Abstract

Thunbergia laurifolia leaves were dried by freeze drying (FD) and microwave heat pump dehumidified air drying (MHPD). The dried leaves were stored in polypropylene (PP) or aluminum laminated pouches (ALP) at 15, 25 or 35 °C and 60% RH. The samples were held for 180 days to observe changes in moisture content, color, total phenolics, antioxidant activity, catechin and caffeic acid. In general, samples in PP had a greater increase in moisture. Total phenolics content and ferric-reducing antioxidant power values increased for 120 days, then decreased thereafter. After 180 days, both FD and MHPD samples packaged in ALP and stored at 15 °C had the greatest total phenolics, antioxidant activity and bioactive compounds amongst the storage conditions. The first-order equation best described degradation behavior of catechin and caffeic acid for both drying technologies investigated.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Thunbergia laurifolia belongs to the group of flowering plants known as Acanthaceae, and is commonly known as the “blue trumpet vine” or “rang chuet”. The plant is native to Southeast Asia and found throughout Thailand. It has been used to treat poisoning from insecticides, ethyl alcohol, arsenic and strychnine (Tangpong and Satarug 2010). T. laurifolia contains several phenolic compounds that act as potent antioxidants or chelation agents (Srida et al. 2002).

The production of T. laurifolia teas and powders has increased considerably in recent years. To manufacture a product that retains vital phytochemicals, has acceptable shelf life and presents with acceptable consumer quality attributes requires careful selection of sample pre-treatments, drying methods and storage conditions. Relatively high temperatures and long drying times can diminish color, flavor, nutrients and desired phytochemicals. Low temperature techniques such as freeze or vacuum drying are beneficial for preserving color and chemical compounds in dried leaf products (Ratti 2001). These methods have some disadvantages related to batch-wise processing and long drying times. An interesting hybrid drying technology, known as heat pump dehumidified air drying (HPD), has proven to be effective for producing high quality herb and green leaf powders (Phoungchandang et al. 2003; Potisate et al. 2015). These systems improve efficiency by using a dehumidifier to reduce water vapor in the air, then using the extracted heat to increase the temperature of the drying air. Heat transfer efficiency can be further improved by incorporating microwave radiation.

After drying, long term storage can lead to loss of color, nutrients and bioactive compounds. For green-leaf products, the maintenance of color is associated with high-quality and freshness. Some quality factors are unseen by the consumer, yet expected in the product. Thus, for medicinal herbs or other functional products, the retention of antioxidants or specific phytochemicals is expected. The maintenance of dried products qualities depends on the moisture level of the products, along with environmental conditions and any packaging barriers to moisture or oxygen.

Little is known about the effects of drying conditions, storage and packaging on dried leaf products such as T. laurifolia. The first goal of this research was to determine the effects of microwave heat pump dehumidified air drying (MHPD) on the initial quality of T. laurifolia leaves. These results were compared to those from samples prepared by freeze-drying (FD). Next, the effects of storage temperature between 15 and 35 °C were examined, and how this determines changes in color, phenolic compounds, and antioxidant capacity during storage. In addition, two types of packaging material (polypropylene; PP and aluminum laminated pouches; ALP) were studied. The results were analyzed in terms of several kinetic models.

Materials and methods

Materials

Thunbergia laurifolia leaves were harvested from a private orchard located at Khon Kaen University, Khon Kaen, Thailand. Young leaves (1st and 2nd pairs from the top of the stem) were picked and washed in 5 ppm chlorinated water. Before drying, the leaves were blanched for 4 min to inhibit enzymatic browning during drying, using a steam-microwave process described by Phahom et al. (2017).

Drying treatments

Thunbergia laurifolia leaves were processed by two methods, namely freeze drying and microwave heat pump dehumidified air drying. For freeze drying, 80 g samples of blanched leaves (previously frozen at − 60 °C) were placed on cylindrical aluminum trays. Each of the five trays had a surface area of 0.88 m2 and a diameter of 375 mm. These were placed onto the freeze dryer shelves (Christ, DELTA 2-24 LSC, Fisher Scientific, England) and the leaves were dried for 24 h at 5 Pa. The plate temperature was programmed to ramp from − 60 to 25 °C. The final moisture content of the dried leaves was about 3.74% d.b.

