out via C–S formation using cellulose-derived Fe3O4@Pd NPs (Fig. 9). The magnetically separable NP employed a 98% yield of the product using 1 mol% of the Fe3O4@Pd NPs. The catalyst was reused five times to give a 90% yield of the products (Li et al. 2020).

The formation of indole derivatives (Li et al. 2020)

Santa Barbara Amorphous (SBA-15) is known as a hybrid catalyst due to the combination of organic and organometallic supporters. Thus, mesoporous silica/silicate-aluminosilicates have unique properties (uniform pore size (4.6–30 nm), well-defined pore structure, and size distribution, high surface area, high thermal stability) mostly used as advanced support in metathesis catalyst (Balcar and Cejka 2019; Crucianelli et al. 2019). The mesoporous silica is applied as a support to immobilize the metal nanocatalyst in the heterogeneous catalysts for protecting them from sintering and leaching out as well as for mass transports of reactants, intermediates, and products (Wang et al. 2020). A recent study by Tamoradi et al. (2019) on BA-15@ABA-M (M = Cu, Ni, and Pd) reported an efficient, novel, and green catalyst oxidative under mild conditions. The immobilized Cu, Ni, and Pd complexes on SBA-15 mesostructured were carried out for coupling of thiols for the synthesis of disulfide compounds using H2O2 as an oxidant. The catalyst was stable, used for a wide range of thiols with excellent yield and shorter reaction time. At the end of the operation, the SBA-15@ABA-M catalyst was separated from the reaction mixture by simple filtration, washed with ethyl acetate to remove the residual products, and the catalyst has been reused for several runs and performed without any metal leaching or significant decrease in its activity. Finally, the proposed reaction mechanism has been deduced (Fig. 10a, b).

a Proposed mechanism for oxidative coupling of thiols in the presence of SBA-15@ABA-M (M=Ni, Cu and Pd) b Recycling test of the prepared catalysts for the oxidation of 4-methylthiophen under optimized conditions in the presence of SBA-15@ABA-Cu, SBA-15@ABA-Ni, and SBA-15@ABA-Pd (Tamoradi et al. 2019)

A magnetically recycled heterogeneous nanocatalyst has been fabricated via functionalization of SBA-15 with Schiff base ligand, and then immobilization of Pd NPs (Fe3O4–Pd@SF‐SBA‐15) for C–C Heck coupling reaction. The catalytic activity of Fe3O4–Pd@SF‐SBA‐15 was investigated on the synthesis of stilbene from aryl halides with styrene derivatives as a model of reaction as shown in the reaction mechanism and 97% yield of stilbene has been obtained after 40-min reaction time (Fig. 11). The Fe3O4–Pd@SF‐SBA‐15 nanocatalyst can be reused eight times without a significant loss of its catalytic activity. Stability evaluation of the nanocatalyst via Inductively Coupled Plasma Optical Emission Spectrometry (ICP‐OES) and X-ray diffraction (XRD) confirmed that only 0.093 wt% of Pd was leached after the eighth cycle (Khodaei and Dehghan 2018).

Mechanism of Fe3O4–Pd@SF‐SBA‐15‐catalyzed Heck reaction (Khodaei and Dehghan 2018)

Palladium NPs supported on magnesium ferrite catalyst (Pd/MgFe2O4) was applied for the synthesis of a marketed anticancer drug PCI-32765 under the name IMBRUVICAVR (Ibrutinib-BTK inhibitor) following the C–C coupling (Suzuki) and C–N coupling reactions. The nanocatalyst showed outstanding activity with 99% yield using 0.2 mol% of Pd/MgFe2O4 loading with 495 and 247.7 h−1 turnover number (TON) and TOF, respectively, towards ligand-less Suzuki coupling reaction using greener solvent mixture water: ethanol to synthesize the 5-(4-phenoxyphenyl)-7H-pyrrolo[2,3-d]pyrimidin-4-ylamine intermediate for the marketing drug PCI-32765 (Dasari et al. 2020).

Works reported by researchers on the C–C coupling reactions using different nanocatalyst under a certain reaction conditions are summarized in Table 5 below.

Reduction reactions

The reduction reaction is a central and vital reaction type used to manufacture different important industrial products such as biologically active compounds, pharmaceutical ingredients, dyes, rubbers, and other chemicals in different chemical industries. Traditionally, the hydrogenation and reduction reactions are performed under the transition metal catalysts (Pt, Pd, Ni, Cu, Ru) applying toxic reducing agents like NaBH4, LiAlH4, hydrazine, etc. which are not safe (Gawande et al. 2016). Various structures of aniline, major building blocks, and drug and dye intermediates are obtained from the nitroaryl compounds via nanocatalysts in a reasonable yield and conversion (Huang et al. 2018). Consequently, several approaches have been designed to produce stable, reusable, and durable heterogeneous nanocatalysts (Shokouhimehr 2015). Gold NPs (Au NPs) are among the promising catalyst with excellent activity, plasmonic property, and separations from organic reactions. Supported Au NPs are stable and recyclable compared with the other NPs (Table 6). Immobilization or functionalization of Au NPs with supporting materials, particularly with iron-based materials, is beneficial in terms of ease of separation and stability (Sharma et al. 2016a; Moon et al. 2018; Kazemi 2020a). The nanocatalysts in the form of Au/AlO3, Au/Fe2O3, Au/TiO2, Au/ZnO, and Au/SiO2 are studied for organic reactions (Ballarin et al. 2017; Martins et al. 2017). Bhaduri et al. (2019) used recyclable Au/SiO2–shell/Fe3O4–core for the reduction of nitroaromatic compounds. The Au nanocomposites have been tested for the reduction of 4-nitrophenol (4-NP) and 2-nitroaniline (2-NA) under an aqueous solution with NaBH4. The magnetically recyclable nanocomposite was highly stable (∼ 3 months), reused up to 10 runs, and high activity of 100% conversion within 225 s, 700 ppm of 4-NP or 2-NA was observed.

