Abstract

The susceptibility of Teucrium polium essential oil (EO) as an antioxidant for canola oil was studied. Major compounds of the EO were 11-acetoxyeudesman-4-α-ol (26.3%) and α-bisabolol (24.6%). Different concentrations (200, 600 and 1200 ppm) of EO and synthetic antioxidant BHA (200 ppm) were added to canola oil and incubated for 60 days at room temperature. Acid value (AV), peroxide value (PV), carbonyl value (CV), iodine value (IV), total phenolics (TP), total polar compounds (TPC) and oxidative stability index (OSI) of canola oil were determined. Antioxidant capacity of the EO was measured by DPPH and β-carotene–linoleic acid assays. Results exhibited that DPPH and β-carotene–linoleic acid experiment detections on the EO were analogous in high concentrations to those detected on BHA. Moreover, incorporated EO samples had better AV, PV, CV, IV, TP and TPC than control. EO at concentration of 600 ppm indicated higher antioxidant activity in canola oil compared with BHA.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

One of the main causes of oils shelf life and quality characteristics fluctuations is lipid oxidation (da Silva and Jorge 2014). Degradation of food odor, flavor, taste, texture and nutritional value specially fat-soluble vitamins are the most significant consequences of lipid oxidation (Gallego et al. 2013). Moreover, this reaction can be a potential threat to human health by degradation of proteins, enzymes and biological membranes (Malheiro et al. 2013).

Nowadays, synthetic antioxidants, particularly, butylated hydroxyanisole (BHA) and butylated hydroxytoluene (BHT), are widely applied in decelerating lipids oxidative degradation because of more effective and cheaper than natural plant-based antioxidants. Nevertheless, concerns about the safety of using these additives in food have grown increasingly. Several researches have indicated that prolonged consumption of synthetic antioxidants can cause risks to human health including DNA damage and carcinogenesis (Politeo et al. 2007). These have gave raised to growing attention in the investigation for naturally available antioxidants in recent years (Farahmandfar et al. 2015). Studies have shown that phenolic compounds from herbal origins can function as antioxidants by chelating metals, decomposing peroxides, scavenging free radicals and oxygen (Zheng et al. 2012).

The genus Teucrium L. belongs to the Lamiaceae family and includes more than 300 species, among which 12 vegetate as wild plants in Iran (Rechinger 1982). These herbs have been applied in traditional medicine for thousands of years for asthma and coughs (Djabou et al. 2011). Essential oil (EO) of Teucrium have been the topic of various studies and varied chemical compositions were discovered; mono and sesquiterpenes compounds seem to be the dominant components in the EO of Teucrium (Ali et al. 2008). Conforming to the species investigated and herb source, EO outputs limited from 0.05 to 1.5% and quantities of the major compounds demonstrated remarkable discrepancies (Ali et al. 2008).

Teucrium polium L. is a perennial plant and can be seen in the calcareous soils up to thousand meters of sea level in March to June in the southern part of Iran, especially Fars and Khuzestan provinces. It has been found that the T. polium have an antimicrobial, antiulcer, antispasmodic, anorexic, antipyretic, anticancer and antimutagenic attributes (Raei et al. 2014).

The aim of this investigation was to appraise the in vitro antioxidant activity of Teucrium polium L. EO and assess it’s effectiveness on decelerating the oxidation of canola oil during storage than butylated hydroxyanisole (BHA) as a synthetic antioxidant.

Materials and methods

Materials

Gathering of T. polium L. herb was performed at full flowering stage from Rostam county region in May, Fars province, south of Iran. Canola oil as refined, bleached, deodorized and without synthetic antioxidant was obtained from Shomal Agro-industry Complex Co., Behshahr, Iran. All chemicals and solvents applied in this investigation were of analytical grade and provided by Sigma (USA) and Merck (Germany).

