Abstract

‘Cempedak’ (Artocarpus integer) is an aromatic fruit that looks similar to jackfruit. Response surface methodology was used to optimize the spray-drying process to produce ‘cempedak’ fruit powder, with inlet air temperature (140–180 °C) and maltodextrin (DE 10) concentrations (5–15% w/w) as independent variables. Statistical analysis revealed that these variables significantly affected process yield, moisture content, water activity, hygroscopicity, L* value of powder and carotenoid content. Inlet air temperature had a negative correlation with all significant variables. At the same time, maltodextrin concentration was found to be positively correlated with all significant powder variables except process yield and moisture content. The recommended optimum spray-drying conditions for drying ‘cempedak’ juice were inlet air temperature and maltodextrin concentration of 160 °C and 15% (w/w), respectively. Under optimized spray-drying conditions, the yield of ‘cempedak’ powder was 60.5%, with moisture content, water activity, hygroscopicity and carotenoid content of 6.07%, 0.22, 25.8 g/100 g and 1.00 mg/g, respectively.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

‘Cempedak’ (Artocarpus integer) is a seasonal fruit with reduced availability throughout the year. Because of its attractive aroma and nutritional value, it is beneficial to produce value-added products from the fruit [1]. It was reported that all five ‘cempedak’ varieties studied have a high content of α-carotene (2.30–45.27 μg/100 gFW), followed by β-carotene (2.30–12.23 μg/100 gFW), in which CH28 having the highest content [2].

Total carbohydrates (fresh cut) for ripe ‘cempedak’ was 16.2%—28.3 g/100 g, which was comparable to the 25.8 g/100 g reported by Janick and Paull [3] and Subhadrabandhu [4]. Potassium was the prevalent mineral found in ‘cempedak’ fruit (184–434 mg). This is followed by Calcium (40 mg) and Sodium (25 mg). Phosphorus and Ferum were the minor elements in with a concentration that is less than 10 mg/100 g. It is also noted that ‘cempedak’ contains 65–80 μg of carotene and 13.3–17.7 mg of vitamin C. The ‘cempedak’ fruit can be consumed either ripe or unripe. The flesh can either be consumed fresh, processed into a refreshing juice or creamed to make jams and cakes. Unripe ‘cempedak’ is eaten along with vegetables, or in soup or cooked in coconut milk [3, 4]. The ripe and unripe flesh is salted in Malaysia and used as a pickle called jerami. The ‘cempedak’ fruit is can be preserved in syrup [1]. According to Lim [1], ‘cempedak’ are being fried whereby the perianth balls are coated with flour and deep fried to make into fritters for consumption as dessert or snacks. The perianths are also candied or made into chips by sun-drying [5]. A few recipes to produce ‘cempedak’ pudding, bread and pie has been introduced by DOA [6].

Spray-drying can be applied to convert the ‘cempedak’ pulp into a powder that would have a longer shelf-life. It is envisaged that the use of ‘cempedak’ fruit powder in various food products will increase their economic value. Spray-drying is commonly adapted for dehydration of products that are sensitive to heat, resulting in powders with good physicochemical qualities. Besides that, fruit powders are stable with lower water activity, and reduced weight makes it easier to transport and store [7]. The spray-drying method has been widely applied in the production of many fruit powders such as mango, watermelon and acai [7,8,9].

Response surface methodology (RSM) is defined as an empirical modeling technique commonly used, as it is viewed as comprehensive, simple and highly efficient [10]. Mathematical and statistical methods were applied in RSM to determine the relationship between factors to achieve the optimum conditions for all significant responses [11]. Besides, RSM also reduced the number of experiments needed [12].

The physicochemical properties of food powders were reported to be influenced by the spray-drying parameters [9, 13, 14]. The application of RSM in finding the optimum spray-drying parameters of spray-dried fruits such as acai, pomegranate and acelora were reported [7, 15, 16]. In the spray-drying of acai juice, the effects of inlet air temperature and feed flow rate as spray dryer process parameter and also carrier concentration (maltodextrin) on process yield and outlet air temperature; physical and chemical properties of powder namely moisture content, hygroscopicity and anthocyanin retention of acai powder were determined [1]. They concluded that process yield was positively affected by inlet temperature while negatively influenced by maltodextrin. On the other hand, powder hygroscopicity decreased with decrease inlet temperature and an increase in maltodextrin concentration. The effect of inlet temperature and maltodextrin concentration on the physical properties of powder were assessed in the spray-drying of pineapple, Solanum lasiocarpum and papaya juice [17,18,19].

