Abstract

The aim of the present study was to evaluate the effect of methanolic Prosopis farcta extract (PFE; 0, 200, 400, 600, 800 and 1000 ppm) on storage stabilization of canola oil during 24 days of accelerated storage. The canola oil was mainly comprised of oleic acid (65.01%), linoleic acid (19.56%), linolenic acid (8.11%) and palmitic acid (4.48%). The 1, 1-diphenyl-2-picrylhydrazyl radical scavenging activity and β-carotene bleaching ability of the PFE were 1.16 μg/ml and 0.09 mg/ml, respectively. Our study showed that total phenolic content of PFE was 365.72 ± 6.21 mg gallic acid/g of dried fruit quantified by Folin–Ciocalteu’s method. Peroxide value, p-anisidine value and thiobarbituric acid value exhibited that PFE at concentration levels of 400, 600, 800 and 1000 ppm in canola oil had good antioxidant effect. According to the results of the present study. The induction periods of treated samples were significantly increased with increasing of PFE concentration. Indeed, the induction periods of oil were improved from 1.99 (control) to 3.32, 4.56, 8.32, 9.89 and 13.34 h by addition of 200, 400, 600, 800 and 1000 ppm of PFE, respectively.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Plant essential oils (EOs) and extracts have been applied in traditional medicine and also as additives to increase the shelf life of foods (Zhang et al. 2010). Most of their properties are caused by secondary metabolites such as volatile compounds (Rezaei and Shahbazi 2018). Commercial EOs and extracts have been categorized as Generally Recognized as Safe (GRAS) at low concentration for food use (Iqbal and Bhanger 2007). Recently, obtained EOs and extracts of various herb species such as red grape seed, Ferulago angulate, raspberry, sesame and Ziziphora clinopodioides have become popular, and numerous studies have been conducted to determine their antimicrobial and antioxidant activities in in vitro and food models (Shaker 2006; Alizadeh et al. 2016; Asnaashari et al. 2015; Mohdaly et al. 2011; Shahbazi 2017, 2015).

Prosopis farcta (known as Kohorak in Persian) is a member of Fabaceae and sub-family of Mimosoideae that widely distributed in the dry and semi-dry tropical and sub-tropical areas of America, southwestern Asia and northern Africa (Asadollahi et al. 2014). Prosopis genera are exhibit a high degree of tolerance to heat, drought, alkalinity and salinity, and therefore thrive in central, eastern and southwestern parts of Iran (Hajinezhad et al. 2015). The fruit of this plant has been traditionally used in Iranian folk medicine to cure cough, bronchitis, gallstones, common cold, infectious diarrhea, stomach disorder and venereal diseases. Local people consume the fruit of this plant after pulverizing and blending with other constituents as a food (Omidi and Ghazaghi 2013). The antioxidant, antimicrobial and antiparasitic properties of Prosopis genous has been previously documented (Rahman et al. 2011).

Fats, vegetable oils and foods containing fat are basic sources for vital precursors of metabolic processes in the body, energy storage, and important compounds of cell membranes and other biological conformations (Mohdaly et al. 2011). It plays critical roles in the absorption of fat-soluble nutrients and acts as essential fatty acids, cellular transport components, fat-soluble vitamins and dietary supplements. Despite biological and nutritional actions, lipids enact a basic role in the quality, processing, texture and organoleptic characteristics of food crops (Dupont et al. 1996). Quality of oils and fats especially those containing high contents of unsaturated fatty acids is changed through destructive reactions both during long-term storage and heating (Mohdaly et al. 2011). The major subversive process is oxidation and destruction of its products, resulted in rancid odors, unpleasant flavors and discoloration as well as loss of nutritional qualities (Shaker 2006). Prevention of this process is essential for the food producers and individuals involved in the food milling from the plant to the consumers. Synthetic antioxidants especially butylated hydroxyanisole (BHA), butylated hydroxytoluene (BHT) and tert-butyl hydroquinone (TBHQ) have been used to prolong shelf life and frying stability of vegetable oils and foods containing fat in many countries (Iqbal and Bhanger 2007). However, these substances may be implicated in diseases result from oxidative damages including cancer and carcinogenesis (Upadhyay et al. 2017). There is an increasing trend among researchers and consumers to replace synthetic antioxidants with natural materials. Previous studies investigated antioxidant effects of fruits, vegetables, seeds and barks extracts containing polyphenols, carotenoids and tocopherols on the stability of vegetable oils (Upadhyay et al. 2017; Iqbal and Bhanger 2007; Mohdaly et al. 2011; Shaker 2006; Ben-Ali et al. 2014; Agregán et al. 2017; Asnaashari et al. 2015). Based on our knowledge, there was no a comprehensive study on the antioxidant property of P. farcta extract (PFE) in food models especially vegetable oils. Therefore, the aim of the present study was to evaluate the effect of methanolic PFE (0, 200, 400, 600, 800 and 1000 ppm) on storage stabilization of canola oil during 24 days of accelerated storage.

