Abstract

Al–12Si–3Cu–1 Mg–1.78Ni alloy is widely used for piston parts in automobile industry. The present paper investigates the effect of aging time for 1–16 h at 180 °C after solution treatment of the alloy at 500 °C for 5 h, on alloys prepared by gravity casting and squeeze casting. The wear rate of the alloy shows a minimum at an intermediate aging time. The hardness and ultimate tensile strength showed a peak at intermediate aging time. Mechanical properties and wear resistance are found to be better in squeeze cast alloy. The result are explained based on the microstructure developed during casting process and on heat treatment for various durations.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

The automobile industry is increasingly using aluminium–silicon alloys cast at near eutectic and aging-hardened due to their good wear resistance, low thermal expansion, relatively high specific strength at low specific weight and low cost, resulting in affordable improvements in fuel efficiency. By heat treatment, the microstructure of near eutectic aluminium silicon alloys can be modified and its properties improved [1]. Factors like the temperature and aging time affect not only the as-cast microstructure but also the mechanical properties and wear characteristics of heat treated Al–Si alloys [2, 3]. Copper is added for arresting natural aging but increases the kinetics of artificial aging. Nickel and magnesium are added to increase the strength [4]. An improvement in wear resistance of 390 Al alloys after heat treatment was observed. Yasmin et al. [5] studied the mechanical and wear properties of Al–Si eutectic alloy and found that full heat treatment has a great influence on the wear and mechanical properties of the Al–Si piston alloy. Haque and Sharif [6] also noted that heat treatment show a great influence on the mechanical and wear properties of the Al–Si piston alloy as it reduces the wear rate and increases the ultimate tensile strength. Modern casting processes like squeeze casting are used to cast Al–Si alloys to overcome the disadvantages of the conventional die-casting process [7]. In the present study influence of aging time on mechanical and wear properties of cast Al–Si–Cu–Mg–Ni piston alloy has been investigated. The study also aims to understand the effect of heat treatment on the mechanical and wear properties of both as cast and squeeze cast Al–Si–Cu–Mg–Ni piston alloy.

2 Experimental Procedure

2.1 Preparation of Castings

The experimental alloys are prepared using as received LM6 alloy ingots, Al–30 % Cu master alloy, Al–20 %Mg master alloy and Al–75 %Ni master alloy. The LM6 alloys are melted in graphite crucibles in an electrical resistance pit furnace at 800 °C. After the alloy melted completely, the alloying elements (Cu, Mg, and Ni) are added to obtain the expected compositions. A graphite lance is used to bubble pure, dry nitrogen gas for about 60 min into the melt to degas it and remove the hydrogen and inclusions. After alloy addition and degassing, the slag on the top of the melt is removed. It is then poured into the preheated molds for gravity die-cast alloy. For squeeze casting, a measured quantity of the liquid metal (2 kg) is poured into the die cavity and 100 MPa pressure is applied to the casting for 2 min. All the alloys under investigation are solutionized at 500 °C for 5 h followed by water quenching and artificial aging at 180 °C for 1, 2, 4, 6, 8, 9, 10, 12, and 16 h.

2.2 Preparation of Samples

An optical emission spectrometer was used to determine the chemical compositions of the alloys investigated in the study. A Leica DMRX 82 optical microscope was employed for observing the microstructures of the as-cast and heat-treated specimens. The tensile properties of the alloy samples were evaluated using a universal testing machine (Instron Model 1195-5500R) at room temperature. The dimensions of the specimens used for the tensile tests are shown in Fig. 1. A Brinell hardness machine (Indentec) was employed to determine the hardness values of the samples (diameter of indenter ball 2.5 mm and load 62.5 kg). For conducting wear tests, DUCOM TR-20LE pin-on-disc wear testing apparatus under dry sliding conditions in the ambient air at room temperature was used. The sliding distance of the pin and the velocity of the disc are fixed at 1800 m and 2 m/s respectively. Each test was for 15 min duration with a load of 20 N. Wear surface morphology and fracture surface of the tensile samples were studied under scanning electron microscope.

