Abstract

The present study was undertaken to develop finger millet incorporated noodles for diabetic patients. Finger millet variety VL-149 was taken. The finger millet flour and refined wheat flour (RWF) were evaluated for nutrient composition. The finger millet flour (FMF) was blended in various proportions (30 to 50%) in refined wheat flour and used for the preparation of noodles. Control consisted of RWF noodles. Sensory quality and nutrient composition of finger millet noodles was evaluated. The 30% finger millet incorporated noodles were selected best on the basis of sensory evaluation. Noodles in that proportion along with control were evaluated for glycemic response. Nutrient composition of noodles showed that 50% finger millet incorporated noodles contained highest amount of crude fat (1.15%), total ash (1.40%), crude fiber (1.28%), carbohydrate (78.54%), physiological energy (351.36 kcal), insoluble dietary fiber (5.45%), soluble dietary fiber (3.71%), iron (5.58%) and calcium (88.39%), respectively. However, control RWF noodles contained highest amount of starch (63.02%), amylose (8.72%) and amylopectin (54.29%). The glycemic index (GI) of 30% finger millet incorporated noodles (best selected by sensory evaluation) was observed significantly lower (45.13) than control noodles (62.59). It was found that finger millet flour incorporated noodles were found nutritious and showed hypoglycemic effect.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Finger millet (Eleusine coracana) commonly known as ragi and mandua in India is the most widely grown small millet in the world. It has assumed a status of important staple food in East and Central Africa and in India (Jenkins et al. 1982). India is the major producer of finger millet contributing nearly 60% of the global production. It is better adapted to higher rainfall areas (600–1,200 mm) particularly acid soils and matures within 100 to 130 days. One of the striking features of finger millet is its ability to adjust in different agro-climatic conditions which is reflected in having highest productivity among millets (Gopalan et al., 2002). Finger millet is extensively grown in the states of Karnataka, Tamil Nadu, Andhra Pradesh and parts of North India (Vijayakumari et al. 2003). It also occupies third important place after rice and wheat in Uttarakhand. In India, it is consumed generally by a small segment of the population in the form of dumpling, porridge and roti.

In recent years, finger millet has gained importance, because of its nutritional strength in terms of dietary and functional fiber, starch pattern, as well as high calcium and iron contents. The calcium and iron contents in finger millet varieties have been reported to be 220–450 and 3–20%, respectively (Balakrishna Rao et al., 1973). Lakshmi and Sumathi (2002) reported that consumption of finger millet based diet resulted in significantly lower plasma glucose levels, mean peak rise and area under the curve. Low glycemic index nutritious food products prepared from millets can be used as an effective supportive therapy in the management of diabetes mellitus (Arora and Srivastava, 2002).

Diabetes is one of the leading causes of death in developed countries. In USA, it is the fourth leading cause of death and in at least 30 other developed countries severe hypoglycemia also figures as a cause of death and disability (Health and Lifestyle Management Series, 2004). The incidence of diabetes mellitus is increasing both in the developed and developing countries. Growing westernization, adoption of obesogenic life style, diet and genetic susceptibility may contribute to alarming increase in prevalence of diabetes mellitus. It is projected that the world wide prevalence of diabetes is likely to increase to more than 300 million by the year 2025 (Ferrarnine 1998). Nowhere is the diabetes epidemic more pronounced than in India as the World Health Organization reports show that 32 million Indians suffered from diabetes in the year 2000. The International Diabetes Federation estimated the total number of diabetic subjects to be around 40.9 million in India and this is further set to rise to 69.9 million by the year 2025 (Mohan et al., 2007). Over the past 30 years the status of diabetes has changed from being considered as a mild disorder of the elderly to one of the major causes of morbidity and mortality affecting the youth and middle aged people. Diet is a cornerstone for the management of diabetes mellitus. Therapeutic diets can alter the deleterious metabolic dearangement of diabetic state. Dietary management of diabetes mellitus involves the reduction of postprandial hyperglycemia and results in good glycemic control (Mani et al. 1993). Finger millet have high proportion of unavailable carbohydrates which slow the release of sugars and thereby responsible for low glycemic index. Although the nutritive value of millets is well noted yet the utilization of millets is not wide spread. Various millet flours can be exploited for industrial uses in different food products by determining their functional characteristics (Singh et al., 2005). Development of acceptable food products through the judicious uses of such foods and later on its commercialization may serve the people suffering from diabetes in an excellent way. There is tremendous opportunity to develop functional food targeted for those at risk for diabetes. The millet grains offer many opportunities for utilization in diversified products. Millets are suitable for the production of flakes and extruded products such as noodles and vermicelli. It may be possible to target functional foods for management of diabetes in those who already have type II diabetes. In view of the above consideration the present study was undertaken to develop finger millet incorporated noodles for the management of diabetes disorder.

