Abstract

Apple pomace treated by steam explosion (SE-AP) was mixed with wheat flour, the wheat dough characteristics and biscuit quality are deserved to investigate. In this paper, the characteristics of wheat dough blended with SE-AP, including sedimentation values, pasting properties, and farinographic features were measured; the textural properties and sensory evaluation of the blended biscuits were analyzed. The results showed that the sedimentation values of wheat dough gradually decreased when SE-AP was less than 10%, which was almost no influence on the biscuit quality. The more SE-AP was added, the less values of peak viscosity, trough viscosity and final viscosity, which was disadvantage to the processing quality of wheat flour; however, the values of breakdown and setback increased with the addition of SE-AP, which improved the processing quality. Dough development time, stability time, and farinograph quality number decreased with the addition of SE-AP, which was unfavourable to the quality of wheat flour. When the addition of SE-AP was less than 10%, the hardness of biscuits decreased, springiness and resilience increased, and the chewability improved. According to the texture properties and organoleptic evaluation, the sensor score of the biscuits made from weak-gluten wheat with 10% (m/m) SE-AP added was the highest.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

In large-scale apple industries, enormous quantities of fresh apple are used to produce apple juice. However, the rise of the apple processing industry has inevitably increased the production of apple pomace (AP), which is the by-product from the processing of apple juice concentrate. Apart from being used as animal feed (Steyn et al. 2017), these residues are mainly discarded, and thereby comprise an industrial waste burden on the environment. AP can be used as an important source of dietary fibre (DF) (Carson et al. 1994), including soluble dietary fibre (SDF) and insoluble dietary fibre (IDF). SDF is known for its hypocholesterolaemic effect (Sudha et al. 2007; Figuerola et al. 2005) and has great efficacy in preventing chronic diseases such as cardiovascular disease and coronary heart disease (Kendall et al. 2010; Kaczmarczyk et al. 2012). Given these advantages, the SDF content in AP dietary fibre is an important indicator of its effective physiological function. With changes in modern dietary structures, the levels of SDF intake have started to decrease. However, as health professionals and consumers become more aware of associated health problems, there is growing demand for foods rich in SDF (Foschia et al. 2013), especially for developing fibre-containing food products. AP is high in total dietary fibre (TDF), typically ranging from 51 to 77%, but the level of SDF in dietary fibre is only 6% (Sudha et al. 2007; Liang et al. 2017). Therefore, improving SDF content of apple pomace by steam-explosion technology contributes to fully utilizing apple by-products.

Steam explosion (SE) (at 160–260 °C, 0.69–4.83 MPa) is an effective method for the pretreatment of biomass materials like orange peel (Wang et al. 2015), corn stover (Li et al. 2015), wheat straw (Monschein and Nidetzky 2016), and wood pellets (Tang et al. 2018) for conversion of these materials into food ingredients, fuel, or chemicals. SE pretreatment utilizes hot steam for several minutes followed by explosive decompression of the biomass that results in breakage of the interconnections between the fibrous rigid structure and the crystal structure of fibrous macromolecules (Li et al. 2015). The SE process degrades hemicellulose and softens lignin, which promotes the dissolution of SDF. Furthermore, SE pretreatment causes the cleavage of chemical bonds of insoluble macromolecular components (cellulose, insoluble hemicellulose), thereby forming smaller molecules that can be converted into SDF (Wang et al. 2015). Preliminary research has shown that the content of SDF in AP treated by SE increased by 3.76 times (Liang et al. 2017).