Isolation of essential oil

Fresh aerial parts of T. polium were dried in the shade and at ambient temperature, then, 100 g of them comminuted and shedded in a flask having 1200 mL distilled water and then hydrodistilled for 3 h, applying a Clevenger type apparatus (British Pharmacopoeia 1988). The resulting EO was dried over anhydrous Na2SO4 and stored in sealed vials at 4 °C until analyzes.

Analyses of the essential oil

The EO was analysed by gas chromatography applying an Agilent-technology chromatograph with HP-5 column (30 m × 0.32 mm i.d. × 0.25 mm). Oven temperature was set as follows: 60–210 °C at 3 °C per min, 210–240 °C at 20 °C per min and held for 8.5 min. Injector and detector temperatures were 280 °C and 290 °C, respectively. The carrier gas was nitrogen at the continuous flow of 1 mL per min, and split ratio was 1:50. GC–MS analysis was performed using an Agilent 7890 operating at ionization energy of 70 eV, equipped with a HP-5 MS capillary column (30 m × 0.25 mm i.d. × 25 mm, phenyl methyl siloxane). The carrier gas was Helium at the continuous flow of 1 mL per min, and split ratio was 1:50. FID peak areas electronic integration were used to compute the EO constituents percentage. The EO components were identified based on analogy of Kovats retention indices (Panovska et al. 2007) applying a similar sequences of n-alkanes (C6–C24) under alike GC–MS status and their mass spectrum was contrasted with the Wiley Library (Wiley 7.0).

1,1-Diphenyl-2-picrylhydrazyl (DPPH) radical scavenging activity

The influence of the EO on DPPH˙ reduction was assayed according to the procedure described by Burits and Bucar (2000) with small modifications. Briefly, 0.5 mL of the EO methanolic solution at various concentrations (200, 600 and 1200 ppm) were separately added to the DPPH˙ methanolic solution (3 mL, 0.2 mmol/L). The resulting mixture was vigorously stirred and incubated for 30 min at room temperature. Then, the samples absorbance were measured against pure methanol at 517 nm by a spectrophotometer (GBC, Cintra 20). The samples antiradical activity were expressed as:

where Ablank and Asample are the absorbance values of the control sample and test compound sample, respectively.

β-Carotene-linoleic acid bleaching assay

The antioxidant capacity of EO was investigated using the β-carotene bleaching method by the procedure described by Farahmandfar et al. (2015). Briefly, 0.5 mg of β-carotene was dissolved in 1 mL of chloroform. Then, 20 mg of linoleic acid and 200 mg of Tween 40 were added. The rotary vacuum evaporator was used to remove the chloroform from mixture. The oxygenated distilled water (100 mL) was added to the flask with vigorous stirring. Then, 2.5 mL of this mixture was admixed with 350 µL of EO at different concentrations (200, 600 and 1200 ppm) in test tube. The same method was performed for blank (β-carotene stock solution in addition to the solvents).

Reading the absorbance of the sample was spectrophotometrically determined at 490 nm. Reading was done immediately (t = 0 min) and after 120 min of incubation at 50 °C. The EO antioxidant activity was expressed as:

where A0 and A120 are the absorbance values of the control sample at 0 min and test compound sample at 120 min, respectively.

Sample preparation

EO was added to refined canola oil at concentrations of 200, 600 and 1200 ppm (CE-200 ppm, CE-600 ppm, CE-1200 ppm). Reference BHA was also applied at it’s legal limit of 200 ppm as positive control. Then oil samples (50 mL) were transferred to dark coloured glass bottles and stored for 60 days at room temperature. In order to perform analyses of oil samples, aliquots were removed from each bottle at same time intervals (15 days).

Oil sample analyses

Acid value (AV)

The AV was measured according to the AOCS Official Method Cd 3d-63 (AOCS 1998). For this purpose, initially, the oil sample (5 g) was dissolved in toluene–isopropyl alcohol solution (1:1 v/v, 50 mL). Then, the obtained solution was titrated with standard solution of potassium hydroxide in isopropyl alcohol (0.1 M) to a pink end point in the presence of phenolphthalein as the indicator. The AV was calculated as following formula and expressed in mg of KOH per g of oil.

where V is the KOH volume added to the oil sample, C is the concentration of KOH and W is the mass of the oil sample in grams.

