Abstract

In an effort to implement principles of traditional concentrated grape must fermentation to the production of new generation balsamic vinegars (BVs), the specific goals of the study were the isolation and molecular identification of the predominant yeasts in concentrated grape must (cv. Xinomavro), their technological characterization and the evaluation of the fermentative aptitude of the selected strains. Tolerance against 5-hydroxymethyl-furfural (HMF) and furfural, acetic acid and glucose concentration was examined by appropriate methods and tests. The enological characteristics studied were acetic acid and H2S production, foaming and flocculation ability and key enzymatic activity. PCR–RFLP analysis revealed only the presence of Saccharomyces cerevisiae and Hanseniaspora uvarum among the 14 predominant osmophilic yeast isolates. Tolerance to both HMF and furfural was found strain- and dose-dependent and was suggested as a critical factor in the pre-selection of yeast starters. The most tolerant yeasts to these stress factors, a S. cerevisiae and a non-Saccharomyces strains, showed satisfactory growth in the presence of high glucose and acetic acid content (up to 600 g/L and 2 % w/w, respectively) and desirable enological characteristics. Results from the comparative evaluation of the fermentative aptitude of these strains with a commercial wine strain highlighted that the isolates had glucophilic behaviour and ability to produce desirable amounts of ethanol (100–120 g/kg) in short time (~20 d). The key volatiles useful for varietal discrimination and differentiation between the BVs and the traditional ones were also evaluated.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Traditional balsamic vinegar (TBV) is a unique product, the outcome of a complex, laborious, multistep small scale process that combines elements of art and skill of generations of artisans in the area of Modena and Reggio Emilia in Italy (Giudici et al. 2015). Despite its high market value, the long time periods required for each step do not coincide with the contemporary industrial demands for large scale, fast production of food products. The new generation of balsamic vinegars (BVs) that are currently traded worldwide take advantage of technological advances in their production line (Giudici et al. 2015; Mattia 2004). Nevertheless, simple blending of concentrated grape must (CGM) with vinegar and shorter ageing periods before marketing cannot easily lead to products of comparable sensory and physicochemical characteristics to the traditional ones, as clearly shown in our recent publications (Hatzidimitriou et al. 2015; Lalou et al. 2015).

Our perspective is to develop high quality new generation BVs not by simple blending practices but by implementing principles adopted in TBV production for centuries, which are currently scientifically justified (Giudici et al. 2015). Over the last decade, the role of yeasts in TBV production and their influence on the final quality of the product was recognized and the first publications on their ecology appeared (Solieri and Giudici 2005, 2008; Giudici et al. 2009). Until then the acetic fermentation had been considered the key stage in its production, but the importance of yeast metabolism in shaping the chemical properties of TBV was rather overlooked. As a consequence, the selection of proper starters for the alcoholic fermentation emerges as a critical factor in the production of BVs beyond TBV. CGM contains some inhibitory factors, such as the high sugar content, low pH value, the presence of furanic derivatives and the increasing concentration of ethyl alcohol, which may counteract yeast survival and growth (Giudici et al. 2009; 2015; Solieri and Giudici 2005). Considering these characteristics, it cannot be expected that starters specific to wine production possess all the desirable technological features that positively affect the performance of the bioprocess and the quality of the end product. On the other hand, indigenous species are well adapted to grow on a specific substrate (Capece et al. 2012) but under the uncontrolled conditions of traditional spontaneous fermentation their optimum performance cannot be guaranteed. Moreover, exploitation of the most appropriate indigenous species for BV production coincides with the current trend for modernization of fermentation processes and quality standardization of traditional fermented products (e.g. Modha et al. 2015).

Aiming at standardizing the production of a new BV with specific varietal traits that can be declared on the label of the end product, we report a thorough study on the molecular identification of endogenous yeast strains and their effectiveness on alcoholic fermentation of CGM. The latter was obtained from Xinomavro variety, the most important indigenous cultivar of Northern Greece known for supreme quality varietal wines that are characterized by high titratable acidity (7–8.2 g tartaric acid/L) and low pH values (<3.30) (WPANGV 2005). These features are critical initial factors for the development of the desirable sensory characteristics of BVs (Giudici et al. 2015).

Materials and methods

Samples

Fresh must (cv. Xinomavro) was supplied from two vineyards (Naoussa, North-western Greece) for three successive harvest years (2012–2014). Each year, representative samples were boiled down to about 50 % as described by Lalou et al. (2015) and used for yeast strain isolation (Table S1 in Supplementary Material). In 2013 one lot (10 L) of the obtained concentrate was put into a wooden barrel at room temperature to be fermented spontaneously by indigenous yeasts.

Yeast strains

The commercial active dry wine yeast strains Vitilevure MT YSEO (Saccharomyces cerevisiae), Vitilevure GY YSEO (S. cerevisiae) and Vitilevure DV10 (S. bayanus) were provided by Ampelooeniki S.A. (Thessaloniki, Greece).

Yeast isolation and enumeration

Yeast isolation from unfermented and fermented concentrates was accomplished according to the method described by Combina et al. (2008). The selective high sugar (500 g/L) agar substrate (MYG50, pH 5.0) was used to evaluate survival of osmophilic yeasts. Total yeast population was screened on Tryptone Glucose Yeast Extract (TGYE) agar medium (pH 6.0). All the media were supplemented with chloramphenicol (150 ppm) to prevent bacterial growth. Plates with MYG50 or TGYE agar were aerobically incubated at 25 °C for 7 and 5 days, respectively, and used for cell count. Representative isolates per each different yeast colony morphotype developed onto the MYG50 were selected from the highest dilution plates and purified by successive sub-culturing onto Yeast Extract Peptone Dextrose (YEPD) agar (pH 5.8). In total, 14 isolates were obtained. The codes of isolates per CGM sample are shown in Table S1. All the isolates were maintained in YEPD agar plates at 4 °C till use and sub-cultured at 1 month intervals.

