Abstract

This paper presents the salient features of a study undertaken to characterize the geotechnical properties of dredged sediments from a typical reservoir in India by preparing GIS maps of geotechnical data based on the Inverse Distance Weighted technique. Potential of using the fine sediments (< 425 µm) of the dredged material after stabilization in earth work applications is subsequently examined through a series of compaction tests, UCC and CBR tests. The stabilizers used are Class C fly ash, hydrated lime and Ca-lignosulfonate. Results of the study indicate that the prepared spatial maps can serve as useful tools in proper planning of cost-effective dredging operation. The study also indicates that Class C fly ash, in general is a superior stabilizer among the various stabilizers considered for improving fine reservoir sediments, improvement in undrained shear strength and unsoaked CBR value being about fourfold and sixfold, respectively. However, hydrated lime is seen to be a more effective stabilizer than fly ash under sustained rainfall (soaked) condition. Addition of lignosulphonate is seen to improve the ductile nature of the stabilized dredged sediment without much loss of shear strength. SEM analysis provided deep insight into the flocculation and agglomeration mechanism and nature of the stabilized material.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Dams and reservoirs are designed and operated to eventually get filled up with sediments over its life time. However, it is usually seen that the actual rate of reservoir sedimentation is higher than the designed rate and eventually results in complicated social and environmental impacts, including dam safety and water storage capacity issues. This can be attributed to various factors, such as extreme weather events like heavy rainfall and floods causing increased soil erosion, changes in land use pattern and shortcomings in sediment control measures. As a result, as time passes, natural sedimentation gradually intensifies, extending beyond the reservoir's designed functional storage. These combined factors underscore the critical importance of implementing effective sediment management strategies to ensure the long-term functionality of reservoirs. (Patra et al.2019; Chinnasamy et al. 2020). This is especially true for nations like India, which have numerous dams and reservoirs. India has 5254 completed large dams and approximately 447 large dams under construction, the storage capacity of majority of which has been reduced due to excessive sedimentation (Patra et al. 2019).

Dredging is a usually adopted means for removing sediments from the dams. Since sand is an excellent construction material, it can be extracted from dredge sediments which contain sand in significant proportion. However, if the dredge material has less sand content, its extraction is uneconomical and such sediments are usually discarded as such without reuse. Such bulk fine sediments need an appropriate disposal plan after dredging. The disposal or reuse of dredged fine sediments have become a regional environmental challenge due to its large quantity and poor engineering properties. This paper addresses the said topic.

Improving the engineering properties of fine dredged sediment has been investigated in the past to examine its potential for reuse in earth work projects (Yoobanpot et al 2020; Jamsawang et al. 2020; Imene et al 2021). Stabilization using traditional calcium-based additives such as, quicklime, gypsum and Portland cement have been of paramount importance to engineering designers in recent decades (Puppala et al. 2006; Horpibulsuk et al. 2013). However, excess usage of such stabilizers considerably increases the construction cost (Reddy et al. 2018). Hence researchers started to extend the stabilization studies to all kinds of industrial solid wastes with self-cementitious property (Develioglu and Pulat 2019). For example, fly ash is used as an alternative to conventional materials in the construction of geotechnical and geoenvironmental projects (Wang et al (2013)). In particular, class C fly ash which contains highly reactive calcium aluminate which is self-cementitious and having smooth surface characteristics, is reported to have great potential to be used as soil stabilizer (Senol et al. 2006). Class F fly ash, on the other hand, which is of siliceous or siliceous and aluminous origin and has poor or no binding property by themselves need activators to initiate binding and the size of the particles reduces its participation in pozzolanic reactions (Sharma and Hymavathi2016; Wang et al (2018). Some researchers have attempted non-traditional stabilizers well in conjunction with traditional stabilizers to trigger out lime-based stabilization in problematic soils. Recent studies started experimenting between the combinations of stabilizers such as lime-fly ash, fly ash -steel slag, cement-fly ash, cement-GGBS and cement-lime-copper slag to improve the engineering behaviour of weak soils (Phanikumar 2009; Sharma and Hymavathi 2016; Zhang et al. 2018; Yoobanpot et al. 2020). The study by Indraratna et al. 2022) identified that soil stabilized using combination of fly ash and coal wash can be used as an alternative to natural rock aggregates for base/subbase of roads. Such ecologically friendly stabilized fill materials in construction have become cost-effective solutions. There exist some unresolved issues with respect to calcium based traditional stabilization, which include the difficulty of obtaining intact samples of hard materials, which are often very strong and brittle (Ijaz et al. 2020). On the other hand, studies on non-traditional stabilizers in sediment stabilization have revealed the effectiveness of non-biodegradable substances such as lignin to increase soil strength and durability in an environmentally friendly way (Zhang et al. 2020; Ijaz et al. 2020). Lignin stabilization has also shown to improve the performance of low plastic soil-related problems such as ductility and erosion resistance (Indraratna et al. 2013). Recycled lignin has excellent potential for stabilizing silty soil in infrastructure construction (Li et al. 2019). However, only a few studies are available on investigations to overcome the shortcomings of calcium-based stabilizers using non-traditional stabilizers. Thus, it can be seen that the potential of effective and sustainable reuse of fine sediments of the dredge soil after stabilization using traditional and non-traditional stabilizers is still worth investigating.