Materials and methods

Materials

Refined, bleached and deodorized canola oil used in the present study was kindly supplied by Nazgol Oil Company (Mahydasht, Kermanshah, Iran). P. farcta was obtained from the suburb of Lorestan province, Iran. The species of the plant was authenticated by Dr. Seyyed Ali Masoumi, a plant taxonomist, at Razi University, Kermanshah, Iran. 1, 1-Diphenyl-2-picrylhydrazyl (DPPH), p-anisidine (4-amino-anisol; 4-methoxy-anilin), 2-tiobarbituric acid (TBA) and TBHQ were purchased from Merck, Germany. Other chemicals were of analytical grade and purchased from Sigma, UK.

Extraction procedure

The fruits of P. farcta were air-dried for 2 weeks at ambient temperature (24 ± 1 °C) and then ground to obtain a fine powder using a Moulinex food processor. 1 g of the ground fruit was initially extracted on a magnetic stirrer (IKA, Germany) using 10 ml pure methanol as a solvent for 24 h in a dark place at room temperature. The extract was passed through a Whatman No. 4 filter paper, the residue was extracted again and then evaporated under pressure below 40 °C to remove the solvent and stored at refrigerated temperature for further use.

In-vitro antioxidant activity of methanolic Prosopis farcta extract

DPPH radical scavenging assay

DPPH radical scavenging assay of the extract was performed according to the published method by Mohdaly et al. (2011) with some minor modifications. 50 µl of a methanolic solution of the extract at various concentrations was added to 200 ml DPPH solution (0.004% in methanol). The control was prepared by adding 50 µl solvent to DPPH solution. Afterward, the mixture was gently shaken and incubated in a darkness at ambient temperature for 30 min. The resulting solutions absorbance was measured at 517 nm using a spectrophotometer (Shimadzu UV mini 1240, Duisburg, Germany). The radical scavenging activity was measured by the following equation (Asnaashari et al. 2015):

Where AS and ADPPH are absorbance of samples and DPPH solution, respectively.

β-Carotene bleaching method

The β-carotene bleaching ability of the extract was also evaluated as previously described method by Ben-Ali et al. (2014).

Fatty acid composition of canola oil

Gas chromatography of canola oil was performed on a Thermo Quest Finningan apparatus with a flame ionization detector (FID). Fatty acid composition of the canola oil was transesterified into their corresponding fatty acid methyl esters (FAME) by vigorous shaking of a solution of oil in hexane (0.3 g in 7 ml) with 2 ml 7 N methanolic potassium hydroxide at 50–55 °C for 10 min. The FAME was identified using an HP-5890 chromatograph (Hewlett-Packard, CA, USA) equipped with a CPSIL (Supelco, Bellefonte, PA, USA) capillary column of fused silica (30 m in length 0.25 mm i.d., 0.25 mm film thickness). Helium (purity: 99.99%; flow rate 1.2 ml/min and split ratio 1:20) was the carrier gas. The column temperature was initially programmed at 50 °C for 6 min and then gradually increased up to 265 °C at 2.5 °C/min. Finally, the temperature was increased to 280 °C at 15 °C/min and held isothermally for 3 min (Farahmandfar et al. 2015).

Sample preparation for oxidative stability of canola oil

The PFE was added to the canola oil free of additives at five concentration levels including 200, 400, 600, 800 and 1000 ppm, based on extract weight, to examine its antioxidant activity. TBHQ as a control antioxidant at a level of 1000 ppm was also used to compare the efficay of a natural antioxidant. A control sample without the extract and/or synthetic antioxidant was also considered. All oil samples were placed in dark brown coloured bottels with narrow necks, subjected to acceralted oxidation in the dark in an oven at 65 °C for a period of 24 days.