All the colonies were also cultivated onto Wallerstein Laboratory Nutrient (WLN) agar (pH 5.5) at 25 °C for 5 days. As reference strains were used Vitilevure MT and DV10.

Molecular characterization

Genetic characterization was performed for all yeast isolates and for the reference strains Vitilevure MT, DV10 and GY. Yeast identification was carried out by means of PCR–RFLP of the 5.8S-Internal Transcribed Spacers ribosomal region, as described by Granchi et al. (1999). For the amplification of ITS region of 5.8S rRNA gene, the primer pairs used were ITS1 and ITS4 (White et al. 1990). PCR products were digested without further purification with restriction enzymes HaeIII, CfoI and DdeI (Promega, Milan, Italy). Restriction fragments were run onto a 2.0 % (w/v) agarose gel in a 0.5 TBE buffer, stained with ethidium bromide and visualized under UV light. DNA fragment sizes were determined by comparison with a molecular marker 100 bp ladder (New England Bio-Labs, Beverly, USA). Yeasts were identified at a species level by comparing the amplified product and their restriction fragment sizes with those described elsewhere (e.g. Esteve-Zarzoso et al. 1999). Strain typing of S. cerevisiae isolates were performed by amplification of inter- region, using the primers pair δ2 (5′-GTGGATTTTTATTCCAAC-3′) (Ness et al. 1993) and δ12 (5′-TCAACAATGGAATCCCAAC-3′) (Legras and Karst 2003). DNA extraction from yeast isolates was carried out using the synthetic resin Instagene Matrix (Bio-Rad, Hercules, CA, USA), according to the manufacturer’s instruction. The DNA was then stored at −20 °C till analysis. Quantification of extracted DNA was performed spectrophotometrically at 260 nm. The DNA extracted by this method was used in the PCR reaction, as described by Le Jeune et al. (2006).

Inoculum preparation

Inoculum of all strains was prepared by transferring a loopful of cells from the YEPD agar plates to 50 mL YEPD broth (pH = 5.5) in 250-mL Erlenmeyer flasks. Cultures were grown aerobically in a shaking incubator at 30 °C/200 rpm to a final OD660 value of ~2. Yeast cells were collected by centrifugation (3000×g, 10 min), washed twice with sterile potassium phosphate buffer (pH 7.4) and suspended in the same buffer to achieve cell concentration of ~1 × 108/mL.

Screening for technological characteristics

The resistance to various levels of known antimicrobial substances present in the CGM was tested onto YEPD agar plates without (control) or supplemented with 0.1, 0.5, 1, 2 and 3 g/L of 5-hydroxymethyl-furfural (HMF) (≥99 %) (Sigma Aldrich, Milan, Italy) or 0.01, 0.02, 0.1, 0.5 and 1 g/L of furfural (99 %) (Sigma Aldrich). The plates were incubated at 25 °C for 3 days.

Custer’s Chalk Agar medium was used to differentiate the strains able to produce acetic acid from glucose, following the protocol described by Suárez Valles et al. (2008).

The acetic acid tolerance of selected isolates was examined in YPDA plates supplemented with 1 and 2 % of acetic acid according to the protocol described by Ma et al. (2015). The plates were incubated at 25 °C for 3 days.

The H2S production was evaluated on Biggy Agar medium. Semi-quantification of H2S production was carried out as proposed by Comitini et al. (2011).

The protease activity was evaluated on a medium containing (g/L) yeast extract (3), malt extract (3), peptone (5), glucose (10), NaCl (5), and agar (15). An equal volume of skimmed milk powder (UAB Litamilk, Vilnious, Lithuania) dissolved in sterile water (to achieve a final concentration of 10 g/L) was prepared in a separate vessel. The two solutions were sterilized, mixed and poured into sterile Petri dishes, which were inoculated with 105 cells/mL. The plates were incubated at 25 °C for 3 days. The presence of a halo around the inoculum indicated protease activity.

Decarboxylation of ferulic and p-coumaric acids by yeasts was determined according to protocol reported by Viana et al. (2008). The β-glucosidase and ester hydrolase activities were evaluated as reported by Comitini et al. (2011). The foam production test was performed according to Regodón (1997). The flocculation test was performed according to Sosa and Farías (2012).

Growth kinetics in synthetic medium with different glucose content

Τhe growth kinetics of selected isolates was examined in YEPD broth containing glucose level of 200, 400 or 600 g/L. A 40 μL aliquot of the inoculum was transferred in 60 mL of the above-mentioned medium providing final OD660 value of 0.01. Microbial growth was monitored by measuring OD660 value. Data were analysed according to the modified Gompertz equation described in Tofalo and Chaves-López (2009).

Fermentation performance in CGM

Fermentation performance of selected isolates was studied in CGM containing 228 and 235 g/kg glucose and fructose, respectively. Before inoculation in CGM (106 cell/mL), the strains were grown in a liquid medium (pH 4.5) composed of 175 g/L anhydrous glucose, 175 g/L fructose, 20 g/L malt extract and 5 g/L yeast extract for adaptation to osmotic shock. Semi-anaerobic experiments were carried out in Erlenmeyer flasks containing 300 mL of the CGM. The substrate was inoculated with 3.5 × 106 cell/mL. The experiments were performed at 25 °C for 30 days and yeast growth was monitored both by OD660 measurement and viable yeast count. Control experiments using CGM without inoculation and inoculated with the commercial strain DV10, suitable for sweet wine fermentation, took place under the same conditions.

