Abstract

This study investigated the effect of drying temperature on the stability and quality of spray-dried coconut milk. A low concentration (1–2% w/w) of sodium caseinate (SC) was used as emulsifying agent with 8–9% of maltodextrin. The spray drying temperature was varied from 140 to 180 °C. Emulsions prepared at different SC concentration remained stable without phase separation for 24 h. Higher the SC concentration produced smaller-sized of droplet and powder particles. The spray dried coconut milk has a skin-forming structure. Emulsion with low concentration of SC (1% w/w) is unstable during atomisation process due to re-coalescence of fat. Adding SC to the emulsion reduce the moisture content to less than 5%. However, drying the emulsions at 180 °C gave negative impact to the powder properties. Some particles rupture and lead to high free fat content, high insolubility and larger fat droplet size. Presence of fleck is also noticed in the powder.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Spray dried coconut milk powder is plant-based milk and widely used in Asian foods and beverages. Spray drying is a process where liquid is atomised to form small droplets and then fed into a hot medium. The numerous small droplets have a large surface area that allows the fast removal of moisture. However, several studies have found that although near-instantaneous evaporation (milliseconds) could be achieved, some delicate components are still affected by the thermal contact (Fang et al. 2012; Haque and Adhikari 2015).

Water and fat are the major components in coconut milk, making it a natural oil-in-water emulsion. This emulsion is obtained by the extraction of grated coconut meat. Fresh coconut milk contains almost 40% fat and 4% protein (Seow and Gwee 1997). Because coconut milk is a high-fat emulsion, additives are required to minimise the oxidation of fat and to allow the powder to flow freely when spray drying the coconut milk. Additives are required to achieve a stable emulsion which leads to production of a stable powder. Santana et al. (2017) found out that more than 20% of maltodextrin is required to allow the free flow of babassu coconut milk from the atomiser. Therefore, it is not possible to produce 100% natural coconut milk powder.

The quality of milk-based powder is determined by the dispersibility and stability of the powder which correlated to its functional and physical properties, respectively (Sharma et al. 2012). These properties are significantly affected by the operating conditions during the spray-drying process and the wall materials used (Danviriyakul et al. 2002). Recent studies found that emulsion stability such as the minimum fat size (Soottitantawat et al. 2005) and creaming deceleration (Jafari et al. 2007) play an important role in producing a stable powder. Proteins in the emulsion act as emulsifying agents that retard the chemical and physical changes of fat. Proteins form a protective layer that prevents the instability of fat products—both emulsion and powder. The protected fats are less prone to lipid oxidation or oxidative rancidity (Vignolles et al. 2007), which contributes to off-odours and flavours and the release of toxic compounds (Chen et al. 2008).

Coconut protein consists of albumin and globulin (Tangsuphoom and Coupland 2008). However, this natural protein is insufficient to encapsulate fat and is easily altered at high temperatures. Therefore, synthetic proteins such as sodium caseinate (SC) have been widely used as additive to make sufficient amount of emulsifier. SC was selected in this study due to its heat-resistant properties and provide better encapsulation properties (Gharsallaoui and Chambin 2007). Tangsuphoom and Coupland (2008) have reported that sodium caseinate improves the stability of coconut milk emulsion which attributed to a decrease in fat size during homogenisation. However, at high treatment temperature i.e. 178 °C, Fang et al. (2012) found that the proteins may denature and interact with sodium caseinate to form protein complexes, which are also known as co-aggregates and leads to insolubility of powder.

Previous works investigated the effect of various emulsifiers on the properties of coconut milk powder. Polysaccharide has been widely used as emulsifier. Combination of polysaccharide and protein has also being considered for example gelatine and maltodextrin (Le and Le 2015), skim milk and dextrin (Hassan 1987) and, maltodextrin and soya protein isolate (Le and Vuong 2009). Even though effect of SC as emulsifier to various type of fruits, vegetables and oils has been extensively conducted, but interaction of SC with natural existing components in coconut milk during spray drying might lead to different results. Furthermore, there are not many reports on the effect of varying spray drying temperature on the stabilized coconut milk emulsion at low concentration of emulsifier.

