Abstract

This study was aimed at spray drying hydrolysed casein using gum Arabic as the carrier agent, in order to decrease the bitter taste. Three formulations with differing proportions of hydrolysed casein: gum Arabic (10:90, 20:80 and 30:70) were prepared and characterized. They were evaluated for their moisture content, water activity, hygroscopicity, dispersibility in water and in oil, particle size and distribution, particle morphology, thermal behaviour (DSC) and bitter taste by a trained sensory panel using a paired-comparison test (free samples vs. spray dried samples). The proportion of hydrolysed casein did not affect the morphology of the microspheres. The spray drying process increased product stability and modified the dissolution time, but had no effect on the ability of the material to dissolve in either water or oil. The sensory tests showed that the spray drying process using gum Arabic as the carrier was efficient in attenuating or masking the bitter taste of the hydrolysed casein.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

According to the technical information provided by the manufacturer Kerry Bio-Science, Hyprol, a casein hydrolysate, is a high quality source of peptides, including casein phosphopeptides. This product is recommended as a soluble peptide source in enteral nutrition, infant food formulations and the protein enrichment of food and beverages. Despite these properties, Hyprol has an intensely bitter taste, which limits its direct addition as a food ingredient (Rocha et al. 2009).

The spray drying is a well known industrial technology used extensively on a large scale for drying and powdering different materials (Sagar and Kumar 2010). In a previous study by the authors’ research group, the technology of spray drying using mixtures of gelatine and soy protein isolate as the carriers was efficient in attenuating or masking the bitter taste of the casein hydrolysate, and also in reducing the hygroscopicity and increasing the Tg of this ingredient, thus improving its stability (Favaro-Trindade et al. 2010). However, soy protein can be allergenic, and in some countries the use of bovine gelatine has been discouraged due to the risk of bovine spongiform encephalopathy(Lagemaat et al. 2007; Karim and Bhat 2008). Thus, in this study, gum Arabic was chosen as the carrier to spray dry the casein hydrolysate.

Gum Arabic is an exudate from certain Acacia (family leguminosae) trees that grow in semi-arid land across sub-Saharan Africa. It is a complex heteropolysaccharide with a highly ramified structure, and the main chain is formed of d-galactopyranose units joined by β-d glycosidic bonds (1 → 3). Side chains with variable chemical structures formed from d-galactopyranose, L-rhamnose, L-arabinofuranose and d-galacturonic acid are linked to the main chain by β-(1 → 6) bonds (BeMiller and Whistler 1996). This gum is widely used in the food industry and is nontoxic, odourless and tasteless. It is also the most widely used encapsulating material in microencapsulation by spray drying, mainly because of its good emulsifying capacity and low viscosity in aqueous solution, which aids the spray drying process (Righetto and Netto 2005).

The aims of this research were to study the potential of gum Arabic as the carrier agent for casein hydrolysate, and to evaluate the efficiency of the spray drying process in reducing the bitter taste of the hydrolysate.

Material and methods

Materials

The active material used was casein hydrolysate (CH) (Hyprol 8052, Kerry Bio-Science, Brazil). Gum Arabic (GA) (Instantgum BA—Colloıdes Naturels Brazil, São Paulo, Brazil) was used as the carrier agent.

Spray drying

Three aqueous solutions were prepared, all containing 30 g solids/100 g of solution. The solids consisted of CH and GA in a ratio of 10:90, 20:80 and 30:70 and the samples obtained were called G1, G2 and G3, respectively.

The solutions were spray dried using a SD 5.0 (Labmaq, Brazil) pilot scale spray dryer. The solutions were fed by a peristaltic pump at a fixed rate of 3.6 L/h. Drying was carried out in the concurrent mode. The solutions, initially at room temperature (23–25 °C), were spray dried using 50 L/min of compressed air, and the inlet and outlet air temperatures were 140 and 110 °C, respectively.

The products were stored in glass bottles at room temperature, in a dry place in the absence of light.

The processing and analyses, except for the sensory tests, were carried out in triplicate.

Particle characterization

Moisture

Moisture content of the samples was determined using an Ohaus, MB35 moisture analyzer (USA), according to Oliveira et al. (2007a).

Dissolution time

Dissolution time of the powders was determined by adding 2 g of the material to 50 mL of distilled water or soybean oil at 26 °C (El-Tinay and Ismail 1985). The mixture was mechanically stirred (Tecnal, 50–60 Hz, 0.2 A) at 892 rpm using a 2 mm × 7 mm magnetic stirring bar. The time required for complete dissolution (clearness of the solution) was recorded.

