Abstract

The aim of this study was to develop fortified breads of durum wheat semolina (DW) partially substituted at 10%, 15%, 20% and 30% with white sorghum or yellow pea wholemeal flours (WS, YP, respectively) or using wholemeal flour from a natural mixture of rye and durum wheat (RDW). The physico-chemical composition of the raw materials, rheological properties of dough, the bread quality characteristics, glycaemic index and sensory quality of bread were examined. Compared to 100% DW, 100% YP had twice the protein levels, RDW had almost three times the dietary fibre, while the colorimetric indices for WS and YP flour addition showed increased redness (for RDW) and similar yellowness (for YP). With respect to the control dough (100% DW), RDW and addition of WS or YP produced showed negative impact on water absorption (RDW, WS), stability (RDW, YP), dough strength (RDW, WS, YP), tenacity and extensibility ratio (RDW, YP), loaf volume (RDW, WS, YP), yellowness (RDW, WS) and sensory acceptance of bread (RDW, WS). However, these changes were counterbalanced by higher dietary fibre and lower glycaemic index of the breads, especially for RDW and at high additions of WS and YP (20–30%). Moreover, breads fortified with YP were better in terms of colour and overall acceptability scores.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Bread is an essential part of the diet throughout the world, and it is consumed daily, so it represents an ideal food to use as a vehicle for health-promoting substances. Today, advances in food science and technology have led to increased demand for cereal-based products that are rich in bioactive compounds (Dziki et al. 2014). These foods can be obtained by using wholegrain or fractionated flour alone or in combination with non-cereal flour derived from pulses and vegetables (Angioloni and Collar 2012; Ktenioudaki and Gallagher 2012).

Among the bioactive compounds in breads, dietary fibre has an important role, as it is associated with prevention of cholesterol and fat deposition, and constipation, with decreased blood glucose levels and regulation of intestinal functions, and with protection against colon cancer (Ötles and Ozgoz 2014). Unfortunately, the detrimental effects of high fibre content on bread quality are also well known, which result in low acceptability by consumers for breads with wholemeal flour or specifically added fibre (Angioloni and Collar 2012; Goméz et al. 2018). Indeed, baked products rich in fibre can have adverse effects on the quality of the final product, which can result in reduced bread loaf volume, hard crumb, bitter flavours and/or darker colours. Studies thus continue to determine how such problems can be mitigated, together with the quest for new sources of fibre, and their potential health benefits (Ktenioudaki and Gallagher 2012).

Thus, to introduce more dietary fibre into the diet, it is necessary to add fibre-rich flours or pure dietary fibre to flours with an intrinsic good structure of gluten protein. Previous studies have demonstrated that minor cereals such as rye (Rosén et al. 2009) and white sorghum (Ratnavathi and Patil 2013) represent interesting ingredients to improve bread nutritional and health values, with some cases also demonstrating reduction of the glycaemic index (Juntunen et al. 2003). Recently, many attempts have been made to produce cereal-based foods that contain pulse-derived ingredients (Angioloni and Collar 2012; Asif et al. 2013), as these can be considered a promising candidate for development of functional foods with low glycaemic index (de Almeida Costa et al. 2006; Asif et al. 2013, and references therein; Previtali et al. 2014).

The aim of the present study was to develop biofortified durum wheat breads that are high in dietary fibre and have reduced in vitro glycaemic responses, through partial semolina replacement with gluten free cereal (white sorghum) or pulse (yellow pea) wholemeal flours, or using wholemeal flour from a natural mixture of rye and durum wheat.

Materials and methods

Raw materials

Durum wheat (Triticum turgidum L. subsp. durum Desf.) semolina was kindly provided by ‘Valle del Dittaino’ Agricultural Cooperative Society a.r.l. (Enna, Italy), a local industrial bakery with a durum wheat mill (Golfetto, Padova, Italy). The rye–wheat grain used was a natural mix of rye (Secale cereale L.) and durum wheat landraces directly from a field cultivated on an organic farm in the Apulia region (Italy) over the 2014–2015 growing season. The white sorghum (Sorghum vulgare Pers.) and high-protein yellow pea (Pisum sativum L.) species were grown in Foggia (Italy) in a field of the CREA-CI, again, over the 2014–2015 growing season, and under organic conditions.