The goal of this study was to improve the quality of dried coconut milk with minimum usage of emulsifier. The effect of drying temperature and the concentration of sodium caseinate on some functional and physical properties of dried coconut milk were investigated. The functional properties were selected based on their functionality in reconstitution and storage of powder. The studied functional properties were insolubility, thermostability, particle density and bulk density. The physical properties i.e. moisture content, free fat content, powder structure, particle size and particle size distribution were also employed for evaluating the final dried product.

Materials and methods

Materials

A local retailer supplied the grated coconut meat for this study. R&M Chemical (Essex, UK) supplied the (96.5% protein) sodium caseinate (SC), ammonium hydroxide, ethanol (95%), diethyl ether, and petroleum ether used in this study. Maltodextrin (DE10) is used for to produce secondary emulsion.

Emulsion preparation

The coconut milk was obtained via the mechanical extraction of the grated meat. Water was added to the grated meat with weight ratio of 1:1 prior to extraction process. A filter cloth was used to filter out the remaining solid. One and 2% w/w of SC were then added to the coconut milk to produce stabilized primary emulsion (Abdullah et al. 2018). At first, SC was mixed with the coconut milk and homogenised using sonicator (Qsonica, Newtown, CT, USA) at an 80% amplitude setting and 5 min exposure time. To obtain secondary emulsion with 10% total solid added, maltodextrin with different concentrations (8–9% w/w) was then added to the primary emulsion and stirred for 30 min at 500 rpm using magnetic stirrer. A total of 600 g of emulsion prepared for spray drying process.

Emulsion composition and characterisation

The protein content (AOAC 16th 981.10) and the fat content (AOAC 16th 905.02 & 989.05) of the coconut milk were determined by standard method (AOAC 1995). The methods to characterise the secondary emulsion i.e. the creaming index, the emulsion droplet size, and viscosity, were conducted similarly to the researchers’ previous study on the characterisation of a primary emulsion (Abdullah et al. 2018).

Spray drying

The spray drying of coconut milk was conducted with a lab scale co-current spray dryer (SD05 Labplant). A 0.7 mm nozzle atomiser was used to atomise the emulsion. The feed rate and atomiser pressure were fixed at 350 ml/h and 2 bars, respectively. The inlet drying temperatures were varied at 140 °C, 160 °C, and 180 °C with the outlet temperature ranging from 85 to 105 °C. The powders obtained were weighed and stored in a desiccator.

Powder analysis

Analysis of moisture content

Oven drying method was used for analysis of moisture content. The oven was set to a temperature of 105 ± 2 °C. Then, 2 grams of the sample was accurately weighed and dried in the oven for 3 h. The sample was then cooled in a desiccator and then weighed again. The sample was continuously dried and weighed until a constant weight was achieved.

Analysis of fat droplet size and powder particle size

Both the fat droplet size and particle size of powder analyses were conducted using a Malvern Mastersizer Hydro 2000MU machine. For the droplet size analysis, 15 mL of distilled water was mixed with 1 g of the sample. Then, the mixture was mildly stirred at 60 °C for 30 min. The temperature was increased to 60 °C to de-crystallise the fat in the powder. The sample was added to 1% SDS solution until obstruction in the range of 10–20% was achieved. The droplet size was determined based on D50 values. Meanwhile, the particle size of powder analysis was conducted using isopropanol as a dispersant by adding 10 mL of isopropanol to 1 g powder (Jafari et al. 2007). The isopropanol and coconut milk refractive indices were 1.39 and 1.34, respectively. The addition of the sample to the dispersant was continued until 10–20% obstruction was reached.

Free fat analysis

The free fat powder analysis was conducted using solvent extraction based on method proposed by (Jafari et al. 2008). First, the coconut milk powder was accurately weighed at 1 g. The sample was then put inside an extraction tube. This was followed by the addition of petroleum ether (25 mL) to the powder, which was then vigorously shaken for 10 min. The mixture was left standing for 30 min to allow complete separation. The mixtures were then separated using a Whatman filter paper. The filtrate was transferred to a petri dish and the solvent evaporated in a heated water bath. The extracted oil was then dried in an oven at 102 ± 2 °C until a constant weight was achieved.

