Abstract

Karst Collapse Columns (KCC) are special geologic structures in the Carboniferous-Permian coalfields of the northern China. It is easy to generate severe water inrush accidents during mining activities, which can cause many casualties and property losses. To evaluate the impact of the KCC on the coalmine during the excavation and exploration of the Panel 90102 at the Yangjian Coalmine, the Shanxi Province, five KCC were detected by combining geophysical exploration and drilling information and by considering the Ordovician limestone aquifer analyses of water pressure, aquifer thickness, water-content conditions, electric conductivity, and the physical properties of the rocks. The hydrogeological characteristics of the five collapse columns (CC) are determined, which helped evaluate the impact of each collapse column’s water pressure on the Panel 90102. For the sake of solving the threat of water inrush from the five CC, two of them were grouted and consolidated to prevent the Ordovician aquifer water from flowing into the Panel 90102. The results have greatly improved the safety of the roadway advancing and mining activities in the Panel 90102.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Background

Coal is a common-used energy source and overexploitation in China. Mining operations safety is a big problem, for example, water inrush in the coal mine face. At present, great progress has been made in the research on mining failure of overlying strata and mechanism of coal mine water inrush in coal mines (Zhao et al. 2014; Guo et al. 2016; Liu et al. 2018; Wang et al. 2019a; Yin et al. 2019). However, the study of coal mine karst collapse columns is still absent. In the coal mines of northern China, the Ordovician limestone aquifer, which has a high confined water head and the water flow is controlled by faults and karst collapse columns, is the main factor affecting the coal seams. Mining activities can transform the aquifer into an underground channels for the water-bearing rock, endangering mine safety (Wu et al. 2016). Statistical data show that karst collapse columns exist in 45 coal mines and more than 20 large coal fields in China. Take the Fangezhuang Coalmine in Kailuan for an example that shows the dangers of karst collapse columns. Due to the exposure of the collapse column, the most serious water inrush accident in the history of the world's coalmining occurred in 2171 plane of the mine in 1984. The maximum water inflow into the mine was 123,180 m3/h, and three coalmines were flooded near the area. This resulted in more than 1 billion yuan economic losses (145 million US$), and the loss of coal production of nearly 8.5 Mt (Zhong et al. 2001). Because the exposure of a hidden collapse column during the excavation of coal roadway, another water inrush accident occurred in the Luotuoshan coalmine, Wuhai, Inner Mongolia, March 1, 2010. 70 min after the water inrush, the water volume of the submerged roadway was 67,000 m3, and the peak rate of the water burst was 60,036 m3/h, which caused 31 deaths (Zhang et al. 2015).

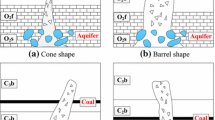

Karst collapse columns are commonly found in the northern China and seriously threat mining activities. Since the 1960s, hydrogeologists have been studying the causes, formations, distributions and detection means of karst columns in China. For the formation of the collapse column, the four recognized causes are gravity collapse, gypsum erosion, vacuum erosion, and hydrothermal genesis (Palmer et al. 1991; Marinezt et al. 1998; Hatzor et al. 2002; Li et al. 2008). Generally, the formations of karst collapse columns are: from the gap to the dissolved hole to the cave, and finally to the collapse of the cave. The formation of caves is the important and prerequisite for karst collapse columns (Su et al. 1997). Many scholars have summarized four essential material conditions for the development of karst collapse columns: soluble rock layers; saturated water quality; good groundwater channels; groundwater discharges that exacerbate groundwater alternation (Yin et al. 2004). Detection and prediction of collapse columns mainly involve two aspects in China (Cao et al. 2012; Yang et al. 2016): (1) geophysical exploration, such as the use of radio-wave detection, surveying potential collapse areas using the direct-current method and transient electromagnetic method, hydrogeological anomalies can be examined using advanced geophysical methods based on reconnaissance studies. (2) Geophysical methods can be combined with on-site drilling to verify the geological anomalies, enabling accurate control of the mine area surrounding collapse column. Basic research is carried out to investigate the development and mechanism of formation of collapse columns, water inrush, the structure of rock and surrounding rock. To study the water inrush affected by the karst collapse column, laboratory simulation tests and numerical simulations are performed to explain the structural characteristics and development of the collapse column. Based on geophysical data and study results, damage control methods such as injected grouting transformation and leaving water pillars (Liang 2015) have been used to prevent and mitigate karst collapse column water damage.

This paper focuses on the impact of karst collapse columns on the mining safety of Yangjian Coalmine. Combination of geophysical and drilling exploration methods to identify collapse columns, assess the risk of water inrush from the coal seam floor and accumulate water in old empty areas that affect coal mine safety production. Preliminarily judge the water conductivity of the structure, the water richness of the coal rock layer, and grout the dangerous collapse columns.

