Abstract

The tomato processing industry generates high amounts of waste, mainly tomato skins and seeds, which create environmental problems. These residues are attractive sources of valuable bioactive components and pigments. A relatively simple recovery technology could consist of production of powders to be directly incorporated into foods. Tomato waste coming from a Romanian tomato processing unit were analyzed for the content of several bioactive compounds like ascorbic acid, β-carotene, lycopene, total phenolics, mineral and trace elements. In addition, its antioxidant capacity was assayed. Results revealed that tomato waste (skins and seeds) could be successfully utilized as functional ingredient for the formulation of antioxidant rich functional foods. Dry tomato processing waste were used to supplement wheat flour at 6 and 10 % levels (w/w flour basis) and the effects on the bread’s physicochemical, baking and sensorial characteristics were studied. The following changes were observed: increase in moisture content, titratable acidity and bread crumb elasticity, reduction in specific volume and bread crumb porosity. The addition of dry tomato waste at 6 % resulted in bread with good sensory characteristics and overall acceptability but as the amount of dry tomato waste increased to 10 %, bread was less acceptable.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Tomato (Lycopersicon esculentum) is an important vegetable crop worldwide, being one of the most consumed vegetables, both fresh and as processed products such as tomato juice, soup, paste, puree, ketchup, sauce and canned tomato (Pinela et al. 2012). Its high consumption all year round makes it one of the main sources of minerals, vitamins and antioxidants (Adalid et al. 2010). Regular consumption of tomatoes and tomato products has been correlated with a reduction in susceptibility to various types of cancers and cardiovascular diseases (Borguini and Da Silva Torres 2009). These positive effects are attributed to the antioxidant compounds present in tomato such as vitamin C and E, carotenoids, polyphenols, which play a key role in the health protection mechanisms by scavenging free radicals (Ray et al. 2011). Also tomatoes are a great source of trace elements, i.e., selenium, copper, manganese and zinc, which are cofactors of antioxidant enzymes (Martínez-Valverde et al. 2002).

Tomatoes and tomato-based food products constitute the major dietary source of lycopene, a carotenoid with a non-cyclic, not branched structure which has demonstrated antioxidant properties and potential role in the prevention of chronic diseases (Borguini and Da Silva Torres 2009). Besides lycopene, tomatoes also contain α-, β-, γ-, δ-carotene, and lutein and also neurosporene, phytoene, and phytofluene (Capanoglu et al. 2010), which are believed to act synergistically with lycopene (Shixian et al. 2005). Of all the carotenoid pigments, lycopene is not only the most abundant but also is the most efficient free radical scavenger, with a capacity found to be more than twice that of β-carotene (Capanoglu et al. 2010). Lycopene content in tomatoes can vary widely from 10 to 200 mg/kg fresh weight with typical values of 40–90 mg/kg fresh weight, depending on genetics, environmental factors (temperature, light, water and nutrient availability), agricultural techniques (plant growth regulators, harvesting date) and on post-harvest storage conditions (Helyes et al. 2009; Martínez-Valverde et al. 2002; Nobre et al. 2009).

The studies concerning the localization of the antioxidant compounds in different tomato fractions (skin, seeds and pulp) agree that the skin fraction of all cultivars had significantly higher levels of total phenolics, total flavonoids, lycopene, ascorbic acid and antioxidant activity compared to their pulp and seed fractions (George et al. 2004; Toor and Savage 2005). As well, many studies showed the richness of tomato seeds in nutrients: carotenoids, proteins, polyphenols, minerals, fibers and oils (Demirbas 2010; Eller et al. 2010; Liadakis et al. 1995; Persia et al. 2003; Toor and Savage 2005; Zuorro et al. 2013).

Million tons of tomatoes are processed yearly to produce juice, sauces, purees, pastes, and canned tomatoes, resulting in large amounts of tomato peel, pulp, and seeds as industrial waste (Papaioannou and Karabelas 2012). When tomatoes are processed into products like ketchup, sauces or juice, 3-7 % of their weight becomes waste (Savatović et al. 2010). Although these by-products of plant food processing represent a major disposal problem for the food industry, they are also promising sources of compounds which may be used in the food, pharmaceutical and cosmetic industries because of their favourable technological or nutritional properties (Schieber et al. 2001). If these products remain unutilized, they not only add to the disposal problem but also aggravate environmental pollution (Calvo et al. 2008).