For the MHPD, 30 g of blanched T. laurifolia leaves were initially dried at 900 W for 1 min in a microwave dryer (Electrolux, model EMS3067X, China) as described by Phahom et al. (2017). After microwave drying, the samples were placed in the heat pump dehumidified air dryer as described by Phoungchandang et al. (2003) and dried at 40 °C for 25 min. The final moisture content of dried leaves was about 6.65% d.b.

Storage studies

Approximately 2 g of dried leaves, from both FD and MHPD, were placed into either a 6 × 9” polypropylene pouch (ULINE Pleasant Prairie, WI, USA) or a high-barrier aluminum laminate pouch (ABC Packaging, Westlake, OH, USA). The former was constructed of 2-mil polypropylene and had a water vapor transmission rate of 260 g/m2·24 h, and an oxygen permeability of 81,000 cc/m2·24 h. The latter consisted of alternating layers of aluminum and polyethylene (ALP; 12 µm of polyethylene terephthalate (PET) and 70 µm linear low density polyethylene (LLDPE) laminated with 7 µm aluminum). The laminate bags had a water vapor transmission rate of 0.15 g/m2·24 h, and an oxygen permeability of 0.2 cc/m2·24 h. The samples were heat-sealed under vacuum (~ 800 mPA absolute) using a Henkelman vacuum packaging machine (Henkelman, Elmherst, IL, USA).

The samples were stored in Model 317522 environmental chambers (Hotpak, Warminster, PA, USA) at 15, 25 or 35 °C (± 0.2 °C) and constant relative humidity of 60% for 180 days. The measured properties included moisture content, water activity, total phenolics, antioxidant activity (FRAP) and ion chelating efficiency, as well as specific quantification of the bioactive compounds (catechin and caffeic acid). Samples were removed and assayed every 60 days of storage. Dried leaves at 0 day of storage were used as a control.

Color measurement

The color of the dried T. laurifolia leaves was measured with a colorimeter (Konica Minolta, CR-400; Minolta Co. Ltd., Tokyo, Japan) and recorded using the CIE L*a*b* system. In addition, the H* (hue angle) was calculated to evaluate the yellow–green color of the dried leaves.

Total color difference (ΔE*) was also determined as an overall measure between treated and control samples:

Moisture content and water activity

The moisture content of the dried T. laurifolia leaves was measured using a Mettler-Toledo halogen moisture analyzer (Mettler Toledo, HG63, Greifensee, Switzerland). Samples were dried at 125 °C until a constant mass (± 0.01%) was achieved as determined by the automatic weighing mechanism.

The water activity (aw) of the dried leaves was determined at 20 °C using an AquaLab 4TE meter (Decagon Devices Inc., Pullman, WA, USA).

Phenolics extraction

Thunbergia laurifolia leaf powder (1.5 g) was extracted with three 120 mL portions of 70% (v/v) aqueous methanol (Phahom et al. 2017). The mixture was agitated in a shaking water bath (Toronto Surplus & Scientific Inc., Richmond Hill, ON, Canada) at 50 °C for 60 min after which the sample was filtered through Whatman No. 1 filter paper, leaving the extracted compounds in the filtrate. The methanol was then evaporated off at 45 °C and 200 mbar (Büchi Corporation, Rotavapor R-210, Flawil, Switzerland). The residual aqueous mixture was dried using a VirTis Benchtop “K” freeze dryer (SP Industries, Warminster, PA, USA). The dried powder was weighed, placed in a brown bottle and stored at − 80 °C. The powder was used to determine the total phenolics content, antioxidant activity and bioactive phenolic compounds present.

Total phenolics content

The total phenolics content (TPC) of the extracts was determined using the Folin–Ciocalteu assay adapted from Oonsivilai et al. (2008). Five mg of each extract was dissolved in anhydrous methanol in a 25 mL volumetric flask. The TPC analyses were performed in test tubes using 0.5 mL of the methanolic extract, 8 mL of deionized water, 0.5 mL of Folin and Ciocalteu’s phenol reagent and 1 mL of sodium carbonate (7%, w/v). The mixtures were vortexed for 30 s and held at room temperature (21 °C) for 45 min to allow for maximal color development. Following this period, a portion of the reaction mixture from each tube was transferred to a 1 cm borosilicate glass cuvette and the absorbance measured at λ = 765 nm. A standard curve was constructed from solutions of catechin (2.5–25 µg/mL). Results were expressed as mg catechin equivalents (CE)/g dry weight (d.w.).