Analytical procedures for canola oil enriched with methanolic Prosopis farcta extract

Rancimat test

Determination of oxidative stability index (OSI) of canola oil sample (3 g) at 120 °C was conducted using a Rancimat (Metrohm model 734, Herisan, Switzerland) at an airflow of 20 l/h (Farahmandfar et al. 2015). In this method, formation of volatile acids is appreciated by changing electrical conductivity when they exclude from the oxidizing oils by air.

p-Anisidine value (AV) and peroxide value (PV)

p-Anisidine value (AV) and peroxide value (PV) were determined based on the method described by Agregán et al. (2017).

Tiobarbituric acid test (TBA)

In order to evaluate TBA of treated and un-treated samples, an aliquot of 5 g of each oil sample was mixed with 25 ml 1-butanol with 5 ml TBA reagent, heated at 100 °C for 120 min and then the absorbance was measured at 530 nm using a spectrophotometer (Asnaashari et al. 2015).

Statistical analysis

Statistical analysis was performed in a completely randomized design in three repetitions. ANOVA was used to analyze the data and significant differences (P < 0.05) were determined by Duncan’s multiple range test.

Results and discussion

Fatty acid composition of canola oil

The fatty acid composition of canola oil at day 0 is given in Table 1. As it can be seen, the canola oil is mainly comprised oleic acid (65.01%), linoleic acid (19.56%), linolenic acid (8.11%) and palmitic acid (4.48%). Myristic acid (0.04%) and gadoleic acid (0.22%) content were very low, indicating good quality of canola oil sample (Asnaashari et al. 2015). The fatty acid composition of canola oil was in agreement with those reported by Agregán et al. (2017). Accordingly, the highest fatty acid was oleic acid (63.09%), followed by linoleic acid (19.68%), linolenic acid (8.25%) and palmitic acid (4.57%). In another study (Jenab et al. 2013), oleic acid (48.9%) and linoleic acid (29.8%) were reported as the major fatty acid compounds of canola oil, which was in agreement with our results. Moreover, the percentages of major fatty acid composition of canola oil in the present study were higher than reported by Huang et al. (2008). According to their results, the percentages of oleic acid and linoleic acid as the main compounds were found to be 59.1% and 18.8%, respectively.

Fatty acid profiles in oxidized canola oil

Changes of fatty acids after 24 days in thermally-oxidized canola oils are shown in Table 1. In untreated samples, as oxidation time increased from day 0 to day 24, the percentages of unsaturated fatty acids decreased and investigated saturated fatty acids increased. Moreover, the changes of fatty acids in treated samples with PFE (200, 400, 600, 800 and 1000 ppm) or TBHQ 1000 ppm were remarkably slower compared to those in control samples. The canola oil samples treated with TBHQ 1000 ppm and PFE 1000 ppm exhibited the lowest fatty acid changes for the entire of study period. The changes of fatty acids analyzed by GC-FID during sunflower oil oxidation have been reported by Kim et al. (2013) which were consistent with our findings. Based on their results, saturated fatty acids (palmitic and stearic acids) increased and unsaturated fatty acids especially linoleic acid decreased continuously.

In-vitro antioxidant activity of methanolic Prosopis farcta extract

Phenolic compounds are the main components of herbs that play a pivotal role in DPPH free radical scavenging as well as antioxidant capacity. They present the ability of scavenging the free radicals that can trigger oxidative stress and further detrimental conditions. Inhibition of free radical scavenging was evaluated by the DPPH assay (Shahbazi 2018). The DPPH radical scavenging activity and β-carotene bleaching ability of the PFE were found to be 1.16 μg/ml and 0.09 mg/ml, respectively. The in vitro antioxidant activity of Prosopis species was evaluated in the previous studies (Poudineh et al. 2015; Lajnef et al. 2015). According to the results of Poudineh et al. (2015), the IC50 value of PFE obtained from Sistan region (east of Iran) was 1.51 μg/ml, which was in agreement with our findings. In another study (Lajnef et al. 2015), the scavenging ability on DPPH radical of the PFE was reported as 455 μg/ml. From a comparison of our results with values reported in the literature for other Prosopis species, it was interesting that PFE showed stronger antioxidant capacity than P. laevigata (García-Andrade et al. 2013), P. juliflora (Napar et al. 2012) and P. cineraria (Dharani et al. 2011). It has been demonstrated that phenolic compounds are the main components of herbs that play a critical role in DPPH free radical scavenging as well as antioxidant capacity. Free radical scavenging activity, transition metal-chelating activity, and singlet-oxygen quenching capacity are identified as influential mechanisms underlying the antioxidant effects of phenolic compounds (Shahbazi 2017). Moreover, differences in antioxidant effects of extracts among studies may be explained with variability of plant species, the method used for antioxidant evaluation, structure and interaction between phenolic compounds of antioxidants (Djeridane et al. 2006).

