Abstract

Physicochemical, antioxidant, phenolic profile and muffin-making properties of white, yellow and purple corn accessions were evaluated. HPLC analysis revealed the presence of ferulic acid, quercetin, sinapic acid, gallic acid and protocatechuic acid in different corn accessions. Ferulic acid was the major phenolic acid present in all accessions. Total phenolic content (TPC), DPPH and ABTS inhibition ranged from 903 to 1843 µg GAE/g, 0.73–0.89 and 3.81–4.92 µM trolox/mg, respectively. Purple accessions had higher TPC than yellow and white accessions. Pasting profiles of different accessions revealed high thermal stability indicated by low breakdown viscosity. Muffin-making properties were determined as batter rheology and muffin specific volume, texture and sensory analysis. Storage modulus (G′) and loss modulus (G″) of batters for white colored exhibited the highest while yellow colored had the lowest value. Firmness and TPC of muffins ranged from 3.1 to 5.9 N and 811–1406 µg GAE/g, respectively. Muffin cohesiveness and chewiness were correlated positively, whereas firmness was negatively related to paste viscosities. Antioxidant activity was correlated to phenolic content of the muffins. Sensory analysis revealed that muffins prepared from yellow corn accession (IC447648) were highly acceptable, while those made from purple corn (IC447644) were not liked much.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

The outcomes of celiac disease or gluten intolerance increased several fold globally (Shevkani et al. 2015). The inflammatory response of gluten protein found in cereals such as wheat, rye and barley causes swelling and damage of mucosal layer of small intestine thus lead to the chronic abdominal pain and impaired digestion of food and poor absorption of nutrients, minerals and vitamins. The gluten intolerant patients are advised to consume gluten free diet for the entire life, the only available treatment known at present. The elasticity, viscosity and other textural properties of gluten make them suitable for wider applications in baking industry. The lack of visco-elasticity makes commercial available gluten-free products inferior with textural and sensory attributes (Sakač et al. 2011).

Muffins are popularly consumed breakfast as well as evening snack foods, mainly consist refined wheat flour, milk, eggs, sugar and fat or oil. Non-wheat flours are generally thought not to be useful in the preparation of this product due to the poor viscoelastic networks and gas holding capacity of non-gluten flour that resulted in production of muffins with weak textural and sensory parameters such as low sponginess, weak expansion ratio and high levels of hardness (Gallagher et al. 2004). Shevkani et al. (2015) reported that the lack of polymeric network in gluten free flours appeared to be the most challenging technological obstacles in making high quality gluten free muffins.

Corn is called as the queen of cereals as its genetic yield potential is the highest among different cereals. It is at present the 3rd most cultivated food cereal in the world followed by wheat and rice (Wang et al. 2008). The consumption of corn in its various forms stands third position after rice and wheat. The color of corn grains ranges from yellow, white and red to purple (Singh et al. 2011). Del Pozo-Insfran et al. (2006) reported that the nutritional value of pigmented corn (having high amounts of anthocyanins as well as carotenoids) having floury endosperm was better compared to most of the dent counterparts.

Although starch is the major component of corn grains, yet these contain zein protein. Unlike wheat gluten, it is not able to form viscoelastic networks upon hydration, although it can be made functional at higher temperatures (Bugusu et al. 2001). It can therefore be desirable to develop functional gluten-free products containing corn. Erickson et al. (2012) reported that zein-based doughs had properties similar to wheat dough. Moreover, these authors reported that presence of zein fibrous β-sheet-rich protein networks improved the quality of gluten-free dough. Sanchez et al. (2004) made gluten-free formulations in case of bread utilizing corn and rice flours along with hydrocolloids (as binding agents) and proteins. Recently, Herranz et al. (2017) prepared good quality batters using chickpea flour, corn starch and egg white. In spite of this, in India eggless baked products can be an important prospect where significant proportion of the population is vegetarian (Shevkani et al. 2015). However, the authors did not find reports documenting the utilisation of corn flours in the production of eggless gluten-free muffins without any gum addition. Therefore, the objective of this work was to study the suitability of different Indian corn accessions (varying in color) in the making of eggless gluten-free muffins. These muffins were examined for the physicochemical, antioxidant, texture and sensory properties.