Several studies have been carried out to determine the performances and nutritive value of tomato waste as nutrient supplement for animal feed (Persia et al. 2003; Ventura et al. 2009). Knoblich et al. (2005) investigated the transfer of carotenoids to the egg yolk when peel and seed byproducts were included at 75 g/kg in hen diets. They found that approximately 0.1 % of the lycopene in peel byproduct and approximately 0.7 % of the lycopene in the seed byproduct was transferred from the feed to the yolk.

Nowadays, there is an increasing trend towards utilization of tomato processing by-products as a source of functional components (Kong et al. 2010). It is of interest the extraction of lycopene and β-carotene since they are widely used as food colorants, functional food ingredients, or as component of dietary supplements, nutraceuticals, pharmaceuticals and cosmetic products (Sabio et al. 2003). For example, Benakmoum et al. (2008) proposed to enrich low quality edible oils such as refined olive oil, extra virgin olive oil and refined sunflower oil by carotenoids and lycopene from tomato peels or tomato puree in order to increase the thermal stability to these oils.

Many studies have been carried out with the view to increase the recovery of lycopene from tomato by-products especially tomato waste. Application of high hydrostatic pressure processing without heating (Jun 2006), enzymatic treatment using cellulase and pectinase (Choudhari and Ananthanarayan 2007; Lavecchia and Zuorro 2008) or surfactants (Papaioannou and Karabelas 2012) and supercritical fluid extraction (Baysal et al. 2000; Rozzi et al. 2002; Topal et al. 2006) are some of the solutions proposed. However, the extraction technologies used at present do not seem to allow the efficient recovery of carotenoids (Papaioannou and Karabelas 2012). Therefore, some food scientists have proposed to avoid lycopene extraction by recycling the raw or dried lycopene-rich by-products directly as food ingredients. Thus, Calvo et al. (2008) described experiments performed to develop dry fermented sausages enriched with lycopene by adding dried tomato peel to the meat mixture during the sausage production. García et al. (2009) proposed the direct addition of dry tomato peel to raw and cooked hamburgers while Alves et al. (2012) used tomato waste to yield efficient protection against lipid oxidation in high-pressure processed minced chicken meat. Altan et al. (2008) investigated the extrusion processability of barley flour with the combination of tomato pomace to produce snack foods and they evaluated the sensory properties and the overall acceptability of these products.

The first goal of the present study was to evaluate a sample of tomato waste coming from the processing industry of tomato for the content of total phenolics, lycopene, β-carotene, ascorbic acid, mineral (Na, K, Ca, Mg) and trace elements (Fe, Mn, Cu, Cr, Zn, B) as well for its antioxidant capacity. The high moisture levels and susceptibility to microbial spoilage make quite problematic the storage and processing of tomato wastes, therefore these must be dried to be used as food ingredients. Finally, we aimed to experiment the possibility to supplement wheat flour with dry tomato waste at 6 and 10 % levels in order to produce a new assortment of bread enriched in lycopene and other bioactive compounds and to provide a use for this waste from the tomato industry.

Materials and methods

Raw material and preparation of dehydrated tomato waste

The tomato wastes used in this study (skins and seeds) were obtained from Leader International (a tomato processing unit in Caracal, Romania). The raw material had a moisture content of around 70 % and a titratable acidity of 0.22 % (as citric).

The samples were stored at −18 °C until analysis. Experiments were conducted in three repetitions, and the results were expressed as average ± standard deviation.

Tomato waste was dried in the tray dryer at 60 °C until its moisture content reached under 12 % (wet basis). The drying air velocity was kept constant. Initial moisture content (%) of tomato waste was determined gravimetrically by the oven drying method at 105 °C. Titratable acidity (% as citric acid) was determined by titration the water extract of tomato waste with 0.1 N NaOH to an end point of neutral pH (8.1). The dried tomato wastes were cooled, ground (0.05–0.70 mm particle size), packed in aluminium coated polyethylene bags and stored in ambient conditions for further analysis and use.

