Abstract

A central composite design was used to optimize the spray drying process for developing cupuassu (Theobroma grandiflorum) powder. The influence of inlet air temperature (Tinlet) (120–180 °C), feeding rate (Ffeed) (3–12 mL/min) and maltodextrin concentration (Cmalto) (10–40%) on the properties of moisture, water activity (aw), hygroscopicity, water solubility index (WSI), ascorbic acid (AA) and total phenolic compounds (TPC) were analyzed using response surface methodology and desirability function. In addition, powder morphology was assessed using scanning electron microscopy. The Tinlet and Ffeed parameters significantly influenced the moisture and aw, while the other responses (hygroscopicity, WSI, AA and TPC) were influenced by the Tinlet and Cmalto parameters. The highest Cmalto and intermediate Tinlet and Ffeed levels showed the best morphological characteristics (particles integrity, spheres shapes and smooth surfaces). The desirability function defined the optimal process conditions as Tinlet = 150 °C, Ffeed = 7.5 mL/min and Cmalto = 40%.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Cupuassu (Theobroma grandiflorum) is one of the most important native fruits from the Amazon region with a wide economic potential due to its several possibilities for food applications, such as ice cream, juice, yogurt, liquors, wines, jellies, filling for chocolate candies, among other products. This fruit is very appreciated and consumed in Brazil. The cupuassu pulp and its by-products are also well accepted in different countries around the world.

Cupuassu has a hard brown shell and seeds surrounded by a yellowish-white pulp, which presents high fiber content and intense aroma, but it is not usually consumed in natura due to its high acidity (Pugliese et al. 2013; Pereira et al. 2017). This pulp also contains important bioactive compounds such as ascorbic acid and phenolic compounds resulting in antioxidant capacity (Costa et al. 2017). These cupuassu pulp characteristics stand out as excellent alternative for obtaining a powdered product.

There are many drying processes available for use on industrial scale, but freeze-drying, foam mat drying and spray drying are the most used processes to obtain powdered fruits. Among these techniques, spray drying is the most economically viable (Shishir and Chen 2017). Therefore, this process is more employed by the food industry to obtain powdered fruits (Fazaeli et al. 2012; Igual et al. 2014; Caliskan and Dirim 2016) and represents an alternative to improve the conservation of the product, resulting in a powder with higher stability and longer shelf-life (Ferrari and Aguirre 2012).

The spray drying process consists in atomizing a solution or suspension in a drying chamber, which receives a flow of hot air that causes rapid evaporation of the liquid and formation of powdered particles. In this process, it is highlighted the short drying time compared to other drying processes that enables heat-sensitive products to be dehydrated while not affecting considerably their quality since it allows flavor, color and nutrients to be retained in the product (Ferrari and Aguirre 2012; Phisut 2012; Santana et al. 2016).

Inlet air temperature, type and concentration of the carrier agent and feeding rate are the operational conditions, which have shown the most important impacts on the quality and stability of spray dried powder products (Tonon et al. 2008; Fazaeli et al. 2012; Phisut 2012; Silva et al. 2014; Shishir and Chen 2017). An increase of inlet temperature reduced the moisture content and water activity (aw) in black mulberry powder (Fazaeli et al. 2012), umbu powder (Silva et al. 2014) and avocado powder (Dantas et al. 2018). Bioactive compounds were also degraded with increasing drying temperature, e.g. anthocyanin and ascorbic acid in pomegranate powder (Muzaffar et al. 2016) and ascorbic acid in acerola-seriguela powder (Ribeiro et al. 2019).

An increase of maltodextrin content reduced the hygroscopicity and increased the solubility in lychee powder (Kingwatee et al. 2015) and sour cherry powder (Moghaddam et al. 2017). It also improved the anthocyanin retention in lychee powder (Kingwatee et al. 2015) and ascorbic acid in avocado powder (Dantas et al. 2018). On the other hand, an increase in feeding rate increased the moisture content and aw in umbu powder (Silva et al. 2014) and tamarind powder (Muzaffar and Kumar 2015). Thus, determining the optimized operational conditions for spray drying to a given product is important to obtain better physicochemical and nutritional characteristics (Muzaffar et al. 2016; Pires and Pena 2017; Ribeiro et al. 2019).

Fruit composition and the type of carrier agent also influenced the properties of the powdered product (Phisut 2012). In the case of fruits, the presence of sugars and organic acids of low molecular weight in the composition, which have low glass transition temperatures may limit the spray drying process due problems such as stickiness and high hygroscopicity (Bhandari and Hartel 2005; Muzaffar et al. 2016). These characteristics cause clumping and adherence of particles to the dryer walls, hindering product flow and process yield (Fazaeli et al. 2012; Muzaffar and Kumar 2015). Thus, drying aids, in which maltodextrin is one of the most common (Kha et al. 2010; Mishra et al. 2014), are employed in the product formulation to minimize stickiness problems and, consequently, reduce powder hygroscopicity (Phisut 2012; Shishir and Chen 2017). Maltodextrin offers advantages such as low commercial cost, neutral aroma and flavor, low viscosity at high solids concentrations and good protection against oxidation (Caliskan and Dirim 2016; Santana et al. 2016).