Materials and methods

Materials

Nine different colored corn accessions viz. yellow (IC447648, IC447641, IC361709), white (IC361712, IC447509, IC447328) and purple (IC447643, IC447647, IC447644) were procured from National Bureau of Plant Genetic Resources (NBPGR), New Delhi (India). Corn flour obtained after milling different corn accessions, soya protein isolate (90% protein content), dairy whitener (EveryDay, Nestle India Ltd., Moga, India), sugar (ground), refined sunflower oil, baking powder (NaHCO3), glycerol monostearate (Loba chemicals, Mumbai, India) and salt (NaCl) were used in the muffins preparation. Gallic acid, Folin–Ciocalteu reagent, quercetin, sodium nitrite, aluminum chloride, DPPH (2,2-diphenyl-1-picrylhydrazyl), ABTS (2,20-azinobis3-ethylbenzothiazoline- 6-sulfonic acid) and Trolox (6-hydroxy-2,5,7,8-tetramethylchroman-2-carboxylic acid) were of molecular biology grade purchased from Sigma–Aldrich Company Ltd (St Louis, USA). Analytical grade potassium persulphate, sodium hydroxide pellets, sodium carbonate, methanol and hexane were purchased from Sisco research laboratories Ltd. (India).

Physicochemical and pasting properties of flours

Flours from different corn accessions were estimated for moisture, ash, fat and protein content using AOAC standard methods (1990). Color parameters (L*, a*, b*) of grains and their flours were determined using an Ultra Scan VIS Hunter Lab (Hunter Assoc. Laboratory Inc., Reston, Va., U.S.A.) as described earlier (Shevkani et al. 2014). Pasting properties were determined using the methodology of Thakur et al. (2015) using Rapid Visco Analyzer (RVA-4, Newport Scientific, Warriewood, Australia). Pasting temperature (PT), peak viscosity (PV), final viscosity (FV), breakdown viscosity (BV), and setback viscosity (SB) were recorded.

Total phenolic content (TPC) and antioxidant activity of flours

TPC was determined using Singleton et al. (1999) with slight modifications. The results were reported as μg GAE (gallic acid equivalents)/g. Total antioxidant activity was determined using DPPH (2,2-diphenyl-1-picrylhydrazyl; Sigma-Aldrich, St Louis, USA) and ABTS (2,2′-azinobis3 etheylbenzothiazoline-6-sulfonic acid; Sigma-Aldrich, St Louis, USA) free radical scavenging assays using the methodology of Singh et al. (2015). The antioxidant capacity was expressed as μM trolox/mg.

HPLC analysis of flours

Corn flour was defatted twice with hexane, dried at 30 °C and extracted twice with 80% methanol at a 1:5 ratio (w/v) for 2 h on an orbital shaker at 25 °C. The mixture was centrifuged at 5000 g for 10 min. The supernatant was passed through a 0.2 µm filter (Pall Corporation, New York, USA) and directly used for HPLC analysis.

HPLC analysis was carried out on a HPLC system (Infinity 1260, Agilent Technologies, Santa Clara, CA, USA) equipped with diode-array detector. Detection of polyphenols was conducted at 280 nm by using a C-18 column (250 mm × 4.6 mm, 5 µm particle size; Enable G, Spinco Biotech Pvt. Ltd., Chennai, India) at running temperature of 35 °C with 10 µL injection volume. The flow rate was kept constant at 0.6 mL/min. Mobile phase A was mixture of 0.1% acetic acid with ultrapure water, whereas the mobile phase B was a mixture of 0.1% acetic acid and methanol. The gradient programme was as follows: 0–5 min, 5% B; 5–10 min, 10% B; 10–25 min, 20% B; 25–35 min, 23% B; 35–45 min, 28% B; 45–60 min, 35% B; 60–75 min, 50% B; 75–80 min, 55% B; 80–85 min, 75% B; 85–90 min, 35% B; 90–95 min, 5% B. The peaks of samples were identified by comparing the corresponding retention times with those of the standards and quantified by standard curves between peak area and concentration of standards.

Batter and muffin preparation

The batter of muffins was prepared as described by Shevkani et al. (2015). Batter (35 g) was poured in oiled aluminium muffin cups and kept at 170 °C for 22 min in a preheated oven (National Manufacturing Company, Lincoln, NE, USA). The muffins after being removed from the oven were allowed to cool at room temperature (for about 1 h) and were sealed in air tight PET (polyethylene terephthalate) jars and stored at room temperature for 24 h for further analysis.

