Abstract

Dry soybean (Glycine max) residue (SBR) is a byproduct rich in dietary fibre and protein with high levels of essential amino acids. The effects due to the substitution of refined wheat flour with 5% or 10% SBR in dough rheology and hot-press tortilla texture, dimensions, colour, protein and dietary fibre contents were studied. Substitution of 10% SBR improved flour in terms of gluten strength and sedimentation without significantly affecting dough hardness, cohesiveness, adhesiveness, and extensibility. The dimensions, colour and sensory acceptance of the supplemented tortillas were not affected by the addition of the SBR. The 10% SBR tortillas contained 1.77 times more insoluble dietary fibre, protein content of 9.3%, in vitro protein digestibility of 84% and protein digestibility corrected amino acid score (PDCAAS) of 52.63%. Results indicated that wheat flour tortillas with 10% SBR an excellent alternative to regular counterparts owing to their higher dietary fibre and protein quantity and quality.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Soybean (Glycine max) residue (SBR) is a byproduct derived from the processing of protein concentrates or isolates. In contrast to cereal-based fibre byproducts, the SBR is also rich in proteins that contain high levels of lysine and tryptophan. SBR composition varies agreeding to extraction process (soymilk, tofu, protein concentrate or protein isolate), but in almost all cases is rich in insoluble dietary fibre (more than 50%). Consequently, SBR can be used as a food ingredient to boost dietary fibre and protein levels in processed foods (O’Toole 1999). SBR has a high protein efficiency ratio and can be a potential source of low-cost vegetable protein for human consumption (Ma et al. 1997). Dried SBR has been evaluated in processed pork meats, fermented products, textured soybean product, beef patties, biscuits and other foods (Wang et al. 2015; Chang-Vong and Liu 2016; O’Toole 1999).

Wheat-flour tortillas was originated in Mexico and can be defined as a circular chemically-leavened flatbread with a light colour. Their dimensions are 2 mm thick and diameters between 15 cm to 33 cm. They are consumed in the form of tacos with beans or different meats, cheeses, avocado, jam and other fillings (Serna-Saldivar 2016). In the last years, wheat-flour tortillas have become one of the fastest growing bakery products, increasing their popularity especially in the United States and other industrialized countries. After bread, wheat-flour tortillas are the second most sold bakery item in the United States. The tortilla industry has gained 9–10% rate of growth the last 10 years. Current sales of both corn and wheat-flour tortillas in the United States reached slightly over 11 billion dollars in 2013 (Day 2015). Fast food restaurants prefer the use of wheat-flour tortillas due to their texture characteristics, which are related with elasticity and flexibility, features which greatly influence quality for the production of wraps, tacos, and related food products. Wheat-flour tortillas present a soft texture and light colour, which are two of the most desirable attributes examined by consumers. Tortillas are usually manufactured from refined and bleached wheat flour, which contains 10.5 and 2.4 g/100 g of protein and dietary fibre content, respectively (U.S. Dept. of Agriculture, USDA 2017). The enrichment or improvement of nutritional attributes of tortillas has focused in terms of protein, dietary fibre and or antioxidant capacity. Whole wheat-flour, oat:inulin mixes, whole and defatted soy flour, whole kamut flour, carrot juice, whole waxy barley, pinto bean flour, sprouted whole-wheat flour, sorghum polyphenols, distillers dried grains with solubles are some ingredients previously evaluated in tortilla (Scazzina et al. 2008; Anton et al. 2009; Prasopsunwattana et al. 2009; Barros et al. 2010; Heredia-Olea et al. 2015; Pourafsar et al. 2015; Liu et al. 2017; Perez-Carrillo et al. 2015; Serna-Saldivar 2016). In all cases, the challenge is to retain tortilla quality attributes like colour, texture and organoleptic acceptance. Dried SBR has been successfully used to improve dietary fibre and protein content in different products. However, SBR has not been tested in wheat-flour tortillas. This research aimed to evaluate the effect of substituting various level of wheat flour with SBR on dough rheology and texture, dimensions, colour, protein and dietary fibre contents of wheat-flour tortillas manufactured by the hot-press procedure.