The effect of inlet temperature, drying aid/acerola, percent replace of maltodextrin by crystalline cellulose on the moisture content, and hygroscopicity of acelora powder showed that higher inlet temperature decreases the moisture content and hygroscopicity of the powders. In contrast, the carrier decreases the hygroscopicity of powder produced [16]. RSM has also been used to determine the effect of Celluclast® 1.5 L concentration, maltodextrin concentration and spray-dryer inlet air temperature on the process yield and physical properties of pumpkin powder [20], in which process yield increases the process yield and reduces its stickiness with the increase in maltodextrin concentration.

With the addition of carriers such as maltodextrin, the stickiness issue that is caused by compounds such as sugar, gums (hydrocolloids) and carbohydrates can be resolved [9, 14]. Maltodextrin is widely used in the production of fruit powders and is also reasonably cheap [21]. Maltodextrin functions as an encapsulator, which helps to prevent any undesirable effects such as loss of flavor, degradation of color and separation of ingredients. With maltodextrin addition in the spray-drying process, the powder produced have better powder yield. In addition, maltodextrin which functions as wall material, when added into the spray-drying feed, it envelopes the juices, encapsulating the sugar components, which tends to be sticky. This in turn, produces powder that is more free-flowing and good powder properties [22].

To date, although there are ‘cempedak’ chips, cakes and other ‘cempedak’-based dessert, its fruit powder has not been produced commercially; therefore, the present research aims to develop a more versatile and stable product: ‘cempedak’ fruit powder, by investigating the effects of spray-dryer inlet air temperature and maltodextrin concentration on ‘cempedak’ fruit powder properties using ‘cempedak’ fruit puree treated with 1.2% (v/w) Celluclast® 1.5 L as the spray-drying feed. Response surface analysis was utilized in the determination of model for estimation of the physical properties of ‘cempedak’ fruit powder, in which the desired product should be of good yield with moisture content, water activity and hygroscopicity of the fruit powder, with good retention of its color and carotenoid content.

Materials and methods

Raw materials

‘Cempedak’ (Artocarpus integer) variety used in this study, CH28, was procured from the Department of Agriculture, Serdang, Selangor, Malaysia. Maltodextrin 10 DE was supplied by Bronson and Jacobs Ptd. Ltd. (Kuala Lumpur, Malaysia). Celluclast® 1.5 L (the cellulolytic enzyme used for enzyme-aided production of ‘cempedak’ juice) was purchased from Novozymes, Denmark.

Preparation of the spray-dryer feed

‘Cempedak’ fruit (syncarp) was slit into half, and fruit bulbs that comprised the pulp (aril) and seed were removed from the central core. Fruit pulp was separated from seed before it was vacuum packed in transparent polyethylene plastic bags (200 g of pulp per packet) and stored in the dark at − 20 °C. Before experiments, the ‘cempedak’ pulp was thawed at room temperature and cut into smaller pieces, and then homogenized into a puree at low speed using a commercial blender. To prepare ‘cempedak’ juice, the ‘cempedak’ puree (100 g) was mixed with distilled water at 1:2 puree: water ratio and incubated with 1.2% (v/w) Celluclast® 1.5 L for 1 h at 45 °C and 100 rpm in a shaking water bath (WNB 14, Memmert GmbH & Co. KG., Schwabach, Germany). After incubation, the end product (liquefied ‘cempedak’ puree) was immediately subjected to pasteurization at 90 °C for 5 min (in a water bath) to inactivate the added enzyme and endogenous enzymes, and microorganisms that might be present [23].

Spray-drying process

To prepare the feed for spray-drying, the liquefied ‘cempedak’ puree, which went through filtration via muslin cloth, was added with maltodextrin DE 10 (2.9–17.1% w/w). The total soluble solids of the feed before spray-drying was 10% wet basis. The mixture was then homogenized using a lab homogenizer (T25, IKA-Werke Gmbh & Co., Staufen, Germany) at 9500 rpm [24], before left at room temperature for 30 min. The maltodextrin-containing feed was spray-dried in a Büchi B-290 mini spray-dryer equipped with the two-fluid nozzles and compressed air (Büchi Labortechnik AG, Flawil, Switzerland). The dryer was operated at a flow rate of 900 m3/min air, while the dryer aspirator rate and pump rate were kept constant at 100 and 10%, respectively. The outlet air temperatures used ranged from 85–95 °C, with a feed flow rate of 5 mL/min. Spray-drying was performed in an experimental design generated from RSM (Table 1). During the spray drying process, the feed mixture was constantly stirred. Spray-dried ‘cempedak’ fruit powders were collected from the product vessel. It is then vacuum packed and stored in the dark condition at − 20 °C until further analysis.