Determination of oxidative stability and antioxidant activity indices of canola oil samples

The oxidative stability index was considered as a resistance ability of vegetable oils to oxidative rancidity (Ben-Ali et al. 2014). The induction periods of treated and un-treated canola oil samples are presented in Table 2. According to the results of the present study, the induction periods of treated samples were significantly increased with increasing of PFE concentration (P < 0.05). Indeed, the induction periods of oil samples were improved from 1.99 ± 0.05 (control) to 3.32 ± 0.08, 4.56 ± 0.04, 8.32 ± 0.01, 9.89 ± 0.06 and 13.34 ± 0.11 h by addition of 200, 400, 600, 800 and 1000 ppm of PFE, respectively. The highest stability of canola oil samples enriched with PFE could be attributed to the powerful antioxidant activity of polyphenols of PFE. Our study showed that total phenolic content of PFE was 365.72 ± 6.21 mg gallic acid/g of dried fruit quantified by Folin–Ciocalteu’s method. Based on published results of Iqbal and Bhanger (2007), antioxidant activity index (AAI) was used for determination of antioxidant efficacy and calculated as the ratio of induction period of stabilized sample to that of control. Accordingly, the AAIs of canola oil samples containing 200, 400, 600, 800 and 1000 ppm were found to be 1.66, 2.29, 4.18, 4.96 and 6.70, respectively, suggesting a good antioxidant effectiveness of PFE at all concentrations on stability of canola oil. Ben-Ali et al. (2014) also reported that oxidative stabilization of sunflower oil treated with basil (Ocimum basilicum) extract at concentration levels of 500 and 1000 ppm was significantly higher than control group (1.98 h) by 8.23 and 11.63 h, respectively. Iqbal and Bhanger (2007) showed that induction periods and AAIs were increased by increasing concentration of garlic extract.

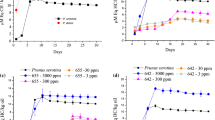

Effect on peroxide value (PV)

Oxidative damage to fatty acids induces lipid peroxidation that promotes not only the production of off-flavors and off-odors, but also the reduction of food shelf life (Khezrian and Shahbazi 2018). Figure 1 shows the trend of lipid peroxidation under different treatment conditions. In the present study, the initial PV of untreated sample was found to be 0.09 meq peroxide/kg. PV was increased up to 151.9 meq peroxide/kg for control sample after 20 days of storage and after that sharply reduced (121.2 meq peroxide/kg) at the end of designated study period. This trend might be related to the volatilization of some breakdown products of lipid hydroperoxides after long heating times, formed in the primary stages of oxidation which decreased the PV (Shahidi et al. 1992). The significant difference between the initial peroxidation on day eight and other values measured during the next days of storage demonstrated oil sample degradation. Overall, the addition of different concentrations of PFE significantly reduced this trend except for those values on day four. However, the PVs of treated samples were also progressively increased up to 37.25–76.33 after 24 days of storage (P < 0.05), indicating progression of lipid oxidation. Lipid oxidation as a complex process consists of free radical chain mechanisms that culminate in the synthesis of fatty acyl peroxides or other oxidation products (Khezrian and Shahbazi 2018). The results of the present study indicated that PVs of canola oil samples containing PFE at concentrations of 200, 400, 600, 800 and 1000 ppm were significantly lower than untreated samples during designated study period (P < 0.05). It has believed that natural essential oils and extracts are composed of the active compounds with antioxidant effects including terpenes, terpenoids and phenylpropenes. Owing to the presence of such active compounds in the extracts, these natural products can delay lipid oxidation through various mechanisms have been involved including reduction of hydroperoxides formation or production of secondary products of autoxidation (Gertz et al. 2000). Delfanian et al. (2016b) also reported that the thermo-oxidative stability of soybean oil treated with jujube fruit extract at concentration of 600 ppm significantly improved in comparison with control group. Chong et al. (2015) found that mangosteen peel extract at 200 ppm exhibited inhibitory effect against increasing PV content of sunflower oil up to 24 days under accelerated storage conditions.