Analytical determinations

HMF content in the CGM as well as ethanol, residual sugars and glycerol, at specific time intervals, were quantified using HPLC as described by Lalou et al. (2015). Total acidity was determined by titration with 0.5 M sodium hydroxide solution. Yeast assimilable nitrogen was estimated using the Sorensen formol titration technique (Gump et al. 2001). The ethanol yield was expressed as g ethanol produced per g sugar used, while the fermentation efficiency was expressed as a percentage (%) of the theoretical yield.

Total volatile compounds were determined by liquid–liquid extraction followed by GC analysis of the extract as described by Lalou et al. (2013) after slight modifications to the solvent to sample ratio (25:5, v/v) and the oven temperature program (hold at 40 °C for 2 min, raised to 230 °C at a rate of 4 °C/min, hold at 230 °C for 5 min). Compound identification was conducted by first comparing their mass spectra with those included in the National Institute of Standards and Technology (NIST) Mass Spectral Database US Environmental Protection Agency (EPA)/National Institute of Health (NIH) Mass Spectral Database and by comparison of their mass spectra and retentions time with those of standard compounds. The internal standard used was 4-methyl-2-pentanol (99 %) (Sigma Aldrich) (Marrufo-Curtido et al. 2015) at a concentration of 228 μg/mL in the final sample.

Statistical analysis

A nonlinear curve fitting routine based on the GRG2 generalized reduced gradient nonlinear solving method was used to fit the nonlinear model to the measured data (cell load as OD660 values) on microbial growth. Statistical differences in growth kinetic data of different yeast strains in different environmental conditions were found by one-way ANOVA, followed by the Duncan’s test (p < 0.05 confidence level) using the SPSS 14.0 software (SPSS Inc., Chicago, IL, USA).

Results and discussion

Initial trials were focused on the successful isolation of predominant indigenous yeast species from Xinomavro grape variety. Τhe yeast isolates were identified and characterized by molecular methods and tested for technological characteristics useful for selection of starter cultures for CGM fermentation. Next, the most prominent ones were evaluated for their effectiveness on fermentation outcomes (ethanol yield and productivity, fermentation efficiency, residual glucose and fructose balance, secondary metabolite formation). The findings are presented in Tables 1, 2, 3, and Figs. 1, 2, 3 and discussed in the following sections.

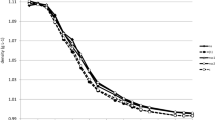

Growth curves of the selected yeast strains 121, 143 and F13 in response to a 200 g/L, b 400 g/L and c 600 g/L glucose. Experimental data are given with empty symbols and predicted values from the modified Gompertz model with lines. [as inset table the responding growth parameters. *Mean value of three independent experiments ± standard deviation (sd); Mean values in the same column with the same superscript indicate that there are no significant differences between them (p < 0.05)]

Yeast isolation and molecular characterization

The concentration of grape must at about 50 % of the initial volume led to a CGM sugar composition (Table S1, samples A–C in Supplementary Material) within the desirable range for osmotolerant TBV-associated yeasts (Giudici et al. 2015). As reported in Table S1, it was possible to isolate yeasts from CGM although at a lower population rate (<103 cfu/mL) in comparison to that isolated from the spontaneously fermented CGM (sample D, 6.55 log cfu/mL). In all samples, colony counts detected on TGY and MYG50 were similar, suggesting that only yeasts capable to survive in extremely high sugar levels (as much as 400 g/L) were present (Combina et al. 2008). In order to focus on the most osmophilic ones, only predominant yeast colonies grown on MYG50 were isolated. Osmophilicity has been pointed out as a critical feature to obtain a “well-fermented cooked must” (Solieri and Giudici 2008).

Initially, isolates were presumptively differentiated based on colony morphology onto WLN agar. As shown in Figure S1 (see Supplementary Material), colonies of yeasts isolated from samples A, B and D showed white or creamy color, while yeasts isolated from sample C formed dark green colonies. The reference strains Vitilevure MT and DV10 formed light blue and light green with darker center colonies, respectively. Since morphological characteristics offer only a tentative evidence of yeast differentiation, the molecular identification and characterization of the isolates was necessary.

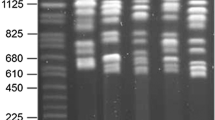

Yeast isolates were identified according to their ITS-RFLP profile. The 5.8S-ITS region amplified by PCR yielded fragments of two different sizes, ~850 and 750 bp, respectively. The first fragment, exhibited by the isolates 121–136 and F13, it was typical of the species belonging to Saccharomyces genus, whereas an ITS product of 750 bp can be assigned to Hanseniaspora spp., as described previously by Esteve-Zarzoso et al. (1999). All the fragments were subjected to restriction analysis with HaeIII and CfoI enzymes, whereas only fragments characterized by 750 bp molecular size were subjected to digestion with DdeI. The PCR and RFLP analysis of the isolates showed variation of the size of the fragments for the different species. The yeast species identified and their rDNA gene RFLP patterns obtained are indicated in Table 1. Two species were identified among the yeast isolates; corresponding to S. cerevisiae (samples A, B, D), and H. uvarum (sample C).