Materials and methods

Finger millet (Eleusina coracana) genotype VL-149 was procured from Krishi Vigyan Kendra, Majhera, District Almora of Uttarakhand, India. Refined wheat flour (Triticum aestivum) and other ingredients were procured from GBPUA&T, Pantnagar, Uttarakhand, India. Both the finger millet flour and refined wheat flour were mixed and passed through a 100 mesh sieve to obtain a fine powder. Four flour blends were prepared by incorporating finger millet flour with refined wheat flour at 0, 30, 40 and 50% levels and were assessed for different nutritional quality parameters.

Nutritional quality of ingredients

Nutritional quality of FMF and RWF was analyzed for nutrient composition. Crude protein of FMF and RWF was determined according to AOAC (1975). Protein fractions (albumin, globulin, prolamin and glutelin) of the samples were estimated by the method described by Landry and Mourex (1953). Total dietary fiber (soluble and insoluble) was estimated by the method of Asp and Josanson (1981). Starch content was estimated by the method of Cerning and Guilbot (1973) and Clegg (1956). Amylose and amylopectin were estimated by using the method of Thayumanavan and Sadasivum (1984). Minerals (iron and calcium) were estimated by the method of Raghuramulu et al. (2003).

Preparation of finger millet incorporated noodles

Finger millet incorporated noodles (FMIN) were prepared by incorporating FMF to RWF at 30%, 40% and 50% levels. Control noodles were prepared with RWF without the incorporation of FMF.

Evaluation of noodles for nutritive value

Nutritional quality of FMIN and refined wheat flour noodles (RWFN) were analyzed for nutrient composition. Proximate composition (moisture, protein, fat, ash and crude fiber) of different noodles were analyzed according to AOAC (1975). Protein fractions (albumin, globulin, prolamine and glutelin) were analyzed by the method of Landry and Mourex (1953). Total dietary fiber (soluble and insoluble) was estimated according to the method of Asp and Josanson (1981). Starch was estimated by the method of Cerning and Guilbot (1973) and Clegg (1956). Amylose and amylopectin were estimated by using the method described by Thayumanavan and Sadasivum (1984). Minerals (iron and calcium) were estimated according to the method of Raghuramulu et al. (2003).

Physico-chemical characteristics of noodles

Cooking quality of noodles was assessed for different parameters i.e. optimum cooking time, volume increase upon cooking, total solid loss and per cent water uptake and cooked weight following the procedure given by AACC method (1962).

Texture analysis

Hardness of noodles was performed on texture analyzer (Stable Microsystems Model TA—XTZ, UK) using 5 mm cylindrical stainless probe. The texture analyzer setting were fixed (return to start option, pre test speed—5.0 mm/s, test speed—1.0 mm/s, post test speed—10.0 mm/s, stop plot at target distance 30% compression). The values were expressed in Newton.

Evaluation of noodles for sensory quality

FMIN were evaluated for sensory quality characteristics. The ‘Nine Point Hedonic scale’ was used to test the liking or disliking for noodles while the ‘Score Card Method’ was used to test which contribute to the acceptability of the product. Evaluation was done by a trained panel of ten members according to the method given by Amerine et al., 1965.