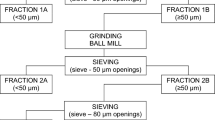

The samples of white sorghum (WS), yellow pea (YP) and rye–wheat (RDW) were ground as wholemeal flours (laboratory mill 120, Perten Instruments AB, Huddinge, Sweden) and passed through a 500-µm (35-mesh) screen. The flour blends were made by substituting the 100% durum wheat semolina (DW, control) with WS or YP at 10% (WS/YP-10), 15% (WS/YP-15), 20% (WS/YP-20) and 30% (WS/YP-30) (w/w), while RDW was used as the 100% mixture.

Physico-chemical analyses of raw materials and flour blends

Protein content was determined using the Kjeldahl method, according to the American Association of Cereal Chemists (AACC) approved method 46-13.01 (AACC International 2000). The multiplication factors used were 5.7 for cereals and 6.25 for pulses.

Dry gluten, ash content, α-amylase activity and colorimetric indices were measured according to Spina et al. (2015). Total, soluble and insoluble dietary fibre were determined using the enzymatic–gravimetric procedure, according to AACC method 32-07.01 (AACC International 2000).

The analyses of the raw materials and flour blends were carried out in duplicate.

Rheological tests on doughs of semolina and flour blends

The visco-elastic and mixing properties and strengths of the doughs were measured using a farinograph (Brabender Instruments, Duisburg, Germany) and an alveograph (Chopin MA 82; Tripette and Renaud, Villeneuve-la-Garenne, France), as described by Spina et al. (2015). The measures were replicated twice.

Breadmaking trials and bread fibre evaluation

The baking tests were performed on the different flour blends and on RDW according to AACC approved method 10-10.03, which was modified for durum wheat, as reported by Boggini and Pogna (1989), slightly modified. Two loaves of 140–150 g were obtained per sample, using the following formula (based on flour weight): 100 g flour (14% moisture basis), 6% sugar, 3% compressed yeast, 3% shortening, 2% NaCl, and 80 ppm ascorbic acid. In the experimental baking laboratory (temperature, 25 ± 2 °C), all of the ingredients were mixed with distilled water in the farinograph, following the water absorption and development mixing time (mixing bowl, 200 g; National Manufacturing Company, Lincoln, Nebraska). The doughs were leavened at 29 ± 1.41 °C and at 82.5% ± 3.54% relative humidity in a thermostated proofing cabinet equipped with a steam humidifier (SD series; Carel S.r.l., Brugine, Padova, Italy), for 1.75 h. The dough was sheeted in a roller, then it was proofed for another 50 min, and a second sheeting roll was performed. The doughs were sheeted through the sheeting rolls, and after an additional 25 min, they were manually rounded and placed into individual metal bread moulds. The doughs were then proofed for another 50 min, for a total fermentation time of 3.83 h. They were then baked in a humidified, ventilated and thermostated electric oven (Giorik, Sedico, Bolzano, Italy) for exactly 18 min at 215–220 °C. In this way, a total of 20 loaves were obtained and 1 h after their removal from the oven they were characterised for loaf volume, height and weight, development of crumb porosity, internal structure, crust thickness and roughness, and crumb and crust colour, as described by Spina et al. (2015). All of these parameters were compared to the control loaf prepared from 100% DW. All tests were carried out in duplicate.

Estimated glycaemic response of breads

In this study, no clinical trials were performed on patients, with the glycaemic index estimated by in vitro digestion of the breads.