Plant-mediated Au NPs of different size have been fabricated using sun-dried Coffea arabica seed (CAS) extracts for the reduction of 4-NP. The synthesis strategy of size and shape control was implemented by adjusting the pH concentration of the plant extract (Fig. 12a) (Bogireddy et al. 2018). The bioinspired NPs showed a 100% reduction of the nitrophenol to aminophenol. Fountoulaki et al. (2014) studied the reduction of nitroaromatics using mesoporous titania-supported gold NP assemblies (Au/MTA) nanocatalyst in the presence of NaBH4 or 1,3,3-tetramethyl disiloxane (TMDS). Electron-withdrawing-containing nitroaromatic compounds was reduced faster than the electron-donating-containing one. The nanocatalyst showed an excellent yield (> 99%) of products using ethanol as a solvent and TMDS as a hydrogen source. Depending on the proposed reaction mechanism, the B–H or Si–H bond cleavage occurs at the rate-determining step to give [Au]–H which facilitates the rapid reduction of nitroarenes (Fig. 12b).

a A schematic representation of the shape and size control of Au NPs in CAS extract-mediated synthesis process through pH variation. The SEM images presented in the right column correspond to the samples prepared at corresponding pH values of the reaction mixtures (Bogireddy et al. 2018) © Royal Society of Chemistry, reproduced with permission b Proposed mechanism for the reduction of nitroarenes using NaBH4 or TMDS catalyzed by gold nanoparticles (Fountoulaki et al. 2014)

It has been found that Au nanocatalyst has demonstrated excellent performance in many organic reactions such as selective reduction and oxidation. However, the high cost of Au should be considered in future developments (Albero and García 2019). Though, Au NP showed excellent and selective reduction for nitroaromatic reduction, the origins of its catalytic performances are not properly deduced (Zhao et al. 2019a).

Ag NPs have been fabricated stabilizing on the combination of porous igneous rock volcanic pumice (VP) and Chitosan (CTS) polymeric network for the reduction of nitrobenzene to aniline. The Ag@VP/CTS composite has been able to reduce the nitrobenzene in a very short period of time through an electron transfer system. The catalyst was magnetically collected from the reaction mixtures, washed with water, oven-dried, and further reused for eight successive cycles without significant loss. Only 5% of its catalytic activity has been reduced in the eighth series since the first run (Fig. 13a). Furthermore, SEM, Transmission Electron Microscope (TEM), EDX images, FTIR, and XRD spectrum of the nanocatalyst confirmed that no changes have been observed in its morphology, size distribution, and characteristic spectra compared with the fresh sample (Fig. 13b–f) (Taheri-ledari et al. 2020).

a Recyclability diagram b the FTIR spectra of fresh and recovered catalyst c SEM image d EDX spectrum e XRD pattern and f TEM image of the recovered Ag@VP/CTS nanocatalyst (Taheri-ledari et al. 2020)

Jacinto et al. (2009a) studied the catalytic application of amino acid-modified silica-coated magnetic Pt(0) NPs for the hydrogenation of alkenes and ketones. A series of hydrogenation reactions was carried out against benzene, toluene, styrene, p-xylene, and prop-1-en-2-ylbenzene and the catalyst showed 98.9% of the conversion of styrene to ethylbenzene, 100% selectivity for the conversion of prop-1-en-2-ylbenzene to cumene. Similarly, over 99% conversion of ketones to alcohols was achieved by the catalyst (e.g.; 3-pentanone to 3-pentanol) at 1200 h−1 TON. Finally, the catalyst was recovered using an external magnet and reused several times (14 successive reductions) without losing its activity. Activated palladium sucrose NP (APdS NP) was used for the reduction of nitrobenzene derivatives into aniline derivatives. A 100% yield of the products was obtained and the NPs was effective, green, recyclable, and non-hazardous catalyst (Samsonu et al. 2018). Stable, effective Pd NPs stabilized by Pd/PEG was used for the reduction of styrene to ethylbenzene, the reduction reaction carried out at higher styrene concentration to exhibit 100% conversion in 90 min at room temperature; however, the conversion decreases to 80% upon decreasing the styrene concentration. Similarly, the catalyst Pd/PEG was used to reduce nitrobenzene with 93% conversion and 100% selectivity (Harraz et al. 2012). Zeynizadeh et al. (2017) fabricate magnetically recoverable NiFe2O4@Cu nanocatalyst for the reduction of nitroarenes to arylamines in the presence of NaBH4. The reduction reaction of the nitroamines was taking place in 1 min, 0.15 g of NPs load, and 1:2.5 molar ratio of the substrate to NBH4 to yield > 95% of arylamines. The NP was recovered using an external magnet, washed with ethanol, dried in the atmosphere, and reused further seven times without losing its catalytic activity. Similar studies have been conducted by Shokouhimehr et al. (2018) to synthesize magnetically retrievable nanocomposite embedded with Pd nanocatalyst (MRN–Pd) for the reduction of nitroaromatics in aqueous solution. The heterogeneous nanocatalyst was recycled with an external magnet and reused several times without noticeable loss of its activity to retain 95% yield in the seventh run. Thus, the supported Pd nanocatalyst was stable, durable, and easily separated by a small magnet (Table 7).

In another study, the above authors synthesized hydroxyapatite (HAP)-supported Pd nanocatalyst for the reduction of nitroaromatics and oxidation of alcohols under aqueous solution using NaBH4 and H2O2, respectively. The catalyst afforded excellent performance and stability in a continuous work-up for six runs without significant loss in both the reduction and oxidation reactions (Fig. 14a) (Shokouhimehr et al. 2019). Zhang et al. (2020) reported the synthesis of Prussian blue analogs (PBAs) modified Pd nanocatalyst for the reduction of nitroaromatics to amino aromatic. The composite exhibited excellent activity due to the multiple electron transfer that was improved the poor electronic conductivity of the PBAs. Out of the six types of hexacyanoferrate(III)-based PBAs, MHCFe (M = Mn, Fe, Co, Ni, Cu, and Zn), the FeHCFe nanocatalyst was noticeability performed better activity in the reduction of the nitroaromatics. The Pd-loaded nanocatalyst (FeHCFe@Pd) showed excellent yields in both the electron-withdrawing and -donating group containing nitroaromatics to give 90–99% yield in 5 min. The FeHCFe@Pd nanocatalyst promises an advantage such as a small amount of the catalyst (5 mg) was enough for the complete conversion, it was selective only for the reduction of nitro groups to their corresponding amino groups, it exhibited a TOF value of 1.43 s−1, the composite was recycled and reused 5 times without significant loss (Fig. 14b).

a Reusability of HAP-Pd catalyst in heterogeneous reduction of nitrobenzene (gray columns) and oxidation of cycloheptanol (black columns (Shokouhimehr et al. 2019) © MDPI, reproduced with permission b Repeated cycling studies for the reduction of nitrophenol to aminophenol using the FeHCFe@Pd catalyst (Zhang et al. 2020)

Photocatalytic reduction of aromatic nitro compounds to aromatic amines using CdS NPs was carried out by Eskandari et al. (2014) under light-emitting diode (LED) irradiation. The CdS photocatalyst showed excellent activity and yield in the reduction reaction with aromatic nitro compounds having electron-withdrawing substituents (CN, COR, NO2, Cl) to give a higher yield than electron-donating groups (Me, OMe, OH). Furthermore, the photocatalyst (CdS) shows highly selective, performed in mild conditions, and can be reused six times. Other NPs like Ni nanoparticles-polyvinyl amine/SBA-15 (Ni-PVAm/SBA-15), Cu, and N-TiO2 were also showed good activity as summarized in Table 8.

