Abstract

Food industry produces considerable amounts of by-products that represent a severe problem from both economic and pollution points of view. The bioactive compounds still present in food by-products offer the possibility to re-use them to develop added value products. In the current work some by-products were incorporated into curd during production of Primosale cheese. Specifically, two concentrations (i.e., 50 and 100 g Kg−1) of flours from different by-products (i.e., red and white wine grape pomace; tomato peel, broccoli and artichokes by-products), as source of dietary fibres and bioactive compounds were tested. The swelling and water retention capacity of flours, in addition to physicochemical characteristics of cheese (cheese weight loss, dry substance in the whey, cheese moisture content and pH), bioactive compounds (total phenolic compounds, total flavonoids and antioxidant activity) and sensory profile were evaluated. Results highlighted that addition of by-products to Primosale cheese improved the nutritional properties and some sensory attributes such as friability and adhesiveness. Among the tested by-products, the most attractive result was obtained for Primosale cheese with artichoke by-products.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

By-products of food processing represent the major disposal problem for food industry. Principally, food waste is devolved to animal feed or fertilization (Helkar et al. 2016). However, different studies highlight that fruit and vegetables by-products can be a wealthy source of bioactive compounds (Abou-zeid 2016). In particular, carotenoids, fibres, polyphenols, tocopherols, vitamins, and other microelements were abundantly found in different by-products from vegetable origin. Their functional properties give the possibility to enrich food products and satisfy consumer demand for food with less synthetic compounds, more natural and rich in healthful nutrients. It is well known that the components of fruit and vegetables, if consumed daily in sufficient amount, could play an important role to prevent cancer and other diseases (Abou-zeid 2016).

Wine grape pomace, by-products of wine production, is characterized by skins and seeds and represents about 25% of the initial wine weight (Dwyer et al. 2014). A considerable amount of bioactive compounds (phenolic compounds and antioxidant dietary fibre) are retained in both red and white wine grape pomace (Dwyer et al. 2014; Tseng and Zhao 2013). A greater content in total dietary fibres was found for red wine grape pomace (around 50%) compared to white grape pomace (around 20%) (Dwyer et al. 2014). The bioactive elements in wine grape pomace allow a vast range of applications including functional foods, cosmetics, pharmaceutical and supplements (Garcìa-Lomillo and Gonzàlez-SanJosè 2017). In the literature, the addition of wine grape pomace flours or extracts were proposed in bread (Aghamirzaei et al. 2015), biscuits (Karnopp et al. 2015), pasta (Marinelli et al. 2015), fermented milk (Aliakbarian et al. 2015); yogurt (Marchiani et al. 2016a), cheese (Da Silva et al. 2015; Marchiani et al. 2016b;) and meat products (Garcìa-Lomillo and Gonzàlez-SanJosè 2017). Large amounts of by-products are also produced by the tomato industry. Tomatoes and tomato by-products are characterized by antioxidant activity, mainly due to the carotenoids, including lycopene and lutein (Calvo et al. 2008). The addition of tomato by-products to fermented sausages, meat products (Calvo et al. 2008) and dry pasta (Padalino et al. 2015) was yet studied. In the artichoke industry the edible part is obtained with the production of about 66% of by-products (leaves, external bracts and stems). In particular, artichoke is a natural source of dietary fibres and antioxidant compounds (Lattanzio et al. 2009; Boubaker et al. 2016). The phenolic compounds concentration changes among cultivars and it is influenced by plants, age, agronomic and post-harvest conditions. A few applications of artichoke by-products are still reported in the literature. Boubaker et al. (2016) and Frutos et al. (2008) proposed artichokes by-products as source of fibre in bread. Broccoli have high content of bioactive phyto-chemicals, such as nitrogen-sulfur compounds, phenolic compounds, vitamins (C, E, A, K), essential minerals (K, Ca, Fe), as well as dietary fibres. The potential anticancer properties of broccoli nutrients were abundantly demonstrated (Domìnguez-Perles et al. 2010). Datt Sharma et al. (2011) studied the physical and sensory properties of cheese enriched with dry broccoli.

In general, the addition of vegetable by-products to dairy products can improve the nutritional characteristics, reduces the absorption of cholesterol, decreases hypertension, gastrointestinal disorders, coronary heart disease and diabetes and can also improve some technological aspects as yield, by weight and firmness (Abou-zeid 2016). However, some negative sensory changes can occur, as brittleness increase and firmness reduction (Da Silva et al. 2015). In dairy sector, the addition of by-products was proposed for yogurt (Dello Staffolo et al. 2004; Gahruie et al. 2015; Tseng and Zhao 2013), spreadable cheese and semi-hard cheese (Abd Elhamid 2016; Marchiani et al. 2016b).