Hygroscopicity

For hygroscopicity analysis, samples (about 2 g) of each powder were placed in petri dishes at 25 °C in an airtight plastic container filled with a saturated Na2SO4 solution (81 % RH). After 1 week, the samples were weighed and the hygroscopicity expressed as g of water absorbed/100 g of dry solids (Cai and Corke 2000).

Water activity—Aw

Water activity was measured using an Aqualab 3 analyzer (Decagon Devices, USA) at 25 °C, after stabilization of the samples at this temperature for 1 h.

Particle size measurement

Particle size distribution was measured using a Mastersizer S laser light diffraction equipment (Malvern Instruments, Malvern, UK). An aliquot of each powder was suspended in isopropanol with magnetic agitation, and the particle size distribution monitored during each test, until successive readings were constant. The particle size was expressed as the mean diameter over the volume distribution.

Morphology

Morphology of the particles was observed using a scanning electron microscope (JEOL JSM–T300, Tokyo, Japan) at an accelerating voltage of 5 kV. Before observation, the samples were coated with gold/palladium in an atmosphere of argon using a Balzers evaporator (model SCD 050, Baltec Lichtenstein, Austria) (Oliveira et al. 2007b). The methodology described by Santos et al. (2005) was used to break the microspheres and observe the wall, the inside and the core distribution, applying liquid nitrogen and successive cuts with a metal blade (barber’s type) in all directions, and over the entire length of the powdered sample.

Moisture sorption isotherm and differential scanning calorimetry (DSC)

Samples (1 g) were weighed and placed in desiccators containing saturated salt solutions (LiCl, MgCl2, K2CO3, NaNO2 and KCl) at 25 °C with water activities ranging from 0.11 to 0.84. After equilibration (about 2 weeks), aliquots were withdrawn for the DSC analysis, and the remaining material was used to determine the equilibrium moisture content and water activity at 25 °C. Phase transitions were determined by differential scanning calorimetry using a DSC TA2010 controlled by a TA5000 module (TA Instruments, Newcastle, USA). Samples of about 10 mg were conditioned in TA aluminium pans, hermetically sealed and heated at 10 °C min−1 from −120 to 120 °C, in an inert atmosphere (45 mL min−1 of N2). An empty pan was used as the reference. Liquid nitrogen was used to cool the sample before the scans. After the first run, the samples showing devitrification peaks were annealed at the devitrification peak temperature (Td) for 30 min before the second DSC scan.

Sensory evaluation

Sensory evaluation was carried out with the aim of choosing the best CH/GA proportion, using ranking discriminative tests. The panellists received 3 samples (G1, G2 and G3) served at random in plastic cups (approximately 5 g of powder in each). In each test, the panellists were instructed to rank the samples in an increasing order according to the bitter taste.

The less bitter spray-dried sample, selected in the ranking discriminative tests, was compared with a mechanically mixed sample containing the same concentrations of CH and GA powders by the two way paired-comparison test (Meilgaard et al. 1991). A pair of samples (approximately 5 g each) was randomly served to the panel in white plastic cups coded with random three-digit numbers. The panellists were asked to assign the most bitter sample and were instructed to rinse their mouths with water between samples.

Both tests were carried out in individual booths with trained panellists, who were previously selected as a function of their acuity in perceiving the bitter taste.

Statistical analysis

The experimental data was analyzed by SAS (Statistic Analysis System) (2001), version 8.02, using the PROC ANOVA procedure. Tukey’s Honestly Significant Difference (HSD) was adopted as the multiple comparison procedure. The analyses, except for the sensory tests, were carried out in triplicate.

Results and discussion

Particle characterization

Morphology

The concentration of CH did not affect the morphology of the microspheres, since the three formulations showed similar morphologies. The particles showed a globular shape with concavities, and the appearance of concavities on the surface was attributed to the rapid evaporation of liquid droplets during the spray drying process (Fig. 1a). These concavities are characteristic of particles including polymers such as gum Arabic and maltodextrin in their composition, and negatively affect the flow conditions (Rosenberg et al. 1985). However, the addition of mannitol to the formulation resulted in an improvement in the physical properties of microspheres containing propolis and gelatine, because mannitol retains some of the water molecules linked to its structure, and is able to fill the empty internal spaces in the microparticles, preserving the hydration, avoiding depressions on the surface, and assuring more uniform microparticle walls (Bruschi et al. 2003).