Magnetic graphene oxide-supported Pd NP (C–Fe3O4–Pd) catalyst is prepared for the reduction of nitrobenzene to aniline under room temperature and 30 min reaction to exhibit 100% conversion, 99% selectivity, 99% yield using NaBH4 as a hydrogen donor. Similarly, substituted nitrobenzene derivatives also reduced in the same condition to exhibit good yields and conversions. Finally, the catalyst (C–Fe3O4–Pd) was recovered and reused several times by washing with water, ethanol, and drying under an oven to perform its catalytic activity without an apparent loss (Zhou et al. 2016). Zamani et al. (2018) synthesized Walnut shell-stabilized copper NPs (Cu NP/WS) for the reduction of nitroarenes and benzonitriles and the C–C coupling reaction using water as a solvent. The Cu NP/WS showed remarkable catalytic activity and stability to reuse several times without significantly losing its initial activity. The small size of the NPs (15–22 nm) plays a crucial role in the reduction of nitroarenes and benzonitriles in water up to 100% yield products (Table 9).

A study by Baruwati et al. (2009) on a magnetically recoverable supported ruthenium catalyst supported on magnetic NPs (NiFe2O4) has successfully used for the hydrogenation of alkynes to alkane and the reduction of carbonyl compounds to alcohols. High yield products (> 95%) were achieved even after the fifth reaction cycle at room temperature. Similar studies by Polshettiwar et al. (2009) were conducted using the nano-ferrite catalyst for the hydrogenation reactions (Table 10).

Veisi et al. (2021) used Fritillaria imperialis flower extract-mediated Pd NPs-fabricated magnetic Fe3O4 (Fe3O4@Fritillaria/Pd) nanocomposite for the reduction of nitroarenes. Excellent results (98%) yield of aniline derivatives was obtained. The green, bioinspired, and magnetically separable nanocomposite catalyst was stable and performed for seven consecutive runs. TEM and EDX analysis of the 7 reused nanocomposites do not show any structural, morphological, or any sign of agglomeration (Fig. 15a, b, d). Finally, the proposed reaction mechanism was forwarded. The hydrazine first adsorbs on the surface of Pd NPs followed by N2 formation and subsequent nitroarenes adsorption on the catalyst surface results in the formation of aniline (Fig. 15c).

TEM images of a fresh, b 7 times reused Fe3O4@Fritillaria/Pd NPs c Reaction mechanism for the reduction of nitrobenzene over Fe3O4@Fritillaria/Pd catalyst d Reusability of Fe3O4@Fritillaria/Pd catalyst for reduction of nitrobenzene (Veisi et al. 2021)

Abu-reziq et al. (2007) synthesized Pt NPs supported on magnetite NPs for the purpose of hydrogenation of alkynes and reduction of α-β-unsaturated aldehydes into alcohols. The NPs were stable, readily recoverable by an external magnet, suitable in ILs, and selective to isomers (cis products) for alkyne hydrogenation and allyl alcohols were mainly produced. For example, the product of diphenylacetylene hydrogenation yields cis-stilbene (95%) and trans-stilbene (5%), 1-ethynyl-4-methylben-zene to 1-methyl-4-vinylbenzene (88%) and 1-ethyl-4-methylbenzene (12%), cinnamaldehyde to 3-phenylprop-2-en-1-ol (99%), and 2-methyl-3-phenylacrylal-dehyde to 2-methyl-3-phenylprop-2-en-1-ol (90%) was achieved using the catalyst. Stein et al. (2011) synthesized iron nanoparticles (Fe-NPs) supported on chemically derived graphene (CDG) for the reduction of alkene and alkyne to their corresponding alkane under THF, room temperature, and 30 bars. The hydrogenation of styrene, cyclooctene, 1-hexene, 1-octene, norbornene, and 1-phenyl-1-propyne results in 99, 99, 100, 100, 100, and 100% product yields (alkane); however, cyclopentene, cyclohexene, and trans-stilbene yield 73, 79, and 7% of the products only. The Fe NP-CDG exhibited good catalytic activity in most of the alkene including cyclic alkene, but unsuitable for the hydrogenation of internal double bonds of a cyclic system; on the other hand, no product was achieved in the hydrogenation of tri- and tetrasubstituted olefins. Disubstituted alkynes were catalyzed better than the terminal once. The catalyst was stable and reused in several runs without significantly altering the catalytic activity. A monodisperse Ni NPs was reported for stereo- and chemoselective semihydrogenation of alkynes to alkenes. The NPs were prepared using fructose@SiO2, glucose@SiO2, manose@SiO2, and galactose@SiO2 supporting materials and pyrolyzed at 800 °C. All the Ni-base NPs were carried out for the semihydrogenation of diphenylacetylene to stilbene at 10 bar H2, 2 mL acetonitrile, 110 °C, 15 h, and 10 mg of catalyst (1.6 mol% Ni) to exhibited > 99% conversion, 94% yield, 99:1% selectivity of Z:E isomers of stilbene and 5% yield of alkane. Diphenylacetylene derivatives (with different electron-withdrawing and -donating groups) were also tested using the catalyst and high-yield products with stereo- (98–100% Z-alkene formation) and chemo-selectivity were observed. Finally, the NPs were recycled and reused for seven consecutive runs to give > 90% yield and similar selectivity (Murugesan et al. 2019). Fan et al. (2017) fabricated TiO2-supported Pd catalysts (Pd/TiO2) for phenylacetylene semihydrogenation to styrene. Three samples of the NPs were prepared using photodeposition (PD) and deposition–precipitation method (DP) both supported on the anatase TiO2, and further thermally dried PD at 300 °C (PD-300). The DP catalyst showed higher initial performance in the conversion of phenylacetylene to styrene reaches 100% at 40 min but after 60 min, the selectivity of styrene is failed to 0%. In contrast, the PD catalyst retains high selectivity of forming styrene even after a 100-min reaction time with a 95% selectivity. The PD-300 catalyst was also performed similarly to the PD but declined rapidly when the conversion reaches 100%. This is due to the reason that quasi-spherical Pd ensembles (regular) arrangement was observed on the DP catalyst while thermal treatment of Pd disorganized the structure to have various boundaries in PD and PD-300. The reduction of nitroaromatic to aromatic amines extensively studied using NPs as a catalyst. Since the nitroimines are toxic and environmentally unfriendly, reduction to their corresponding nontoxic amines is important. For example, nitrophenol can be transformed into harmless aminophenol that is an important intermediate for dyes and pharmaceuticals in advanced yield (Table 11) (Zhang et al. 2019a). Water-soluble Pd NPs have been used for selective hydrogenation of phenol to cyclohexanone. The water-soluble Pd NPs were stabilized over PVP and > 99% conversions have been achieved in 16 h, 1 atm H2, and 90 °C to cyclohexanone with > 99% selectivity; however, the use of Ru NPs showed 99% dominantly to cyclohexanol (99.8% selectivity). Another nanocatalyst such as Pt NPs has been also checked for the hydrogenation of phenol and the conversion of phenol to cyclohexanone decreased to 19.2% with 77.2.% selectivity (Zhu et al. 2014).