The proposed work addresses the dredged sediment reuse problem in one of the irrigation sources of Kerala in South India (namely Mangalam dam). The bottom sediments have decreased the reservoir capacity of this dam to nearly one-fifth after the devastating floods during 2018 and 2019. Preliminary investigations have indicated that the dredged soil from Mangalam reservoir contains both fine (clay and silt) and coarse soil fractions. Since sand is costly and is in higher demand, it can be extracted from the dredge. However, reusing fine sediments less than 425 µm in size is significant to avoid the issue of bulk disposal. This paper addresses the said problem.

A systematic study on the characterization and spatial distribution of engineering properties of sediments in the reservoir is a prerequisite to implement any effective engineered disposal method. It has been shown that (Tripathi et al. 2015; Shit et al. 2016) geographic information system (GIS) can be used to prepare the geostatistical maps of soil properties to display the heterogeneity and diversity of soil types. Robinson and Metternicht (2006) has reported that the best choice for interpolating the soil properties for spatial variation is the inverse distance weighted spatial interpolation (IDW) technique. Geostatistical techniques can be used to characterize the land resource inventories, which also address the issue of regional diversity of soil quality (Hengl et al. 2004). Previous studies have extensively explored the use of geographic information systems (GIS) to generate maps depicting the spatial distribution and frequencies of landslides, providing valuable information for reducing risks and aiding in land use planning, particularly in urban areas (Bourenane et al. 2021). Building upon this knowledge, the proposed study aims to contribute to the understanding of sediment characteristics within reservoirs using Arc GIS.

The first phase of the study involves characterizing dredged sediment collected from different sampling locations in the water spread area of the Mangalam reservoir. By analyzing and mapping the geotechnical data of the dredged sediments, spatial distribution maps can be created, offering insights into the sediment characteristics within the reservoir. This comprehensive understanding of the reservoir's sediment properties can have significant implications for sediment management and inform potential sediment reuse planning. The second phase includes the identification of a suitable stabilizer for treating the fine component of the reservoir sediment (< 425 µm) left after sand extraction, which forms the bulk of the dredge material, to make it ideal for pavement subgrade and embankment fill material. The proposed study intends to examine the potential of Class C fly ash and hydrated lime stabilizers and in addition, the effectiveness of natural bio-polymer Ca-lignosulphonate (byproduct of paper, wood, and biomass industries) in combination with fly ash and hydrated lime for stabilizing the reservoir fine sediments. Undrained shear strength determined through unconfined compression tests, compaction characteristics and California Bearing Ratio (soaked and unsoaked) are planned to be used as the parameters for evaluating the effectiveness of various stabilizers. Also, the micro examination of stabilized soil to understand soil stabilizer interaction mechanism is proposed to be carried out by scanning electron microscope (SEM) studies.

Study area

The proposed study area, namely Mangalam Dam is built across the Cherukunnam river, Kerala, India. The canal system irrigates 3440 ha of land. The reservoir is between latitudes 667908 N and longitude 1161710 E. The water spread area of the dam is 3.96 sq. km and capacity is 25.344 Mm3 at FRL + 77.88 m. The base map is projected on UTM Zone 43N. For preparing a digital map showing the variation of geotechnical properties of sediments of Mangalam dam, 30 number of soil samples from the water spread area of the dam were used, locations of which are depicted in Fig. 1. The latitude and longitude of grid points were recorded using a shapefile of the research region, which is partitioned into 50 m2 size grids.

Materials and methodology

Samples for geostatistical analysis

Soil samples available with the Kerala Engineering Research Institute (KERI) from the water spread area of the dam at 500 m spacing within 2.3 m depth of the reservoir were used for the present study. The samples R1 to R30 (Table 1) used for characterization were randomly selected by authors from the collected samples of KERI to represent samples from different locations of the reservoir. The core number mentioned in Table 1 (and in Fig. 1) specifies the exact location of the sampling points as per the KERI records. The samples from various locations are designated as R1 to R30 (Table 1). The depths from which each of these 30 samples were collected are also indicated in Table 1. Collected soil samples were kept in plastic bags and stored. The soil samples were then oven dried and particle size distribution, specific gravity, liquid limit and plastic limit were determined as per ASTM D 422-63 (2007), ASTM D 854-14 (2014) and ASTM D 4318-10 (2010), respectively. Properties of the tested samples are also summarized in Table 1.