Due to the few dairy applications recorded, the objective of this study was to evaluate the effect of the addition of different flours from dry vegetable by-products (i.e., red and white wine grape pomace, tomato peel, broccoli and artichokes by-products), on physicochemical and sensory properties of Primosale cheese, a fresh soft cheese made up of full milk and characterized by a short aging period (24 h). Each vegetable flour was added at two concentrations (i.e., 50 and 100 g kg−1). Swelling and water retention capacity of flours, cheese weight loss, dry substance in the whey, cheese moisture content, pH, total phenolic compounds, total flavonoids, antioxidant activity and sensory cheese profile were evaluated for each product.

Materials and methods

By-products

White and red wine grape pomace (made up of skins, seeds and stalks), tomato peels, broccoli and artichoke by-products were provided by a local company of Foggia (Southern Italy). The samples were dried at 30 ± 2 °C in a dryer (SG600, Namad, Rome, Italy) for 48 h. The dry vegetables by-products were reduced to fine powder by a hammer mill (16/BV-Beccaria s.r.l., Cuneo, Italy) and then stored at 4 °C until the utilization. The swelling and the water retention capacity (WRC) of each dry vegetable flour (Vby-p) were calculated as suggested by Robertson et al. (2000) and reported in Table 1.

Cheese production

Primosale cheese was produced by direct acidification with lactic acid. In particular, 50 L of pasteurized raw milk were processed by pilot plant (MilkyLab, Modena, Italia) located in Foggia, in the university laboratory. Milk with 3.7 g L−1 of fat, 3.45 g L−1 of protein and 12.9% of total solids was purchased from Granarolo S.p.A. (branch office of Gioia del Colle, Italy) and transported in refrigerated conditions to the laboratory. Cold milk (7.6 °C) was acidified with 70:30 v/v of lactic acid solution (strength 80%, Perrin’s Chemicals, Triggiano, Italy) up to pH 5.83 ± 0.02. Subsequently, 6 g kg−1 of NaCl and 0.04 g kg−1 of CaCl2 were dissolved in heated milk (38 ± 0.2 °C). For the coagulation phase, 12 mL of liquid rennet (CHY-MAX® Plus, CHR HANSEN, Denmark, 200 IMCU/mL) were added and consequently, the curd was collected in perforated basket and properly mixed with the different vegetable by-products in concentrations of 50 and 100 g kg−1of curd. In particular, broccoli by-products (Br5 and Br10), white wine grape pomace (WG5 and WG10), red wine grape pomace (RG5 and RG10), artichoke by-products (Ar5 and Ar10) and tomato peels (TP5 and TP10) were tested. Primosale cheese without any dry vegetables was also produced as control sample (Cntr). To promote the whey removal, the obtained cheese samples were turned after 15, 30, 45 and 60 min. The realized samples (300 ± 10 g initial weight) were placed under refrigerated conditions (4 ± 1 °C) and left to drain for 24 h before the experimental analyses.

Physicochemical cheese characteristics

To evaluate the influence of the different Vby-p during cheese making, some technological aspects and cheese characteristics were evaluated. In particular, cheese weight loss, dry substance in the whey, cheese moisture content and pH were measured.

Cheese weight loss

The weight loss was determined by a digital precision balance (± 0.1 g) (Gibertini Europe, Italy), according to Costa et al. (2016).

Whey dry substance

The whey released from each sample was collected and dried. Percentage dry matter was measured as the remaining weight of sample after drying and expressed as percentage of the wet sample: (weight of dry whey)/(weight of raw whey)×100.

Cheese moisture content

According to Costa et al. (2016) a thermal balance (Sartorius, Göottingen, Germany) set at 130 °C was used for moisture content determination.

pH

Primosale cheese pH was measured using a pH meter (Hanna instruments, Italia).

For each analysis two replicates were carried out using two different cheese samples.

Extraction and determination of bioactive compounds

All reagents used for chemical analysis were purchased from Sigma-Aldrich (Milan, Italy) and were of analytical grade.

