Abstract

Infrared-hot air method, when properly applied, can be used for achieving a high-quality product. The objective of this study was to determine the rheological properties of cake batters and physico-chemical, textural and sensory properties of sponge cake supplemented with four different levels (control, 5 %, 10 %, and 15 %) of button mushroom powder. The button mushroom slices were dried in an infrared–hot air dryer (250 W and 60 °C). The physical (volume, density, color) and chemical (moisture, protein, fat and ash) attributes were determined in the cakes. Increasing the level of substitution from 5 % to 15 % button mushroom powder significantly (p < 0.05) increased the protein and ash. The apparent viscosity in cake batter, and volume, springiness, and cohesiveness values of baked cakes increased with increasing button mushroom powder levels whereas the density, consistency, hardness, gumminess, chewiness and crumb L, b values of samples showed a reverse trend. Sensory evaluation results indicated that cake with 10 % button mushroom powder was rated the most acceptable.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

The button mushroom is the most widely cultivated and consumed mushroom throughout the world and it contributes about 40 % of the total world production of mushroom (Giri and Prasad, 2007). Drying is one of the important preservation methods employed for storage of mushroom and dried mushrooms are valuable ingredients in a variety of sauces, bread, biscuit and soups (Ibrahium and Hegazy, 2014).

The enrichment of sponge cake with protein may be achieved through the incorporation of rich protein sources. Button mushroom is one of these sources, which have a great potential, due to their high and good quality-protein (Ibrahium and Hegazy, 2014). The effect of partial replacement of wheat flour by different levels (10, 20 and 30 %) of the mixture of mushroom powder and sweet potato flour at equal rates (1:1 w:w) on the chemical and sensory characteristics for produced biscuits was evaluated by Ibrahium and Hegazy (2014). The results revealed that biscuits processed from wheat flour supplemented by 10 % or 20 % of mushroom powder/sweet potato flour mixture exhibited a good sensory properties and better acceptability.

One of the ways to shorten the drying time is to supply heat by infrared radiation. This method of heating is especially suitable to dry thin layers of material with large surface exposed to radiation. Their efficiency is between 80 % and 90 %, the emitted radiation is in narrow wavelength range and they are miniaturized (Sakai and Hanzawa, 1994; Sandu, 1986). It is used for heating and cooking soybeans, cereal grains, cocoa beans and nuts, ready-to-eat products, braising meat and frying (Ratti and Mujumdar, 1995). Drying of seaweed, vegetables, fish flakes and pasta is also done in tunnel infrared dryers (Nowak and Lewicki, 2004; Pan et al., 2008).

Infrared drying was applied before or after freeze-drying of shiitake mushroom to shorten the drying time, to enhance the rehydration, and to better preserve the aroma compounds and color by Wang et al. (2015). The results showed that the combination of freeze-drying (for 4 h) followed by infrared drying saves 48 % time compared to freeze-drying while keeping the product quality at an acceptable level. The application of infrared drying also helps produce a more porous microstructure in dried shiitake mushrooms.

Heat transfer coefficients are high, the process time is short, and the cost of energy is low. Since air is transparent to infrared radiation, the process can be done at ambient air temperature. Equipment can be compact and automated with a high degree of control over process parameters (Nowak and Lewicki, 2004; Salehi and Kashaninejad, 2015a).

The combination of infrared with hot air provides the synergistic effect, resulting in an efficient drying process. Energy and quality aspects were studied during combined far infrared and convective drying of barley (Afzal et al., 1999). A laboratory scale batch dryer was used for this purpose. The total energy required for the combination mode drying reduced by nearly 245 % when compared with hot air drying at 70 °C.

Infrared-hot air method, when properly applied, can be used for achieving a high-quality product. Therefore, the aim of this study was to determine the rheological properties of batters and physico-chemical, textural and sensory properties of sponge cake supplemented with four different levels (control, 5 %, 10 %, and 15 %) of button mushroom powder dried in an infrared–hot air dryer.

Materials and methods

Infrared –hot air drying of button mushroom

Fresh button mushrooms (Agaricus bisporus) were obtained from market and kept in cold storage at 4–5 °C. Slices of button mushroom with 5 mm thickness were prepared with the aid of a steel cutter. They were immediately placed into the dryer. Hence, drying of thin layers seems to be more efficient at far-infrared radiation (FIR, 25–100 μm), while drying of thicker bodies should give better results at near-infrared radiation (NIR, 0.75–3.00 μm) (Nowak and Lewicki, 2004). The button mushroom slices were dried in an infrared –hot air dryer (Infrared radiation lamp (NIR), Philips, Germany) with 250 W power and 60 °C with air at a velocity of 2 m/s. Then the dried samples stored in an air-tight packet till the experiments. The dried samples were milled and passed through a 50 mesh sieve. Then the milled powder was weighed and stored in an air-tight bottle till the experiments.