Scanning electron microscopy analysis of powder microstructure

The microstructure of the powder was examined using Hitachi S-3400N Scanning Electron Microscope (Japan). In this method, a double-sided tape attached to a sample stub was prepared on which a small amount of powder was placed. The specimens were coated with gold prior to analysis with the Scanning Electron Microscope. The analysis was conducted at voltage of 15 kV.

Apparent particle density and bulk density

To calculate the bulk density of the powder, the weight of the powder was divided by the volume occupied by the powder in g/cm3. 2.0 g of powder was placed into a 10 mL graduated measuring cylinder and the occupied volume of the powder is recorded.

A helium gas pycnometer (AccuPyc 1330, Micromeritics, Norcross, GA, USA) was used to determine the apparent particle density of the powder. The sample was placed in a 3.5 m3 sample cup and the weight of the sample was accurately measured at 2.0 g. Then, the sample was placed in a pycnometer chamber for further analysis.

Insolubility

The method proposed by Sadat et al. (2017) with slight modifications, was used to conduct the insolubility test for this study. First, the coconut milk solution was prepared by reconstituting 1 g coconut milk powder with 19 mL of distilled water. The mixture was mildly stirred for 1 h at 27 °C. This was followed by transferring the sample to 15 mL centrifuge tube and centrifuged at 700 g for 10 min using Hettich Universal 320 benchtop Centrifuge (Tuttlingen, Germany). The cream and supernatant parts were carefully removed without disturbing the sediment. Water was added to the sediment and then the mixture was mixed vigorously and re-centrifuged as before. The amount of sediment was read and expressed in millilitres and termed as the insolubility index.

Thermostability

The thermostability was examined using a vegetable oil bath. First, the coconut milk solution was prepared by reconstituting 1 g coconut milk powder with 10 mL of distilled water. 3 mL of solution was placed in a sealed glass tube. The tube was immersed in a hot oil bath controlled at 130 °C. The time between immersing the sample and the initial formation of the clots was recorded as the thermostability time.

Statistical analysis

Most of the experiments were performed in triplicates. Statistical analyses were conducted using Minitab software. A one-way ANOVA (Analysis of Variance) was performed where P < 0.05 was set as the significant difference threshold.

Results

Composition and characterisation of emulsion

The compositions and characterisation of the emulsion were performed prior to the spray-drying process. The composition of the main components i.e. ratio of protein and fat and the emulsion characteristics are outlined in Table 1. The fat droplet size, creaming index, and viscosity of the emulsion were characterised to indicate the stability of the emulsion (Carneiro et al. 2013).

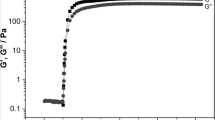

Coconut milk with 1 and 2% w/w of SC produced highly stable emulsion as there was no phase separation in the emulsions has been observed 24 h after homogenisation process i.e. creaming index at 0%. However, emulsion with 2% w/wo f SC is more stable in term of droplet size. Minimal flocculation was observed in emulsion with the fat droplets produced are at nano-range size. The level of flocculation is determined based on the differences between the primary and effective particle size. The effective and primary particle size represents the fat droplet size when the emulsion is dispersed in distilled water and in 1% SDS solution, respectively. These results have similar trend with stability analysis for primary emulsion in Abdullah et al. (2018). At a shear rate of 100 s−1, the viscosity of emulsion with 2% w/w is higher due to increase in protein–protein interactions.

Functional properties

The useful functional properties of the reconstituted powder are the solubility and thermostability of the emulsion, as presented in Table 2. Thermostability must be accounted for because high temperatures are usually used to mix the coconut milk powder with water in preparation of food and beverages. There was no obvious trend in thermostability of reconstituted powder with respect to the different drying temperatures and SC concentrations. The powder in all the samples took about 129–143 s to begin coagulating.