The yeasts identified as S. cerevisiae and the commercial strains Vitilevure MT, DV10 and GY were genotyped by interdelta analysis using the primer pair δ2/δ12 (Legras and Karst 2003). Seven different profiles were found among the wild isolates (lanes 1–11, Figure S2 in Supplementary Material), which were different from the patterns exhibited by the commercial starters (lanes 12–14, Figure S2). All the S. cerevisiae yeasts isolated from sample A (lanes 1–4, Figure S2) showed the same molecular profile, whereas among yeasts isolated from sample B five different profiles were found (lanes 5–10, Figure S2) and only two isolates (133 and 134) showed the same pattern. The strain F13, isolated from sample D, showed a molecular profile different from each other. The results confirmed that the S. cerevisiae isolates were wild ones, different from the commercial starters used at cellar level. Furthermore, these data confirmed that the S. cerevisiae species, although it is a non-osmophilic species, is abundant and detected with a high frequency in CGM fermentation (Solieri and Giudici 2008).

Technological characterization

Knowledge on the technological characteristics and metabolic profile of indigenous yeasts in the balsamic vinegar production is rather limited albeit critical in order to find certain species- or strain-specific effects on BV quality (Solieri and Giudici 2008). Thus, the next part of the present study was focused on isolates characteristics considered to be crucial for efficient CGM fermentation. This approach will allow for the screening and selection of novel starter cultures as a potential tool to standardize the manufacturing process of a new BV.

HMF and furfural tolerance test

One important inhibitory factor that may influence negatively the kinetics of alcoholic fermentation of CGM is the formation of furanic compounds (mainly HMF and furfural) as a result of non-enzymatic browning reactions during grape must heating (Cocchi et al. 2007). HMF concentration seems to vary from very low (~70 mg/kg) to extremely high (~4000 mg/kg) values in CGMs while furfural content is reported to be ~25-fold lower than that of HMF (e.g. Cocchi et al. 2007; Tagliazucchi et al. 2013). Inhibitor stress to DNA and membrane damage, inactivation of key enzymes involved in carbon metabolism and increased yeast sensitivity to osmotic stress (Field et al. 2015; Lewis et al. 2008). Considering that these toxic effects may slow down growth, reduce ethanol production and even cause cell death (Field et al. 2015), selection of strains should also include such a trial. To investigate this trait, 8 isolates which exhibited different molecular profiles (codes 121, 131–133, 135, 136, F13 and 143) were cultivated on YPDA plates, supplemented with concentrations of HMF and furfural similar to the ones expected in a CGM. As shown in Table S1, the value of HMF content (65–250 mg/kg) for samples A–C were similar to the lower limits reported in literature. This was attributed to an expected reduction in the HMF content due to its reaction with antocyanins and flavonoids in red grape must matrix (Tagliazucchi et al. 2013). In all cases, HMF was a less inhibiting factor than furfural, which strongly repressed yeast growth at much lower level (Fig. 1). This inhibitory pattern was also recorded in the work of Tian et al. (2011) for an adapted inhibitor-tolerant yeast strain. Yeast survival decreased for both inhibitors with increasing concentration but the degree of inhibition was strain-dependent. Cell exposure to 0.1–1.0 g/L HMF resulted in a decrease in yeast survival up to 60 and 97 %, respectively, in function of the strain (Fig. 1a). Strains 121 and F13 were proved to be the most resistant to HMF, retaining 56 and 63 % of their initial population in the presence of 1 g/L HMF, respectively. At three-fold higher concentration of the inhibitor, strain 121 was the only one that survived (data not shown). On the other hand, strains 135 and 136 were the least resistant to HMF as only ~40 % cell viability was evidenced after exposure to the lowest inhibitor concentration (0.1 g/L).

Regarding the effect of furfural, even its 20-fold lower concentration (0.005 g/L) suppressed the yeast growth by ~25 % of the strains 131 and 135 (Fig. 1b). The inhibitory effect became even more pronounced at higher furfural concentrations. At 0.5 g/L only the strains 121 and 143 maintained 40 and 22 % of the initial population, respectively. Strain 143 showed the highest resistance to furfural being able to grow at 1 g/L furfural. The above findings revealed that strains 121 and 143 were the most suitable candidates for growth in CGMs containing high concentrations of HMF and furfural. The inhibitor-tolerant yeast strains seem to convert the furanic derivatives into less toxic compounds (Lewis et al. 2008).

Although HMF is recognized as an important constituent of CGM and consequently of TBV, this inhibitor is not included among the critical factors for the selection of the starter cultures for TBV alcoholic fermentation (Solieri and Giudici 2008) yet. In the present study, the high variability found among the strains for the HMF tolerance suggests that this is an important criterion for their pre-selection as yeast starters and should be considered along with other critical factors, such as osmophilicity and glucophilicity, in the production line of high quality new generation BV.

Enological characteristics

The results of the main enological characteristics tested, namely, production of acetic acid and H2S, as well as key enzymatic activities, for the strains of the different molecular profiles are shown in Table 2. The majority of the S. cerevisiae strains were classified as non- or low-acetic acid producers. Only strains 121 and F13 developed a halo larger than 3 mm on Custer’s Chalk Agar medium, hence, being classified as medium acetic acid producers. The H. uvarum strain (code 143) was also classified as medium acetic acid producer. It’s well known the ability of non-Saccharomyces yeasts, such as H. uvarum, to produce more acetic acid than S. cerevisiae (e.g., Capece et al. 2005).

