Abstract

In this work, chemical degradation of oil was determined as a function of frying time during intermittent deep-fat frying (i.e. 185 °C for 5 h per day for 12 days) and was correlated with the thermal characteristics as measured by Differential Scanning Calorimetry (DSC) and proton mobility by Low-Field Nuclear Magnetic Resonance (LF-NMR). Linear increases of FFAs and PV were observed as a function of frying time. FFAs and PV were strongly correlated with the melting enthalpy. The melting enthalpy of oil decreased exponentially, and the melting temperature remained nearly same until 30 h of frying time followed by a sharp increase. The relaxation times of rigid, semi-rigid and mobile protons (i.e. T2b, T21, and T22) decreased with the increase of frying time. The decrease of T21, and T22 were steeper as compared to the T2b. A strong correlation was observed between conventional chemical parameters (i.e. PV and FFAs), and T21 and T22. The populations of the three pools of protons as identified by Inverse Laplace Transformation and Gaussian distribution function showed the interchange of the protons with the chemical changes during frying. It is concluded that chemical free DSC and LF-NMR could be potential methods to monitor frying oil degradation.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Deep fat frying involves immersion of food pieces in a very hot oil (e.g. 160–190 °C). The unique organoleptic properties of fried products make these very popular to the consumers. Oil used for frying migrates into the food product during frying and in some cases it makes up to 36% of the final product, for example potato chips. However, there are several health concerns for these snacks when these are prepared by deep fat frying. The oil used during frying degrades due to continuous or repeated exposure to high frying temperatures and atmospheric oxygen, such as oxidation, hydrolysis and polymerization of oil (Nayak et al. 2016). The formation of new chemical compounds during frying diminishes the quality of fried foods and causes negative health effects (Choe and Min 2007). These compounds include volatiles, such as aldehydes, ketones, alcohols, acids; and non-volatile compounds. The non-volatiles are usually characterized by higher molecular weight in the frying oil, and these could be absorbed by the fried foods (Choe and Min 2007). Free fatty acids (FFAs) is one of the commonly used tests used to monitor oil quality by evaluating the hydrolyzed fatty acids (Frega et al.1999). Similarly, peroxide value (PV) indicates the formation of primary oxidation products and para-anisidine value (p-AV) indicates the secondary oxidative products (Nayak et al. 2016). In addition, the polymerization reactions at high temperature can be tested by measuring total polar compounds (TPC) (Nayak et al. 2016). The conventional methods, which are currently used to determine the degree of oil abuse are costly, time consuming and involves several chemical reagents.

Differential Scanning Calorimetry (DSC) is one of the most frequently used methods in thermal analysis of foods. Over the last 60 years, the differential thermal analysis is being used in analyzing fat and oils (Tan and Man 1999). Gloria and Aguilera (1998) studied the thermal characteristics of heated oils (180 °C for 10 h) and found that crystallization peak (i.e. melting of oil) shifted to lower temperatures and enthalpies was reduced as compared to the fresh oil. This was due to the increase of oxidation as assessed by the increase in polar compounds. Under similar heating conditions (180 °C for 12 h), Tan and Man (1999) used DSC to monitor the oxidation of three vegetable oils (i.e. corn oil, palm olein and soybean oil) and observed that the peak of crystallization shifted to lower temperature as well as enthalpy decreased dramatically. Similar results were also reported by Pambou-Tobi et al. (2016). Literature also showed that DSC can be used to detect adulteration of oils (Tomaszewska-Gras 2016). Tan and Man (2002) assessed the potential of using DSC in determining the oxidative stability of oils. They considered twelve different vegetable oils, which were held at isothermal temperatures of 100–140 °C in the presence of oxygen and observed a correlation between the onset melting as measured by DSC and the oxidation stability index (OSI). The stability of oils was considered when OSI remained nearly same over heating time and a sharp increase in OSI indicated the onset of the instability due to rapid acceleration of oxidation.

Nuclear Magnetic Resonance (NMR) method has been widely investigated as one of the rapid, safe, non-invasive and non-destructive analytical method. This technique is based on the relaxation of NMR nuclei (specifically 1H and 13C) (Marcone et al. 2013). HF-NMR has been used widely to investigate formation of polar compounds, lipid oxidation, and determine polyunsaturated fatty acids (PUFA) (Marcone et al. 2013). Del Coco et al. (2021) used HF-NMR spectroscopy to determine polyunsaturated fatty acids (PUFA) as well as tyrosol and hydroxytyrosol derivatives, such as oleocanthal, oleacein, and elenolic acid in the extra virgin oils. However, HF-NMR is very costly and complex for the sample preparation, measurement and data analysis. In these aspects, LF-NMR is much cheaper and simple for analysis.