Dynamic oscillatory rheology of the muffin batters

Dynamic viscoelastic behaviour of batter made for muffins preparation was studied using a dynamic rheometer (Haake RS 6000; Thermo Electron, Karlsruhe, Germany) equipped with parallel plate geometry (35 mm diameter). The rheological properties of muffin batters were determined using the methodology of Singh et al. (2015). The values for storage modulus (G′) and loss modulus (G″) were recorded. G′, G″ and tan δ (G″/G′), were recorded at a fixed frequency of 1 Hz and stress of 0.3 Pa, respectively (these values were within LVR).

Muffin characteristics

Muffin volume, height, texture and color of crust and crumb were determined after 24 h from baking using the method described by Shevkani and Singh (2014). Water activity of the crumb from the centre of the muffin was determined using Aqua Lab (Decagon Devices, Pullman, WA, USA). Total phenolic content and antioxidant activity of muffins was also estimated as described previously in “Total phenolic content (TPC) and antioxidant activity of flours” section. Color difference in L*, a* and b* values between a sample and a reference were evaluated. A positive ∆L* value indicates that sample is more bright than the reference. Positive ∆a* or positive ∆b* values indicates the sample is more red or more yellow than the reference, respectively. The color difference between corn grains and muffins (crust and crumb) as well as corn flour and muffins (crust and crumb) was calculated. ∆E was determined based on ∆L*, ∆a* and ∆b* values, between corn grains and muffins (crust and crumb) as well as corn flour and muffins (crust and crumb) (Good 2002). Sensory evaluation was done according to the methodology of Singh et al. (2016). The panellists evaluated randomly presented muffins for appearance, taste, texture, color and overall acceptability using a 9-point hedonic scale.

Statistical analysis

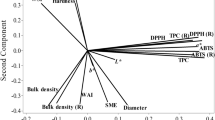

This data was subjected to analysis of variance (ANOVA) and Principal component analysis (PCA) using Minitab Statistical software (State College, PA, USA). PCA loading plot (Supplementary Figure S1 a) provides an overview of the relationships between the various studied parameters.

Results and discussions

Physicochemical characteristics of grains and flours

Various corn accessions showed significant differences in grain and flour color characteristics (Fig. 1). Grains from IC447648, IC447641 and IC361709 were yellow, IC361712, IC447509 and IC447328 were white and IC447643, IC447647 and IC447644 were brownish-purple. The ANOVA showed significant difference in L*, a* and b* values of grains and flours due to both accessions and color while the differences were more pronounced due to accessions (Supplementary Table S1). The color values of flours from different corn accessions are shown in Supplementary Table S2. IC447647 purple corn showed the lowest and IC361712 white corn showed the highest L* value. A higher L* value of grit and flour was reported earlier by Thakur et al. (2015). IC447509 showed a negative value of a* indicating a slight green ting. IC447641 yellow corn showed the highest b* value, while IC361712 white corn showed the lowest. Sandhu et al. (2007) reported the highest b* value for flour, which might be due to the presence of higher amounts of carotenoids. Similar results have been reported previously for different fractions obtained from dry milling of corn (Shevkani et al. 2014).

The results of ANOVA showed a significant difference in fat, ash, moisture and protein content (Supplementary Table S1). The differences were mainly due to the accessions than color, it is inferred that there were inter as well as intra-varietal differences. The moisture content of flour from different accessions was within the safe storage limit which is recommended for the long term storage and to avoid insect infestation and microbial growth (Adair et al. 1973) and also affect the quality and palatability of grains (Oko and Onyekwere 2010). IC447644 purple corn showed the lowest and IC447648 white corn showed the highest moisture content (Table 1). Ash content gives an idea to determine the level of essential minerals present in the food (Edeogu et al 2007). IC447328 white corn showed the lowest, while IC447509 white corn showed the highest ash content (Table 1). IC447644 purple corn had the highest protein content, while the lowest was observed for Yellow corn (IC361709 and IC447641). Fat content was the highest for IC447648 yellow corn while IC447643 purple corn showed the lowest value. Shevkani et al. (2014) reported similar results for different corn fractions. PCA showed a positive relation between ash and fat content, indicating that the accessions with higher amount of lipids also had high content of inorganic matter (Supplementary Figure S1 a).