Materials and methods

Raw materials

Commercial refined all-purpose wheat (Triticum aestivum L) flour (Harina Selecta by Molinera de Mexico SA de CV) with an extraction rate of 74–76% was procured from a local market. The dehydrated soybean (Glycine max) residue (SBR), obtained after the conventional process of production of soybean isolates, was donated by Industrias Nutrigrains SAPI de CV.

Preparation of tortillas

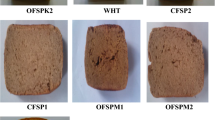

Three different tortilla treatments were produced: control (100% refined wheat flour) and two experimental tortillas containing 5% (5-SBR) or 10% (10-SBR) in the composite flour. The baker’s formulation employed based on 3000 g flour (14% mb) included 390 g of vegetable shortening, 45 g iodized salt, 60 g low fat dry milk, 60 g double acting baking powder, 9 g SSL and 6 g CMC. These ingredients were first blended at low speed with hook attachment for 4 min. Then, the predetermined volume of distilled water (40 °C) was added and mixed at slow speed for 1 min and then changed to medium speed until attaining development of optimum dough texture. Resulting doughs were divided into 30.00 ± 0.05 g pieces, mechanically rounded, and immediately allowed to rest in a proof cabinet (National Manufacturing Co., Lincoln, NE) adjusted to 29 °C and 85% RH for 30 min. Then, each dough ball was flattened using a commercial inclined hot press for 3.13 s. The temperature of the hot plates was adjusted at 187 °C ± 5 °C and the gap between the hot plates adjusted to 1.75 mm. The resulting flattened tortilla discs were baked on a four-pass circular moving griddle set at different temperatures (Manufacturas C&D Industriales, Monterrey, NL, Mexico). The average residence time of the tortillas on each pass was 11 s. The consecutive baking temperatures for the four stages of the oven were 200 °C ± 5 °C, 260 °C ± 5 °C, 265 °C ± 5 °C and finally 230 °C ± 5 °C. Tortillas were flipped over when changing from each of the baking plates, so each side of the tortillas baked for 22 s. The baked tortillas were first cooled on a cooling rack for about 20 s and then on a table at room temperature (25 °C ± 3 °C) for 30 min. The resulting tortillas were immediately placed inside sealed polyethylene bags and kept at room temperature for further evaluations (Serna-Saldivar 2012).

Physicochemical analysis of flours and tortillas

Crude protein was determined following the micro-Kjeldahl procedure (Method 46-13.01, AACC International 2000) whereas the complete amino acid profile according to AOAC (2006) official method 982.30 E (a). For amino acid analysis, samples were first hydrolyzed with 6 N HCl, and the resulting hydrolysates evaporated to dryness in a Rotavapor (Büchi, Flawil, Switzerland) set at 37 °C and then washed twice with distilled water. Amino acids were determined with an HPLC system (Waters 1525 binary pump, Milford MA, U.S.A.) equipped with a 3.9 × 150 mm AccQ-Tag column packed with silica bonded with C18, a fluorescence detector (Waters 2475 multi fluorescence), and an autosampler (Waters 717 plus). The AccQ-Fluor reagent and AccQ-Tag amino acid analysis were used. Also, moisture, crude fat and ash were evaluated according to approved methods 44-15A, 30-20 and 08-01.01 (AACC International 2000) respectively. Total dietary soluble and insoluble fibres were determined using the commercial kit Total Dietary Fibre provided by Megazyme, following approved methods 32-45.01 and 32-50.01 of the AACC International 2000.

Soybean residue characterization

The SBR was characterized regarding water absorption (WAI) and water solubility (WSI) indexes (Serna-Saldivar 2012) whereas reducing sugars quantified following the HPLC procedure recommended by Whistler et al. (1964). Approximately one gram of SBR was mixed with 10 ml of ethanol (95% v/v), centrifuged (Thermo Scientific centrifuge) at 7000 rpm for 20 min and the ethanol evaporated in a GeneVac EZ-2 Plus operating at 38 °C, 39 mbar and 100 rpm for 2 h. The sample left was re-suspended in 1.5 mL of warm water (70–80 °C), purified on a Sep-pak C18 pre column (Waters Associates, Miliford). Prepared sample was injected (10 μL) in a 300 mm Shodex SP 0810 (Japan) column at 85 °C in the HPLC equipped with an isocratic pump using water as eluent at 0.6 mL/min and a refracting index detector operating at 50 °C.