Currently, the development of functional foods that are rich in dietary fibre is attracting increased attention. Ćetković et al. (2008) reported that apple pomace was regarded as a valuable source of natural antioxidants and bioactive compounds. Kohajdová et al. (2014) added 5% AP powder to wheat dough, and the properties of the mixtures, such as the volume, thickness, width, and spread ratio of biscuits were improved, and the sensory characteristics of the biscuits were as good as the control. Mannuramath et al. (2015) reported that little millet flour bran could be used to substitute for flour up to 30% in the preparation of high-fibre biscuits. On the other hand, Sudha et al. (2016) added dehydrated apple pomace (DAP) to prepare a baked product with health benefits and found that the DAP-blended products showed good free-radical scavenging activity. With continued research, an increasing list of functional food products have been added to bread, cake, biscuits, and other foods to increase their nutrient values. These have included hazelnut testa (Anil 2007), butternut fibres (Pla et al. 2011), blueberry and grape seed powder, and poppy seed (Aksoylu et al. 2015). Therefore, use of SE-AP powder with high SDF content to produce biscuits is significant in its utilization of apple pomace by-products and through its improvement of the nutritional value of biscuits.

The aim of this research was to incorporate different levels of SE-AP powder as a source of DF into biscuits, especially SDF. The effects of the SE-AP powder on the pasting characteristics and farinographic properties of strong-gluten wheat (SGW) and weak-gluten wheat (WGW) and the texture and sensory properties of biscuits were investigated.

Materials and methods

Materials

Apple pomace powders, provided by SDIC Zhonglu Fruit Juice (Beijing, China), were prepared by pressing juice and then drying the residue in a drying oven at 40 °C for 12 h. SGW and WGW were purchased from Suntory Flour Group (Xinxiang, China). Commercial SGW flour (20% protein, 3% fat, and 24% carbohydrates; w/w) and commercial WGW flour (13% protein, 3% fat, and 24% carbohydrates; w/w) were used in this study. Other ingredients for biscuits such as white sugar, butter, eggs, and milk powder were all purchased from a local supermarket in Xinxiang, China.

Preparation of SE-AP powders

AP powder was steam-exploded by using the QBS-80 steam explosion apparatus (Hebi Zhengdao Bioenergy, Henan, China). About 300 g of apple pomace was passed through a 60-mesh sieve and then placed into the steam explosion system cylinder (0.415 L of effective explosion chamber volume), and the pressure of the device was set to 0.51 MPa. High-pressure steam (160–260 °C) entered the cylinder from the intake valve. The pressure holding time was 168 s, and then the intake valve was closed. The pulse width of the steam explosion apparatus was 8.75 ms, and in this instant, high-density energy was released to complete the explosion of AP. The steamed AP powder was collected and stored at − 20 °C.

Chemical analysis

The main components of the treated and untreated AP powders were determined according to standard AOAC (2000) methods for analysis of protein (method 955.04); fat (method 920.39); TDF, IDF, and SDF (method 991.43); moisture (method 925.09); and ash (method 942.05).

Preparation of wheat flour blends

SGW flour and WGW flour were substituted with SE-AP powder at different levels: 0% (control sample), and 2, 4, 6, 8, 10, 12, 14, and 16% (w/w). The wheat flour blends were packaged in ziplock bags of the PE polyethylene material (Gerry Plastic CO., LTD, Taizhou, Jiangsu, China) and stored at 4 °C.

Sedimentation value determination

The sedimentation value was determined by the sodium dodecyl sulphate sedimentation test according to standard AACC International (2000) approved method 56-70.

Pasting properties

Pasting properties of the blends were analysed by rapid visco analysis (RVA-IV, Newport Scientific, Warriewood, Australia) according to the method of Díaz-Calderón et al. (2018) with minor modification. Three grams of sample were added into the RVA aluminium canister, and distilled water was added to 25 mL. The sample was stirred evenly with a blender and then tested in the instrument with a heating/cooling procedure. The initial temperature was held at 50 °C for 1 min, then increased to 95 °C over a period of 4 min, held at 95 °C for 5.5 min, cooled to 50 °C over 4 min, and held at 50 °C for 4 min. The rotation speed of the slurry was 960 rpm in the initial 10 s and then 160 rpm for the remainder. The measured pasting properties were peak viscosity, trough viscosity, final viscosity, breakdown value, and setback value.

