Abstract

Practitioners who are working with mixture experiments often found that the existing mixture designs fail to provide the mixture combinations in a true sense. This problem can be overcomed by using the concept of uniform designs with mixture experiments. Uniform designs aim at scattering the points uniformly in the experimental region. Uniform mixture design can be applied in the fields like material science, chemical engineering, food science, agriculture and in many other areas where the composition of the mixtures is required to obtain response/outcome. In this paper, an attempt has been made to construct uniform mixture designs for s component mixtures using the uniform design in s-dimensional spherical region. A transformation is proposed for constructing uniform designs in s-dimensional spherical region by using the existing designs in 2-dimensional spherical region. The uniformity of the constructed designs is measured by distance-based approach and the uniformity of the mixture designs is measured by \({\mathrm{DM}}_{2}\)-discrepancy.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Mixture experiments involve mixing of different ingredients to form end products. In these experiments, the response depends on the proportions of the ingredients present in the mixture and not on the total amount of the mixture. For example, the cleaning power of a detergent which is formed by mixing Alcohol Ethoxylate, Alkyl Ethoxy Sulphate, Amine Oxide, Carboxymethyl Cellulose (CMC), Citric Acid, Cyclodextrin, Diethyl Ester Dimethyl Ammonium Chloride, Ethanol, Hydrogen Peroxide, Percarbonate, Sodium carbonate, Sodium Hypochlorite, Zinc Phthalocyanine Sulphonate (ZPS) depends on the proportions of these ingredients in the detergent.

Quenouille (1953) led the foundation of a mixture experiments. For a mixture with s components or ingredients, if \({\text{x}}_{{\text{i}}}\) represents the proportion of the \({\text{ith}}\) component in the mixture, then

with \(\mathop \sum \nolimits_{{{\text{i}} = 1}}^{{\text{s}}} {\text{x}}_{{\text{i}}} = {\text{x}}_{1} + {\text{x}}_{2} + \ldots + {\text{x}}_{{\text{s}}} = 1\)

The factor space for the s component mixture is the \(\left( {s - 1} \right)\) dimensional simplex \(S_{s - 1}\) given by

The term simplex design was first used by Claringbold (1955) during his study on joint action of hormones. Scheffé (1958, 1963) introduced simplex lattice and simplex centroid designs with corresponding associated models. Mixture experiments have wide applications in different fields. Bezerra et al. (2020) used mixture design in chemometric for optimization of any stage of an analytical method. Zhou et al. (2007) used mixture designs to design the formulation of pure cultures in Tibetan Kefir. Bahram Parvar et al. (2015) discussed application of simplex centroid design to optimize stabilizer combinations for ice cream manufacture. For more details on mixture experiments see Cornell (2011).

In many pharmaceuticals and petrochemicals industries there is a need of large number of design points that are scattered uniformly over the experimental region. Fang (1980) and Wang and Fang (1981) were the first to introduce uniform design based on Quasi Monte Carlo method and Number-Theoretic net (NT-net) method. Uniform design is obtained by using the concept of U-type design based on NT-net design. The NT-net design is obtained by using good lattice point (glp) generator. There are several other methods defined in literature for obtaining NT-net design. However, glp method is used because of its economic computation and good performance (Hua and Wang (1981) and Shaw (1988)). Zhou and Xu (2015) have also mentioned that the design obtained by using the glp generator possesses low discrepancy. The glp method was proposed by Korobov (1959a, 1959b) and was further discussed by Hua and Wang (1981), Fang and Wang (1994). Fang and Wang (1994) and Borkowski and Piepel (2009) introduced distance-based criteria to measure the uniformity of a design. Ning et. al. (2011) gave \({\text{DM}}_{2}\)-discrepancy to measure the uniformity of a mixture design.

Often experimenter is not interested in mixture combinations in entire simplex rather, the interest lies in a smaller subregion inside the simplex (see Cornell 2011, pp 108). One such region can be spherical region. In response surface methodology, extensive research exists for designs in spherical regions. In Box-Behnken designs (Box and Behnken (1960)) and hybrid designs of Roquemore (1976) spherical region is considered. Talke and Borkowski (2016) proposed a method for the generation of the uniform design in 2-and 3-dimensional spherical regions. Lai et al. (2021) used coordinate descent method to construct uniform designs over continuous domain in computer experiments. Uniform mixture designs can be useful for dealing with multi response problem (see Menchaca-Mendez et al. (2022)).