The insolubility is observed for sample dried at 180 °C with insolubility of > 0.2 mL. The insolubility of the powder might be due to the denaturation of natural coconut milk protein especially globulin at high treatment temperatures which denatured at temperature around 80 °C (Tangsuphoom and Coupland 2009). Even though sodium caseinate is known to form good interactions with water due to the organisation of its structure (Sadat et al. 2017) but the denatured protein might interact with sodium caseinate to form protein complexes, which form a skin-like structure that protects the particles from interacting with water (Singh 2007).

The density of powder is one of the most important functional properties for determining its storage conditions. Too low a density is undesirable because a higher volume container will be required for storage besides increasing the chances for lipid oxidation (Carneiro et al. 2013) but the powder will be easy to reconstitute (Seifu et al. 2018). Results of particle and bulk densities of the coconut milk powder in Table 2 shows that increasing the drying temperature led to lower particle density (0.97–1.09 g/cm3, P < 0.05). The lowest particle density and bulk density was observed at the highest temperature and 2% w/w of SC with 0.97 g/cm3 and 0.25 g/cm3, respectively. This is due to increase of particle size with formation of hollow in the particle (Walton 2000). This finding also suggesting that the powder produced had a skin-forming morphology where more air is trapped inside the particle at high drying temperature thus reducing the bulk density (Kwapińska and Zbiciński 2005). This morphological structure is advantageous for reconstitution of powder as capillary condensation in hollow particle increase solubility and wettability of powder. On the other hand, at high SC the reduction of the bulk density is due to minimal particle sticking in the drying process (Goula and Adamopoulos 2010). The minimal flocculation of emulsion helps reducing the particle sticking.

Dried coconut milk powder—moisture content

At all drying temperature, samples produced powder with a lower than 5% moisture content. Low moisture content is crucial to avoid the powder from caking (Subtil and Thomazini 2014) and to meet the requirements of powder quality (< 5%). As expected, the moisture content decreased as the temperature increased. A hotter inlet air temperature increased the mass and heat transfer thus promoted a greater driving force of water removal (Toro-sierra et al. 2013). The moisture content of sample spray dried at 180 °C was 3.76% and 3.64% for 1% w/w and 2% w/w of SC, respectively. It was found that the different concentrations of SC did not significantly affect moisture content as different ratios of wall material do not affect the evaporation rate in the spray-drying process (Hogan et al. 2001a).

Droplet size of the reconstituted powder and particle size of powder

The volume mean diameter (D50) was used to represent the droplet size of reconstituted powder and particle size of powder and is listed in Table 3. For the sample added with 2% w/w of SC, at low and medium drying temperatures, the droplet size did not significantly change before or after drying, signifying that the emulsion was stable during atomisation and the spray-drying process (Jafari et al. 2007). This might be due to the nano-size of the particles that increased the stability of the emulsion. It also might be due to the presence of unabsorbed protein at high concentrations of SC (2% w/w). The unabsorbed proteins helped prevent the re-coalescence of fat during the spray-drying process (Taneja et al. 2013). Droplet size of sample with 1% w/w of SC grew into a larger-sized area even dried at low temperature treatment. The interface film could rupture during atomisation. Therefore, the new interface requires the re-absorbance of protein. Insufficient amounts of protein could cause the re-coalescence of droplets, which in turn, increase droplet size (Taneja et al. 2013).

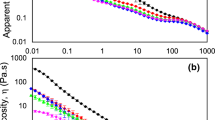

Significant changes in droplet size were observed for sample dried at 180 °C (≥ 15 µm, P > 0.05). This might be due to the presence of insoluble particles (flecks), which were formed from fat, sodium caseinate, and denatured protein and/or a combination of the three due to the high heat treatment in the spray-drying process (Toikkanen et al. 2018). This finding is also supported by the droplet size distribution in Fig. 1a. The size distribution shifted towards a large size range ≥ 10 µm which attributed to the measurement of fleck size instead of droplet size. Based on Gaussian deconvolution of particle size distribution for sample dried at 180 °C as shown in Fig. 1b, there are two distinct peaks in the large size range which suggests the present of two components. Population 1 and 2 are referring to the fats as similar populations are also noticed in other samples. Population 3 is a new population that suggesting the present of flecks in the reconstituted powder.