Extraction of bioactive compounds

The extraction of phenolic compounds from both vegetable flours and cheese samples was performed as described by Rashidinejad et al. (2013) with slight modifications. Briefly, 1 g of sample was mixed with 50 mL of acidified methanol (95% MeOH containing 1% HCl) and extracted for 30 min at 50 °C in a water bath (Grant OLS200, Cambridge, UK) at 200 rpm. The mixture was cooled and filtered by using a cheese-cloth and the residues were washed with 2 mL of the same solvent. The obtained extracts were analysed immediately. Extraction was carried out in triplicate for each sample.

Total phenolic compounds

Total phenolic compounds both in vegetable flours and in fortified cheese were determined in triplicate by UV–vis spectrophotometry according to the Folin–Ciocalteu method, as described by Spinelli et al. (2015). The total phenolic content was expressed as mg of gallic acid equivalents (GAEs) per gram of dry weight (dw).

Total flavonoids

Total flavonoids content both in vegetable flours and in fortified cheese was determined in triplicate by the aluminium chloride colorimetric method, as reported by Marinelli et al. (2015). The total amount of flavonoids was expressed in mg of quercetin equivalents (QEs) per gram of dry weight (dw).

Antioxidant activity

The antioxidant activity in vegetable flours and in cheeses was assessed using two methods: ABTS (2,2-azino-bis(3-ethylbenzothiazoline-6-sulfonic acid diammonium salt) and FRAP (ferric reducing antioxidant power) assays. ABTS assay, based on the ability of antioxidants to interact with the radical cation ABTS·+ inhibiting its absorption at 734 nm. The antioxidant activity was calculated according to Marinelli et al. (2015) and expressed as mg Trolox (6-hydroxy-2,5,7,8-tetramethylchroman-2-carboxylic acid) equivalents (TEs) for gram of dry weight.

The FRAP assay was carried out according to the procedure described by Benzie and Strain (1996) with slight modifications. The FRAP reagent was prepared by mixing 100 mL of 300 mM acetate buffer at pH = 3.6 (consisting of 3.1 g of sodium acetate trihydrate (CH3COONa·3H2O) and 16 mL of acetic acid glacial (CH3COOH) per litre of buffer solution, 10 mL of 10 mM TPTZ (2,4,6-Tripyridyl-s-Triazine) solution (0.031 g TPTZ in 10 mL of 40 mM HCl dissolved at 50 °C) and 10 mL of 20 mM ferric chloride (FeCl3) aqueous solution. The FRAP solution was prepared on the day of analysis and held at 37 °C. An amount of 3 mL of FRAP reagent was added to 200 µL of each properly diluted extract. The mixture was left to react for 30 min at 37 °C and then the absorbance was read at 593 nm. The calibration curve was obtained using as standard ferrous sulfate heptahydrate (FeSO4·7H2O) at concentrations from 0.0125 to 0.6 mM (R2 = 0.9981). The antioxidant activity was expressed as μmol of ferrous equivalent Fe(II) per gram of dried sample (μmol FeSO4·7H2O/g dw). Tests were carried out in triplicate.

Sensory analysis

The sensory profile of cheese samples with and without by-products was evaluated by a panel test. To the aim, the intensity of odour and aroma, sweet, salty, bitter and acid in addition to tactile sensations relative to astringency, spicy, fibre, friability, adhesiveness, hardness and humidity were taken into account. Each sensory attribute was definite as reported by Niro et al. (2014). The intensity of each attribute was quantified on a 7-point increasing scale (Faccia et al. 2013). The sensory panel consisted of eleven trained judges who were previously trained in cheese profiling. Panel training sessions were performed to familiarise the panellists with the language and the products under investigation (Faccia et al. 2013). For sensory analysis, cheese samples, tempered at room temperature (20 ± 1 °C), were coded with three-digit randomized numbers and served in a random order.

Statistical analysis

The experimental data were compared by one-way Anova (Statistica 7.1 for Windows). To determine significance among differences a Duncan’s multiple range test, with the option of homogeneous groups (p < 0.05), was adopted. Furthermore, Pearson correlation coefficients (CORR procedure) were calculated to examine the relationship between sensory attributes and physicochemical characteristics of enriched cheese samples.