Analysis of spray-dried ‘cempedak’ fruit powder

Process yield

Product recovery, expressed as process yield, is defined as the ratio of powder mass to the mass of total solids in feed mixture [25,26,27]. Only the powder collected from the product vessel was used to calculate the product yield and excluded powder that adhered to the drying chamber or cyclone wall [13]. This is because powder accumulated in the chamber wall have different properties due to the intense heat exposure during the drying process, rendering them useless to be considered as a product [28]. The process yield of ‘cempedak’ fruit powder was calculated based on the formula below (Eq. 1):

Moisture content and water activity

The moisture content of the spray-dried ‘cempedak’ fruit powders was analyzed according to AOAC2000 [29]. The aw of the spray-dried ‘cempedak’ fruit powders was measured using a water activity meter (PRE 00207, AquaLab Pre, Decagon Devices, Inc., Pullman, USA).

Color (L*, a*, b*)

A HunterLab Ultra-Scan Color Flez spectrophotometer (Hunter Associate Laboratory Inc., Reston, USA) was employed to determine the color of ‘cempedak’ fruit powder [18]. The instrument was calibrated using a white tile and black tile, before filling the sample cup with ‘cempedak’ powder. After covering the sample cup with a black color cover cup, the color analysis was conducted at room temperature, and its readings were expressed in L* (lightness–darkness), a* (greenness–redness) and b* value (blueness–yellowness).

Carotenoid content

The carotenoid content of the ‘cempedak’ fruit powders was determined by mixing 1 g ‘cempedak’ fruit powder and 10 mL distilled water as the starting sample [30]. Cold acetone (50 mL) was added to the suspension, mixed and allowed to stand for 15 min before filtration through a Whatman filter and Büchner funnel with pump suction. The residue was treated with 15 mL cold acetone for further extraction, and the filtrate (extract) pooled.

The ‘cempedak’ extract (1/3 of the total volume) was added to petroleum ether (20 mL) in a 500 mL separatory funnel, followed by the addition of 300 mL of distilled water. After mixing, separation of phases was allowed to take place, where the bottom colorless aqueous layer was discarded. Another 1/3 of the ‘cempedak’ extract was added to the organic phase in the separatory funnel, followed by the addition of water, and the separation process was repeated.

Once the final 1/3 of the extract had been similarly treated as described above, the upper organic layer containing the carotenoid extract (yellow color) was collected. The extract was filtered through anhydrous sodium sulfate (15 g) to remove residual moisture, and the solvent was evaporated using a rotary evaporator at 35 °C. Acetone (10 mL) was then added to the round bottom flask to dissolve the carotenoids, followed by measuring the absorbance of the solution with a spectrophotometer at 450 nm. An β-carotene standard curve was constructed using different concentrations of the β-carotene (Sigma-Aldrich, USA) standard solution (0–6 mg/mL).

Hygroscopicity

The hygroscopicity of the ‘cempedak’ powder was measured by placing 2 g ‘cempedak’ fruit powder into a pre-weighed petri dish (100 mm × 15 mm) and the dish was then placed in an airtight desiccator containing 500 mL of a saturated solution of Na2SO4, for one week at room temperature [24]. The hygroscopicity was calculated as grams of adsorbed moisture/100 g dry solids [31].

Experimental design and statistical analysis

A central composite design was applied for the spray-drying of ‘cempedak’ juice (filtered enzyme-liquefied ‘cempedak’ puree). In which, 5 levels of inlet air temperature (132–188 °C) and maltodextrin concentration (2.9–17.1% w/w), with a total of 14 combinations, inclusive of a central point and two axial points (Table 1). The following polynomial equation (Eq. 2) was fitted to the data:

where b0 was a constant; b1, b2 = linear coefficients; b12 = cross-product coefficients; and b11, b22 = quadratic coefficients.

The analysis of variance (ANOVA), test for the lack of fit and the determination of the regression coefficients with the contour plot was carried out using the Design Expert 10 software (Stat-Ease, USA), in which equations generated will be used for evaluation linear, quadratic and interactive effects of independent variables on the chosen response. To determine the optimal parameters, the inlet temperature and the maltodextrin ranges is fixed; and criteria for desirable responses is set to be maximized or minimized, accordingly at a different importance level. An optimal point suggesting inlet temperature and maltodextrin conditions, with its predictive value, will be generated by the Design Expert software. This is followed by experiments to validate the optimized value.

Results and discussion

Through RSM, simultaneous determination of the independent variable’s effect [either main and interaction, assessed as linear, quadratic and interaction terms of spray-dryer air inlet air temperature (x1) and maltodextrin concentration (x2)] on each response (Yi) can be performed. Experimental responses of spray-dried ‘cempedak’ fruit powder were shown in Table 2. Tables 3 and 4, on the other hand, exhibited the regression model and estimated regression coefficients for response variables, and determination coefficients (R2), R2 (adj), F-value and p-value of lack of fit. The R2 values of all significant variables were found to be more than 0.8, except for the L* value of ‘cempedak’ fruit powder (0.78), which indicates that the response surface models were able to explain the majority of responses variables [32].