There is significant difference in particle size of powder dried at 160 °C and 180 °C (P > 0.05). This study hypothesises that the reduction in particle size of powder at 180 °C might be due to exploded particles, which caused the mean size to decrease. Based on the particle size analysis, it is found out that sample with 2% w/w SC that dried at 160 °C has the highest encapsulation efficiency. The encapsulation efficiency can be determined based on the differences between the particle size of powder and droplet size of reconstituted powder. Large differences indicates good encapsulation efficiency, as the fats are assumed to fully cover the inside wall materials and thus giving lower free fat content (Jafari et al. 2007).

Structure of the dried powder

The SEM analysis is conducted for powder at different SC concentrations dried at 160 °C and 180 °C. Figure 2a shows powder produced at 160 °C with 1% w/w of SC. The particle dispersed better, as individual particles with small and uniform sizes were formed, indicating perfect encapsulation. Taneja et al. (2015) also found similar findings where stable emulsion was found to result in the high encapsulation of soybean oil. At high SC concentration (Fig. 2b), surface dents were observed. This could be due to the shrinkage of excessive protein (Hogan et al. 2001b). This result proving that emulsion with 2% w/w of SC contains excessive protein and supporting the finding in droplet analysis in “Droplet size of the reconstituted powder and particle size of powder” section.

The particle breakage is observed in all sample heated at 180 °C as shown in Fig. 2c, d. The rapid heating of the vapour in the capsules causes the internal pressure to increase and the shells to burst (Esser-kahn et al. 2011). This might also be due to the low solid concentrations, which led to a thin and weak crust. The hollow structure of the exploded particle as observed in Fig. 2d also confirmed that the coconut milk powder produced has a skin-forming structure as discussed in “Functional properties” section.

The free fat content of coconut milk powder

Figure 3 shows the free fat content in the coconut milk powder in this study. It is found that increasing the drying temperature increased the extractable fat. The highest amount of free fat was obtained for the samples dried at 180 °C. This result is in agreement with the result of Kelly et al. (2014) who found out that high drying temperature leads to low fat encapsulation regardless oil type. This might be attributed to the oil inside the powder originating from the cracks, pores, and explosions of particles (Vega and Roos 2006). This result reveals that a low drying temperature implies a greater fat encapsulation in the coconut milk powder.

Conclusion

The effect of drying temperature on the functional properties and physical properties of spray-dried coconut milk was investigated. The fat particles in this dried product can be stabilized by adding 2% w/w SC and taking into account the presence of unabsorbed protein. Even though highly stable emulsion was used, but the low concentration of emulsifier cannot withstand high drying temperature. A high temperature treatment negatively impacts the fat size, free fat content, and insolubility of the powder due to rupture of particles and formation of complex interaction of components. Lower drying temperatures (below 160 °C) enable to obtain the dried coconut milk with better solubility, microstructure and free fat content. Our next task will be introduction of this developed technology into industrial practice.

References

Abdullah Z, Taip FS, Mustapa Kamal SM, Abdul Rahman RZ (2018) Effect of sodium caseinate concentration and sonication amplitude on the stability and physical characteristics of homogenized coconut milk. J Food Process Preserv 42(11):e13773

AOAC (1995) Official methods of analysis of Association of Official Analytical Chemists. DC, USA, Washington

Carneiro HCF, Tonon RV, Grosso CRF, Hubinger MD (2013) Effect of different combination of wall materials on the encapsulation efficiency of flaxseed oil microencapsulated by spray drying. J Food Eng 115:443–451

Chen B, Mcclements DJ, Decker EA (2008) Oxidation in different food matrices how physical structure impacts lipid oxidation in oil-in-water emulsions and bulk oils. Lipid oxidation: challenges in food systems. AOCS Press, Urbana. https://doi.org/10.1016/B978-0-9830791-6-3.50006-0