Hydrogeology of the study area

Due to the NNE uplift to the Taihang Mountain fault, the karst water systems of Shanxi plateaus have large-scale limestone exposed. The exposed area of every karst water system is generally 1000 ~ 2000 km2. Karst collapse columns are distributed in the Carboniferous-Permian coal fields in North China, and the total number of karst collapse columns currently discovered has exceeded 10,000, of which about 90% are concentrated in some coal fields between the coast of Fenhe River in Shanxi and the eastern foot of Taihang Mountain. There are only a few sporadic distributions in the remaining coal fields, and a small number of well fields have not yet found karst collapse columns (Yin et al. 2019). The groundwater always moves deep along the cracks between layers and is controlled by the relative position of the recharge and drainage areas. Therefore, fault locations that are consistent or close to the direction of the rock formation and recharge to the drainage area, groundwater move smoothly and circulation depth is also large. The study area is on the runoff zone with karst development and abundant water, and the Ordovician limestone karst water is generally thick, buried deep, and rich in water. It is a hidden aquifer that threaten the Carboniferous-Permian coal seam, especially at large structure region and small structure fracture zone of the mining area, the Ordovician limestone is strong water-rich karst aquifer with the upper-Carboniferous coal seam or hydraulic connection through the fracture zone that poses a huge threat to mining activities. Studying the development rules of karst and the characteristics of subsidence columns are the keys to prevent and control mine water, and it also provides theoretical basis for liberating coal reserves.

The Yangjing Coalmine is located in Shuozhou City, northern Shanxi Province, China (Fig. 1), the river in this area belongs to Sanggan River system in Haihe River Basin. The mining area is one of the arid regions in Shanxi with less precipitation, and the multi-year average rainfall from 1957 to 1984 is 433 mm, and the drought index is 3.46. This is a loess hilly area with strong terrain erosion and cutting, ravines and valleys developed, the bottom of the loess layer is mostly the Pliocene lacustrine red clay deposits, which has a certain water blocking effect and affects atmospheric precipitation. The gully is cut to the Shihe Formation bedrock, which has the effect of draining groundwater, the loess cover of the Luzigou anticline is thin, the bedrock is buried shallow, and cracks are developed, and it is better to accept atmospheric precipitation recharge.

This area is located between the Ma Ying strong runoff zone of the Ordovician and Cambrian karst groundwater in the Shentou karst spring area. The elevation of the water level of the Shentouquan group is 1058.2 ~ 1063.4 m. According to observations since 1956, the annual average flow 7.648 m3/s, the average spring discharge was 5.52 m3/s from 1980 to 2003. In 2005, the spring discharge was 4.70 m3/s. The elevation of the ash karst groundwater level in the eastern part of the Maguan River is 1055.79 ~ 1065.24 m. The groundwater flows from the northeast and northwest, converging to the Shentou Spring, karst is generally developed, the water-rich type is medium to very strong, and the water quality is excellent.

The Danshui ditch fault is the main geological feature in the region, while secondary faults are also common. Generally, the geological and hydrogeological conditions in the area are complex, leading to the development of collapse columns. The coal-bearing strata in the area are Carboniferous Permian strata, deposited directly above the Middle Ordovician. The Middle Ordovician consists of thick limestone, located more than 50 m below the upper main mining seam. The location of the faults and high pressure in the aquifers are the main threat to the mining operations. The stratigraphic column (Fig. 2) shows that the main water-filled aquifer is the Ordovician limestone karst aquifer which is more than 800 m. The water abundance in the aquifer is not uniform, aquifer pumping tests showed units-inflow range of 0.12–93.36 L/s·m, indicating an extremely uneven flow. The Ordovician limestone water pressure in the mine floor reached a maximum value of 2.265 MPa, posing a serious threat to mine safety.

Research methods

In combination with the geological conditions of the Yangjian Coalmine in mining activities, the impact of geological anomalies (such as potential subsidence columns) should be thoroughly investigated to reduce the threat of mine water inrush, promote disaster prevention and control and ensure safe mining operations.

Geophysical exploration methods

Geophysical techniques have wide applications (Nabighian, 1988, 1991; Essa et al. 2008; Um et al. 2010; Mehanee 2015; Rajab and Tarazi 2018; Mehanee et al. 2020). In recent years, geophysical techniques have become more common in studies of collapse columns (Liu et al. 2009, 2014; Du et al. 2016; Yin et al. 2018). The electromagnetic wave perspective method (Dong et al. 2003; Dennis and Cull 2012; Jiao et al. 2014) has been used for surveying the study area. The principle is the use of electromagnetic waves to detect anomalies in the subsurface (Mehanee and Zhdanov 2002, 2004; Wannamaker et al. 1984; Pellerin et al. 2005, 2007). Rocks exhibit different electrical properties (resistivity and dielectric constant) depending on their composition content (Kamenetsky and Trigubovich 2011; Kozhevnikov and Antonov 2018; Tiwari et al. 2018). The level of absorbed electromagnetic energy will change, with low-resistivity rock having higher absorbance of electromagnetic waves than high-resistivity rocks. When the wave encounters the interface of a fault structure, the electromagnetic wave will be reflected or refracted at the interface, resulting in energy loss. In mine geology, if electromagnetic waves emitted by the transmitting source encounter a fault, collapse column, water-bearing fracture, coal seam thinning area or any other structure as they propagate through the coal seam, the wave energy might be absorbed or completely shielded. The monitoring receiver will receive a weak signal or no signal, which is interpreted as an anomaly, indicating the possible location and range of an anomalous body. When encountering abnormal points, sudden points, repeat observations, and encrypt the measurement points if necessary; when the instrument fails, find out the cause in time, and return to the measured points for repeated observations. After confirming that the performance of the instrument is normal, you can continue to observe; after each observation point is completed, the operator should respond to the data and curve. Carry out a comprehensive inspection and move the station after passing the test.