Oxidation reaction

The oxidation reaction is the most important chemical process in organic chemistry and is central to the design and development of new and novel value-added products. Aldehydes, ketones, epoxides, and organic acids are the most important sources of drugs, vitamins, fragrances, and selective oxidation of these products from alcohols, unsaturated hydrocarbons, and other sources are required. Conventionally, oxidation reactions are performed at high temperature and pressure using stoichiometric amounts of oxidants, such as chromates, oxalyl chloride, or hypervalent iodides, permanganate, or N-chlorosuccinimide, and volatile organic solvents which are not environmentally benign due to the release of a large amount of hazardous waste byproducts. As well, it is difficult to recycle and separate catalysts from the products (Guo et al. 2011; Imamura et al. 2013; Gawande et al. 2016). Therefore, the oxidation reaction carried out under mild conditions having a high yield and recovery with minimum waste byproducts is vital. Nowadays, nano-level catalysts are applied in oxidation reactions to produce reasonable results with remarkable selection, conversions, and separation (Liu et al. 2015).

Jacinto et al. (2009b) have reported Ru(0) and Ru(III) catalysts functionalized on silica-coated magnetic support that possess great catalytic performance and recovery properties. Thus, the magnetically separable Ru(III) catalyst (Fe3O4/SiO2/Ru3+) was used for the oxidation of primary and secondary alcohols to their corresponding aldehydes and ketones with remarkable conversion and selectivity as shown in Table 12 below. In addition, the magnetically separate Ru(0) form was active for the hydrogenation of cyclohexene with a conversion of > 99% and 420 h−1 TOF.

Ali et al. (2015) also studied the oxidation of benzylic alcohols using copper-manganese mixed oxide NPs (CuMn2) as a catalyst. Thus, the CuMn2 nanocatalyst showed excellent catalytic performance for the oxidation of benzylic alcohols to their corresponding aldehydes with > 99% selectivity and 100% conversion in a very short period of time and 100 °C. However, NiFeO4 MNCs performed below a 90% conversion and had a longer reaction time. The reaction is highly dependent on the electronic, steric effects of the substituents, and electron-withdrawing groups attached to the benzylic alcohols which demand a long time to complete the reaction (Table 13).

Alcohol oxidation was carried out by the copper(II) phthalocyanine nanocatalyst, using water as a solvent and tetra-n-butyl-ammonium-peroxo-monosulfate (n-Bu4NHSO5) as an oxidant at 85 °C. Both aliphatic and aromatic alcohol derivatives were employed in the oxidation reaction by the nanocatalysts and 80–95% yield of products has been achieved by varying the substituents on the cyclic alkane and aromatic alcohol derivatives; however, only 64% yield of propanone was obtained from 2-propanol. Finally, the catalyst has been separated from the product by simple extraction with ether and reused several times without any change in its activity (Kheirjou et al. 2016). A novel DNA–Montmorillonite (MMT hybrid)-supported Pt, Pd, and Au NPs were successfully prepared for the conversion of alcohols to aldehydes, acids, and esters selectivity and effectively using water as a solvent. Thus, the natural DNA–MMT-supported NPs showed remarkable selection oxidation of the primary alcohols. Yields of up to 98, 94, and 98% of carboxylic acid, esters, and aldehyde were obtained corresponding to Pd/DNA–MMT, Au/DNA–MMT, and Pt/DNA–MMT catalysts, respectively. Catalysts have been separated by a simple phase separation process for subsequent reuse (Tang et al. 2013). Mn-graphene oxide nanocomposite (Mn2+/GO) was applied for alkene catalytic epoxidation typically, for styrene epoxidation in H2O2 (30 wt%) in the presence of NaHCO3. The nanocomposite showed superior catalytic activity for the epoxidation of styrene with almost 95% of the yield of styrene epoxide obtained over the Mn2+ ions loaded on the GO nanosheet and giving a high TOF value of 2000 h−1. Various alkenes were also undergoing epoxidation by the Mn2+/GO nanocomposite to yield 85–97% epoxide products and 96–99% conversions. Alkenes with a high electron density of the conjugated systems were highly effective due to the possibility of electrophilic cycloadditions (Zheng et al. 2014). A recyclable magnetic cobalt ferrite NP (CoFe2O4) was also applied for the oxidation of alkenes such as styrene, methyl styrene, 4-methoxystyrene, 4-nitrostyrene, cyclohexene, and 1-heptene to the corresponding carbonyl compounds. Oxidation of cyclohexene results in an allylic oxidation product, 2-cyclohexene-1-one with 75% yield and terminal olefins like 1-heptene was also transformed to epoxides with good yield and selectivity using t-BuOOH as an oxidant (Kooti and Afshari 2012). Oxidation of alcohols to aldehydes is very difficult in organic chemistry because over-oxidation occurs immediately to carboxylic acids and ester. Zhao et al. (2019b) studied the selective oxidation of alcohols to aldehydes using very small size (2 nm) Ru NPs. The non-supported Ru NPs were checked for the oxidation of aliphatic, aromatic, and unsaturated alcohols to aldehydes under a mild condition without the use of toxic solvents to exhibit > 90% selectivity. It shows an 85% selectivity for octanol-to-octanal conversion, which is 5–7 times higher than the other large-size Ru catalyst and the reference Ru/Al2O3 catalyst. Similarly, Bhat et al. (2014) fabricated a nickel hydroxyl-coated nano-cobalt ferrite catalyst for the selective oxidation of alcohol into aldehydes. The magnetically recoverable nanocatalyst was active for the oxidation of primary and secondary alcohols with 87% conversion efficiency and 97% selectivity to their corresponding aldehydes in a reasonable yield (Table 15).

Mirfakhraei et al. (2018) designed sulfonated-polyethylene glycol-coated Fe3O4 nanocomposite (Fe3O4/PEG–SO3H) as an effective and ecological nanocatalyst for the selective oxidation of sulfides to sulfoxides or sulfones. The immobilized MNC offered almost 100% yield of the products in 10 min. Further, the catalyst was recycled by a magnetic device and reused 13 times without loss. The leaching of the catalyst leaching was controlled with HFT and the quality of the catalyst was preserved. The TEM images of the fresh nanocatalyst and the recycled catalyst after 12 cycles confirmed that the morphology and chemical structures of the nanocatalyst was retained (Fig. 16a, b, e). Elemental analysis of the 12th recycled catalyst demonstrated that the leaching of the active catalytic locations was less than 5% of the total quantity of the catalytic site. Finally, the proposed mechanism for the oxidation of sulfide to the corresponding sulfoxide or sulfone using the Fe3O4/PEG–SO3H was investigated (Fig. 16c, d).