Ferric-reducing antioxidant power (FRAP) assay

The reducing capacity of each leaf extract was determined by the FRAP assay, as adapted from Oonsivilai et al. (2008). Twenty-five mg of each extract was dissolved in anhydrous methanol in a 25 mL volumetric flask. The FRAP reagent was prepared fresh daily using 250 mL of acetate buffer (pH 3.6) with 10 mM of 2,4,6-tripyridyl-S-triazine (TPTZ), 40 mM HCl and 20 mM ferrous chloride hexahydrate (FeCl3·6H2O). Each assay was performed in a test tube using 0.04 mL of the methanolic extract, 1.6 mL of deionized water and 4.5 mL of the FRAP reagent. The mixture in each tube was vortexed for 30 s. After 15 min, the absorbance of the mixtures was measured at 593 nm. A standard curve was constructed with an iron sulfate heptahydrate solution (FeSO4·7H2O) at five different concentrations ranging from 10 to 200 µM. The antioxidant activity of the extract was reported as µmol Fe(II) equivalent/g d.w.

Chelating efficiency assay

The method of Tan and Chan (2014) was used to determine the chelating efficiency of the T. laurifolia extracts. Different extract concentrations were prepared in 2 mL anhydrous methanol, then added into test tubes followed by 0.16 mL of 0.1 mM FeSO4. Next, 1 mL of 0.25 mM ferrozine was added to each tube, which was then vortexed for 30 s. The mixture was held at ~ 20 °C for 10 min. The absorbance of the complex was then measured at 562 nm. The ability to chelate ferrous iron was calculated as:

The chelating ability was expressed as CEC50, that is the effective concentration in mg/mL that chelates 50% of the ferrous ion.

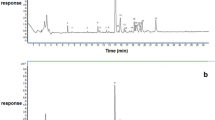

Determination of catechin and caffeic acid

The powdered extract (25 mg) was dissolved in 10 mL anhydrous methanol (Phahom et al. 2017). Samples were hydrolyzed so the aglycone forms could be assayed. Hydrolysis was conducted by adding 10 mL of 6 M HCl to the mixture, which was then heated at 90 °C for 2 h. The hydrolyzed extracts were filtered through a 0.22 µm Phenex RC filter (Phenomenex, Torrance, CA) prior to HPLC analyses.

Samples were analyzed using the HPLC method described by Ma et al. (2014). Phenolics were separated with an Agilent 1200 HPLC with the quaternary pump, autosampler, thermostated column, and UV–Vis diode array detection, and analyzed with 3D ChemStation software (Agilent Technologies, Santa Clara, CA, USA). A reversed-phase Luna C18 column (4.6 × 250 mm, 5-µm particle size; Phenomenex, Torrance, CA, USA) was utilized. A gradient elution was employed consisting of mobile phase A (H2O/CH3CN/CH3COOH, 93:5:2, v/v/v) and mobile phase B (H2O/CH3CN/CH3COOH, 58:40:2, v/v/v) from 0 to 100% B over a 50-min period at a flow rate of 1 mL/min. A volume of 15 µL was injected for each extract. Detection wavelengths were 276 nm (catechin) and 327 nm (caffeic acid). Identification of components was made by matching UV–Vis spectra and retention time mapping with the commercial (+)-catechin and caffeic acid standards (Sigma-Aldrich Chemical Co., St. Louis, MO, USA).

Statistical analysis

Statistical analysis was conducted using SPSS 19.0 (SPSS, Inc., Chicago, IL). A split–split-plot design (4 × 2 × 3) was used in the study. The main plot was time (0, 60, 120 and 180 days); the sub-plot was packaging types (PP and ALP); and the sub-sub plot was temperatures (15, 25, and 35 °C). Three replications were used to determine each parameter. Duncan’s multiple range test was used to compare the significance of treatment means at a 95% confidence interval.