The H. uvarum strain 143 was also considered as a medium-H2S producer when tested on Biggy Agar medium (development of dark brown colonies). Regarding S. cerevisiae yeasts, strains varied in relative sulphite reductase activity from non-H2S (strains 132, 135) to medium-H2S producers (strains 121, 131, 136, F13). H2S formation by yeasts has been previously described to be a strain-dependent phenomenon, influenced also by various environmental and fermentation conditions (Rankine 1963). The presence of H2S above its detection threshold is undesirable in food and beverages as it exerts an unpleasant odor of rotten egg.

None of the strains showed protease or hydroxycinnamic acid decarboxylase activity, while glycosidase activity was detected only for strain 131 (Table 2). As such activities could influence negatively the flavor and color of BV (Comitini et al. 2011; Viana et al. 2008), the findings were promising for the pre-selection of the strains. Moreover, strain 143 (H. uvarum) exhibited the lowest esterase activity and the F13 strain the highest one. Esterase activity modifies the flavor of fermented products, e.g. wine, by catalyzing the cleavage of esters and the formation of new ester bonds that affect positively or negatively flavor (Saerens et al. 2010).

Foaming and flocculation ability

Adopting the scale proposed for grape must fermentation (Regodón 1997), all the isolates showed from medium to high foam production (Table 2). High foaming is considered an undesirable trait in fermentation although it improves nutrient mass transfer. On the other hand, flocculation ability of yeast cells is important in the downstream process for yeast cell separation. Such ability may not be critical in TBV production but it gains importance when an accelerated fermentation is sought. Flocculation can also offer protection against the inhibitory effect of high concentration of furanic derivatives in CGM as it is a natural way of yeast immobilization (Westman et al. 2014). Regarding the S. cerevisiae yeasts, all the strains, except strain 132, exhibited a very high flocculation degree (85–99 %). The H. uvarum strain used was less successful (61 % degree of flocculation).

On the basis of these results, three strains, 121, F13 (S. cerevisiae) and 143 (H. uvarum) were selected for evaluation of their fermentative aptitude in CGM from cv Xinomavro.

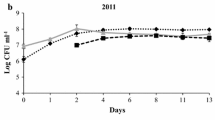

Fermentation performance of the selected strains in CGM

The fermentation performance of the selected yeast strains was evaluated at micro-scale fermentation trials using Xinomavro CGM (glucose and fructose content of 228 and 235 g/kg, respectively). The effectiveness of indigenous strains was compared with that of a commercial wine strain suitable for sweet wine production (DV10). As shown in Fig. 2a, F13 strain failed to overcome the stressful environment of CGM. Strain 121 responded better than the industrial starter DV10 in terms of (1) adaptation behaviour, (2) maximum cell yield, and (3) survival at the end of the fermentation. Specifically, during the lag phase the population of strain 121 remained stable for approximately 5 days whereas DV10 was highly stressed losing 3 logs during the first 6 days. The maximum cell population reached by DV10 strain was lower than that of strain 121 (11 log10 cfu/mL vs. 9 log10cfu/mL after 15 days, respectively) and a remarkable cell death during the last stage of fermentation process was observed for the commercial strain. The concentrations of sugars and ethanol at late stages of fermentation are likely two of the main causes of the lack of viability of the industrial strain. The non-Saccharomyces strain 143 exhibited a growth pattern similar to strain 121, although to a less efficient degree. Indigenous yeasts did not contaminate the processes as no growth was observed in the CGM without inoculation.

In parallel, the selected indigenous strains were cultivated in a synthetic medium, containing all the necessary growth factors and sugar concentration of 200, 400 or 600 g/L. This experiment was useful to evaluate the tolerance to high sugar concentration and to analyse the regulation mechanisms underlying their growth in the complex environment of CGM. As data in Fig. 3b show, in contrast to CGM, the synthetic medium with 400 g/L glucose that is mimicking the high sugar content of the former was suitable for fast growth of all the strains. In fact, strains 121 and 143 grew faster in synthetic medium with 400 g/L glucose than in that with 200 g/L glucose. As regards strain 121, Amax value was higher in the former case (Fig. 3a, b). These observations are attributed to the osmotolerant characteristics of the strains as well as to the abundance in essential nutrients such as nitrogen (2 g/L vs. 0.6 g/kg of synthetic medium and CGM, respectively) and the absence of furanic compounds that can delay yeast growth. The most distinct difference was observed for strain F13, which was the fastest growing one, achieving also a high cell yield (µmax = 0.049 h−1, Amax = 1.946) in the synthetic medium. Strain F13 previously characterized as dominant at middle stage of spontaneous fermentation of CGM was found to behave differently when it was inoculated at the beginning of the process. This may be due to differences in the composition of the freshly prepared CGM. According to data in Fig. 3, all strains were able to grow even at 600 g/L glucose despite the extended lag phases and the lower maximum growth rates and biomass yields in comparison with those at 200 and 400 g/L glucose.

