Abstract

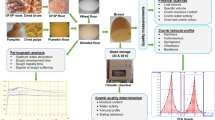

Trends on the use of non-wheat flours for bread production has led to researches on improving the rheological characteristics of such non-wheat flours. This aim of this study was to determine the effect of soy concentrate on the protein and rheological behaviour (pasting and mixolab) of the orange-fleshed sweet potato composite flour as well as the physical and sensory qualities of the bread produced. The experimental design to obtain the optimum blends was carried out using optimum design of response surface methodology; with sweat potato, soy bean concentrate, date palm flour and potato starch as the independent variables. The result shows that protein values ranged from 6.19 to 21.10%, carotenoid values ranged from 0.11 to 26.18 mg/100 g. pasting temperature ranged from 68.50 to 82.33 °C; peak viscosity ranged between 159 and 1040 RVU, the breakdown value ranged between 24 and 272 RVU and the setback value ranged from 75 to 368 RVU. The bread loaf weights ranged from 111 to 256 g and the specific loaf volume ranged from 0.7 to 1.6cm3/g. The bread samples varied significantly (p < 0.05) with the consumer’s acceptability in terms of aroma, appearance, taste and overall acceptability. It was observed that soy-concentrate increase the protein content and improves rheological properties of the composite flour for the production of gluten free bread.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Gluten intolerance known as celiac disease (CD), is a disorder described by destruction to the mucosa portion of small intestine triggered by the consumption of wheat proteins known as gluten (Jagelaviciute & Cizeikiene 2021). This gluten consists of two proteins called prolamines and glutenins. Prolamines are found in wheat in the form of gliadins, in barley in the form of hordeins, in rye in the form of secalins and in oat in the form of avenins (Di Cairano et al. 2018). Glutens are toxic to human health thereby causing inflammation, weakening and hyperplasia of the small-intestinal crypts of the celiac patient due to the existence of multiple proline and glutamine residues, making the effected person resilient to the gastrointestinal absorption and deamination via tissue trans-glutaminase. Once patient is diagnosed with CD, such patient’s live without gluten-containing foods in whole or partial, all lifelong. To-date, a lifelong gluten-free food is the only treatment for CD patients (Pruimboom & De Punder 2015).

Gluten-free products (gluten-free bread, gluten-free beer etc) are food that strictly excludes the use of gluten in foods products (Różyło et al. 2015). Gluten-free baked foods such for bread production in particular remains a processing challenge due to lack of viscoelastic properties, improving viscoelasticity of non-wheat ot gluten-free doughs can be obtained by several factors such as inclusion of protein source, dietary fibre foods, hydrocolloids (Awolu et al. 2018; Bourekoua et al. 2018; Jagelaviciute & Cizeikiene 2021). Gluten- free foods include sweet potato, sorghum, millet, maize, yam, cocoa yam, Acha etc.

Orange flesh sweet potato (OFSP) is the orange variety of sweet potato which is globally an important staple food crop (Oloniyo et al. 2021; Omoba et al. 2020). It is a rich source of fiber, minerals (calcium, potassium, phosphorous, magnesium), vitamins (A, E, C and B complex) and carotenes (Oloniyo et al. 2021) but it is low in protein (Oloniyo et al. 2021; Tumuhimbise et al. 2019; Haile & Getahun 2018). Addition of protein-rich crops will also improve the protein content of gluten-free foods (Oloniyo et al. 2020). The utilization of OFSP has been limited because of its low protein content as reported by (Haile & Getahun 2018; Tumuhimbise, et al. 2019; Oloniyo et al. 2021) and so, there is a need to incorporate protein-rich foods into OFSP-based composite flours. OFSP has being used by researchers for the development of bread (Tumuhimbise et al. 2019; Omoba et al. 2020; Oloniyo et al. 2021) but there are limited information on the use of soy-concentrate as a source of protein with OFSP composite flour for the production of bread and product optimization of the OFSP-based composite flours. Thus, this study aimed to determine the effect of soy concentrate, date palm flour and sweat potato starch on the protein content and rheological behaviour (pasting and mixolab) of the orange-fleshed sweet potato composite flour; the physical and sensory characteristics of bread developed from the composite flour was evaluated.