Peroxide value (PV)

The PV was determined according to the AOCS Official Method Cd 8–53 (AOCS 1998). For this purpose, the oil sample (5 g) was dissolved in a solution of acetic acid–chloroform (3:2 v/v, 30 mL) and then saturated potassium iodide solution (0.5 mL) was added. The resulting solution was placed at room temperature under dark condition for 1 min. In the following, distilled water (30 mL) was added. The reaction solution was titrated with standard sodium thiosulfate (0.1 N) to a pale yellow and then, the starch indictor (2 mL) was added and titration process was continued until reaching the endpoint of colorless. The PV was calculated as following formula and expressed in meq O2 per kg of oil.

where N is the normality of sodium thiosulfate, S is the volume of sodium thiosulfate added to the oil sample, B is the volume of sodium thiosulfate added to the blank sample and W is the mass of the oil sample in grams.

Carbonyl value (CV)

The CV was determined according to the procedure reported by Endo et al. (2001). 2-Propanol (1000 g) and sodium borohydride (0.5 g) were mixed together, afterwards, refluxion (1 h) and distillation operations were performed in order to eliminate all carbonyl compounds. The sample of 2,4-dinitrophenylhydrazine (DNPH) was provided by solving DNPH (50 mg) in a solvent (100 mL) having concentrated hydrochloric acid (3.5 mL, 37%). The oil sample (1 g) was produced with adding the solvent containing triphenylphosphine (0.4 mg/mL) to reach 10 mL. Moreover, 50–500 μM of 2,4-decadienal in 2-propanol solutions were prepared. Then, 1 mL of oil solution or standard carbonyl compound solution and 1 mL of DNPH solution were mixed. The resulting mixture was heated for 20 min at 40 °C and cooled in water bath after adding 8 mL of KOH (2%). The absorbance of supernatant was measured at 420 nm after centrifuging (2000×g for 5 min). The results were expressed in µmol of 2,4-decadienal per g of oil.

Iodine value (IV)

The IV was measured according to the Wijs method (AOAC 1995). Briefly, 0.3 g of oil sample was dissolved in chloroform (15 mL) with shaking. Then, the Wijs reagent (25 mL) was added to the mixture and hold at room temperature in the dark condition for 1 h. Afterwards, the potassium iodide (20 mL, 10% water solution) and water (100 mL) were added to the mixture. The resulted mixture was titrated with standard sodium thiosulfate (0.1 N) using some drops of starch solution as indicator, after iodine formed an intensively blue complex with it, the end point was defined by the fading of the indicator color. The IV was calculated as following formula and expressed as g I2 used per 100 g of oil.

where Vblank is the volume of sodium thiosulfate consumed for blank, Vsample is the volume of sodium thiosulfate consumed for oil sample and W is the oil sample weight in grams.

Total phenolics (TP)

The TP content of oil samples was determined according to the Folin–Ciocalteu procedure developed by Zheng et al. (2012) with small modifications. Briefly, the oil sample (100 mg) was blended with the 0.5 mL of Folin–Ciocalteu reagent and 2 mL of methanol. The resulted mixture was stirred and sodium carbonate (1.5 mL, 15%) was added and then the mixture was stirred for 30 s. Afterwards, the mixture was diluted with distilled water to reach 7 mL and incubated at 50 °C for 20 min. In the following, after centrifugation of the mixture at 2000×g for 10 min, the absorbance of the upper layer was measured at 750 nm. The results were expressed in mg of gallic acid per kg of oil.