Compositional characterization of raw tomato waste

Carotenoids

Determination was based on a spectrophotometric analysis following the method developed by Nagata and Yamashita (1992) for the simultaneous determination of chlorophyll and carotenoids in tomato fruit. Sixteen milliliters of acetone–hexane (4:6) solvent were added to 1.0 g of minced tomato waste and mixed in a test-tube. Automatically, two phases separated, and an aliquot was taken from the upper solution for measurement of optical density at 663, 645, 505, and 453 nm in a spectrophotometer (Varian Cary 50 UV–vis, Varian Co., USA). Lycopene and β-carotene contents were calculated according to the equations: Lycopene (mg/100 mL of extract) = − 0.0458 × A663 + 0.204 × A645 + 0.372 × A505 – 0.0806 × A453; β-Carotene (mg 100/mL of extract) = 0.216 × A663 – 1.22 × A645 – 0.304 × A505 + 0.452 × A453. Lycopene and β-carotene were finally expressed as mg/kg fresh weight (fw).

Ascorbic acid

Ascorbic acid was extracted and analyzed by reversed-phase HPLC according to Nour et al. (2010). Tomato waste (5 g) was mixed and diluted to 100 mL with 0.1 N HCl. After 30 min the extraction solution was centrifuged at 4200 rpm for 10 min. The supernatant was filtered through 0.2 μm pore size filter.

HPLC analysis was performed on a Finningan Surveyor Plus system (Thermo Electron Corporation, San Jose, CA, USA) coupled with a photodiode array detector (DAD) set at 245 nm. The separation was performed using a Hypersil Gold aQ column (25 cm × 4.6 mm) with a particle size of 5 μm while a 50 mM water solution of KH2PO4 buffer adjusted to pH 2.8 with ortho-phosphoric acid was used as the mobile phase. The column temperature was kept at 10 °C and the flow rate at 0.7 mL/min. All the results were expressed in mg/kg fw. Acetonitrile was HPLC grade (Merck, Germany) while potassium dihydrogen orthophosphate and phosphoric acid were of analytical purity (Sigma-Aldrich, Germany). Ultrapure water was obtained from a Milli-Q water purification system (TGI Pure Water Systems, USA).

Total phenolic content

Total phenolic content was assessed by using the Folin-Ciocalteu phenol reagent method (Singleton and Rossi 1965). Folin Ciocalteu reagent (2 N, Merk), gallic acid (99 % purity, Sigma) and anhydrous sodium carbonate (99 % purity, Sigma) were used.

Samples (3 g of minced tomato waste) were extracted with 5 mL methanol in an ultrasonic bath for 45 min at ambient temperature. After extraction, the samples were centrifuged for 5 min at 4200 rpm. Supernatants were filtered through polyamide membranes with pore diameter of 0.45 μm and stored at −20 °C. 100 μL of each tomato waste methanolic extract were mixed with 5 mL distilled water and 500 μL Folin-Ciocalteau reagent. After 30 s to 8 min, 1.5 mL of sodium carbonate (20 % w/v) was added. The reaction mixture was diluted with distilled water to a final volume of 10 mL. The same procedure was also applied to the standard solutions of gallic acid. The absorbance at 765 nm of each mixture was measured on a Varian Cary 50 UV spectrophotometer (Varian Co., USA) after incubation for 30 min at 40 °C. Results were expressed as mg of gallic acid equivalents (GAE)/kg fw.

Antioxidant activity

Relative antioxidant activity was measured in methanol tomato waste extracts using the DPPH (2,2-diphenyl-1-picrylhydrazyl) assay. Methanol (Merck, Germany), 2,2-diphenyl-1-picrylhydrazyl (DPPH) (Sigma-Aldrich, Germany), and 6-hydroxy-2,5,7,8-tetramethylchroman-2-carboxylic acid (Trolox) (Merck, Germany) were employed. The extraction of samples was made according to the same protocol as described for total phenolic content. The free radical scavenging ability of the extracts against DPPH free radical was evaluated as described by Oliveira et al. (2008), with some modifications. Briefly, each methanol tomato waste extract (50 μL) was mixed with 3 mL of a 0.004 % (v/v) DPPH methanolic solution. The mixture was incubated for 30 min at room temperature in the dark and the absorbance was measured at 517 nm on Varian Cary 50 UV–vis spectrophotometer. The DPPH free radical scavenging ability was subsequently calculated with respect to the Trolox (6-hydroxy-2,5,7,8-tetramethylchroman-2-carboxylic acid), which was used as a standard reference to convert the inhibition capability of each extract solution to the mmol Trolox equivalent antioxidant activity (TEAC)/L. The radical was freshly prepared and protected from light. A blank control of methanol/water mixture was run in each assay. Results were expressed in mmol Trolox/kg fw.