Farinographic properties

The farinographic properties were investigated according to ICC 115/1 (2004) using a Farinograph-E Electronic Toner (Brabender, Duisburg, Germany). The measured farinographic properties were water absorption, development time, stability time, degree of softening, and farinograph quality number.

Biscuit preparation

Biscuit was prepared with wheat flour blends according to the formula as follows: 30 g of SE-AP/WGW flour blend [0, 2, 4, 6, 8, 10, 12, 14, and 16% SE-AP (w/w)], 38 g of butter, 11 g of sugar, 6 g of egg white, and 2 g of milk powder. Butter was creamed in a JYL-F700 mixer (Jiuyang, Hangzhou, China) and egg white, milk powder, and sugar were added to the cream and mixed for 2 min at 150 rpm to obtain a homogeneous cream. Wheat flour blend was added to the cream and mixed for 3 min at 70 rpm. The biscuit dough was sheeted to a thickness of 38 mm, cut into circular shapes using a 45-mm-diameter manual cutter and baked at 180 °C for 10 min and then cooled to room temperature.

Texture profile analysis of biscuits

The texture profile of the biscuits was analysed by a food texture analyser (TA-XT plus, Stable Micro System, Surry, UK) fitted with a cylinder probe (P/36, 36 mm stainless cylinder). A pre-test speed of 2.0 mm s−1 and a test speed of 1.0 mm s−1 were used. A P/36 cylinder probe was used to measure the required compression force. The time between the two compression stops was 10 s, and the force required to compress 50% of the biscuit was recorded. The textures of the biscuits were measured including hardness, chewiness, springiness, resilience, and cohesiveness. Each biscuit sample was determined in triplicate and the data was expressed as mean ± standard deviation.

Sensory analysis of biscuits

Sensory evaluation of the biscuits was carried out using a nine-point hedonic scale. The hedonic scale ranges from 1 to 9, where 1 corresponds to “extreme dislike” and 9 corresponds to “extreme like”. Sensory testing was conducted by 30 untrained panellists of both sexes between the ages of 18 and 55 years (Soltani et al. 2017; Noor Aziah et al. 2012). The biscuits were evaluated by each panellist for appearance (appearance, integrity), colour (intensity of darkness), taste, aroma (noticeable aroma, burnt smell), texture (roughness, graininess, crispness), and overall acceptability.

Statistical analysis

SPSS 22.0 statistical software (SPSS, Chicago, IL, USA) was used for analysis of variance, and the significance test (p < 0.05) was performed by Duncan’s new complex method. All analyses were performed in triplicate, and the statistical significance was determined using the mean values ± standard deviation.

Results and discussion

Analysis of main components of untreated AP and SE-AP

The compositions of untreated AP and SE-AP are shown in Table 1. There was no significant difference in fat, ash, protein, and dietary fibre contents between untreated AP and SE-AP (p = 0.05). However, IDF was reduced from 71.05 ± 1.06% to 42.68 ± 0.93%, SDF increased from 5.22 ± 0.28% to 30.36 ± 0.52% and increased by 5.82 times. Liang et al. (2017) reported that the fibre of SE-AP was more porous, loose, and dilatant than untreated AP, and the water-holding capacity, oil-holding capacity, and swelling capacity of SDF of SE-AP were improved by 58.9%, 66.7% and 58.5%, respectively. Therefore, mixing SE-AP powder with wheat flour is likely to have beneficial effects on the properties of the blends and biscuits.

Effect of SE-AP on sedimentation values of wheat flour blends

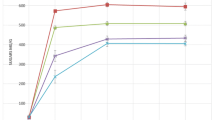

Sedimentation value is a comprehensive index that reflects the quality and quantity of wheat protein and gluten and is used to assess the baking quality of flour. Figure 1 shows when the addition of SE-AP was 0–10%, the blend sedimentation value was gradually decreased from 17.8 ± 0.12 mL to 16.2 ± 0.32 mL for SGW/SE-AP blends, and from 15.8 ± 0.38 mL to 14.0 ± 0.38 mL for WGW/SE-AP blends. When the addition of SE-AP was higher than 10%, the sedimentation values of the blends decreased significantly (p < 0.05), which shows that SE-AP can dilute the gluten protein in wheat flour. When the SE-AP addition was less than 10%, the decline in sedimentation value was not obvious because of the higher content and looser structure of SDF in SE-AP. When the SE-AP addition was higher than 10%, the gluten protein in the blends was not sufficient to maintain the dough stability, and the sedimentation values of the blends were noticeably decreased.