Transient electromagnetic is a reasonable and effective geophysical detection method to detect water accumulation in goafs, structural conductivity and water abundance.

-

(1)

The use of large wireframes for transient electromagnetic detection of goafs on the ground has the advantages that underground detection cannot have (Meju et al. 2000; Asten et al. 2012; Yang et al. 2014; Liang and Qian 2011). It is not necessary to consider explosion protection on the ground, and high-power transmitting instruments can be used, which can effectively suppress interference. At the same time, the directivity of the small wire frame emitted by mine transient electromagnetic method can be used to detect advance detection of the roadway heading, vertical and horizontal of the water-containing anomalous body within a certain depth below the floor of the roadway. Combining surface and underground transient electromagnetic detection, surface and point exploration crosses, so that geological anomalies can be accurately and scientifically divided.

-

(2)

Downhole tracking and excavation detection, by collecting the hydrogeological data of the excavated roadway in time, and then making necessary parameter corrections, and strive to continuously improve the detection accuracy (Combrinck 2001; Bao et al. 2004; Xue et al. 2007; Wojciech et al. 2011; Sharlov et al. 2017). After completing the detection task from left to rear after head-on, should also press top-to-bottom (45°, 30°, 15°, 0°, − 15°, − 30°, − 45°) at center of the head-up direction to collect a set of data on vertical section of the head to assist the data processing and interpretation in front of the head.

-

(3)

The downhole measurement device is closer to target body, which will greatly increase intensity of induction signal of anomalous body; the cause of errors that occurred during previous detection are basically due to the metal interference at detection site (Wiggins et al. 1994; Zhihai et al. 2010; Xiong-Wu et al. 2013).

Drilling exploration methods

Exploration drilling is the most direct method of mine water-hazard exploration and it can also reveal water-rich anomalies (Wei et al. 2018; Yin et al. 2019a). Drilling can determine the composition and physical properties of strata, including water conductivity, thus leading to early detection of a developing collapse column and enabling a comprehensive risk assessment of columns. At the same time, core drilling can reveal other hydrogeological conditions and water sources, providing useful information for mitigating water-triggered threats to the safety of coal mining area (Li et al. 2011b).

An important means of exploration and development of groundwater during hydrogeological drilling, the purpose of which is to further accurately determine the burial conditions of aquifers, groundwater movement laws, and the quality and quantity of aquifers based on hydrogeological mapping of entire region. Provide necessary evidence for the development and utilization of groundwater and the prevention and control of groundwater (Hyne 1984; Zacny et al. 2008; Shi et al. 2013; Saikia and Sarkar 2013).

The drilling conditions of Panel 90102: 53 drilling holes were constructed at 260, 340, 418, 420, and 850 m along the track of the working face, with a footage of 70 ~ 130 m, of which 43 holes revealed the abnormal sequence of rocks and coal seams, indicating the development zone of the subsidence column was revealed, and only a small amount of water flowed out of the No. 2 borehole at 418 m along the track, and then stopped, indicating that each subsidence column was well developed, the cementation was relatively dense, and it was neither rich nor conductive.

Water inrush risk assessment method

The risk assessment of floor water inrush is a quantitative assessment of the risk of water outburst in each point (or each panel) using a mathematical model that reflects the influencing factors and mechanisms of action of each water inrush case in a specific mining area (Zhu et al. 2013). In China, combined with existing experience in groundwater hazard control technology, the most commonly used and applicable method for assessing the risk of floor water inrush is to calculate the water-inrush coefficient (Qiang et al. 2012).

where T is the water-inrush coefficient for aquifers below the coal layer floor, in MPa/m; P is the aquifer pressure, in MPa; M is the floor aquiclude thickness, in m.

The Chinese Mining Bureau of Science and Technology provided guidelines for critical values based on data from coal mines in northern China. Based on Table 1, it can be determined that the critical water inrush coefficient of normal geological blocks is less than or equal to 0.1 MPa/m, and the critical water inrush coefficient of structurally damaged blocks is less than or equal 0.06 MPa/m.

The floor water inrush is usually the result of the combined effect of many influencing factors, resulting in complex geological conditions which vary between different mining areas. In addition to determining water-inrush coefficient, the assessment of water inrush risk involves considerations of the tectonic setting of the mine, collapse columns and other structures that may impact water inrush (Qiang 2014; Wang et al. 2019b).