The model fitness, which is measured by the lack of fit, was found to have no significant p-value (Table 3), which indicates that the regression models are sufficient to describe the variation of the responses. Table 4, on the other hand, tabulates the probability of regression coefficients in terms of p-value and F-ratio, respectively, in the polynomial response surface models. The linear effect of inlet air temperature and maltodextrin was significant for all responses found in the table (Table 4). On the other hand, the quadratic effects of air inlet air temperature and maltodextrin concentration in all in all response regression were non-significant (p > 0.05), except for moisture content.

Influence of independent variables on process yield of spray-dried ‘cempedak’ fruit powder

Based on observations made during preliminary work on spray-drying, there was hardly any powder accumulated in the product vessel for the feed without maltodextrin, as most of the powder stick to the wall chamber and cyclone instead. However, maltodextrin, when added to the spray-dryer feed, was able to form a film around the solids in feed, which in turn produces a flour-like powder that is non-hygroscopic and free-flowing [33]. The linear effects of inlet air temperature and maltodextrin concentration were found to be significant (p ≤ 0.05) on process yield (Y1) (Table 3), with the linear effect of inlet air temperature having a slightly higher F-ratio (Table 4). This indicates that both inlet air temperature and maltodextrin concentration were critical factors that lead to an increase in the process yield of ‘cempedak’ fruit powder.

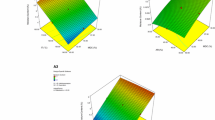

Table 2 tabulates the process yields of ‘cempedak’ fruit powders spray-dried using the experimental runs shown in Table 1. The process yield (Y1) of ‘cempedak’ fruit powder ranges from 42.8 to 62.4% (Table 2). The range of successful total recovery of powder is reported to be approximately 50% [22]. Figure 1 shows the 3D response surface plot for inlet air temperature and maltodextrin concentration effect on the process yield of spray-dried ‘cempedak’ fruit powder. ‘Cempedak’ is rich in sugar, where these low molecular weight sugar caused a low glass transition temperature of powder produced, hence most of them will adhere to the chamber wall. Maltodextrin is added to increase the glass transition temperature, which aims to prevent or reduce powder stickiness [34]. Tables 3 and 4 show that there is a negative correlation between inlet air temperature and the yield of ‘cempedak’ fruit powder. This is attributable to the reduction of powder production and yield caused by the melting of the powder that sticks on the chamber wall [35].

Figure 1 presents the positive effect of maltodextrin concentration on process yield. It has been suggested that the surface stickiness of low molecular weight sugars (glucose, sucrose and fructose) and organic acids could be altered by maltodextrin, in which it will facilitate better drying with a product that is less sticky [36]. This happens as the addition of maltodextrin causes better particle dispersion, decreasing the cohesive forces between them [21]. Hence, it can be stated that the addition of maltodextrin to ‘cempedak’ juice has influenced the properties of the ‘cempedak’ powder, causing changes in its microstructure.

Effect of independent variables on the moisture content and water activity of spray-dried ‘cempedak’ fruit powder

Caking is influenced by the amount of residual moisture that will affect the final quality of the powder [27]. Moisture content is the water composition in food, while water activity it’s the free water that is available for biochemical reactions, which affects its shelf-life [37]. It is reported that powder moisture content below 10% is considered safe microbiologically [38]. In the case of ‘cempedak’ fruit powder, the moisture content ranged from 6.03 to 7.13% (Table 2). The linear effect of inlet air temperature has the highest F-ratio (Table 4), indicating that inlet temperature has a bigger influence on the moisture content of spray-dried ‘cempedak’ fruit powder, as compared to maltodextrin concentration.

The water activity (Y3) of the encapsulated powder (Table 2) varied from 0.19 to 0.27, and the fruit powder can thus are categorized as microbiologically and biochemically stable [38]. From Table 4, it can also be seen that both the linear effects of inlet air temperature and maltodextrin concentration significantly influenced the water activity of spray-dried ‘cempedak’ fruit powder, with inlet air temperature having the highest significant effect (p ≤ 0.05). 3-D response surfaces plot gave better visualization on the effects of independent variables on the moisture content, and water activity is shown in Figs. 2 and 3, respectively. From both figures, it is observed that inlet air temperature has negative correlations with the moisture and water activity of spray-dried ‘cempedak’ fruit powder. There is a large temperature gradient between atomized spray-drying feed and the drying air when the spray-drying was performed at a higher inlet temperature. The higher rate of heat transfer to particle, providing a better driving force for moisture evaporation, in turn, produces powders with lower moisture content [9].