Considering the current trends for nutritious and fast-prepared foods, instant powdered products obtained from the juices and pulp of fruit are emerging as an interesting alternative and great economic potential for replacing artificial juices. This type of product can also be used in the development of new functional ingredients for food enrichment (Pombo et al. 2019). Additionally, for presenting low moisture and water activity, the dried products are more shelf stable, besides being easier to use, more economical to package and store (Sagar and Suresh Kumar 2010).

As mentioned, cupuassu is a fruit that presents great economic interest, due to its sensory and nutritional characteristics. On the other hand, the cupuassu products have generally low added value. Thus, obtaining a more versatility product from cupuassu pulp, as cupuassu powder, is an important alternative to add value to this fruit. Spray drying is the most suitable process to obtain this type of product; however, there are no reports in the scientific literature that can be safely used to obtain the powdered cupuassu by spray drying. Therefore, this study aimed to optimize the spray drying process for developing cupuassu powder in order to obtain a product with minimum values of moisture, aw and hygroscopicity; and maximum values of WSI, AA and TPC, as well as the best morphological characteristics.

Material and methods

Material

The cupuassu pulp was supplied by the Mixed Agricultural Cooperative from Tome-Açu (CAMTA, Tome-Açu, Para, Brazil) (02° 25′ 08" S and 48° 09′ 08" W). A quantity of 20 kg of whole pulp were stored in polyethylene bags with capacity for 1 kg each, frozen at −18 °C and transported to the Federal University of Para (UFPA) (01° 27′ 21" S and 48° 30′ 16" W). For the experiments, the pulp was thawed under refrigeration (≈ 4 °C) and then brought to room temperature (≈ 25 °C). Maltodextrin dextrose equivalent 20 (Maltogill 20, Cargill Agrícola SA, Uberlândia, Brazil) was used as the carrier agent in the drying process.

Characterization of cupuassu pulp

Methodologies of the AOAC (1997) were used to determine the cupuassu pulp moisture in a vacuum oven at 70 °C (Marconi MA030/12, São Paulo, Brazil) (method 920.151); ashes (method 940.26); crude protein (method 920.152) (nitrogen-protein conversion factor of 6.25); lipids (method 963.15); total and reducing sugars (method 920.183b); total titratable acidity (method 942.15A); pH in a potentiometer (Hanna HI 2221, Woonsocket, USA) (method 981.12); and ascorbic acid (AA) (method 967.21). Other analyses were performed: total phenolic compounds (TPC) according to the methodology proposed by Singleton and Rossi (1965), using a spectrophotometer (Pharmacia Biotech Ultrospec 2000, Michigan, USA) at a λmax of 760 nm and expressed as mg of gallic acid equivalents (GAE) per gram of sample; total soluble solids by direct reading in a benchtop refractometer (Quimis Q767BD, Diadema, São Paulo, Brazil); water activity (aw) by direct reading in a digital thermohygrometer (Aqualab 4TEV, Decagon, Pullman, USA) at 25 °C; and instrumental color by reading the direct reflectance of the coordinates L* (lightness), a* (redness\greenness), b* (yellowness\blueness), C* (chroma—color intensity), and h° (hue angle—values of 0°, 90°, 180°, and 270° denote pure red, pure yellow, pure green, and pure blue colors, respectively) in a digital colorimeter (Konica Minolta CR-400, Osaka, Japan). All analyses were carried out in triplicate.

Pulp preparation and drying

In order to ensure the feeding rate into the spray dryer and keep the atomizing nozzle from clogging, pulp dilution and homogenization assays were carried out. Based on those assays, the pre-treatment condition was set as pulp dilution with water at 1:1 ratio, homogenization in a colloidal mill (56-RC-6332, São Paulo, Brazil) for 3 min and filtration with 0.30 mm mesh sieve. The amount of maltodextrin calculated in relation to the dry matter was added to the mixture at different concentrations (10–40%). The mixture at the temperature of 25 °C was homogenized until complete dissolution of maltodextrin and then pumped into the spray dryer by a peristaltic pump. The drying assays employed a mini spray dryer (Büchi B-290, Büchi Labortechnik AG, Flawil, Switzerland). The equipment was programmed to operate with parallel current flow, 0.7 mm inner diameter injector nozzle, aspiration air flow set at 100%, compressed air pressure set at 0.8 MPa, drying air flow rate set at 35 m3/h and different conditions of inlet air temperature (120–180 °C) and feed flow rate (3–12 mL/min) were used. The dried powders were collected in a vessel at the base of the cyclone, packaged in glass containers (to avoid contact with oxygen) protected with aluminum film (to keep light from entering) and stored at room temperature (≈ 25 °C).

Powder analyses

The powdered products obtained under the different experimental conditions underwent analyses of moisture, aw, AA and TPC following the methodologies informed in section Characterization of cupuassu pulp. The following properties were also determined:

Hygroscopicity Determined according to the methodology proposed by Cai and Corke (2000). Samples with approximately 0.5 g and known moisture were placed in a desiccator containing a saturated NaCl solution. The set was kept at 25 °C with relative humidity of 75.4% and, after ten days, the samples were weighed. Hygroscopicity was expressed as the mass of water adsorbed in relation to the dry mass of the sample (g/100 g dry base—db).