In this paper, the karst collapse column is treated by grouting technology (Oda 1986; Yang et al. 2002; Li et al. 2011a; Zhang et al. 2012).The basic principle of the grouting transformation is that concrete slurry is injected into the water-occupied layer, the fault fissures or channels in the rock under high pressure, so that they become the whole of aquifuge to improve the geological conditions and the ability of destruction of the aquifers. This method is widely used to control groundwater inflow into mines in China. The pulp used for grouting can be divided into ground pulp and underground slurry, both types of pulp being very efficient grouting slurries.

Exploration of karst collapse columns

Results of physical exploration exploration

For the electromagnetic method used in this study is that the receivers record the magnetic field intensity poit by point within a certain range along another roadway with the wave transmitter fixed at a certain point of the roadway. To determine the position and distribution range of anomaly area, the position of the transmitter and receiver were swapped and the process repeated. The Panel 90102 is located in the northwestern part of the Yangjian Coalmine, with a burial depth of about 280 m ~ 340 m, an oblique length of about 220 m, and a mining length of about 1 km. 38 transmission points were set along Panel 90102 at 50 m intervals, with the receiving points being 10 m apart. Each transmission point is recorded by 11 receiving points, totaling 418 data points.

The tomographic image (Fig. 3) shows a higher intensity in the soft layer. Combined with hydrological and ground pressure data, two abnormal areas (No 1, No 2) were identified, which included five collapse columns (XL1–XL5), see Fig. 4.

Drilling exploration results

According to the geophysical exploration, 53 drilling sites were set in the transport roadway of Panel 90102 to verify the geological conditions surrounding the five collapse columns identified in the electromagnetic survey. The engineering parameters are shown in Table 2. Of the 53 boreholes, 43 revealed abnormalities in the rock and coal seams, indicating the development of the collapse columns. However, the collapse columns were found to consist of dense material due to reduced water flow, indicating the low water content and weak conductivity of the collapse columns.

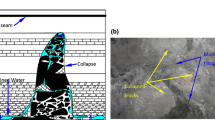

The drilling results showed that there were five collapsed columns (Fig. 5), mainly composed of sandstone, mudstone and coal rock debris. No water flow was observed during more than three months of monitoring. During the process, xl1 was exposed, and water gushed from the bottom of the tunnel. The exploration results are shown in Table 3.

The characteristics of the collapse column exposed through construction are as follows:

-

(1)

From the perspective of geomorphology, the shape of the collapse column area encountered is not obvious, and no depression basin has been formed.

-

(2)

The overall shape of the sinking column is an irregular vertebra with upper, lower, and large, and it is mostly elliptical on the horizontal section, with different lengths on the long and short axes.

-

(3)

The rock pillars of the sinking columns have clear edges and corners, irregular shapes, disorderly arrangements, mixed sizes, and mostly clay filling and bonding. After observing the characteristics of the rock blocks of each sinking column, most of them are sandstone and sandy mudstone. There are small amount of FeS2 nodules and calcite crystals. From the exposed and drilling conditions, several subsidence column structures in this area are relatively dense, but the rock blocks will soften when encountering water, which will cause blockage of the drill pipe when drilling. Conditions, difficulty in digging and supporting.

-

(4)

The contact interface between the subsidence column and the surrounding rock is often irregularly jagged, with clear boundaries, and the occurrence of the surrounding rock at the contact point is basically normal. The coal seams and the top and bottom of the contact zone are generally free of implication. When approaching the collapse column, Rock formations are fissured, and coal seams are somewhat broken.

-

(5)

The water content in most of the subsidence columns is close to the water content of coal seams. Some columns have a small stream during drilling, the flow is less than 0.1 m3/h, and it basically stops with time.

-

(6)

According to the monitoring of the ventilation department, when the various subsidence columns were exposed, there was no abnormal gas emission in the working face, but when the Panel 90102 was excavated, the H2S odor in some sections was obvious.

Comprehensive evaluation results

This time, the water inrush risk evaluation of the coal floor of the 9# coal mine in Yangjian Coalmine was carried out. Due to the limited water inrush data of the mine, the critical water inrush coefficient suitable for the mine could not be calculated, so the critical coefficient in the regulations was still used.

Through analysis and research, for the 9# coal seam of Yangjian Coalmine, the borehole 9# coal seam floor pottery of each drilling point was calculated from the thickness of each borehole aquifer and the pressure of the seam floor ash confined hydraulic pressure according to the water inrush coefficient method. The water inrush coefficient value of the limestone water inrush (Table 4), and then interpolated to generate a contour map of the water inrush coefficient in the study area (Fig. 6).

It can be seen from Fig. 6 that the coefficient of water inrush in the western Yangjian coalmine is relatively large, and the maximum value of water inrush coefficient is about 0.054 MPa/m which is caused by the thinness of the impermeable aquifer in the west, based on the analysis of the water pressure, effective thickness of the impermeable aquifer and the degree of structural development. The water inrush coefficient value gradually increases from east to west in the mining area under pressure. The water inrush coefficient value of Panel 90102 of 9# coal seam is 0.025–0.035 MPa/m, which belongs to the safe area.