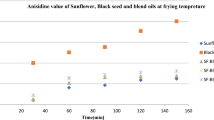

Effect on p-anisidine value (AV)

AV is applied to determine the secondary products of oil oxidation. Its base is the reaction of p methoxy aniline (anisidine) and aldehydic compounds especially 2, 4-dienals and 2-alkenals, as principle metabolites of decomposition of hydroperoxide compounds (Laguerre et al. 2007). It is a reliable method for calculation of oxidative rancidity in oils, fats and fatty foods. As it can be observed in Fig. 2, the initial AV was found to be 2.03 and reached to 48.52, 35.86, 21.59, 17.33, 13.87 and 10.45 for control and samples containing 200, 400, 600, 800 and 1000 ppm PFE at the end of study period (Fig. 2). For all samples, AVs were significantly increased with increasing storage time (P < 0.05). Based on our findings, addition of PFE at different concentrations were significantly delayed the formation of secondary products of oxidation compared to control group (P < 0.05). These results are in general agreement with previous studies (Zhang et al. 2010; Alizadeh et al. 2016). Zhang et al. (2010) investigated the oxidative stability of sunflower oil enriched with carnosic acid and compared with synthetic antioxidants (TBHQ, BHA and BHT) during accelerated storage. According to their findings, at the end of study period, AVs of the oil samples enriched with rosemary extract containing carnosic acid at percentages of 24, 60 and 98% were 1.5, 2.5 and 3.5-folds less than that of control sample. Ling et al. (2015) indicated that unripe banana peel extract at concentrations of 200 and 300 ppm is sufficient enough to exhibit a protective effect in retarding secondary oxidation of sunflower oil. Alizadeh et al. (2016) also reported that antioxidant effects of rosemary and Ferulago angulate extracts resulted in shelf life of treated oil samples compared to un-treated one. The results of Delfanian et al. (2016a) showed that oxidative alteration of soybean oil samples treated with ethanol–water extract of skin (400 and 1000 mg/kg) and ethanol extract of pulp (100 and 400 mg/kg) of loquat fruit (Eriobotrya japonica Lindl.) is better than that of TBHQ 100 ppm during heating process (180 °C) for 24 h. Moreover, TBHQ was exhibited higher antioxidant activity than PFE at 200 ppm probably due to its ability to donate hydrogen owing to the existence of two para-hydroxyl groups in its construction (Alizadeh et al. 2016).

Effect on tiobarbituric acid (TBA) test

TBAs, as another lipid oxidation index, of untreated and treated samples during accelerated storage are described in Fig. 3. The results showed that TBA values of all treatments significantly increased during 24 days of storage (P < 0.05). In control group, the TBAs were increased from 0.04 to 1.21 mg malonaldehyde (MDA)/kg oil after 24 days. Obviously, the TBA values of samples enriched with PFE were always lower than control group (approximately 0.38–0.96 mg malonaldehyde (MDA)/kg oil). This observation was similar to the results from Zhang et al. (2010) who reported that initial TBA was 0.25 mg MDA/kg and it was exceeded 0.3 mg MDA/kg in control at the end of storage day. Some reports showed that the antioxidant effects of natural compounds such as rosemary extract (Zhang et al. 2010), garlic extract (Iqbal and Bhanger 2007), red grape seed and peel extracts (Shaker 2006), raspberry (Rubus fruticosus) leaves extract (Asnaashari et al. 2015), loquat fruit (Eriobotrya japonica Lindl.) extract (Delfanian et al. 2016a), unripe banana (Musa acuminata Colla) peel extract (Ling et al. 2015), rambutan fruit (Nephelium lappaceum) extract (Mei et al. 2014) and jujube fruit (Ziziphus mauritiana Lam.) extract (Delfanian et al. 2016b) on retarding lipid oxidation of edible oils.

Conclusion

The findings of this study indicated that all samples treated with PFE could reduce lipid oxidation of canola oil during 24 days of accelerated storage. A significant elevation of PV, AV and TBA inhibition was observed in oil samples treated with PFE at concentration levels of 400, 600, 800 and 1000 ppm. In addition, future studies are necessary to examine the accurate mechanism of action and toxicology of the mentioned extract.