Water solubility index (WSI) WSI was determined using the methodology proposed by Anderson et al. (1970). Approximately 0.5 g of the sample and 10 mL of water at 25 °C were placed in a centrifuge tube (with lid). The set was agitated for 30 min with a mechanical stirrer and then centrifuged at 1046×g for 10 min. The supernatant liquid was transferred to a crucible and dried at 105 °C for 8 h. The WSI was determined from the ratio between the weight of the evaporation residue (WER) and the dry weight of the sample (WS) (WSI (%) = (WER/WS) × 100).

Experimental design and process optimization

The study used a 23 central composite design (CCD) with eight factorial points (levels ± 1), six axial points (one variable at level ± α and two at level 0), and three replicates in the central point (level 0), with a total amount of 17 assays (first four columns in Table 1). Inlet air temperature (Tinlet, X1), feeding rate (Ffeed, X2) and maltodextrin concentration (Cmalto, X3) were selected as independent variables for the spray drying process. The dependent variables were moisture, aw, hygroscopicity, WSI, AA and TPC. The effects of the variables on the responses were analyzed by the response surface methodology (RSM). A second-order polynomial regression model was used to predict the responses as described by the following equation:

where Y is the response (dependent variable); β0 represents the constant term; β1, β2 and β3, the linear coefficients; β11, β22 and β33, the quadratic coefficients; and β12, β13 and β23, the interaction coefficients.

Since the coefficients of Eq. 1 are not always statistically significant, a statistical analysis was performed to verify the influence of the factors and their interactions on the responses at a 95% confidence level. Analysis of variance (ANOVA) was performed based on the significant factors to verify the significance of the regression and the lack-of-fit according to F-test and to indicate if the model is significant predictive. The coefficient of determination (R2) was used to verify the fit of the model to the experimental data. The desirability function was used to optimize the spray drying process of cupuassu pulp (Derringer and Suich 1980). The desirability values are found between 0 and 1, where 0 represents a completely undesired value and 1, the most desirable value. Rates of desirability variation (s and t) of 2 and a factor grid of 10 were used to obtain the desirability function plot. The analysis of variance (ANOVA), response surfaces and desirability function were performed using Statistica 7.0.

Scanning electron microscopy

Powder morphology obtained at the different experimental conditions was evaluated by scanning electron microscopy (SEM) in the Nanomanipulation Laboratory (PPGF/UFPA). The samples were fixated onto stubs with conventional conductive double-sided adhesive tape and metallized with a gold/palladium allow in a mini sputter coater (Quorum Technologies SC7620, Kent, UK), using 5 mA current for 120 s. The samples were analyzed in a scanning electron microscope (Tescan Vega3, Brno, Czech Republic) using electron beam current of 85–90 µA, 5 kV acceleration voltage, approximately 15 mm working distance (WD), and 2000 × magnification.

Results and discussion

Characterization of cupuassu pulp

Table 2 shows the physicochemical characterization and color parameters of in natura cupuassu pulp. The results indicate that the pulp has good nutritional quality due to the low fat content and considerable contents of minerals and proteins, besides over 40% of the sugars as the reducing type. In general, the results are according to Rogez et al. (2004), who also detected total dietary fiber in cupuassu pulp (1.73%). Pérez-Mora et al. (2018) detected citric acid (2.90%) and malic acid (0.79%) in T. grandiflorum pulp. These analyses were not performed in the present study.

The AA is within the range reported by Martim et al. (2013) (18.80–28.07 mg/100 g pulp) and TPC is within the values observed by Kuskoski et al. (2006) and Vissotto et al. (2013) (20.5–80 mg GAE/100 g pulp). The color parameter indicates the yellowish-white color for the cupuassu pulp. On the other hand, although the high acidity and low pH (< 4.0) limit microbial growth in the product, the high moisture and aw (> 0.6) values (Kha et al. 2010), as well as the sugar content, favor the degradative processes in cupuassu pulp. A simple way to extend the shelf-life of this pulp is reducing the moisture and, consequently, the aw of the product through a drying process.

Drying process of cupuassu pulp

Table 1 (columns five to ten) presents the values of the responses moisture, aw, hygroscopicity, WSI, AA and TPC of the products obtained at the different experimental conditions. Table 3 shows the values of estimated effects of the linear and quadratic factors and their interactions (inlet air temperature, Tinlet; feeding rate, Ffeed; and maltodextrin concentration, Cmalto) on the responses and Table 4 presents the results of the analysis of variance (ANOVA), used to verify the significance of the regression and using F-test for the lack-of-fit, as well as the coefficients of determination (R2). The values that correspond to the ANOVA were obtained after eliminating non-significant (p > 0.05) factors. The analysis of the responses is presented below.