Panel 90102 has a 50 m bottom water barrier and bottom plate pressure of 1.3 MPa; only considering the water pressure and the thickness of the aquifer, the water inrush value is about 0.026 MPa/m, which is less than 0.06 MPa/m; therefore, the panel is considered safe. However, many influence factors, such as geological formations, groundwater conditions and other environmental are not taken into account on the theory of water-inrush coefficient method. For example, if the Ordovician limestone aquifer has a high-water content, even if the water-inrush coefficient is less than 0.06 MPa/m, water inrush events may occur in this area. Five collapse columns were exposed in Panel 90102. Geophysical prospecting data, drilling results and mining data from the top of the face 4# of the coal mine found five subsidence columns consisting of dense rock of low water content. However, collapse columns XL1, XL4 and XL5 are connected to the aquifer through the floor of the working face, which makes the panel prone to water inrush. While the threat of the XL5 collapse column has been ruled out, it is necessary to control the XL1 and XL4 collapse columns.

Treatment of karst collapse column

Although the 9# coal floor can constitute an effective aquifer, due to the development of karst collapse pillars in the Panel 90102, the bottom drum is more serious, and at the same time there are more internal cracks in the aquifer. It may become a water inrush threat channel, so the above water inrush dangerous channels need to be blocked to eliminate the hidden danger of water inrush.

For the mine water inrush passage blocking technology, the grouting is used to strengthen or reconstruct the stratum between the bottom plate and the aquifer (aqueous layer that is not rich in water), so that the water inrush passage is blocked, thereby forming a truly effective water barrier. This paper focuses on the research of the channel with threat of water inrush in the Panel 90102 of Yangjian Coalmine. Through theoretical analysis of the technology of grouting and blocking, grouting and blocking of the channel of water inrush is summarized and improved on the basis of practice. Adopt the combination of exploration and injection that can take into account the geological conditions and grouting parameters of the working face, and can effectively block the water inrush threat channel.

Grouting process

Considering the special structure of Panel 90102, near water-rich anomalies and other characteristics, floor grouting reinforcement can be used to enhance the mechanical strength of the floor and increase the thickness of the floor aquiclude. In this technique, a number of grouting holes are drilled above the Ordovician limestone block, reinforcing the floor aquiclude and stabilizing the floor of the coal panel. By blocking the water from the Ordovician limestone aquifer, the collapse of the column can be prevented.

Panel 90102 of the Yangjian Coalmine has five collapse columns; of these, columns XL1 and XL4 need to be grouted. Using XL1 as an example, the minimum thickness of the safety floor aquiclude for XL1 was calculated as 30 m. The probe hole is designed to reach the bottom of the column at a depth of 35 m, to ensure that it extends to the actual collapse column boundary, the designed hole depth out of the border after 6 m for the final hole. According to the characteristics of floor of Panel 90102, it is determined that the horizontal plane of the grouting layer is the aquiclude of the Benxi Formation above the top of the Ordovician limestone block. The cement slurry is injected into the karst collapse column. The grouting holes are spaced 24 m apart, and the collapse column boundaries are located on the east and west sides of the subsidence column. Five holes are drilled along the west side and five holes along the east side as shown in Fig. 7.

After the grouting operation, the scope of the collapse column in Panel 90102 is calculated (green line, Fig. 7). The boundary contour of XL1 is reduced by 16 m along the longitudinal axis. The water is not effluent from the drilling and the void has been filled in XL1 collapse column. In addition, several water inrush points disappear in Panel 90102, which indicates that the effect of XL1 collapse column treatment engineering is good.

Grouting effect

To verify the effect of the interception project, the engineering community mainly uses methods such as ultrasonic exploration, geophysical exploration methods and field drilling. According to the practice of the water inrush threat channel interception project in the Panel 90102 of the Yangjian Coalmine, the bottom drum area and XL1, through the hydraulic connection between the on-site drilling construction and the drilling construction, and the exploration process, the blocking effect of the water inrush channel can be initially verified.

Analysis of the compactness and hydraulic conductivity of the subsidence column

According to the 1# hole, 60 m of the final hole is drilled, and the 4# hole is 98.7 m, the small hole is 0.6m3/h, and the 0# hole is drilled to 61 m without water, while the 2# hole, Analysis of the situation where there is no water out of the 6 hole holes such as 5# hole, 7# hole, 9# hole, 8# hole, 6# hole, etc., the XL1 cylinder is well cemented, the interior is dense, and there are cracks only at the edge of the cylinder. Weak conductivity (or related to faults at the edge of the subsidence column, which needs to be confirmed by further exploration work).

Analysis of slurry diffusion radius

According to the analysis of the drilling effluent condition and grouting volume of the three holes in the early stage and six holes in the later stage, the slurry diffusion radius is less than 24 m. However, due to the weak conductivity of the sinker column, and the gap of the sinker column has been filled by grouting Reinforcement, with a certain water resistance (for example: the pressure of water pressure before grouting is 5 ~ 6 MPa when the hole of 6# hole is final, no slurry is fed).

Re-judgment of the outline of the sinking column

After the injection hole for the collapse column exiting the boundary of the collapse column, the rock formations that pass through into the normal formation are in order. According to this principle, the outline of the possible range of the collapse column can be re-delineated to delineate the collapse column originally delineated by the detection. The contour is corrected.