With an increase in maltodextrin concentration, there is a slight decrease in moisture content and water activity (Figs. 2, 3). Abadio et al. [39] reported a decrease in the moisture content of pineapple powder when maltodextrin concentration from 10 to 15% (w/v). The reduction of moisture content and water activity of powder with an increase of carrier concentration is attributed to the increase of feed solids, causing a reduction in total moisture available for the evaporation process [40, 41].

Effect of independent variables on the color of spray-dried ‘cempedak’ fruit powder

In the food industry, the color of food powder is considered as an important parameter, where it reflects the sensory attractiveness. It indicates the nutrients and bioactive compounds exhibit color (pigments) [37]. In this study, the spray-dried ‘cempedak’ fruit powders obtained were yellowish, which is an attractive quality. As shown in Table 3, both the inlet air temperature and maltodextrin concentration have influences on the powder’s lightness (L*, Y4). The L* values of the powders ranged from 62.35–77.96. Data in Tables 3 and 4 showed that the linear term of both inlet air temperature and maltodextrin concentration has a significant effect on lightness of ‘cempedak’ fruit powder, with maltodextrin concentration having the higher significance.

The surface response plot in Fig. 4 serves to illustrate the effects of inlet air temperature and maltodextrin concentration on the lightness of spray-dried ‘cempedak’ fruit powder. Inlet air temperature has a significant but negative effect (p ≤ 0.05) on the lightness of the powder. The sugar that is present in ‘cempedak’ fruit contributes to the browning of the powders when they are spray-dried at higher inlet temperatures. In the production of watermelon powder, L* values of the powders decreased, indicating that the color of the powders is darker when spray-dried at a higher inlet air temperature [9].

However, there was a negative effect (p ≤ 0.05) with a slightly higher F-ratio (indicating more influence on the response) on ‘cempedak’ fruit powder lightness, as shown in Tables 3 and 4. The L* values increased with an increase of maltodextrin concentration (white) when spray-dried at inlet temperature below 200 °C [41, 42]. Conversely, these independent variables (Table 3) did not have significant effects (p > 0.05) on powder a* (greenness–redness, Y5) and b* (blueness–yellowness, Y6) values. The powders obtained have a* values and b* values that range from 7.42–13.23 and 25.48–37.45, respectively (Table 2).

Effect of independent variables on carotenoid content of spray-dried ‘cempedak’ fruit powder

The carotenoid content (Y7) of spray-dried ‘cempedak’ fruit powder was found to be negatively proportional to the linear effects of the inlet air temperature and maltodextrin concentration (Table 3, 4). The linear effect of inlet air temperature has the biggest influence on powder’s carotenoid content (highest F-ratio). The effect of inlet air temperature and maltodextrin concentration on the carotenoid content of ‘cempedak’ fruit powder is shown in Fig. 5.

From Table 2, the carotenoid content of ‘cempedak’ powder ranges from 1.16–2.09 mg/g. This is in agreement with the previous report, where a total of 1.09 mg/g (109 mg/100 g) dry weight total carotenoid content in ‘cempedak’ flesh (variety not stated) [43]. As can be seen in Fig. 5, the carotenoid content of ‘cempedak’ fruit powder decreased with an increase in inlet air temperature. With higher inlet air temperature, the powder obtained has higher moisture content [41]. The increase of moisture content will result in a greater degree of aggregation, leading to a reduction of oxygen exposure to carotenoid, decrease its loss [28]. Carotenoids are also susceptible to heat destruction, attributed to their highly unsaturated chemical structure [9]. This is also supported by Grabowski et al. [44] in the spray-drying of sweet potato puree, where the total amount of carotenoids is reduced with an increase in temperature. Also, the total carotenoids content in gac (Momordica cochinchinensis) powder was decreasing with the increase of maltodextrin from 10 to 30% [41].

The Recommended Dietary Allowance (RDA) for vitamin A is defined as 0.6–0.9 mg/day, which is approximately 7–10.8 mg of β-carotene [45]. In this respect, although there is a decrease in total carotenoids content, the spray-dried ‘cempedak’ fruit powders may still contribute to vitamin A intake.

Effect of independent variables on the hygroscopicity of spray-dried ‘cempedak’ fruit powder

Powder hygroscopicity is the ability of the powder to absorb moisture from the humid environment [46]. Results in Table 3 indicated that the hygroscopicity of spray-dried ‘cempedak’ fruit powder was negatively correlated to the inlet air temperature, where an increase in inlet temperature leads to a decrease in hygroscopicity value. From Table 4, it is found that both the linear effect of independent variables (inlet air temperature and maltodextrin concentration) significantly (p ≤ 0.05) influenced the hygroscopicity of ‘cempedak’ fruit powder (Y8). The hygroscopicity values of spray-dried ‘cempedak’ fruit powders ranged from 30–38% (Table 2). These values are lower than the hygroscopicity of spray-dried Amaranthus powder, which is in the range of 44.6–49.5%, probably due to the different water uptake capacity of powder type and also the amount of carrier agent applied [31].

