Abstract

In the present study, we have synthesized nanocrystalline Fe x Ni80−xCo20 (x = 20 and 40) alloys via modified sodium borohydride reduction route in aqueous medium. The phase purity and microstructural analysis of the materials were done using powder X-ray diffraction (XRD) and transmission electron microscopy (TEM). Fe–Ni–Co alloys crystallize in face centered cubic (fcc) structure having the values of lattice parameters, a = 3.5460 and 3.5634 Å, for Fe20Ni60Co20 and Fe40Ni40Co20, respectively. The average crystallite sizes were found to be 30 and 26 nm for Fe20Ni60Co20 and Fe40Ni40Co20, respectively. Fe20Ni60Co20 and Fe40Ni40Co20 alloys crystallize in nearly spherical shape morphologies having TEM particle sizes of 24 and 36 nm, respectively. Selected area electron diffraction (SAED) patterns confirm face centered cubic crystal structure and polycrystalline nature of the materials. Low temperature studies indicate that Fe–Ni–Co alloys show ferromagnetism at least up to 300 K. The effective magnetic anisotropy constant (K) for Fe20Ni60Co20 and Fe40Ni40Co20 alloys are found to be 14 and 4.2 kJm−3, respectively. These results have been explained on the basis of size, shape and surface effects in the nano-materials. The contribution corresponding to spin relaxation and dipolar interactions between nano-particles on magnetic characteristics of Fe20Ni60Co20 and Fe40Ni40Co20 alloys have been explained qualitatively during the magnetic analysis.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Fe–Ni–Co alloys have been receiving technological importance due to their size and shape sensitive magnetic and microstructural properties [1, 2]. Especially, these alloys are widely used as electromagnetic wave absorption (EMA) materials for commercial and military applications [3]. In electronic industries, these materials are used for recording, storage devices, material’s sealing, press working, photo-etching and thermal resistance purposes due to their unique magnetic and thermo-physical properties [4]. In case of Permalloy (Fe–Ni), zero magnetocrystalline anisotropy is required to achieve soft magnetic properties. And zero magnetocrystalline anisotropy can be obtained by reducing crystallite size to less than the length of an exchange-coupled region [5, 6]. Permalloys, containing 75–82 wt% Ni have high initial permeability which reduces area of hysteresis loop and coercivity value to the soft magnetic regime [7]. Further, it has been observed that doping of small amount of cobalt in Fe–Ni alloys show enhancement in magnetic properties with small hysteresis loss [8]. Greve et al. have studied nano-structured Fe54Ni27Co19 and PTFE nanocomposites for their magnetic high frequency applications in gigahertz range [9]. Fe–Ni–Co alloys having 29 % Ni and 17 wt% of Co is known as KOVAR and it has wider usage, such as sealing of metal and hard glass parts, in the electronic industries [4]. It has been reported that structure and magnetic properties Fe–Ni–Co ternary alloys depend on the synthetic methodology and subsequent heat treatments of the materials [10]. Fe–Ni–Co ternary alloys can be synthesized by using hydrazine hydrate method, vapor phase deposition, mechanical method, sonochemical method, hydrogen plasma–metal reaction etc. [3, 9–12]. In our previous study, we have reported the novel chemical reduction method using sodium borohydride as reducing agent in aqueous medium for such kind of materials [13, 14]. Chemical reduction method plays important role in controlling size and microstructure of the nanomaterials. Soft magnetic properties of Fe–Co–Ni alloys are related to the fcc cubic structure with no or little anisotropy in the material [13]. In addition, in nanocrystalline form, the soft magnetic properties are closely related to microstructural effects such as grain size, dispersion of crystal axes, non-magnetic layer, order–disorder phase transformation etc. [6, 7]. The methodology favors the formation of nano-crystalline materials with controlled size distribution. The magnetic properties of the materials were observed to vary with compositions and show size and/or surface effects. However, there is limited study available in the literature on low temperature superparamagnetic properties on PEG coated FexNi80−xCo20 (x = 20 and 40) alloys via modified sodium borohydride reduction route. Therefore, motivation lies in this regard to explore the magnetic properties of Fe–Ni–Co nano-materials which are close to single domain size range. The synthesis, structural, electron microscopy and low temperature (FC and ZFC) magnetic studies on coated FexNi80−xCo20 (x = 20 and 40) alloys have been presented in this paper.