Now question arises, is it possible to construct uniform mixture designs in higher dimensional space using the designs in lower dimensional spherical region. In this paper, a method is proposed for obtaining the uniform designs in s-dimensional spherical region using the design in 2-dimensional spherical region given by Talke and Borkowski (2016). The discrepancy of the constructed designs is measured using three distance-based criteria. The constructed designs are then transformed into mixture designs using the transformation proposed for this purpose. The uniformity of the mixture designs is computed by D \({\text{M}}_{2}\)-discrepancy and the design with minimum value is selected.

The paper is organized as follows. In Sect. 2, various measures of uniformity are described. In Sect. 3, a method is proposed for obtaining the design in s- dimensional spherical region from the designs in 2-dimensional spherical region. Section 4 proposes a transformation to obtain mixture designs from the designs in spherical region. Section 5 outlines the conclusion of the paper.

2 Uniformity criteria

Fang (1980) and Wang and Fang (1981) were the first to apply the idea of Number-theoretic methods (NTM) to experimental designs. Number-theoretic method or Quasi Monte Carlo method is a combination of number-theory and numerical analysis and has a variety of applications in statistics. Discrepancy is a measure of uniformity which provides a way of construction of uniform design. Fang and Wang (1994) introduced the root mean square distance (RMSD) to measure the uniformity of mixtures designs. Borkowski and Piepel (2009) introduced criteria based on average distance (AD) and maximum distance (MD).

Generally Monte Carlo sampling method is used to compute these values. In this method two sets a training set and a sampling set are taken and the design points of these sets are obtained using Number-Theoretic net (NT-net). From the given training set, a sampling set with smaller number of runs is obtained and the value of uniformity measure of the sampling set is evaluated based on the training set. However, in this article, different sampling sets are generated based on different glp generator and the training set is separately generated by an appropriate glp generator which is selected arbitrarily. The criteria values of different sampling sets are evaluated using the training set. For higher dimensional spherical region, there is no discrepancy measures are available in the literature. Therefore, the distance-based approach is preferred for measuring uniformity.

Suppose \({\text{D}} = \left\{ {x_{j} = \left( {x_{j1} ,x_{j2} , \ldots ,x_{js} } \right); j = 1,2, \ldots ,n} \right\}\) represents a sampling set i.e. a design with s components and n runs for which the distance based uniformity measures are to be computed and \({\text{T}} = \left\{ {t_{k} = \left( {t_{k1} ,t_{k2} , \ldots ,t_{ks} } \right),k = 1,2, \ldots ,N} \right\}\) represent a training set consisting of N \(( > n)\) runs and s components. Then D and T matrices of order \({\text{n}} \times {\text{s}}\) and \({\text{N}} \times {\text{s}}\) respectively, where

Let \(d_{s}^{2} \left( {x_{j} ,t_{k} } \right)\) denote the Euclidean distance between the points \(x_{j}\) and \(t_{k}\) scaled between 0 and 1, then

and the three distance-based criteria are defined as follows:

-

1)

\({\text{RMSD}}\left( {\text{D}} \right) = \sqrt {\frac{{\sum\nolimits_{{k = 1}}^{N} m in_{{1 \le \,j\, \le n}} d_{s}^{2} \left( {x_{j} ,t_{k} } \right)}}{N}}\)

-

2)

\({\text{AD}}\left( {\text{D}} \right) = \frac{1}{N}\sum\nolimits_{{k = 1}}^{N} m in_{{1\, \le \,j\, \le \,n}} d_{s} \left( {x_{j} ,t_{k} } \right)\)

-

3)

\({\text{MD}}\left( {\text{D}} \right) = max_{{1\, \le \,k\, \le \,N}} \left( {min_{{1\, \le \,j\, \le \,n}} d_{s} \left( {x_{j} ,t_{k} } \right)} \right)\)

The above mentioned distance-based measures can also be applied for mixture experiments where \(\mathop \sum \nolimits_{i = 1}^{s} x_{ji} = 1\) and \(\mathop \sum \nolimits_{i = 1}^{s} t_{ki} = 1\) to measure the uniformity of the design.

When the number of runs is small, the uniformity of a mixture design can be measured using the \({\text{DM}}_{2}\)-discrepancy which is generalization of star discrepancy (Ning et al. 2011). Star discrepancy given by Weyl (1916) is a basic and simplest measure of uniformity. Ning et al. (2011) gave the following analytical expression to compute the \({\text{DM}}_{2}\)-discrepancy value of a design \({\text{P}}_{{\text{n}}}\) with n runs defined over the s-dimensional simplex \(T^{s}\).

where \(\left\{ {0,1} \right\}^{s - 1} = \left\{ {\left( {t_{1} ,t_{2} , \ldots ,t_{s - 1} } \right):t_{i} = 0~ {\text{or }} 1} \right\}.\)

Xiao et al. (2023) applied wighted centered \(L_{2}\)-discrepancy for obtaining the sequentially weighted uniform design.