The effects of inlet air temperature and maltodextrin concentration on hygroscopicity are illustrated in Fig. 6, which shows that an increase in inlet air temperature results in a decrease in the hygroscopicity of ‘cempedak’ fruit powder. Feed mixture spray-dried at lower temperatures tends to produce a powder with higher hygroscopicity [16]. This is because at lower inlet air temperature, powders obtained have higher moisture contents, and water has the tendency to decrease the glass transition temperature, causing the powder to be more hygroscopic [20]. Inlet air temperature was also reported to decrease the hygroscopicity of spray-dried red pitaya peel powder [24].

As compared to inlet temperature, maltodextrin concentration has a greater influence on the hygroscopicity of ‘cempedak’ fruit powder (Table 4), with lowest hygroscopicity obtained when highest maltodextrin concentration was added (Fig. 6). As maltodextrin itself is low in hygroscopicity, its addition can modify the balance of hydrophilic/hydrophobic sites of the powder particles, thus decreasing the amount of water absorbed [47]. In the spray-drying of cactus pear juice and betacyanin pigment, there was also hygroscopicity reduction with increasing maltodextrin concentration [31, 48].

Optimization of independent variables

To obtain an optimal region, the limit for each variable was narrowed down, where each goal was minimized or maximized based on the desired properties of the spray-dried ‘cempedak’ fruit powder (Table 5), such as low moisture content, minimized color difference; the enhanced nutritive value can be obtained with higher carotenoids content. Numerical optimization was also performed to determine the exact value of multiple response optimization. Results indicated that ‘cempedak’ juice spray-dried at 160 °C with the addition of maltodextrin (1.5% w/w) was predicted to be optimal parameters, with response values under optimum conditions for process yield, moisture content, water activity, hygroscopicity, L* value of powder and carotenoid content are tabulated in Table 6.

Verification of the final models

From Table 6, it was found that the experimental response values were close to the predicted ones, in which there was no significant difference found (p > 0.05) in the aspect of for process yield, moisture content, water activity and L* value of powder. This indicates that the model used was suitable to be applied in the optimization of the production of spray-dried ‘cempedak’ fruit powder.

Conclusion

In the optimization of spray-dried ‘cempedak’ fruit powder, inlet air temperature and maltodextrin (DE 10) concentrations, 14 runs were generated using central composite design. All response variables, which includes process yield, moisture content, water activity, hygroscopicity, L* value of powder and carotenoid content were fitted with the response surface models, with most of the reduced model having a high overall coefficient of determination value (R2 > 0.80), except for L* value of powder. All the responses were significantly influenced by carotenoids content and hygroscopicity of ‘cempedak’ fruit powder. The factors that most significantly affect the responses are the linear term of inlet air temperature was the most significant, followed by a linear term of maltodextrin concentration. The multiple response optimization shows that the combined level of 160 °C inlet air temperature, and 15% (w/w) maltodextrin DE 10 as the optimum parameters for the spray-drying of the ‘cempedak’ juice.

References

T.K. Lim, in Edible Medicinal and Non-Medicinal Plant, vol. 3. Fruits, pp. 337–343 (Springer, Dordrecht, 2012)

L.P. Pui, R. Karim, Y.A. Yusof, C.W. Wong, H.M. Ghazali, Physicochemical and sensory properties of selected ‘cempedak’ (Artocarpus integer L.) fruit varieties. Int. Food Res. J. 25(2), 861–869 (2018)

J. Janick, R.E. Paull, The Encyclopedia of Fruits and Nuts (Cambridge University Press, Cambridge, 2008)

S. Subhadrabandhu, Under-Utilized Tropical Fruits of Thailand, Rap publication 26 (Food and Agriculture Organization of the United Nations regional office for Asia and the Pacific, Bangkok, 2001)

C.H. Chong, C.L. Law, M. Cloke, C.L. Hii, L.C. Abdullah, W.R.W. Daud, Drying kinetics and product quality of dried Chempedak. J. Food Eng. 88(4), 522–527 (2008)

Department of Agriculture (DOA), Pakej teknologi cempedak (Jabatan Pertanian Malaysia, Putrajaya, 2001) (in Malay)

R.V. Tonon, C. Brabet, D. Pallet, P. Brat, M.D. Hubinger, Physicochemical and morphological characterisation of açai (Euterpe oleraceae Mart.) powder produced with different carrier agents. Int. J. Food Sci. Technol. 44, 1950–1958 (2009)