2 Experimental

For this investigation, we have procured ferric chloride hexahydrate (FeCl3·6H2O), nickel chloride hexahydrate (NiCl2·6H2O), cobalt chloride hexahydrate (CoCl2·6H2O), sodium borohydride (NaBH4) and polyethylene glycol (PEG-200) from Molychem, India and used without further purification. We have synthesized Fe–Ni–Co ternary alloy nanoparticles of two different compositions (i.e. Fe20Ni60Co20 and Fe40Ni40Co20) in similar synthetic strategy as per our previously reported method [13]. In summary, 4.5 mmol metal chloride(s) were dissolved in 50 ml 1 M HCl in order to keep the pH value of reaction mixture below 6.5 till completion of reaction. Next, 50 ml 1 M NaBH4 (aq.) was added to the resulting solution drop by drop under vigorous stirring in time duration of 20 min. During the progress of reaction, temperature was maintained at 25–30 °C. The resulting black colored solid were capped with PEG-200 (2 ml) and separated after an hour. The synthesized alloys nanoparticles were heat treated at 600 °C for 2 h under high purity N2 (g) atmosphere in order to get crystalline materials.

Instrumental characterizations of the materials were done by X-ray diffraction method (XRD), transmission electron microscopy (TEM) and vibrating sample magnetometer (VSM). XRD patterns were recorded using a powder X-ray diffractometer (Model: Mini Flex II, Japan) using Cu Kα radiation (λ = 0.154 nm) at scan speed of 3o per minute. Crystallite size was estimated using Scherrer equation, t = 0.9λ/Bcosθ, where t is crystallite size, λ is wavelength of X-ray radiation, B is full width at half maximum (FWHM) in radian and θ is the diffraction angle [15]. The size, shape morphology and selected area electron diffraction (SAED) of materials were examined by TEM measurements (Model: PHILIPS CM200). The magnetization measurements at low temperatures (20–300 K) were carried out on solid powder material using vibrating sample magnetometer (Model: Lakeshore VSM 7410) in field cooled (FC) and zero field cooled (ZFC) conditions. The sample was first cooled to 20 K in the absence of external magnetic field and then warmed to 300 K in the presence of external magnetic field and the magnetization was recorded as ZFC. The FC measurements were done after ZFC measurements and the magnetization was recorded while cooling the sample down from 300 K to 20 K with 100 Oe field.

3 Results and Discussion

3.1 X-ray Diffraction Studies

The X-ray diffraction (XRD) patterns for Fe20Ni60Co20 and Fe40Ni40Co20 ternary alloys heat treated at 600 °C under high purity N2 (g) atmosphere are shown in Fig. 1 and the inset shows the XRD patterns for corresponding as-synthesized materials. It should be noted that as prepared materials are amorphous in nature. This may be due to the presence of boron during the synthesis process which prevents grain growth and crystallization. However, the particle size after reduction is very small (< 5 nm). In order to study magnetic properties of well defined nano-crystals we have heat treated the materials at various temperatures, i.e. 25–600 °C. Up to 550 °C, the heat treated materials were X-ray amorphous and broad peaks centered at 2θ values of ~ 44o were obtained. However, we could able to get well crystallized pure face centered cubic (fcc) nanocrystals at 600 °C. Spacing between the crystal planes (d-values) and lattice parameters were estimated by least square method and are summarized in Table 1. The peaks in XRD patterns were broader which may be attributed majorly to nanocrystalline nature of the materials. Fe20Ni60Co20 and Fe40Ni40Co20 alloys crystallize in face centered cubic (fcc) crystal structure and the observed d values for (111), (200) and (220) agrees well with the calculated d values (see Table 1). The estimated crystallite sizes for Fe–Ni–Co alloys are presented in Table 2. The values of lattice parameters were found to be 3.5460 Ǻ and 3.5634 Ǻ whereas crystallite sizes were 30 and 26 nm for Fe20Ni60Co20 and Fe40Ni40Co20, respectively. The absence of diffraction lines corresponding to Fe-oxide in the XRD study indicates more oxidation resistivity in Fe–Ni–Co materials synthesized in the present study [12]. The values of lattice parameters and their increasing trend with increasing Fe content are in accordance with literature reported studies for fcc Fe–Ni–Co alloys [13].