As per the principle of IDW approach, soil parameters from the unsampled location are the weighted average of known sample points within the local neighborhood around the unsampled location (Robinson et al. 2006). As a result, by using the same set of values at all times, the IDW approach generates continuous fields of characteristics. It is evident from the soil classification shown in Table 1 that dredged sediments from nearly 50% of the sample locations are fine grained soils. Preliminary studies indicates that these soils require treatment before reuse. It is also seen from Table 1 that coarse grained soils present in the remaining 50% of sample locations contain high percentage of silt and/or clay (classified as SC or SM). Thus, major quantity of the dredged sediments after sand extraction, need to be stabilized for reuse.

Samples for stabilization and testing

As mentioned in the previous section, the samples used for stabilization studies are the finer portion of dredged sediment after sand extraction. Test procedures as per ASTM standards mentioned in the previous sections were adopted to determine physical and index properties of sediments, along with compaction tests (ASTM D1557 (2021)), unconfined compression tests (ASTM D2166 (2016)) and CBR tests (ASTM D1883 (2016)). Typical properties of a finer fraction used for soil stabilization studies are presented in Table 2. The sample R17 collected from the location of (M 453 (668775 N, 1161825 E) is selected for stabilization studies. Sample had a silt content of about 51%. The additives used for stabilization include Class C fly ash (FA), hydrated lime (HL) and. Ca-lignosulfonate (LS). Cementitious property, cost effectiveness and local availability were the prime reasons for choosing the above stabilizers. In particular, class C type of fly ash was chosen since it has self-cementation property and since it contains significant amount of lime/Cao. Class F fly ash, on the other hand, contains a very little amount of lime and further requires another cementing agent to initiate stabilization and hence, not considered in the present study. The constituents and properties of FA and HL are shown in Table 3, while those of Ca-lignosulfonate (LS) are presented in Table 4. Grain size distribution of fly ash and hydrated lime are shown in Fig. 2 along with that of the fine sediment. The mean particle size of sediment, HL and FA are 0.045 mm, 0.06 mm and 0.08 mm, respectively. The combinations of soil stabilizer mixes used in the present study are summarized in Table 5.

Reported studies using class C fly ash, hydrated lime and Ca-lignosulfonate have indicated that optimum dosages of these stabilizers for various engineering applications are significantly different. Optimum fly ash percentage is generally seen higher compared to that of hydrated lime and Ca-lignosulfonate. In the present investigation, a few trial studies were carried out to examine the range of percentage additions that would result in significant soil improvement. Based on the preliminary results obtained, authors decided to choose the mixing combinations shown in Table 5. Specimens for unconfined compression tests and CBR tests were prepared at optimum moisture content and maximum dry density determined through compaction tests. SEM analysis was used to study the stabilization mechanism.

Result and discussion

Geostatistical analysis of sediments from Mangalam reservoir

Figure 3a shows the spatial distribution of soil sediments of size < 2 µm (clay fractions). The dredged sediments collected contain nearly 0–21% clay fraction. A high percentage of clay content is present in the Northwest area (M 1160(667425N, 1162425W, white zone)). Major portion of the water spread area contains 6–10% of clay content (yellow zone). Figure 3b shows the spatial distribution of sediments < 75 µm (combined clay and silt fractions) in the entire water spread area. Areas with combined clay and silt fraction ranging from 45 to 70% are seen concentrated in the Northwest (M 359 (667825 N, 1162175°W)) and East (M 453 (668775 N, 1161825 E)) regions. Obviously, dredging of these regions for sand extraction would not be economical. Sand is predominantly seen in the Southwest region (combined clay and silt fraction ≤ 30%) of M 1016 sampling location (668025 N, 1160725 E) and in a few other patches (green zone) and sand extraction from dredge material will be most economical at these locations.

From the geographic distribution of liquid limit and plasticity index values (Fig. 4a, b), it can be seen that weakest of the material is concentrated in the West region, specifically at M558 (667625 N, 1161725 E). In the south and south west regions, the liquid limit is relatively low and varies from 25 to 45% and the plasticity index varies in the range of 4.5–12% (in particular, M 1016 yellow zone, (668025 N, 1160725 E) of Fig. 4b). The soil in this region contains relatively more sand fraction and has less plasticity compared to that in the Northwest region. A careful examination of Figs. 3b, 4a, b also suggests that sample R17 from Northeast portion of the region (M 453) would be a preferable location that require dredging of bulk fine sediments for reuse after stabilization. The effect of various stabilizers on improving the engineering behaviour of fine sediments from this location (< 425 µm) is presented in the subsequent sections.

Effect of stabilization on compaction characteristics of fine sediments

The sediment portion passing through 425 μm was mixed with three stabilizers in different proportions (as presented in Table 5) and maximum dry density (ɤdmax) and optimum moisture content (OMC) were determined. Figure 5 shows the compaction characteristics of fine sediment-fly ash mixes. The sediment, when treated with FA in varying percentages of 0%, 5%, 10% and 15%, significant improvement in ɤdmax was observed for a fly ash content of 10%. After stabilization with fly ash, the ɤd max value of silt soil increased from 1.7 to 1.84 g/cc. OMC increased from 18.3 to 19% for 10% FA (only a slight increase compared to that of untreated sediment). The addition of percentages of binder content by volume to the soil makes the mixture well graded, resulting in an increase in the maximum dry density (Sharma and Hymavathi 2016).