M. Cano-Chauca, P.C. Stringheta, A.M. Ramos, J. Cal-Vidal, Effect of the carriers on the microstructure of mango powder obtained by spray drying and its functional characterization. Innov. Food Sci. Emerg. Technol. 6, 420–428 (2005)

S.Y. Quek, N.K. Chok, P. Swedlund, The physicochemical properties of spray dried watermelon powders. Chem. Eng. Process. 46, 386–392 (2007)

M. Khalilian Movahhed, M. Mohebbi, Spray drying and process optimization of carrot–celery juice. J. Food Process. Preserv. 40(2), 212–225 (2016)

I. Andrade, H. Flores, Optimization of spray drying of roselle extract (Hibiscus sabdariffa L.). In Proceedings of the 14th International Drying Symposium, vol. A, São Paulo, Brazil, pp. 597–604 (2004)

D.H. Huntington, The influence of the spray drying process on product properties. Dry. Technol. 22(6), 1261–1287 (2004)

G.R. Chegini, B. Ghabadian, Effect of spray-drying conditions on physical properties of orange juice powder. Dry. Technol. 23, 657–668 (2005)

S. Chew, C. Tan, L. Pui, P. Chong, B. Gunasekaran, K. Nyam, Encapsulation technologies: a tool for functional foods development. ITIJEE 8(5S), 154–160 (2019)

S.H. Yousefi, Z. Ehmam-Djomeh, S.M. Mousavi, Comparison of artificial neural network (ANN) and response surface methodology (RSM) in the prediction of quality parameters of spray-dried pomegranate juice. Dry. Technol. 27, 910–927 (2009)

G.E.G. Moreira, M.G.M. Costa, A.C.R. de Souza, E.S. de Brito, M.F.D. de Medeiros, H.M.C. de Azeredo, Physical properties of spray dried acerola extract as affected by temperature and drying aids. LWT Food Sci. Technol. 4, 641–645 (2009)

C.W. Wong, L.P. Pui, J.M.L. Ng, Production of spray-dried Sarawak pineapple (Ananas comosus) powder from enzyme liquefied puree. Int. Food Res. J. 22(4), 1631–1636 (2015)

F. Shavakhi, H.C. Boo, A. Osman, H.M. Ghazali, Effects of enzymatic liquefaction, maltodextrin concentration, and spray-dryer air inlet temperature on pumpkin powder characteristics. Food Bioprocess Technol. 5(7), 2837–2847 (2012)

L.S. Chang, S.M.E. Yong, L.P. Pui, Production of spray-dried “Terung Asam” (Solanum lasiocarpum Dunal) powder. Walailak J. Sci. Technol. (2020a) (in press)

L.S. Chang, Y.L. Tan, L.P. Pui, Production of spray-dried enzyme-liquefied papaya (Carica papaya L.) powder. Braz. J. Food Technol. 23, e2019181 (2020b) (in press)

T. Mahendran, Physico-chemical properties and sensory characteristics of dehydrated guava concentrate: effect of drying method and maltodextrin concentration. Trop. Agric. Res. Ext. 13, 49–54 (2010)

B.R. Bhandari, N. Dutta, T. Howes, Problems associated with spray drying of sugar-rich food. Dry. Technol. 15, 671–684 (1997)

A.R. Nur‘Aliaa, M.K. Siti Mazlina, F.S. Taip, Effects of commercial pectinases application on selected properties of red pitaya juice. J. Food Process Eng. 34, 1523–1534 (2011)

J. Bakar, S.C. Ee, K. Muhammad, D.M. Hashim, N. Adzahan, Spray-drying optimization for red pitaya peel (Hylocereus polyrhizus). Food Bioprocess Technol. 6, 1332–1342 (2013)

A.M. Goula, K.G. Adamopoulos, Spray drying of tomato pulp: effect of feed concentration. Dry. Technol. 22(10), 2309–2330 (2004)

R.V. Tonon, C. Brabet, M.D. Hubinger, Influence of process conditions on the physicochemical properties of acai (Euterpe oleraceae Mart.) powder produced by spray drying. J. Food Eng. 88, 411–418 (2008)

M.R. Zareifard, M. Niakousari, Z. Shokrollahi, S. Javadian, A feasibility study on the drying of lime juice: the relationship between the key operating parameters of a small laboratory spray dryer and product quality. Food Bioprocess Technol. 5, 1896–1906 (2012)

A.M. Goula, K.G. Adamopoulos, Spray drying of tomato pulp-in dehumidified air: II. The effect on powder properties. J. Food Eng. 66, 35–42 (2005)

AOAC, Official Methods of Analysis (Association of Official Analytical Chemists Inc., Virginia, 2000)

D.B. Rodriguez-Amaya, M. Kimura, HarvestPlus Handbook for Carotenoid Analysis, vol. 2 (International Food Policy Research Institute, Washington, 2004)