Materials and methods

Materials

Cream fleshed sweet potato and the two varieties of orange-fleshed sweet potato (mother’s delight– UMUSP002 and King J—UMUSP001) used in this study were cultivated and harvested at five months of maturity from a private farm at Oba Ile, Akure, Ondo State, Nigeria. Soybeans (TGX923-1E variety), were obtained from Niger State, Nigeria. The control sample (Wheat flour) was purchased from Crown Flour Mill industry at Apapa, Lagos State, Nigeria. Date palm and other ingredients (yeast and margarine) were obtained from shasha Market in Akure, Nigeria.

Methods

Samples preparation

Preparation of sweet potato flour

Sweet potato tuber varieties were processed into flour as described by Oloniyo et al. (2020). Two hundred kilograms (200 kg) of the sweet potato tubers were cleaned, peeled and divided into smaller pieces using sharp stainless table knife; the pieces of tubers were dried at 60 °C for 48 h in an oven. Then, the dried pieces of tubers were milled with a disc mill and screened via 250 μm mesh sifter to uniform finer flour. The flour was stored at 4 °C in an airtight polyethylene bag prior to use.

Preparation of soy concentrate flour (SCF)

Soy concentrate flour was obtained from Soy bean as described by Oloniyo et al. (2020). Soybeans (3.0 kg) were drenched in water (10 L) at 40 °C for 20 h. The drenched soy beans were drained and milled, water was added at a ratio of 6:1 to form slurry which was filtered to separate soy residue from its milk. Soymilk was then boiled for 5 min thereafter 15 ml of lemon juice (coagulants) was added to one (1) litre of soy milk to concentrate the milk; the concentrated milk was collected into a clean muslin cloth and pressed for 6 h. The obtained soy concentrate (SC) was dried at 40 °C for 24 h, milled, cooled and sieved through 250 μm mesh size. The soy concentrate powder was stored at 4 °C in an airtight container prior to analysis.

Preparation of date palm powder

Date palm fruits were processed into powder by a method described by Sadiq et al. (2013). Date palm were de - pitted manually and dried at 50 °C for 24 h. The dried sample were reduced into smaller units using pestle and mortar, afterward it was milled into a fine particle. The powder were sieved through 150μm-mesh sieve and stored in an airtight container at 4 °C prior to analysis.

Experimental design for the flour blends

Response Surface Methodology (Design Expert, 8.0.3.1 trial version) was used to design the experiment in this study. OFSP flour, soy concentrate flour (SCF), date palm flour and sweet potato starch were the independent variables, while protein and β-carotene contents were the dependent variables. The independent variables ranges were OFSP (56–70g/100g) and SCF (06–20g/100g); date palm flour (10g/100g) and potato starch flour (14g/100g). Thirteen samples were generated out from each of the variety of sweet potato used as shown in Table 1a & b. Samples with the best response variables were used for bread production while wheat flour was used as the control samples.

Determination of protein content

Protein content of the composite flour was determined using Kjeldahl method (nitrogen content multiplied by 6.25) as described by AOAC (2012).

Determination of carotenoid content

The carotenoid content of the composite flour was determined as described by Rodriguez-Amaya and Kimura (2004).

Determination of pasting characteristics

The pasting properties of the flour samples were carried out using a Rapid Visco Analyser (RVA) (Perten Instruments RVA 4500) as described by Scientific (1998).

Determination of rheological (Mixolab) parameters of sweet potato composite flour

The rheological (mixolab) parameters were determined as described by Dhaka et al. (2012) using the Mixolab analyser (Chopin, Tripetteet Renaud, Paris, France). All measurements were performed using the Mixolab standard Chopin + protocol (ICC No. 173).