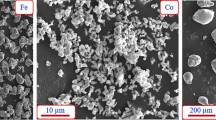

3.2 TEM Studies

TEM micrographs and selected area electron diffraction (SAED) pattern for Fe20Ni60Co20 and Fe40Ni40Co20 alloys heat treated at 600 °C are shown in Fig. 2. The estimated average particle sizes for Fe–Ni–Co alloys from TEM micrographs are summarized in Table 2. TEM micrograph studies confirm that the synthesized Fe–Ni–Co alloys have nearly spherical morphology having average TEM particle sizes of 24 and 36 nm for Fe20Ni60Co20 and Fe40Ni40Co20 alloys, respectively. Although, there is indication of the presence of some agglomerated fractions of the nanomaterials in TEM micrographs, the TEM particle sizes, i.e. 24 and 36 nm, are comparable with the average XRD crystallite sizes, i.e. 30 and 26 nm, for Fe20Ni60Co20 and Fe40Ni40Co20, respectively. In our TEM investigation, the micrographs indicate broader distribution of particle sizes. The reason can be majorly due to the chemical methodology adopted for synthesis and surface modifications by dissolved species leading to agglomerations [16]. As in the present synthesis methodology, we have used high concentration of borohydride (i.e. 1 M) in presence of Cl− ions, PEG etc. in order to reduce metal ions; grain growth leading to agglomeration is dominant. In SAED pattern, the formation of diffraction rings indicates polycrystalline nature of the materials. The interplanar spacing (d-value) for (111) and (200) crystal planes from SAED patterns were found to be 2.0449 Ǻ and 1.7667 Ǻ for Fe20Ni60Co20 and 2.0576 Ǻ and 1.7921 Ǻ for Fe40Ni40Co20, respectively. The interplanar spacing obtained for (111) and (200) planes from SAED patterns matches well with the corresponding values obtained from XRD results.(Table 1). These results indicate the formation of pure fcc Fe–Ni–Co ternary alloy phases.

3.3 Magnetic Studies

Room temperature magnetic hysteresis studies for Fe20Ni60Co20 and Fe40Ni40Co20 materials have been reported in our previous work [13]. Magnetic characteristics indicate the majorly presence of size and surface effects in the materials [13]. In this investigation, we have extended our work to study low temperature magnetic characteristics of Fe–Ni–Co ternary alloys. Temperature dependence magnetic measurements of Fe–Ni–Co alloys were carried out in order to study thermo-magnetic properties of the materials. Magnetization versus temperature plots Fe20Ni60Co20 and Fe40Ni40Co20 in field cooled (FC) and zero field cooled (ZFC) conditions at 100 Oe of applied field are presented in Fig. 3. An irreversible nature of FC/ZFC curves reveals the presence of magnetic interactions, spin relaxation effect and single domain particles having blocking temperature of approximately at 300 K.

An energy barrier is associated with change in magnetization state in fine particle system. This barrier is proportional to the difference in magnitude of magnetization between FC and ZFC curve at a particular temperature. This is related to spin relaxation mechanism. In Fe–Ni–Co alloys, field cooled (FC) magnetization values are larger than the zero field cooled (ZFC) magnetization values and which showing the ferromagnetic nature of the materials. It has been observed that FC/ZFC plots show thermo-magnetic irreversibility below 300 K and indicate some fraction of Fe–Ni–Co nanoparticles may become superparamagnetic above 300 K. The ZFC magnetization increases rapidly during the heating at temperatures up to 100 and 130 K for Fe20Ni60Co20 and Fe40Ni40Co20, respectively. The FC and ZFC curves for both the ternary compositions differ significantly. This may be well understood from the altered intrinsic magnetic structure due to difference in Fe contents in the alloys. This may be a major reason which is evident from higher values of magnetizations for Fe40Ni40Co20 alloys compared to Fe20Ni60Co20 with the application of external field of 100 Oe. The FC curve includes the total magnetization contributed from all particles whereas the ZFC curve measures the magnetization contributed from such nanoparticles whose energy barriers are overcome by the thermal energy (kBT) at the measuring temperature [17]. This variation in magnetic behavior may be attributed to the presence of interparticle dipolar magnetic interactions among nanoparticles having spin relaxation. Such kinds of interpretations have been reported in the literature [18, 19].

For spherical nanoparticles, the effective magnetic anisotropy constant (Keff) can be determined by using the formula, Keff = 25kBTB/V, where TB is blocking temperature, V is particle volume and kB is the Boltzmann constant [20]. Assuming the value of blocking temperature (TB) equal to 300 K and the particle volume from TEM, the effective magnetic anisotropy constants (Keff) for Fe20Ni60Co20 and Fe40Ni40Co20 were found to be 14 and 4.2 kJm−3, respectively (Table 2). These values are less in magnitude compared the value for Co (25 kJm−3) and Ni (13 kJm−3) [18]. Keff values for Fe–Ni–Co alloys decrease with increasing Fe content and the materials drift towards softer in magnetic behavior with increasing Fe contents.