Total polar compounds (TPC)

The TPC was determined according to the procedure described by Farahmandfar et al. (2015). In detail, 63–100 μm of silica gel 60 (95 parts), dried (12 h, 160 °C), was mixed with water (five parts) and shaked vigorously (1 min) and kept 12 h. Then, silica gel 60 (1 g) was compressed and filled between two cotton wool balls into a pipette tip (5 mL). The oil sample (500 mg) was pipetted into a volumetric flask (5 mL). After that, it was dissolved in toluene (4 mL) and filled with the toluene. The solution (1 mL) was pipetted on top of the pipette tip, under a well ventilated fume hood. The solution was soaked in and then the pipette tip was washed with eluent (1 mL) and after soaking in, were added with eluent (7 mL). After the 15 min of elution operation, the end of the tip was washed with toluene (500 μL). Then the solvent was removed and weighing TPC in percentage (w/w) was performed by the following formula:

where W is the weight of oil sample and W1 is the weight of nonpolar compounds in milligrams.

Oxidative stability index (OSI)

The OSI of oil sample was measured by Metrohm Rancimat model 743 (Herisau, Switzerland) according to the procedure described by Farhoosh (2007). All oil samples (3 g) were investigated in 120 °C under a constant air flow rate of 15 L/h.

Statistical analysis

All results of three independent experiments were expressed as the mean ± standard deviation (SD). The data were analyzed by analysis of variance (ANOVA) and the Duncan’s test for the 5% significance level. Each of which were done with the SPSS software, Version 21 (IBM, New York, USA).

Results and discussion

Essential oil composition

The yield of EO of aerial parts in T. polium was 0.45% (w/w). Nineteen main constituents were identified in the EO (Table 1). These compounds contained 89.2% of the total EO. The section of sesquiterpene was the major section of EO (78.5%), whilst monoterpene hydrocarbon (10.7%) constituted a lesser portions. The major constituents of the EO were 11-acetoxyeudesman-4-α-ol (26.3%), α-bisabolol (24.6%), β-Caryophyllene (9.8%), Caryophylleneoxide (5.3%), β-Pinene (4.2%), Dehydro-sesquicineol (3.7%), α-Pinene (3.1%) and α-Humulene (2.4%).

Essential oil antioxidant activity

In different studies, the capability of natural extracts and EOs as non-synthetic antioxidants has been characterized, and they are attended to be a suitable superseded to synthetic antioxidants in the human diet (Calo et al. 2015; Falowo et al. 2014; Sacchetti et al. 2005). In this investigation, the antioxidant activity of EO was appraised by two distinct procedures: DPPH˙ scavenging assay and β-carotene bleaching test. In the DPPH assay, the stable free radical with dark violet color interact with the antioxidants and turn to a blend with no coloration, therefore the discoloration rating demonstrates the potentials of free radical scavenging of the analyzed compound (Samojlik et al. 2010). DPPH˙ scavenging activity of EO confined from 28.74 to 89.13% at the evaluated concentrations (Table 2). An intensification in concentration resulted to an intensification in radical scavenging activity of EO.

The β-carotene bleaching test was applied to specify the potential of EO to prevent lipid peroxidation. It is a helpful analysis since it is carried out in an emulsion, status analogous to those evident in food-stuffs (Nikolic et al. 2014). The consequences acquired with this procedure are mentioned in Table 2 and it is feasible to see that the inhibitory efficacy of EO against oxidation of linoleic acid in an emulsion had a concentration dependent manner, like the DPPH assay. The inhibitory effects of various concentrations of EO in a β-carotene–linoleate system were found to be significantly different (p < 0.05) and the highest and lowest values were 86.91 and 32.94%, respectively. Moreover, the results of positive control (BHA) were 94.8 and 90.18% in the DPPH assay and β-Carotene bleaching test, which were all higher than those of EO.

Antioxidant activity represented by analyzed EO rationalizes customary uses of T. polium L. The terpenoid and phenolic components existing in the EOs chemical composition are directly related to their antioxidant action, chiefly because of their redox attributes performed by different conceivable mechanisms: hydrogen donors, free radical-scavenging activity, singlet oxygen quenching capacity and transition metal chelating activity (Liyana-Pathirana and Shahidi 2006).