In-vitro digestion

In-vitro digestion of the breads was carried out as described by Wolter et al. (2013), with slight modifications. Briefly, the breads (5 g) were tipped into a digestion vessel with 50 mL distilled water and 5 mL maleate buffer (0.2 M, pH 6.0, containing 0.15 g/L CaCl2, 0.1 g/L sodium azide) in a heating block at 37 °C (GFL 1092, Germany), and left to equilibrate for 15 min. The digestion was started by addition of 0.1 mL amyloglucosidase (A 7095; Sigma Aldrich, Milan, Italy) and 1 mL 2 g/100 g pancreatin (P7545; Sigma Aldrich) in quick succession, with the vessel stirred at 130 rpm. At 0, 20, 60 and 120 min, 0.5 mL of digested sample was removed for analysis of the glucose released. After the 120-min sampling, the digests were homogenised (Ultraturrax; IKA, Staufen, Germany), to convert them into slurries. The incubations continued for 1 h, with 0.5 mL aliquots of digested samples removed for analysis of the glucose released.

Analysis of digested starch

The samples removed during digestion were added to 2.0 mL ethanol, and mixed. After 1 h, the ethanolic subsamples were centrifuged (2000 × g, 2 min; Biofuge Fresco Heraeus, Germany) and a 50-μL aliquot of the supernatant was added to 0.25 mL amyloglucosidase (E-AMGDF; Megazyme International Ireland Ltd; 1 mL per 100 mL in 0.1 M sodium acetate buffer, pH 5.2) for 10 min at 20 °C. Then, 0.75 mL DNS solution [10 g/L 3,5-dinitrosalcylic acid, 16 g/L NaOH, 300 g/L Na–K tartarate (Sigma Aldrich)] was added to the tubes. The tubes were heated for 15 min in boiling water, then left to cool in cold water for 1 h, after which 4 mL water (15 °C) was added to each. After mixing, the reducing sugar concentration was measured colorimetrically (530 nm) using a UV–Vis spectrophotometer (model 1700; Shimadzu Corporation, Kyoto, Japan). Glucose standards of 10.0 mg/mL were used. The data were then plotted as glucose (mg/g sample) versus time. The glycaemic index was calculated by dividing the area under the hydrolysis curve of the sample (0–180 min) by the corresponding area obtained for the control sample (100% DW bread) over the same time duration (Goni et al. 1997).

Sensory analysis

The experimental breads were evaluated for their sensorial attributes by 10 trained tasters (four men, six women; ages, 28–45 years). These panellists were selected on the basis of their sensory skills, and they were also trained in the identification of particular attributes by evaluation of commercial durum wheat breads. Each sample was sliced and placed on a white plate and identified by a random three-digit code. The bread samples were evaluated for the attributes of colour, appearance, odour, crust and crumb consistency, and large bubbles, using a 9-point scale, where 1 corresponded to ‘extremely unpleasant’, 9 to ‘extremely pleasant’, and 5 represented the acceptability threshold (Previtali et al. 2014).

Statistical analyses

The experimental data were subjected to one-way variance analysis (ANOVA) using the Statsoft 6.0 programme (Vigonza, Padova, Italy). Differences among means were determined using Tukey tests, at the p < 0.01 probability level for all parameters, except for crust consistency (p < 0.05). The data are expressed as means ± standard deviation.

All of the data were also subjected to principal component analysis (PCA) based on correlation matrices, to identify a limited number of variables, called ‘factors’, that accounted for a significant proportion of the total variance, using the Statistical Package for Social Sciences software (SPSS, version 21.0; IBM Statistics).

Results and discussion

Raw materials and flour-blend characteristics

In comparison to 100% DW control, 100% YP flour had twice the amount of protein, confirming results reported in the literature for pulses (Table 1; Asif et al. 2013; Dabija et al. 2017). YP flour additions showed higher protein contents than DW, as for RDW (100%). WS (100%) and WS blends showed lower protein content with respect to DW, thus influencing the quality of the bread (Sibanda et al. 2015).