Mineral and trace elements content

Sodium (Na), calcium (Ca), magnesium (Mg), potassium (K), iron (Fe), manganese (Mn), copper (Cu), zinc (Zn), chromium (Cr), and boron (B) were determined by microwave digestion followed by inductively coupled plasma mass spectrometry (ICP-MS) analysis according to the method previously described by Cosmulescu et al. (2009). Briefly, samples of approximately 2.0 g tomato waste were weighed in TFM vessels, over that 5 mL nitric acid 65 % and 2 mL hydrogen peroxide 30 % were added. The vessels were then closed and mounted in special outer vessels and heated in the Milestone digestion microwave system. Reagent blanks were included in each series of digestions. After digestion was completed, the clear, colourless solution was transferred into a 50 mL volumetric flask and make up to the mark with ultrapure water. The sample solutions were stored in polyethylene vials at 6 °C until analysis. An Elan 9000 inductively coupled plasma mass spectrometer (Perkin Elmer Sciex, Canada) equipped with Meinhard nebulizer and Scott-type double-pass spray chamber was used. The results were expressed in mg/kg fw.

Bread supplemented with dry tomato waste

Materials

The white wheat flour used in this study was from Baneasa – Moara S.A. (Romania). The characteristics of the flour were as follows: protein content 13.2 %, ash 0.65 %, moisture 14.1 % and wet gluten 30.5 %. The standard methods used were: moisture content 44-15.02 A, wet gluten 38-10.01 A, crude protein 46-11.02, and ash 08-01 (American Association of Cereal Chemists 2003). All chemical analyses of the flour were made in triplicate.

Breadmaking procedure

The basic dough recipe for bread production (300 g flour basis) consisted of: salt (5 g), yeast “Fala” (a commercial brand from Lesaffre Group, France) (9 g), improver (0.3 g) (Gamma B3, Zeelandia International, Netherlands) and the required water at 25 °C. Breads were supplemented at two levels with dried tomato waste (6.0 %, and 10.0 % w/w based on flour weight). Bread doughs were prepared by mixing all ingredients until they reached maximum development. Fermented doughs were obtained after a two-step bulk fermentation and proofing up to the optimum volume increase. After the first step, the fermented doughs were hand-moulded and put into pans for proofing at 30 °C and then baked at 220 °C for 25 min. Proofing was made in a fermentation cabinet at 30 °C and 80 % relative humidity while the baking process was carried out in a Multi Deck baking oven model EF 100 (Ozkoseoglu Heat Industry, Istanbul, Turkey). Following baking, the bread loaves were cooled on cooling racks at room temperature. Twelve loaves were obtained from each formulation. The bread loaves were packed for testing and then assessed for their proximate composition and characteristics.

Bread quality assessment

In order to evaluate the bread quality, the volume, weight, specific volume, titratable acidity, moisture content, bread crumb porosity and elasticity were determined.

Loaf volume was determined by a bread volumeter (Fornet, Chopin, France) using rapeseed displacement. The specific volume of the loaf was calculated using the following equation:

Moisture content was determined following the ICC Method (2004).

Bread crumb porosity (%) was determined by the ratio of pores volume to total volum of a known volume of crumb, knowing its mass and density. A cylindrical piece of crumb was cut from a 60 mm slice obtained from the middle of the loaf by a cylindrical sharpened brass perforator (internal diameter 45 mm) and weighed. The slices were obtained by cutting the bread transversely using a cutter to obtain uniform slices of 60 mm thickness. To obtain an average porosity, three cylinders, from three different areas, were analysed.

For determination of bread crumb elasticity (%) a piece of bread crumb was cut as previously described and pressed to the half of its height for 1 min using a screw-driven pressing device which consisted of a fixed and a mobile plate and a ruler. Then, the pressure was removed and after 1 min the height of the compressed piece of crumb was measured. The elasticity values were obtained as the ratio (given as percentage) between the height after compression and recovery, and the initial height.

Measurements of all the above quality parameters were performed in three replicates.