Preparation of gluten-free breads

Dough flour from composite sweet potato was processed into bread according to the method described by Oloniyo et al. (2020). Bread constituents are 450 g of composite flour, 8 g of concentrate dry yeast, 4 g of common table salt, 60 g of margarine and 130–160 ml of water. Choleywood’s method for bread making was used for the bread production (Cauvain 2015). The dried ingredients were weighed into a clean container and mixed for 3 min. It was allowed to rest for the interval of 30 min. Yeasts fine particles was liquefied in warm water inside a separate clean container; the liquefied yeast was then added to the dried mixed ingredients above and then kneaded at 25 °C for 15 min. Kneaded dough was divided into a clean baking pan and allowed to ferment in a dark room in order to proof it for 45 min at 37 °C. The dough was allowed to relax (untouched) and the yeast was able to produce carbon IV oxide (Co2) thereby leading to the formation of air spaces within the dough, this allows the dough to increase in size (Onyango 2016). Immediately, after the proofing process, the dough was gently arranged on a tray in an electric hot oven and bake at high temperature of 220 °C for 30 min. After baking process, the loaf of bread was carefully removed from the oven and allowed to cool at room temperature before the evaluation of the bread properties.

Physical qualities of sweet potato composite bread

Determination of loaf height

Loaf height was determined as described by Mi and Ejeh (2018).The bread height was determined by using a measuring rule.

Determination of loaf weight

The loaf weight was determined as described by Bakare et al. (2016). The weights of the bread loaves were taking after 20 min of cooling immediately after baking; this was done using the laboratory Mettler Toledo (A204) digital weighing scale.

Determination of weight loss

The weight loss of the bread was determined as described by Bakare et al. (2016). The dough was weighed before baking, and the breads were weighed after baking. The percent weight loss of the bread samples was calculated as:

Determination of loaf volume and specific loaf volume

The loaf volume and specific volume were determined by using the method described by Shittu et al. (2008). Loaf volume was calculated using rape seed displacement method using measuring cylinder and recorded as loaf volume in cm3.

Determination of oven spring

Oven spring was determined according to the method described by Shittu et al.(2008).The oven spring of the dough was determined by using a measuring rule.

Determination of the sensory qualities of composite sweet potato bread

Sensory evaluation (SE) of the bread sample was carried out as described by the method of Oloniyo et al. (2020). SE of the bread was carried using sixty (60) trained panelists (forty-two (42) male and eighteen (18) female undergraduate students) from the Federal University of Technology, Akure (FUTA), Nigeria. The SE protocol was approved by the Ethics Committee at the School of Agriculture & Agricultural Technology (SAAT) of Federal University of technology Akure, Nigeria (FUTA/SAAT/2018/021) and conformed to the ethical principles set forth in the Declaration of Federal Government of Nigeria. Training session of about thirty (30) min was conducted for the panelist on how to assess the samples. The evaluation was carried out two (2) h after the baking process. Panelists were instructed to rates each bread separately using a nine-point hedonic scales with the rating measure of: 1—Dislike extremely, 2—Dislike very much, 3—Dislike moderately, 4- Dislike slightly, 5—Neither like nor dislike, 6—Like slightly, 7—Like moderately, 8—Like very much and 9—Like extremely for all the bread quality attributes (Aroma, appearance, taste, and overall acceptability).

Statistical analysis

The data were generated in triplicate and analyzed using Statistical Package for Social Sciences (SPSS) Version 21. The significant differences between the means were separated using Duncan Multiple Range Test (DMRT) at 95% confidence level (P ≤ 0.05).

Results and discussion

Protein and carotenoid content of sweet potato based composite flour blends

The protein and β carotene content of the three varieties of sweet potato was shown in Table 2. The highest protein contents were found in the samples with 20% substitution of soy concentrate flour in all the varieties of sweet potato with 19.6, 21.07 and 18.34 % in OFSPM2, OFSPK2 and CFSP2 flour blends. This result was in agreement with the report of Wang et al. (2019) that soybean is a good source of plant protein.