For gluten levels, although RDW showed slightly higher values than DW, it was weaker and sticky due to both the low gluten quality in durum wheat landraces and the secalin in rye (Tatham and Shewry 1991). The 100% WS and 100% YP showed no gluten (de Almeida Costa et al. 2006; Pontieri et al. 2013), while the flour blends prepared by substituting DW with WS or YP from 10 to 30% showed decreasing contents for gluten, with respect to DW.

Significantly greater ash contents were seen for WS and YP, in agreement with de Almeida Costa et al. (2006) and Ratnavathi and Patil (2013). Intermediate levels were seen for RDW and YP-30 while addition of WS or YP showed ash contents similar to DW, which indicated that these are suitable flours for processing into food products.

An optimal falling number (good α-amylase activity) was seen for RDW and WS and YP-30 flours. Supplementing DW with YP resulted in decreased falling number, in agreement with Des Marchais et al. (2011), with no clear trend seen for WS additions.

The highest total dietary fibre levels were seen for RDW and YP, in agreement with Juntunen et al. (2003) and Asif et al. (2013). Addition of YP or WS resulted in decreased total and insoluble dietary fibre contents with respect to their corresponding 100% wholemeals, while the soluble dietary fibre increased or remained unchanged. The insoluble dietary fibre is mainly responsible for the high water-holding capacity that reduces the intestinal transit time (McRorie and McKeown 2017), which was confirmed as the predominant fibre fraction in most cereal products.

DW showed the highest lightness (L*) and yellowness (b*), and the lowest redness (a*). The RDW, 100% WS and WS additions were characterised by high a* and low b* and L*. The 100% YP and the different YP additions showed values similar to DW for L* and b*. The a* and b* variations observed across the flours reflect their differences in pigment composition (Dziki et al. 2014; Dabija et al. 2017).

Rheology on dough made from semolina and flour blends

The rheological properties and bread-baking potential of different composite flours are reported in Table 2. DW showed a moderate farinograph dough development time (correlated to gluten quality and starch granule size) and high water absorption and dough stability (correlated to kneading tolerance), which were associated with low softening index (due to the strong gluten matrix formed by the mechanical action). Furthermore, DW was characterised by a good dough strength (W), and adequate tenacity and extensibility, as shown by the P/L ratio. These data were in agreement with Spina et al. (2015) and Giannone et al. (2016).

In comparison with the DW dough, RDW showed significantly lower water absorption, stability and dough strength, as reflected in the significantly lower P/L ratio. At the increasing levels of WS additions, the water absorption decreased and dough development time increased, to reach significance at WS-30 with respect to DW, while the dough strength decreased and P/L ratio remained unchanged (WS-10 to WS-20) or increased (WS-30). These data partially confirmed earlier reports (Ratnavathi and Patil 2013; Sibanda et al. 2015), in which increasing integration with sorghum flour resulted in increased P/L ratio and decreased dough strength, as a result of the competition between starch granules and protein for available water, thus resulting in longer development time. Instead, supplementing DW with YP at 10% induced a significant increase in dough water absorption, which was typically observed when semolina was enriched with protein (Des Marchais et al., 2011, and references therein). Only at YP-30, there was a significant increase in mixing time, in agreement with studies that have used chickpea flour (Sabanis et al. 2006; Mohammed et al. 2012). Dough stability compared to DW was significantly reduced for all YP additions, reaching the lowest for YP-30, which reflected an increased degree of softening. Moreover, significant reductions in P/L ratio and dough strength of 50% were seen for YP-10, and with these increased to 79% for YP-15 to YP-30. These large reductions in the alveograph indices for YP addition with respect to WS addition might be due to the different dietary fibre compositions of these flours. These will have an impact on dough strength and stability, possibly arising from reduced numbers of hydroxyl groups in the fibre that can interact with water through hydrogen bonding, which will reduce the extent of the gluten network, and consequently weaken the dough (Wang and de Barber 2002; Dhingra and Jood 2004). Moreover, Mohammed et al. (2014) reported that weakening of the gluten network can be attributed to an intense incompatibility between the protein spectrum of pulses and the semolina gluten protein.