Sensory analysis

Sensory evaluation of the fresh bread was performed using a one to nine hedonic rating scale method, where nine means extreme satisfaction and one, extreme dissatisfaction. A total of 30 panelists recruited among university staff and postgraduate students were involved in the evaluation for crust and crumb colour, aroma, taste, texture and overall acceptability. They were regular bread consumers and were used to participate in sensory analyses of different foods. One day after bread making, samples were sliced and placed in recipients randomly codified. A slice of each formulation was given to every consumer, and a sample of the whole bread of each formula was shown to evaluate the external appearance. All samples were presented at the same time. The panelists were instructed to rate the attributes indicating their degree of liking or disliking by putting a number as provided in the hedonic scale according to their preference. For each of the attributes, the average of the panelist scores was calculated.

Statistical Analysis

Experimental data from bread quality assessment and sensory analysis were submitted to one-way analysis of variance (ANOVA) using Statgraphics Centurion XVI software (StatPoint Technologies, Warrenton, VA, USA). All data were presented as mean values of three replicates ± standard deviation. When analysis of variance indicated significant F values, multiple sample comparison was also performed using LSD multiple range test at p < 0.05.

Results and discussion

Compositional characterization of raw tomato waste

Table 1 shows the results for compositional characterization of tomato processing waste.

The tomato processing waste used in our study had a moisture content of 70 % (wet basis). High moisture contents, ranging from 63 % (Celma et al. 2012) to 92.7 % (Lavelli and Torresani 2011) were also found in tomato waste samples recovered from different industrial processes, hence these products are highly susceptible to microbial proliferation. For this reason, the tomato waste needs to be dried in order to preserve it for later use.

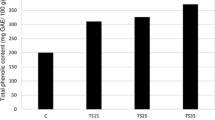

Tomato waste is a potential source of natural antioxidants. In our study a high level of phenolic content was found (865.77 mg GAE/kg), which can be explained by the higher concentrations of polyphenolic compounds in the skins and seeds than in the pulp as reported by previous studies (George et al. 2004; Toor and Savage 2005). Phenolic compounds tend to accumulate in the dermal tissues of plant body because of their potential role in protection against ultraviolet radiations, to act as attractants in fruit dispersal, and as defence chemicals against pathogens and predators (Toor and Savage 2005). Chérif et al. (2010) found a total polyphenols content determined by the Folin-Ciocalteu method of 1516 mg GAE/kg in tomato waste while Toor and Savage (2005), in a study of the major antioxidants contents in the different fractions of tomatoes, found a total phenolic content of 291 mg GAE/kg in skins and 220 mg GAE/kg in seeds. The differences in phenolic content between our study and some others could be due to different tomato cultivars, growing conditions and processing methods (i.e., the amount of seeds, pulp, and skins in the waste by-product).

Regarding the lycopene content of different tomato fractions, Toor and Savage (2005) reported 87 mg/kg in skins and 16 mg/kg in seeds. Sabio et al. (2003) established also that seeds do not contribute much to the carotenoids content of the skins + seeds sample and exert a dilution effect on the carotenoids content of the waste. We found an average lycopene content of 174 mg/kg in our tomato waste sample while Chérif et al. (2010) reported a lycopene content of 227 mg/kg in industrial tomato waste.

The tomato waste used in our study recorded an ascorbic acid content of 111.89 mg/kg while Toor and Savage (2005) found an ascorbic acid content of 169 mg/kg in tomato skins and 84 mg/kg in tomato seeds. Considering the content of antioxidant compounds, it is of great interest to determine the total antioxidant activity expressed by the capacity to scavenge the stable free radical DPPH. In the methanolic extracts, the antiradical activity relates particularly to polyphenols and to ascorbic acid. For the evaluated tomato waste sample we found an antioxidant activity of 2.46 mmol Trolox/kg. This result is in agreement with the work of Toor and Savage (2005) who found an hydrophilic antioxidant activity of 2.126 mmol Trolox/kg in tomato skins, 1.14 mmol Trolox/kg in tomato seeds while the antioxidant activity of the pulp was only 0.82 mmol Trolox/kg.

The mineral content of tomato processing waste is presented in Table 2. Tomato waste can be considered a good source of some mineral elements, some of them with antioxidant properties.

Among macroelements, K presented the highest content (3030.17 mg/kg), followed by Mg (210.9 mg/kg) and Ca (131.8 mg/kg). Tomato waste contain also trace elements, i.e., copper, manganese and zinc, which are cofactors of antioxidant enzymes and play a key role in the protection mechanisms by scavenging free radicals.

In conclusion, the rate of lycopene and other bioactive compounds in tomato waste justifies a valorization of these residues of the tomato processing industry.