Pasting properties of flours

Pasting curves of flours from different accessions are shown in Supplementary Figure S2 (b). During heating, the gelatinization of starch granules occurred in which these underwent swelling, leading to the disruption of crystalline structure and leaching of amylose. PT, indicating the minimum temperature required for cooking of flours. This was the highest for IC447648 yellow corn, while the lowest was observed for IC447641 yellow corn (Table 2). PV was the viscosity when the rate of starch granule swelling was equal to the rate of their breakdown (Crosbie and Ross 2007). The highest value of PV was observed for IC361712 white corn, while the lowest value for IC361709 yellow corn (Table 2). BV indicating the stability of starch granules at high temperature and shear was observed for five accessions (IC447641 yellow corn, IC361709 yellow corn, IC361712 white corn, IC447643 purple corn, and IC447644 purple corn) only. SV, indicating the degree of retrogradation in the starch pastes during cooling. The lowest value of SV was observed for IC361709 yellow corn, while the highest was for IC447328 white corn (Table 2). Low SV values indicated lower tendency of starch pastes to retrograde. PCA revealed that PT showed a positive relation with fat and ash content (Supplementary Figure S1 a). Shevkani et al. (2014) reported that lipids may increase the integrity of starch granules which delayed the initiation of gelatinization, thus increased PT of corn fractions. Moreover, positive relations were observed amongst different pasting parameters (PV, SV and FV). Higher BV, SV and FV have been reported previously for corn starches with high PV (Singh et al. 2014).

Total phenolic content and antioxidant activity of flours

The results of ANOVA showed significant differences in TPC, DPPH inhibition and ABTS inhibition due to accessions and color; however, accessions had a greater effect than color (Supplementary Table S1). The highest value of TPC was observed for IC447643 purple corn, while the lowest was observed for IC447509 white corn (Table 1). Adom and Liu (2002) reported higher TPC for corn than wheat and rice. Purple corn had a high TPC probably due to the high amount of anthocyanins (Singh et al. 2014). PCA revealed that TPC related positively to a* and b* values but negatively to L* value (Supplementary Figure S1 a), suggesting that dark colored flours had higher content of phenolic compounds as compared to the lighter ones.

IC447328 white corn showed the highest DPPH inhibition, while IC447648 yellow corn showed the lowest. IC447641 yellow corn showed the highest ABTS inhibition, while IC361709 yellow corn showed the lowest (Table 1). Adom et al. (2005) reported a higher antioxidant capacity in corn as compared to oat, rice and wheat. The higher values of DPPH and ABTS inhibition for IC447328 white corn and IC447641 yellow corn might be due to the presence of higher amounts of lutein and zeaxanthin than other accessions (de la Parra et al. 2007). Moreover, it was interesting to note that a negative relation between DPPH and ABTS values for flours (Supplementary Figure S1 a).

HPLC analysis of flours

HPLC chromatograms of flours analyzed for polyphenols are shown in Fig. 2. HPLC analysis showed the presence of quercetin, ferulic acid, sinapic acid and protocatechuic acid in the range of 1066–1894, 1860–6275, 1466–1532, and 1471–1507 mg/100 g, respectively (Table 3). Ramos-Escudero et al. (2012) also previously identified these phenolic compounds in corn. Ferulic acid was the major phenolic acid present in all the accessions. López et al. (2004) also reported that ferulic acid was present in eighteen stains of mexican corn. IC447648 yellow corn showed the highest concentration of ferulic acid, whereas IC447643 purple corn showed the lowest. The highest content of quercetin was reported for IC447648 yellow corn, while the lowest was for IC361712 yellow corn and was not detected in purple accessions. Moreover, gallic acid was present in negligible amounts in IC447648, IC447641, IC361709 and IC447328 accessions.