Low-field NMR (LF-NMR) has been reported as a useful tool to evaluate authenticity and quality of virgin olive oil (Sacco et al. 2000) and corn, peanut, rapeseed, and soybean oils (Zhang et al. 2013). LF-NMR was used to determine the quality and classification of food products (Shao and Li 2012), and was applied to determine the fat contents in foods (Todt et al. 2006. The method was also reported as a powerful tool for on-line (or in situ) and the rapid analysis of physicochemical properties of cereal food materials (Ghosh and Tombokan 2009) and it generates guarantee real-time food processing control (Shao and Li, 2012). In the case of LF-NMR, it is commonly used to predict two or three pools of protons from LF-NMR signals, and relaxation times and absorbance peaks of the rigid (i.e. T2b and A2b), semi-rigid (i.e. T21 and A21) and mobile (i.e. T22 and A22) protons are determined. Gu et al. (2021) used LF-NMR and fluorescence spectroscopy to evaluate the total polar compounds in oil during frying. They observed that the amplitudes of the semi-rigid (A21) and mobile (A22) pools of protons decreased with the increase of frying time due to the formation of oxidative products, especially polar compounds. Wang et al. (2019) studied the characteristics of palm oil during French fries as a function of frying time. They used the parameters T21, T22, A21, and A22 to relate with the total polar compounds. The degradation of frying oil in microwave vacuum frying was measured by peroxide value (PV), acid value (AV) and total polar compounds (TPC) as well as LF-NMR parameters T2b, T21, T22, A21, A22, and A23 (Sun et al. 2019).

In the literature, limited research is presented on the use of DSC and Low-Field Nuclear Magnetic Relaxation (LF-NMR) to monitor the degradation of oil during frying. LF-NMR was mainly used to monitor the oxidation of oil during heating process and negligible results were reported by simulating the commercial frying process. In addition, limited results were reported considering both DSC and LF-NMR in comparison to the conventional analysis of frying oil oxidation.

The objectives of this study were to use LF-NMR and DSC for evaluating the degradation of oil used in frying of potato chips and to compare the parameters with the conventionally used chemical parameters, i.e. free fatty acids (FFAs) and peroxide value (PV). In addition, potential of the chemical free LF-NMR and DSC methods was explored to determine the degradation of frying oil.

Materials and methods

Frying process

Potatoes (Solanum tuberosum L. cv. Diamant) were acquired from the local market. These had light yellow flesh color with oval shaped of 10 cm long. Potato strips (10 × 10 × 45 mm) were prepared by a food processor (Braun CombiMax 700, Braun, UK). These were washed in a cold water to remove starch adhering to the surface and surface water was removed by placing the potato strips between two layers of tissue papers. Sunflower oil (i.e. refined, bleached and deodorized from Areej Vegetables Oils and Derivatives, Muscat, Oman) was used as a frying medium. The fatty acid profile of the oils is shown in Table 1.

The intermittent frying cycles were simulated as follows. A batch of potato strips (100 g) was fried for 4 min at 185 °C in 8L-capacity fryer (Prestige fryer model # 54915, TTK Prestige Limited, Karnataka, India). After 11 min, another batch of fresh potato strips was fried again for 4 min in the same oil. Similarly, 20 batches were fried for 4 min with 11 min intervals (i.e. total frying operation was 5 h including waiting time). Similar steps were followed for 12 days using same batch of oil. After each day of frying operation, oil was kept in the same fryer by covering with its lid. Oil samples (150 ml) were taken from the fryer at the end of each frying day, placed in an amber bottle and stored at – 18 °C for further analysis. In this work, the frying time is presented as “frying hours” to describe the total frying without including the holding times. Considering the objective of using LF-NMR and DSC in evaluating the degradation of frying oil, the experiments were designed by simulating commercial frying process (i.e. 20 consecutive batches of potato strips with frying time 4 min and waiting 11 min intervals) to deteriorate frying oil over time (i.e. 12 days). The LF-NMR (i.e. relaxation times and relaxation peak areas) DSC (i.e. onset and peak melting temperatures and enthalpy of melting) parameters and conventionally used chemical parameters (i.e. FFAs and PV) were measured over frying time. These LF-NMR and DSC parameters were compared with the conventionally used chemical parameters.

Chemical analysis of oil

The effect of repeated frying on oil quality was determined by measuring the free fatty acids (FFAs) and peroxide value (PV). FFAs were determined according to AOCS method Ca 5a–40 (AOCS, 1998). Oil sample (25 g) was titrated with 0.01 N sodium hydroxide until a permanent pink color persisted for at least 30 s and phenolphthalein (1%, v/v) was used as an indicator. FFA (%) was calculated using the formula as follows:

Peroxide value was expressed as milliequivalents of peroxides (mEq) per 1000 g of test sample according to AOCS Cd 8b–90 (AOCS, 1998). Oil sample (8 g) was dissolved with 30 ml of acetic acid and then 0.5 ml of saturated potassium iodide and 30 ml of distilled water were added. The solution was titrated with Na2S2O3 until yellow color disappeared. Starch (1% w/v) was then used as an indicator and titration was carried out until blue color faded. A blank determination was conducted. Peroxide Value (PV) (mEq/kg) was calculated using the following equation:

where, S and B are the amount of Na2S2O3 (ml) used for the test sample, and the blank, respectively; and N is the normality of Na2S2O3.