Figure 6 illustrates compaction curves for hydrated lime-stabilized fine sediments with varying additive levels. HL increased the dry density from 1.7 to 1.74 g/cc at 4% dosage. When lime content was increased to 6%, the OMC of stabilized soil increased and dry density improvement is less. The cause for this variation of OMC is mainly because of the hydration response of lime, which leads to flocculation, soil material bulking and consumption of considerable amount of moisture as reported by Jha and Sivapullaiah (2015). These results are in confirmation with the results of Hussey et al. (2010) also, who reported that the optimum dosage of HL is considerably less compared to that of FA. Further, Reddy et al. (2018) also have reported an optimum lime content of 4% for stabilizing black cotton soil. In the present study of dredged fine sediments, optimum dosage of FA and HL are obtained as 10% and 4%, respectively.

Compaction curves for lignin-stabilized sediment (Fig. 7) indicates that addition of LS has no noticeable effect on dry density but OMC is seen to change significantly. It may be noted herein that FA and HL have higher specific gravity than untreated fine dredged sediment, whereas LS has a specific gravity lower than that of the sediment. This would probably be the reason for the differences in the behaviour of LS stabilization compared to FA and HL stabilization. Increased dry density may also be achieved due to filling of voids in soil by the additives. Particle size distribution curves of fine sediment, FA and HL (Fig. 2) indicate that grain sizes of soil is less compared to FA and HL. Thus, there is only less chance of filling of sediment voids by HL or FA. On the other hand, it was seen that 99% of Ca-LS particles used in this study passed through 0.075 mm sieve. Therefore, the lignin fines fill the pore space and a cementing material is subsequently formed which gives a glue type bonding between soil grains. Higher specific gravity of fly ash compared to that of hydrated lime and Ca-lignosulfonate could be the reason for the greater dry density of FA treated soil.

Effect of stabilization on undrained shear strength of fine sediments

The effect of FA on unconfined compressive strength (qu) tested after 7- days and 28-days curing are shown in Fig. 8a, b. It is seen that as curing time increases, qu increases at all FA contents used in the study. For 10% FA, qu obtained for 7-day curing is 140 kPa and that for 28-days curing is 396 kPa, the corresponding percentage increases in qu being very significant (155% and 415%, respectively) (Table 6). At FA content of 15%, there is only a small increase in qu even after 28 days curing. FA content up to optimum dosage is expected to result in more pozzolanic reactions and thus more cementitious bonds between the soil particles develop over time (Yu et al. 2017; Jamsawangeet et al. 2022). The reaction between SiO2 of the fine dredge sediment and Ca(OH)2 of FA is the reason for enhancement of strength. To get an optimum performance, the proportion of SiO2 and Ca(OH)2 should be appropriate. 10% FA content would have provided the most suitable proportion of SiO2 and Ca(OH)2, yielding an optimal performance. FA content in excess of optimum is in the degrading/inert zone and is uneconomical compared to that in the active region (optimum). Tastan et al., (2011) has reported that strength benefits accrued by adding FA to organic soil begin to diminish beyond a content about 10–20%. Similar findings have been reported from the studies on stabilized CL and ML soils by Senol et al. (2006) as well.

Figure 9a, b show the effect of hydrated lime stabilization on qu. It is evident herein as well that qu increases as curing time increases for all HL concentrations. qu values for 7-days and 28-days curing at 4% HL are observed to be about 130 kPa and 300 kPa, respectively (the corresponding enhancements being 136% and 290%, respectively, as could be seen from Table 6). These values are lesser compared to those obtained with 10% FA addition. Hussey et al. (2010) has reported that lower additive percentage of HL can improve the strength almost similar to greater percentage of FA in early curing time due to availability of more Ca (OH) for chemical reaction.

Early strength development in hydrated lime stabilized soil is reported to be due to the flocculation and agglomeration of soil particles caused by the hydration reaction (Boardman et al. 2001). However, the long-term strength growth is due to pozzolanic processes. Pozzolanic reactions between the minerals of the soil and the free calcium hydroxide induces the precipitation of cement hydrated compounds. This explains, in general, greater strength values for extended curing times.

The stabilization effect of LS on fine dredge sediment shown in Fig.10a, b suggests that the extent of strength improvement is less compared to those obtained with FA and HL additives. Optimum benefits are seen for LS addition of 4% (percentage improvement being about only 28% and 56% for 7-day and 28-day curing, respectively). Somewhat similar trend in strength improvement is reported by Singh and Sahoo (2021) from their studies on lignosulphonate treated highly plastic clay. The reason for the relatively low extent of improvement may be the fact that lignin in stabilized soil primarily improves cohesion only due to the coating of cement gel formed on the surface of soil particles, as pointed out by Indraratna et al. (2008). The bonding of lignosulfonate with soil particle provides waterproof effect due to its hydrophobic properties and flocculation induced by cationic exchange with soil particles causes the strength improvement to some extent (Alazigha et al. 2018).