Dynamic rheology of muffin batters

A significant variation in G′ and G″ of batter from different colored corn accessions was observed and more pronounced among accessions (Supplementary Table S1). G′ and G″ of batters prepared from flours of different corn accessions are given in (Supplementary Figure S1 c). All batters showed a predominance of elastic behaviour with G′ was higher than G″ which has been reported earlier by Matos et al. (2014) and Shevkani et al. (2015) for gluten-free muffin batters. Amongst different accessions, white colored IC447328 exhibited the highest G′ and G″, while yellow colored IC447647 had the lowest values for same. Rheological properties of batters influenced the quality of gluten-free muffins, as the batters must be sufficiently viscoelastic to trap gas bubbles during mixing and has the capacity to retain during baking (Shevkani and Singh 2014). The amount of proteins in the batter has been reported to influence the viscoelasticity as these bind/absorb water which reduced the availability of free water and facilitated the movement of particles in the batter (Shevkani et al. 2015).

Appearance and color

Analysis of variance showed significant difference in color characteristics of muffins due to both corn accessions and color (Supplementary Table S1). L*, a* and b* values of muffins prepared from different corn accessions are given in Table 2. IC447648 (yellow corn), IC361712 (white corn) and IC447643 (purple corn) resulted into muffins with the highest L* value for crust and crumb among different colored accessions, respectively. IC447648 (yellow corn), IC361712 and IC447328 (white corn) and IC447643 and IC447644 (purple corn) showed the highest value of a* for crust and crumb amongst accessions. IC447648 (yellow corn) showed the highest values of b* for crust and crumb amongst the yellow accessions. While corn accessions (IC361712 and IC447328) showed the highest values of b* for crust and crumb amongst white accessions. IC447643 (purple corn) showed the highest b* values for crust and crumb amongst purple accessions. The exposure of high temperatures during the baking process caused the development of color of the crust, final texture and flavour of muffins mainly due to caramelization and Mailliard reactions (Singh et al. 2015). L* values of muffin crusts and crumbs were positively related with chewiness, cohesiveness and aw, while negatively related with firmness and specific volume (Supplementary Figure S1 a).

The color difference between corn flours and muffins (crust and crumb) are shown in Supplementary Table S1 (a) and (b). IC447648 yellow corn, IC447641 yellow corn, IC447509 (white corn), IC447328 (white corn), IC447644 (purple corn) showed positive ∆L* value and IC361709 (yellow corn), IC361712 (white corn), IC447643 (purple corn), IC447647 (purple corn) showed negative ∆L* value for crust respectively, while crumb of various accessions showed a negative ∆L* value except IC447509 (white corn) and IC447644 (purple corn). IC447648 (yellow corn), IC447641 (yellow corn), IC361709 (yellow corn), IC447647 (purple corn), IC447644 (purple corn) showed positive ∆a* value and IC361712 (white corn), IC447509 (white corn), IC447328 (white corn), IC447643 (purple corn) showed negative ∆a* value for crust, respectively but in case of crumb all accessions showed a positive ∆a* value. All accessions showed a negative ∆b* value for crust and crumb with reference to corn grains. Similarly, all accessions showed a positive ∆L* value and negative ∆a* and ∆b* value for both crusts as well as crumbs. Total color difference (∆E) of muffins (crust and crumb) with reference to grains and flour was significantly different in both cases (Supplementary Table S2 and S3). Higher color difference may be attributed to difference in grain milling resulted into higher amount of endosperm which further enhanced the color of muffins during baking. ∆E was significantly higher for corn flour and muffins (crust and crumb) than that from corn grains and muffins (crust and crumb).

Specific volume and height

A significant variation in specific volume and height of muffins was observed due to accessions as well as color (Supplementary Table S1). Specific volume of baked products is an important quality criterion as it provides quantitative measurements about the performance of baking (Tronsmo et al. 2003). Yellow corn accessions viz. IC447648 and IC44764 showed the highest specific volume and height, while the lowest was observed for IC361712 (white corn) and IC447648 (yellow corn) (Table 4). Singh et al. (2016) reported volume of muffins prepared from wheat varieties in the range 52.00–71.50 ml, many factors such as the mixing and homogenisation time, batter’s rheological properties and the level of air incorporation influences volume and height of the muffins. Higher viscosities improved both cake volume and height (Baixauli et al. 2008).

Total phenolic content and antioxidant activity

The results of ANOVA showed a significant difference in TPC and DPPH inhibition of muffins due to accessions and color (Supplementary Table S1). TPC values of muffins prepared from different accessions of corn are shown in Table 4. Muffins made with IC447648 (yellow corn), IC447328 (white corn) and IC447643 (purple corn) showed the highest TPC amongst yellow, white and purple type accessions, respectively. Soong et al. (2014) reported TPC of 1454 µg GAE/g for corn muffins.