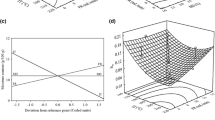

Moisture and water activity

According to the results in Table 1, the low values of moisture (2.23–3.89%) and aw (0.12–0.33) indicates less free water available for biochemical reactions and microbiological activity and, hence, greater shelf-life, which is good for powder stability (Santhalakshmy et al. 2015). The dried foods with low aw are considered stable over browning, microbial growth, hydrolitical and enzymatic reactions (Kha et al. 2010; Caliskan and Dirim 2016). The factors that significantly (p ≤ 0.05) influenced the moisture and aw of the powdered product were Tinlet (negative effect) and Ffeed (positive effect) (Table 3). Higher Tinlet led to lower moisture and aw of the product whereas higher Ffeed increased these responses (Fig. 1a, b). At higher Tinlet, there is a greater temperature gradient between the atomized feed and drying air, which results in greater driving force for water evaporation due to the efficiency of the heat transfer process. On the other hand, higher Ffeed results in shorter contact time between the feed droplets and the air drying that reduces the efficiency of the heat transfer, leading to lower water evaporation rates and, consequently, products with higher moisture contents and aw (Phisut 2012; Shishir and Chen 2017). This result is in agreement with Fazaeli et al. (2012) during spray drying of black mulberry juice.

According to ANOVA (Table 4), the regression was significant (FC > FT) and the lack-of-fit was non-significant (FC < FT), which indicates that the models, adjusted to the moisture content (Eq. 2) and aw (Eq. 3), were significant predictive (p ≤ 0.05). The R2 of 0.72 and 0.87 indicates that the regression model explains 72% and 87% of the total variation in the data observed for the moisture and aw responses, respectively.

Hygroscopicity

Hygroscopicity values ranged from 39.13 to 45.27 g/100 g db (Table 1). The Tinlet (positive effect) and Cmalto (negative effect) factors had a significant influence (p ≤ 0.05) on this response (Table 3). Higher Tinlet values led to more hygroscopic powders whereas higher Cmalto values ensured less hygroscopicity values (Fig. 1c). These behaviors are in agreement with results reported by Tonon et al. (2008) and Ferrari and Aguirre (2012) during spray drying of açaí juice and blackberry pulp. For the Tinlet effect, the behavior observed is attributed to the fact high temperatures decreases the glass transition temperature (Tg) of the amorphous materials (Santhalakshmy et al. 2015) that undergoes changes from glassy to rubbery state due to an increase in its molecular mobility, resulting in structural changes such as stickiness and hygroscopicity (Fang and Bhandari 2011; Shishir and Chen 2017). These problems can be solved by the addition of maltodextrin that has a high molecular weight and increases the Tg of the powder and, consequently, reduces its hygroscopicity and stickiness (Kurozawa et al. 2009; Phisut 2012). Studying bayberry juice spray drying, Fang and Bhandari (2012) related that Tg values increased with the increase of Cmalto.

The significant regression (FC > FT) and the non-significant lack-of-fit (FC < FT) (Table 4) confirm that the model adjusted to the hygroscopicity (Eq. 4) is considered significant predictive (p ≤ 0.05). The R2 value indicates that the regression model explains 88% of the total variation in the data observed.

Water solubility index

The values for WSI ranged between 62.56 and 83.52% (Table 1). The factors that significantly (p ≤ 0.05) affected the WSI response were Tinlet and Cmalto (positive effects) (Table 3). Thus, higher Tinlet and Cmalto increased this response (Fig. 1d). A similar trend was observed by Phoungchandang and Sertwasana (2010) for ginger juice spray drying. According to Torres et al. (2005), when high temperatures are employed, the amount of energy involved in the drying process is enough to break the intermolecular bonds in the product, which favors the exposure of hydroxyls and, consequently, the hydration process of the product. Additionally, low moisture content at higher Tinlet seems to be associated with fast rehydration, since the lower moisture content the less sticky is the powder and, thus, higher will be the surface area in contact with the rehydration water (Fazaeli et al. 2012). The effect observed for Cmalto, in turn, is attributed to the fact that maltodextrin is highly soluble in water (Phisut 2012) due to its high polarity as a function of the hydroxyl groups (OH) in the molecule. According to Negrão–Murakami et al. (2017), this is probably because of the chemical structure of high DE maltodextrins, which have a high number of ramifications with hydrophilic groups and, therefore, it can easily bind to water molecule.

For WSI, ANOVA (Table 4) also showed that the regression was significant (FC > FT) and that the lack-of-fit was non-significant (FC < FT), confirming that the model adjusted to the experimental WSI data (Eq. 5) and can be considered significant predictive (p ≤ 0.05). The R2 value indicates the regression model explains 84% of the total variation in the WSI data observed.

Ascorbic acid and total phenolic compounds

According to the results presented in Table 1, compared with in natura cupuassu pulp, AA contents (65.55–116.04 mg/100 g db) indicate retention of 48.8 to 86.4% of this compound. These values are at the same magnitude order observed by Santana et al. (2016) (42.4–89.5%) for powdered pequi (Caryocar brasiliense) obtained by spray drying. TPC values (54.86–136.91 mg GAE/100 g db) indicate retention of 19.76 to 49.30% of this class of compounds, which values are close to those observed by Silva et al. (2014) (28.88–68.88%) for powdered umbu obtained by spray drying. Both nutrient concentrations were effect negatively by the Tinlet and positively by the Cmalto (Table 3). In general, the retention of heat-sensitive compounds decreases with increasing temperature due to thermal and oxidative degradation (Shishir and Chen 2017). Other authors observed a decrease of this type of compounds at high Tinlet in dried products, such as AA in pomegranate juice powder (Muzaffar et al. 2016) and TPC in amla (Emblica officinalis) juice powder (Mishra et al. 2014).