3 Results and Discussion

3.1 Chemical Analysis

The composition of the experimental alloy, which was analysed using an optical emission spectrometer, is given in Table 1.

3.2 Role of Aging Time on Wear Properties and Mechanical Properties

The wear behaviour, hardness and ultimate tensile strength of the alloy as a function of aging time are shown in Figs. 2, 3 and 4. It is observed the wear rate decreases with an increase in aging time from 1 to 9 h. A significant reduction in wear rate is observed at the aging time of 9 h. At earlier stages of aging, the BHN increase with aging time until it reaches the peak. After reaching the peak, the BHN decreases as a result of over aging. The hardness values exhibit peak at 9 h, resulting from the presence of several hardening phases, including Al2Cu, Mg2Si and Al7CuNi which contribute to the precipitation hardening of the alloys. Similar observations were recorded and explained for Al–Si–Cu–Mg 380 alloy by Muzaffer Zeren [8]. The ultimate tensile strength shows the maximum after aging at 180 °C for 9 h. The ultimate tensile strength increase with an increase in aging time and reaches a maximum at 9 h and decreases after aging for 9 h. After 9 h the specimen is over aged with an increase in aging time. The mechanical properties of Al–Si alloy not only depend on the chemical composition but also on the microstructural features such as morphologies of dendritic α(Al), spheroidization of eutectic silicon and other intermetallic phases within the microstructure. The variation of the morphology and size of eutectic silicon particles results in the improvement in mechanical properties. During solution heat treatment, some particles dissolve back into Al matrix, yielding a solid solution. The degree of solid solution strengthening depends on the number of solute atoms in the Al matrix. During ageing, the precipitation of strengthening phases increases the hardness of the alloy. The variation in the tensile strength is usually in good agreement with the variation in hardness, for example, an alloy with higher hardness typically has a higher tensile strength.

4 Microstructural Observations

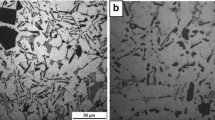

The optical micrographs of as-cast gravity die-cast and heat treated gravity die-cast alloys are represented by Fig. 5. The microstructures of squeeze casted alloy before heat treatment and after heat treatment are represented by Fig. 6. The heat treated conditions were solutionisation, (the samples were heated at a temperature of 500 °C for 5 h) and quenched in cold water (20 °C). After being quenched, the samples were dried in air and then heated to 180 °C for 9 h in an electric oven for ageing. They were then cooled in air. The predominant phase (light grey) in the as-cast microstructure of these alloys is α(Al) face-centred-cubic solid solution. A dendritic network is formed by α-phase which is usually cores, participating in several multi-phase eutectic reactions. Aluminium and silicone binary eutectic is an anomalous eutectic phase as it constitutes a metal (aluminium) and non-metal (silicon). The primary Si particles were larger and faceted, whereas the eutectic Si particles were mostly needle or plate-like in shape. Other intermetallic phase particles are also present in the aluminium dendrite arms. After heat treatment, a very remarkable fragmentation and spheroidization of eutectic Si particles is observed in comparison to plate-shaped as cast specimen. The particle distribution including eutectic silicon and intermetallic phases is more homogeneous after heat treatment.

Microstructure parameters such as amount of massive primary silicon particles, eutectic silicon morphology, silicon crystal and bonding of these particles with soft and tough aluminium matrix are the important factors which should be considered in the analysis of wear behaviour of these alloys. Spheroidization of eutectic silicon grains may be attributed to a reduction in wear rate and increase of mechanical properties with an increase in aging time. Spherical silicon morphology would discourage the crack nucleation and propagation. Since particles of near-spherical shape would cause low-stress concentration at particle–matrix interfaces [9]. The morphology of eutectic silicon is changed to smooth edged near- spherical-shaped, after the heat treatment.