Degradation kinetics and shelf-life

The degradation of catechin and caffeic acid in dried T. laurifolia leaves during storage was modeled by zero and first-order reaction kinetics equations:

where C is the concentration at time (t); C0 is the initial value at time zero; t is the storage time (min); k0 is the zero-order kinetic constant (mg day−1) and k1 is the first-order kinetic constant (day−1).

The measured values of catechin and caffeic acid during storage were fitted to Eqs. 4 and 5 using SPSS 19.0 s. The zero-order constants (Co and ko) and first-order constants (C1 and k1) were calculated using non-linear regression. The coefficient of determination (R2), standard error of estimate (SEE) and root mean square error (RMSE) were used as the basis to select the best fitting model, which provided the highest R2 and the lowest SEE and RMSE values.

The half-life value (t1/2), the time needed for 50% degradation of catechin or caffeic acid, were calculated from the zero or first-order models using:

The dependence of the reaction rate (k) on temperature was determined using the Arrhenius equation:

where, Ea is the activation energy (J/mol); k 2 is the kinetic constant (day−1) at a reference temperature; R is the ideal gas constant (8.3145 J/mol K) and T is the temperature (K).

Results and discussion

Moisture content (MC) and water activity (aw)

Changes in MC and aw during storage are shown for FD (Table 1) and MHPD leaves (Table 2). Initially, the FD samples had lower moisture (3.74% d.b.) than MHPD samples (6.65% d.b.). The corresponding aw values were 0.20 and 0.50, respectively. Storage time, temperature and packaging type were all significant factors for moisture change. Long storage times had the greatest effects on moisture. Specifically, for MPHD samples the greatest moisture gain occurred in PP packaging at 35 °C, increasing from 6.65 to 9.66% d.b. over 180 days. In general, at 180 days samples which were packed in ALP had lower MC than those packed in PP. Interestingly, aw did not vary much in the MPHD samples during storage. Water activity values ranged from 0.41 to 0.50 over all factors. All samples were stored at 60% RH, so there was not a great driving force for moisture transfer into the package contents. In contrast, FD samples had a starting aw of 0.20, and thus saw a greater increase over time. Values ranged from 0.20 at day 0, up to 0.53 for samples stored in PP at 35 °C. Even though the ALP packaging material has minimal water transmission, in some cases samples in ALP did increase in moisture. Thus, either some moisture could migrate through the package, particularly at higher temperatures, or chemical changes involving hydrolysis may add to the water in the products.

Low moisture products are prone to moisture pickup in high humidity environments. One purpose of packaging is to limit moisture transfer into enclosed foods. Swain et al. (2013) reported that MC and aw of dried sweet peppers increased with storage time. There was some pick-up of moisture and change of quality factors even for products in laminate packaging. Dried samples in PP would be expected to have greater increases in MC and aw compared to those in ALP, as PP provided higher rate of water vapor migration from the storage environment into the packaging (Marsh and Bugusu 2007).

Color changes

Changes in the color parameters during storage are shown for FD (Table 1), and for MHPD samples (Table 2). For FD leaves in PP packaging, increasing storage time and temperature resulted in a decrease in hue angle (H*), indicating a slight decrease in green color. Little change was noted for samples at 15 °C, or for any samples contained in ALP packages. The overall color difference (ΔE*) values of dried leaves increased with storage time, particularly for samples in PP packaging. After 180 days, ΔE* also increased with temperature, reaching maximum values of 2.78, 2.82 and 5.75 for samples stored in PP at 15, 25 and 35 °C, respectively. Color change of chlorophyll in dried leaves is promoted by heat and oxygen during storage (Meyer 1973). Post-harvest, chlorophyll in leaves can undergo oxidation, hydrolysis and isomerization. Color loss occurs as the magnesium atom of chlorophyll is replaced by two hydrogen atoms, resulting in change from bright green to olive green.

∆E* values also increased with time for the MHPD powders, but not as much as observed for FD samples. Interestingly, ∆E* increased with increasing storage time and temperature in both PP and ALP packaging for MHPD samples. Hue angle for MHPD samples decreased with storage time, particularly for samples stored at higher temperature. Overall, H* values changed more in MHPD powders than FD powders, although overall color differences were greater in the FD powders. This can be traced to greater changes in lightness (L*) for the FD samples, and this may be related to the fact that these picked up more moisture overall. While it is understood that moisture level affects the tristimulus color values of dried products, only a few researchers have pursued this topic. For example, Özkan et al. (2003) showed that as the moisture content of dried apricots was increased from 15.5 to 30.2%, L* and b* values increased while a* decreased.