The highest carotenoid contents were observed in the samples with 70% substitution of sweet potato flour in all the varieties of sweet potato with 26.18, 8.0 and 5.4 mg/100g in OFSPM1, OFSPK1 CFSP1 flour blends. This agreed with report of Islam et al. (2016) that orange flesh sweet potato is a good source of beta carotene which is a precursor of vitamin A. The high content observed in OFSPM1 could be attributed to the deep orange colour of the sweet potato flesh (Adebisi et al. 2015) compared to other varieties of the sweet potato examined. Findings by Donado-Pestana et al. (2012) showed that OFSP varieties exhibited high carotenoids contents ranging from 7.91 to 12.85 mg/100 g. In addition to being a good source of carotenoids which is a precursor for vitamin A, OFSP is a good source of carotene which is an indigestible compound in foods, when digested by both humans and animals; it is converted to rhodopsin and retinal, a visual pigment and precursor of retinoid acid, which regulates growth and visual development (Le Kang et al. 2017).

Pasting characteristics of sweet potato based composite flour blends

Pasting (RVU) properties of optimized blends of sweet potato based composite flour blends are presented in Table 3. Peak viscosity increase significantly (p < 0.05) with progressive increase in sweet potato flour level and it ranged from 159 to 1040 RVU, for the flour blends. The increase in peak viscosity with an increase in the sweet potato flour level indicates a greater structural rigidity in comparison to control sample (WHT), this agrees with the report of Bakare et al. (2016). Increase peak viscosity had a great influence on the swelling properties of the flour blends. Peak viscosity is the maximum viscosity developed during or soon after the heating portion of the pasting period and it correlates to the quality of the final product. This also gives an indication of the viscous-load likely to be faced throughout the mixing period (Bakare et al. 2016).

Holding strength (torque) indicated the ability of the starch granules to maintain their gelatinized structure when the paste was held at 95 °C for 2 min 30 s under mechanical shearing stress (Bakare et al. 2016). The torque value ranged from 64 to 768 RVU, all the gluten-free samples had a holding strength value that was higher than that of the control sample.

Breakdown (BD) viscosity measured the degree of starch disintegration, it is an indication of hot paste stability of the starch. Flour with low BD viscosity shows better resistance to shear thinning of flour pastes, thus; the smaller the breakdown viscosity, the higher the paste stability (Bakare et al. 2016). The Break down values ranged from 24 to 272 RVU compared to the control sample having 42RVU. The lower the breakdown values of the flour the better the baking quality.

Set back (SB) values of the samples with the highest substitution (20%) of protein in the three varieties considered was the least (75,187 and 92 for OFSP M2, OFSP K2 and CFSP2 varieties respectively).The setback value obtained were higher than WHT (55 RVU) sample for protein selected samples Setback (SB) is the rearrangement of starch molecules and shows the tendency of starch to retrograde (Ma et al. 2019). It is the measure of retrogradation after cooling of starch to 500C thereby leading to syneresis and staling (Bakare et al. 2016; Awolu et al. 2018). The lower the setback value the better the quality of the flour product. The difference observed in pasting temperature is an indication of different gelatinization temperature of flour. Advanced setback values are equivalent to reduced dough digestibility and it is associated with cohesiveness. (Kiin-Kabari et al. 2015) while lesser setback values observed during the cooling process of the paste denote lesser affinity for retrogradation (Ma et al. 2019). Setback viscosity is the phase of the pasting curve after cooling the starches to 50 °C. This stage involved re-association, retrogradation, or reordering of starch molecules (Falade & Okafor 2015; Bakare et al 2016; Kiin-Kabari et al. 2015). Also, the water previously bounded in the viscoelastic gel is released at this stage in a process referred to as syneresis. The higher the setback viscosity value the greater the tendency toward retrogradation (Bakare et al. 2016; Awolu et al. 2018).