Sponge cake preparation

The formulae of sponge cakes at four different button mushroom powder levels were shown in Table 1. The ingredients used in the formula of sponge cakes were cake flour, sucrose, sunflower oil, fresh eggs, whey, baking powder, vanilla, xanthan gum, water and nonfat dry milk powder.

Sucrose and sunflower oil were poured into a bowl, and mixed for 4 min. Whole egg was added to the bowl, and then mixed for 2 min. The sifted cake flour, whey, baking powder, vanilla, xanthan gum, water and nonfat dry milk powder was gradually poured into a bowl, and mixed for 4 min. Water was added to the bowl, and then mixed for 1 min (Salehi et al., 2015).

For each cake, 30 g of cake batter was poured into a cake pan and baked at 195 °C for 20 min in a oven toaster (Noble, Model:KT-45XDRC). The cakes were allowed to cool for 30 min, and then were removed from the pans. The cooled cakes were packed in polypropylene bags at room temperature before physico-chemical and sensory evaluation analyses. The test sponge cake samples prepared with 0 % (control), 5 %, 10 %, and 15 % replacement of cake flour with button mushrooms powder.

The rheological properties of cake batters

The viscosity of sponge cake batters was measured using a rotational viscosimeter manufactured by Brookfield Engineering Laboratories (Brookfield, model RVDV- II+ pro, USA). Immediately after mixing, 200 ml of cake batter was poured into a 200 ml beaker and the viscosity was measured. The rheological parameters of cake batters at different shear rate of 1.9 to 76 s−1 were studied using spindle No.S07 at 18 rotations and 25 °C (Salehi and Kashaninejad, 2015b).

Physico-chemical characteristics of cakes

The physico-chemical characteristics of cake including moisture, protein, fat, carbohydrate and ash were measured. Moisture content of the samples was determined in a oven at 105 °C for 4 h (AOAC, method no. 934.06). The nitrogen conversion factor used for crude protein calculation was 6.25. The carbohydrate content (%) was calculated by subtracting the contents of crude protein, fat, ash, and moisture from 100 % of cakes. The proximate compositions of sponge cakes were averaged from four replications. Results were expressed on a wet basis. The volume and density of the sponge cake was determined by the canola displacement method. The empty cake pan was filled with canola. The volume of sponge cake was averaged from four replications.

Color measurement

The crumb colour determinations of cake samples from the midsection of the cakes were measured with a HP Scanner (Hp Scanjet G3110). Since the computer vision system perceived color as RGB signals, which is device-dependent, the taken images were converted into L*a*b* units to ensure color reproducibility. In the L*a*b* space, the color perception is uniform, and therefore, the difference between two colors corresponds approximately to the color difference perceived by the human eye. L* (lightness/darkness that ranges from 0 to 100), a*(redness/greenness that ranges from −120 to 120) and b* (yellowness/blueness that ranges from −120 to 120) were measured (Salehi and Kashaninejad, 2014). In this study, the image analyses of sponge cakes were performed using Image J software version 1.42e, USA.

Textural properties of cakes

The texture profile analysis (TPA) of sponge cake samples (2 × 2 × 2 cm) from the midsection of the cakes were performed using a texture analyzer (TA-XT Plus, Stable Micro Systems Ltd., Surrey, UK) with a 36 mm diameter cylindrical probe, 50 % compressing and a test speed of 1.0 mm s−1. The crust of cake samples was removed in cake texture determination. A double cycle was programmed and the texture profile was determined using Texture Expert 1.05 software (Stable Microsystems). Other parameters were defined as: pre-test speed 2.0 mm s−1, post-test speed 2.0 mm s−1 and trigger force 5 g. The texture parameters recorded were consistency, hardness, cohesiveness, adhesiveness, springiness, resilience, gumminess, and chewiness, and the texture parameter of cake was averaged from 4 replications.

Sensory evaluation

The hedonic test was used to determine the degree of overall liking for the sponge cakes. For this study, trained consumers were recruited from the students, staff and faculty at Gorgan University. All consumers were interested volunteers and informed that they would be evaluating sponge cakes. For the sponge cake manufacturing study, 20 consumers received four samples and were asked to rate them based on degree of liking on a nine-point hedonic scale (1 = dislike extremely, 5 = neither like nor dislike, 9 = like extremely). Samples were placed on plates and identified with random three-digit numbers. Panelists evaluated the samples in a testing area and were instructed to rinse their mouths with water between samples to minimize any residual effect.