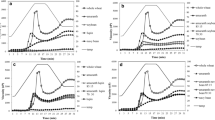

Flours evaluation

The sedimentation and Pelshenke tests of the refined wheat flour and two composite wheat-SBR flours were assayed using AACC International (2000) Methods 56-61.02 and 56-50, respectively. Briefly, the sedimentation test mesures the sedimented volume of a flour slurry after 5 min resting. High gluten flours yield higher sedimentation values because of its water absorption and swelling capacity. On the other hand, the Pelshenke assay consists of the formation of a dough ball with active yeast which is placed in a graduated cylinder with water for fermentation at 30 °C. The value is related to the time required for the dough ball to disrupt so longer times are associated to stronger gluten doughs (Serna-Saldivar 2012). Dough rheological properties were determined with the Mixolab (Chopin, France) according to methods AACC 54-60.01 and ICC 173. This method determined in the same assay the dough rheological properties and the amylograph behavior during heating and cooling cycles. The starch gelatinization was followed during the increase of temperature from 35 to 90 °C at a rate of 2 °C/min. A Mixolab wheat tortilla profile was generated based on these parameters. The texture profile analyses (TPA) of optimally developed doughs were assessed with the TA.XT2i Texture Analyzer (Stable Micro Systems, Godalming, England). Tests were conducted with a cylinder probe acting with a force of 4.9 g with doughs previously placed on a cylinder mould (cylindrically formed doughs with a height of 4.5 cm and diameter of 4.6 cm). Resulting doughs were placed on the base and, for each test, the probe moved downward at a speed of 5 mm/s to determine hardness, adhesiveness, cohesiveness, and springiness. Dough extensibility was also measured using the Kieffer dough and gluten extensibility rig. Small dough cylinders weighing 10 g of flour and about 4 cm long were formed and allowed to rest 40 min. Extensibility was measured like force in tension with a pre-testes speed of 2 mm/s, test speed of 3.3 mm/s and post-test speed of 10.0 mm/s at distance of 75 mm. Five trials per treatment per study were tested.

Tortilla quality evaluation

Ten tortillas from each treatment were randomly selected and measured for diameter and thickness. The diameter of the tortillas was the average of two diagonal measurements, while thickness was measured by measuring five piled tortillas and dividing the result by five. Five tortillas from each treatment were randomly selected and measured for colour using the Konica Minolta Spectrophotometer model CM-700d/600d, where values for L* (brightness or whiteness), a* (redness to greenness) and b* (yellowness to blueness) were obtained. Surface colour was measured from randomly selected spots from each tortilla. The force required to break tortilla strips stored for 5 days at room temperature was assesed using the extensibility test with a TA. XT2i Texture Analyzer (Perez-Carrillo et al. 2015). Likewise, the subjective tortilla texture was also measured with the dowel rollability test (Serna-Saldivar 2012). In vitro protein digestibility was measured following the multienzymatic method of Hsu et al. (977). The Protein Corrected Amino Acid Scores (PDCAAS) were calculated multiplying the protein digestibility times the limiting amino acid score divided by 100.

Sensory evaluation

Thirty untrained panellists evaluated in a sensory evaluation laboratory furnished with individual booths the overall acceptability of the three different tortilla systems. Each panellist was given three coded heated tortilla samples along with a glass of water and a ballot. Panellists were asked to evaluate texture, flavour, and overall acceptance on a seven-point hedonic scale were 1 = dislike very much, 2 = dislike moderately, 3 dislike slightly, 4 = neither like nor dislike, 5 = like slightly, 6 = like moderately, and 7 = like very much (Serna-Saldivar 2012).

Statistical analysis

Flour, dough and tortilla characteristics data were statistically analysed with the MiniTab 16 Statistical Software using ANOVA procedures to determine if there were significant differences among means at a significance level of α = 0.05 and Tukey tests were used for mean comparisons.