The external particle surfaces were continuous, with no cracks, porosity or breaks (Fig. 1). These characteristics are critical to ensure greater protection and retention of the active ingredient, and were also reported by Trindade and Grosso (2000), Bertolini et al. (2001) and by Comunian et al. (2011), who also worked with gum Arabic as the carrier agent for spray drying. It was also observed that the walls were homogeneous, which infers that the hydrolysate and gum Arabic were, in fact, completely dissolved before the spray drying process.

Figure 1b shows a fragmented particle in which a hollow structure is noticeable, suggesting that matrix-type microspheres were obtained. This type of microcapsule is produced when both the active compound and the carrier are hydrophilic; hence they blend together to form the wall of the microsphere. Rocha et al. (2009) and Favaro-Trindade et al. (2010) also noted the presence of such structures when spray drying CH using maltodextrins and mixtures of gelatine and isolated soy protein, respectively. On the other hand, Santos et al. (2005) observed that paprika oleoresin, which is a hydrophobic material, was contained inside vacuoles in the walls of the particle produced by spray drying of paprika oleoresin using gum Arabic. This can be explained by the formation of an emulsion, not a solution, as in the present work, to obtain the microspheres.

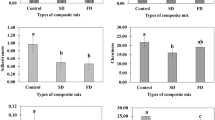

Powder properties

Table 1 shows the values for hygroscopicity, moisture content, Aw, time for dissolution in water and in oil, and the particle size of the free CH and three spray-dried formulations.

The values for the Aw of the free hydrolysate and the formulations were similar and within the expected range for atomized products and also within the values recommended to assure microbiological stability (<0.6). The water content of the formulations was lower than that of the free CH samples. Low moisture content and Aw values are extremely important to assure the stability of spray dried products and to avoid caking. The values obtained were similar to those obtained by Ortiz et al. (2009) who spray dried CH using soy protein isolate.

The free CH and three formulations spray dried with GA were able to dissolve in both water and oil, allowing for a wide variety of applications in diverse products. This was due to the fact that both CH and GA have both hydrophobic and hydrophilic sites, facilitating dissolution in both solvents.

The free CH dissolved faster than the microencapsulated samples in both water and oil. The microspheres took up to six times longer to dissolve in water and 1.2 times longer in oil as compared to the free CH. Thus the use of gum Arabic as a carrier increased the CH dissolution time.

Furthermore, with respect to the dissolution of the spray dried samples, it appears that the sample with the highest CH content and lowest GA content (G3) was the one showing the shortest times and vice versa. This can be explained by the small molecular size and less complex structure of the free CH, which possibly facilitated the interaction between its hydrophobic and hydrophilic sites with the oil and water solvents respectively. Moreover, according to Goula and Adamopoulos (2005), who worked with the dehydration of tomato pulp by spray drying, the higher the moisture content of the powder, the quicker it dissolves in water, which corroborates the results of the present study, since the free CH showed the highest moisture content of all the samples. However, other factors influence this property, such as the polarity of the material forming the particle.

However, with respect to hygroscopicity, there was no difference (P < 0.05) between the values obtained for the free CH and the CH spray dried with gum Arabic, i.e. spray-drying with GA was ineffective in reducing the hygroscopicity of CH. These results were similar to those obtained by Favaro-Trindade et al. (2010), who spray dried CH using mixtures of gelatine and hydrolysed soy protein as the carriers.

The particle size distribution of all the formulations showed a bimodal behaviour, i.e. with two distinct peaks, each with a predominant size. This characteristic allows smaller particles to penetrate into the interstices of the larger particles, such that the material takes up less space.

The particle size of the free hydrolysate was much larger than that of the formulated powders, which can be explained by the inlet fluid viscosity, feed rate and the spray-nozzle and inlet speeds. There was a decrease in particle size with the increasing concentration of CH (Table 1). Figure 2 shows the sorption isotherms of the free CH and of the powders formulated with GA. Analyzing Fig. 2, differences can be observed amongst the isotherms of the free CH and those formulated with GA, which were more evident at an Aw > 0.65. At a given water activity, the equilibrium moisture contents of the samples with GA were lower than that of the pure hydrolysate. Similar results were observed by Kurozawa et al. (2009) for chicken meat hydrolysates spray dried using GA or maltodextrin as the carrier, and by Favaro-Trindade et al. (2010) for the same CH using maltodextrin DE10 and DE20. The presence of additives in the protein hydrolysate probably modified the balance of the hydrophilic/hydrophobic sites, promoting a decrease in the amount of absorbed water (Pérez-Alonso et al. 2006).