Danviriyakul S, McClements DJ, Decker E, Nawar WW, Chinachoti P (2002) Physical stability of spray-dried milk fat emulsion as affected by emulsifiers and processing conditions. J Food Sci 67(6):2183–2189. https://doi.org/10.1111/j.1365-2621.2002.tb09524.x

Esser-kahn AP, Odom SA, Sottos NR, White SR, Moore S (2011) Triggered release from polymer capsules. Macromolecules 44(14):5539–5553

Fang Y, Rogers S, Selomulya C, Dong X (2012) Functionality of milk protein concentrate: effect of spray drying temperature. Biochem Eng J 62:101–105. https://doi.org/10.1016/j.bej.2011.05.007

Gharsallaoui A, Chambin O (2007) Applications of spray-drying in microencapsulation of food ingredients: an overview applications of spray-drying in microencapsulation of food ingredients—an overview. Food Res Int 40(9):1107–1121. https://doi.org/10.1016/j.foodres.2007.07.004

Goula AM, Adamopoulos KG (2010) A new technique for spray drying orange juice concentrate. Innov Food Sci Emerg Technol 11(2):342–351. https://doi.org/10.1016/j.ifset.2009.12.001

Haque MA, Adhikari B (2015) Drying and denaturation of proteins in spray drying process. In: Mujumdar AS (ed) Handbook of industrial drying, 4th edn. CRC Press, Boca Raton, pp 971–985

Hassan MA (1987) Production of spray-dried coconut milk powder. Pertanika 8(1):127–130

Hogan SA, McNamee BF, O’Riordan ED, O’Sullivan M (2001a) Emulsification and microencapsulation properties of sodium caseinate/carbohydrate blends. Int Dairy J 11(3):137–144. https://doi.org/10.1016/S0958-6946(01)00091-7

Hogan SA, McNamee BF, O’Riordan ED, O’Sullivan M (2001b) Microencapsulating properties of sodium caseinate. J Agric Food Chem 49(4):1934–1938. https://doi.org/10.1021/jf000276q

Jafari SM, He Y, Bhandari B (2007) Encapsulation of nanoparticles of d-limonene by spray drying: role of emulsifiers and emulsifying techniques. Dry Technol Int J 25(6):1079–1089. https://doi.org/10.1080/07373930701396758

Jafari SM, Assadpoor E, Bhandari B, He Y (2008) Nano-particle encapsulation of fish oil by spray drying. Food Res Int 41:172–183. https://doi.org/10.1016/j.foodres.2007.11.002

Kelly GM, Mahony JAO, Kelly AL, Callaghan DJO (2014) Physical characteristics of spray-dried dairy powders containing different vegetable oils. J Food Eng 122:122–129. https://doi.org/10.1016/j.jfoodeng.2013.08.028

Kwapińska M, Zbiciński I (2005) Prediction of final product properties after cocurrent spray drying. Dry Technol 23(8):1653–1665. https://doi.org/10.1081/DRT-200065075

Le HDu, Le VVM (2015) Application of ultrasound to microencapsulation of coconut milk fat by spray drying method. J Food Sci Technol 52(4):2474–2478. https://doi.org/10.1007/s13197-014-1285-y

Le VVM, Vuong VM (2009) Optimization of technological parameters in the spray drying of coconut milk powder with high fat content. Sci Technol Dev 12(04):68–74

Sadat A, Ezzatpanah H, Bakhoda H (2017) Solubility and structure of milk powders manufactured with the addition of disodium phosphate and tetrasodium pyrophosphate mixtures. Int J Food Prop 20(11):2645–2657. https://doi.org/10.1080/10942912.2016.1247272

Santana AA, Martin LGP, de Oliveira RA, Kurozawa LE, Park KJ (2017) Spray drying of babassu coconut milk using different carrier agents. Dry Technol 35(1):76–87. https://doi.org/10.1080/07373937.2016.1160111