Results and discussion

SBR characterization

The protein and fat contents of the commercial SBR obtained during production of soybean protein isolate were similar to values reported by Li et al. (2012) but lower compared to values reported for okara by Kumar et al. (2016). Compared with refined wheat flour, SBR contained about twice as much protein, seven times more lysine and at least eight times more total dietary fibre (Table 1). Therefore, the SBR is ideally suited to increase protein quantity and quality, and mainly dietary fibre in wheat flour tortillas. In fact, the composite samples supplemented with 5 or 10% SBR contained 6.22 and 9.26% more protein compared to the wheat flour (Table 2). The two SBR enriched wheat flour tortillas were characterised by improved essential amino acid composition, especially in terms of limiting amino acid lysine (Table 2). Lysine content increased 18 and 30% in 5-SBR and 10-SBR tortillas, respectively. This improvement in lysine increased PDCAAS 0.11 and 0.19 units in the 5-SBR and 10-SBR tortillas, respectively (Table 2). Results of this study indicate that the proposed SBR enrichment intervention improved lysine content, PDCAAS and dietary fibre content of the enriched tortillas. The SBR contains approximately 21% protein which provides approximately 5.5 times more lysine compared to a refined wheat. The enrichment with SBR also slightly improved the amounts of the second limiting essential amino acid threonine. The significant improvements in essential amino acids scores with soybean meal or concentrate enrichment in wheat flour tortillas were previously documented by Acevedo-Pacheco and Serna-Saldívar (2016) and Gonzalez-Agramon and Serna-Saldivar (1988). Kumar et al. (2016) reported higher leucine in SBR obtained from Tofu process.

In regard to dietary fibre, SBR values were similar that reported by Lu et al. (2013) who determined 1.91% of soluble dietary fibre and 55.63% of insoluble dietary fibre in dried okara. Results indicate that the studied SBR contained 3.03% of reducing sugars, from which 1% was galactose. Li et al. (2012) reported in different fractions obtained from okara 2.6% reducing sugars which contained an important amount of galactose and galacturonic acid. These monomeric sugars were mainly derived from pectin and soluble hemicelluloses associated to this fibre rich residue.

WAI and WSI were similar to values reported by Ostermann-Porcel et al. (2017). These parameters enhanced the optimum dough water absorption observed in the experimental SBR enriched tortillas. According to Nishinari et al. (2014), the highly hydrophilic soybean proteins possess a range of other important functional properties such as emulsifying, foaming and water and oil holding capacities. In addition, SBR is known to contain both insoluble and soluble dietary fibre compounds. The soluble fraction is rich in low molecular weight and low methoxyl pectins, which have high water holding capacity (Crandall and McCain 2000). The synergy between the high water binding soybean proteins and pectins significantly increae WAI of tortilla doughs.

Flours evaluation

Flour quality parameters like sedimentation and Pelshenke were affected by supplementation of 5 and 10% of SBR in the refined wheat flour. The 10-SBR flour showed the highest sedimentation and Pelshenke parameters values (Table 3). The contradictory result can be attributed to the low protein dispersibility index of the SBR which increased the sedimentation value (Sivam et al. 2010) and that SBR pectins likely contributed to the sedimented volume.

Table 3 depicts Mixolab parameters of control and composite flours. Dough water absorption, dough development time, and stability increased when SBR was included in the flours. The 5-SBR and 10-SBR composite flours required the lowest torque (C1) to develop the dough. C2 torque increased when SSB content increased in the flour. This difference in C2 torque is important because unexpectedly the gluten network weakening effect was reduced when the two levels of SBR were added. Change in water absorption and C2 parameter could be associated with the soluble dietary fibre present in SBR. Li et al. (2016) observed similar findings when soluble dietary fibre was added. This intervention also caused increased farinograph dough development time and stability. The highest C1 value observed for the composite flour containing 5% SBR and 10% SBR was due to the higher water holding capacity of the soybean proteins rich in globulins and due the higher soluble dietary fibre (Li et al. 2016). Thakur et al. (2017) studied the physicochemical, protein secondary structure, dough rheology of chapatties made with normal or waxy corn meals. The higher protein of the waxy corn meal resulted into more mater absorption for consistent dough development due to changes in zein sencondary β-sheet and antiparallel β-sheet structures that upon hydration created antiparallel intermolecular β-sheet. In regard to starch, the three parameters, C3 (starch gelatinization), C4 (amylase activity) and C5 (starch retrogradation) were reduced when SBR was added to composite flours. Dough texture tests indicated that dough cohesiveness and force of extensibility did not differ among treatment reinforcing the fact that SBR did not have a detrimental effect on this important parameter. However, adhesiveness and springiness were slightly reduced by SBR addition at both 5 and 10% levels likely to the interaction of soybean components with the refined wheat flour (Table 1). Collar, Santos and Rosell (2007) compared different fibres, such as pea and inuline, on dough for bread TPA and observed similar effects, where it was proven that the addittion of fibres significanly changes dough machinability and extensibillity. Substitution of 5% SBR yielded doughs with similar hardness, cohesiveness, adhesiveness and extensibility values compared to the control dough. However, both hardness and extensibility values were only affected by the addition of 10% SBR. The observed differences in dough parameters were affected by the highly hydrophilic soybean protein and dietary fibre content, which changed water absorption rate, water entrapment and therefore the formation of secondary bonds with gluten proteins that permit and preserve the cohesion of starch and proteins. The low extension resistance of the SBR containing doughs can be attributed to the higher insoluble and soluble fiber, contents which are known to disrupt the gluten network (Collar et al. 2007).