The Tg values (Table 2) obtained for the free CH were between −30.8 °C (at Aw = 0.84) and 72.0 °C (at Aw = 0.11), whilst for the spray dried products, the minimum value for Tg was −16.0 °C (at Aw = 0.84) for G3 and 80.2 °C for G2 (at Aw = 0.33). At Aw 0.33, the addition of GA increased the Tg of the free CH from 42.1 °C to values above 70 °C. The addition of increasing amounts of gum Arabic did not clearly influence the Tg of the formulations. At the same Aw, Kurozawa et al. (2009) obtained lower values, Tg of 0.71 °C, for the pure chicken meat hydrolysate protein, and Tg values of 40.4, 53.1 and 58.5 °C with the addition of 10, 20 and 30 % of GA. The characteristics of the components, such as solubility and hydrophobicity, have been cited as factors influencing the Tg in addition to molecular weight (Jardim et al. 1999). The higher Tg values found in the present study were possibly related to the hydrophobic character of casein (Kalichevsky et al. 1993).

It should be noted that the Tg values obtained for G2 and G3 at Aw 0.11 were lower than those obtained at Aw 0.33, which may indicate an analytical problem, since the Tg should decrease with increasing moisture content, due to the plasticizing effect of the water (Roos 1995).

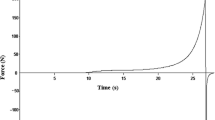

The values for Aw and Tg have been widely used to evaluate storage stability. According to Roos (1995), the prediction of food stability based only on the sorption isotherms data is not adequate, since certain physicochemical and structural characteristics such as stickiness, crispness, collapse, amorphous-to-crystalline transformations and the rates of non-enzymatic browning are better correlated to the glass transition temperature through plasticization by water or the temperature. The state diagrams, which indicate the material’s physical state, combined with the sorption isotherms, represent an important tool in the prediction of food stability with respect to the physical characteristics of the food (Roos 1995; Tonon et al. 2009). The critical water content/water activity is the value at which the glass transition temperature of the product is equal to room temperature. Above this temperature, the amorphous powders are susceptible to deteriorative changes such as collapse, stickiness and caking, resulting in quality loss. Thus, the critical values for water activity and moisture content were obtained for the free hydrolysate and the values for the encapsulated formulations were estimated from the sorption isotherms and the Tg data plotted as a function of Aw, considering a room temperature of 20 °C (Fig. 3). The critical water content was 7.2 g/100 g solids and above 10 g H2O/100 g solids for the formulations. The critical Aw was around 0.38 for the free hydrolysate and for the three formulations it was in the range from 0.62 to 0.68. Thus the formulations with GA can be considered more stable than the free hydrolysate, since they have a higher critical Aw. The free hydrolysate stored at 20 °C should be exposed to a relative humidity (RH) below 40 % while the formulations can be exposed to RH of up to 60 % without suffering physical transformations such as collapse, stickiness or caking. It is worth noting that G1, with the lowest proportion of GA of the formulations, showed the highest critical water content and water activity. To the contrary, Kurozawa et al. (2009) found that the critical values were higher for spray dried chicken meat hydrolysates with larger amounts of GA. According to Tonon et al. (2009), the critical values for pure GA are 10 g/100 g solids and an Aw of 0.535, values which are, respectively, similar and lower than the values found for the formulations G1, G2 and G3.

Sensory evaluation

According to the data provided by Kerry Bio-Science, the hydrolysate 8052 Hyprol can be used up to a maximum proportion of 3 % (w/w) in food formulations, due to the extremely bitter taste and unpleasant smell that result, depreciating the sensory quality. The spray drying technology was proposed to minimize this problem.

Seventeen trained panellists took part in a sensory ranking test to determine the best CH: GA ratio. The rank sums attributed by the panellists were 17, 38 and 47 for G1, G2 and G3 samples, respectively. According to the Newell and MacFarlene table (1987), for 17 panellists and 3 different samples, the least significant difference for the rank sums at a significance level of 5 % is 14. Thus, considering the differences among the rank sums obtained, there were significant differences among the samples, with the G1 treatment being less bitter to the taste of the panellists who performed the test, as compared to treatments G2 and G3. This result demonstrates that the lowest concentration of hydrolysate in the sample resulted in a lower perception of the bitter taste. On the other hand, no significant differences were found between treatments G2 and G3, that is, the judges (selected and trained) did not detect any differences between samples containing 20 or 30 % of the hydrolysate.