IC361709 (yellow corn), IC447328 (white corn) and IC447644 (purple corn) showed the highest DPPH inhibition amongst yellow, white and purple accessions. Meyer et al. (1998) and Stintzing et al. (2002) explained the anthocyanins present in the pigmented corns were responsible for differences in antioxidant capacity between white and blue accessions, while concentration of specific anthocyanin derivative was attributed to differences between blue genotypes. IC447648 (yellow corn), IC447328 (white corn) and IC447643 (purple corn) showed the highest ABTS inhibition amongst yellow, white and purple type accessions. These values were significantly lower than those reported for corn muffins (Soong et al. 2014). A positive relation between DPPH and ABTS inhibition for muffins was observed and the same trend was also noticed between TPC and antioxidant activities of the muffins (Supplementary Figure S1 a).

Water activity

Water activity (aw) of the muffins differed significantly due to both accessions and color (Supplementary Table 1). Muffins from yellow accessions generally had similar values of aw (Table 3). Amongst white and purple accessions IC361712 (white corn) and IC447643 (purple corn) showed the highest values of aw, respectively. A negative relation was observed between TPC and water activity (aw) of muffins (Supplementary Figure S1 a). Lower values of aw are generally desirable as it leads to increase in the shelf life of the product.

Textural properties

Textural characteristics are important parameters for deciding consumer acceptance of a product. These characteristics for gluten-free muffins prepared from different accessions of corn are presented in (Supplementary Table S5). ANOVA revealed that textural characteristics of muffins differed significantly with both accessions and color (Supplementary Table S1). Firmness was defined as the highest force required for compressing the muffin crumb. IC447648 (yellow corn), IC361712 (white corn) and IC447643 (purple corn) showed the highest values amongst yellow, white and purple accessions, respectively. Singh et al. (2016) reported that firmness of wheat muffins varied between 34.00 and 107.00 N. Cohesiveness determined the ability of a material to stick to itself and the internal resistance of food structure (Lu et al. 2010). IC447648 (yellow corn), IC361712 (white corn) and IC447647 (purple corn) showed the highest values of cohesiveness amongst the yellow, white and purple accessions, respectively. Springiness was measured as the extent of recovery between the first and second compression and is a desirable muffin property related with fresh, aerated and elastic product (Shevkani and Singh 2014). IC447641 (yellow corn) and IC361709 (yellow corn) showed similar values amongst yellow accessions, while IC361712 (white corn) and IC447647 (purple corn) showed the highest values amongst white and purple accessions, respectively. IC361712 (white corn) showed the highest value of chewiness, while IC447641 (yellow corn) showed the lowest value amongst yellow, white and purple accessions, respectively. PCA revealed that chewiness, gumminess and cohesiveness were negatively related with the hardness, total phenolic content, antioxidant activity and tan delta (Supplementary Figure S1 a).

Sensory analysis

ANOVA showed a highly significant difference in sensory characteristics due to accessions and color (Supplementary Table S1). Sensory characteristics of GF muffins are shown in (Supplementary Table S6). IC447648 (yellow corn), IC447328 (white corn) and IC447643 (purple corn) showed highest value of appearance, taste, color and overall acceptability amongst yellow, white and purple accessions, respectively. IC447641 (yellow corn), IC361712 (white corn) and IC447647 (purple corn) showed highest value of texture amongst all accessions. Muffins from yellow accessions showed high scores for appearance, taste and color, whereas those prepared with purple accessions scored the lowest (Supplementary Table S6). However, the muffins made from different accessions showed statistically similar scores for texture. The results indicated that muffins from yellow corn accession IC447648 (yellow corn) were the most acceptable.