4 Conclusions

In summary, Fe–Ni–Co alloys nanoparticles of two different compositions have been synthesized via sodium borohydride reduction route. Both Fe–Ni–Co alloys crystallize in fcc crystal structure having crystallite size equal to 30 and 26 nm for Fe20Ni60Co20 and Fe40Ni40Co20, respectively. TEM studies confirm that synthesized materials have spherical morphologies with minute fractions of agglomerations. Estimated values of TEM particle sizes were found to be 24 and 36 nm for Fe20Ni60Co20 and Fe40Ni40Co20, respectively. It is observed that Fe–Ni–Co alloys showing thermo-magnetic irreversibility below 300 K and blocking temperature approximately at 300 K. FC and ZFC magnetic characteristics of Fe–Ni–Co alloys are interpreted on the basis of interparticle interactions among magnetic nanoparticles. The values of effective magnetic anisotropy constants (Keff) are found to be 14 and 4.2 kJm−3 for Fe20Ni60Co20 and Fe40Ni40Co20, respectively.

References

Ikeda K, Kobayashi K, and Fujimoto M, J Appl Phys 92 (2002) 5395.

Ramprasad R, Zurcher P, Petra M, and Miller M, J Appl Phys 96 (2004) 519.

Yan S J, Zhen L, Xu C Y, Jiang J T, Shao W Z, Lu L, and Tang J, J Appl Phys 109 (2011) 07A320.

Bahgat M, Paek M, Park C, and Pak J, Mater Trans 49 (2008) 208.

Ishio S, Kobayashi T, Saito H, Sugawara S, and Kadowaki S, J Magn Magn Mater 164 (1996) 208.

Herzer G, IEEE Trans Magn 26 (1990) 1397.

Vajpai S K, Mahesh B V, and Dube R K, J Alloys Compd 476 (2009) 311.

Vajpai S K, Dube R K, and Tewari A, Metall Mater Trans A 39A (2008) 2725.

Greve H, Pochstein C, Takele H, Zaporojtchenko V, and Faupel F, Appl Phys Lett 89 (2006) 242501.

Jartych E, J Magn Magn Mater 323 (2011) 209.

Shafi K V P M, Gedanken A, Prozorov R, Revesz A, and Lendvai J, J Mater Res 15 (2000) 332.

Li X, and Takahashi S, J Magn Magn Mater 214 (2000) 195.

Dalavi S B, Theerthagiri J, Manivel Raja M, and Panda R N, J Magn Magn Mater 344 (2013) 30.

Kim C W, Kim Y H, Cha H G, Kwon H W, and Kang Y S, J Phys Chem B 110 (2006) 24418.

Culity B D, Elements of X-ray diffraction, Addison Wesley, MA (1956), p 98.

Carroll K J, Hudgins D M, Brown III L W, Yoon S D, Heiman D, Harris V G and Carpenter E E, J Appl Phys 107 (2010) 09A303.

Kim J, Kim J, Kim J, and Kim K H, J Appl Phys 113 (2013) 17A313.

Dalavi S B, and Panda R N, J Magn Magn Mater 374 (2015) 411.

Fang J, Tung L D, Stokes K L, He J, Caruntu D, Zhou W L, and O’Connor C J, J Appl Phys 91 (2002) 8816.

Ibrahim E M M, Hampel S, Wolter A U B, Kath M, El-Gendy A A, Klingeler R, Taschner C, Khavrus V O, Gemming T, Leonhardt A, and Buchner B, J Phys Chem C 116 (2012) 22509.

Acknowledgments

We gratefully acknowledge the financial support from Council of Scientific and Industrial Research (CSIR), New Delhi and Department of Science and Technology (DST), New Delhi. We acknowledge SAIF, IIT Bombay, Mumbai for TEM measurements and SAIF, IIT Madras, Chennai for magnetic measurements.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Dalavi, S.B., Panda, R.N. Structural and Magnetic Properties of Single Domain PEG-Coated FexNi80−xCo20 (x = 20, 40) Ternary Alloys Synthesized by Chemical Method. Trans Indian Inst Met 68 (Suppl 2), 253–257 (2015). https://doi.org/10.1007/s12666-015-0585-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12666-015-0585-x