Regarding ethanol production, strains 121 and 143 were capable of producing higher level of ethanol than the industrial strain (119.9 g/kg after 20 days and 104.8 g/kg after 24 days vs. 78.6 g/kg after 28 days, respectively) (Fig. 2b, Table 3) in CGM environment. According to literature for wine making, this is not common for H. uvarum as this species has been reported to have a weak fermentative power up to 45 g/L (Gobbi et al. 2014). However, the ability to produce higher amounts of ethanol under the osmotic stress of high sugar content (up to 40 oBrix) in CGM has been observed for certain H. uvarum strains (Giudici et al. 2015). For DV10, ethanol content in fermented CGM is not expected to reach the industrial threshold of 8 % (v/v) for the formation of acetic acid at desirable levels (titratable acidity 6–7 %, w/v expressed as acetic acid) (Giudici et al. 2015). Under the applied operational conditions, for the strain 121 an ethanol yield of 0.28 g/g and a fermentation efficiency of 54.9 % of the theoretical value (0.51 g/g) were achieved. The above values were 1.4–1.7 fold lower than those obtained for DV10 (0.40 g/g and 78.4 %, respectively) (Table 3). In our study, lower ethanol yield for strain 121 was attributed to excessive yeast growth, which has determined a reduced ethanol production. However, in terms of productivity, the strain 121 recorded a 2-fold higher value than that for DV10 (0.25 vs 0.12 g/kg h). The lowest ethanol yield (0.23 g/g) and fermentation efficiency (45.1 %) was found for strain 143, but this result was expected by considering that this strain is a non-Saccharomyces yeast (Gobbi et al. 2014).

Focusing on the other important characteristic of yeast strain for BV production, which is the selective fermentation of glucose, the three strains can be considered glucophilic as all of them consumed glucose faster than fructose at all stages of the fermentation process (Fig. 2c). This is a desirable feature considering that the most osmotolerant TBV-associated species show generally a fructophilic metabolism, which results in glucose crystallization in the final product (Solieri and Giudici 2008). For Saccharomyces strains, this finding is already well documented (Viana et al. 2008). For H. uvarum, a well-known apiculate yeast with a strong fructophilic metabolism, a glucophilic feature has also been recorded in recent studies (Viana et al. 2008). It is possible that the discrepancy between glucose and fructose utilization is influenced by external conditions, such as nitrogen supplementation or alcohol accumulation (Berthels et al. 2004; Tofalo et al. 2012).

Strains were expected to differ not only in their basic metabolism but also in the formation of secondary metabolites, which are expected to influence the sensorial quality of the base wine and the final product. As, to the best of our knowledge, no data about the contribution of yeast secondary metabolites in BV production are available, we chose to study the compounds usually examined for sweet wine. High acetic acid content is a desirable characteristic in the fermented CGM since it is expected to facilitate the subsequent acetic fermentation and thus its content was considered important. Strains 121 and 143 produced similar amounts of acetic acid (2.44 and 2.07 g/kg) while a two-fold lower content was recorded for the commercial strain (1.4 g/kg) (Table 3). This finding is in line with the results obtained from testing the above strains for tolerance against acetic acid toxicity. Experimental data, obtained in YPDA plates supplemented with 1 and 2 % of acetic acid showed that the growth ability of the selected strains was not affected by the presence of acetic acid, even at the highest tested concentration (Figure S3 in Supplementary Material). This trait is interesting considering that 1 % of acetic acid is enough to inhibit the majority of the yeasts and has already been recorded as highly desirable for CGM fermentation in the traditional balsamic vinegar fermentation (Giudici et al. 2009).

Glycerol is expected to contribute body and roundness of the fermented CGM. The glycerol content recorded in the fermented CGMs did not differ significantly among the three strains and reached an average value of 16.6 g/kg which was comparable to that reported for sweet wines (Magyar and Tóth 2011). This trend is related to the osmophilicity of the strains in line with literature data about enhanced accumulation of intracellular glycerol in order to counterbalance high osmotic pressure (García-Martínez et al. 2013).

Evaluation of the major volatile compounds was also included in our study and contributed to the differentiation of the examined strains. In all cases, considerable differences in the content of the selected volatile compounds were observed among the fermented CGM (Table 3). Prevalence of alcohols was attributed to the high solid content of CGM, which limits ester formation in favor of free forms in line with observations made for sweet wine production (Mencarelli and Tonutti 2013). Isobutanol was the only compound produced in concentrations below its threshold (40 mg/l) in all cases (2.90–6.2 mg/kg). This could be related to low valine content in the initial grape must and not to degradation during must concentration (Montevecchi et al. 2010). Acetoin (3-hydroxy-2-butanone) and 2,3-butanediol are considered compounds useful to differentiate TBV and BVs (Caligiani et al. 2007). These compounds derive from the reduction of diacetyl but their concentrations are usually inversely correlated (Mencarelli and Tonutti 2013). The highest levels of both compounds were observed for the CGM fermented by DV10, possibly as a result of over-expression of the respective pathway, whereas low levels were detected in CGMs fermented by the wild strains 121 and 143 (19.6 and 10.1 mg/kg, respectively), probably as a consequence of evaporation or its reduction to 2,3-butanediol (46.2 and 39.0 mg/kg, respectively). In all the samples examined, the values for both acetoin and 2,3-butanediol content were much lower than the ones reported in TBV (140–330 mg/L and 420–1670 mg/L, respectively) (Caligiani et al. 2007). This could be attributed to the fact that acetoin is also produced in the course of acetic acid fermentation (Solieri et al. 2012), while 2,3-butanediol content increases significantly during vinegar ageing (Caligiani et al. 2007). Isoamyl alcohol (3-methyl-1-butanol) and phenylethyl alcohol have also been reported in TBV (Solieri et al. 2012). Both of these compounds derive from the catabolism of specific amino acids via the Ehrlich pathway. These compounds impart alcoholic odor and a rose, honey-like aroma in wine (Saerens et al. 2010). The highest concentrations (96 and 142 mg/kg, respectively) for these volatiles were recorded for CGM fermented by strain 121. These values are above their aroma detection thresholds. In general, the amount of 2,3 butanediol, isoamyl alcohol and phenylethyl alcohol were similar to those reported for Xinomavro wines and these values might be considered among the key volatiles for varietal discrimination of products obtained by using grapes from this cultivar (Dourtoglou et al. 2014).