In a second sensory evaluation (paired comparison test), the G1 sample was compared to a mechanically mixed sample of CH and GA containing the same proportions as G1 (10:90). Fifteen panellists performed this test and twelve of them indicated the G1 sample as less bitter than a mechanically mixed sample of CH and GA. According to Meilgaard et al. (1991), at a significance level of 5 % with this number of panellists, the response should contain a minimum of 12 panellists opting for one of the samples, in order to prove a significant difference between them. Therefore, it was proven that the spray drying process led to the attenuation or masking of the bitter taste of the CH.

This finding could be associated with a low rate of dissolution in water, which results in a reduction in the bitter taste of protein hydrolysates, which is directly related to the exposition of hydrophobic groups. Since the formulation took more than five minutes to disperse in water (Table 1), the amount dispersed before the panellists washing their mouths out may not have reached the bitterness threshold. Thus, the decrease in bitterness suggests that these hydrophobic groups became less exposed, possibly due to hydrophobic interactions with the wall material (Mizumoto et al. 2008; Rocha et al. 2009).

This result was similar to those obtained by Ortiz et al. (2009) and by Favaro-Trindade et al. (2010) for spray dried CH with soy protein isolate and blends of gelatine with soy protein isolate, respectively. However, the present study has the advantage of having no health problems associated with the consumption of GA; to the contrary, it is a soluble fibre.

This result is also similar to those obtained using different encapsulation methods (Barbosa et al. 2004; Morais et al. 2005; Mendanha et al. 2009), and has the additional advantage that spray drying is a very simple, continuous and low cost technology, which is easy to scale up.

Conclusion

The results of this study indicate that spray drying with gum Arabic as the carrier is efficient in attenuating or masking the bitter taste of the casein hydrolysate, and also increases the stability of the product during storage. The use of gum Arabic for particles produced by spray-drying is very appealing, due to the biocompatibility and complete absence of toxicity or allergic problems of this material.

References

Barbosa CMS, Morais HA, Delvivo FM, Mansur HS, Oliveira MCO, Silvestre MPC (2004) Papain hydrolysates of casein: molecular weight profile and encapsulation in lipospheres. J Sci Food Agric 84(14):1891–1900

BeMiller JN, Whistler RL (1996) Carbohydrates. In: Fennema OR (ed) Food Chemistry, vol 3. Marcel Dekker, New York, pp 157–224

Bertolini AC, Siani AC, Grosso CRF (2001) Stability of monoterpenes encapsulated in gum arabic by spray-drying. J Agric Food Chem 49:780–785

Bruschi ML, Cardoso MLC, Lucchesi MB, Gremião MPD (2003) Gelatin microparticles containing propolis obtained by spray-drying technique: preparation and characterization. Int J Pharm 264:45–55

Cai YZ, Corke H (2000) Production and properties of spray dried Amaranthus betacyanin pigments. J Food Sci 65:1248–1252

Comunian TA, Monterrey-Quintero ES, Thomazini M, Balieiro JCC, Piccone P, Pittia P, Favaro-Trindade CS (2011) Assessment of production efficiency, physicochemical properties and storage stability of spray-dried chlorophyllide, a natural food colourant, using gum Arabic, maltodextrin and soy protein isolate-based carrier systems. Int J Food Sci Technol 46:1259–1265

El-Tinay AH, Ismail IA (1985) Effect of some additives and processes on the characteristics of agglomerated and granulated spray-dried Roselle powder. Acta Alimentaria Hung 14:283–295

Favaro-Trindade CS, Santana AS, Monterrey-Quintero ES, Trindade MA, Netto FM (2010) The use of spray drying technology to reduce bitter taste of casein hydrolysate. Food Hydrocoll 24:336–340

Goula MA, Adamopoulos KG (2005) Spray drying of tomato pulp in dehumidified air: II. The effect on powder properties. J Food Eng 66:35–42

Jardim DCP, Candido LMB, Netto FM (1999) Sorption isotherms and glass transition temperatures of fish protein hydrolysates with different degrees of hydrolysis. Int J Food Prop 2(3):227–242

Kalichevsky MT, Blanshard JM, Tokarczuck PF (1993) Effect of water content and sugars on the glass transition of casein and sodium caseinate. Int J Food Sci Technol 28:139–151

Karim AA, Bhat R (2008) Gelatin alternatives for the food industry: recent developments, challenges and prospects. Trends Food Sci Technol 19:644–656