The difficulty to obtains intact sample of lime hardened soil due to brittle nature is still a challenge in usage of sole Ca-based traditional stabilizers (Ijaz et al. 2020). Hence the influence of LS in combination with FA and HL was also examined. To the optimum dosages of FA and HL, 2%, 4% and 6% of LS were added and qu values obtained were analyzed. Figure 11a, b show the effect of the combination of FA 10 with various percentages of LS on qu. The maximum value of qu was obtained for SFA 10 -LS 4 combination and is found to be 88 kPa and 206.5 kPa, respectively for 7 days and 28 days of curing (the corresponding enhancement in strength being 60% for 7-days of curing and 168% for 28-days of curing compared to that of untreated fine sediment; Table 6). Such an extent of improvement is quite significant from an engineering point of view.

Figure 12a, b present the combined effect of HL 4 and various percentages of LS on qu values. Maximum improvement in qu is obtained for the SHL 4-LS 4 mix. which are 62.5 kPa and 197 kPa, respectively for 7-days and 28-days of curing. The corresponding percentage improvements are 14% and 155%, respectively. The values of qu (28-days) for SHL 4-LS 4 is low compared to SFA 10-LS 4 mix and better performance than exclusively SLS 4 mix at 28 days of curing. According to Develioglu and Pulat (2019), the strength enhancement of lime-stabilized soil is due to the formation of strong basic environment of lime added within the pore fluid. Lime content enhances the formation of calcium silicate hydrate gel (CSH) leading to increase in strength and making the soil brittle. However, addition of LS with HL induces aggregation of soil particles resulting in the formation of large clusters over the curing period. These clusters form thick soil matrix with fewer pores and imparts ductility to the stabilized dredged soil (Ijaz et al. 2020). which is evident from the observed higher values of failure strain in the stress strain curves of SFA 10-LS4 and SHL4-LS4 (Figs. 11 and 12).

Stress strain behavior of stabilized dredged soil

Figures 8, 9, 10, 11 and 12 depict stress–strain curves of soil treated with FA and HL, alone and in combination with LS. The peak value of stress remains higher in soil stabilized using FA and HL. Individual applications of FA and HL, with extended curing times up to 28 days, resulted in brittle failures (Figs. 8b and 9b). However, the introduction of Ca-LS, in conjunction with Ca-based stabilizers, led to an increase in strain after the peak stress. This phenomenon was notably absent in soils stabilized solely with SFA and SHL. The enhanced strain after peak stress in SFA-LS and SHL-LS signifies a shift in the stress–strain curve after 0.4% strain, indicative of a ductile behavior. Although the loss of strain after the peak is reduced in these combinations, the peak value of stress remains lower than that of soils exclusively stabilized with Ca-based stabilizers.

Notably, the absence of lignin in both FA- and HL-stabilized soils eliminates the reduction in post-peak stress loss, as shown in Figs. 8 and 9. This implies a gradual stress increase in FA-LS and HL-LS stabilized soil, demonstrating the enhancing effect of Ca-LS on resisting post-peak shear strength loss. The decline in post-peak stress in FA- and HL-stabilized soils is attributed to the brittle nature of flocculated/cemented soil, resulting from the formation of coarser cemented soil particles. The observed improvement in minimizing failure cracks and enhancing post-failure strength is attributed to the glue-like behavior imparted by added Ca-LS (Ijaz et al. (2020). Similar behaviour, associated with the use of biopolymers in soil stabilization, has been previously reported by Sujatha et al. (2020). The inclusion of biopolymers introduces soil bridging, a critical factor in mitigating the loss of post-peak strength in stabilized soil and incorporating coir fibers was found to increase compressive strength when biopolymers are added as additives The continuous increase in both strength and stiffness with the duration of curing underscores the potential role of altered hydrogels, including gel hardening due to aging. This emphasizes the long-term improvement in strength and the crucial role of soil bridging facilitated by biopolymers in reducing the loss of post-peak strength in stabilized soil (Sujatha et al. 2018, 2020, Anandh Kumar and Sujatha 2021).

A critical comparison of different stabilizers under different periods of curing can be made from Table 6.