Results and discussion

Physicochemical quality of cheese

In order to evaluate the influence of by-products on fresh cheese, moisture content, pH, cheese weight loss and dry substance in the whey collected during the short ripening time (24 h) were determined and reported in Table 2. As regards the moisture content, in general it can be said that no relevant differences were found among samples. Specifically, most of them recorded moisture values lower than the control cheese, that accounted for about 65% humidity, and a few samples (Br10, WG5 and Ar10) were statistically comparable to the control cheese. Gabr et al. (2016) also found no statistical differences in terms of moisture of soft cheese added with 5, 10 and 15% of black rice powder. Even though each flour was characterized by specific water retention capacity (Robertson et al. 2000), literature data also confirmed that generally addition of vegetable flours to fresh cheese caused a decrease in moisture content (Dibazar et al. 2016).

Table 2 also highlights that the addition of Vby-p in Primosale cheese does not bring a drastic change in pH values, compared to the control sample, except for white and red wine grape pomace that caused greater pH reduction. No pH variability was observed in yogurt added with commercial fibres from apple, bamboo, wheat and inulin (Dello Staffolo et al. 2004) whereas, a pH reduction was observed by Tseng and Zhao (2013) in yogurt added with wine grape pomace.

Looking at the third column of Table 2 it is possible to infer that addition of by-products influenced cheese weight loss during the short ripening time (24 h). In general this study highlights that the highest flours concentrations tested reduced the cheese weight loss due to the water retention capacity of Vby-p, which are particularly abundant in fibres (Abou-zeid 2016; Robertson et al. 2000). As a fact, other studies also confirmed that fibres increase the yield of dairy products (Abd Elhamid 2016; Abou-zeid 2016). In the same column of Table 2 it is possible to observe that an opposed result in terms of weight loss was observed for RG5, Ar5 and TP5 compared to the control, most probably due to the different influence of vegetable flour on syneresis process (Ferreira 2011). Tseng and Zhao (2013) described that the addition of grape pomace flour in concentration of 3% to yogurt produced excessive syneresis. Marchiani et al. (2016b) in the production of semi-hard cheese also observed an increase in syneresis activity. These phenomena can be due to the change of pH that induces the degradation of caseins during the ripening, thus promoting the syneresis activity (Tseng and Zhao 2013; Marchiani et al. 2016b). Likewise, Da Silva et al. (2015) observed that syneresis of curd decreased with increasing concentrations of pomace by-products.

The analysis on the drained whey values reported in the last column of Table 2 points out an increase of dry matter for cheese samples with different Vby-p compared to the control sample, mainly due to the loss of dry flour in the whey during the 24 h of ripening time. An obvious correlation of whey dry matter, weight loss and syneresis activity can be also inferred (Abd Elhamid 2016; Abou-zeid 2016).

Chemical quality

Results of total phenolic content flavonoids and antioxidant activity, are listed in Tables 3. As can be seen, the red wine grape pomace is the vegetable material with the highest amount of total phenols (107.4 ± 2.08 mg GAEs/g dw), flavonoids (12.9 ± 0.39 mg QEs/g dw) and antioxidant activity (127.36 ± 2.89 mg TEs/g dw and 1886 ± 156.7 μmol FeSO4·7H2O/g dw for ABTS and FRAP, respectively), followed by the white wine grape pomace. This result were consistent with other authors (Gonzàlez-Centeno et al. 2014; Marchiani et al. 2016a, b) who considered wine by-products rich source of bioactive compounds. The chemical characterization of cheese samples was shown in Table 4. As expected, the addition of vegetable flours at both concentrations significantly increased the total phenolic content. Only in the case of the TP5 no statistically significant increase was observed compared to the control cheese, most probably due to the low concentration of bioactive compounds in tomato by-products. It is worth noting that in the case of red wine grape pomace, at both 50 and 100 g kg−1, the highest quantity of bioactive compounds (6.92 ± 0.38 and 10.59 ± 0.31 mg GAEs/g dw, respectively) was detected. However, a linear increase in the TPC with the concentration of the vegetable materials cannot be clearly underlined. This trend could be explained by possible interactions between polyphenols and milk proteins. As a fact, a similar behaviour was also observed by Rashidinejad et al. (2016), who incorporated green tea extract into full-fat cheese at different concentrations.

As regards the total flavonoids content, among the Primosale cheese enriched at 50 g kg−1 only the samples with wine pomace were statistically different from the control, whereas, except TP10, all the Primosale cheese enriched at 100 g kg−1 were significantly higher than the control.