Conclusion

Our findings are of practical interest for the development of new generation BVs based on double fermentation process and not on blending practices. The characterized yeast isolates from CGM (cv. Xinomavro) performed well in alcoholic fermentation of the high sugar content substrate and can be used as starters by vinegar manufacturers. The fact that the fermented products retained varietal characteristics enhances the significance of using indigenous species vs commercial strains.

References

Berthels NJ, Cordero Otero RR, Bauer FF, Thevelein JM, Pretorius IS (2004) Discrepancy in glucose and fructose utilisation during fermentation by Saccharomyces cerevisiae wine yeast strains. FEMS Yeast Res 4:683–689

Caligiani A, Acquotti D, Palla G, Bocchi V (2007) Identification and quantification of the main organic components of vinegars by high resolution 1H NMR spectroscopy. Anal Chim Acta 585:110–119

Capece A, Fiore C, Maraz A, Romano P (2005) Molecular and technological approaches to evaluate strain biodiversity in Hanseniaspora uvarum of wine origin. J Appl Microbiol 98:136–144

Capece A, Romaniello R, Siesto G, Romano P (2012) Diversity of Saccharomyces cerevisiae yeasts associated to spontaneously fermenting grapes from an Italian “heroic vine-growing area”. Food Microbiol 31:159–166

Cocchi M, Ferrari G, Manzini D, Manzini D, Marchetti A, Sighinolfi S (2007) Study of the monosaccharides and furfurals evolution during the preparation of cooked grape musts for Aceto Balsamico Tradizionale production. J Food Eng 79:1438–1444

Combina M, Daguerre C, Massera A (2008) Yeast identification in grape juice concentrates from Argentina. Lett Appl Microbiol 46:192–197

Comitini F, Gobbi M, Domizio P, Romani C, Lencioni L, Mannazzu I, Ciani M (2011) Selected non-Saccharomyces wine yeasts in controlled multistarter fermentations with Saccharomyces cerevisiae. Food Microbiol 28:873–882

Dourtoglou V, Antonopoulos A, Dourtoglou T, Lalas S (2014) Discrimination of varietal wines according to their volatiles. Food Chem 159:181–187

Esteve-Zarzoso B, Belloch C, Uruburu F, Querol A (1999) Identification of yeasts by RFLP analysis of the 5.8S rRNA gene and the two ribosomal internal transcribed spacers. Int J Syst Bacteriol 49(1):329–337

Field SJ, Ryden P, Wilson D, James SA, Roberts IN, Richardson DJ, Waldron KW, Clarke TA (2015) Identification of furfural resistant strains of Saccharomyces cerevisiae and Saccharomyces paradoxus from a collection of environmental and industrial isolates. Biotechnol Biofuels 8:33

García-Martínez T, de Lerma NL, Moreno J, Peinado RA, Millán MC, Mauricio JC (2013) Sweet wine production by two osmotolerant Saccharomyces cerevisiae strains. J Food Sci 78:874–879

Giudici P, Gullo M, Solieri L, Falcone PPM (2009) Technological and microbiological aspects of traditional balsamic vinegar and their influence on quality and sensorial properties. In: Taylor S (ed) Advances in food and nutrition research, vol 58, 1st edn. Springer, Amsterdam

Giudici P, Lemmetti F, Mazza S (2015) Balsamic Vinegars. Tradition, Technology, Trade. Springer, Cham

Gobbi M, De Vero L, Solieri L, Comitini F, Oro L, Giudici P, Ciani M (2014) Fermentative aptitude of non-Saccharomyces wine yeast for reduction in the ethanol content in wine. Eur Food Res Technol 239:1–8

Granchi L, Bosco M, Messini A, Vincenzini M (1999) Rapid detection and quantification of yeast species during spontaneous wine fermentation by PCR-RFLP analysis of the rDNA ITS region. J Appl Microbiol 87:949–956

Gump BH, Zoecklein BW, Fugelsang KC (2001) Prediction of prefermentation nutritional status of grape juice. In: Spencer JFT, de Spencer ALR (eds) Methods in biotechnology: Food Microbiology Protocols, vol 14. Human Press, Totowa, pp 1–2

Hatzidimitriou E, Papadopoulou M, Lalou S, Tsimidou MZ (2015) Contribution to the discussion of current state and future perspectives of sensory analysis of balsamic vinegars. Acetic Acid Bact. 4(1):5070

Lalou S, Mantzouridou F, Paraskevopoulou A, Bugarski B, Levic S, Nedovic V (2013) Bioflavour production from orange peel hydrolysate using immobilized Saccharomyces cerevisiae. Appl Microbiol Biotechnol 97:9397–9407

Lalou S, Hatzidimitriou E, Papadopoulou M, Kontogianni VG, Tsiafoulis CG, Tsimidou MZ (2015) Beyond traditional balsamic vinegar: compositional and sensorial characteristics of industrial balsamic vinegars and regulatory requirements. J Food Compos Anal 43:174–184

Le Jeune C, Erny C, Demuyter C, Lollier M (2006) Evolution of the population of Saccharomyces cerevisiae from grape to wine in a spontaneous fermentation. Food Microbiol 23:709–716

Legras JL, Karst F (2003) Optimisation of interdelta analysis for Saccharomyces cerevisiae strain characterisation. FEMS Microbiol Lett 221:249–255