Evaluation of noodles for glycemic index

The FMIN were evaluated for glycemic index. Ten normal female subjects of 24 to 27 years age were selected for determination of glycemic index of control and FMIN for consecutive days by glucose tolerance test. The purpose of the study was explained to each subject as consent to participate in the study was taken. Usual calorie intake by each subject was calculated by 24 h recall method. Body mass index (BMI) of the subjects was calculated. The subject did not take any medication and avoided smoking and any physical exertion during the period of study. Glucose tolerance tests were carried out on overnight fasted subjects with glucose load of 50 g. It was done by adopting the following steps: measurement of fasting blood glucose of subjects, first day 50 g of glucose dissolved in 200 ml taken after 30, 60, 90, 120, and 150 min., on the second day again fasting blood glucose was measured, then the noodles containing 50 g carbohydrate, along with 200 ml water were given to the subjects and their fasting blood sugar was measured. The noodles were given to eat within 10–15 min. and the blood glucose was measured after 30, 60, 90, 120 and 150 min. Blood samples were drawn using finger-prick method. Blood glucose was analyzed by glucose oxidase method. On the test evenings and next mornings, the subjects were interviewed for after-effects of the noodles. Area under curve (AUC) for glucose and for noodles was calculated and GI of noodles was calculated by Wolever 1990a, b.

Statistical analysis

Results were tabulated as mean and SD (S.Em±). Data were subjected to one way ANOVA according to the method of Snedecor and Cochran (1967). Mean of three replicates was used in calculations.

Results and discussion

Nutritional quality of ingredients

Table 1 shows the composition of finger millet and refined wheat flour. The crude protein content of finger millet (VL-149) was observed to be 6.41%. Joshi and Katoch (1990) reported a protein content of 7.1 for finger millet. Refined wheat flour had 8.45% protein. Gopalan et al. (2002) reported protein content of 11% in RWF. Significant difference was found in the protein content of RWF and FMF. The obtained value of crude protein for finger millet falls in the range 4.88–15.58% in 16 varieties of finger millet as reported by Singh and Srivastava (2006).

Dietary fiber plays a multifaceted role in preventing a number of health disorders through their influence in the gastrointestinal tract. The insoluble and soluble dietary fiber content of FMF was 6.97 and 5.29%, respectively (Table 1). Hadimani and Malleshi (1993) reported insoluble dietary fiber content of milled FMF as 5.3% while slightly higher (6.5%) soluble dietary fibre. RWF contained 3.87 and 1.88% insoluble and soluble dietary fiber, respectively which were found significantly lower than insoluble dietary fiber of finger millet flour. The total dietary fiber (TDF) content of finger millet flour was 12.27%. Same result were reported by Hadimani and Malleshi (1993). The TDF content of refined wheat flour was 5.75% which was also found significantly different from the total dietary fiber (TDF) content of finger millet flour.

During the past few years, role of starchy foods in risk of diabetes has been observed by many authors (Cummings, 1997; Raghuram, 1999; Joshi, 2002; Srilakshmi 2001a, b). FMF showed a starch content of 61.27% (Table 1). Same result was reported by Wankhede et al. (1979). The starch content of RWF was 68.98% which was found significantly different from starch content of FMF. Amylose content of FMF was 10.34% which was significantly lower than the amylose content of RWF (14.97%). Amylose content, amylose-to-amylopectin ratio, determines thermal and pasting properties of starch that control the quality of final products and product shelf life. The typical amylose content of wild-type wheat is 1–29% based on total starch (Eriksson 1969). Noodles made from higher amylose content flour imparts higher hardness, gumminess, and chewiness. Reduced amylose content contributes to high noodle springiness, adhesiveness and soft texture (Guo et al., 2003). Eriksson (1969) found there was no linear correlation between amylose content and noodle eating quality, and indicated that the optimum amylose content seemed to be 22%. Amylopectin content of FMF and RWF was 50.93 and 54.01% having significant difference between them.