In summary, through the construction of the bottom drum area of the Panel 90102 of Yangjian Coalmine and the XL1 water inrush threat channel blocking project, several water inrush points disappeared in the Panel 90102, which indicates that the XL1 collapse column treatment project Works well.

Conclusions and suggestions

-

(1)

Karst collapse pillars pose a serious security threat to coal fields in northern China. The collapse pillars in this area are extremely developed. At present, 26 mines have been exposed from four coal mines. Most of the collapse pillars are densely packed and non-conductive. The collapse column is rich in water and conducts water, which is considered to be related to structural faults. Therefore, it is important to study the hydrogeological characteristics of karst collapse columns and take effective measures to control mine safety.

-

(2)

The range, composition, and physical properties of the karst collapse columns in the North China Coalmine were determined by geophysical and drilling methods, and the safety of water inrush was evaluated.

-

(3)

Through the research and practice of grouting and blocking technology for bottom drum cracks and water-conducting sinking columns of Panel 90102 in Yangjian Coalmine, the theoretical analysis of the plugging materials, processes, and blocking methods has been made, and the application has been formed. The grouting technology and experience in this mining area have laid a theoretical and practical foundation for the revision of the plugging scheme and the promotion of experience.

-

(4)

According to the evaluation results, the grouting reinforcement method is used to control the karst collapse column, which can effectively control the water inrush and water damage of the floor.

References

Asten MW (2012) Full transmitter waveform transient electromagnetic modeling and inversion for soundings over coal measures. Geophysics 52(3):279

Bao-Xiang Z, Chun-Hua L (2004) Summarization on applications to groundwater exploration by using transient electromagnetic methods. Prog Geophys 19(3):537–542 (in Chinese)

Cao ZY, Wang W, Wang Y (2012) Numerical simulation and imaging of scattered wave of sunk pillar in coal seam. Chin J Geophys 55(5):1749–1756

Combrinck M (2001) Transient electromagnetic exploration techniques: can they be applied to the landmine discrimination problem? J Afr Earth Sc 33(3–4):693–698

Dennis ZR, Cull JP (2012) Transient electromagnetic surveys for the measurement of near-surface electrical anisotropy. J Appl Geophys 76:64–73

Dong SH, Wang Q (2003) Application of tomography in radio wave tunnels perspective. J Chin Univ Min Technol 32(5):579–582

Du Y, Song C, Chen L, Yang J (2016) PS wave based parallel seismic test for pile length assessment. Soils Found 56:440–448

Essa K, Mehanee S, Smith PD (2008) A new inversion algorithm for estimating the best fitting parameters of some geometrically simple body to measured self-potential anomalies. Explor Geophys 39:155–163

Guo W, Li Y, Yin D et al (2016) Mechanisms of rock burst in hard and thick upper strata and rock-burst controlling technology. Arab J Geosci 9(10):561–583

Hatzor YH, Talesnick M, Tsesarsky M (2002) Continuous and discontinuous stability analysis of the bell-shaped caverns at Bet Guvrin, Israel. Int J Rock Mech Min Sci 39(7):867–886

Hyne NJ (1984) Geology for petroleum exploration, drilling and production

Jiao XF, Jiang ZH, Liu SC (2014) Characteristics of abnormal response of wireless electromagnetic wave perspective in tundish of coal seam. J Min Saf Eng 31(06):1001–1004

Kamenetsky FM, Trigubovich GM (2011) Transient electromagnetic field inmagneto-viscous medium. J Appl Geophys 75:373–378

Kozhevnikov PNO, Antonov EYu (2018) Magnetic viscosity effect on TEM data of an array with a fixed transmitter loop. Russ Geol Geophys 59:690–696

Li YJ, Peng SP, Li PQ (2008) Internal thermal origin mechanism of Karstic collapse column with no smoothly extrinsic cycle. J Coal Sci Eng (China) 2(14):230–234

Li JH, Zhang Y (2011a) Study on drilling technology of karst collapse column. Zhongzhou Coal 188:17–19

Li SC, Zhang X, Zhang QS (2011b) Study on diffusion mechanism and blocking method of water injection grouting for water bursting in underground engineering. Chin J Rock Mechan Eng 30(12):2377–2396

Liang F, Qian R (2011) Application of transient electromagnetic method to coal mine gobs. Chin J Eng Geophys 8(1):29–33 (in Chinese)

Liang CJ (2015) Characteristics of water damage and its application in coal mine collapse column. Energ Energ Conserv 10:29–30

Liu SD, Wu RX, Zhang PS et al (2009) Three-dimensional parallel electric surveying and its applications in water disaster exploration in coal mines. J Chin Coal Soc 34(7):927–932

Liu S, Liu J, Yue J (2014) Development status and key problems of Chinese mining geophysical technology. J China Coal Soc 39(1):19–25. https://doi.org/10.13225/j.cnki.jccs.2013.0587

Liu Y, Xu J, Zhou G (2018) Relation between crack propagation and internal damage in sandstone during shear failure. J Geophys Eng 15(5):2104–2109