Tan et al. (2019) observed similar behavior for the effect of temperature on the AA degradation. These authors observed a reduction in the AA retention rate, with an increase in the inlet air temperature, during the spray drying microencapsulation of AA using a casein gel. According to the results of this research, the AA retention rate in the spray dried powder decreased from 79.2 to 57.6% when the inlet temperature increased from 130 to 190 °C. Zhong et al. (2019) observed redness generation in whey protein isolate and ascorbic acid powder during spray drying process and storage at different temperatures. The authors attribute the redness of the product to AA oxidation in dehydroascorbic acid and other degradation products, which are chemically active with proteins, causing the Maillard reaction. Thus, the cupuassu powder browning observed at temperatures above 160 ºC can be attributed to Maillard reaction.

Increasing Cmalto led to an increase on sensitive compounds retention. The ability of maltodextrins to protect encapsulated products against oxidation is attributed to their film-forming capacity and plastic properties (Igual et al. 2014), which involves and isolates the sensitive compounds within their structure against external factors that may cause degradation. This has been demonstrated in different sensitive compounds, such as AA in acerola-seriguela juice powder (Ribeiro et al. 2019) and TPC in umbu powder (Silva et al. 2014).

The model fitted to the AA response (Eq. 6) can be considered significant predictive (p ≤ 0.05) since ANOVA showed significant regression (FC > FT) and non-significant lack-of-fit (FC < FT) for this response (Table 4). In addition, the regression model explains 92% of the total variance in AA data as a function of the R2 value and, consequently, the response surface was generated (Fig. 1e). On the other hand, the FC > FT indicated that the fit of the regression model to the TPC response was significant (p ≤ 0.05), however, the lack-of-fit was also significant (FC > FT) (Table 4) (Box and Wetz 1973). Therefore, the model fitted to the experimental data for TPC can not be used for predictive purposes. Thus, the regression model and response surface for TPC are not presented.

Powder morphology

The powder morphology was evaluated by SEM at different Tinlet (120, 150 and 180 °C), Ffeed (3, 7.5 and 12 mL/min) and Cmalto (10, 25 and 40%), as shown in Fig. 2. Overall, the particles showed spherical shape and several sizes, which are typical characteristics of materials produced by spray drying (Tonon et al. 2008; Santana et al. 2016; Pires and Pena 2017).

SEM images of the cupuassu powders obtained at different Tinlet: 120 °C (a), 150 °C (b) and 180 °C (c), with Ffeed = 7.5 mL/min and Cmalto = 25%; Ffeed: 3 mL/min (d), 7.5 mL/min (e) and 12 mL/min (f), with Tinlet = 150 °C and Cmalto = 25%; and Cmalto: 10% (g), 25% (h) and 40% (i), with Tinlet = 150 °C and Ffeed = 7.5 mL/min

The particles obtained at 120 °C (Fig. 2a) showed irregular shapes with surface imperfections and larger diameters. The particles produced at 150 °C (Fig. 2b) were less agglomerated and spherical with some smooth surfaces, which is an advantage on the flow properties of the powders. At 180 °C (Fig. 2c) the particles were more agglomerated with prevalence of smooth microspheres, with a strong adherence of smaller particles onto larger ones. Surface imperfections occur when the water diffusion is slower and the particle remains moist and supple for long period of time because of the low Tinlet, allowing more time for structures to deform, shrink and collapse (Ferrari and Aguirre 2012; Silva et al. 2014). At higher drying temperatures, particles tend to inflate and form a smooth and hard crust due to quick water evaporation and the high pressure generated inside the particles (Tonon et al. 2008; Ferrari and Aguirre 2012). According to Fazaeli et al. (2012), the adherence of particles demonstrates the presence of amorphous surfaces. Amorphous materials undergoes change from a glassy to rubbery state due to an increase in the Tinlet that decreases the glass transition temperature (Tg) of the product, which promotes an increase in its molecular mobility and may result in structural changes such as stickiness and collapse (Santhalakshmy et al. 2015). The stickiness state of the particle can cause inter particle cohesion or material adhesion on the drying chamber wall, affecting the free flowability (Fang and Bhandari 2012).

Particles obtained at low Ffeed (3 mL/min) showed regular spherical shapes and smooth surfaces with strong adherence between the particles due to the presence of amorphous surfaces (Fig. 2d). At intermediate Ffeed (7.5 mL/min), particles were spherical with some smooth surfaces and more dispersed (Fig. 2e). Particles produced at high Ffeed (12 mL/min) presented irregular shapes with surface imperfections (Fig. 2f). For lower Ffeed, there is a greater contact between atomized droplets and air drying, resulting in faster water evaporation and, consequently, causing formation of a smooth and hard crust (Kurozawa et al. 2009). Higher Ffeed imply in a shorter contact time between the feed and drying air and making the heat transfer less efficient and causing lower water evaporation (Phisut 2012). Thus, heat transfer was not high enough to form the outermost solid shell of the droplets and the particle remains moist and supple, allowing the deformation and surface imperfections of the microspheres (Ferrari and Aguirre 2012; Silva et al. 2014).