Thermal analysis by Differential Scanning Calorimetry (DSC)

Thermal Analysis of oil was measured using differential scanning calorimetry (DSC Q200, TA Instruments, New Castle, DE, USA), TA Instruments, New Castle, Delware). The temperature and enthalpy of DSC were calibrated using lithium and distilled water. Oil sample of 3 mg was placed in a T-zero aluminum pan and it was hermitically sealed. Sample in a sealed pan was equilibrated at 25 °C for 5 min and then cooled to – 90 °C at 5 °C/min. It was then equilibrated for 5 min, and heated up to 100 °C at a rate of 5 °C/min. Melting of oil was determined from the endothermic peak and characterized by onset and peak temperature (°C), and area of the peak was considered as the enthalpy of oil melting (J/g). Each sample was replicated at least 3 times, and results were recorded as average value and standard deviation.

LF-NMR

Bruker Minispec 20 MHz (mq one with modular or pulse generator, 0.47 T, p20, Karlsruhe, Germany) with NMR data station analysis software was used to study proton mobility of oil. LF-NMR calibration was carried out using three standards provided by the manufacturer. Oil sample was poured inside 10 mm LF-NMR tube up to 3 cm height and the tube with oil was placed inside the NMR sample hole for LF-NMR relaxation measurement at 20 °C. The protocol was first optimized with gain (i.e. 65), number of scans (i.e. 32), and duration of the relaxation. Proton T2 relaxation (i.e. spin–spin) was measured with Carr-Purcell Pulse sequence procedure and signal after first 90° pulse were acquired (i.e. Carr-Purcell-Meiboom-Gill pulse). The sequence considered a pulse separation of 0.04 ms and 2000 data points were collected with a recycle delay of 1.5 s and attenuation 4. Signal intensity was recorded automatically and analyzed by tri-exponential function as Al-Habsi et al. (2017):

where S2o and S2 are the intensities at zero and any time for T2 relaxation, I2b, I21, and I22 are the first, second and third onset intensities for first, second and third linear regions of T2 relaxation curve (i.e. pre-exponential factors). T2b, T21, and T22 are the relaxation times for the rigid, semi-rigid and mobile protons in the frying oil, and t is the relaxation time (ms), respectively. Intensities values (S2) as a function of time were standardized by dividing with initial intensity (S2o), while initial intensity varied within the replicated samples. The pre-exponent factors and relaxation times were plotted as a function of “frying time” as hours in order to identify the degree of oil degradation. Graphical method was used to determine clearly the number of segments (i.e. numbers of linear portions of the plot ln (S2) versus time) rather presuming numbers of relaxation components (Al-Habsi et al 2017). In addition, relaxation curve was converted to Inverse Laplace Transformation and relaxation peaks were determined with Gaussian distribution function using Bruker ILT-CONTIN software. The three peak areas were considered as the pools of rigid (A2b), semi-rigid (A21), and mobile (A22) protons.

Statistical analysis

Five replicates were performed for each treatment and value are presented as mean ± standard uncertainty (i.e. data are presented as standard uncertainty defined as the average standard deviation of all data points as a function of time multiplied by 2, with a confidence level of 0.95). Pearson’s correlation was performed using JASP software, (version. 0.11.1.0 (JASP Team, 2019)) for determining the relationships between LF-NMR parameters and chemical parameters. Linear regression was performed for LF-NMR relaxation analysis using Microsoft Excel (Microsoft Office Professional Plus 2013, Microsoft Corporation). Partial Least Square (PLS) regression between FFA and LF-NMR data was carried out using XLSTAT tool (v. 2022.1.1, Addinsoft, New York, USA) (Addinsoft (2022)).

Results and discussion

Chemical analysis of oil

Figure 1A and B show linear increase of FFAs (p < 0.001, r2 = 0.963) and PV (p < 0.001, r2 = 0.999) as a function of “frying time”, respectively. Initially, the PV value increased with frying time and then reached to a slower increasing rate. The initial increase was due to the formation of hydroperoxides as measured PV and these were considered as the primary oxidation compounds formed in edible oils due to oxidation and thermal decomposition (Park and Kim 2016). However, hydroperoxides were not stable and decomposed into secondary oxidative products and this restricted further increase of PV value at the later stage of frying (Park and Kim 2016; Man and Swe 1995).