Statistical analysis

Each measurement was conducted in quadruplicate, except for the sensory evaluation (n = 20). The experimental data were subjected to an analysis of variance (ANOVA) for a completely random design using a statistical analysis system (SAS 9.1 Institute, Inc.). Duncan’s multiple range tests were used to determine the difference among means at the level of 0.05.

Results and discussion

The rheological properties of cake batters

A good cake batter must retain sufficient viscosity to prevent the incorporated air bubbles from rising to the surface and being lost during initial heating (Lu et al., 2010). Shear rate dependency of the apparent viscosity of sponge cake batters is shown in Fig. 1. It was found that the apparent viscosity of cake batters decreased as the shear rate increased (shear thinning or pseudoplastic behavior). The apparent viscosity of cake batters clearly decreased from 72.8 to 13.7 Pa.s with increasing shear rate from 1.9 to 76 s−1 (10 % button mushroom powder).

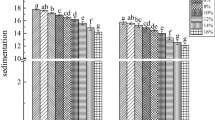

In general, the addition of mushroom powder to the cake formula led to increase in the viscosity of cake batters (Fig. 2). The batter with 15 % mushroom powder exhibited the highest viscosity among all cake batters. In the present study, the apparent viscosity of cake batters varied from 12.55 to 18.20 Pa.s (shear rate = 60 s−1) depending on the button mushroom powder level. De Fouw et al. (1982) reported an increase in batter viscosity when 15 % flour was replaced with either unheated or roasted navy bean hulls. Masoodi et al. (2002) also reported that batter viscosity increased with increasing apple pomace level and decreasing particle size.

Physico-chemical characteristics of cakes

Changes in cake characteristics with added button mushroom powder are shown in Table 2. The fat contents of cake were not significantly different. The protein and ash content of sponge cake increased significantly with the increasing button mushroom powder level.

A significant increase in cake volume was noted with an increase in the button mushroom powder level. The control sample had an average cake volume of 66.68 ml, increasing to 67.20, 67.96, and 69.65 ml for 5, 10, and 15 %, respectively. Masoodi et al. (2002) reported a cake volume decreased with increasing apple pomace levels.

Color measurement

The results of color measurement of sponge cake supplemented with button mushroom powder dried in an infrared–hot air dryer are presented in table 3. The crumb colour of samples was affected by the replacement of cake flour with button mushroom powder. In general, as button mushroom powder level increased, the crumb colour became darker. The control sponge cake exhibited a light color, with L*, a* and b* equal to 88.78, −2.60 and 33.47, respectively. The crumb of the control sample was lighter and more yellow than any of the other cakes. For crumb colour, as the level of button mushroom powder increased, the L and b values decreased but the a value increased, indicating that a darker, redder, and less yellow crumb was obtained as a result of button mushroom powder substitution.

Textural properties of cakes

In texture profile analysis, the hardness of samples measured showed that the cake became softer with increasing levels of button mushroom powder (Table 4). The firmness of cakes was directly related to the density of the tested materials (indirectly to its volume). The weight of samples was not significantly different among any of the cakes in this study. Thus, the decrease in hardness was mainly related to the volume of these cakes. The area under the curve up to the target deformation was taken as a measurement of consistency. TPA results showed a decrease in the cake consistency with an increased level of button mushroom powder. The consistency values decreased from 4578.83 to 1797.03 g.s with increasing button mushroom powder levels from 0 to 15 %.

Cohesiveness quantifies the internal resistance of food structure. Briefly, cohesiveness is the ability of a material to stick to itself. TPA results showed an increase in the cake cohesiveness with an increased level of button mushroom powder.

Springiness measures elasticity by determining the extent of recovery between the first and second compression. Resilience is the ratio of recoverable energy as the first compression is relieved. TPA results showed not significantly different in the cake springiness and resilience with increased level of button mushroom powder.

Gumminess is determined by hardness multiplied by cohesiveness. Chewiness is determined by gumminess multiplied by springiness, and represents the amount of energy needed to disintegrate a food for swallowing. TPA results showed a decrease in the cake gumminess and chewiness with increased level of button mushroom powder. Overall, as the percentage of button mushroom powder increased, consistency, hardness, gumminess, and chewiness decreased whereas cohesiveness increased.