Monitoring oil oxidative stability

Acid value

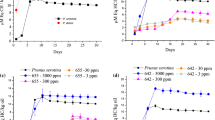

AV evaluates free fatty acids and is generally regarded to be one of the major factors to show the edible oils quality, refining degree and also the quality variation within storage (Osawa et al. 2007; Tasan et al. 2011). AV raises by the oil deterioration and differ relevant to the kind of oil and the oil commercial category (Paul and Mittal 1997). As shown in Fig. 1a, it can be found that the primary AV of oil samples with different concentrations of EO were evidently lower than those of others. The AV of the five types of oil samples enhanced gradually within 15 days of storage time, then the AV enhanced significantly, particularly for the control and BHA supplemented oil samples. After 60 days of storage at 25 °C, AV of the control (without EO and BHA added) had a maximum of 0.99 mg/g. AVs of canola oil supplemented with 200, 600 and 1200 ppm of EO were 0.52, 0.36, and 0.47 mg/g, respectively, whilst the value for oil supplemented with BHA was 0.83 mg/g. Significant differences (p < 0.05) in AVs were seen among the control and the canola oil supplemented with EO and BHA. Obviously, 600 ppm of EO had the best inhibitory effects on AV than others.

Peroxide value

Peroxides are the principal primary compounds of oil oxidation and are measurable by the PV (Malheiro et al. 2013). A greater PV indicates a weaker oxidative stability of oil (Naghshineh et al. 2010). Figure 1b shows the changes of oil samples PV during the storage stability test. Results demonstrated that PV in all samples increased with time due to oxidation of oil, as anticipated. The control sample attained a maximum PV of 2.38 meq/kg at the end of storage period. A significant difference (p < 0.05) in PV was seen among the control and canola oil samples having EO and BHA, all of which decelerated the level of peroxide growth. The PV of canola oil samples with 200, 600 and 1200 ppm of EO and BHA were 1.56, 1.02, 1.35 and 2.05 meq/kg, respectively, after 60 days of storage at 25 °C. Moreover, the antioxidant efficacies of EO different concentrations were superior compared with the BHA. However, CE-600 ppm had the best result and exhibited the lowest PV among these treatments.

Carbonyl value

Decomposition of oil peroxides during storage produces a number of secondary oxidation components, with carbonyl compounds being the most noted. However some of the carbonyl compounds generated are volatile, but a significant amount remains. So, the assessment of CV is extremely momentous for appraising the quality of edible oils, since carbonyl compounds mostly cause to rancid and unpleasant tastes and odors, and decrease the nutritional value (Endo et al. 2001). As can be observed in Fig. 1c, the EO decreased CV at different concentrations (200, 600 and 1200 ppm) and storage periods compared to the control. In all canola oil samples CV demonstrated a trend to growth from beginning of the test to the end of storage time. However, for the CE-600 ppm the gradual enhancement in CV during experiment was significantly (p < 0.05) lower than other treated oil samples. But, at the end of storage time, there was no significant difference (p < 0.05) between 600 ppm of EO and BHA in preventing CV enhancement of canola oil. More specifically, on day 60, the CV of control, CE-200 ppm, CE-600 ppm, CE-1200 ppm and BHA treated sample were 20.11, 16.36, 13.11, 18.61 and 13.57 µmol/g, respectively.

Iodine value

The IV is a factor applied to determine the unsaturations existent in the carbon chains of a triglyceride, therewith specifying it and investigating it’s quality. Generally, the content of unsaturated fatty acids in oil and fat reduces during storage. There is a comparative loss of the IV and a reduce in the C18:2 fatty acid of oil (Cuesta et al. 1991; Tynek et al. 2001). The IV in oil samples during storage is shown in Fig. 1d. The IV in all samples decreased as storage time increased. Among the five kinds of oil samples, control sample was found to had the lowest IV in all times of storage period. The incorporation of EO in canola oil decelerated the rate of reduction of IV than control. In comparison, 600 ppm of EO and BHA showed a stronger ability to prevent reduction of IV and there was no significant difference (p < 0.05) between them during storage time. For the full treatments of the control, 200, 600, 1200 ppm of EO and BHA oils, the IVs on day 60 were 73.26, 86.91, 101.46, 93.22 and 103.98 gr/100 gr, respectively.