Kurozawa LE, Park KJ, Hubinger MD (2009) Effect of maltodextrin and gum arabic on water sorption and glass transition temperature of spray dried chicken meat hydrolysate protein. J Food Eng 91:287–296

Lagemaat J, Silván JM, Moreno FJ, Olano A, Castillo MD (2007) In vitro glycation and antigenicity of soy proteins. Food Res Int 40:153–160

Meilgaard M, Civille GV, Carr BT (1991) Sensory Evaluation Techniques, 2nd edn. CRC Press, Florida, USA

Mendanha DV, Ortiz SEM, Favaro-Trindade CS, Mauri A, Monterrey-Quintero ES, Thomazini M (2009) Microencapsulation of casein hydrolysate by complex coacervation with SPI/pectin. Food Res Int 42(8):1099–1104

Mizumoto T, Tamura T, Kawai H, Kajiyama A, Itai S (2008) Formulations desing of taste-masked particles, including famotidine, for oral fast disintegrating dosage form. Chem Pharm Bull 56(4):530–535

Morais HA, De Marco LM, Oliveira MC, Silvestre MPC (2005) Casein hydrolysates using papain: peptide profile and encapsulation in liposomes. Acta Aliment 34(1):59–69

Newell GJ, MacFarlane JD (1987) Expanded tables for multiple comparison procedures in the analysis of ranked data. J Food Sci 52(6):1721–1725

Oliveira AC, Moretti TS, Boschini C, Baliero JCC, Freitas AP, Freitas O, Favaro-Trindade CS (2007a) Microencapsulation of B. lactis (BI 01) and L. acidophilus (LAC 4) by complex coacervation followed by spouted-bed drying. Drying Technol 25:1687–1693

Oliveira AC, Moretti TS, Boschini C, Baliero JCC, Freitas O, Favaro-Trindade CS (2007b) Stability of microencapsulated B. lactis (BI 01) and L. acidophilus (LAC 4) by complex coacervation followed by spray drying. J Microencapsul 24(7):685b–693b

Ortiz SEM, Mauri A, Monterrey-Quintero ES, Trindade MA, Santana AS, Favaro-Trindade CS (2009) Production and properties of casein hydrolysate microencapsulated by spray drying with soybean protein isolate. LWT – Food. Sci Technol 42:919–923

Pérez-Alonso C, Beristain CI, Lobato-Calleros C, Rodriguez-Huezo ME, Vernon-Carter EJ (2006) Thermodynamic analysis of the sorption isotherms of pure and blended carbohydrate polymers. J Food Eng 77(4):753–760

Righetto AM, Netto FM (2005) Effect of encapsulating materials on water sorption. glass transition and stability of encapsulated juice from immature acerola. Int J Food Prop 8:337–346

Rocha GA, Trindade MA, Netto FM, Favaro-Trindade CS (2009) Microcapsules of casein hydrolysate: production, characterization, and application in protein bar. Food Sci Technol Int 15(4):407–413

Roos YH (1995) Phase Transitions in Foods, 1st edn. Academic, San Diego, 360p

Rosenberg M, Kopelman IJ, Talmon Y (1985) A scanning electron microscopy study of microencapsulation. J Food Sci 50(1):139–144

Sagar VR, Kumar PS (2010) Recent advances in drying and dehydration of fruits and vegetables: a review. J Food Sci Technol 47(1):15–26

Santos AB, Favaro-Trindade CS, Grosso CRF (2005) Preparo e caracterização de microcápsulas de oleoresina de páprica obtidas por atomização. Cienc Technol Aliment 25(2):322–326

Trindade MA, Grosso CRF (2000) The stability of ascorbic acid microencapsulated in granules of rice starch and in gum Arabic. J Microencapsul 17(2):169–176

Tonon RV, Baroni AF, Brabet C, Gibert O, Pallet D, Hubinger MD (2009) Water sorption and glass transition temperature of spray dried açai (Euterpe oleracea Mart.) juice. J Food Eng 94:215–221

Acknowledgments

The authors are grateful to the Fundação de Amparo à Pesquisa do Estado de São Paulo (FAPESP) for their financial support (Process 05/56674-3) and for the scholarships conceded (Processes 05/55374-6 and 06/56714-8).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Subtil, S.F., Rocha-Selmi, G.A., Thomazini, M. et al. Effect of spray drying on the sensory and physical properties of hydrolysed casein using gum arabic as the carrier. J Food Sci Technol 51, 2014–2021 (2014). https://doi.org/10.1007/s13197-012-0722-z

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13197-012-0722-z