Effects of tomato waste addition on physicochemical and baking characteristics of bread

Results on the physicochemical and baking properties of the control and supplemented bread loaves are given in Table 3. The addition of dry tomato waste significantly (p > 0.05) affects the moisture content of the bread. Moisture contents were higher in bread samples supplemented with dry tomato waste than in control samples. Moisture content of the supplemented breads increased with increasing tomato waste addition. This was attributed to a greater water holding capacity of the dry tomato waste than that of the wheat flour.

The addition of tomato waste determined a significant (P < 0.05) increase of the bread acidity. The increase could be due to the high concentrations (6 and 10 %) of tomato product added in our study, since titratable acidity was higher in the sample with 10 % addition.

The specific volume was lower (P < 0.05) in samples supplemented with dry tomato waste. Generally, volume depends on gas formation, which depends on many factors, such as yeast, fermentable sugars, pH, and gas retention, which is affected by fiber content. The non-endosperm components (germ, bran) exert a dilution effect on the gluten-forming proteins, restrict the water available for gluten hydration and development, or even physically disrupt the starch-gluten matrix. Therefore, the addition of dry tomato waste (skins and seeds), rich in fiber, may reduce the bread volume. On the other side, the differences of specific volume can be determined by the increase of the supplemented bread mass due to their higher moisture content, as it was shown above. As expected, the effect was more evident when the dry tomato waste addition was increased from 6 to 10 %, although no signifficant difference was found between the speciffic volumes of these supplemented samples.

The samples supplemented with dry tomato waste presented higher bread crumb elasticity and slightly lower porosity than controls. The higher specific volume of the control samples correlates with their higher bread crumb porosity as compared with the supplemented samples. These differences can also be perceived in the slice digital images (Fig. 1).

The higher bread crumb elasticity of the supplemented samples can be explained by the inclusion of fiber from skins and seeds, which have viscoelastic properties (Tommonaro et al. 2008).

Although specific volume and porosity differences between the control and supplemented samples are signifficant, they are not large, so we can say that supplementation with dry tomato waste resulted in baking characteristics comparable to 100 % wheat bread.

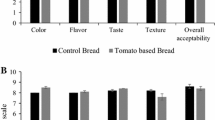

Effects of tomato waste addition on sensorial characteristics of bread

Table 4 shows sensory scores (mean ± standard deviation) for various attributes of white bread and dry tomato waste supplemented breads. All the breads were acceptable, although panellists preferred white bread without addition which registered the highest score for general acceptability.

Scores were lower for bread supplemented with dry tomato waste probably due to the notable differences in colour, flavour and odour of these breads as a result of the original properties of the dry tomato waste. Results also showed that as the amount of dry tomato waste increased to 10 %, bread was less acceptable.

Differences in colour were noticed in the crumb as well in the crust, both having a redish brown shade in supplemented breads as compared with the controls. Also, the darker crust colour may be attributed to the reddish brown colour of the dry tomato waste and to the greater occurence of the Maillard reactions between reducing sugars and amino acids.

No significant differences (P < 0.05) were found among control and supplemented breads in all sensory attributes scores. The crumb colour and the taste seem to be the reasons that lead panelists to indicate bread supplemented with dry tomato waste at 10 % level as the least preferred.

Conclusions

Tomato is rich in antioxidants having beneficial properties for health, but part of this fruit-vegetable, constituting waste coming from food industry, finishes in the refuses. The skin and seed fractions of tomatoes could be used as a valuable added ingredient in other food products. Along with a diet rich in other plant products, tomatoes, and their skins and seeds, could play an important role in improving antioxidant intake in the human diet.

A new assortment of bread enriched in lycopene and other bioactive compounds, of good sensory quality, has been produced by supplementing the wheat bread with dry tomato waste. In this way, by-products of the tomato industry can be used as source of lycopene for foods, without extraction of lycopene, in order to increase the intake of this carotenoid in the diet.

Bread supplemented with dry tomato waste showed good physicochemical characteristics and an adequate sensory profile. Findings of this study have potential to promote the use of the different by-products of the fruits and vegetables processing industry, rich in various bioactive compounds, as food ingredients.