3 Uniform design in the s-dimensional spherical region.

An s-dimensional spherical region of radius \(r\) centred at \(y_{0} = \left( {y_{01} , y_{02} , \ldots , y_{0s} } \right)\) is given by

If \(y_{0} = \left( {0,0, \ldots ,0} \right)\) and \(r = 1\), then it represents the standard spherical region and is given by

Design in s-dimensional spherical region is the set of points which lie inside or on the spherical region (2).

Talke and Borkowski (2016) proposed a method to obtain uniform design in 2-dimensional spherical region. The design points are first obtained in \(C^{2} = \left[ {0, 1} \right]^{2}\). Suppose \(\left\{ {\left( {r_{i} , \theta_{i} } \right);i = 1,2, \ldots ,n.} \right\}\) is the design in \(C^{2}\), then the design in two-dimensional spherical region is given by \(\{ (z_{{i1}} ,z_{{i2}} );\;i = 1,2, \ldots ,n\}\) with

which are uniformly scattered in \(B^{2} = \left\{ {\left( {z_{i1} , z_{i2} } \right):z_{i1}^{2} + z_{i2}^{2} \le 1;i = 1,2, 3, \ldots ,n} \right\}\).

Theorem 1.1:

Let \(\left\{ {\left( {z_{i1} , z_{i2} } \right);i = 1,2, \ldots ,n} \right\}\) be an n-point design in 2-dimensional spherical region \(B^{2}\). For the s-dimensional spherical region, the design \({\text{D}} = \left\{ {\left( {y_{i1} , y_{i2} , \ldots ,y_{is} } \right);i = 1,2, \ldots ,n} \right\}\) can be obtained by using the transformation given below:

The number of design points n is to be taken more than the parameters in the model to be fitted. For example, for the Scheffé (1958) quadratic model with s component n should be more than \(s + \left( {\begin{array}{*{20}c} s \\ 2 \\ \end{array} } \right)\).

Proof:

Consider the design \(z = \left\{ {\left( {z_{i1} , z_{i2} } \right);i = 1,2, \ldots ,n} \right\}\) in 2-dimensional spherical region as.

so that \(z_{i1}^{2} + z_{i2}^{2} = r_{i} .\)

where \(\left\{ {\left( {r_{i} , \theta_{i} } \right);i = 1,2, \ldots ,n} \right\}\) is an NT-net design in unit hypercube dimensions obtained by a generator \(\left( {1, h_{1} } \right)\).

Consider the following vector of dimension \(\left( {1 \times s} \right)\), given by

Define \(y_{ij} = \sqrt {C_{j} z_{i1}^{2} + d_{j} z_{i2}^{2} } ;j = 1, 2, \ldots ,s ; i = 1,2, \ldots , n.\)with \(y_{i1} = \sqrt {\frac{{z_{i1}^{2} }}{{\left( {\begin{array}{*{20}c} s \\ 2 \\ \end{array} } \right)}}} , y_{i2} = \sqrt {\frac{{2z_{i1}^{2} }}{{\left( {\begin{array}{*{20}c} s \\ 2 \\ \end{array} } \right)}} + \frac{{z_{i2}^{2} }}{{\left( {\begin{array}{*{20}c} s \\ 2 \\ \end{array} } \right)}}} , \ldots ,\)

Then

D is the required n-point design in s-dimensional spherical region given in (2). The particular cases for \(s = 3, 4,\) and \(5\) are given in the following theorems.