Bread quality characteristics

One of the major problems facing bakers is the smaller volume of composite bread, as compared to 100% DW (Table 3). With respect to the control bread (100% DW), RDW bread showed general worsening of volume, although the regular internal structure was maintained, while the crust was significantly rougher. Considering the baking data for DW with added WS and YP, these showed some differences. For WS-10, WS-20 and WS-30, and YP-20 and YP-30, the loaf volumes were significantly, and similarly, decreased, while for the other samples, the loaf volumes were essentially unchanged. Decreases in loaf volume have been partly attributed to dilution of the gluten fraction, which is the source of elasticity in dough. This elasticity helps to retain the carbon dioxide produced during fermentation (Solanghi et al. 2017). Also, the dietary fibre can influence the rheological properties of the dough, due to the weak cell-wall gluten structure, which results in less rising of the bread (Almeida et al. 2013). Loaf height is strictly correlated with loaf volume, and showed trends similar to loaf volume, with slight differences across the breads for the loaf weights.

These different formulations also affected the loaf crumb pore development. Here, WS-10 to WS-20 and YP-10 and YP-15 showed significant improvement in crumb porosity compared to DW, while the other formulations were less porous. The internal structure of the loaves when cut in half was generally regular, except for the WS-20, WS-30 and YP-15 to YP-30 breads. These data were in agreement with Dabija et al. (2017), who observed that with increased yellow pea flour addition for bread wheat, more and larger cells were noted. With respect to DW, increasing integration of WS or YP produced stickier breads. This might be due to the water absorbing capacities of the different proteins and to their competition for water with the other constituents in the dough system (e.g., fibre, starch).

All of the loaves had smooth, or almost smooth crusts. The exceptions were for RDW and YP-30 loaves. Similar values were reported by Mohammed et al. (2012) for bread obtained with the addition of chickpea flour.

Compositing also had an effect on colour, as a key quality parameter in terms of consumer acceptability. Compared to the DW bread, the crumb lightness (L*) and the yellowness (b*) of the RDW and WS breads were all significantly reduced, while they remained essentially the same for YP. The redness (a*) was increased (i.e., less negative) from the DW control in all of the samples, with the highest values seen for RDW.

For the crust colour, which is influenced by the flour type and extraction (Pourafshar et al. 2015), there were significantly decreased values for L* and b* for RDW and YP addition, while a* was significantly reduced for RDW and WS-30, and at the higher YP additions.

Dietary fibre and glycaemic index

Table 4 reports the differences in dietary fibre and in vitro glycaemic indices across the experimental breads. The total dietary fibre in the breads was significantly higher for RDW than DW, by almost fourfold. This reflected the significant, and more than fourfold, higher insoluble fibre for RDW and doubled soluble fibre for RDW, compared to DW. These data are in agreement with the literature for rye and wheat (Juntunen et al. 2003; Danza et al. 2014). With respect to DW, the addition of WS resulted in an increasing trend for insoluble, and hence total, dietary fibre, both of which reached significance for WS-30, accompanied by decreased soluble fibre. For YP additions, there were significant large increases for insoluble, soluble and total dietary fibre, which were around twofold higher for YP-30 than the control DW bread. These data reflected the different dietary compositions of pulses (Ofuya and Akhidue 2005; de Almeida Costa et al. 2006), and they were in agreement with Tazrtar et al. (2016), where incorporation of pulses flour into cereal-based products resulted in increased protein, dietary fibre and mineral contents.

The lowest estimated glycaemic indices were observed for YP-30, YP-20, RDW and WS-30. Rosén et al. (2009) reported that with respect to their control bread (100% white flour from Triticum aestivum), the glycaemic index for bread made with wholemeal rye flour was lower. In particular, for the present study, comparing YP-30 to RDW, although the latter exhibited higher fibre levels, YP-30 showed significantly lower glycaemic index, in agreement with Angioloni and Collar (2012). These authors reported that incorporation of pulses into bread formula decreased starch hydrolysis and glycaemic index.