Cream fleshed sweet potato flour based composite had significantly (P ≤ 0.05) lower pasting temperatures (75.05 to 80.70 °C) while high pasting temperature was observed in orange fleshed sweet potato (OFSP 1 and OFSP 2) composite flours, this implies that cream fleshed base composite flour will gel faster than OFSP based composite flour. This property is important in systems where thickening of gels is required at low temperatures in order to reduce energy cost during production. Pasting temperature gives an indication of temperature required to cook the flour beyond its gelatinization point (Bakare et al. 2016; Ma et al. 2019).

Final viscosity (Fv) of the gluten free flour samples ranged from 210 to1136 RVU, but the control sample had a lower value of 114 RVU. High Fv suggests that the paste is highly resistant to mechanical shear which may have influenced the production of more gel. Final viscosity is the section of the paste gel curve where the gelatinized dispersion of starch becomes viscoelastic on cooling resulting in the formation of a loose paste or gel. All the samples had significantly higher final viscosity value (210–1136 RVU) than the control sample indicating that the sample formed a firm gel-like structure after cooking prior cooling. The results agrees with Bakare et al. (2016).

Pasting time (Pt) ranged from 4.07 to 5.60 min. Pasting time (Pt) measured the cooking time and this indicates the duration taken for the starch to reach peak viscosity.

Rheological (Mixolab) parameters of optimized blends of sweet potato based composite flour blends

The rheological properties of the sweet potato based composite flour blends are presented in Table 4. In mixolab analysis, Water-absorption gives an indication of the potential of the protein molecules in the sample to absorb the added water thus; this is an indicator of baking quality as reported by Li et al. (2018). The major factor that contributes to the water absorption includes protein content, starch, damaged starch, pentosans and gluten strength (Sapirstein et al. 2018). All the samples (non-gluten flour blends) had water absorption ranged from 48.4 to 58.1% (Table 4), which is lower than the refined wheat flour (60.8%) used as control, which agreed with the report of Hadnađev et al. (2011) in the production of gluten free flour. The higher the water absorption level, the better the quality of the flour and the productivity of the flour.

Dough development time (DDT) is an important factor because it reflects the time between the first addition of water and the time when the dough seems to have optimum elastic and viscous properties for the retention of gas. DDT depends on the water absorption speed of flour constituents to form a smooth and homogenous appearance (Vizitiu and Danciu 2011). DDT varied between 3 and 9 min for a good quality of baking flour. Dough development time was not taken into consideration when mixing dough for bread baking. All dough were mixed to a temperature of 30 °C. In this study the DDT range from 1.0 to 4.0 min, both for wheat and non-gluten flour. This result is similar to the report of Awolu et al. (2018) but the DDT value was lower than the report of Hadnađev et al. (2011) for non-gluten flour, this may be attributed to the nature of the flour used.

Dough Stability represents the time during which the maximum dough consistency does not change. Stability is an indication of the flour’s tolerance to mixing and stronger flours tend to be more stable (Vizitiu and Danciu 2011). In this study, the dough stability ranged from 1.5 to 23.0 min (Table 3) and agrees with the report of Mailhot and Patton (1988) who recommended a minimum dough stability of 7.5 min for bread making because some of the blends ratio had below 7.5 min. Wheat (Control) sample and the best samples (OFSPM2, OFSPK2 and CFSP 2) with acceptable protein contents, low break down and set back values were used to produced bread.

Two best blends based on the optimization of carotenoid and protein properties were run 1 (70.00% OFSP, 6.00% soy concentrate, 10.00% Date palm, 14.00% potato starch) and run 2 (56.00% OFSP, 20.00% soy concentrate, 10.00% Date palm, 14.00% potato starch) were compared with the control sample. Runs 1 and 2 were used to produce gluten free bread and the bread was analyzed for both physical and sensory qualities.