Total phenolics

Phenolic compounds are extremely substantial herb components due to their scavenging potency on free radicals because of their hydroxyl groups (Hatano et al. 1989). So, phenolic contents of herbal extracts and EOs may perform straightly to their antioxidant function. Figure 2a shows the TP of oil samples through 60 days of storage at 25 °C. The control canola oil sample contained a much lower TP compared with others initially. On day 0, the TP of all three kinds of samples with different concentrations of EO treated showed no significant difference (p < 0.05) than corresponding sample with BHA treated. The TP of all samples with or without incorporated antioxidants reduced with enhancing time. The oxidation and decomposition of phenolic compounds in oils which affected by quantitative and qualitative changes through the time may be the reason of reduction of TP (Gargouri et al. 2014). Nevertheless, in terms of ability to prevent reduction of TP, there was no significant difference (p < 0.05) among 200, 600 and 1200 ppm of EO compared with BHA during storage period.

Total polar compounds

Polar compounds are regarded as non-volatile components that have a greater polarity compared to triacylglycerols as a consequence of oxidative, hydrolytic or thermal deterioration of oils. Therefore, with greater the quantity of TPCs in oil, it’s quality is lower (Gharachorloo et al. 2010). The primary levels of TPC in oils must limit between 0.4 and 6.4% (Lumley 1988). As shown in Fig. 2b, the initial TPC values in all kinds of canola oil samples were within the ranges established for refined oils and there was no significant difference (p < 0.05) among them. These results exhibit that the TPC enhanced significantly with the extended storage times for all of the samples and showed significantly more accelerations on day 15. The highest increases in TPC were observed for the control, which corroborates that the unpreserved oil is more sensitive to oxidation during storage than the oil with the incorporation of antioxidants. On day 60, the oil sample incorporated with BHA showed value that was similar (p < 0.05) to the CE-600 ppm. However, the oil sample treated with 600 ppm of EO had a significantly lower TPC levels compared with all oil samples during storage period, which correlates with results demonstrated with the AV, PV, CV, IV and TP. At the end of storage period, the TPCs of the control, CE-200 ppm, CE-600 ppm, CE-1200 ppm and BHA treated sample were 13.05, 10.72, 9.24,10.23 and 9.56%, respectively.

Oxidative stability index

OSI is significant factor, allowing to appraise oils susceptibility of durability to oxidative deterioration. This factor permitted to specify the potency of antioxidants and to assess the substantial function of trace compounds within oil oxidation (Velasco and Dobarganes 2002). Indeed, this analysis targeted to determine the induction period with tracing volatile acids within oxidation of oils (Mathäus 1996). As can be deduced from Fig. 2c, OSI values of oil samples treated with different concentrations of EO had no statistically significant difference (p < 0.05) compared with control during storage time. These results are distinct from other analyzes of this study. So, our results suggest a possibility that although the OSI analysis is useful for appraising oils quality, however at high temperatures, this test is not suitable for determining antioxidant activity since natural compounds are volatile and perhaps remove from oil by air flow within analysis (Gordon 2001).

Conclusion

The present results clearly showed that EO extracted from T. polium aerial parts had antioxidant activity. Although, canola oil is hard to stabilize due to its high content of polyunsaturated fatty acids, different concentrations of EO were evidenced to indicate protective efficacies for oxidation of canola oil within storage time. Also, 600 ppm of EO was to a higher extent more active compared with other concentrations of EO and synthetic antioxidant BHA. So, the use of T. polium EO could be beneficial and procedure to preserve oils from deterioration.