Powders produced with 40% maltodextrin (Fig. 2i) showed greater particle integrity without wrinkles, shrinkage, cracks or collapses and less agglomerated when compared to the powders produced with 10% and 25% maltodextrin (Fig. 2g, h). A greater particle integrity improves the protective capacity, stability and free flowability of powders (Kurozawa et al. 2009). The Tg values increases with increasing Cmalto due to an increase in the molecular weight and, consequently, a decrease in the molecular mobility of the structure. Thus, the formed film has a relatively higher Tg, remaining in the glassy state (Fang and Bhandari, 2012), which avoids structural changes such as stickiness, hygroscopicity, caking, collapse and adhesiveness between the particles, leading to a product flowability (Phisut 2012).

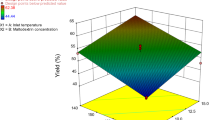

Optimization

In addition to the response surface analysis, the desirability function was used to establish the optimal conditions for the drying process of cupuassu pulp (Fig. 3). The region that allowed the highest overall desirability (0.97), in the experimental domain, occurred at Tinlet = 150 °C, Ffeed = 7.5 mL/min and Cmalto = 40%. Under these conditions, the values of the most desirable responses for the product were: moisture = 2.71%, aw = 0.16, hygroscopicity = 39.64 g/100 g db, WSI = 79.24%, AA = 107.91 mg/100 g db and TPC = 135.23 mg GAE/100 g db. The powder obtained at the optimal condition presented the best morphological characteristics, namely: spherical particles with predominantly smooth surfaces and less agglomerated, which improves the protective capacity, stability and powder flowability (Fig. 2i).

Triplicate experiments were performed under the optimal condition and the powder product had the following values for the same responses: moisture (%) = 2.66 (± < 0.01), aw = 0.162 (± < 0.01), hygroscopicity (g/100 g db) = 39.60 (± 0.28), WSI (%) = 83.01 (± 0.22), AA (mg/100 g) = 105.84 (± 0.01) and TPC (mg GAE/100 g) = 133.75 (± 0.34). A comparison of these values with the ones predicted by the desirability function showed relative errors of 2.2% for moisture, 0.5% for aw, 0.1% for hygroscopicity, 4.8% for WSI, 1.9% for AA and 1.1% for TPC, i.e., the values of the properties obtained experimentally under the optimal condition match the predicted values. Such results confirm the efficiency of the methodology employed to predict the optimal conditions for the spray drying process of the cupuassu pulp.

The color parameter values of the powder at the optimal condition was L* = 86.11 (± 0.43), a* = −4.73 (± 0.08), b* = 24.45 (± 0.24), C* = 24.59 (± 0.40), and h° = 100.78 (± 0.20), which indicates that, despite the addition of maltodextrin, the standard color of cupuassu pulp was maintained in the powdered product. According to Kha et al. (2010), due to the white color of maltodextrin, which added large amounts of this carrier agent to the formulation, may cause depreciation in the product’s characteristic color.

Conclusion

The procedure to obtain powdered cupuassu pulp by spray drying was studied for the first time. According to the study, powders with lower aw and moisture content occur when Tinlet increased and Ffeed decreased; lower Tinlet and higher Cmalto led to less hygroscopic powders and greater retention of bioactive compounds (AA and TPC); and higher WSI were attributed to the increases of the Cmalto and Tinlet. The powder morphology with the best characteristics as dispersion, uniform appearance with smooth and intact surfaces was obtained with the highest Cmalto and intermediate Tinlet and Ffeed. Thus, the optimal operational conditions for the spray drying process of cupuassu pulp added with an equal amount of water were: inlet air temperature of 150 °C, feeding rate of the pulp into the dryer of 7.5 mL/min and addition of 40% maltodextrin to the dry extract of the pulp. Under these conditions, the powder presented moisture of 2.66%, aw of 0.16, hygroscopicity of 39.60 g/100 g db, WSI of 83.01%, AA of 105.84 mg/100 g db and TPC of 133.75 mg GAE/100 g db.

References

Anderson RA, Conway VFP, Griffin EL (1970) Gelatinization of corn grits by roll cooking, extrusion cooking and steaming. Starch/Stärke 22(4):130–135. https://doi.org/10.1002/star.19700220408

AOAC (1997) Official methods of analysis of the Association of Official Analytical Chemists, 16th edn. AOAC, Washington DC

Bhandari BR, Hartel RW (2005) Phase transitions during food powder production and powder stability. In: Onwulata C (ed) Encapsulated and powdered foods. Taylor & Francis, New York, pp 261–292

Box GEP, Wetz J (1973) Criteria for judging adequacy of estimation by an approximate response function. University of Wisconsin, Wisconsin

Cai YZ, Corke H (2000) Production and properties of spray-dried Amaranthus betacyanin pigments. J Food Sci 65(6):1248–1252. https://doi.org/10.1111/j.1365-2621.2000.tb10273.x

Caliskan G, Dirim SN (2016) The effect of different drying processes and the amounts of maltodextrin addition on the powder properties of sumac extract powders. Powder Technol 287:308–314. https://doi.org/10.1016/j.powtec.2015.10.019

Costa MP, Monteiro MLG, Frasao BS, Silva VLM, Rodrigues BL, Chiappini CCJ, Conte-Junior CA (2017) Consumer perception, health information, and instrumental parameters of cupuassu (Theobroma grandiflorum) goat milk yogurts. J Dairy Sci 100(1):157–168. https://doi.org/10.3168/jds.2016-11315