Similarly, linear increase of FFAs and PV was also reported as a function of frying temperatures (Rukmini and Raharjo 2010). This could be due to the formation of free fatty acids during frying when carboxylic groups are present in polymeric products (Choe and Min 2007). During frying, free fatty acids accumulated due to the hydrolysis of fatty acids in the triglycerides (Choe and Min 2007). This could cause off-flavor and makes the oil less acceptable (Frega et al. 1999). Peroxide Value (PV) was also increased linearly and could be due to the formation of hydroperoxides with the progressive degradation of oil during frying cycles (Choe and Min 2007; Park and Kim 2016).

Thermal analysis

Figure 2A shows a typical thermogram obtained for fresh oil. Peaks 1 and 2 indicated the melting of oil and area of the peaks indicated the melting enthalpy of oil. Initially, a sharp decrease of enthalpy was observed with the increase of “frying time”, followed by a slower decrease (Fig. 2B). Similarly, Pambou-Tobi et al. (2016) reported that heating decreased the enthalpy of oil melting. Tan and Man (1999) reported 58–90% decrease in the enthalpy of oil when it was heated at 180 °C for 12 h. The similar trend was also observed by Gloria and Aguilera (1998) when oil was heated for 10 h. The decreasing trends in melting enthalpy of oil could be attributed to the formation of free fatty acids, partial glycerides and oxidative products (Man and Swe 1995). In addition, the decrease of enthalpy could be due to the formation PV and FFAs as shown in Fig. 1 (Tan and Man, 1999). A strong correlation was found between enthalpy of oil melting and the chemical properties of oil (FFAs and PV) (p value < 0.001 and R2: – 0.909 and – 0.938) (Fig. 2E and F). This might be linked to the increase in oxidation and polymerization of polar compounds, which tended to increase with frying. FFAs value could be used to decide the frying oil discard point. For example, it was considered that FFAs level of 0.5% can be considered as the threshold of oil discard for the potato chips production, while it can go up to 1% in the production of French fries (Nayak, et al. 2016).

The onset melting temperature did not change until 30 h of frying, however a sharp increase was observed after 30 h (Fig. 2C). Similarly, a sharp increase in the melting peak temperature was observed after 30 h of frying time (Fig. 2D). According to literature, melting temperature of oil was highly dependent on the individual fatty acids present in the triglycerides (i.e. high percentage of saturated fatty acids increased the oil melting temperature) (Pernetti et al. 2007). Since unsaturated fatty acids are more vulnerable to oxidation (Arroyo et al. 1995), their proportion deceased due to oil degradation and hence the ratio of saturated: unsaturated was increased (Li et al. 2015). It is known that the melting point of saturated fatty acids is higher than the unsaturated fatty acids. Tan and Man (1999) showed that the thermogram of palm olein was different from corn and soybean oils and attributed that this was due to the differences in the degree of saturation. It was reported that a decrease in the melting onset and peak temperatures was observed when oil was heated alone and oxidized (Gloria and Aguilera 1998; Pambou-Tobi et al. 2016; Tan and Man 1999). However, in the case of frying of potato in this study, the melting temperatures increased instead of showing a decreasing trend. This could be explained by the presence of starch and its interactions with the frying oil. In addition, collapsing of water vapor bubbles on the potato strips at high temperature could also play a role by enhancing the reaction and interaction. This structure formation of amylose (i.e. amylose–lipid or amylose-palmitic acid complex) with oil during heating was explained earlier (Kugimiya et al.1980). Similar increase was also reported when oleo-gel was formed when ethyl cellulose was heated with canola oil; and the melting peak increased as oil was heated with ethyl cellulose as compared to oil heated alone. Therefore, higher viscosity of the ethyl cellulose caused higher shift of the melting peak (Davidovich-Pinhas et al. 2015). In the future work, it would be interesting to measure the formation of any complex polymeric compounds. Santana et al. (Santanaa et al. 2008) observed the increase of melting peak when solid fat fraction increased by hydrogenation, a process which is known to increase the saturated: unsaturated ratio.