References

Adalid AM, Roselló S, Nuez F (2010) Evaluation and selection of tomato accessions (Solanum section Lycopersicon) for content of lycopene, β-carotene and ascorbic acid. J Food Compos Anal 23:613–618

Altan A, McCarthy KL, Maskan M (2008) Evaluation of snack foods from barley-tomato pomace blends by extrusion processing. J Food Eng 84:231–242

Alves AB, Bragagnolo N, da Silva MG, Skibsted LH, Orlien V (2012) Antioxidant protection of high-pressure processed minced chicken meat by industrial tomato products. Food Bioprod Process 90:499–505

American Association of Cereal Chemists (2003) Approved methods of the AACC. St. Paul, MN

Baysal T, Ersus S, Starmans DAJ (2000) Supercritical CO2 extraction of β-carotene and lycopene from tomato paste waste. J Agric Food Chem 48:5507–5511

Benakmoum A, Abbeddou S, Ammouche A, Kefalas P, Gerasopoulos D (2008) Valorisation of low quality edible oil with tomato peel waste. Food Chem 110:684–690

Borguini RG, Da Silva Torres EAF (2009) Tomatoes and tomato products as dietary sources of antioxidants. Food Rev Int 25:313–325

Calvo MM, García ML, Selgas MD (2008) Dry fermented sausages enriched with lycopene from tomato peel. Meat Sci 80:167–172

Capanoglu E, Beekwilder J, Boyacioglu D, De Vos RCH, Hall RD (2010) The effect of industrial food processing on potentially health-beneficial tomato antioxidants. Crit Rev Food Sci 50:919–930

Celma AR, Cuadros F, López-Rodríguez F (2012) Characterization of pellets from industrial tomato residues. Food Bioprod Process 90:700–706

Chérif JK, Jémai S, Rahal NB, Jrad A, Trabelsi-Ayadi M (2010) Study of antioxidant content and antiradical capacity of fresh and industrial waste of Tunisian tomato. Valorization of Tunisian tomato in bioactive molecules. Tunis J Med Plants Nat Prod 4:116–125

Choudhari SM, Ananthanarayan L (2007) Enzyme aided extraction of lycopene from tomato tissues. Food Chem 102:77–81

Cosmulescu S, Baciu A, Achim G, Botu M, Trandafir I (2009) Mineral composition of fruits in different walnut (Juglans regia L.) cultivars. Not Bot Horti Agrobo 37(2):156–160

Demirbas A (2010) Oil, micronutrient and heavy metal contents of tomatoes. Food Chem 118:504–507

Eller FJ, Moser JK, Kenar JA, Taylor SL (2010) Extraction and analysis of tomato seed oil. J Am Oil Chem Soc 87:755–762

García ML, Calvo MM, Selgas MD (2009) Beef hamburgers enriched with lycopene using dry tomato peel as ingredient. Meat Sci 83:45–49

George B, Kaur C, Khurdiya DS, Kapoor HC (2004) Antioxidants in tomato (Lycopersium esculentum) as a function of genotype. Food Chem 84:45–51

Helyes L, Lugasi A, Pogonyi Á, Pék Z (2009) Effect of variety and grafting on lycopene content of tomato (Lycopersicon Lycopersicum L. Karsten) fruit. Acta Aliment Hung 38:27–34

ICC (2004) Determination of the Moisture Content of Cereals and Cereal Products 449 (Practical method). International Association for Cereal Science and Technology. 450 Standard method 110. Approved 1960, revised 1976

Jun X (2006) Application of high hydrostatic pressure processing of food to extracting lycopene from tomato paste waste. High Press Res 26:33–41

Knoblich M, Anderson B, Latshaw D (2005) Analyses of tomato peel and seed byproducts and their use as a source of carotenoids. J Sci Food Agric 85:1166–1170

Kong KW, Khoo HE, Prasad KN, Ismail A, Tan CP, Rajab NF (2010) Revealing the power of the natural red pigment lycopene. Molecules 15:959–987

Lavecchia R, Zuorro A (2008) Improved lycopene extraction from tomato peels using cell-wall degrading enzymes. Eur Food Res Technol 228:153–158

Lavelli V, Torresani MC (2011) Modelling the stability of lycopene-rich by-products of tomato processing. Food Chem 125:529–535

Liadakis GN, Tzia C, Oreopoulou V, Thomopoulos CD (1995) Protein isolation from tomato seed meal, extraction optimization. J Food Sci 60:477–482