Tortilla quality evaluation

Table 2 summarises results of pilot plant hot-press tortilla trials performed with optimally developed doughs. Optimum dough mixing time were lowest for the 10-SBR dough likely due to its lower gluten and higher fibre contents that are known to reduce the time to reach maximum dough consistency (Collar et al. 2007). No significant differences among tortilla treatments were found when yield and tortilla diameter and thickness were compared.

Tortilla colour is an important parameter related to quality and overall acceptability. Unlike bran sources for most cereals, the high dietary fibre SBR did not significantly affect the colour of the enriched tortilla. Results indicated that the tortilla surface lightness or L* values were not significantly different among treatments. Alviola and Awika (2010) observed that a* in wheat flour tortillas was near to zero which agrees with results presented herein. The 10-SBR tortillas had the highest b* value that laid within typical values for white flour tortillas (Alviola and Awika 2010). Barros et al. (2010) observed that whole grain wheat tortillas were redder and yellower compared to counterparts produced with refined flour.

Ash contents among tortillas slightly differed among treatments (Table 2) because the refined wheat flour averaged 0.45% ash compared to the SBR which contained about 21.5 times higher amounts (Table 1). These differences were observed despite the addition of 1.5% salt to the tortilla formulation. The 10-SBR tortilla contained 15.41% more ash compared to the control tortilla. As planned, the 5 or 10-SBR tortillas contained higher levels of both soluble and insoluble dietary fibre fractions. The 10-SBR tortillas contained 1.77 times more insoluble dietary fibre compared to the control tortilla. In respect of protein, the 10-SBR tortilla contained 7% more protein with better digestibility. The significant improvements of protein, ash and dietary fibre contents have been reported for other types of enriched tortillas with whole soy flour, whole kamut flour and carrot juice but these tortillas were redder and yellower compared to the control (Scazzina et al. 2008). Besides the higher dietary fibre and protein contents, the experimental SBR tortillas had a better essential amino acid profile and PDCAAS compared to the control counterpart. For all tortillas, lysine was the most limiting amino acid. The control, 5-SBR and 10-SBR containing tortillas provided 47.4, 58.0 and 68.6% of the lysine required by an infant, respectively.

Table 2 summarises the sensory evaluation scores for each type of tortilla. Results indicated that all tortillas had similar acceptability. Even though some significant differences in colour measurements were found regarding a* and b* values among treatments, no significant differences were observed on colour parameters assessed by the sensory panel.