Proton mobility as measured by LF-NMR

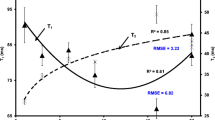

The T2b, T21 and T22 indicated that the relaxations of rigid, semi-rigid and mobile protons in the frying oil. The relaxation times and pre-exponent intensities are shown in Fig. 3 as a function of oil-use time. The rigid protons could be linked to the protons in the saturated fatty acids, while semi-rigid and mobile proton could be linked to the unsaturated fatty acids (i.e. mono and poly unsaturated). The relaxation times of rigid (T2b), semi-rigid (T21) and mobile (T22) protons of fresh frying oil were 4.4, 12.7 and 167.4 ms, respectively. Similarly, Del Coco et al. (2021) reported three LF-NMR signals corresponded to the saturated, mono- and poly-unsaturated fatty acids in olive oil. The relaxation times (T2b, T21 and T22) decreased with the increase of oil-use time, however the decrease of T21 and T22 (r2 = 0.982) (Fig. 4A) were much steeper as compared to the T2b (r2 = 0.564) (Fig. 4B and C). Similarly, Wang et al. (2019) observed that T21 and T22 of palm oil decreased with the increase of frying time. Considering Principle Component analysis (PCA), it was reported that both mono- and poly-unsaturated fatty acids was the discriminating variables (Del Coco et al. 2021). Sun et al. (2019) observed the decrease of T2b, T21 and T22 with the increase of PV, AV and TPC of frying oil used in the vacuum microwave frying. This supports the results of this study as identified three pools of protons with different relaxation times. In literature, there is no conclusive work that explain the different peaks that arise from NMR signals if lipids. Berman et al. (2013) did extensive work in studying the proton mobility in lipids. They reported that the rapeseed oil showed two peaks while the third peak was assigned for the biodiesel mixed with oil (Berman et al. 2013). They found that triglycerides would have lower mobility because of their rigid structure (three FAs esterified to a glycerol backbone) as compared to individuals FAMEs which have high freedom of movement. In the same study, authors used Primal–dual interior method for convex objectives (PDCO) algorithm technique to analyze NMR data. The algorithm revealed four peaks for rapeseed oil. This was attributed to four different segmental-motion with descending mobility: head-to-head (most rigid), double-bonds, aliphatic chain and tail (most mobile). Peaks have been described by the different mobility of molecules (fatty acids) or by the different proton pools. Berman et al. (2015) reported two peaks of T2 in Oleic acid (OA) and methyl oleate (MO) as a result of distinct mobility on the chain. The heating temperature significantly affected the peak values and location (ms) due to its mobility or intermolecular interactions. The high temperature, oxygen and water vapor during frying resulted a series of chemical reactions and caused the formation of different products (Choe and Min 2007). This caused significant changes in the chemical composition of oil in terms of more triglycerides and less free fatty acids and polar compounds to more free fatty acids, dimers, polar compounds. The intercept of rigid protons (I2b) showed insignificant change over the entire frying time (P < 0.05), while I21 (semi-rigid) and I22 (mobile) showed a sharp decrease after 40 h of frying. The variations of intercept depended on the degree of steep decrease of the proton mobility. Since rigid protons had low decrease of the slope (i.e. mobility), therefore it was expected that I2b would be low in variation.

Thermal relaxation as a function of frying time. A: Relaxation time (T2b) for the rigid proton, B: Relaxation time (T21) for the semi-rigid proton, C: Relaxation time (T22) for the mobile proton D: Pre-exponent (I2b) of rigid proton, E: Pre-exponent (I21) of semi-rigid proton, F: Pre-exponent (I21) of mobile proton

The stability of fatty acids during thermal degradation is highly linked to the degree of saturation. Fatty acids with more double bound (e.g. C18:3) are more susceptible to degradation of fatty acids with less double bonds. Decrease in T2b, and increase in T21 (due to increased mobility of proton in lateral branched) and T22 (due to increased mobility of protons in the free-ends) was reported. In this study, all types of protons in oil decreased their mobility with the frying time. It can be noticed from the frying time that there was no significant change in I2b (p = 0.782, Fig. 4D), while I21 and I22 remained nearly constant up to 6 days heating and then these were decreased sharply (Fig. 4E and F). This was related to the sharp increase of oil melting temperature after 30 h of frying (Fig. 2C and D). Guillen and Uriarte (2012) showed that the degradation of unsaturated fatty acids caused a reduction in the intensities of the LF-NMR signals.

T2b showed moderate correlation with PV (r = 0.736) and FFAs (r = 0.749) and T21 and T22 showed high correlation with PV (r = 0.967) and FFAs (r = 0.973) (Table 1). The regression lines are shown in Fig. 5. Similarly, Wang et al. (2019) observed T21 and T22 decreased with the increase of total polar compounds of palm oil during potato frying; however, T22 was much steeper than T21. The 1H NMR signals intensity can be affected by the chemical compounds, which are formed during polymerization of oil (Marcone et al. 2013). The decrease in relaxation times could be due to the polymerization of fatty acids or structure formation of fatty acids with extracted starch of potato chips during frying process. In addition, both water and starch could interact with the polar compounds formed in the drying oil. These merging of different pools of protons due to polymerization could be observed when distribution of peaks are explained in the next section.