Significantly higher iron content (8.63%) was reported in FMF than RWF (4.29%). Similar results were also reported by Singh and Srivastava, 2006. The calcium content of FMF was found to be 181.99 mg/100 g (Table 1) which was about 10 times that found in RWF (18.20 mg/100 g). Hadimani and Malleshi (1993) also reported 162.8 mg/100 g calcium in milled and 454.2 mg/100 g in deglumed finger millet.

Analysis of flours for protein fractions showed that, albumin, globulin, prolamine and glutelin for FMF were 13.33, 14.07, 22.11 and 10.62%, respectively and RWF contained 14.92, 3.12, 32.25 and 15.17%, respectively. RWF contained significantly higher amount of albumin, prolamine and glutelin than FMF except globulin (Table 1). Landry and Mourex (1953) reported finger millet albumin/globulin, prolamines 2, prolamines 3 and glutelin content as 9.6–13.0, 7.0–29.7, 24.6–36.2 and 2.5–3%, respectively.

Nutritional quality of noodles

Table 2 shows the nutrient composition of noodles. It was found that 50% FMIN contained highest amount of crude fat (1.15%), total ash (1.40%), crude fiber (1.28%), carbohydrate (78.54%), physiological energy (351.36 kcal), IDF (5.45%), SDF (3.71%), TDF (9.16%), iron (5.58%) and calcium (88.39%), respectively. However, RWF noodles contained highest amount of moisture (14.15%), protein(8.16%), starch (63.02%), amylose (8.72%) and amylopectin (54.29%). Protein content was found to be decreased (p ≤ 0.05) by increasing finger millet flour with refined wheat flourdue to having lower content of protein in finger millet.

According to BIS: 1485-(1976), macaroni products must contain 12% moisture, 0.7% total ash content. Low ash content in flour is an advantage for noodles because it is responsible for noodle discoloration and the presence of enzyme polyphenoloxidase is believed to be partially responsible for noodle darkening. The moisture, wet gluten and ash content of wheat flour should be in the range of 12–13, 27–28 and 0.5%, respectively (Kruger et al., 1994).

Results on protein fractions of noodles (Table 2) showed that control noodles contained highest amount of albumin (14.08%), prolamine (30.69%) and glutelin (14.16%). A 50% FMIN contained highest amount of globulin (7.53%). Flour proteins are mainly responsible for variation in noodle water absorption. Among protein fractions, monomeric soluble protein fractions are highly negatively correlated with water absorption. Gluten fractions are negatively correlated with noodle dough water absorption (Kuktaitie et al., 2004). Wang et al. (2004) found that soluble glutenins in flour were a significant factor in decreased noodle brightness related to increased flour protein. Quantitative increases in lower molecular weight polymeric protein and soluble monomeric albumins and globulins were more strongly associated with the decreased noodle water absorption than were increases in gliadins or high molecular weight polymeric proteins (Ohm et al., 2008). Singh et al. (2004) observed that some high molecular weight glutelin subunits are distinctly associated with dough strength.

Physico-chemical characteristics of noodles

It was found that optimum cooking time decreased as the FMF content was increased (p ≤ 0.05) with the RWF. The optimum cooking time of noodles from RWF and FMF ranged from 6 to 5 min. Noodles prepared from 100% RWF required maximum cooking time i.e. 11 min. to reach the optimum texture level, whereas lowest optimum cooking time was shown by the noodles prepared from 50:50 RWF and FMF. These findings are contrary to Singh et al. (1989), who reported the opposite trend in case of soy fortified noodles. However when the cooking time was increased to 10–20 min. it leads to changes in physicochemical properties of noodles. Two temperature were used mainly to check the losses occur due to over cooking of noodles.

Noodles prepared from RWF showed higher cooked weight as compared to those prepared from FMF incorporated blends. Cooked weight of control product was 3.70 and 4.13 g/g after 10 and 20 min. of cooking, respectively. Incorporation of FMF with RWF at 30 to 50% level gradually decreased (p ≤ 0.05) the cooked weight from 3.15 to 2.62 g/g and 3.55 to 3.05 g/g after 10 and 20 min of cooking, respectively (Table 3). The decrease in the cooked weight was apparently due to increased cooking losses or gruel losses. Sudha et al. (1998) reported similar findings in case of vermicelli prepared from finger millet and its blend with semolina.