Lewis Liu Z, Moon J, Andersh BJ, Slininger PJ, Weber S (2008) Multiple gene-mediated NAD(P)H-dependent aldehyde reduction is a mechanism of in situ detoxification of furfural and 5-hydroxymethylfurfural by Saccharomyces cerevisiae. Appl Microbiol Biotechnol 81:743–753

Ma C, Wei X, Sun C, Zhang F, Xu J, Zhao X, Bai F (2015) Improvement of acetic acid tolerance of Saccharomyces cerevisiae using a zinc-finger-based artificial transcription factor and identification of novel genes involved in acetic acid tolerance. Appl Microbiol Biotechnol 99:2441–2449

Magyar I, Tóth T (2011) Comparative evaluation of some oenological properties in wine strains of Candida stellata, Candida zemplinina, Saccharomyces uvarum and Saccharomyces cerevisiae. Food Microbiol 28:94–100

Marrufo-Curtido A, Cejudo-Bastante MJ, Rodríguez-Dodero MC, Natera-Marín R, Castro-Mejías R, García-Barroso C, Durán-Guerrero E (2015) Novel vinegar-derived product enriched with dietary fiber: effect on polyphenolic profile, volatile composition and sensory analysis. J Food Sci Technol 52:7608–7624

Mattia G (2004) Balsamic vinegar of Modena: from product to market value: competitive strategy of a typical Italian product. Br Food J 106:722–745

Mencarelli F, Tonutti P (2013) Sweet, Reinforced and Fortified Wines: Grape Biochemistry, Technology and Vinification. Wiley, Oxford

Modha HM, Patel NM, Patel HG, Patel KN (2015) Process standardization for the manufacture of Thabdi Peda. J Food Sci Technol 52:3283–3290

Montevecchi G, Masino F, Chinnici F, Antonelli A (2010) Occurrence and evolution of amino acids during grape must cooking. Food Chem 121:69–77

Ness F, Lavallee F, Dubourdieu D, Aigle M, Dulaub L (1993) Identification of yeast strains using the polymerase chain reaction. J Sci Food Agric 6:89–94

Rankine BC (1963) Nature, origin and prevention of hydrogen sulphide aroma in wines. J Sci Food Agric 14:79–91

Regodón J (1997) A simple and effective procedure for selection of wine yeast strains. Food Microbiol 14:247–254

Saerens SMG, Delvaux FR, Verstrepen KJ, Thevelein JM (2010) Production and biological function of volatile esters in Saccharomyces cerevisiae. Microb Biotechnol 3:165–177

Solieri L, Giudici P (2005) Yeast starter selection for traditional balsamic vinegar. Ind Bevande 34:526–531

Solieri L, Giudici P (2008) Yeasts associated to Traditional Balsamic Vinegar: ecological and technological features. Int J Food Microbiol 125:36–45

Solieri L, Dakal TC, Giudici P (2012) Next-generation sequencing and its potential impact on food microbial genomics. Ann Microbiol 63:21–37

Sosa OA, Farías ME (2012) Influence of culture and nutritional conditions on self-flocculation of a Kloeckera apiculata wine strain. Food Technol Biotechnol 50:66–72

Suárez Valles B, Pando Bedriñana R, Lastra Queipo A, Mangas Alonso JJ (2008) Screening of cider yeasts for sparkling cider production (Champenoise method). Food Microbiol 25:690–697

Tagliazucchi D, Verzelloni E, Helal A, Conte A (2013) Effect of grape variety on the evolution of sugars, hydroxymethylfurfural, polyphenols and antioxidant activity during grape must cooking. Int J Food Sci Technol 48:808–816

Tian S, Zhu J, Yang X (2011) Evaluation of an adapted inhibitor-tolerant yeast strain for ethanol production from combined hydrolysate of softwood. Appl Energy 88:1792–1796

Tofalo R, Chaves-López C (2009) Molecular identification and osmotolerant profile of wine yeasts that ferment a high sugar grape must. Int J Food Microbiol 130:179–187

Tofalo R, Schirone M, Torriani S, Rantsiou K, Cocolin L, Perpetuini G, Suzzi G (2012) Diversity of Candida zemplinina strains from grapes and Italian wines. Food Microbiol 29:18–26

Viana F, Gil JV, Genovés S, Vallés S, Manzanares P (2008) Rational selection of non-Saccharomyces wine yeasts for mixed starters based on ester formation and enological traits. Food Microbiol 25:778–785

Westman JO, Mapelli V, Taherzadeh MJ, Franzen CJ (2014) Flocculation causes inhibitor tolerance in Saccharomyces cerevisiae for second-generation bioethanol production. Appl Environ Microbiol 80:6908–6918

White TJ, Bruns T, Lee S, Taylor J (1990) Amplification and direct sequencing of fungal ribosomal RNA genes for phylogenetics. PCR Protoc 18:315–322

Wine Producers Association of the Northern Greece Vineyard (2005) Study “Redefining Zone OPAP Naoussa Goumenissa” (In Greek) Available at: http://www.wineroads.gr/fileviewer.php?file_id=2291

Acknowledgments

The authors wish to thank wineries Boutari Company SA (Giannakohori, Imathia, Greece) and Stelios Kechris Domaine (Kalochori, Thessaloniki, Greece) for providing the Xinomavro grape must.

Author information

Authors and Affiliations

Corresponding author

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Lalou, S., Capece, A., Mantzouridou, F.T. et al. Implementing principles of traditional concentrated grape must fermentation to the production of new generation balsamic vinegars. Starter selection and effectiveness. J Food Sci Technol 53, 3424–3436 (2016). https://doi.org/10.1007/s13197-016-2306-9

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13197-016-2306-9