The relaxation curve was converted to Inverse Laplace Transformation and relaxation peaks were determined with Gaussian function using Bruker ILT-CONTIN software. In the case of fresh oil, Fig. 5A shows the three peak areas of the rigid (A2b), semi-rigid (A21), and mobile (A22) pools of protons. Fig. 5B shows the fried oil after 60 h. In this case of fried oil after 60 h, another small peak was observed close to the rigid protons (Fig. 5B). The split of the rigid proton peak with a small peak indicated the formation of another type of minor rigid protons. Similarly, Hou et al. (2020) used A2b, A21 and A22 to classify edible oils with the supports of a neural network. Another extra minor peak was also observed after 15 h of frying. The pools (i.e. numbers) of rigid protons (A2b) show bi-phasic relation with the PV value of frying oil (Fig. 6A) (i.e. remained nearly constant until 36 meq O2/kg followed by a sharp increase), while semi-rigid (A21) protons show a single phasic linear decrease with PV (Fig. 6B). However, mobile protons (A22) shows biphasic decrease (i.e. remained nearly constant until 36 meq O2/kg followed by a sharp decrease) (Fig. 6C). The increase or decrease of A2b, A21, and A22 indicated the interchange of the protons within rigid, semi-rigid and mobile pools of protons. The decrease of A21, and A22 and increase of A2b with PV indicated semi-rigid and mobile proton pools converted to rigid pools of protons. In the case of FFAs, A2b increased (Fig. 6D) while A21 (Fig. 6E) and A22 (Fig. 6F) decreased after FFAs 0.3–0.4%. This also indicated the interchange of the pools of protons (i.e. rigid, semi-rigid and mobile) with the increase of FFAs. Gu et al. (2021) observed a decrease of A21 and A22 with the increase of polar compounds formed during frying. This caused increased viscosity and low flow-ability of the oil with an increase of frying time (Zhang et al. 2013). However, Gu et al. (2021) did not observe any interchange of the pools of protons. Wang et al. (2019) observed decrease of T21 and T22 with the increase of total polar compound, while A21 increased and A22 remained nearly same (i.e. no interchange of the pools of protons). Sun et al. (2019) identified that A2b and A23 increased with the increase of PV, AV and TPC, while A22 remained nearly same. In the cases of the three pools of protons, they did not observe any interchange of the protons. It could be mentioned that relaxation times of the rigid, semi-rigid and mobile protons indicated characteristics of the three pools of protons and relaxation peaks indicated the populations of each pool of protons, which could be interchanged. Considering the linear relationships of the relaxation times with PV and FFAs, it would be better to use these parameters (i.e. T2b, T21, and T22) to relate with the conventional chemical parameters (i.e. PV and FFAs) in order to characterize the frying oil. Partial least square (PLS) regression was used to model the relationship between FFA and LF-NMR data. (Table 2). From the Variable Importance in the Production (VIP) values, T21, I22 and T22 were the most important for FFA prediction, while I2b and I21 were the least one. This was also supported by the correlation matrix with high correlation between FFA and T21, I22 and T22 (i.e. − 0.882, − 0847 and − 0.787, respectively) (Table 3). Therefore, this study supported that fat oxidation (i.e. FFA) can be predicted from the simple chemical free measurement by LF-NMR.

LF-NMR method measured over all signal of the sample containing multicomponent complex mixture, however it was difficult to determine the interference of the other components, when a specific component(s) was measured. Although LF-NMR is a simple chemical free method of analysis. Further research needs to be targeted to determine the specificity and sensitivity of the LF-NMR method when it is used in complex food samples.

Conclusion

Free fatty acids and peroxide value were found to increase linearly with the frying time, indicating continuous degradation of frying oil. The enthalpy of oil melting decreased with the increase of the frying time, while the onset temperature and peak temperatures remained nearly constant up to 30 h of frying, and then these were sharply increased. This was related to the increase in hydroperoxides and free fatty acids formation during frying. A strong correlation (r = – 0.967 and – 0.954, p < 0.001) was found between the enthalpy and chemical properties. LF-NMR identified three pools of protons in the oil (i.e. rigid, semi-rigid and mobile). The relaxation times (i.e. T2b, T21 and T22) characterized the different pools of protons and these decreased linearly with the conventional chemical properties (i.e. PV and FFAs). However, a steeper decrease was observed for T21 and T22 as compared to the T2b. This could be due to the formation of unsaturated fatty acids during thermal degradation of oil. The intensities (i.e. numbers) of the pools of protons were also estimated from distribution curves and these were related to the chemical properties. The rigid pools of protons (i.e. A2b) remained constant until PV value of 36 meq O2/kg and FFAs of 0.3% and then increased sharply, whereas semi-rigid (i.e. A21) and mobile (A22) decreased. This was due to the exchange of semi-rigid and mobile pools of protons to the rigid protons. It was evident that both DSC and LF-NMR could be promising methods to monitor the quality of oil during frying. However, specificity and sensitivity of these methods need to be further checked considering different types of oils and foods.

Availability of data and material

This manuscript is an honest, accurate, and transparent account of the study being reported.