TEM images of fresh a and b reused catalyst Fe3O4/PEG–SO3H after the 12th run c Fe3O4/PEG–SO3H catalyzed the oxidation of using H2O2 d Proposed mechanism for the oxidation of sulfide to the corresponding sulfoxide or sulfone with aqueous hydrogen peroxide in the presence of Fe3O4/PEG–SO3H e Reusability of the nanocatalyst (Mirfakhraei et al. 2018)

In other studies, bipyridinium IL-bridged periodic mesoporous organosilica (Bipy-PMOs-IL) which was used as a support to immobilize oxygen-rich molybdenum (VI)-based oxido-peroxido complex (MoO(O2)2@Bipy-PMO-IL) has been used for selective sulfide oxidation in the presence of H2O2. The hybrid catalyst showed excellent performance and easy work-up at ambient temperatures for the oxidation of sulfide derivatives. The MoO(O2)2@Bipy-PMO-IL catalyst was reused for five consecutive runs without significant loss; however, the MoO(O2)2@SBA-15 (without IL) significantly decreases its activity after the second run. The performance of the hybrid nanocomposite for the selective oxidation reaction of sulfides to sulfoxides under optimized conditions is summarized in Table 14 below (Moaser et al. 2020).

An early study by Yarmohammadi et al. (2021) also reported the oxidation of sulfide derivative into sulfoxides using copper-based on diaminonaphthalene-coated magnetic NPs (CoFe2O4–DAN–Cu(II)). Under optimum conditions, 0.025 g of a load of catalyst, 1 mmol of sulfide, 30% H2O2 (0.5 Ml) at 25 °C, the synthesis yields of sulfoxides, symmetrical sulfides, and disulfides were about 99%, 95%, and 96%, respectively, with the highest selectivity. The catalyst was recycled nine times using a magnet and operated without significantly losing its catalytic activity as summarized in Table 15.

Condensation and hydration reactions

Condensation and hydration reactions are very important in organic synthesis as well as in the chemical industries due to their wide range of intermediates for fragrance, medicine, agricultural chemicals, cosmetics, etc. In addition to this, the reactions are carried out biologically in protein formation via a peptide bond, carbohydrate (glycosidic), and other biochemical reactions and biomass hydrolysis like starch, lignin, hemicellulose for energy fuels in different chemical process (de Wild 2015; Höfer 2015). Therefore, the insolubility of the NPs in the hydration or condensation reaction makes them easily separated from the reaction products, solving one of the biggest problems associated with homogeneous catalysts (Downs and Tyler 2014).

Safari and Gandomi-Ravandi (2014) fabricated a carbon nanotube decorated Ag NP (Ag-CNT) as a heterogeneous nanocomposite catalyst for the synthesis of 2-aryl-2,3-dihydroquinazolin-4(1H)-ones as shown in Fig. 17. The synthesis of 2-aryl-2,3-dihydroquinazolin-4(1H)-one was carried out under ultrasonic irradiation since this method is convenient and gives good yields in a short period of time, high selectivity under mild condition. The effect of solvents on the yield of the product was also observed. The yield of the sonication of o-aminobezamide with benzaldehyde reaction was affected by a solvent and a 97% yield of the product was achieved using EtOH solvent in 5-min reaction time.

Sonication of anthranilamide and aldehydes with Ag–CNTs as catalyst (Safari and Gandomi-Ravandi 2014)

Abaeezadeh et al. (2019) used magnetic mesoporous MCM‐41 silica-supported ionic liquid/palladium complex (Fe3O4@MCM@IL/Pd) nanocatalyst for the synthesis of pyrano[2,3‐d]pyrimidine derivatives. The core-structure nanocatalyst was recoverable and efficient for one-pot synthesis of the compounds under ultrasound and solvent-free conditions. A one-pot nucleophilic condensation between benzaldehyde, malononitrile, and barbituric acid under optimal conditions has taken place. The catalyst has been recovered and reused 12 times without noticeable loss of its initial performance (Table 16). Only 0.014 mol% of the catalyst was sufficient to give 96% isolated yield of the product at 40 °C and 10 min reaction time. At the end of each run, the catalyst was recovered using an external magnet and washed with ethanol.

Mitsudome et al. (2009) studied the nanocatalyst hydroxyapatite-supported silver NPs (AgHAP) for the hydration of nitrile derivatives to their corresponding amines. Aromatic nitriles and their aliphatic nitrile derivatives have been hydrolyzed into amides. Hydration of heteroaromatic nitriles is usually difficult and the reaction rates are much lower than the other aromatic and aliphatic nitriles due to the strong coordination with metal centers. Thus, the AgHAP solves the problem of the difficulty of hydrating heteroaromatic nitriles, and 99% of yield products were obtained in less than 50 min reaction time (Table 17). Finally, the NP was highly efficient and reusable in the hydration reaction without any significant loss.

Ghasemzadeh and Safaei-ghomi (2015) use a ZnO NP to synthesize the biological and pharmaceutical compounds (benzo[b][1,5]diazepines) in a simple one-pot approach. The catalyst (ZnO) showed a superior catalytic activity and easily recyclable in a mild condition. A 93% yield of the product was obtained in 3.5 h; however, using another catalyst like Ni, CuO, MnO, and bulk ZnO only 45, 45, 52, and 62% yields products have been obtained, respectively. They also proposed the reaction mechanism of forming 1,5-benzodiazepin-2-ones using the ZnO NPs catalyst as shown in Fig. 18 below. The catalyst was separated from the reaction medium by dissolving the mixture with methanol and followed by centrifugation.

Proposed reaction pathway for the synthesis of 1,5-benzodiazepin-2-ones by ZnO NPs (Ghasemzadeh and Safaei-ghomi 2015)

Grirrane et al. (2009) use supported gold NP catalysts (Au/C, Au/TiO2) for the oxidation of benzylamines (primary amines) to N-benzylidene benzylamines with molecular oxygen in toluene. The nanocatalyst was highly active, selective with extraordinary performance in the N–N coupling reaction. They have also studied that the catalyst can be used for other heterocyclic amines having sulfur in their ring. 96% conversion with 98% selectivity has been obtained using Au/C for the production of A in 8 min and 99% conversion and selectivity has been obtained to produce product B using the same catalyst in 120 min. However, a 91% conversion and 86% selectivity have been observed for product B using Au/TiO2 in 1800 min (Fig. 19).