Texture

The textural shelf life of tortilla plays a critical role regarding quality and acceptance to consumers; results of these parameters are shown in Table 4. As expected, the lowest break force values related to tortilla softness were found on fresh tortillas (day 0). The 10-SBR tortillas reported the lowest force to break values likely due to its highest fibre content. Dietary fibre can affect hydration properties, like kinetics of water uptake and holding (Wang et al. 2015). As expected, the tortilla break force values increased after 1 day of storage. In terms of the effects of SBR addition, the tortilla containing 10% SBR was the one that became harder and less flexible after 5 days storage (Table 3). This could be explained by the gluten dilution effect due to SBR addition and that the SBR fiber somehow affected the gluten secondary structure. Results agreed with Bock and Damodaran (2013) who demonstrated that bran supplementation to gluten containing dough affected the distribution of water and promoted partial dehydratation of the gluten by collapsing β-spirals into intermolecular β-sheet structures. This dehydration induced a harder tortilla texture as the storage days progressed. Results for tortilla rollability of reheated tortillas are summarised in Table 4. Results indicated that the reheated control tortillas did not break on day 0 and gradually loose texture throughout storage. The 10-SBR tortilla was comparatively less susceptible to break compared to the tortilla system containing 5-SBR. Tortillas that retain more water after baking tend to preserve their rollability longer. Traynham et al. (2007) observed in wheat flour blends with soy flours that increasing the total amount of soy protein in the flour blend allowed more protein–water interactions. Furthermore, proteins play an important role in many food systems because of their high nutritional value and functional properties. They may dissociate and associate in different ways and form gels upon heating. The capacity of gels to retain water, lipids, sugar, flavours, and other ingredients is useful. The interaction of the ingredients in the formulation and the type of proteins present in the SBR may have influenced the observed rollability results.

Conclusion

Results of this study indicate that enrichment intervention with 5 or 10% of soybean residue improved lysine content, PDCAAS and dietary fibre content of wheat flour tortillas obtained following the hot press manufacturing procedure. The dough mixing time, dough handling properties and features of baked tortillas were practically the same indicating that the proposed SBR supplementation was effective. The SBR enriched tortillas with two or three times higher total dietary fibre and improved protein quality had similar organolpetic and colour properties compared to regular tortillas. Therefore, the 10% SBR supplemented tortillas with similar physical and organoleptic features judged by untrained panellists are an excellent alternative to new consumers because of their higher protein and dietary fibre contents.

References

AACC International (2000) Approved methods of the American association of cereal chemists, 10th edn. AACC International, St. Paul

Acevedo-Pacheco L, Serna-Saldívar SO (2016) In vivo protein quality of selected cereal-based staple foods enriched with soybean proteins. Food Nutr Res 60:31382. https://doi.org/10.3402/fnr.v60.31382

Alviola JN, Awika JM (2010) Relationship between objective and subjective wheat flour tortilla quality evaluation methods. Cereal Chem 87:481–485

Anton AA, Lukow OM, Fulcher RG, Arntfield SD (2009) Shelf stability and sensory properties of flour tortillas fortified with pinto bean (Phaseolus vulgaris L.) flour: effect of hydrocolloid addition. LWT Food Sci Technol 42:23–29

AOAC (2006) Official methods of analysis. Method 982.30 E(a), chapter 45.3.05, acid hydrolysis. 23rd edn. Association of Official Analytical Chemists, Gaithersburg, MD

Barros F, Alviola JN, Rooney LW (2010) Comparison of quality of refined and whole wheat tortillas. J Cereal Sci 51:50–56

Bock JE, Damodaran S (2013) Bran-induced changes in water structure and gluten conformation in model gluten dough studied by Fourier transform infrared spectroscopy. Food Hydrocoll 31:146–155

Chang-Vong W, Liu S-Q (2016) Biovalorisation of okara (soybean residue) for food and nutrition. Trends Food Sci Technol 52:139–147

Collar C, Santos E, Rosell CM (2007) Assessment of the rheological profile of fibre-enriched bread doughs by response surface methodology. J Food Eng 78:820–826

Crandall PG, McCain AM (2000) Isolation and characterization of pectinaceuous substances fromo soybean byproducts. J Food Process Preserv 24:407–422

Day B (2015) Category insight: tortilla evolution. Food Business News. https://www.foodbusinessnews.net/articles/6638-category-insight-tortilla-evolution. Accessed 4 Feb 2018

Gonzalez-Agramon M, Serna-Saldivar SO (1988) Effect of defatted soybean and soybean isolate fortification on the nutritional, physical, chemical and sensory properties of wheat flour tortillas. J Food Sci 53:793–797

Heredia-Olea E, Martínez-Martínez A, Payan-Tamez S, Palomera-Santandreu I, Guajardo-Flores S, Perez-Carrillo E () Effect of inuline and oatmeal addition on fat and dietary fiber content in hot press wheat flour tortilla. J Food Res 4:44–50

Hsu HW, Vavak DL, Satterlee LD, Miller GA (1977) A mulltienzyme technique for estimating protein digestibility. J Food Sci 42:1269–1273