Theorem 1.2:

Let \(\left\{ {\left( {z_{i1} , z_{i2} } \right);i = 1,2, \ldots ,n} \right\}\) be the n-point design in 2-dimensional spherical region \(B^{2}\), then for the 3-dimensional spherical region, the design \({\text{D}} = \left\{ {\left( {y_{i1} , y_{i2} , y_{i3} } \right);i = 1,2, \ldots ,n} \right\}\) can be obtained by using the transformation given below:

Theorem 1.3:

Let \(\left\{ {\left( {z_{i1} , z_{i2} } \right);i = 1,2, \ldots ,n} \right\}\) be the n-point design in 2-dimensional spherical region \(B^{2}\), then for the 4-dimensional spherical region, the design \({\text{D}} = \left\{ {\left( {y_{i1} , y_{i2} , y_{i3} ,y_{i4} } \right);i = 1,2, \ldots ,n} \right\}\) can be obtained by using the transformation given below:

Theorem 1.4:

Let \(\left\{ {\left( {z_{i1} , z_{i2} } \right);i = 1,2, \ldots ,n} \right\}\) be the n-point design in 2-dimensional spherical region \(B^{2}\), then for the 5-dimensional spherical region, the design \({\text{D}} = \left\{ {\left( {y_{i1} , y_{i2} , y_{i3} ,y_{i4} , y_{i5} } \right);i = 1,2, \ldots ,n} \right\}\) can be obtained by using the transformation given below:

3.1 Illustrations:

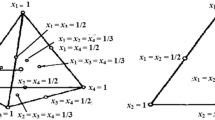

Let us consider the case of 3-, 4-, and 5-dimensional spherical regions.

3.1.1 Case 1: 3-dimensional spherical region

Consider a design in 2-dimensional spherical region with 11 design points.

For \(n = 11\), the initial candidate generating vector is \(H_{11} = \left\{ {1, 2, 3, 4, 5, 6, 7, 8, 9, 10} \right\}\) and the list of generators are given in Table 1.

From the list of all the possible generators given in Table 1, the designs in 2- dimensional spherical regions are obtained and are transformed into the designs in 3-dimensional spherical region using Theorem 1.2. The values of three distance-based measures are computed for all the constructed designs which are given in Table 2. These values are computed on the basis of 8000 evaluation points by using the generator \(\left( {1, 7} \right).\)

From the Table 2, it can be observed that the criteria values of the designs obtained by generators \(\left( {1, 4} \right), \left( {2, 8} \right), \left( {4, 5} \right), \left( {5, 9} \right)\) and \(\left( {8, 10} \right)\) are same and lowest among all possible design.

3.1.2 Case 2: 4-dimensional spherical region

Consider a design in 2-dimensional spherical region with 18 design points.

For \(n = 18\), the initial candidate generating vector \(H_{18}\) is given by

Different generating vectors for constructing uniform designs in 4-dimensional spherical region are given in Table 3.

From the list of all the possible generators given in Table 3, the designs in 2- dimensional spherical regions are obtained and the designs are transformed into the design in 4-dimensional spherical region using the Theorem 1.3. The criteria value of the design in 4-dimensional spherical region is obtained and is given in Table 4. For computing the criteria values a design obtained by using the generator \(\left( {1, 13} \right)\) is considered and the criteria values are computed on the basis of 10,000 evaluation points.

From the Table 4, it can be observed that the designs obtained using the generators \(\left( {1, 7} \right), \left( {5, 17} \right), \left( {7, 13} \right)\) have lowest RMSD and AD value and the designs with generators \(\left( {1, 11} \right), \left( {11, 13} \right), \left( {13, 17} \right)\) have lowest MD value.

3.1.3 Case 3: 5-dimensional spherical region

Consider the design in 5-dimensional spherical regions using the design in 2- dimensional spherical region with \(n = 21\) design points.

For \(n = 21\), the initial candidate generating vector \(H_{21}\) is given by

Different generating vectors for constructing uniform designs in 5-dimensional spherical region are given in Table 5. For computing the criteria values a design obtained by using the generator \(\left( {7, 13} \right)\) is considered and the criteria values are computed on the basis of 12,000 evaluation points.

From the list of all possible generators, the designs in 2-dimensional spherical regions are obtained and the designs are transformed into the design in 5-dimensional spherical region using the Theorem 1.4. The criteria value of the design in 5- dimensional spherical region is given in Table 6.

From the Table 6, it can be observed that the designs obtained using the generators \(\left( {1, 17} \right), \left( {2, 13} \right), \left( {4, 5} \right), \left( {8, 10} \right), \left( {11, 19} \right), \left( {16, 20} \right)\) have the lowest RMSD and AD values and the design with generator \(\left( {1, 2} \right), \left( {2, 4} \right), \left( {5, 10} \right), \left( {8, 16} \right), \left( {10, 20} \right)\) have the same lowest MD value.