Martínez-Valverde I, Periago MJ, Provan G, Chesson A (2002) Phenolic compounds, lycopene and antioxidant activity in commercial varieties of tomato (Lycopersicum esculentum). J Sci Food Agric 82:323–330

Nagata M, Yamashita I (1992) Simple method for simultaneous determination of chlorophyll and carotenoids in tomato fruit. J Jpn Soc Food Sci Technol 39:925–928

Nobre BP, Palavra AF, Pessoa FLP, Mendes RL (2009) Supercritical CO2 extraction of trans-lycopene from Portuguese tomato industrial waste. Food Chem 116:680–685

Nour V, Trandafir I, Ionica ME (2010) HPLC organic acid analysis in different citrus juices under reverse phase conditions. Not Bot Horti Agrobo 38(1):44–48

Oliveira I, Sousa A, Ferreira ICFR, Bento A, Estevinho L, Pereira JA (2008) Total phenols, antioxidant potential and antimicrobial activity of walnut (Juglans regia L.) green husks. Food Chem Toxicol 46:2326–2331

Papaioannou EH, Karabelas AJ (2012) Lycopene recovery from tomato peel under mild conditions assisted by enzymatic pre-treatment and non-ionic surfactants. Acta Biochim Pol 59:71–74

Persia ME, Parsons CM, Schang M, Azcona J (2003) Nutritional evaluation of dried tomato seeds. Poult Sci 82:141–146

Pinela J, Barros L, Carvalho AM, Ferreira IC (2012) Nutritional composition and antioxidant activity of four tomato (Lycopersicon esculentum L.) farmer’ varieties in Northeastern Portugal homegardens. Food Chem Toxicol 50:829–834

Ray RC, El Sheikha AF, Panda SH, Montet D (2011) Anti-oxidant properties and other functional attributes of tomato: an overview. Int J Food Ferment Technol 1:139–148

Rozzi NL, Singh RK, Vierling RA, Watkins BA (2002) Supercritical fluid extraction of lycopene from tomato processing byproducts. J Agric Food Chem 50:2638–2643

Sabio E, Lozano M, Montero de Espinosa V, Mendes RL, Pereira AP, Palavra AF, Coelho JA (2003) Lycopene and β-carotene extraction from tomato processing waste using supercritical CO2. Ind Eng Chem Res 42:6641–6646

Savatović SM, Gordana S, Ćetković GS, Čanadanović-Brunet JM, Djilas SM (2010) Utilisation of tomato waste as a source of polyphenolic antioxidants. Acta Period Technol 41:187–194

Schieber A, Stintzing FC, Carle R (2001) By-products of plant food processing as a source of functional compounds – recent developments. Trends Food Sci Technol 12:401–413

Shixian Q, Dai Y, Kakuda Y, Shi J, Mittal G, Yeung D, Jiang Y (2005) Synergistic anti-oxidative effects of lycopene with other bioactive compounds. Food Rev Int 21:295–311

Singleton VL, Rossi JA (1965) Colorimetry of total phenolics with phosphomolybdic–phosphotungstic acid reagent. Am J Enol Vitic 16:144–158

Tommonaro G, Poli A, De Rosa S, Nicolaus B (2008) Tomato derived polysaccharides for biotechnological applications: chemical and biological approaches. Molecules 13:1384–1398

Toor RK, Savage GP (2005) Antioxidant activity in different fractions of tomatoes. Food Res Int 38:487–494

Topal U, Sasaki M, Goto M, Hayakawa K (2006) Extraction of lycopene from tomato skin with supercritical carbon dioxide: effect of operating conditions and solubility analysis. J Agric Food Chem 54:5604–5610

Ventura MR, Pieltain MC, Castanon JIR (2009) Evaluation of tomato crop by-products as feed for goats. Anim Feed Sci Technol 154:271–275

Zuorro A, Lavecchia R, Medici F, Piga L (2013) Enzyme-assisted production of tomato seed oil enriched with lycopene from tomato pomace. Food Bioprocess Technol 6(12):3499–3509

Acknowledgments

This work benefited from the networking activities within the european funded COST ACTION FA1106 QualityFruit

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Nour, V., Ionica, M.E. & Trandafir, I. Bread enriched in lycopene and other bioactive compounds by addition of dry tomato waste. J Food Sci Technol 52, 8260–8267 (2015). https://doi.org/10.1007/s13197-015-1934-9

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13197-015-1934-9