It is clear from the microstructures that the increase in the applied pressure causes a decrease in the grain size of the primary α phase.

where Tf is the equilibrium freezing temperature, V1 and Vs are the specific volume of the liquid and solid respectively and Lf is the latent heat of freezing [10]. From the Eq. 1, it is clear that Tf should increase with an increase in pressure. With increase in freezing point leads to undercooling in the melt, which increases the nucleation sites bringing about a finer grain size. Apart from the undercooling, the applied pressure leads to high heat transfer rate (that is high cooling rate) due to more effective contact area. Obviously, the increase in freezing point and high heat transfer rate resulted in the refinement of the grain size of the alloy.

5 SEM Study

Fractography of heat treated die-cast and squeeze cast samples are presented in Fig. 7. Linkage of cracks between eutectic particles, shrinkage pores and microcracks inside the silicon particles were observed on the fracture surface. Shrinkage pores affect the alloys tensile strength and ductility. SEM fractograph of the alloy shows the following fracture sequence; initiation of microcrack inside Si particle, formation of slipping band in the Al dendrite, links between the cracks which can be both micro and macro, and the growth of crack. During tensile deformation, heterogeneous microstructure induces complex stresses in the eutectic silicon and intermetallic particles.

SEM micrographs of the wear surface of heat treated die-cast and heat treated, squeeze cast alloys is shown in Fig. 8. It can be observed that heat treated alloys are subjected to shallow and narrow micro grooves than cast alloys. Common surface features like micro groove, craters due to micro-cutting and scoring marks on the wear surface due to abrasions of all the alloys are revealed. The wear behaviour of materials is largely dependent on surface material, physical structures and surface conditions as well as the sliding conditions of the normal load and abrasive medium. Materials under abrasive wear conditions are primarily removed by ploughing and micro-cutting. These mechanisms need penetration of materials by hard abrasive particles which in turn is controlled by the hardness of the material. Therefore, hardness of alloys plays a significant role in controlling the wear rate during the sliding against the abrasive medium. Micro-cutting is a major factor in abrasive wear. The volume of the wear groove produced is completely related to the material loss due to micro-cutting.

6 Conclusions

For the alloy, solution treatment at 495 °C for 5 h and then quenching in cold water and aging at 180 °C for 9 h is optimum.

Heat treatment of alloy showed an improvement in the abrasive wear rate and mechanical properties. Heat treatment of alloy showed spheroidization of eutectic silicon. Increase in aging time refines and distributes the eutectic silicon particles in aluminum matrix and modify the dendritic structure.

The overall investigation shows that the heat treated squeeze cast alloy has higher ultimate tensile strength, hardness and wear resistance properties. However in order to obtain the best combination of the structure and properties of this material, further investigation is needed.

References

Li W, Ji-rong L, Guo-dong L, and Quiong-hua L, J Huzhong Univ Sci Technol 36 (2008) 92.

Raincon E, Lopez H, and Cineros H, Mater Sci Eng 519 (2009) 128.

Lee K, Kwon Y N, and Lee S, J Alloy Compd 461 (2008) 532.

Wang G, Bian X, Wang W, and Zhang J, Mater Lett 57 (2003) 4083.

Yasmin T, Khalid A, and Haque M M, J Mater Process Technol 153 (2004) 833.

Haque M M, and Sharif A, J Mater Process Technol 118 (2001) 69.

Murray M T, and Murray M, Fundam Alum Metall (2011) 57 217.

Zeren M, J Mater Process Technol 169 (2005) 292.

Dwivedi D K, Mater Sci Technol 19 (2003) 1091.

Franklin J R, and Das A A, Br Foundrym 77 (1984) 150.

Conflict of interest

None

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Krishnankutty, P., Kanjirathinkal, A., Joseph, M.A. et al. Effect of Aging Time on Mechanical Properties and Wear Characteristics of Near Eutectic Al–Si–Cu–Mg–Ni Piston Alloy. Trans Indian Inst Met 68 (Suppl 1), 25–30 (2015). https://doi.org/10.1007/s12666-015-0584-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12666-015-0584-y