Thus, it would appear that in addition to the added fibre, the protein components also have important roles in restricting the availability of starch, as well as the starch–protein interactions and other components (e.g., tannin, phenols), potentially through inhibition of enzymatic hydrolysis of starch (Sivam et al. 2010). In addition, Dabija et al. (2017) reported a modification in dough structure due to the high protein in YP, where with increased substitution levels of YP in DW there were increased protein levels and decreased starch granules.

Sensory evaluation

Sensory analysis was carried out to evaluate the acceptability of breads made using different formulations (Table 5). As compared to DW bread, RDW bread had the lowest colour, appearance and crumb consistency values, together with lack of large bubbles. This may be potentially due to the high total dietary fibre for RDW, which may have changed the gluten network and decreased the baking quality (Goméz et al. 2018; Dabija et al. 2017).

Considering the breads enriched with WS, the acceptability scores generally decreased with increased proportions of WS. These data are in agreement with those of Khating et al. (2014), who reported that breads made from up to 15% sorghum flour were acceptable, while at 20% and 25% sorghum flour, the overall acceptability scores were significantly reduced in terms of crumb consistency and large bubbles, as compared with the control (100% wheat flour).

For addition of YP to DW, the breads were more appreciated and more similar to DW, except for some attributes for YP-30. Dabija et al. (2017) reported that the best sensorial results in terms of appearance, taste and colour were obtained with the addition of pea flour into bread by up to 10%, where higher proportions led to worsening of the product from the sensory point of view.

Correlations between different properties

The different raw materials, dough rheological properties, and bread characteristics were examined through principal component analysis (PCA) to provide an outline of relationships among these parameters.

The first two PCs (Fig. 1) explain 75.2% of the variation, with PC1 explaining 53.52%. PC1 allowed the breads to be distinguished in relation to the different ingredients. The DW bread was discriminated from that of RDW for both axes. For PC1, the increasing proportions of YP addition in the breads were negatively loaded. PC2 highly discriminated the YP breads from the WS breads, in terms of the proportions of YP and WS included. The YP breads were positively correlated to PC2, while the increasing proportions of WS were negatively correlated to PC2. Along the PC1 axis of Fig. 1, the highest positive loading values for loaf height, crust colour (as L*, a*, b*) and glycaemic index can be seen, along with negative loading values for soluble, insoluble and total dietary fibre, and crust appearance and roughness. PC2 was mostly effective in terms of crumb colour (b*, L*), water absorption, soluble dietary fibre and softening index. The two rheological parameters of development mixing time and dough stability negatively affected PC2, as did crumb colour (a*).

Within this framework, it appears that increasing proportions of YP in the bread correlated to high levels of soluble, insoluble and total dietary fibre, which affected the dough rheological properties and the physical characteristics of the resulting bread. Crust colour (a*, L*) and loaf height were more correlated to the WS breads.

The results shown by the PCA appear to be in agreement with the rheological, baking, and sensory results discussed above, allowing the reduction of these many variables into two principal components, as shown previously in other studies (Sabanis and Tzia 2009).

Conclusion

The results showed RDW and addition of WS or YP into DW bread formulations can improve nutraceutical properties of bread in terms of dietary fibre, and consequently, of in vitro glycaemic index, especially at high level of addition. However, RDW and increasing additions of WS/YP showed variable effect on dough viscoelastic characteristics, bread quality, and sensorial attributes.