Effect of SE-AP on pasting properties of wheat flour blends

The pasting properties of wheat flour are an important indicator of starch quality. Table 2 shows the pasting properties of the wheat flour/SE-AP blends. It is evident that peak viscosity, trough viscosity and final viscosity of the SGW/SE-AP and WGW/SE-AP blends decreased significantly with the increase of SE-AP (p < 0.05). This may be because starch in wheat flour has adhesive properties and gluten in the flour bonds to form a delicate dough after heating. However, with the addition of SE-AP, the quality and quantity of starch of the blends were reduced, resulting in a drop in starch viscosity.

The breakdown reflects the shear resistance of the starch paste at high temperature and the stability of the hot starch paste. Larger breakdown indicates weaker shear resistance of the starch paste and lower stability of the hot starch paste. Table 2 shows that the breakdown value of the blends was reduced with the addition of SE-AP, suggesting that the addition of SE-AP can improve the stability of starch paste during wheat flour processing.

The setback value reflects the trends of starch aging. The setback values decreased with the addition of SE-AP (Table 2), indicating that the addition of SE-AP may increase the aging resistance of flour products. SE-AP powder contains a large amount of SDF, which shows strong water absorption. This restricts the available moisture of flour and hinders the expansion of starch in wheat flour so that a large proportion of starch in the blends was inadequately gelatinized, resulting in a decrease in final viscosity and setback (Ism et al. 2007). Similar results were reported by Li et al. (2012) and Ktenioudaki et al. (2013), where the peak viscosity, breakdown, and setback of the blends reduced after adding superfine green tea powder and brewer’s spent grain in wheat flour, respectively.

The results showed that the stability and anti-aging ability of the dough could be slightly enhanced by the addition of SE-AP powder, but the viscosity decreased because of the dilution of starch. This would have an adverse effect on the flour pasting properties of the blend.

Effect of SE-AP on farinographic properties of wheat flour blends

The farinographic properties of SGW/SE-AP and WGW/SE-AP blends are shown in Table 3. With the increased addition of SE-AP powders, the farinographic properties of the two blends changed greatly. As the SE-AP content increased, the water absorption of dough for both blends increased gradually. This was probably because of the increased amounts of SDF, which contains large numbers of hydroxyl groups and can be hydrated by hydrogen bonds. In addition, pentosan from SDF can also absorb moisture from its gel properties and increase the water absorption of dough (Izydorczyk and Biliaderis 1995). Formation time and stabilization time of the dough of the two blends decreased gradually; however, when the added SE-AP powder was higher than 8%, formation time and stabilization time of WGW/SE-AP blends increased slightly. This may be because the added SE-AP diluted the gluten protein of wheat flour early and destroyed the continuity of the dough, resulting in decreased formation time and stabilization time of the two dough blends (Sudha et al. 2007). As the proportion of SE-AP was increased to more than 8%, the water absorption capacity of the dough increased and SDF in the SE-AP powder, having certain gelation characteristics, was able to form a network structure and thereby promote the dough formation time and the stability time. Similar results were obtained by Ahmad et al. (2016).

The degree of softening represents the resistance of the dough to the shear force generated by mechanical agitation, and a higher degree of softening reflects a poorer gluten quality (Tietze et al. 2017). The degree of softening rapidly increased with increased SE-AP addition, although the degree of softening increased more slowly when the added SE-AP powder was less than 10%. The farinograph quality numbers of the two blends presented downward trends (Table 3). Farinograph quality number and degree of softening showed that the SE-AP mixed with SGW or WGW, and diluted the gluten protein of wheat flour, which adversely affected the farinographic properties of the dough. When the SE-AP powder content was less than 10%, this disadvantageous effect was less pronounced.