If the generator giving minimum value of RMSD and AD is different from the generator giving minimum value of MD, then this generator may be considered as optimal generator whereas if the generator giving the smallest value of AD is also different from the generator giving minimum value of RMSD, then the generator for RMSD is considered as optimal generator as RMSD is least affected by variation of points near the boundary. However, in mixture space this might not be true. Therefore, the designs in mixture space are generated by considering all the generators chosen on the basis of RMSD, AD, and MD values. The method for obtaining mixture design from the designs in s-dimensional spherical region is described in the next section.

4 Method of obtaining mixture design using the design in the spherical region

Suppose that \(\left\{ {\left( {y_{i1} , y_{i2} , \ldots , y_{is} } \right);i = 1,2, \ldots ,n} \right\}\) represents a design in the s-dimensional spherical region. Then the mixture design \(\left\{ {\left( {x_{i1} , x_{i2} , \ldots , x_{is} } \right);i = 1,2, \ldots ,n} \right\}\) which satisfies Eq. (1) can be obtained by using the following transformation

where \(t_{i1} = y_{i1}\),\(t_{ij} = \left| {y_{ij} - \mathop \sum \nolimits_{k = 1}^{j} \frac{{y_{ik} }}{j}} \right|;j = 2, 3, \ldots ,s.\)

In this case, the design is constructed by considering the absolute deviation of the design points from the central points. From all the possible designs, the design with minimum value of \({\text{DM}}_{2}\)-discrepancy is chosen.

Example 1:

Consider 11 run designs in 3-dimensional spherical region obtained in Sect. 3. It is observed that the designs obtained by using the generator \(\left( {1, 4} \right), \left( {2, 8} \right), \left( {4, 5} \right), \left( {5, 9} \right)\) and \(\left( {8, 10} \right)\) are best in terms of uniformity. Using these designs, the mixture designs are obtained by using the transformation (5). The \({\text{DM}}_{2}\) value of the mixture designs is computed and is given in Table 7 with corresponding generators.

From the Table 7, it can be observed that the \({\text{DM}}_{2}\) value of the design obtained by using the generator \(\left( {8, 10} \right)\) is lowest. The uniform mixture design and corresponding uniform design in 3-dimensional spherical region based on generator (8, 10) are given in Table 8.

Example 2:

Consider 18 run designs in 4-dimensional spherical region obtained in Sect. 3. The designs obtained by using the generator \(\left( {1, 7} \right), \left( {5, 17} \right),\) and \(\left( {7, 13} \right)\) are best in terms of uniformity. Using these designs, the mixture designs are obtained by using the transformation (5). The \({\text{DM}}_{2}\) value of the mixture designs is computed and is given in Table 9 with corresponding generator.

From the Table 9, it can be observed that the \({\text{DM}}_{2}\) value of the design obtained by using the generator \(\left( {11, 13} \right)\) is lowest. The uniform mixture design and the corresponding uniform design in the 4-dimensional spherical region based on generator \(\left( {11, 13} \right)\) are given in Table 10.

Example 3:

Consider 21 run designs in 5-dimensional spherical region obtained in Sect. 3. The designs obtained by using the generator \(\left( {1, 17} \right), \left( {2, 13} \right), \left( {4, 5} \right), \left( {8, 10} \right), \left( {11, 19} \right),\) and \(\left( {16, 20} \right)\) are best in terms of uniformity. Using these designs, the mixture designs are obtained by using the transformation (5). The \({\text{DM}}_{2}\) value of the mixture designs is computed and is given in Table 11 along with corresponding generators.

From the Table 11, it can be observed that the \({\text{DM}}_{2}\) value of the design obtained by using the generator \(\left( {1, 17} \right)\) is lowest. The uniform mixture design and the corresponding uniform design in 5-dimensional spherical region based on generator \(\left( {1, 17} \right)\) are given in Table 12.

5 Conclusion

Mixture experimental design is a powerful tool that can be used in quality control and product formulation. The space filling property of the uniform design makes it suitable for generating uniformly scattered design points for the mixture experiments. In present scenario, the uniform mixture design has come up as a useful statistical tool that can improve the overall performance and quality of the product by generating the design points that are uniformly scattered in the experimental region. Different experimental region can produce different mixture combinations, resulting in different final product. In this paper, spherical region is considered and the design in s-dimensional spherical region is obtained by considering the existing design in 2-dimensional spherical region. A transformation to construct uniform mixture design is also proposed in this paper. The proposed method is useful in the sense that it only need the design in 2-dimensional spherical regions to construct the desired mixture designs in higher dimensional region. Designs for 3, 4, and 5 component mixtures are constructed and the value of \({\text{DM}}_{2}\)-discrepancy is calculated. It is observed that the mixture designs based on the designs in spherical region with lowest ‘MD’ value possess maximum uniformity in the simplex region. Thus, the uniformity is preserved when proposed transformation is used for obtaining the mixture design from the design in spherical region.