References

Addinsoft (2022) XLSTAT statistical and data analysis solution. New York, USA. https://www.xlstat.com/en

Al-Habsi NA, Al-Hadhrami S, Al-Kasbi H, Rahman MS (2017) Molecular mobility of fish flesh measured by low-field nuclear magnetic resonance (LF-NMR) relaxation: effects of freeze–thaw cycles. Fish Sci 83(5):845–851. https://doi.org/10.1007/s12562-017-1114-0

Arroyo R, Cuesta C, Sánchez-Montero JM, Sánchez-Muniz FJ (1995) High performance size exclusion chromatography of palm olein used for frying. Eur J Lipid Sci Technol 97:292–296. https://doi.org/10.1002/lipi.19950970714

Berman P, Levi O, Parmet Y, Saunders M, Wiesman Z (2013) Laplace inversion of low-resolution NMR relaxometry data using sparse representation methods. Concepts Magn Reson Part A 42(3):72–88. https://doi.org/10.1002/cmr.a.21263

Berman P, Nitzan M, Luiz AC, Tiago BM, Charles L, Ofer L, Yisrael P, Michael S, Zeev W (2015) Study of liquid-phase molecular packing interactions and morphology of fatty acid methyl esters (biodiesel). Biotechnol Biofuels 8(1):1–16. https://doi.org/10.1186/s13068-014-0194-7

Choe E, Min DB (2007) Chemistry of deep-fat frying oils. J Food Sci 72:R77–R86. https://doi.org/10.1111/j.1750-3841.2007.00352.x

Davidovich-Pinhas M, Barbut S, Marangoni AG (2015) The gelation of oil using ethyl cellulose. Carbohydr Polym 117:869–878. https://doi.org/10.1016/j.carbpol.2014.10.035

Del Coco L, Girelli CR, Angile F, Mascio I, Montemurro C, Distaso E, Tamburrano P, Chiurlia S, Clodoveo ML, Corbo F, Amirante R, Schena FP, Fanizzi FP (2021) NMR-based metabolomic study of apulian coratina extra virgin olive extracted with a combined ultrasound and thermal conditioning process in an industrial setting. Food Chem 345:128778. https://doi.org/10.1016/j.foodchem.2020.128778

Frega N, Mozzon M, Lecker G (1999) Effects of free fatty acids on oxidative stability of vegetable oil. J Am Oil Chem Soc 76:325–329. https://doi.org/10.1007/s11746-999-0239-4

Ghosh S, Tombokan X (2009) TD-NMR technology: a noninvasive tool for high-throughput QC and rapid cereal product improvement. Cereal Foods World 54:152–157. https://doi.org/10.1094/CFW-54-4-0152

Gloria H, Aguilera JM (1998) Assessment of the quality of heated oils by differential scanning calorimetry. J Agric Food Chem 46:1363–1368. https://doi.org/10.1021/jf9703664

Gu H, Huang X, Sun Y, Chen Q, Wei Z, Lv R (2021) Intelligent evaluation of total polar compounds (TPC) content of frying oil based on fluorescence spectroscopy and low-field NMR. Food Chem 342:1–8. https://doi.org/10.1016/j.foodchem.2020.128242

Guillén MD, Uriarte PS (2012) Study by 1H NMR spectroscopy of the evolution of extra virgin olive oil composition submitted to frying temperature in an industrial fryer for a prolonged period of time. Food Chem 134:162–172. https://doi.org/10.1016/j.foodchem.2012.02.083

Hou X, Wang G, Wang X, Ge X, Fan Y, Nie S (2020) Convolutional neural network based approach for classification of edible oils using low-field nuclear magnetic resonance. Journal of Food Composition and Analysis 92: https://doi.org/10.1016/j.jfca.2020.103566

JASP Team (2019). JASP (Version 0.11.1.0)[Computer software]

Kugimiya M, Donovan JW, Wong RY (1980) Phase transition of amylose-lipid complexes in starches: a calorimetric study. Starch 32:265–270. https://doi.org/10.1002/star.19800320805

Li X, Wu X, Liu R, Jin Q, Wang X (2015) Effect of frying conditions on fatty acid profile and total polar materials via viscosity. J Food Eng 166:349–355. https://doi.org/10.1016/j.jfoodeng.2015.07.007

Man YC, Swe PZ (1995) Thermal analysis of failed-batch palm oil by differential scanning calorimetry. J Am Oil Chem Soc 72:1529–1532. https://doi.org/10.1007/BF02577848

Marcone MF, Wang S, Albabish W, Nie S, Somnarain D, Hill A (2013) Diverse food-based applications of nuclear magnetic resonance (NMR) technology. Food Res Int 51:729–747. https://doi.org/10.1016/j.foodres.2012.12.046

Nayak PK, Dash UMA, Rayaguru K, Krishnan KR (2016) Physio-chemical changes during repeated frying of cooked oil: a review. J Food Biochem 40:371–390. https://doi.org/10.1111/jfbc.12215