Oxidation of heteroaryl amines to the corresponding N-arylidene arylmethanamines (Grirrane et al. 2009)

Recoverable graphene-based strontium MNC (MSrFerGO NCs) has been synthesized under solvent-free conditions for the synthesis of acridine derivatives from dimedone, aromatic amines/ammonium acetate, and various aromatic aldehydes (Fig. 20). The nanocatalyst was novel and green for the synthesis of the biologically active compounds in a simple procedure, 97% yield, magnetic separable, and reusable several times without significant loss of its catalytic behavior (Mousavi et al. 2019a). Bimetallic Pd–Ni alloy NPs supported on graphite oxide (GO) have been reported to catalyze the Knoevenagel condensation reaction between aldehydes and malononitrile. The nanocatalyst was stable and reused several runs without decreasing its catalytic activity, the reaction was taking place in a short time with straightforward work-up procedures under mild conditions (Lolak et al. 2019).

In another study, fur-imine-functionalized graphene oxide-immobilized copper oxide nanoparticle (Cu(II)-Fur-APTES/GO) was synthesized for the synthesis of xanthene compounds. The nanocatalyst exhibited excellent yields (95%) of products in 25–50-min reaction time, easy work-up, simple product separations without byproducts. The (Cu(II)-Fur-APTES/GO) has been separated from the reaction mixtures via centrifugation, washing with ethyl acetate and ethanol, dried under vacuum, and reused for five runs without noticeable effect. Further, high-resolution transmission electron microscopy (HRTEM) images of the five times reused Cu(II)-Fur-APTES/GO nanocatalyst showed in Fig. 21c confirm no significant morphology change was observed compared to the fresh HRTEM images (Fig. 21a, b) indicating no agglomeration of CuO NPs occur. Finally, Cu(II)-Fur-APTES/GO activates the carbonyl group of benzaldehyde to make it more susceptible to nucleophilic attack by 5,5-dimethyl-1,3-cyclo-hexanedione to form intermediate (I); the addition of another molecule of 5,5-dimethyl-1,3-cyclohex-anedione via Michael addition results in the formation of intermediate (II). Intramolecular cyclization occurs after the successful elimination of H2O which regenerates the nanocatalyst (Fig. 21d) (Subodh et al. 2018).

HRTEM micrographs of a, b fresh Cu(II)-Fur-APTES/GO nanocatalyst, and c recovered Cu(II)-Fur-APTES/GO nanocatalyst d Plausible mechanism for synthesis of xanthenes using the Cu(II)-Fur-APTES/GO nanocatalyst (Subodh et al. 2018)

A novel and reusable SrFeGO magnetic nanocatalyst for a potential synthesis of β‐enamino ketones in a highly pure form without the need for chromatographic purifications has been investigated (Fig. 22). The nanocatalyst was recovered using an external magnet and reused several times without a significant decrease in the synthesis efficiency. It also found that the synthesis protocol shows an excellent yield of up to 98% in a very short period of time. As a result, the nanocatalyst has been effective in solvent-free, easy work-up procedures and environmentally sound analytical procedures (Mousavi et al. 2019b).

SrFeGO NC-catalyzed synthesis of β‐enamino ketones (Mousavi et al. 2019b)

Baghbanian and Farhang (2014) synthesized a magnetically recoverable and reusable CuFe2O4 nanocatalyst for the synthesis of quinoline and quinazoline derivatives. As shown in Fig. 23a, b a plausible mechanism for the formation of quinazolines and quinolines using CuFe2O4 NPs, methylene ketones are expected activated by the catalyst leads to aldol condensation to forms intermediate I and dehydration (II) and protonation between the carbonyl and amine results in ring closure and intermediate III is formed and eventually the removal of H2O gives the quinoline derivatives. Finally, the CuFe2O4 NPs was recovered by an external magnet, washed with distilled water and ethanol, dried in an oven, and reused five times to give 95, 94, 92, 92, and 88% yield of the products consequently. Mazloumi and Shirini (2020) use nanoporous TiO2 (TiO2-[bip]-NH2+HSO4−) supported on IL bridges to synthesize quinoline, quinazoline, and spiro-quinazoline derivatives under solvent-free conditions. Electron-withdrawing and -donating groups containing aromatic aldehydes in their para position of the benzene ring were converted in a shorter time than the Cl and Br containing in the meta position. The aromatic aldehydes that contain NO2, OH−, and Cl in the para position also converted with a lower yield to their corresponding quinoline, quinazoline, and spiro-quinazoline derivatives due to the steric hindrance. The nanoporous catalyst was recovered by filtration using ethanol, dried at room temperature, and reused several times to provide 94%, 93%, 90%, and 90% yields in the first, second, third, and fourth cycles in 5-, 6-, 6-, and 8-min reaction time, respectively.

The proposed mechanism for the synthesis a quinazolines and b quinolines using CuFe2O4 NPs (Baghbanian and Farhang 2014)

A very recent study by Shaker and Elhamifar (2021) on magnetic Ti-loaded phenylene-based nanoporous organosilica (Mag@Ti–NOS) nanocomposite has been carried out for the synthesis of tetrahydrobenzo[b]pyrans using multicomponent synthesis pathway, condensation of 1 mol of each malononitrile, aldehyde, dimedone, 0.23 mol% Mag@Ti–NOS catalyst, and 5 ml H2O took place. The supported MNCs was performed in water at 50 °C under ultrasonic conditions. The nanocomposite was recovered using a magnet and reused up to ten passes with no perceptible effect. The recovered nanocatalyst was washed using a Soxhlet apparatus by ethanol to characterize using XRD, FTIR, and SEM after 8 runs, confirming the retaining of the catalyst as a uniform spherical structure providing the same as the fresh nanocatalyst (Fig. 24a–f).

a WA-PXRD pattern of the fresh Mag@Ti–NOS nanocomposite b WA-PXRD pattern of the recovered Mag@Ti–NOS nanocatalyst after eight times of recovery and reuse c FTIR spectrum of fresh Mag@Ti–NOS d FTIR of recovered Mag@Ti–NOS nanocatalyst e Reusability of the Mag@Ti–NOS nanocatalyst in the synthesis of tetrahydrobenzo[b]pyrans f SEM image of the Mag@Ti–NOS nanocomposite g The SEM image of the recovered Mag@Ti NOS nanocatalyst (Shaker and Elhamifar 2021)

Heterocyclic scaffolds

Designing and synthesizing of diverse functionalized complex heterocyclic compounds are challenging. The formation of multi-bonds in one operation becomes one of the major challenges in chemistry (Ahooie et al. 2018). The rapid growth of catalyst chemistry provides a robust and efficient catalyst that can be realized in a multicomponent reaction (MCR). In the MCR three or more substrates are combined in a single reaction vessel to form the product. Biologically important compounds such as substituted pyridine, tetrazole, and imidazoles are synthesized in such a way using MNCs (Kidwai et al. 2012; Forouzandehdel et al. 2020; Pawar and Chikate 2021). MCRs offered rapid and convergent construction of compounds from their starting reactants without isolation and purification of the intermediates, it saves time, cost, and energy than classical methods (Wang and Astruc 2014). These days, biologically active heterocyclic compounds are synthesized using a one-pot MCR (Ezzatzadeh et al. 2017). The synthesis of heterocyclic compounds such as triazoles, tetrazoles, pyrroles, etc. through multicomponent coupling reactions showed remarkable advantages of efficiency, waste minimization, and cost over the traditional synthetic approaches. Biologically active compounds and pharmaceutical intermediate route compounds are synthesized using the 1, 3-dipolar cycloaddition (Gawande et al. 2014; Motahharifar et al. 2020).