References

BahramParvar M, Tehrani MM, Razavi S, Koocheki A (2015) Application of simplex-centroid mixture design to optimize stabilizer combinations for ice cream manufacture. J Food Sci Technol 52(3):1480–1488

Bezerra MA, Lemos VA, Novaes CG, de Jesus RM, Souza Filho HR, Araújo SA, Alves JPS (2020) Application of mixture design in analytical chemistry. Microchem J 152:104336

Borkowski JJ, Piepel GF (2009) Uniform designs for highly constrained mixture experiments. J Qual Technol 41(1):35–47

Box GE, Behnken DW (1960) Some new three level designs for the study of quantitative variables. Technometrics 2(4):455–475

Claringbold PJ (1955) Use of the simplex design in the study of joint action of related hormones. Biometrics 11(2):174–185

Cornell JA (2011) Experiments with mixtures: designs, models, and the analysis of mixture data. John Wiley & Sons

Fang KT (1980) Uniform design: application of number-theoretic methods in experimental design. Acta Math Appl Sin 3:363–372

Fang KT, Wang Y (1994) Number-theoretic methods in statistics. CRC Press

Hua LK, Wang Y (1981) Applications of number theory to numerical analysis. Springer and Science Press, Berlin and Beijing

Korobov NM (1959a) The approximate computation of multiple integrals. Dokl Akad Nauk SSSR 124:1207–1210

Korobov NM (1959b) Computation of multiple integrals by the method of optimal coefficients, Vestnik Moskow Univ. Sec Math Astr Fiz Him 4:19–25

Lai J, Fang KT, Peng X, Lin Y (2021) Construction of uniform designs over continuous domain in computer experiments. Communications in Statistics-Simulation and Computation pp 1–17

Menchaca-Mendez A, Zapotecas-Martínez S, García-Velázquez LM, Coello CAC (2022) Uniform mixture design via evolutionary multi-objective optimization. Swarm Evol Comput 68:100979

Ning JH, Zhou YD, Fang KT (2011) Discrepancy for uniform design of experiments with mixtures. J Statis Plan Inference 141(4):1487–1496

Quenouille MH (1953) The design and analysis of experiments. Charles Griffin and Company, London, England

Roquemore KG (1976) Hybrid designs for quadratic response surfaces. Technometrics 18(4):419–423

Scheffé H (1958) Experiments with mixtures. J Roy Stat Soc Ser B (methodol) 20(2):344–360

Scheffé H (1963) The simplex-centroid design for experiments with mixtures. J Roy Stat Soc Ser B (methodol) 25(2):235–251

Shaw JEH (1988) A quasirandom approach to integration in Bayesian statistics. Ann Statis pp 895–914

Talke IS, Borkowski JJ (2016) Measures of uniformity for space-filling uniform designs in a spherical region. Int J Exp Des Process Optim 5:23–40

Wang Y, Fang KT (1981) A note on uniform distribution and experimental design. Kexue Tongbao (chinese) 26:485–489

Weyl H (1916) über die gleichverteilung der zahlem mod eins. Math Annals 77:313–352

Xiao Y, Wang S, Qin H, Ning J (2023) Sequentially weighted uniform designs. Statistics pp 1–20

Zhou Y, Xu H (2015) Space-filling properties of good lattice point sets. Biometrika 102(4):959–966

Zhou JZ, Liu XL, Huang KH, Dong MS, Jiang HH (2007) Application of the mixture design to design the formulation of pure cultures in Tibetan kefir. Agric Sci China 6(11):1383–1389

Acknowledgements

The authors like to extend sincere appreciation to the editor and anonymous reviewers for their insightful feedback in significantly shaping the manuscript.

Funding

This work was supported by Faculty Research Programme (FRP) grant vide Ref No. /IoE/2021/12/FRP from Institute of Eminence (IoE), University of Delhi, Delhi.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors have no conflict of interest to declare that are relevant to the content of this article.

Human and animal partcipants

The authors declare that this research work does not include any participation of human or animals.

Informed consent

Not applicable.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Singh, P., Shukla, H. Uniform mixture designs using designs in 2-dimensional spherical region. Int J Syst Assur Eng Manag 14, 1888–1897 (2023). https://doi.org/10.1007/s13198-023-02019-7

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13198-023-02019-7