Physical characteristics of sweet potato composite bread

The physical characteristics of sweet potato composite bread are presented in Table 5. The height of dough of sweet potato composite dough ranged from 4.3 to 5.8 cm. The height loaf of sweet potato composite bread ranged from 6.0 to 7.3 cm. Loaf weight of sweet potato composite bread ranged from 111.0 to 256.8 g.The high loaf weight values observed in OFSPM 2, OFSPK2, CFSP2, OFSPM 1, OFSPK1 and CFSP1 could be attributed to increase in moisture absorbed and less carbon dioxide gas retention of in the dough this result into heavy dough thus heavy loaves (Mi and Ejeh 2018). Loaf weight is mainly influenced by the amount of dough baked, the percentage of moisture content and carbon dioxide (Co2) diffused out during baking (Shittu et al. 2008). WHT bread had the lowest weight.

The weight loss of sweet potato composite dough ranged from 24.3 to 39.6%, weight loss occurs in bread due to fermentation losses brought about by amylases of starch, utilization of soluble sugar by yeast and by evaporation of moisture during baking (Bakare et al. 2016). The high weight loss observed in this study could be attributed to their ability to form viscous dough while imbibing large amount of water which were lost during the baking (Bakare et al. 2016).

The specific volume of sweet potato composite bread ranged from 0.7 to 1.6. The higher specific volume values observed in OFSPM 2, OFSPK2, CFSP2, OFSPM 1, OFSPK1 and CFSP1, this could be as a result to the lack of gluten in the dough thereby resulting into less carbon dioxide gas retention and a dense texture (Makinde and Akinoso 2014). The least value was observed in WHT, the obtained results correspond to the findings of Mi and Ejeh (2018). Gluten causes the dough to extend and trap carbon dioxide gas produced by yeast through fermentation process in bread making, this causes the dough to be elastic and retain high volume. High temperature used in baking process coagulates the gluten structure and makes it rigid without collapsing (Mepha et al. 2007).

The oven spring of sweet potato composite bread ranged from 0.6 to 1.0 cm. The results obtained was lower than the findings of Edun et al. (2018) who reported that oven spring of bread substituted with OFSP flour ranged 0.15–0.45 cm. Oven spring is an important baking quality. It measures the dough strength against heat-related changes that take place in the oven. This is affected by a number of variables such as gluten composition, rate of starch gelatinization, yeast viability among other factors (Bae et al. 2014).

The pictures of the bread samples are shown in Fig. 1.

Sensory evaluation of bread

The sensory attributes of the bread samples scored were showed in Fig. 2. The bread samples varied significantly (p < 0.05) in terms of aroma, appearance, taste and overall acceptability. Aroma ranged from 4.20 to 7.35, appearance ranged from to 6.34 to 7.76, taste ranged from 6.71 to 8.02 while the overall acceptance ranged from 3.70 to 7.50. The obtained result agrees with the report of Bourekoua et al. (2018). The appearance and taste of the bread were strongly influenced by the colour of the sweet potato varieties used. OFSPK2 and OFSPK1 bread samples scored the highest after the controlled sample in terms of overall acceptability. Taste is an important attribute in acceptance of food product. This finding confirms the report by Preedy et al. (2011) that sweet potato flour adds natural sweetness (taste) to processed foods. OFSPK2 bread compared favourably with wheat (WHT) control sample.

Conclusion

In this study, It was observed that 20% incorporation of soy concentrate into orange fleshed sweet potato flour (non- gluten flour) enhanced the protein content of bread (non- gluten bread) produced. Also orange fleshed sweet potato composite flour consisting of 56% of sweet potato flour, 20% of soy concentrate, 10% of date palm and 14% of potato starch had a good rheological property for bread making compared to other samples. Sensory evaluation showed that OFSPK2 (56% of sweet potato flour, 20% of soy concentrate, 10% of date palm and 14% of potato starch) bread had a better physical quality and the highest overall acceptability rating by the consumers.