Antioxidant activity

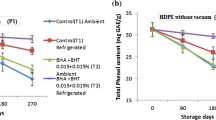

Antioxidant activities of dried T. laurifolia leaves during storage are also reported in Tables 1 and 2 for FD and MHPD samples, respectively. Overall, all factors were significant for antioxidant activity as measured by TPC and FRAP. Greatest changes occurred for samples stored in PP and at higher temperatures. It should be noted that while TPC is not an antioxidant assay, it often correlates with other antioxidant assays. From days 0 to 120, TPC and FRAP values generally increased for all samples regardless of drying method or packaging used for storage. Increases in measured phenolic compounds may be found after processing or storing some products. One theory is that bound phenolics may be released or liberated into free forms after heating or other processes that alter the food structure (Li and Shah 2013). This process is temperature dependent, as samples stored at higher temperature had greater levels of TPC and FRAP at day 120. However, at longer storage times (180 days) these values decreased. In fact, the decreases in TPC and FRAP values at 180 days were greater at higher temperature. This led to the interesting observation that higher TPC or FRAP values might be reached at 120 days in samples at 35 °C, which then decreased to levels below those of samples held at 15 °C. In general, ALP packaging with low storage temperature was most effective at maintaining consistent antioxidant activity in the dried leaves, and relatively high values after 180 days. Studies have shown antioxidant properties of dried fruit are more stable in multilayer packaging, as it has good barrier properties against the light, gases and water vapor (Zoric et al. 2016; Gvozdenovic et al. 2007).

It was also observed that TPC and FRAP values were greater in MHPD than in FD samples. Samples were dried at 40 °C by MHPD, and while this is not an exceptionally high drying temperature, it is greater than that used in freeze drying. In addition, during MHPD moisture can move in the liquid state, while in FD water is constrained to the solid state. Thus, one hypothesis is that the higher temperatures and freedom of motion for samples dried by the MHPD leads to greater release of phenolic compounds than occurs in freeze drying.

The CEC50 value is the concentration of extract that chelated 50% of the ferrous ion. Thus, lower CEC50 values indicate a greater chelating efficiency than higher values. The samples kept in ALP packaging possessed lower CEC50 values than those in PP packaging for both FD and MHPD samples (Tables 1, 2). That is, ALP packaging did a better job of preserving the chelation properties of the samples. Interestingly, the FRAP values were inversely correlated with CEC50 values (R2 = 0.85). This suggests that factors that make for antioxidant properties may also be useful for metal ion chelation. Mirzaei and Khatami (2013) and Oliveri (1997) indicated that metals ions including iron, copper and lead are catalysts in the oxidation pathway, and promote free radical development. In addition, phenolic compounds such as flavonoids are good antioxidants due to their free radical scavenging properties and have additional pharmacological actions related to Fe2+ chelating ability (Havsteen 1983).

Bioactive compounds

With respect to specific phenolic compounds, T. laurifolia leaves have significant levels of catechin and caffeic acid. Levels of these compounds during storage are presented in Table 3. Initial levels of catechin were similar in the two dried products, with 27.89 mg/g d.w. in FD samples and 28.55 mg/g d.w. in MHPD samples. In all cases, levels of the two compounds decreased throughout the 180 days storage period. The changes in these compounds were greater with higher temperature. After 180 days of storage, ALP packaging and storage at 15 °C resulted in the highest catechin and caffeic acid levels, while PP packaging and storage temperature at 35 °C resulted in the lowest catechin and caffeic acid content. At a given temperature and storage day, samples in ALP packaging had higher levels than those in PP packaging, although the differences were not great.

Li et al. (2011) demonstrated that both temperature and moisture content affected the degradation of catechin in green tea products. Increasing relative humidity led to increased rates of catechin degradation in green tea power during storage (Komatsu et al. 1992). Water absorbed into amorphous systems acts as a plasticizer and possible reactant, and accelerates chemical reactions by enhancing molecular mobility as well as changing the local environment (Ortiz et al. 2009). Bioactive compounds of dried products contained in laminated packaging had greater stability than those in single layer packaging, as the laminated material had greater barrier properties against the light, gas and vapor transmission (Gvozdenovic et al. 2007).