Water absorption of noodles prepared from different blends was in the range of 163.11 to 256.98% depending upon the cooking time. Water absorption was maximum in the control sample being 236 and 312% after 10 and 20 min. of cooking, respectively (Table 3). With the increase in cooking time, water absorption of noodles prepared from different levels of FMIN increased (p ≤ 0.05). However, for a given cooking time water absorption decreased as the FMF concentration increased from 30 to 50%. Similar result was reported by Liceti et al. (1995).

The total solid losses of control noodles were found as 7.90% after 10 min. of cooking. The total solid losses gradually increased (p ≤ 0.05) with the increase in level of FMF. It was observed that as the cooking time was increased to 20 min. there was substantial increase in total solid losses. The values ranged from 16.05 to 26.80% and 20.22 to 29.11% after 10 and 20 min. of cooking, respectively (Table 3). Similar observations were reported by Singh et al. (1989) for soy fortified noodles. They reported the total solid losses in the range of 6.1–12.9% with the increase in cooking time from 10 to 25 min. Sudha et al. (1998) reported that up to 25% FMF incorporation in semolina, cooking losses were less but above this level cooking losses increased gradually.

Initial volume of dry noodles prepared from different blends was more or less similar (78.9–80 ml/100 g). Incorporation of FMF with RWF for preparation of noodles caused decreased (p ≤ 0.05) in hydrated volume from 321 to 200.66 ml/100 g after 10 min. of cooking. With the increase in cooking time from 10 to 20 min, there was significant increase in hydrated volume. Volume after cooking for 20 min. increased from 220.33 to 377.33 ml/100 g of 50 to 0% of FMIN, respectively (Table 3). The maximum hydrated volume was noted in case of control noodles. Similar result was found by Grant et al., 1993

Acceptability of any product depends on its physical characteristics. The hardness of finger millet incorporated noodles at 30, 40, 50% levels and control noodles, was found to be 1.61 N, 1.51 N, 1.40 N and 1.93 N, respectively. Significant difference has been found between control and FMIN in hardness. Non significant different was found between 30 and 40% finger millet incorporated noodles and also between 40 and 50% FMIN with regard to hardness. Significant difference was observed between 30 and 50% FMIN in hardness. It was observed that as the FMF percentage increased with RWF, the hardness decreased, as reported by Snow and O’Deo 1981.

Sensory quality of noodles

Sensory evaluation of noodles containing FMF revealed that noodles from 70:30 ratio of RWF and FMF was liked very much, obtained score of 8.70 on the 9 point Hedonic scale. That noodles obtained similar preference score as control RWF noodles (8.66). Sensory evaluation of FMIN by score card method revealed that 30% FMIN obtained significantly higher scores for colour, appearance, flavour, taste, texture, after taste and over all acceptability than 40 and 50% FMIN. Non significant difference was found between 30% FMIN and control noodles with regard to colour, flavour, taste, texture, after taste and over all acceptability except appearance (Table 4).

Glycemic index of noodles

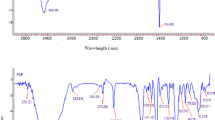

Low glycemic index foods produce low blood glucose and insulin response in normal subjects and improve blood glucose control in type 2 diabetic patients. The glycemic index (GI) of 30% finger millet incorporated noodles and control refined wheat flour noodles were evaluated in ten normal female subjects aged 24–26 years. The BMI of these subjects ranged from 18.50 to 23.91. For 50 g equicarbohydrate portion 64.97 g of noodles containing 30% finger millet flour and 65.66 g of control refined wheat flour noodles were served. The blood glucose response curve (BGRC) was plotted by analyzing blood glucose at fasting state and after 30, 60, 90, 120 and 150 min of consumption of the food product. The maximum rise for glucose, RWF noodles and FMIN was observed at 30 min. The mean area under BGRC (mg min/100 ml) was 2,172, 3,012 and 4,812 mg min/100 ml, for noodles containing 30% FMF, control RWF noodles and glucose, respectively. The lowest GI value (45.13) was observed for noodles containing 30% FMF and RWF noodles showed a GI value of 62.59 (Fig. 1). Similar result for glucose load in normal subjects has been reported by Wolever (1990a, b) and Burton and Lightowler (2006).