References

AOAC (2012). Official methods of analysis.19th edition. Association of Official Analytical chemists. Washington DC.

Awolu O, Sudha L, Manohar B (2018) Influence of defatted mango kernel seed flour addition on the rheological characteristics and cookie making quality of wheat flour. Food Sci Nutr 6(8):2363–2373

Bae W, Lee B, Hou GG, Lee S (2014) Physicochemical characterization of whole-grain wheat flour in a frozen dough system for bake off technology. J Cereal Sci 60(3):520–525

Bakare AH, Osundahunsi OF, Olusanya JO (2016) Rheological, baking, and sensory properties of composite bread dough with breadfruit (Artocarpus communis Forst) and wheat flours. Food Sci Nutr 4(4):573–587

Bourekoua H, Różyło R, Gawlik-Dziki U, Benatallah L, Zidoune MN, Dziki D (2018) Evaluation of physical, sensorial, and antioxidant properties of gluten-free bread enriched with Moringa Oleifera leaf powder. Eur Food Res Technol 244:189–195

Cauvain, S. (2015).Bread making processes.In Technology of breadmaking. Springer, Cham. 23–55

Dhaka V, Gulia N & Khatkar B.S (2012) Application of Mixolab to Assess the Bread Making Quality of Wheat Varieties. 1: 183. doi:https://doi.org/10.4172/scientificreports.183

Di Cairano M, Galgano F, Tolve R, Caruso MC, Condelli N (2018) Focus on gluten free biscuits: ingredients and issues. Trends Food Sci Technol 81:203–212

Edun AA, Olatunde GO, Shittu TA, Adeogun AI (2019) Flour, dough and bread properties of wheat flour substituted with orange-fleshed sweetpotato flour. J Culinary Sci Tech 17(3):268–289

Falade KO, Okafor CA (2015) Physical, functional, and pasting properties of flours from corms of two Cocoyam (Colocasia esculenta and Xanthosoma sagittifolium) cultivars. J Food Sci Technol. 52(6):3440–3448

Hadnađev TD, Torbica A, Hadnađev M (2011) Rheological properties of wheat flour substitutes/alternative crops assessed by Mixolab. Procedia Food Sci 1:328–334

Haile A, Getahun D (2018) Evaluation of nutritional and anti nutrition factors of orange-fleshed sweet potato and haricot bean blended mashed food for pre-school children: the case of Dale Woreda Southern Ethiopia. Food Sci Tech 6(1):10–19

Jagelaviciute J, Cizeikiene D (2021) The influence of non-traditional sourdough made with quinoa, hemp and chia flour on the characteristics of gluten-free maize/rice bread. LWT. 137:110457

Kiin-Kabari DB, Eke-Ejiofor J, Giami SY (2015) Functional and Pasting Properties of Wheat / Plantain Flours Enriched with Bambara Groundnut Protein Concentrate. Int J Food Sci Nut Eng 5(2):75–81

Ma Z, Ma M, Zhou D, Li X, Hu X (2019) The retrogradation characteristics of pullulanase debranched field pea starch: effects of storage time and temperature. Int J Biol Macromol 134:984–992

Mailhot, W. C & Patton, J. C. (1988).Criteria of flour quality.In Y. Pomeranz (Ed.).Wheat: Chemistry and technology 2: 69–90

Makinde FM, Akinoso R (2014) Physical, nutritional and sensory qualities of bread samples made with wheat and black sesame (Sesamum indicum Linn) flours. Int Food Res J 21(4):1635–1640

Mi Y, Ejeh DD (2018) Production of bambara groundnut substituted whole wheat bread: functional properties and quality characteristics. J Nutr 8(5):1000731