Moghaddam et al. (2015) applied nickel ferrite NPs for the synthesis of pyrroles. The catalyst was used effectively to synthesize the product in an average yield of 70–96% in different amounts of catalyst concentration, at 100 °C, 3–4 h. The catalyst was reused nine times without significant loss. After each run, the catalyst was separated by an external magnetic field and washed with distilled water. They proposed a facile, efficient, eco-friendly, and one-pot process for the four-component synthesis of pyrroles with nickel ferrite NPs as a recyclable catalyst as shown in Fig. 25.

Proposed reaction mechanism of synthesizing pyrroles (Moghaddam et al. 2015)

Khorramabadi et al. (2020) used a facile method to synthesize Cu NPs coated with Fe3O4 magnetic NPs. The nanocatalyst was able to perform at 100 °C, without the use of a solvent to synthesize various tetrazole compounds with the highest product yield > 90%. The catalyst has been separated from the product via filtration, washed with ethanol, and dried in a vacuum, and reused five times without losing its activity to yield 94%, 90%, 86%, 83%, and 81% corresponding to the first, second, third, fourth, and fifth cycles, respectively. In another study, Fe3O4@HT@AEPH2-CoII, a bifunctional heterogeneous nanocomposite has been synthesized via amino-functionalized (Fe3O4@ hydrotalcite (HT)) with 2-aminoethyl dihydrogen phosphate (AEPH2) and then CoII immobilized onto an aminated ferrite NPs results in the formation of, Fe3O4@HT@AEPH2-CoII. The catalyst was used for the preparation of substituted 1H-tetrazoles from a sodium azide, triethyl orthoformate, and amine. The nanocatalyst promotes the cyclization reaction via facilitating the elimination reaction (Fig. 26). Finally, the catalyst exhibited a 95% pure yield of tetrazole. The catalyst has been recovered using an external magnet, washed with ethyl acetate, and dried and used for five runs without deterioration (Salimi et al. 2020).

The suggested mechanism for the synthesis of tetrazoles with Fe3O4@HT@AEPH2-CoII (Salimi et al. 2020)

Zhi‑tao (2020) used bimetallic Ni@Pd confined in a metal–organic framework cavity for the cycloaddition of amine (propargylic amines) with carbon dioxide in an aqueous solution to produce 2-oxazolidinones (Fig. 27) in a one-pot synthesis. The catalyst was stable even in moisture and thermal conditions, highly selective, and recovered up to ten times to be reused. Excellent yields (95%) of the product have been obtain and it was found that very little leaching (0.4%) of the catalyst was observed in each run.

Novel γ-Fe2O3 supported on hydroxyapatite (HAP) NPs was synthesized by Kale et al. (2013) for the fabrication of disubstituted 1,2,3-triazoles from terminal alkynes and in situ-generated organic azide in aqueous media without the addition of any reagent or base. The γ-Fe2O3–HAP NPs showed 100% regioselectivity for the cycloaddition reaction with five times recovering using an external magnet and reusing without trailing its initial activity. Other various aromatic or aliphatic halides and alkynes are synthesized using this NP and offered a good yield (up to 94%) using only water as a solvent making it a green method. Clarina and Rama (2018) reported the [3 + 2] cycloaddition of nitriles with sodium azide using ZnO NPs anchored on reduced graphene oxide (ZnO–RGO) and green solvent (water). The study was extended to various aromatic, heteroaromatic, aliphatic nitriles, and aromatic nitriles with electron-withdrawing groups at the para position convert in a very short period of time than the electron-donating groups to give the highest yield of > 86% (Table 18). The catalyst was removed by simple filtration from the reaction and washed with distilled water and ethanol to remove organic products, dried at 100 °C for 1 h.

An effective and recyclable Cu@imine/Fe3O4 MNCs catalyst was applied for the synthesis of biologically important polysubstituted pyrroles and 1,2,4,5-tetrasubstituted imidazole derivatives under normal reaction conditions and one-pot MCRs synthesis (Fig. 28). Promising yields up to 95% of the products are formed using 0.36 mol% of the catalyst at 80 °C and early at 35 min when the R1 and R groups are aniline and benzaldehyde, respectively. Similarly, the benzil and RCHO were also replaced by ethyl acetoacetate and nitromethane, respectively, and gives up to 98% in 20-min reaction time using the nanocatalyst. The product was dissolved using hot mixtures of ethyl acetate and ethanol (4:1); then nanocatalyst was recovered using an external magnet, washed with chloroform, dried, and reused for a minimum of six turns (Thwin et al. 2019).

Preparation of 1,2,4,5-tetrasubstituted imidazoles derivatives using Cu@imine/Fe3O4 MNPs as a catalyst (Thwin et al. 2019)

A recent study by Khan and Siddiqui (2018) reported the synthesis of cerium-immobilized silicotungstic acid nanoparticle-impregnated zirconia (Ce@STANPs/ZrO2), for the multicomponent synthesis of imidazole derivatives under MW in water. The reaction has been taken using isatin, benzaldehyde, and ammonium acetate to produce a 94% isolated yield of 2-phenyl-3,4-dihydroimidazo[4,5-b]indole. The catalyst has been recycled by extraction with ethyl acetate and filtration up to seven times and offered 88% conversion. SEM, XRD, and FTIR characterizations of the fresh and seven times reused Ce@STANPs/ZrO2 confirmed that the surface morphology and spectrum patterns of the recovered catalyst do not show any structural changes (Fig. 29a–c). The reaction mechanism applying the catalyst was also deduced as shown in Fig. 29d.