References

Ali NAA, Wurster M, Arnold N, Lindequist U, Wessjohan L (2008) Chemical composition of the essential oil of Teucrium yemense deflers. Rec Nat Prod 2:25–32

AOAC (1995) Official analytical chemists. Official methods of analysis, 16th edn. AOAC, Arlington

AOCS (1998) Official methods and recommended practices of the American Oil Chemists’ Society, 5th edn. AOCS, Chicago, IL

British Pharmacopoeia (1988) British Pharmacopoeia. HMSO, Landon, pp 137–138

Burits M, Bucar F (2000) Antioxidant activity of Nigella sativa essential oil. Phytother Res 14:323–328

Calo JR, Crandall PG, O’Bryan CA, Ricke SC (2015) Essential oils as antimicrobials in food systems—a review. Food Control 54:111–119

Cuesta C, Sanchez-Muniz FJ, Hernandez I (1991) Evaluation of non polar methyl esters by column and gas chromatography for the assessment of used frying oils. J Am Oil Chem Soc 68:443–445

da Silva A, Jorge N (2014) Influence of Lentinus edodes and Agaricus blazei extracts on the prevention of oxidation and retention of tocopherols in soybean oil in an accelerated storage test. J Food Sci Technol 51:1208–1212

Djabou N, Battesti MJ, Allali H, Desjobert JM, Varesi L, Costa J, Muselli A (2011) Chemical and genetic differentiation of Corsican subspecies of Teucrium flavum L. Phytochem 72:1390–1399

Endo Y, Li CM, Tagiri-Endo M, Fugimoto K (2001) A modified method for the estimation of total carbonyl compounds in heated and frying oils using 2-propanol as a solvent. J Am Oil Chem Soc 10:1021–1024

Falowo AB, Fayemi PO, Muchenje V (2014) Natural antioxidants against lipid-protein oxidative deterioration in meat and meat products: a review. Food Res Int 64:171–181

Farahmandfar R, Asnaashari M, Sayyad R (2015) Comparison antioxidant activity of Tarom Mahali rice bran extracted from different extraction methods and its effect on canola oil stabilization. J Food Sci Technol 52:6385–6394

Farhoosh R (2007) The effect of operational parameters of the Rancimat method on the determination of the oxidative stability measures and shelf-life prediction of soybean oil. J Am Oil Chem Soc 84:205–209

Gallego MG, Gordon M, Segovia F, Skowyra M, Almajano M (2013) Antioxidant properties of three aromatic herbs (rosemary, thyme and lavender) in oil-in-water emulsions. J Am Oil Chem Soc 90:1559–1568

Gargouri B, Zribi A, Bouaziz M (2014) Effect of containers on the quality of Chemlali olive oil during storage. J Food Sci Technol 52:1948–1959

Gharachorloo M, Ghavami M, Mahdiani M, Azizinezhad R (2010) The effects of microwave frying on physicochemical properties of frying and sunflower oils. J Am Oil Chem Soc 87:355–360

Gordon M (2001) In: Pokorny J, Yanishlieva N, Gordon M (eds) Antioxidants in food: practical applications. Woodhead Publishing Ltd, Cambridge, pp 71–84

Hatano T, Edamatsu R, Hiramatsu M, Mori A, Fujita Y, Yasuhara T, Yoshida T, Okuda T (1989) Effects of the interaction of tannins with co-existing substances. VI. Effects of tannins and related polyphenols on superoxide anion radical and on DPPH radical. Chem Pharm Bull 37:2016–2021

Liyana-Pathirana CM, Shahidi F (2006) Antioxidant properties of commercial soft and hard winter wheats (Triticum aestivum L) and their milling fractions. J Sci Food Agric 86:477–485

Lumley ID (1988) Polar compounds in heated oils. In: Varela G, Bender AE, Morton ID (eds) Frying of foods: principles, changes, new approaches. Ellis Horwood, Chichester, pp 166–173