Pambou-Tobi N, Arab-Tehrany E, Niamayoua RK, Linder M (2016) RSM applied for optimization of deep-fat fried ripe plantain slices and study of oxidation kinetics of oil by a DSC and polar methods. J Food Sci Technol 53:269–280. https://doi.org/10.1007/s13197-015-2021-y

Park JM, Kim JM (2016) Monitoring of used frying oils and frying times for frying chicken nuggets using peroxide value and acid value. Food Sci Anim Resour 36:612. https://doi.org/10.5851/kosfa.2016.36.5.612

Pernetti M, van Malssen KF, Flöter E, Bot A (2007) Structuring of edible oils by alternatives to crystalline fat. Curr Opin Colloid Interface Sci 12:221–231. https://doi.org/10.1016/j.cocis.2007.07.002

Rukmini A, Raharjo S (2010) Pattern of peroxide value changes in virgin coconut oil (VCO) due to photo-oxidation sensitized by chlorophyll. J Am Oil Chem Soc 87:1407–1412. https://doi.org/10.1007/s11746-010-1641-7

Sacco A, Brescia MA, Liuzzi V, Reniero F, Guillou G, Ghelli S, Van Der Meer P (2000) Characterization of italian olive oils based on analytical and nuclear magnetic resonance determinations. J Am Oil Chem Soc 77:619–625. https://doi.org/10.1007/s11746-000-0100-y

Santanaa A, Fernandez X, Larrayoz MA, Recasens F (2008) Vegetable fat hydrogenation in supercritical-fluid solvents: melting behavior analysis by DSC and NMR. J Supercrit Fluids 46:322–328. https://doi.org/10.1016/j.supflu.2008.03.003

Shao X, Li Y (2012) Classification and prediction by LF NMR. Food Bioprocess Technol 5:1817–1823. https://doi.org/10.1007/s11947-010-0455-9

Sun Y, Zhang M, Fan D (2019) Effect of ultrasonic on deterioration of oil in microwave vacuum frying and prediction of frying oil quality based on low field nuclear magnetic resonance (LF-NMR). Ultrason Sonochem 51:77–89. https://doi.org/10.1016/j.ultsonch.2018.10.015

Tan CP, Man YC (1999) Differential scanning calorimetric analysis for monitoring the oxidation of heated oils. Food Chem 67:177–184. https://doi.org/10.1007/s11746-999-0203-3

Tan CP, Man YC (2002) Recent developments in differential scanning calorimetry for assessing oxidative deterioration of vegetable oils. Trends Food Sci Technol 13:312–318. https://doi.org/10.1016/S0924-2244(02)00165-6f

Tomaszewska-Gras J (2016) Rapid quantitative determination of butter adulteration with palm oil using the DSC technique. Food Control 60:629–635. https://doi.org/10.1016/j.foodcont.2015.09.001

Todt H, Guthausen G, Burk W, Schmalbein D, Kamlowski A (2006) Water/moisture and fat analysis by time-domain NMR. Food Chem 96:436–440. https://doi.org/10.1016/j.foodchem.2005.04.032

Wang C, Su G, Wang X, Nie S (2019) Rapid assessment of deep frying oil quality as well as water and fat contents in french fries by low-field nuclear magnetic resonance. J Agric Food Chem 67:2361–2368. https://doi.org/10.1021/acs.jafc.8b05639

Zhang Q, Saleh AS, Shen Q (2013) Discrimination of edible vegetable oil adulteration with used frying oil by low field nuclear magnetic resonance. Food Bioprocess Technol 6:2562–2570. https://doi.org/10.1007/s11947-012-0826-5

Acknowledgements

Authors would like to acknowledge the Sultan Qaboos University for their support to this research project.

Funding

Research was supported by Sultan Qaboos University as it appears in the acknowledgement.

Author information

Authors and Affiliations

Contributions

MAl-K: conceptualization, Methodology, Writing—Original Draft. NAl-H: conceptualization, methodology, Writing—Review & Editing. SAAl-Y: Investigation, ASAl-K: Investigation. AMAl-B: Investigation, IAl-S: Investigation. MSR: Conceptualization, Formal analysis, Supervision, Writing—Review & Editing.

Corresponding author

Ethics declarations

Conflicts of interest

No conflict of interest to be declared.

Consent for publication

All authors have agreed to send the manuscript for possible publication in Food and Bioprocess Technology.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Al-Khusaibi, M., Al-Habsi, N.A., Al-Yamani, S.A. et al. Possibility of using low-field nuclear magnetic resonance (LF-NMR) and differential scanning calorimetry (DSC) to monitor frying oil degradation. J Food Sci Technol 59, 4176–4186 (2022). https://doi.org/10.1007/s13197-022-05471-8

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13197-022-05471-8