References

Agregán R, Lorenzo JM, Munekata PE, Dominguez R, Carballo J, Franco D (2017) Assessment of the antioxidant activity of Bifurcaria bifurcata aqueous extract on canola oil. Effect of extract concentration on the oxidation stability and volatile compound generation during oil storage. Food Res Int 99:1095–1102

Alizadeh L, Nayebzadeh K, Mohammadi A (2016) A comparative study on the in vitro antioxidant activity of tocopherol and extracts from rosemary and Ferulago angulata on oil oxidation during deep frying of potato slices. J Food Sci Technol 53:611–620

Asadollahi A, Sarir H, Omidi A, Torbati MBM (2014) Hepatoprotective potential of Prosopis farcta beans extracts against acetaminophen-induced hepatotoxicity in wister rats. Int J Prev Med 5:1281–1283

Asnaashari M, Tajik R, Khodaparast MHH (2015) Antioxidant activity of raspberry (Rubus fruticosus) leaves extract and its effect on oxidative stability of sunflower oil. J Food Sci Technol 52:5180–5187

Ben-Ali M, Dhouib K, Damak M, Allouche N (2014) Stabilization of sunflower oil during accelerated storage: use of basil extract as a potential alternative to synthetic antioxidants. Int J Food Prop 17:1547–1559

Chong YM, Chang SK, Sia WCM, Yim HS (2015) Antioxidant efficacy of mangosteen (Garcinia mangostana Linn.) peel extracts in sunflower oil during accelerated storage. Food Biosci 12:18–25

Delfanian M, Esmaeilzadeh Kenari R, Sahari MA (2016a) Oxidative stability of refined soybean oil enriched with loquat fruit (Eriobotrya japonica Lindl.) skin and pulp extracts. J Food Process Preserv 40:386–395

Delfanian M, Esmaeilzadeh Kenari R, Sahari MA (2016b) Utilization of jujube fruit (Ziziphus mauritiana Lam.) extracts as natural antioxidants in stability of frying oil. Int J Food Prop 19:789–801

Dharani B, Sumathi S, Sivaprabha J, Padma P (2011) In vitro antioxidant potential of Prosopis cineraria leaves. J Nat Prod Plant Resour 1:26–32

Djeridane A, Yousfi M, Nadjemi B, Boutassouna D, Stocker P, Vidal N (2006) Antioxidant activity of some Algerian medicinal plants extracts containing phenolic compounds. Food Chem 97:654–660

Dupont J, Holub BJ, Knapp HR, Meydani M (1996) Fatty acid-related functions. Am J Clin Nutr 63:991S–993S

Farahmandfar R, Asnaashari M, Sayyad R (2015) Comparison antioxidant activity of Tarom Mahali rice bran extracted from different extraction methods and its effect on canola oil stabilization. J Food Sci Technol 52:6385–6394

García-Andrade M, González-Laredo R, Rocha-Guzmán N, Gallegos-Infante J, Rosales-Castro M, Medina-Torres L (2013) Mesquite leaves (Prosopis laevigata), a natural resource with antioxidant capacity and cardioprotection potential. Ind Crops Prod 44:336–342

Gertz C, Klostermann S, Kochhar SP (2000) Testing and comparing oxidative stability of vegetable oils and fats at frying temperature. Eur J Lipid Sci Technol 102:543–551

Hajinezhad M, Esmaeel Zadeh Bahabadi S, Miri H, Davari I, Darvish Sargazi M (2015) Effect of hydroalcoholic extract of Prosopis farcta pod on liver histopathology and malondialdehyde level in streptozotocin diabetic rats. Horizon Med Sci 21:31–36

Huang SSY, Fu CHL, Higgs DA, Balfry SK, Schulte PM, Brauner CJ (2008) Effects of dietary canola oil level on growth performance, fatty acid composition and ionoregulatory development of spring chinook salmon parr, Oncorhynchus tshawytscha. Aquaculture 274(1):109–117

Iqbal S, Bhanger M (2007) Stabilization of sunflower oil by garlic extract during accelerated storage. Food Chem 100:246–254

Jenab E, Temelli F, Curtis JM (2013) Lipase-catalysed interesterification between canola oil and fully hydrogenated canola oil in contact with supercritical carbon dioxide. Food Chem 141:2220–2228

Khezrian A, Shahbazi Y (2018) Application of nanocompostie chitosan and carboxymethyl cellulose films containing natural preservative compounds in minced camel’s meat. Int J Biol Macromol 106:1146–1158