Malheiro R, Rodrigues N, Manzke G, Bento A, Pereira JA, Casal S (2013) The use of olive leaves and tea extracts as effective antioxidants against the oxidation of soybean oil under microwave heating. Ind Crop Prod 44:37–43

Mathäus B (1996) Determination of the oxidative stability of vegetable oils by Rancimat and conductivity and chemiluminescence measurements. J Am Oil Chem Soc 73:1039–1043

Naghshineh M, Ariffin AA, Ghazali HM, Mirhosseini H, Mohammad AS (2010) Effect of saturated/unsaturated fatty acid ratio on physicochemical properties of palm olein-olive oil blend. J Am Oil Chem Soc 87:255–262

Nikolic M, Glamoclija J, Ferreira ICFR, Calhelha RC, Fernandes A, Markovic T, Markovic D, Giweli A, Sokovic M (2014) Chemical composition, antimicrobial, antioxidant and antitumor activity of Thymus serpyllum L., Thymus algeriensis Boiss. and Reut and Thymus vulgaris L. essential oils. Ind Crop Prod 52:183–190

Osawa CC, Goncalves LA, Ragassi S (2007) Correlation between free fatty acids of vegetable oils evaluated by rapid tests and by the official method. J Food Comp Anal 20:523–528

Panovska TK, Kulevanova S, Gjorgoski I, Bogdanova M, Petrushevska G (2007) Hepatoprotective effect of the ethyl acetate extract of Teucrium polium L. against carbon tetrachloride-induced hepatic injury in rats. Acta Pharm 57:241–248

Paul S, Mittal GS (1997) Regulating the use of degraded oil/fat in deep fat/oil food frying. Crit Rev Food Sci Nutr 37:635–662

Politeo O, Jukic M, Milos M (2007) Chemical composition and antioxidant capacity of free volatile aglycones from basil (Ocimum basilicum L.) compared with its essential oil. Food Chem 101:379–385

Raei F, Ashoori N, Eftekhar F, Yousefzadi M (2014) Chemical composition and antibacterial activity of Teucrium polium essential oil against urinary isolates of Klebsiella pneumonia. J Essent Oil Res 26:65–69

Rechinger K (1982) Flora Iranica: no. 150. Labiatae. Graz, Akademische Druck, p 2

Sacchetti G, Maietti S, Muzzoli M, Scaglianti M, Manfredini S, Radice M, Bruni R (2005) Comparative evaluation of 11 essential oils of different origin as functional antioxidants, antiradicals and antimicrobials in foods. Food Chem 91:621–632

Samojlik I, Lakic N, Mimica-Dukic N, Dakovic-Svajcer K, Bozin B (2010) Antioxidant and hepatoprotective potential of essential oils of coriander (Coriandrum sativum L.) and Caraway (Carum carvi L.) (Apiaceae). J Agric Food Chem 58:8848–8853

Tasan M, Gecgel U, Demirci M (2011) Effects of storage and industrial oilseed extraction methods on the quality and stability characteristics of crude sunflower oil (Helianthus annuus L.). Grasas Aceites 62:389–398

Tynek M, Hazuka Z, Pawlowicz R, Dudek M (2001) Changes in the frying medium during deep frying of food rich in proteins and carbohydrates. J Food Lipids 8:251–261

Velasco J, Dobarganes C (2002) Oxidative stability of virgin olive oil. Eur J Lipid Sci Technol 104:661–676

Zheng L, Huang X, Wang L, Chen Z (2012) Physicochemical properties, chemical composition and antioxidant activity of Dalbergia odorifera T. Chen seed oil. J Am Oil Chem Soc 89:883–890

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Sayyad, R., Farahmandfar, R. Influence of Teucrium polium L. essential oil on the oxidative stability of canola oil during storage. J Food Sci Technol 54, 3073–3081 (2017). https://doi.org/10.1007/s13197-017-2743-0

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13197-017-2743-0