Marinezt JD, Johnson KS, Neal JT (1998) Sinkholes in evaporate rocks. Am Sci 86:39–52

Mehanee S (2015) Tracing of paleo-shear zones using self-potential data inversion: case studies from the KTB, Rittsteig, and Grossensees graphite-bearing fault planes, Earth. Planets Space 67:14. https://doi.org/10.1186/s40623-014-0174-y

Mehanee S, Smith PD (2007) The influence of discretizing conductivity gradients in the 3-D finite difference em forward modelling algorithms. Aseg Extended Abstracts 4:224–233. https://doi.org/10.1071/ASEG2007ab089

Mehanee S, Zhdanov M (2002) Two-dimensional magnetotelluric inversion of blocky geoelectrical structures. J Geophys Res Solid Earth. https://doi.org/10.1029/2001JB000191

Mehanee S, Zhdanov M (2004) A quasi-analytical boundary condition for three-dimensional finite difference electromagnetic modeling. Radio Sci 39:RS6014. https://doi.org/10.1029/2004RS003029

Mehanee S, Essa KS, Diab ZE (2020) Magnetic data interpretation using a new R-parameter imaging method with application to mineral exploration. Nat Resour Res. https://doi.org/10.1007/s11053-020-09690-8

Meju MA, Fenning PJ, Hawkins TRW, Meju MA (2000) Evaluation of small-loop transient electromagnetic soundings to locate the sherwood sandstone aquifer and confining formations at well sites in the Vale of York, England. J Appl Geophys 44(2):217–236

Nabighian MN (1988) Electromagnetic methods in applied geophysics, vol 1. Theory, Society of Exploration Geophysicist (SEG), Tulsa, USA, p 513

Nabighian MN (1991) Electromagnetic methods in applied geophysics. vol 2. Applications, Society of Exploration Geophysicist (SEG), Tulsa, USA, p 347

Oda M (1986) An equivalent continuum model for coupled stress and fluid flow analysis in jointed rock masses. Water Resour Res 22(13):1845–1856

Palmer AN (1991) Origin and morphology of limestone caves. Geol Soc Am Bull 103(1):1–21

Pellerin L, Wannamaker PE (2005) Multi-dimensional electromagnetic modeling and inversion with application to near-surface earth investigations. Comput Electron Agric 46:71–102. https://doi.org/10.1016/j.compag.2004.11.017

Qiang W (2014) Progress, problems and prospects of prevention and control technology of mine water and reutilization in China. J China Coal Soc 39(5):795-805. https://doi.org/10.1322/j.cnki.jccs.2014.0478 (in Chinese)

Qiang W, Suqi Z, Shuning D et al (2012) Dissection of main technical points in “Coal Mine Safety Regulations(water control part)” modification. Coal Geol China 24(7):34-37 (in Chinese)

Rajab JSA, Tarazi EA (2018) Illuminating and optimising a three-dimensional model of an oil shale seam and its volume distribution using the transient electromagnetic induction method, central part of Jordan. Geophys Prospect 66:603–625

Saikia K, Sarkar BC (2013) Exploration drilling optimisation using geostatistics: a case in jharia coalfield, india. Applied Earth Science 115(1):13–22

Sharlov MV, Buddo IV, Misyurkeeva NV, Shelokhov IA, Agafonov YuA (2017) Transient electromagnetic surveys for highresolution near-surface exploration: basics and case studies. First Break 35(9):63–71

Shengdong L, Jing L, Jianhua Y (2014) Development status and key problems of Chinese mining geophysical technology. J China Coal Soc 39(1):19-25. https://doi.org/10.13225/j.cnki.jccs.2013.0587

Shi X, Dewei T, Qiquan Q et al (2013) Development of a drilling and coring test-bed for lunar subsurface exploration. In: IEEE International Conference on Robotics & Biomimetics. IEEE, pp 2124–2129. https://doi.org/10.1109/ROBIO.2013.6739783

Su CY, Han P (1997) The formation mechanism of karst collapse column. Shanxi Coal 05:16–18 (in Chinese)

Tiwari AK, Maurya SP, Singh NP (2018) TEM response of a large loop source over the multilayer earth models. Int J Geophys 2018:1–7

Um ES, Harris JM, Alumbaugh DL (2010) 3D time-domain simulation of electromagnetic diffusion phenomena: a finite-element electric-field approach. Geophysics 75(4):F115–F126

Wang D, Shi L (2019a) Source identification of mine water inrush: a discussion on the application of hydrochemical method. Arab J Geosci 12(2):58

Wang D, Shi L (2019b) Source identification of mine water inrush: a discussion on the application of hydrochemical method. Arab J Geosci. https://doi.org/10.1007/s12517-018-4076-3

Wannamaker PE, Hohmann GW (1984) Electromagnetic modeling of three-dimensional bodies in layered earths using integral equations. Geophysics 49(1):60

Wei J, Sun L, Huang B, Bilal M, Zhang Z (2018) Verification, improvement and application of aerosol optical depths in China Part I: Inter-comparison of NPP-VIIRS and Aqua-MODIS. Atmos Environ 175:221–233

Wiggins CM, Thomas DE (1994) Transient electromagnetic interference in substations. IEEE Trans Power Delivery 9(4):1869–1884

Wojciech KLITYŃSKI, & Paweł TARGOSZ. (2011). Principles of the transient electromagnetic method and possibilities of its application to oil and gas exploration. Geology, Geophysics\\s&\\senvironment.