Kumar V, Rani A, Husain L (2016) Investigations of amino acids profile, fatty acids composition, isoflavones content and antioxidative properties in soy okara. Asian J Chem 14:903–906

Li B, Lu F, Nan H, Liu Y (2012) Isolation and structural characterization of okara polysaccharides. Molecules 17:753–761

Li Q, Liu R, Wu T, Wang M, Zhang M (2016) Soluble dietary fiber fractions in wheat bran and their interactions with wheat gluten have impacts on dough properties. J Agric Food Chem 64:8735–8744

Liu T, Hou GG, Cardin M, Marquart L, Dubat A (2017) Quality attributes of whole-wheat flour tortillas with sprouted whole-wheat flour substitution. LWT Food Sci Technol 77:1–7

Lu F, Liu Y, Li B (2013) Okara dietary fiber and hypoglycemic effect of okara foods. Bioact Carbohydr Diet Fibre 2:126–132

Ma CY, Liu WS, Kwok KC, Kwok F (1997) Isolation and characterization of proteins from soymilk residue (okara). Food Res Int 29:799–805

Nishinari K, Fang Y, Guo S, Phillips GO (2014) Soy proteins: a review on composition, aggregation and emulsification. Food Hydrocoll 39:301–318

O’Toole DK (1999) Characteristics and use of okara, the soybean residue from soy milk production-a review. J Agric Food Chem 47:363–371

Ostermann-Porcel MV, Rinaldoni AN, Rodriguez-Furlán LT, Campderrós ME (2017) Quality assessment of dried okara as a source of production of gluten-free flour. J Sci Food Agric 97:2934–2941

Perez-Carrillo E, Chew-Guevara AA, Heredia-Olea E, Chuck-Hernandez C, Serna-Saldivar SO (2015) Evaluation of the functionality of five different soybean proteins in hot-press wheat flour tortillas. Cereal Chem 92:98–104

Pourafsar S, Rosentrater KA, Krishnan P (2015) Changes in chemical and physical properties of Latin American wheat flour based tortillas substituted with different levels of distillers dried grains with solubles (DDGS). J Food Sci Technol 52:5243–5249

Prasopsunwattana N, Botero-Omary M, Ardnt EA, Cooke PH, Flores RA, Yokoyama W, Toma A, Chongcham S, Lee SP (2009) Particle size effects on the quality of flour tortillas enriched with whole grain waxy barley. Cereal Chem 86:439–451

Scazzina F, Del Rio D, Serventi L, Carini E, Vittadini E (2008) Development of nutritionally enhanced tortillas. Food Biophys 3:235–240

Serna-Saldivar SO (2012) Cereal grains: laboratory reference and procedures manual. CRC Press, Boca Raton, p 368

Serna-Saldivar SO (2016) Nutrition and fortification of corn and wheat tortillas. In: Rooney LW, Serna Saldivar SO (eds) Tortillas: wheat flour and corn products. Elsevier Inc., Amsterdam, pp 29–63

Sivam AS, Sun-Waterhouse D, Quek SY, Perera CO (2010) Properties of bread dough with added fiber polysaccharides and phenolic antioxidants: a review. J Food Sci 75(8):R163–R174

Thakur S, Singh N, Kaur A (2017) Characteristic of normal and waxy corn: physicochemical, protein secondary structure, dough rheology and chapatti making properties. J Food Sci Technol 54:3285–3296

USDA (2017) National Nutrient Database for Standard Reference. https://ndb.nal.usda.gov/ndb/. Accessed 4 Feb 2018

Wang S, Chang T, Wang C, Shi L, Wang W, Yang H, Cui M (2015) Effect of particle size of soya okara on textural, colour, sensory and rheological properties of pork meat gels. J Food Qual 38:248–255

Whistler RL, Smith RJ, BeMiller JN (1964) Methods in carbohydrate chemistry. Academic, New York

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

All authors have not conflict of interest to declare.

Rights and permissions

About this article

Cite this article

Montemayor-Mora, G., Hernández-Reyes, K.E., Heredia-Olea, E. et al. Rheology, acceptability and texture of wheat flour tortillas supplemented with soybean residue. J Food Sci Technol 55, 4964–4972 (2018). https://doi.org/10.1007/s13197-018-3432-3

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13197-018-3432-3