Seifu M, Tola YB, Mohammed A, Astatkie T (2018) Effect of variety and drying temperature on physicochemical quality, functional property, and sensory acceptability of dried onion powder. Food Sci Nutr 6(6):1641–1649. https://doi.org/10.1002/fsn3.707

Seow CC, Gwee CN (1997) Review coconut milk: chemistry and technology. Int J Food Sci Technol. https://doi.org/10.1046/j.1365-2621.1997.00400.x

Sharma A, Jana AH, Chavan RS (2012) Functionality of milk powders and milk-based powders for end use applications—a review. Compr Rev Food Sci Food Saf 11(5):518–528. https://doi.org/10.1111/j.1541-4337.2012.00199.x

Singh H (2007) Interactions of milk proteins during the manufacture of milk powders. Le Lait 87:413–423

Soottitantawat A, Bigeard F, Yoshii H, Furuta T (2005) Influence of emulsion and powder size on the stability of encapsulated d-limonene by spray drying. Innov Food Sci Emerg Technol 6:107–114. https://doi.org/10.1016/j.ifset.2004.09.003

Subtil SF, Thomazini M (2014) Effect of spray drying on the sensory and physical properties of hydrolysed casein using gum arabic as the carrier. J Food Process Technol 51(9):2014–2021. https://doi.org/10.1007/s13197-012-0722-z

Taneja A, Ye A, Jones JR, Archer R, Singh H (2013) Behaviour of oil droplets during spray drying of milk-protein-stabilised oil-in-water emulsions. Int Dairy J 28:15–23. https://doi.org/10.1016/j.idairyj.2012.08.004

Taneja A, Ye A, Singh H (2015) Influence of protein concentration on the stability of oil-in-water emulsions formed with aggregated milk proteins during spray drying. Dairy Sci Technol 95:279–293. https://doi.org/10.1007/s13594-014-0208-z

Tangsuphoom N, Coupland JN (2008) Effect of surface-active stabilizers on the microstructure and stability of coconut milk emulsions. Food Hydrocoll 22:1233–1242. https://doi.org/10.1016/j.foodhyd.2007.08.002

Tangsuphoom N, Coupland JN (2009) Effect of thermal treatments on the properties of coconut milk emulsions prepared with surface-active stabilizers. Food Hydrocoll 23(7):1792–1800. https://doi.org/10.1016/j.foodhyd.2008.12.001

Toikkanen O, Outinen M, Malafronte L, Rojas OJ (2018) Formation and structure of insoluble particles in reconstituted model infant formula powders. Int Dairy J 82:19–27. https://doi.org/10.1016/j.idairyj.2018.03.001

Toro-sierra J, Schumann J, Kulozik U (2013) Impact of spray-drying conditions on the particle size of microparticulated whey protein fractions. Dairy Sci Technol 93:487–503. https://doi.org/10.1007/s13594-013-0124-7

Vega C, Roos YH (2006) Invited review: spray-dried dairy and dairy-like emulsions—compositional considerations. J Dairy Sci 89(2):383–401. https://doi.org/10.3168/jds.S0022-0302(06)72103-8

Vignolles M-L, Jeantet R, Lopez C, Schuck P (2007) Free fat, surface fat and dairy powders: interactions between process and product. A review. Le Lait 87:187–236. https://doi.org/10.1051/lait:2007010

Walton DE (2000) The morphology of spray-dried particles a qualitative view. Dry Technol 18(9):1943–1986. https://doi.org/10.1080/07373930008917822

Acknowledgements

This work was Funded by the Universiti Putra Malaysia under Geran Putra Berimpak (Vote No. 9532300) and this financial support is acknowledged.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Abdullah, Z., Taip, F.S., Mustapa Kamal, S.M. et al. The effect of drying temperature and sodium caseinate concentration on the functional and physical properties of spray-dried coconut milk. J Food Sci Technol 58, 3174–3182 (2021). https://doi.org/10.1007/s13197-020-04820-9

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13197-020-04820-9