Sensory evaluation

For measuring product liking and preference, the hedonic scale is a unique scale, providing both reliable and valid results (Stone et al., 2012). Statistically significant differences evaluated by the trained consumers were found in the crumb colour, flavour, texture and overall liking scores among the control, 5, 10 and 15 % (Table 5). However, the sensory characteristics liking scores of 15 % were lower than those of the other cakes and the 15 % was slightly darker. On a nine-point hedonic scale, the sensory results of the control, 5 and 10 % were in the range of 5.8–7.3, indicating that these three cakes were moderately acceptable. The sensory characteristics liking results pointed out that a partial replacement of cake flour with up to 10 % button mushroom powder in sponge cakes is satisfactory.

Conclusions

Bakery products are consumed all over the world. A successful and novel formulation of sponge cake production with button mushroom was developed. Button mushroom is a good source of protein and minerals. Increasing the level of substitution from 5 % to 15 % button mushroom powder increased the protein and ash. The apparent viscosity in cake batter, and volume, springiness, and cohesiveness values of baked cakes increased with increasing button mushroom powder levels. For crumb colour, as the level of button mushroom powder increased, the L and b values decreased but the a value increased, indicating that a darker, redder, and less yellow crumb was obtained as a result of button mushroom powder substitution. The sensory characteristics liking results pointed out that a partial replacement of cake flour with up to 10 % button mushroom powder in sponge cakes is satisfactory.

References

Afzal T, Abe T, Hikida Y (1999) Energy and quality aspects during combined FIR-convection drying of barley. J Food Eng 42(4):177–182

De Fouw C, Zabik M, Uebersa M, Aguilera J, Lusas E (1982) Use of unheated and heat-treated navy bean hulls as a source of dietary fiber in spice flavored layer cakes. Cereal Chem 59:229–230

Giri S, Prasad S (2007) Drying kinetics and rehydration characteristics of microwave-vacuum and convective hot-air dried mushrooms. J Food Eng 78(2):512–521

Ibrahium M, Hegazy A (2014) Effect of replacement of wheat flour with mushroom powder and sweet potato flour on nutritional composition and sensory characteristics of biscuits. Curr Sci Int 3(1):26–33

Lu T-M, Lee C-C, Mau J-L, Lin S-D (2010) Quality and antioxidant property of green tea sponge cake. Food Chem 119(3):1090–1095

Masoodi F, Sharma B, Chauhan G (2002) Use of apple pomace as a source of dietary fiber in cakes. Plant Foods Hum Nutr 57(2):121–128

Nowak D, Lewicki PP (2004) Infrared drying of apple slices. Innov Food Sci & Emerg Technol 5(3):353–360

Pan Z, Shih C, McHugh TH, Hirschberg E (2008) Study of banana dehydration using sequential infrared radiation heating and freeze-drying. LWT-Food Sci and Technol 41(10):1944–1951

Ratti C, Mujumdar A (1995) Infrared drying. In: Mujumdar AS (ed) Handbook of industrial drying, vol 1, Second edn. Marcel Dekker Inc, NY, pp. 567–588

Sakai N, Hanzawa T (1994) Applications and advances in far-infrared heating in Japan. Trends Food Sci Technol 5(11):357–362

Salehi F, Kashaninejad M (2014) Effect of different drying methods on rheological and textural properties of balangu seed gum. Dry Technol 32(6):720–727

Salehi F, Kashaninejad M (2015a) Effect of drying methods on rheological and textural properties, and color changes of wild sage seed gum. J Food Sci Technol 52(11):7361–7368

Salehi F, Kashaninejad M (2015b) Static rheological study of Ocimum basilicum seed gum. Int J Food Eng 11(1):97–103

Salehi, F., Kashaninejad, M., Akbari, E., Sobhani, S.M., Asadi, F., (2015). Potential of sponge cake making using infrared–hot air dried carrot. J Texture Stud

Sandu C (1986) Infrared radiative drying in food engineering: a process analysis. Biotechnol Prog 2(3):109–119

Stone H, Bleibaum R, Thomas HA (2012) Sensory evaluation practices, 4 th edn. Academic press, New York, NY

Wang H-c, Zhang M, Adhikari B (2015) Drying of shiitake mushroom by combining freeze-drying and mid-infrared radiation. Food and Bioprod Process 94:507–517

Acknowledgments

This research was supported by Iran National Science Foundation (INSF) through a Grant No. 92044245 to Mahdi Kashaninejad. The authors would like to thank gratefully Iran National Science Foundation, INSF, for financial support of the research project.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Salehi, F., Kashaninejad, M., Asadi, F. et al. Improvement of quality attributes of sponge cake using infrared dried button mushroom. J Food Sci Technol 53, 1418–1423 (2016). https://doi.org/10.1007/s13197-015-2165-9

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13197-015-2165-9