Failure modes of specimens

Figure 13 illustrates the failure patterns observed in untreated and treated soil with different stabilizers over an extended period of strain. It can be seen that specimens of untreated soil and soil stabilized using 10% FA as well as using 4% HL failed through shear cracking with no noticeable bulging. However, when lignin is added up to 4% in the soil, failure occurred after considerable bulging around the mid-depth. Following compression, a significant reduction in surface cracks was also observed for these specimens. As the biopolymer content was further increased, the soil specimen underwent distinct failure mechanisms, including the development of cracks around the middle, suggesting the possibility of biopolymer saturation at the 4% threshold. A noteworthy shift in the failure pattern from FA/HL alone addition is evident for the combinations of fly ash (FA) and lignin stabilization (LS), as well as for hydrated lime (HL) and LS, with significant bulging and noticeable reduction in surface cracks observed in both these cases. These observations hint towards an increase in post-peak strength resistance, emphasizing the significance of the 4% LS addition in combination with both FA and HL. Such a combination not only transforms the failure mode from brittle to ductile but also showcases enhanced resistance to failure.

Effect of stabilization on California bearing ratio of fine sediments

Table 7 summarizes the effect of stabilization on unsoaked and soaked CBR values of dredge sediment. It is seen that both unsoaked and soaked CBR values of untreated sediment are very low for using as pavement subgrades and hence cannot be used without modification for field applications.

From a comparison of the soaked CBR values of SHL 4 and SFA 10, it can be inferred that for heavy rainfall conditions SHL 4 stabilized soils can be expected to perform much better than FA stabilized soil. The probable reason for this behavior could be the presence of calcium hydroxide in lime-treated soil which enhances the pozzolanic and hydration reactions between soil and HL. It is reported that the hydration and cementation properties of lime with water make the soil more resistant to penetration (Cheng et al. 2018). Improvement in CBR values of soaked sample of SFA 10 is relatively low because of insufficient curing time. When LS 4 is added exclusively to the soil, the CBR values obtained are seen not significantly improved (2.4% and 1.3% for unsoaked and soaked specimens). When a combination of LS 4 with FA 10 (SFA 10-LS 4) is used, the unsoaked and soaked CBR values increases to 3% and 1.8%, respectively. Even the combinations of LS with either SFA or SHL do not result in significant improvement in CBR value, compared to SFA/HL alone additions.

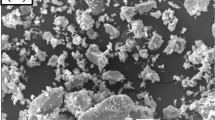

Micro structural analysis of stabilized fine sediments

Figure 14 shows the SEM image of untreated sediment sample which has several pores but no visible gluing between soil particles. The soil particles are not in a packed structure. The reason for the failure of soil structure while loading is probably the lack of bonding between particles. The influence of FA on microstructural alterations (observations at mm scale level) of treated sediments with 28-day curing can be seen from Fig. 15. In SFA 10 sample, the clay and silt particles form inter-and intra-aggregate bonding with FA particles. SEM micrographs of FA-treated soil shows particle aggregation, which improves the strength of individual soil particle due to substantial curing.

Figure 16 illustrates the SEM images of SHL 4 sample, in which the cementation and agglomeration of individual particle forms more stable microstructure than particles of untreated soil. According to the micrographs, soil treated with HL and FA has a solid structure with coarser particles and strong links in aggregates. This gives superior resistance to applied forces. As the curing process progresses, flocculation of fine particles with additives is developed, and aggregate formation causes the strengthening of the soil structure against applied forces. But usually, the calcium-based stabilizer treated soil sample fails by brittle nature. The reason behind the brittle failure of calcium-based stabilizer-treated soil was reported in the previous studies (Ijaz et al. 2020; Jha and Sivapullaiah 2015) as the presence of pores between agglomerated particles. This increases the porosity of stabilized soil matrix more than untreated soil. As a result, brittle failure occurs in calcium-based stabilizers treated soil.

In case of the SLS 4 image (Fig. 17), it is found that the LS will be filled within the pores and act as a glue-type bond between the soil particles. When lignin is applied to soils, the solid particles are coated and bonded with this cementing agent, and the soil pore volume is significantly reduced. In LS stabilized soil, the particles are coated with cementing gel, covering the wide holes between particles and enhance the cohesion of soil aggregates (Zhang et al. 2018). In the present study based on the SEM pictures, it can be deduced that lignin serves as a cementing agent to bind soil particles together. In addition, the precipitated cementing chemical coats soil particles, forcing them closer together and acting like a gel material that fills the pores. It avoids the sudden collapse of soil matrix under compressive load, which will control the failure in a ductile nature. In LS-stabilized soil, polymer bridging may be the critical contributor to improved performance. Similar findings have been reported by Indraratna et al. (2008) and Vinod et al. (2010). The present study, thus, suggests that FA or HL addition in combination with LS would be a better option of stabilization, since both strength and ductility are seen improved.

Conclusions

A potential framework for geotechnical characterization of dredged reservoir sediments and their sustainable reuse after stabilization is presented in this paper. Use of GIS mapping to create a digital map of soil properties, facilitating the identification of suitable locations for economic dredging, particularly for sand extraction is proposed. Furthermore, the study explores the potential of both traditional and nontraditional stabilizers in improving the quality of fine reservoir sediments. Such a broader examination of stabilizers adds to our understanding of the range of options available for sediment stabilization, contributing to a more sustainable approach to sediment management. In brief, the integration of GIS mapping and a comprehensive investigation into stabilizer options represents a significant advancement in the field, paving the way for a more effective and environmentally conscious sediment management practice.