Degradation kinetics and shelf-life prediction

The degradation kinetics of catechin and caffeic acid were investigated using zero- and first-order models. Table 4 shows the fitted variables resulting from regression analyses of the models. It was found that the first-order equation was better fit the degradation of both catechin and caffeic acid than the zero-order equation. Overall, R2 values for the first-order fit were in the ranges from 0.921 to 0.991, while those for the zero-order model ranged from 0.780 to 0.982. The first-order models also had lower SEE and RMSE than zero-order models in equivalent circumstances. The degradation of catechin has been reported to follow first-order kinetics in green tea products (Komatsu et al. 1992).

The reaction rate constant (k) was primarily dependent upon temperature. Ea values (Table 5) ranged from 8.90 to 15.58 kJ/mol K. In all cases, reaction rates for either catechin or caffeic acid loss were greater in PP than ALP packaging. The differences were the greatest for FD samples. Overall, ALP packaging and storage temperature at 15 °C resulted in the lowest rate of catechin or caffeic acid loss. The Ea values were in keeping with those of Potisate et al. (2015), Komatsu et al. (1992) and Yang et al. (2008) who determined that the Ea of total flavonoids, catechin and anthocyanin in dried products were in the ranges from 13.08 to 19.69 kJ/mol.

The half-life (t1/2) of bioactive compounds for both freeze and MHPD dried T. laurifolia leaves are presented in Table 5. As expected, increasing temperature led to shorter half-lives for the two compounds. ALP led to greater t1/2 than PP packaging under the same storage conditions. For example, caffeic acid in FD samples had a t1/2 ranging from 128 to 92 days in PP packages, and from 139 to 109 days in ALP packages. From the Table 5, the results indicated that the MHPD products have a greater shelf-life with respect to specific phenolics. The study of Zoric et al. (2016) found that t1/2 values were higher in samples stored at low temperature (4 °C), and that storage at lower temperatures prolonged the shelf life of cherry products.

Conclusion

The effects of packaging materials, storage temperatures and times on MC, aw, color parameters, total phenolics, antioxidant activities and bioactive compounds were studied in this research. It was found that moisture content and aw increased with storage time and temperature, with greatest changes found in the FD product. ALP packaging resulted in lower MC and aw of the dried leaves than PP packaging in both FD and MHPD, but there was some increase in moisture even in ALP samples. Increasing storage time and temperature led to a small decrease in hue angle and increase in total color difference. After 180 days of storage, samples in ALP packaging had greater total phenolics, antioxidant activities and bioactive compounds than those in PP. Catechin and caffeic acid also decreased with storage temperature and storage time in both PP and ALP packaging. First-order kinetics was the best equation to describe degradation behavior of catechin and caffeic acid. Half-life (t1/2) values were in the ranges from 152.3 to 362.8 and 91.9 to 150 days for catechin and caffeic acid, respectively. Activation energies were in the ranges from 11.94 to 14.07 and 8.90 to 15.58 kJ/mol K for catechin and caffeic acid, respectively. The dried sample from MHPD packed in ALP, and stored at 15 °C were the best potential storage conditions to extend the shelf-life of dried T. laurifolia leaves.

References

Gvozdenovic JJ, Aljilji AR, Lazic VL, Tepic AN, Svrzic GV (2007) Influence of protective characteristics of packaging material on packed dried fruits. Acta Perioda Technol 38:21–28

Havsteen B (1983) A class of natural products of high pharmacological potency. Biochem Pharmacol 32:1141–1148

Komatsu Y, Suematsu S, Yoshihiro H, Saigo H, Matsuda R, Hara K (1992) Effect of pH and temperature on reaction kinetics of catechins in green tea infusion. Biosci Biotechnol Biochem 57:907–910

Li S, Shah NP (2013) Effects of various heat treatments on phenolic profiles and antioxidant activities of Pleurotus eryngii extracts. J Food Sci 78:1122–1129