Kim TS, Yeo J, Kim JY, Kim MJ, Lee J (2013) Determination of the degree of oxidation in highly-oxidised lipids using profile changes of fatty acids. Food Chem 138:1792–1799

Laguerre M, Lecomte J, Villeneuve P (2007) Evaluation of the ability of antioxidants to counteract lipid oxidation: existing methods, new trends and challenges. Prog Lipid Res 46:244–282

Lajnef HB, Mejri H, Feriani A, Khemiri S, Saadaoui E, Nasri N, Tlili N (2015) Prosopis farcta seeds: potential source of protein and unsaturated fatty acids? J Am Oil Chem Soc 92:1043–1050

Ling SSC, Chang SK, Sia WCM, Yim HS (2015) Antioxidant efficacy of unripe banana (Musa acuminata Colla) peel extracts in sunflower oil during accelerated storage. Acta Sci Pol Technol Aliment 14(4):343–356

Mei WSC, Ismail A, Esa NM, Akowuah GA, Wai HC, Seng YH (2014) The effectiveness of rambutan (Nephelium lappaceum L.) extract in stabilization of sunflower oil under accelerated conditions. Antioxidants 3:371–386

Mohdaly AA, Smetanska I, Ramadan MF, Sarhan MA, Mahmoud A (2011) Antioxidant potential of sesame (Sesamum indicum) cake extract in stabilization of sunflower and soybean oils. Ind Crops Prod 34:952–959

Napar AA, Bux H, Zia MA, Ahmad MZ, Iqbal A, Roomi S, Muhammad I, Shah SH (2012) Antimicrobial and antioxidant activities of Mimosaceae plants; Acacia modesta wall (Phulai), Prosopis cineraria (Linn.) and Prosopis juliflora (Swartz). J Med Plants Res 6:2962–2970

Omidi A, Ghazaghi M (2013) Prosopis farcta beans increase HDL cholesterol and decrease LDL cholesterol in ostriches (Struthio camelus). Trop Anim Health Prod 45:431–434

Poudineh Z, Amiri R, Najafi S, Mir N (2015) Total phenolic content, antioxidant, and antibacterial activities of seed and pod of Prosopis farcta from Sistan region, Iran. AJA 2(2):1–5

Rahman AA, Samoylenko V, Jacob MR, Sahu R, Jain SK, Khan SI, Tekwani BL, Muhammad I (2011) Antiparasitic and antimicrobial indolizidines from the leaves of Prosopis glandulosa var. glandulosa. Planta Med 77:1639–1643

Rezaei F, Shahbazi Y (2018) Shelf-life extension and quality attributes of sauced silver carp fillet: a comparison among direct addition, edible coating and biodegradable film. LWT-Food Sci Technol 87:122–133

Shahbazi Y (2015) Ziziphora clinopodioides essential oil and nisin as potential antimicrobial agents against Escherichia coli O157:H7 in Doogh (Iranian yoghurt drink). J Pathogens 2015:1–5

Shahbazi Y (2017) Chemical compositions, antioxidant and antimicrobial properties of Ziziphora clinopodioides Lam. essential oils collected from different parts of Iran. J Food Sci Technol 54:3491–3503

Shahbazi Y (2018) Application of carboxymethyl cellulose and chitosan coatings containing Mentha spicata essential oil in fresh strawberries. Int J Biol Macromol 112:264–272

Shahidi F, Janitha P, Wanasundara P (1992) Phenolic antioxidants. Crit Rev Food Sci Nutr 32:67–103

Shaker ES (2006) Antioxidative effect of extracts from red grape seed and peel on lipid oxidation in oils of sunflower. LWT-Food Sci Technol 39:883–892

Upadhyay R, Sehwag S, Mishra HN (2017) Chemometric approach to develop frying stable sunflower oil blends stabilized with oleoresin rosemary and ascorbyl palmitate. Food Chem 218:496–504

Zhang Y, Yang L, Zu Y, Chen X, Wang F, Liu F (2010) Oxidative stability of sunflower oil supplemented with carnosic acid compared with synthetic antioxidants during accelerated storage. Food Chem 118:656–662

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Shahbazi, Y., Shavisi, N. Effect of methanolic Prosopis farcta extract on storage stabilization of canola oil. J Food Sci Technol 56, 420–427 (2019). https://doi.org/10.1007/s13197-018-3503-5

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13197-018-3503-5