The specific conclusions of the study are:

-

1.

GIS maps showing spatial distribution of percentage clay fraction, combined clay and silt fractions, liquid limit and plasticity index of sediments in the water spread area of the reservoir can serve as useful tools for planning the dredging operations of reservoirs. Locations of dredge with high sand content and those with high fine sediment content can be demarcated using such maps prepared out of geotechnical properties of smaller numbers of randomly collected samples. Dredge for sand extraction and that for re-use after stabilization can be separately processed based on dredge locations in the map. For the present study area (Mangalam reservoir), south-west region (particularly, M 1016) is demarcated as sand-rich zone whereas north-east region (M 453) is identified as location of fine sediments.

-

2.

Studies on stabilization of the finer fractions (< 425 µm) of the dredge sediment show that optimum dosage of class C fly ash, hydrated lime and Ca-lignosulphonate are 10%, 4% and 4%, respectively.

-

3.

Studies on relative effectiveness of various stabilizers such as class C fly ash, hydrated lime Ca-lignosulphonate, combination of FA + LS mix and combination of HL + LS mix on fine dredged sediments indicate that maximum percentage improvement in undrained shear strength (of about 415%) results from adding 10% fly ash with a 28-day curing period.

-

4.

Introduction of Ca-LS, in conjunction with Ca-based stabilizers, leads to reduction in post-peak shear strength loss and an increase in strain after the peak stress.

-

5.

Individual applications of FA and HL, with extended curing times up to 28 days, result in brittle failures whereas addition of lignosulphonate to FA and HL helps in improving the ductile nature of the stabilized dredged sediment.

-

6.

The percentage improvements in unsoaked CBR values of the stabilized dredged sediments are about 508%, 258% and 100% with addition of 10% FA, 4% HL and 4% LS, respectively. which are quite significant from a practical point of view.

-

7.

Hydrated lime is the most effective stabilizer for the fine dredged sediment under soaked state (which simulates sustained rainfall condition).

-

8.

SEM images show that sediments treated with HL and FA have a solid structure with coarser particles and strong bonding in aggregates. In LS-treated soil, the cementing chemical coats the particle, and a glue-type bonding (polymer bridging) is developed, which improves the ductility of the soil.

In the present scenario with much focus on sustainable development worldwide, the findings reported herein suggest an effective method for reuse of the dredged waste sediments from reservoir beds. The applicability of the findings, however, is limited to short-term requirements. Long-term performance of the stabilized sediments needs to be investigated through further studies. Also, further refinement in the GIS maps can be made using a large body of data. Still, the research work described in this paper can be considered to provide a good basis for potential future generic framework on characterization and reuse of reservoir sediments.

References

Alazigha D, Indraratna B, Vinod JS, Heitor A (2018) Mechanisms of stabilization of expansive soil with lignosulfonate admixture. Transport Geotech 14:81–92. https://doi.org/10.1016/j.trgeo.2017.11.001

Anandha Kumar S, Sujatha ER (2021) Experimental investigation on the shear strength and deformation behavior of xanthan gum and guar gum treated clayey sand. Geomech Eng 26(2):101–115

ASTM D1557-12 (2021) Standard test methods for laboratory compaction characteristics of soil using modified effort. ASTM International, West Conshohocken. www.astm.org

ASTM D1883-16 (2016) Standard test method for California bearing ratio (CBR) of laboratory-compacted soil. Standard. ASTM, West Conshohocken. www.astm.org

ASTM D2166-16 (2016) Standard test method for unconfined compressive strength of cohesive soil. ASTM International, West Conshohocken. www.astm.org

ASTM D422–63 (2007) Standard test method for particle-size analysis of soils (Withdrawn 2016). ASTM International, West Conshohocken. www.astm.org

ASTM D4318-10 (2010) Standard test methods for liquid limit, plastic limit, and plasticity index of soils of soil solids by water pycnometer. ASTM International, West Conshohocken. www.astm.org

ASTM D854-14 (2014) Standard test methods for specific gravity of soil solids by water pycnometer. ASTM International, West Conshohocken. www.astm.org

Boardman DI, Glendinning S, Rogers CDF (2001) Development of stabilization and solidification in lime-clay mixes. Geotechnique 50(6):533–543. https://doi.org/10.1680/geot.2001.51.6.533

Bourenane H, Braham M, Bouhadad Y, Meziani AA (2021) Spatial distribution, controlling factors and failure mechanisms of the large-scale landslides in the urban area of Azazga city (northern Algeria). Environ Earth Sci 80(313):1–23. https://doi.org/10.1007/s12665-021-09607-5

Cheng Y, Wang S, Li J, Huang X, Li C, Wu J (2018) Engineering and mineralogical properties of stabilized expansive soil compositing lime and natural pozzolans. Constr Build Mater 187:1031–1038. https://doi.org/10.1016/j.conbuildmat.2018.08.061