From the point of view of the antioxidant activity, all the fortifications at 50 g kg−1 resulted in a significant increase. The results were comparable between ABTS and FRAP assays. Primosale cheese enriched to 100 g kg−1 only TP10 was not statistically different from the control sample. As expected, the Primosale cheese fortified with red wine grape pomace had the highest antioxidant activity, followed by WP, Br, Ar and TP. The same trend was also observed for total phenolic content. In fact, according to Alonso et al. (2002) there is a positive correlation between the antioxidant activity and the total polyphenolic content of samples. Also Rashidinejad et al. (2013) observed a strong correlation between TPC and FRAP assay. Therefore, the obtained results are in accordance with data presented in the literature. Other authors tried to enrich dairy products, in particular yogurt, with bioactive compounds mostly derived from red wine grape pomace. Marchiani et al. (2016a) fortified yogurt with wine skin flours and observed a significantly higher total phenolic content and antioxidant activity than the control. Rashidinejad et al. (2016) incorporated green tea extract into full-fat cheeses to investigate the effect of green tea catechins on antioxidant properties, thus observing a significant increase of TPC and antioxidant activity at all concentrations. Datt Sharma et al. (2011) tested cheese powder obtained by freeze-dried blended with dry broccoli and observed an increase of total antioxidant capacity, total polyphenolics and total carotenoids.

Sensory profile

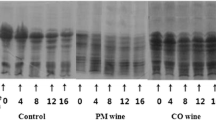

In Fig. 1 cheese sensory profile is reported. As can be observed comparing control and treated samples, the addition of Vby-p modified the sensory attributes. Some changes in sensory parameters were also reported in other dairy products added with fibers or by-products (Abd Elhamid 2016; Abou-zeid 2016; Da Silva et al. 2015). Specifically, in our study, comparable profiles were observed when same by-products were tested at the two concentrations even though, a perception amplified was reported for cheese with 100 g kg−1 of Vby-p. For all vegetable flours an increase of odour and aroma intensity as well as increased tactile sensations (astringent, fibrous, friability, adhesiveness and humidity) were detected compared to the control sample. More in detail, white and red wine grape pomace increased astringent, fibrous, friability and also acid perception. Both tested grape pomace negatively influenced cheese hardness probably due to the final cheese pH that affected curd structure, thus promoting cheese softening and consequent syneresis (Tseng and Zhao 2013). The hardness of cheese was increased with the adding of tomato peel, broccoli and artichokes by-products; this is most probably due to the fact that Vby-p conferred homogeneous and compact body to the cheese. Any panelists reported spicy sensation whereas, bitter was only perceived when broccoli (Br5 and Br10) and artichokes (Ar10) by-products were used. Bitter sensation in broccoli-treated samples can be related to the presence of bioactive phito-chemical compounds such as nitrogen-sulphur compounds (Domìnguez-Perles et al. 2010), whereas, cynarin and phenolic acid may be responsible for the bitterness of the artichokes (Helkar et al. 2016).

Sensory profile of cheese with different vegetable by-products. a CNTR: control Primosale cheese; WG5: white wine grape pomace Primosale cheese enriched to 50 g kg−1; RG5: red wine grape pomace Primosale cheese enriched to 50 g kg−1; b CNTR: control Primosale cheese; Ar5: artichoke Primosale cheese enriched to 50 g kg−1; TP5: tomato peel Primosale cheese enriched to 50 g kg−1 Br5: broccoli Primosale cheese enriched to 50 g kg−1; c CNTR: control Primosale cheese; WG10: white wine grape pomace Primosale cheese enriched to 100 g kg−1; RG10: red wine grape pomace Primosale cheese enriched to 100 g kg−1; d CNTR: control Primosale cheese; Ar10: artichoke Primosale cheese enriched to 100 g kg−1; TP10: tomato peel Primosale cheese enriched to 100 g kg−1 Br10: broccoli Primosale cheese enriched to 100 g kg−1

Correlations among physicochemical and sensory characteristics

Table 5 shows the statistical correlations between physicochemical (cheese moisture, cheese weight loss and dry substance in the whey) and sensory parameters (fibrous, adhesiveness and friability). It can be noted that for cheese samples with Vby-p significant correlations were found. A highly positive correlation was observed between sensory parameters and dry substance in the whey for all treated cheese samples. This significant correlation is due to the fact that an increase of dry substance in the whey also increased the perception of fibrous, friable and adhesive (Abou-zeid 2016). A negative correlation was instead observed between weigh loss and fibrous, friability and adhesiveness for broccoli and white wine grape pomace. In particular, the water retention capacity of Vby-p reduced the weight loss of cheese, thus also improving the sensory parameters (Ferreira 2011). Moreover, highly negative correlation exists between cheese moisture content and sensory characteristics of red wine grape pomace and tomato peel. Dibazar et al. (2016) also studied the effect of grape fibres and demonstrated that moisture and syneresis of samples significantly reduced by increasing fibres amount.