Effect of SE-AP on texture properties of biscuits

The production of steamed breads requires SGW to maintain their shape and structure; however, the production of biscuits and other cakes can only be shaped by weak gluten flour. The effect of SE-AP on the texture characteristics of biscuits was investigated in WGW blends substituted with SE-AP powder.

Figure 2 shows the texture properties of the biscuits made from WGW/SE-AP blends. When the addition of SE-AP powder was 0–10%, the hardness of the biscuits gradually decreased. With inclusion of SE-AP, a dense network structure was formed between dietary fibre and gluten protein, which increased the retention of water in biscuits and reduced the hardness. The springiness, resilience, and cohesiveness of biscuits also increased significantly as the content of SE-AP increased from 0 to 10%. This is probably caused by the compact structure formed between the void structure of SDF in SE-AP powder and the gluten protein in WGW. When the content of SE-AP powder was less than 10%, the biscuits exhibited better chewiness because of reduced hardness. However, when the content of SE-AP powder exceeded 10%, the chewiness of the biscuits decreased significantly because of diluted gluten protein and decreased adhesiveness of the dough.

Sensory evaluation of biscuits

The effects of SE-AP and WGW incorporation on the sensory parameters of biscuits are shown in Table 4. As the addition of SE-AP powder was increased from 0 to 10%, the appearance, taste, aroma, and other scores gradually increased. The addition of 10% SE-AP powder significantly affected the sensory quality of biscuits. However, when the added SE-AP reached 12–16%, the overall sensory score of the biscuit decreased rapidly. Significant differences were observed in the overall acceptance of biscuits made with lower level of additives up to 10% SE-AP (p < 0.05). Similar results were presented in the earlier studies of Kohajdová et al. (2014) and Sudha et al. (2007). Kohajdová et al. (2014) confirmed that biscuits containing 5% AP did not show a marked change in quality, and Sudha et al. (2007) reported that AP could serve as a good source of polyphenols and dietary fibre. Therefore, the effect of added SE-AP to biscuit was clearly beneficial when compared with untreated samples. The addition of 10% SE-AP in WGW not only increased the content of SDF in biscuits, but also enhanced the processing performance of wheat flour and improved the sensory qualities such as biscuit shape, mouthfeel, aroma, and texture.

Conclusion

Addition of SE-AP powder to wheat flour caused a drop in the sedimentation value of the mixed powder. As the SE-AP powder addition was increased from 0 to 10%, the sedimentation value decreased slowly, but it decreased significantly when the SE-AP powder content exceeded 10%. The stability and anti-aging properties of the flour mixture were improved, but the viscosity was reduced. Because of the increased content of SDF, the farinographic properties and water holding capacity of the blends increased, the formation time and stabilization time of the dough decreased, the degree of softening increased, and the farinograph quality number dropped. The texture characteristics of the blended biscuits changed and the overall acceptability score of the biscuits increased when the SE-AP content was 2–10%. When the SE-AP content was higher than 10%, the overall acceptability of the biscuits declined rapidly. In summary, substitution of WGW with 10% SE-AP powder gave biscuits that were evaluated as the most acceptable. Compared with the control group (0% SE-AP), the sensory acceptability of the mixed powder biscuits was not reduced significantly, while the incorporation of SDF acts as a supplement to improve body health.