Conclusion

This study demonstrated the potential of using corn flours from different accessions in designing of gluten-free eggless muffins without extra addition of gums. The study showed flours from different corn accessions differed significantly for physicochemical, antioxidant, pasting and good quality gluten-free eggless muffins with good sensory characteristics muffin-making properties. Sinapic acid, quercetin, ferulic acid, protocatechuic acid and gallic acid were present in different accessions in varying concentration. Further, purple corn accessions had higher content of polyphenols and showed higher values of antioxidant activities than white and yellow accessions. Muffins made with IC447648 yellow corn accession were the most acceptable and had the high amounts of phenolic compounds as well as antioxidant activity. Future studies can be framed for determining and increasing the shelf lives of these muffins. It would also be advantageous to conduct a larger sensory study for generating results that are more statistically viable. Additionally, studies on utilising corn varieties or accessions in gluten-free baked products might gain momentum with this study as the designing process of these muffins is direct as well as simple. Moreover, with the increase in incidences of egg allergies around the world, these eggless muffins might also be helpful.

References

Adair CR, Bollich CN, Bowman DH, Joson NE, Johnston TH, Webb BD, Atkins JG (1973) Rice breeding and testing method in the United States. In: Rice in the United States: varieties and production. Department of Agriculture of the United States, pp 22–27

Adom KK, Liu RH (2002) Antioxidant activity of grains. J Agric Food Chem 50:6182–6187

Adom KK, Sorrells ME, Liu RH (2005) Phytochemicals and antioxidant activity of milled fractions of different wheat varieties. J Agric Food Chem 53:2297–2306

AOAC (1990) Official methods of analysis, 15th edn. Association of Official Analytical Chemists, Washington, DC

Baixauli R, Sanz T, Salvador A, Fiszman SM (2008) Muffins with resistant starch: baking performance in relation to the rheological properties of the batter. J Cereal Sci 47:502–509

Bugusu BA, Campanella O, Hamaker BR (2001) Improvement of sorghum-wheat composite dough rheological properties and breadmaking quality through zein addition 1. Cereal Chem 78:31–35

Crosbie GB, Ross AS (2007) The RVA handbook. American Association of Cereal Chemists, International Press, Boston

de la Parra C, Serna Saldivar SO, Liu RH (2007) Effect of processing on the phytochemical profiles and antioxidant activity of corn for production of masa, tortillas, and tortilla chips. J Agric Food Chem 55:4177–4183

Del Pozo-Insfran D, Brenes CH, Saldivar SOS, Talcott ST (2006) Polyphenolic and antioxidant content of white and blue corn (Zea mays L.) products. Food Res Int 39:696–703

Edeogu CO, Ezeonu FC, Okaka ANC, Ekuma CE, Elom SO (2007) Proximate composition of staple food crops in Ebonyi State (South Eastern Nigeria). Int J Biotechnol Biochem 3(1):1–8

Erickson DP, Campanella OH, Hamaker BR (2012) Functionalizing maize zein in viscoelastic dough systems through fibrous, β-sheet-rich protein networks: an alternative, physicochemical approach to gluten-free breadmaking. Trends Food Sci Technol 24(2):74–81

Gallagher E, Gormley TR, Arendt EK (2004) Recent advances in the formulation of gluten-free cereal-based products. Trends Food Sci Technol 15(3):143–152

Good H (2002) Measurement of color in cereal products. Cereal Foods World 47:5–6

Herranz B, Canet W, Alvarez MD (2017) Corn starch and egg white enriched gluten-free chickpea flour batters: rheological and structural properties. Int J Food Prop. https://doi.org/10.1080/10942912.2017.1299760

López ACB, Pereira AJG, Junqueira RG (2004) Flour mixture of rice flour, corn and cassava starch in the production of gluten-free white bread. Braz Arch Biol Technol 47:63–70

Lu TM, Lee CC, Mau JL, Lin SD (2010) Quality and antioxidant property of green tea sponge cake. Food Chem 119:1090–1095

Matos ME, Sanz T, Rosell CM (2014) Establishing the function of proteins on the rheological and quality properties of rice based gluten free muffins. Food Hydrocoll 35:150–158

Meyer AS, Heinonen M, Frankel EN (1998) Antioxidant interactions of catechin, cyanidin, caffeic acid, quercetin, and ellagic acid on human LDL oxidation. Food Chem 861:71–75

Oko AO, Onyekwere SC (2010) Studies on the proximate chemical composition and mineral element contents of five new lowland rice varieties in Ebonyi State. Int J Biotechnol Biochem 6(6):949–955