References

AACC (American Association of Cereal Chemists) International (2000) Approved method, 11th edn. AACC International, St. Paul

Almeida EL, Chang YK, Steel CJ (2013) Dietary fibre sources in bread: influence on technological quality. LWT Food Sci Technol 50(2):545–553

Angioloni A, Collar C (2012) High legume-wheat matrices: an alternative to promote bread nutritional value meeting dough viscoelastic restrictions. Eur Food Res Technol 234:273–284

Asif M, Rooney LW, Ali R, Riaz MN (2013) Application and opportunities of pulses in food system: a review. Crit Rev Food Sci Nutr 53(11):1168–1179

Boggini G, Pogna NE (1989) The breadmaking quality and storage protein composition of Italian durum wheat. J Cereal Sci 9(2):131–138

Dabija A, Codină GG, Fradinho P (2017) Effect of yellow pea flour addition on wheat flour dough and bread quality. Rom Biotechnol Lett 22(5):12888

Danza A, Mastromatteo M, Lecce L, Spinelli S, Laverse J et al (2014) Effect of wholemeal durum wheat varieties on bread quality. Int J Food Sci Nutr 5:977–988

de Almeida Costa GE, da Silva Queiroz-Monici K, Pissini Machado Reis SM, Costa de Oliveira A (2006) Chemical composition, dietary fibre and resistant starch contents of raw and cooked pea, common bean, chickpea and lentil legumes. Food Chem 94(3):327–330

Des Marchais LP, Foisy M, Mercier S, Villeneuve S, Mondor M (2011) Bread-making potential of pea protein isolate produced by a novel ultrafiltration/diafiltration process. In: 11th international congress on engineering and food (ICEF11), Procedia food science, vol 1, pp 1425–1430. https://doi.org/10.1016/j.profoo.2011.09.211

Dhingra S, Jood S (2004) Effect of flour blending on functional, baking and organoleptic characteristics of bread. Int J Food Sci Technol 39(2):213–222

Dziki D, Różyło R, Gawlik-Dziki U, Swieca M (2014) Current trends in the enhancement of antioxidant activity of wheat bread by the addition of plant materials rich in phenolic compounds. Trends Food Sci Technol 40(1):48–61

Giannone V, Lauro MR, Spina A, Pasqualone A, Auditore L et al (2016) A novel α-amylase-lipase formulation as anti-staling agent in durum wheat bread. LWT Food Sci Technol 65:381–389

Goméz M, Ronda F, Blanco CA, Apesteguia A (2018) Effect of dietary fibre on dough rheology and bread quality. Eur Food Res Technol 216:51–56

Goni I, Garcia-Alonso A, Saura-Calixto F (1997) A starch hydrolysis procedure to estimate glycaemic index. Nutr Res 17:427–437

Juntunen KS, Laaksonen DE, Autio K, Niskanen LK, Holst JJ et al (2003) Structural differences between rye and wheat breads but not total fiber content may explain the lower postprandial insulin response to rye bread. Am J Clin Nutr 78:957–964

Khating KP, Kenghe RN, Yenge GB, Ingale VM, Shelar SD (2014) Effect of blending sorghum flour on dough rheology of wheat bread. Int J Agric Biol Eng 7(1):117–124

Ktenioudaki A, Gallagher E (2012) Recent advances in the development of high-fibre baked products. Trends Food Sci Technol 28(1):4–14

McRorie JW Jr, McKeown NM (2017) Understanding the physics of functional fibers in the gastrointestinal tract: an evidence-based approach to resolving enduring misconceptions about insoluble and soluble fiber. J Acad Nutr Diet 117:251–264

Mohammed I, Ahmeda AR, Sengea B (2012) Dough rheology and bread quality of wheat–chickpea flour blends. Ind Crops Prod 36:196–202

Mohammed I, Adberahman R, Ahmed BS (2014) Effects of chickpea flour on wheat pasting properties and bread making quality. J Food Sci Technol 51(9):1902–1910

Ofuya ZM, Akhidue V (2005) The role of pulses in human nutrition: a review. J Appl Sci Environ Manag 9(3):99–104

Ötles S, Ozgoz S (2014) Health effects of dietary fiber. Acta Sci Pol Technol Aliment 2:91–202

Pontieri P, Mamone G, De Caro S, Tuinstra MR, Roemer E et al (2013) Sorghum, a healthy and gluten-free food for celiac patients as demonstrated by genome, biochemical, and immunochemical analyses. J Agric Food Chem 61(10):2565–2571