SEM image of a fresh catalyst (Ce@STANPs/ZrO2) b recycled catalyst after the seventh run c zirconia d plausible mechanism for the synthesis of imidazoles derivatives (Khan and Siddiqui 2018)

2-Phenylquinazoline derivatives were synthesized using a magnetically recoverable iron oxide (γ-Fe2O3) nanocatalyst (MRIONC) under solvent-free conditions. The catalyst was separated and reused five times without losing using an external magnet and the presence of electron-withdrawing substituents on the aniline increases the yield of the product. Characterization of the MRIONC using XRD, TEM, and FTIR revealed that no substantial changes of the fresh and reused catalyst have been observed, spherical structure and spectrum characteristic patterns of the original structures of the maghemite catalyst have retained (Fig. 30a–e) (Anand et al. 2012).

TEM images of a fresh, b used MRIONC c FTIR spectra of fresh and used MRIONC d recyclability of the catalyst for the synthesis of 2-phenylquinazolines e XRD patterns of fresh and used MRIONC (Anand et al. 2012)

Kalhor et al. (2019) synthesized pyrimidine derivatives under solvent-free conditions using the multifunctional Fe3O4@zeolite–SO3H MNCs. The MNCs activate the reactant and intermediate during the nucleophilic attack of 1,8-diaminonaphthalene following the imine formation with subsequent elimination of water. Intramolecular nucleophilic attack with the second amine leads to the formation of pyrimidine by cyclization (Fig. 31a). Excellent isolated yields (97%) have been obtained. The nanocatalyst has been separated using a magnet, washed with hot ethanol and dried at room temperature, and reused six times without deterioration. In another study, the above authors used Fe3O4/SO3H@zeolite-Y to synthesize pyrimidine and trisubstituted imidazoles. They have synthesized the pyrimidine derivatives similar to their previous reaction mechanism to obtain an isolated 98% yield of the product. The trisubstituted imidazole derivatives were synthesized using one-pot MCRs (aldehyde, benzil, and ammonium acetate) considering as a model of reaction. The multifunctional Fe3O4/SO3H@zeolite-Y nanocatalyst activates the cycloaddition due to its Lewis (Fe3O4) and Brønsted acid (SO3H) sites. The polarized aldehyde group (1) results in the formation of hydroxyl-amine intermediate (1a) and further dehydrated to imine (2a), the addition of ammonium acetate produces diamine intermediate (A) and the condensation with benzil (3), cyclization, and dehydration with rearrangement via imino intermediate (B) results in the formation of the trisubstituted imidazole (4) (Fig. 31b). The nanocatalyst was recovered using an external magnet, washed with ethyl acetate and dried at 50 °C, and reused for five consecutive runs without noticeable loss of its initial activity (Kalhor and Zarnegar 2019).

Similarly, an early study by Arora et al. (2021) used sulfamic acid-functionalized hollow magnetically separable solid-acid (HMS-SA) nanocatalyst for the synthesis of 2,4,5-trisubstituted imidazoles under ultrasonic irradiation. A one-pot three-component reaction of benzil (1 mmol), benzaldehyde (1 mmol), ammonium acetate (5 mmol), and 30 mg load of the catalyst have been employed to give 99% yield of the product in 25-min reaction time.

Dehalogenation

Halogenated hydrocarbons, mostly chlorinated aromatic hydrocarbons, chlorinated alkanes, olefins, organochlorine pesticides, and other bromine and chlorine-containing organic compounds are important chemical raw materials and organic solvents, which are widely used in medicine, leather, electronics, pesticide, and herbicide industries. The effluent of these chemical byproducts in the production and use spreading of the products in agricultural activities pose a threat to the environment and human health (Li et al. 2019). The dehalogenation reaction is mostly practiced in the water treatment to remove the toxic halogens such as Cl from the polychlorinated, organochlorine, chlorophenols, and others frequently used in insecticide, sanitizer compounds (Fig. 32) (Li et al. 2018). Most of the chlorophenols (CPs) are persistent and difficult to degrade and bioaccumulate an extended period of time. Therefore, a catalyst that can be tolerated in organic and inorganic compounds in wastewater or other chemical industries is required (Hildebrand et al. 2009).

Dechlorinations of persistent pesticides such as dichlorodiphenyltrichloroethane (DDT) have been carried out by bimetallic Fe/Pd NPs to offer up to 93% removal efficiency and till it has a minimum concentration below the carcinogenesis limit (Ulucan-altuntas and Debik 2020). Similar studies by Corte et al. (2011) was reported for the dechlorination of diclofenac and trichlorethylene (TCE) via biologically mediated Pd, Au, and Pd/Au NPs. The bio-Pd/Fe shows better activity in the dechlorination reaction to achieve 78% efficiency than the monometallic NPs in the diclofenac dechlorination and the TCE was also transformed to ethane via the bio-Pd/Au. Huang et al. (2012) prepared Pd NPs encapsulated in the mesoporous cages of amine-functionalized metal–organic frameworks (MOFs) MIL-101(Cr)–NH2 catalyst for the dehalogenation of aryl chlorides in water under mild conditions. The nanocatalyst shows excellent catalytic performance in the dehalogenation reaction using water (Table 19). The catalytic activity of Pd/ MIL-101(Cr)–NH2 decreases by only 6% in the fifth cycle to provide a 92% yield of the product. Finally, the catalyst was separated readily through centrifugation. Xu and Yang (2008) also studied the catalytic performance of water-soluble Pd NPs against the dehalogenation of aryl chloride, bromide, and iodide. Thus, the experiment was carried out for 3 h to give 98% yields as confirmed by the GC–MS data. The catalyst was used repeatedly several times without purification, but its catalytic performance decreased in the second and third runs.

Bimetallic Ni/Fe NP was applied for the catalytic dechlorination of para-nitrochlorobenzene (p-NCB). The bimetallic catalyst shows prominent activity in removing the chlorine from the aromatic compound with 100% efficiency for a particle with 2.0% Ni but reduces to 51% upon reducing the amount of Ni to 0.5%. As a result Ni plays a crucial role in reducing the activation energy of the reaction (Xu et al. 2009). The removal of the halogens from the organic compounds can also be carried out by the cross-coupling reaction such as Ullmann, Heck, Suzuki, Stille, Sonogashira, Kumada, Negishi, and Hiyama since the halogens are removed during the C–C coupling reaction (Navarro et al. 2004).

Factors that affect the catalytic activities of the nanocatalysts in organic reactions

The catalytic performance of the nanocatalyst is affected by multiple factors when interacting in the reaction with the substrates. The NPs are synthesized and designed in different shapes, sizes, stoichiometric compositions (state art), surface area to volume ratio, and incorporate with varieties of supporting, stabilizing, or capping agents. These factors are arising from the synthesis of the NPs and strongly affect the catalytic activity of the nanocatalyst in the reaction. On the other hand, factors such as the concentration of the substrate, load/concentration of the nanocatalyst, and the solvent are observed during the course of interaction between the nanocatalyst and the substrate (Fig. 33).

Particle size