References

AACC International (2000) Approved methods of the American Association of cereal chemists, 10th edn. AACC International, St Paul, MN

Ahmad M, Nache M, Waffenschmidt S et al (2016) Characterization of farinographic kneading process for different types of wheat flours using fluorescence spectroscopy and chemometrics. Food Control 66:44–52. https://doi.org/10.1016/j.foodcont.2016.01.029

Aksoylu Z, Özlem Ç, Köse E (2015) Effects of blueberry, grape seed powder and poppy seed incorporation on physicochemical and sensory properties of biscuit. J Food Qual 38(3):164–174. https://doi.org/10.1111/jfq.12133

Anil M (2007) Using of hazelnut testa as a source of dietary fiber in breadmaking. J Food Eng 80(1):61–67. https://doi.org/10.1016/j.jfoodeng.2006.05.003

AOAC (2000) Official methods of analysis. Association of Official Analytical Chemists, Washington, DC

Carson KJ, Collins JL, Penfield MP (1994) Unrefined, dried apple pomace as a potential food ingredient. J Food Sci 59(6):1213–1215. https://doi.org/10.1111/j.1365-2621.1994.tb14679.x

Ćetković G, Čanadanović-Brunet J, Djilas S et al (2008) Assessment of polyphenolic content and in vitro, antiradical characteristics of apple pomace. Food Chem 109(2):340–347. https://doi.org/10.1016/j.foodchem.2007.12.046

Díaz-Calderón P, Macnaughtan B, Hill S et al (2018) Changes in gelatinisation and pasting properties of various starches (wheat, maize and waxy maize) by the addition of bacterial cellulose fibrils. Food Hydrocoll 80(July):274–280

Figuerola F, Hurtado ML, Estevez AM et al (2005) Fibre concentrates from apple pomace and citrus peel as potential fibre sources for food enrichment. Food Chem 91(3):395–401. https://doi.org/10.1016/j.foodchem.2004.04.036

Foschia M, Peressini D, Sensidoni A et al (2013) The effects of dietary fibre addition on the quality of common cereal products. J Cereal Sci 58(2):216–227. https://doi.org/10.1016/j.jcs.2013.05.010

Ism Z, Yamauchi H, Kim SJ et al (2007) RVA study of mixtures of wheat flour and potato starches with different phosphorus contents. Food Chem 102(4):1105–1111. https://doi.org/10.1016/j.foodchem.2006.06.056

Izydorczyk MS, Biliaderis CG (1995) Cereal arabinoxylans: advances in structure and physicochemical properties. Carbohydr Polym 28(1):33–48. https://doi.org/10.1016/0144-8617(95)00077-1

Kaczmarczyk MM, Miller MJ, Freund GG (2012) The health benefits of dietary fiber: beyond the usual suspects of type 2 diabetes mellitus, cardiovascular disease and colon cancer. Metab Clin Exp 61:1058–1066. https://doi.org/10.1016/j.metabol.2012.01.017

Kendall CWC, Esfahani A, Jenkins DJA (2010) The link between dietary fibre and human health. Food Hydrocolloids 24(1):42–48. https://doi.org/10.1016/j.foodhyd.2009.08.002

Kohajdová Z, Karovičová J, Magala M et al (2014) Effect of apple pomace powder addition on farinographic properties of wheat dough and biscuits quality. Chem Pap 68(8):1059–1065. https://doi.org/10.2478/s11696-014-0567-1

Ktenioudaki A, O'Shea N, Gallagher E (2013) Rheological properties of wheat dough supplemented with functional by-products of food processing: Brewer’s spent grain and apple pomace. J Food Eng 116(2):362–368. https://doi.org/10.1016/j.jfoodeng.2012.12.005

Li M, Zhang JH, Zhu KX et al (2012) Effect of superfine green tea powder on the thermodynamic, rheological and fresh noodle making properties of wheat flour. LWT Food Sci Technol 46(1):28. https://doi.org/10.1016/j.lwt.2011.11.005

Li J, Zhang R, Siddhu MA et al (2015) Enhancing methane production of corn stover through a novel way: sequent pretreatment of potassium hydroxide and steam explosion. Bioresour Technol 181:345–350. https://doi.org/10.1016/j.biortech.2015.01.050

Liang X, Ran J, Sun J et al (2017) Steam-explosion-modified optimization of soluble dietary fiber extraction from apple pomace using response surface methodology. CyTA J Food 16(1):20–26. https://doi.org/10.1080/19476337.2017.1333158