Y.Z. Cai, H. Corke, Production and properties of spray-dried Amaranthus betacyanin prigments. J. Food Sci. 65, 1248–1252 (2000)

M.A. De Oliveira, G.A. de Maia, R.W. de Figueirado, A.C.R. de Souza, E.S. de Brito, H.M. de Azeredo, Addition of cashew tree gum to maltodextrin-based carriers for spray drying of cashew apple juice. Int. J. Food Sci. Technol. 44, 641–645 (2009)

C.A. Chopda, D.M. Barrett, Optimization of guava juice and powder production. J. Food Process. Preserv. 25, 411–430 (2001)

A.K. Shrestha, T. Ua-Arak, B.P. Adhikari, T. Howes, B.R. Bhandari, Glass transition behavior of spray dried orange juice powder measured by differential scanning calorimetry (DSC) and thermal mechanical compression test (TMCT). Int. J. Food Prop. 10(3), 661–673 (2007)

G.R. Chegini, B. Ghobadian, Spray dryer parameters for fruit juice drying. World J. Agric. Sci. 3(2), 230–236 (2007)

G. Caliskan, S.N. Dirim, The effects of the different drying conditions and the amounts of maltodextrin addition during spray drying of sumac extract. Food Bioprod. Process. 91, 539–548 (2013)

T.C. Kha, M.H. Nguyen, P.D. Roach, C.E. Stathopoulos, Microencapsulation of Gac oil: optimisation of spray drying conditions using response surface methodology. Powder Technol. 264, 298–309 (2014)

N.L. Tze, P.H. Chong, Y.A. Yusof, N.L. Chin, R.A. Talib, F.S. Tapi, M.G. Aziz, Physicochemical and nutritional properties of spray-dried pitaya fruit powder as natural colorant. Food Sci. Biotechnol. 21(3), 675–682 (2012)

F.D.B. Abadio, A.M. Domingues, S.V. Borges, V.M. Oliveira, Physical properties of powdered pineapple (Ananas comosus) juice—effect of maltodextrin concentration and atomization speed. J. Food Eng. 64, 285–287 (2004)

J.A. Grabowski, V.D. Truong, C.R. Daubert, Spray-drying of amylase hydrolyzed sweet potato puree and physicochemical properties of powder. J. Food Sci. 71, 209–217 (2006)

T.C. Kha, M.H. Nguyen, P.D. Roach, Effects of spray drying conditions on the physicochemical and antioxidant properties of the Gac (Momordica cochinchinensis) fruit aril powder. J. Food Eng. 98, 385–392 (2010)

P. Mishra, S. Mishra, C.L. Mahanta, Effect of maltodextrin concentration and inlet temperature during spray drying on physicochemical and antioxidant properties of amla (Emblica officinalis) juice powder. Food Bioprod. Process. 92(3), 252–258 (2013)

M.F. Abu Bakar, F. Abdul Kari, E. Perisamy, Comparison of phytochemicals and antioxidant properties of different fruit parts of selected Artocarpus species from Sabah, Malaysia. Sains Malaysiana 44(3), 355–363 (2015)

J.A. Grabowski, V.D. Truong, C.R. Daubert, Nutritional and rheological characterization of spray dried sweet potato powder. LWT 41, 206–216 (2008)

E.R. Monsen, Dietary reference intakes for the antioxidant nutrients: vitamin C, vitamin E, selenium, and carotenoids. J. Am. Diet. Assoc. 100(6), 637–640 (2000)

S.S. Vidović, J.Z. Vladić, Z.G. Vaštag, Z.P. Zeković, L.M. Popović, Maltodextrin as a carrier of health benefit compounds in Satureja Montana dry powder obtained by spray drying technique. Powder Technol. 258, 209–215 (2014)

W. Wang, W.B. Zhou, Characterization of spray-dried soy sauce powders using maltodextrin as carrier. J. Food Eng. 109, 399–405 (2012)

G.R. Rodríguez-Hernández, R. González-García, A. Grajales-Lagunes, M.A. Ruiz-Cabrera, M. Abud-Archila, Spray-drying of cactus pear juice (Opuntia streptacantha): effect on the physicochemical properties of powder and reconstituted product. Dry. Technol. 23(4), 955–973 (2005)

Acknowledgements

This study was supported by the Universiti Putra Malaysia, Malaysia, under Project no. GP IPS/2013/9399839.

Author information

Authors and Affiliations

Corresponding authors

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Pui, L.P., Karim, R., Yusof, Y.A. et al. Optimization of spray-drying parameters for the production of ‘Cempedak’ (Artocarpus integer) fruit powder. Food Measure 14, 3238–3249 (2020). https://doi.org/10.1007/s11694-020-00565-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11694-020-00565-3