Dantas D, Pasquali MA, Cavalcanti-Mata M, Duarte ME, Lisboa HM (2018) Influence of spray drying conditions on the properties of avocado powder drink. Food Chem 266:284–291. https://doi.org/10.1016/j.foodchem.2018.06.016

Derringer G, Suich R (1980) Simultaneous optimization of several response variables. J Qual Technol 12(4):214–219. https://doi.org/10.1080/00224065.1980.11980968

Fang Z, Bhandari B (2011) Effect of spray drying and storage on the stability of bayberry polyphenols. Food Chem 129(3):1139–1147. https://doi.org/10.1016/j.foodchem.2011.05.093

Fang Z, Bhandari B (2012) Comparing the efficiency of protein and maltodextrin on spray drying of bayberry juice. Food Res Int 48(2):478–483. https://doi.org/10.1016/j.foodres.2012.05.025

Fazaeli M, Emam-djomed Z, Ashtari AK, Omid M (2012) Effect of spray drying conditions and feed composition on the physical properties of black mulberry juice powder. Food Bioprod Process 90(4):667–675. https://doi.org/10.1016/j.fbp.2012.04.006

Ferrari CC, Aguirre JM (2012) Spray drying of blackberry pulp using maltodextrin as carrier agent. Braz J Food Technol 15(2):157–165. https://doi.org/10.1590/S1981-67232012005000009

Igual M, Ramire S, Mosquerac LH, Martínez-Navarretea N (2014) Optimization of spray drying conditions for lulo (Solanum quitoense L.) pulp. Powder Technol 256:233–238. https://doi.org/10.1016/j.powtec.2014.02.003

Kha TC, Nguyen MH, Roach PD (2010) Effects of spray drying conditions on the physicochemical and antioxidant properties of the Gac (Momordica cochinchinensis) fruit aril powder. J Food Eng 98(3):385–392. https://doi.org/10.1016/j.jfoodeng.2010.01.016

Kingwatee N, Apichartsrangkoon A, Chaikham P, Worametrachanon S, Techarung J, Pankasemsuk T (2015) Spray drying Lactobacillus casei 01 in lychee juice varied carrier materials. LWT Food Sci Technol 62:847–853. https://doi.org/10.1016/j.lwt.2014.12.007

Kurozawa LE, Morassi AG, Vanzo AA, Park KJ, Hubinger MD (2009) Influence of spray drying conditions on physicochemical properties of chicken meat powder. Drying Technol 27(11):1248–1257. https://doi.org/10.1080/07373930903267187

Kuskoski EM, Asuero AG, Morales MT, Fett R (2006) Wild fruits and pulps of frozen fruits: antioxidant activity, polyphenols and anthocyanins. Cienc Rural 36(4):1283–1287. https://doi.org/10.1590/S0103-84782006000400037

Martim SR, Cardoso Neto J, Oliveira IMA (2013) Physicochemical characteristics and enzymatic activity of peroxidase and polyphenoloxidase in four genotypes of cupuaçu (Theobroma grandiflorum Willd ex-Spreng Schum) submitted to freezing. Semina Cienc Agrar 34(5):2265–2276. https://doi.org/10.5433/1679-0359.2013v34n5p2265

Mishra P, Mishra S, Mahanta CL (2014) Effect of maltodextrin concentration and inlet temperature during spray drying on physicochemical and antioxidant properties of amla (Emblica officinalis) juice powder. Food Bioprod Process 92(3):252–258. https://doi.org/10.1016/j.fbp.2013.08.003

Moghaddam AD, Pero M, Askari GR (2017) Optimizing spray drying conditions of sour cherry juice based on physicochemical properties, using response surface methodology (RSM). J Food Sci Technol 54(1):174–184. https://doi.org/10.1007/s13197-016-2449-8

Muzaffar K, Dinkarrao BV, Kumar P (2016) Optimization of spray drying conditions for production of quality pomegranate juice powder. Cogent Food Agric 2:1–9. https://doi.org/10.1080/23311932.2015.1127583

Muzaffar K, Kumar P (2015) Parameter optimization for spray drying of tamarind pulp using response surface methodology. Powder Technol 279:179–184. https://doi.org/10.1016/j.powtec.2015.04.010

Negrão-Murakami AN, Nunes GL, Pinto SS, Murakami FS, Amante ER, Petrus JCC, Prudêncio ES, Amboni RDMC (2017) Influence of DE-value of maltodextrin on the physicochemical properties, antioxidant activity, and storage stability of spray dried concentrated mate (Ilex paraguariensis A. St. Hil.). LWT Food Sci Technol 79:561–567. https://doi.org/10.1016/j.lwt.2016.11.002

Pereira ALF, Feitosa WSC, Abreu VKG, Lemos TO, Gomes WF, Narain N, Rodrigues S (2017) Impact of fermentation conditions on the quality and sensory properties of a probiotic cupuassu (Theobroma grandiflorum) beverage. Food Res Int 100:603–611. https://doi.org/10.1016/j.foodres.2017.07.055

Pérez-Mora W, Jorrin-Novo JV, Melgarejo LM (2018) Substantial equivalence analysis in fruits from three Theobroma species through chemical composition and protein profiling. Food Chem 240:496–504. https://doi.org/10.1016/j.foodchem.2017.07.128