Ramos-Escudero F, Muñoz AM, Alvarado-Ortíz C, Alvarado Á, Yáñez JA (2012) Purple corn (Zea mays L.) phenolic compounds profile and its assessment as an agent against oxidative stress in isolated mouse organs. J Med Food 15:206–215

Sakač M, Torbica A, Sedej I, Hadnađev M (2011) Influence of breadmaking on antioxidant capacity of gluten free breads based on rice and buckwheat flours. Food Res Int 44(9):2806–2813

Sanchez HD, Osella CA, De La Torre MA (2004) Use of response surface methodology to optimize gluten-free bread fortified with soy flour and dry milk. Food Sci Technol Int 10:5–9

Sandhu KS, Singh N, Malhi NS (2007) Some properties of corn grains and their flours I: physicochemical, functional and chapati-making properties of flours. Food Chem 101:938–946

Shevkani K, Singh N (2014) Influence of kidney bean, field pea and amaranth protein isolates on the characteristics of starch-based gluten-free muffins. Int J Food Sci Technol 49:2237–2244

Shevkani K, Kaur A, Singh G, Singh B, Singh N (2014) Composition, rheological and extrusion behaviour of fractions produced by three successive reduction dry milling of corn. Food Bioprocess Technol 7:1414–1423

Shevkani K, Kaur A, Kumar S, Singh N (2015) Cowpea protein isolates: functional properties and application in gluten-free rice muffins. LWT Food Sci Technol 63:927–933

Singh N, Singh S, Shevkani K (2011) Maize: composition, bioactive constituents, and unleavened bread. In: Preedy VR, Watson RR, Patel VB (eds) Flour and breads and their fortification in health and disease prevention, Elsevier Inc., pp 89–99

Singh N, Kaur A, Shevkani K (2014) Maize: grain structure, composition, milling, and starch characteristics. In: Chaudhry DP (ed) Maize: nutrition dynamics and novel uses India. Springer, pp 65–76

Singh JP, Kaur A, Shevkani K, Singh N (2015) Influence of jambolan (Syzygium cumini) and xanthan gum incorporation on the physicochemical, antioxidant and sensory properties of gluten-free eggless rice muffins. Int J Food Sci Technol 50:1190–1197

Singh N, Kaur A, Katyal M, Bhinder S, Ahlawat AK, Singh AM (2016) Diversity in quality traits amongst Indian wheat varieties II: paste, dough and muffin making properties. Food Chem 197:316–324

Singleton VL, Orthofer R, Lamuela-Raventos RM (1999) Analysis of total phenols and other oxidation substrates and antioxidants by means of folin–ciocalteu reagent. Methods Enzymol 299C:152–178

Soong YY, Tan SP, Leong LP, Henry JK (2014) Total antioxidant capacity and starch digestibility of muffins baked with rice, wheat, oat, corn and barley flour. Food Chem 164:462–469

Stintzing FC, Stintzing AS, Carle R, Frei B, Wrolstad RE (2002) Color and antioxidant properties of cyanidin-based anthocyanin pigments. J Agric Food Chem 50:6172–6181

Thakur S, Kaur A, Singh N, Virdi AS (2015) Successive reduction dry milling of normal and waxy corn: grain, grit and flour properties. J Food Sci 80:C1144–C1155

Tronsmo KM, Færgestad EM, Schofield JD, Magnus EM (2003) Wheat protein quality in relation to baking performance evaluated by the Chorleywood bread process and a hearth bread baking test. J Cereal Sci 38:205–215

Wang Y, King JM, Xu Z, Losso J, Prudente A (2008) Lutein from ozone-treated corn retains antimutagenic properties. J Agric Food Chem 56:7942–7949

Acknowledgements

NS acknowledges SERB for financially supporting a research project (SERB/SR/SO/PS/13/2011). ST acknowledges UGC-BSR for providing financial assistance in the form of Fellowship. Authors also acknowledge Dr. Jai Chand Rana, NBPGR, New Delhi (India) for providing corn accessions.

Author information

Authors and Affiliations

Corresponding author

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Trehan, S., Singh, N. & Kaur, A. Characteristics of white, yellow, purple corn accessions: phenolic profile, textural, rheological properties and muffin making potential. J Food Sci Technol 55, 2334–2343 (2018). https://doi.org/10.1007/s13197-018-3171-5

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13197-018-3171-5