Pourafshar S, Rosentrater KA, Krishnan PG (2015) Using alternative flours as partial replacement of barbari bread formulation (traditional Iranian bread). J Food Sci Technol 52(9):5691–5699

Previtali MA, Mastromatteo M, De Vita P, Ficco DBM, Conte A et al (2014) Effect of the lentil flour and hydrocolloids on baking characteristics of wholemeal durum wheat bread. Int J Food Sci Technol 49:2382–2390

Ratnavathi CV, Patil JV (2013) Sorghum utilization as food. Nutr Food Sci 4(1):1–8

Rosén LAH, Blanco LO, Andersson SUK, Holm C, Östman EM et al (2009) Endosperm and whole grain rye breads are characterized by low post-prandial insulin response and a beneficial blood glucose profile. Nutr J 8:42–52

Sabanis D, Tzia C (2009) Effect of rice, corn and soy flour addition on characteristics of bread produced from different wheat cultivars. Food Bioprocess Technol 2:68–79

Sabanis D, Makri E, Doxastakis G (2006) Effect of durum flour enrichment with chickpea flour on the characteristics of dough and lasagna. J Sci Food Agric 86:1938–1944

Sibanda T, Ncube T, Ngoromani N (2015) Rheological properties and bread making quality of white grain sorghum-wheat flour composites. Int J Food Sci Nutr E 5(4):176–182

Sivam AS, Sun-Waterhouse D, Quek SY, Perera CO (2010) Properties of bread dough with added fiber polysaccharides and phenolic antioxidants: a review. J Food Sci 75(8):R163–R174

Solanghi IA, Shaikh N, Marri A, Soomro AH, Khaskheli G (2017) Loaf characteristics and sensory properties of whole wheat bread fortified with sorghum and rice flour. J Basis Appl Sci 13:606–610

Spina A, Brighina S, Muccilli S, Mazzaglia A, Rapisarda P et al (2015) Partial replacement of NaCl in bread from durum wheat (Triticum turgidum L. subsp. durum Desf.) with KCl and yeast extract: evaluation of quality parameters during long storage. Food Bioproc Tech 8:1089–1101

Tatham AS, Shewry PR (1991) Conformational analysis of the secalin storage proteins of rye (Secale cereale L.). J Cereal Sci 14(1):15–23

Tazrtar K, Zaidi F, Lamacchia C, Haros M (2016) Effect of durum wheat semolina substitution with broad bean flour (Vicia faba) on the Maccheroncini pasta quality. Eur Food Res Technol 242(4):477–485

Wang J, de Barber CB (2002) Effect of the addition of different fibres on wheat dough performance and bread quality. Food Chem 79(2):221–226

Wolter A, Hager AS, Zannini E, Arendt EK (2013) In-vitro starch digestibility and predicted glycaemic indexes of buckwheat, oat, quinoa, sorghum, teff and commercial gluten-free bread. J Cereal Sci 58(3):431–436

Acknowledgements

Part of this study was supported financially by the Regional Operating Programme of Regione Siciliana ‘PO FESR 2007-2013—Asse IV, Obiettivo 4.1.1, Linea di Intervento 4.1.1.2’ under the title of the research program ‘Impiego e valutazione di fibre e sostanze nutraceutiche per l’ottenimento di prodotti da forno salutistici’ (Grant Number 5787/3 of the 14/12/2011). The authors wish to thank Dr Christopher Berrie for scientific English language editorial assistance.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflicts of interest

The authors declare that they have no conflicts of interest.

Rights and permissions

About this article

Cite this article

Ficco, D.B.M., Muccilli, S., Padalino, L. et al. Durum wheat breads ‘high in fibre’ and with reduced in vitro glycaemic response obtained by partial semolina replacement with minor cereals and pulses. J Food Sci Technol 55, 4458–4467 (2018). https://doi.org/10.1007/s13197-018-3374-9

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13197-018-3374-9