Wu Q, Liu YZ, Wu XL (2016) Assessment of groundwater inrush from underlying aquifers in Tunbai coal mine, Shanxi province, China. Environ Earth Sci 75:737

Xiong-Wu HU, Zhang PS, Yan JP, Pei-Gen LI (2013) Experimental analysis on bolt interference during advanced water detection with the mine transient electromagnetic method. J Coal Sci Eng (China) 19(003):407–413

Xue GQ, Yan YJ, Li X (2007) Pseudo-seismic wavelet transformation of transient electromagnetic response in engineering geology exploration. Geophys Res Lett 34(16):377–396

Yang FT, Pang ZH, Duan ZF (2016) Distinguishing between faults and coal collapse columns based on sediment dating: a case study of the Huainan coal field China. Environ Earth Sci 75:959

Yang MJ, Yue ZQ, Lee PK (2002) Prediction of grout penetration in fractured rocks bynumerical simulation. Can Geotech J 39(6):1384–1394

Yang JM, Wei, ZZ, Gao XW, Geology Party No, & CNNC (2014) The application of the methods of high density resistivity method and transient electromagnetic to detecting coal mining goaf and to inspect grouting effect. Prog Geophys 29(1):362–369

Yin SX, Wu Q, Wang SX (2004) Hydrogeological and mechanical basics of water inrush from karstic collapse columns in Northern China. J Chin Coal Soc 02:182–185 (in Chinese)

Yin H, Shi Y, Niu H, Xie D, Wei J, Lefticariu L, Shuanxiang Xu (2018) A GIS-based model of potential groundwater yield zonation for a sandstone aquifer in the Juye Coalfield, Shangdong, China. J Hydrol 557:434–447. https://doi.org/10.1016/j.jhydrol.2017.12.043

Yin H, Zhao H, Xie D, Sang S, Shi Y, Tian M (2019a) Mechanism of mine water inrush from overlying porous aquifer in Quaternary: a case study in Xinhe Coal Mine of Shandong Province, China. Arab J Geosci 12:163. https://doi.org/10.1007/s12517-019-4325-0

Yin H, Zhao H, Xie D et al (2019b) Mechanism of mine water inrush from overlying porous aquifer in Quaternary: a case study in Xinhe Coal Mine of Shandong Province, China. Arab J Geosci 12(5):163

Yin S, Lian H, Liu D et al (2019) 70 years of investigation on Karst collapse column in North China Coalfield: cause of origin, mechanism and prevention[J]. Coal Science and Technology,47(11):1–29. https://doi.org/10.13199/j.cnki.cst.2019.11.001

Yogeshwar P, Tezkan B (2017) Two-dimensional basement modeling of central loop transient electromagnetic data from the central Azraq basin area, Jordan[J]. J Appl Geophys 136:198–210

Zacny K, Bar-Cohen Y, Brennan M, Briggs G, Cooper G, Davis K et al (2008) Drilling systems for extraterrestrial subsurface exploration. Astrobiology 8(3):665–706

Zhang WZ (2015) Three dimensional large scale simulation experiment of collapse column water inrush. J Taiyuan Univ Technol 46(6):685–690

Zhang M, Wang XH, Wang Y (2012) Numerical evaluation of uplifting effect for upper structure by grouting. J Cent South Univ 19:553–561. https://doi.org/10.1007/s11771−012−1039−9

Zhao T, Yin Y, Xiao F et al (2014) Rockburst disaster prediction of isolated coal pillar by electromagnetic radiation based on frictional effect. Scientific World J 2014:814050. https://doi.org/10.1155/2014/814050

Zhihai J, Jianhua Y, Jingcun YU (2010) Experiment in metal disturbance during advanced detection using a transient electromagnetic method in coal mines. Min Sci Technoly (China) 20(6):861–863

Zhong YP (2001) Studies on Integrate Technology of Water Prevention in Kailuan Mines. China Coal Industry Publishing House Press, Beijing

Zhu ZK, Xu ZM, Sun YJ (2013) Study on risk assessment of floor water inrush based on dimensionless multi-source information fusion. J Min Saf Eng 30(06):911–916

Acknowledgements

This research was financially supported by the National Key Research and Development Program of China (No. 2019YFC1805400), the Fundamental Research Funds for the Central Universities (No.2020ZDPY0201) and the National Natural Science Foundation of China (No. U1710253). The authors also thank the editors and reviewers for their constructive suggestions.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Xu, Z., Sun, Y., Gao, S. et al. Comprehensive exploration, safety evaluation and grouting of karst collapse columns in the Yangjian coalmine of the Shanxi province, China. Carbonates Evaporites 36, 16 (2021). https://doi.org/10.1007/s13146-021-00675-z

Accepted:

Published:

DOI: https://doi.org/10.1007/s13146-021-00675-z