Mannuramath M, Yenagi N, Orsat V (2015) Quality evaluation of little millet (Panicum miliare) incorporated functional bread. J Food Sci Technol 52(12):8357–8363. https://doi.org/10.1007/s13197-015-1932-y

Monschein M, Nidetzky B (2016) Effect of pretreatment severity in continuous steam explosion on enzymatic conversion of wheat straw: evidence from kinetic analysis of hydrolysis time courses. Bioresour Technol 200:287–296. https://doi.org/10.1016/j.biortech.2015.10.020

Noor Aziah AA, Mohamad Noor AY, Ho LH (2012) Physicochemical and organoleptic properties of cookies incorporated with legume flour. Int Food Res J 193(6):2661–2668. https://doi.org/10.13140/2.1.4554.8164

Pla MDE, Rojas AM, Gerschenson LN (2011) Effect of butternut (Cucurbita moschata, Duchesne ex Poiret) fibres on bread making, quality and staling. Food Bioprocess Technol 6(3):828–838. https://doi.org/10.1007/s11947-011-0744-y

Soltani M, Hekmat S, Ahmadi L (2017) Microbial and sensory evaluation of probiotic yoghurt supplemented with cereal/pseudo-cereal grains and legumes. Int J Dairy Technol 71:141–148. https://doi.org/10.1111/1471-0307.12389

Steyn L, Meeske R, Cruywagen CW (2017) The effect of dried apple pomace as a replacer for maize in the concentrate for Jersey cows grazing ryegrass pasture on production and rumen metabolism. Anim Feed Sci Technol 234:264–273. https://doi.org/10.1016/j.anifeedsci.2017.10.011

Sudha ML, Baskaran V, Leelavathi K (2007) Apple pomace as a source of dietary fiber and polyphenols and its effect on the rheological characteristics and cake making. Food Chem 104(2):686–692. https://doi.org/10.1016/j.foodchem.2006.12.016

Sudha ML, Dharmesh SM, Pynam H et al (2016) Antioxidant and cyto/DNA protective properties of apple pomace enriched bakery products. J Food Sci Technol 53(4):1–10. https://doi.org/10.1007/s13197-015-2151-2

Tang Y, Chandra RP, Sokhansanj S et al (2018) The role of biomass composition and steam treatment on durability of pellets. Bioenergy Res 11(16):1–10. https://doi.org/10.1007/s12155-018-9900-9

Tietze S, Jekle M, Becker T (2017) Development of wheat dough by means of shearing. J Food Eng 201:1–8. https://doi.org/10.1016/j.jfoodeng.2017.01.001

Wang L, Xu H, Yuan F et al (2015) Preparation and physicochemical properties of soluble dietary fiber from orange peel assisted by steam explosion and dilute acid soaking. Food Chem 185:90–98. https://doi.org/10.1016/j.foodchem.2015.03.112

Acknowledgements

This research was supported by the National Natural Science Foundation of China (No. 31771941), the Agricultural Science and Technology Innovation Program (ASTIP) of the Chinese Academy of Agricultural Sciences (CAAS-ASTIP-2018-ZFRI), the Major Science and Technology Project in Henan (No. 182102110109), and the “Bainong Elite” Innovative Program for University Student (BNYC2017-2-09).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

Xinhong Liang declares that she has no conflict of interest, Longfei Feng declares that he has no conflict of interest, Junjian Ran declares that he has no conflict of interest, Junliang Sun declares that he has no conflict of interest, Zhonggao Jiao declares that he has no conflict of interest, and Benguo Liu declares that she has no conflict of interest.

Human and animal rights

This article does not contain any studies with human participants or animals performed by any of the authors.

Informed consent

Informed consent was obtained from all individual participants included in the study.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Liang, X., Feng, L., Ran, J. et al. Influence of adding steam-exploded apple pomace on wheat flour characteristics and biscuit quality. J Food Sci Technol 57, 3031–3039 (2020). https://doi.org/10.1007/s13197-020-04336-2

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13197-020-04336-2