Conclusion

Extrusion cooking of cereal processing could be successfully applied to finger millet to prepare ready to eat products such as noodles, spaghetti, and vermicelli whose demand is increasing rapidly throughout the world. A 30% blend of finger millet with refined wheat flour was most efficiently used in the noodle formulation. Noodles thus formulated showed higher nutritional value and hypoglycemic effect owing to its high dietary fiber content.

References

AACC (1962) Approved methods of American Association of Cereal Chemists. Cereal Laboratory Methods, St. Paul Minnesota

AOAC (1975) Official methods of analysis of the Association of Official Analytical Chemists. Washington DC

Amerine MA, Pangborn RM, Roseller EB (1965) Principles of sensory evaluation of food. London Academic, New York

Arora S, Srivastava S (2002) Suitability of millet based food products for diabetics. J Food Sci Tech 39(4):319–344

Asp NG, Josanson CG (1981) Techniques for measuring dietary fibre: principal aims of methods and comparison of results obtained by different techniques. In: The analysis of dietary fibre in food

Balakrishna Rao K, Mithyantha MS, Devi LS, Perur NG (1973) Nutrient composition of some new ragi varieties. J Agric Sci Chem 7:562–565

BIS 1485 (1976) Specification for macroni, spaghetti and vermicelli. Bureau of Indian Standards, New Delhi

Burton P, Lightowler JH (2006) Influence of bread volume on glycaemic response and satiety. Br J Nutr 96:877–882

Cerning J, Guilbot J (1973) Changes in carbohydrate composition during maturation of wheat and barley kernel. Cereal Chem 50:220–232

Clegg KM (1956) The application of anthrone reagent in the estimation of starch in cereals. J Sci Food Agr 7:40

Cummings JH (1997) Nutritional implications of dietary fiber. Am J Clin Nutr 31:21–32

Eriksson G (1969) The waxy character. Hereditas 63:180–204

Ferrarnine E (1998) Insulin resistance versus insulin deficiency in non-insulin dependent diabetes mellitus: problems and prospects. Endocr Rev 19:477

Gopalan C, Ramashastri BV, Balasubramanium SC (2002) Nutritive value of Indian foods. National Institute of Nutrition, ICMR, Hyderabad

Grant LA, Dick JW, Shelton DR (1993) Effect of drying temperature, starch damage, sprouting and additives on spaghetti quality characteristics. Cereal Chem 70:676–684

Guo G, Jackson DS, Graybosch RA, Parkhurst AM (2003) Asian salted noodle quality: impact: of amylose content adjustment using wheat flour. Cereal Chem 80:437–445

Hadimani NA, Malleshi NG (1993) Studies on milling physico-chemical properties, nutrient composition and dietary fiber content of small millets. J Food Sci Tech 30(1):17–20

Health and Lifestyle Management Series; Disease management (2004) Apollo Hospitals Educational and Research Foundation, Hyderabad

Jenkins DJA, Ghafari H, Wolever TMS (1982) Relationship between the rate of digestion of foods and post-prandial glycaemia. Diabetologia 22:450–455

Joshi SA (2002) Diet for diabetes mellitus. Nutrition and dietetics 2nd edn Tata Mcgraw-Hill Publishing Company Ltd. pp. 236–237

Joshi HC, Katoch KK (1990) Nutritive value of millets: a comparison with cereals and pseudocereals. Himalayan Res Dev 9:26–28

Kruger JE, Anderson MH, Dexter JE (1994) Effect of flour refinement on raw Cantonese noodles colour and texture. Cereal Chem 71(2):177–182

Kuktaitie R, Larsson H, Johansson E (2004) Variation in protein composition of wheat flour and its relationship to dough mixing behaviour. J Cereal Sci 40:31–39