Conclusion

The results highlighted that from a nutritional point of view cheese samples added with red or white wine grape pomace were the best ones. However, both types of by-products, due to their influence on final pH, induced technological problems to cheese structure. Therefore, the most suitable equilibrium between nutritional value, sensory quality and technological parameters in terms of weight loss during the ripening time, cheese moisture content and pH was obtained for Primosale cheese added with artichoke by-products.

References

Abd Elhamid AM (2016) Physicochemical, rheological and sensory properties of Egyptian Kariesh cheese containing wheat bran. Int J Dairy Technol 69:425–432. https://doi.org/10.1111/1471-0307.12278

Abou-zeid NA (2016) The nutraceutical effects of dairy products fortification with plant components: a review. Int Adv Res Sci Eng Technol 3:1475–1482 (ISSN: 2350-0328)

Aghamirzaei M, Peighambardoust SH, Azadmard-Damirchi S, Majzoobi M (2015) Effects of grape seed powder as a functional ingredient on flour physicochemical characteristics and dough rheological properties. J Agric Sci Technol 17:365–373

Aliakbarian B, Casale M, Paini M, Casazza AA, Lanteri S, Perego P (2015) Production of a novel fermented milk fortified with natural antioxidants and its analysis by NIR spectroscopy. LWT 62:376–383

Alonso AM, Guillèn DA, Barroso CG, Puertas B, Garcìa A (2002) Determination of antioxidant activity of wine by products and its correlation with polyphenolic content. J Agric Food Chem 50:5832–5836

Benzie IFF, Strain JJ (1996) The ferric reducing ability of plasma (FRAP) as a measure of ‘‘antioxidant power’’: the FRAP assay. Anal Biochem 239:70–76

Boubaker M, Omri AEL, Blecker C, Bouzouita N (2016) Fibre concentrate from artichoke (Cynara scolymus L.) stem by-products: characterization and application as a bakery product ingredient. Int Food Sci Technol 0:1–10

Calvo MM, Garcìa ML, Selgas MD (2008) Dry fermented sausages enriched with lycopene from tomato peel. Meat Sci 80:167–172

Costa C, Lucera A, Lacivita V, Saccotelli MA, Conte A, Del Nobile MA (2016) Packaging optimisation for portioned Canestrato di Moliterno cheese. Int J Dairy Technol 69:1–8

Da Silva FD, Matumoto-Pintro PT, Bazinet L, Couillard C, Britten M (2015) Effect of commercial grape extracts on the cheese-making properties of milk. J Dairy Sci 98:1552–1562

Datt Sharma K, Stähler K, Smith B, Melton L (2011) Antioxidant capacity, polyphenolics and pigments of broccoli-cheese powder blends. J Food Sci Technol 48:510–514

Dello Staffolo M, Bertola N, Martino M, Bevilacqua A (2004) Influence of dietary fiber addition on sensory and rheological properties of yogurt. Int Dairy J 14:263–268

Dibazar P, Khosrowshahi Asl A, Zomorodi S (2016) Optimization grape fiber and chitosan amounts in fruit yoghurt using response surface methodology (RSM). J Food Sci Technol 13:75–88

Domìnguez-Perles R, Martìnez-Ballesta MC, Carvajal M, Garcìa-Viguera C, Moreno DA (2010) Broccoli-derived by-products—a promising source of bioactive ingredients. J Food Sci 74:338–392

Dwyer K, Hosseinian F, Rod M (2014) The market potential of grape waste alternatives. J Food Res 3:91–106

Faccia M, Angiolillo L, Mastromatteo M, Conte A, Del Nobile MA (2013) The effect of incorporating calcium lactate in the saline solution on improving the shelf life of fiordilatte cheese. Int J Dairy Technol 66:373–381

Ferreira TG. (2011) Optimization of couagualtion and sineresi processes in cheesemaking using a light backscatter sensor technology. University of Kentucky Master’s Theses. Paper 125. http://uknowledge.uky.edu/gradschool_theses/125. Accessed 16 Feb 2017