Li N, Taylor LS, Mauer LJ (2011) Degradation kinetics of catechin in green tea power: effect of temperature and relative humidity. J Agric Food Chem 59:6082–6090

Ma Y, Kosinska-Cagnazzo A, Kerr WL, Amarowicz R, Swanson RB, Pegg RB (2014) Separation and characterization of phenolic compounds from dry-blanched peanut skins by liquid chromatography–electrospray ionization mass spectrometry. J Chrom A 1356:64–81

Marsh K, Bugusu B (2007) Food packaging roles, materials, and environmental issues. J Food Sci 72:39–55

Meyer LH (1973) Food chemistry. Affiliated East-West Press PVT Ltd, New Delhi

Mirzaei A, Khatami R (2013) Antioxidant and iron chelating activity of Coriander and Petroselinum crispum. Bull Env Pharmacol Life Sci 2:27–31

Oliveri NF (1997) Iron-chelating therapy and the treatment of thalassemia. Blood J 89:739–761

Oonsivilai R, Ferruzzi MG, Ningsanond S (2008) Antioxidant activity and cytotoxicity of rang chuet (Thunbergia laurifolia Lindl.) extracts. As J Food Ag Ind 1:116–128

Ortiz J, Kestur US, Taylor LS, Mauer LJ (2009) Interaction of environment moisture with powder green tea formulations: relationship between catechin stability and moisture-induced phase transformations. J Agric Food Chem 57:4691–4697

Özkan M, Kirca A, Cemeroğlu B (2003) Effect of moisture content on CIE color values in dried apricots. Eur Food Res Technol 216:217–219

Phahom T, Phoungchandang S, Kerr WL (2017) Effects of steam-microwave blanching and different drying processes on drying characteristics and quality aspects of Thunbergia laurifolia Linn. leaves. J Sci Food Agric 97:3211–3219

Phoungchandang S, Sanchai P, Chanchotikul K (2003) The development of dehumidifying dryer for a Thai herb drying (Kaprao leaves). Food J 33:146–155

Potisate Y, Kerr WL, Phoungchandang S (2015) Changes during storage of dried Moringa oleifera by heat pump-assisted dehumidified air drying. Int J Food Sci Technol 50:1224–1233

Ratti C (2001) Hot air and freeze-drying of high-value foods: a review. J Food Eng 49:311–319

Srida C, Hankete J, Aromdee C, Pese M (2002) Antioxidant activity of Thunbergia Laurifolia ethanolic extract. Thai J Pharm Sci 26:29–35

Swain S, Samuel DVK, Kar A (2013) Effect of packaging materials on quality characteristics of osmotically pretreated microwave assisted dried sweet pepper (Capsicum annum L.). J Food Process Technol 4:1–7

Tan YP, Chan EWC (2014) Antioxidant, antityrosinase and antibacterial properties of fresh and processed leaves of Anacardium occidentale and Piper betle. Food Biosci 6:17–23

Tangpong J, Satarug S (2010) Alleviation of lead poisoning in the brain with aqueous leaf extract of the Thunbergia laurifolia (Linn.). Toxicol Lett 198:83–88

Yang Z, Han Y, Gu Z, Fan G, Chen Z (2008) Thermal degradation kinetics of aqueous anthocyanins and visual color of purple corn (Zea mays L.) cob. Innovat Food Sci Emerg Technol 9:341–347

Zoric Z, Pedisic S, Kovacevic DB, Jezek D, Dragovic-Uzelac V (2016) Impact of packaging material and storage conditions on polyphenol stability, color and sensory characteristics of freeze dried sour cherry (Prunus cerasus var. Marasca). J Food Technol 53:1247–1258

Acknowledgements

This work was supported by the Royal Golden Jubilee PhD scholarship (Grant No. PHD/0127/2554), Thailand Research Fund and the office of Higher Education Commission, in cooperation with Khon Kean University and the University of Georgia.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Phahom, T., Kerr, W.L., Pegg, R.B. et al. Effect of packaging types and storage conditions on quality aspects of dried Thunbergia laurifolia leaves and degradation kinetics of bioactive compounds. J Food Sci Technol 54, 4405–4415 (2017). https://doi.org/10.1007/s13197-017-2917-9

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13197-017-2917-9