Lakshmi PK, Sumathi S (2002) Effect of consumption of finger millet on hypoglycaemia in non-insulin dependent diabetes (NIDDM) subjects. Plant Foods Hum Nutr 57(3–4):205–213

Landry J, Mourex T (1953) Protein fraction in millets. Bull Soc Chem Biol 52:1021

Liceti AE, El-Dash AA, Biellei J (1995) Effect of temperature and protein content on physical properties of pasta made from rice enriched with soybean by extrusion cooking. Part 1, effect on water absorption and solubility employing response surface analysis. Nahrung 39:203–208

Mani UV, Prabhu BM, Damle SS, Mani I (1993) Glycemic index of some commonly consumed foods in western India. Asia Pac J Clin Nutr 12:111–114

Mohan V, Sandeep S, Deepa R, Shah B, Varghese C (2007) Epidemiology of type 2 diabetes. Indian scenario. Indian J Med Res 125:217–230

Ohm JB, Ross AS, Peterson CJ, Ong YL (2008) Relationship of high molecular weight glutenin subunit composition and molecular weight distribution of wheat flour protein with water absorption and colour characteristics of noodle dough. Cereal Chem 85(2):123–131

Raghuram TC (1999) Diet and diabetes mellitus. In: Textbook of human nutrition

Raghuramulu N, Madhavan NK, Kalyansundaram S (2003) A manual of laboratory techniques. National Institute of Nutrition, ICMR, Hyderabad, pp 175–177

Singh P, Gurumukh S, Srivastava S, Agarwal P (2005) Functional characteristics of blends containing wheat flour and millet flour. Beverage Food World Feb pp. 28

Singh N, Chauhan GS, Bains GS (1989) Effect of soy flour supplementation on quality of cooked noodles. Int J Food Sci Tech 24(4):111–114

Singh P, Srivastava S (2006) Glycemic response of finger and banyard millet biscuits. J Eco Friendly Agr 1(2):168–170

Singh R, Ushakumari Latha S, Malleshi NG (2004) The functional properties of popped, flaked, extruded and roller dried foxtail millet (Setaria italica). Ind J Food Sci Tech 39:907–915

Snedecor GN, Cochran WG (1967) Statistical methods. Oxford and IBH Publishing Company, New Delhi

Snow P, O’Deo K (1981) Factors affecting the rate of starch in food. Am J Clin Nutr 54:846–854

Srilakshmi B (2001) Diet in diabetes mellitus. In: Dietetics. New Delhi, New Age International, Pvt. Ltd

Srilakshmi B (2001) Food science 2nd edn. New age International Pvt. Ltd. pp. 55–56

Sudha ML, Vetrimani R, Rahim A (1998) Quality of vermicelli from finger millet and its blend with different wheat fractions. Food Res Int 31(2):99–104

Thayumanavan B, Sadasivam S (1984) Plant Foods Hum Nutr 34:253

Vijayakumari J, Mushtari BJ, Shamshad B, Sumangala G (2003) Sensory attributes of ethnic foods from finger millet. Paper presented at CCSHAU, Hisar. Recent trends in millet processing and utilization: 7–12

Wang C, Kovacs MIP, Fowler DB, Holley R (2004) Effects of protein content and composition on white noodle making quality: color. Cereal Chem 81:777–784

Wankhede DB, Shehnaj A, Rao MRR (1979) Carbohydrate composition of finger millet (eleusine coracana) and foxtail millet (setaria italica). Quanl Plant Plant Food Hum Nutr 28(4):293–303

Wolever TMS (1990a) The glycemic index. World Rev Nutr Diet 62:120–185

Wolever TMS (1990b) Relationship between dietary fiber content and composition in foods and the glycemic index. Am J Clin Nutr 51:72–75

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Shukla, K., Srivastava, S. Evaluation of finger millet incorporated noodles for nutritive value and glycemic index. J Food Sci Technol 51, 527–534 (2014). https://doi.org/10.1007/s13197-011-0530-x

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13197-011-0530-x