Frutos MJ, Guilabert-Anton L, Tomas-Bellido A, Hermàndez-Herrero JA (2008) Effect of artichoke (Cynara scolymus L.) fiber on textural and sensory qualities of wheat bread. Food Sci Technol Int 14:49–55

Gabr ASM, Mahgoub SA, Satar ASA, Shehata WM (2016) Evaluation of healthy soft cheese produced by buffalo’s milk fortified with black rice powder. Int J Dairy Sci 11:11–19

Gahruie HH, Eskandari MH, Mesbahi G, Hanifpour MA (2015) Scientific and technical aspects of yogurt fortification: a review. Food Sci Hum Well 4:1–8

Garcìa-Lomillo J, Gonzàlez-SanJosè ML (2017) Applications of wine pomace in the food industry: approaches and functions comprehensive reviews. Food Sci Food Saf 16:3–22

Gonzàlez-Centeno MR, Knoerzer K, Sabarez H, Simal S, Rossellò C, Femenia A (2014) Effect of acoustic frequency and power density on the aqueous ultrasonic-assisted extraction of grape pomace (Vitis vinifera L.)—a response surface approach. Ultrason Sonochem 21:2176–2184

Helkar PB, Sahoo AK, Patil NJ (2016) Review: food Industry by-products used as a functional food ingredients. Int J Waste Resour 6:1–6

Karnopp AR, Figueroa AM, Los PR, Teles JC, Simões DRS, Barana AC, Kubiaki FT, de Oliveira JGB, Granato D (2015) Effects of whole-wheat flour and Bordeaux grape pomace (Vitis labrusca L.) on the sensory, physicochemical and functional properties of cookies. Food Sci Technol 35:750–756

Lattanzio V, Kroon PA, Linsalata V, Cardinali A (2009) Globe artichoke: a functional food and source of nutraceutical ingredients. J Funct Foods 1:131–144

Marchiani R, Bertolino M, Belviso S, Giordano M, Ghirardello D, Torri L, Piochi M, Zeppa G (2016a) Yogurt enrichment with grape pomace: effect of grape cultivar on physicochemical, microbiological and sensory properties. J Food Qual 39:77–89

Marchiani R, Bertolino M, Ghirardello D, Mcsweeney PL, Zeppa G (2016b) Physicochemical and nutritional qualities of grape pomace powder-fortified semi-hard cheeses. J Food Sci Technol 53:1585–1596

Marinelli V, Padalino L, Nardiello D, Del Nobile MA, Conte A (2015) New approach to enrich pasta with polyphenols from grape marc. J Chem 2015:1–8

Niro S, Fratianni A, Tremonte P, Sorrentino E, Tipaldi L, Panfili G, Coppola R (2014) Innovative Caciocavallo cheeses made from a mixture of cow milk with ewe or goat milk. J Dairy Sci 97:1296–1304

Padalino L, Conte A, Lecce L, Likyova D, Sicari V, Pellicanò TM, Poiana M, Del Nobile MA (2015) Durum wheat whole-meal spaghetti with tomato peels: how by-product particles size can affect final quality of pasta. J Food Process Technol 6:1–5

Rashidinejad A, Birch EJ, Sun-Waterhouse D, Everett DW (2013) Effects of catechin on the phenolic content and antioxidant properties of low-fat cheese. Int J Food Sci Technol 48:2448–2455

Rashidinejad A, Birch EJ, Everett DW (2016) A novel functional full-fat hard cheese containing liposomal nanoencapsulated green tea catechins: manufacture and recovery following simulated digestion. Food Funct 7:3283–3294

Robertson JA, de Monredon FD, Dysseler P, Guillon F, Amadò R, Thibault JF (2000) Hydration properties of dietary fibre and resistant starch: a European collaborative study. LWT 33:72–79

Spinelli S, Conte A, Lecce L, Incoronato AL, Del Nobile MA (2015) Microencapsulated propolis to enhance the antioxidant properties of fresh fish burgers. J Food Process Eng 38:527–535

Tseng A, Zhao Y (2013) Wine grape pomace as antioxidant dietary fibre for enhancing nutritional value and improving storability of yogurt and salad dressing. Food Chem 138:356–365

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Costa, C., Lucera, A., Marinelli, V. et al. Influence of different by-products addition on sensory and physicochemical aspects of Primosale cheese. J Food Sci Technol 55, 4174–4183 (2018). https://doi.org/10.1007/s13197-018-3347-z

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13197-018-3347-z