Phisut N (2012) Spray drying technique of fruit juice powder: some factors influencing the properties of product. Int Food Res J 19(4):1297–1306

Phoungchandang S, Sertwasana A (2010) Spray-drying of ginger juice and physicochemical properties of ginger powders. Sci Asia 36:40–45. https://doi.org/10.2306/scienceasia1513-1874.2010.36.040

Pires FCS, Pena RS (2017) Optimization of spray drying process parameters for tucupi powder using the response surface methodology. J Food Sci Technol 54:3459–3472. https://doi.org/10.1007/s13197-017-2803-5

Pombo JCP, Carmo JR, Araújo AL, Medeiros HHBR, Pena RS (2019) Moisture sorption behavior of cupuassu powder. TOFSJ 11:66–73. https://doi.org/10.2174/1874256401911010066

Pugliese AG, Tomas-barberan FA, Truchado P, Genovese MI (2013) Flavonoids, proanthocyanidins, vitamin C, and antioxidant activity of Theobroma grandiflorum (Cupuassu) pulp and seeds. J Agric Food Chem 61:2720–2728. https://doi.org/10.1021/jf304349u

Ribeiro CMCM, Magliano LCSA, Costa MMA, Bezerra TKA, Silva FLH, Maciel MIS (2019) Optimization of the spray drying process conditions for acerola and seriguela juice mix. Food Sci Technol 22:1–8. https://doi.org/10.1590/fst.36217

Rogez H, Buxant R, Mignolet E, Souza JNS, Silva EM, Larondelle Y (2004) Chemical composition of the pulp of three typical Amazonian fruits: araça-boi (Eugenia stipitata), bacuri (Platonia insignis) and cupuaçu (Theobroma grandiflorum). Eur Food Res Technol 218:380–384. https://doi.org/10.1007/s00217-003-0853-6

Sagar VR, Suresh Kumar P (2010) Recent advances in drying and dehydration of fruits and vegetables: a review. J Food Sci Technol 47(1):15–26. https://doi.org/10.1007/s13197-010-0010-8

Santana A, Kurozawa L, Oliveira R, Park K (2016) Spray drying of pequi pulp: process performance and physicochemical and nutritional properties of the powdered pulp. Braz Arch Biol Technol 59:1–11. https://doi.org/10.1590/1678-4324-2016150362

Santhalakshmy S, Bosco SJD, Francis S, Sabeena M (2015) Effect of inlet temperature on physicochemical properties of spray-dried jamun fruit juice powder. Powder Technol 274:37–43. https://doi.org/10.1016/j.powtec.2015.01.016

Shishir MRI, Chen W (2017) Trends of spray drying: A critical review on drying of fruit and vegetable juices. Trends Food Sci Technol 65:49–67. https://doi.org/10.1016/j.tifs.2017.05.006

Silva JA, Maciel MIS, Moura NP, Júnior MS, Melo JV, Azoubel PM, Melo EA (2014) Influence of process conditions on drying by atomization pulp umbu. J Bioprocess Biotech 4(4):1–9. https://doi.org/10.4172/2155-9821.1000163

Singleton VL, Rossi JA (1965) Colorimetry of total phenolics with phosphomolybdic phosphotungstic acid reagents. Am J Enol Viticult 16:144–158

Tan S, Hadinoto K, Ebrahimi A, Langrish T (2019) Fabrication of novel casein gel with controlled release property via acidification, spray drying and tableting approach. Colloid Surface B 177:329–337. https://doi.org/10.1016/j.colsurfb.2019.02.019

Tonon RV, Brabet C, Hubinger MD (2008) Influence of process conditions on the physicochemical properties of açaí (Euterpe oleraceae Mart.) powder produced by spray drying. J Food Eng 88(3):411–418. https://doi.org/10.1016/j.jfoodeng.2008.02.029

Torres LLG, El-Dash AA, Carvalho CWP, Ascheri JLR, Germani R, Miguez M (2005) Moisture content and temperature effects on the processing of unripe banana flour (Musa acuminata, AAA Group) by thermoplastic extrusion. Boletim do CEPPA 23:273–290

Vissotto LC, Rodrigues E, Chisté RC, Benassi MT, Mercadante AZ (2013) Correlation, by multivariate statistical analysis, between the scavenging capacity against reactive oxygen species and the bioactive compounds from frozen fruit pulps. Cienc Tecnol Aliment 33:57–65. https://doi.org/10.1590/S0101-20612013000500010

Zhong C, Tan S, Langrish T (2019) Redness generation via Maillard reactions of whey protein isolate (WPI) and ascorbic acid (vitamin C) in spray-dried powders. J Food Eng 244:11–20. https://doi.org/10.1016/j.jfoodeng.2018.09.020

Acknowledgements

The authors acknowledge Conselho Nacional de Desenvolvimento Científico e Tecnológico (CNPq, Brazil) for the scholarship of J. C. P. Pombo (163360/2015–4) and PROPESP/UFPA for the financial support.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Pombo, J.C.P., de Medeiros, H.H.B.R. & Pena, R.d. Optimization of the spray drying process for developing cupuassu powder. J Food Sci Technol 57, 4501–4513 (2020). https://doi.org/10.1007/s13197-020-04487-2

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13197-020-04487-2