Oloniyo RO, Omoba OS, Awolu OO, Olagunju AI (2020) Orange fleshed sweet potatoes composite bread: a good carrier of beta (β)-carotene and antioxidant properties. J Food Biochem. https://doi.org/10.1111/jfbc.13423

Oloniyo RO, Omoba OS, Awolu OO (2021) Biochemical and antioxidant properties of cream and orange-fleshed sweet potato. Heliyon. 7:e06533

Omoba, O. S., Olagunju, A. I., Iwaeni, O. O & Obafaye, R.O. (2020). Effects of Tiger Nut Fiber on the Quality Characteristics and Consumer Acceptability of Cakes Made from Orange-fleshed Sweet Potato Flour. Journal of Culinary Science & Technology, 1–19.

Onyango C (2016) Starch and modified starch in bread making: A review. African J Food Sci 10(12):344–351

Preedy VR, Watso RR, Patel VB (2011) Flour and breads and their fortification in health and disease prevention. AcademicPress, London, UK

Pruimboom L, De Punder K (2015) The opioid effects of gluten exorphins: asymptomatic celiac disease. J Health Popul Nutr 33(1):1–8

Różyło R, Dziki D, Gawlik-Dziki U, Cacak-Pietrzak G, Miś A, Rudy S (2015) Physical properties of gluten-free bread caused by water addition. Int Agrophys. 29(3):353–364

Sapirstein H, Wu Y, Koksel F, Graf R (2018) A study of factors influencing the water absorption capacity of Canadian hard red winter wheat flour. J Cereal Sci. 81:52–59

Scientific N (1998) Instruction manual for the series 4 rapid visco analyzer. Newport Scientific Pty. Ltd., Australia

Shittu TA, Dixon A, Awonorin SO, Sanni LO, Maziya-Dixon B (2008) Bread from composite cassava–wheat flour II: effect of cassava genotype and nitrogen fertilizer on bread quality. Food Res Int. 41(6):569–578

Tumuhimbise G, Tumwine G, Kyamuhangire W (2019) Amaranth leaves and skimmed milk powders improve the nutritional, functional, physico-chemical and sensory properties of orange fleshed sweet potato flour. Foods 8(1):13–21

Vizitiu D, Danciu I (2011) Evaluation of farinograph and mixolab for prediction of mixing properties of industrial wheat flour. Food Technol 15(2):31–38

Acknowledgements

I would like to thank the International Potato Center (CIP) demonstration farm in Osun State, Nigeria for donating Orange fleshed sweet potato tubers and vines for planting.

Funding

This work was partially supported by the Tertiary Education Trust FUND (TETFUND/ 155C), Institution Based Research (IBR) Grant of The Federal University of Technology, Akure, Nigeria.

Author information

Authors and Affiliations

Contributions

All authors have participated in the conception and design of the research. Analysis and interpretation of the data was carried out by Oloniyo, Rebecca Olajumoke. The manuscript was written by Oloniyo, Rebecca Olajumoke and it was critically revised by Omoba, Olufunmilayo Sade and Awolu, Olugbenga Olufemi. All the authors (Oloniyo, Rebecca Olajumoke, Omoba, Olufunmilayo Sade and Awolu, Olugbenga Olufemi) approved the final version. This manuscript has not been submitted to, nor is under review at, another journal or other publishing venue.

Corresponding author

Ethics declarations

Conflicts of interest

There is no conflict of interest among the authors.

Ethical approval

The Ethics Committee at the School of Agriculture & Agricultural Technology (SAAT) of Federal University of technology Akure, Nigeria (FUTA/SAAT/2018/021) gave the Ethical approval and it conformed to the ethical principles set forth in the Declaration of Federal Government of Nigeria.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Oloniyo, R.O., Omoba, O.S. & Awolu, O.O. Rheological behaviour, physical and sensory properties of orange fleshed sweet potato and soy concentrate bread. J Food Sci Technol 59, 2189–2199 (2022). https://doi.org/10.1007/s13197-021-05232-z

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13197-021-05232-z