Chinnasamy P, Honap VU, Maske AB (2020) Impact of 2018 Kerala floods on soil erosion: need for post-disaster soil management. J Indian Soc Remote Sens 48(10):1373–1388. https://doi.org/10.1007/s12524-020-01162-z

Develioglu I, Pulat HF (2019) Improvement of shear strength characteristics of İzmir Bay’s dredged soil. Arab J Geosci. https://doi.org/10.1007/s12517-019-4825-y

Hengl T, Rossiter DG, Stein A (2004) Soil sampling strategies for spatial prediction by correlation with auxiliary maps. Aust J Soil Res 41(8):1403–1422. https://doi.org/10.1071/SR03005

Horpibulsuk S, Phetchuay C, Chinkulkijniwat A (2013) Soil stabilization by calcium carbide residue and fly ash. J Mater Civ Eng 24(2):184–193. https://doi.org/10.1061/(ASCE)MT.1943-5533.0000370

Hussey NL, Cerato AB, Grasmick JG, Holderby ES, Miller GA, Tabet W (2010) An assessment of soil parameters governing soil strength increases. In: Geo Florida 2010: advances in analysis, modeling & design, ASCE 2702-2711. https://doi.org/10.1061/41095(365)274

Ijaz N, Dai F, Meng L, Rehman Z, Zhang H (2020) Integrating lignosulphonate and hydrated lime for the amelioration of expansive soil: a sustainable waste solution. J Clean Prod. https://doi.org/10.1016/j.jclepro.2020.119985

Imene A, Benamara L, Correia AA, Pinto M, Cunha P (2021) Characterization of dredged sediments of Bouhanifia dam: potential use as a raw material. Arab J Geosci 14:26–31. https://doi.org/10.1007/s12517-021-08742-4

Indraratna B, Muttuvel T, Khabbaz H (2008) Modelling the erosion rate of chemically stabilized soil incorporating tensile force-deformation characteristics. Can Geotech J 46:57–68. https://doi.org/10.1139/T08-103

Indraratna B, Athukorala R, Vinod J (2013) Estimating the rate of erosion of a silty sand treated with lignosulfonate. J Geotech Geoenviron 139(5):701–714. https://doi.org/10.1061/(asce)gt.1943-5606.0000766

Indraratna B, Qi Y, Tawk M, Heitor A, Rujikiatkamjorn C, Navaratnarajah SK (2022) Advances in ground improvement using waste materials for transportation infrastructure. Proc Inst Civ Eng Ground Improv 175(1):3–22. https://doi.org/10.1680/jgrim.20.00007

Jamsawang P, Charoensil S, Namjan T, Jongpradist P, Likitlersuang S (2020) Mechanical and microstructural properties of dredged sediments treated with cement and fly ash for use as road materials. Road Mater Pave Design. https://doi.org/10.1080/14680.629.2020.1772349

Jamsawangeet P, Poorahong H, Jongpradist P, Likitlersuang S, Chaiyaput S (2022) Destructive and nondestructive characteristics of solidified reservoir sediments incorporating microstructural analyses. Bull Eng Geol Environ 81(8):1–25. https://doi.org/10.1007/s10064-022-02797-7

Jha AK, Sivapullaiah PV (2015) Mechanism of improvement in the strength and volume change behavior of lime stabilized soil. Eng Geol 198:53–64. https://doi.org/10.1007/s42947-020-0117-x

Li Y, Zhang Y, Ceylan H, Kim S (2019) Laboratory evaluation of silty soils stabilized with lignosulfonate. In: Airfield and highway pavements, pp 531–540

Patra B, Giri S, Narayan P (2019) Reservoir sedimentation in Indian dams: trends and challenges. In: International dam safety conference, pp 1–10. https://www.researchgate.net/publication/331413681

Phanikumar BR (2009) Effect of lime and fly ash on swell, consolidation and shear strength characteristics of expansive clays: a comparative study. Geo-Mech Geo-Eng J 4(2):175–181

Puppala AJ, Kadam R, Madhyannapu RS, Hoyos LR (2006) Small-strain shear moduli of chemically stabilized sulfate-bearing cohesive soils. J Geotech Geoenviron Eng 132(3):322–336. https://doi.org/10.1061/(asce)1090-0241(2006)132:3(322)

Reddy S, Prasad AC, Vamsi Krishna N (2018) Lime-stabilized black cotton soil and brick powder mixture as subbase material. Adv. Civ. Eng. https://doi.org/10.1155/2018/5834685

Robinson TP, Metternicht G (2006) Testing the performance of spatial interpolation techniques for mapping soil properties. Comput Electron Agric 50(2):97–108. https://doi.org/10.1016/j.compag.2005.07.003

Senol A, Edil TB, Bin-Shafique S, Acosta HA, Benson CH (2006) ‘Soft subgrades’ stabilization by using various fly ashes. Resour Conserv Recycl 46:365–376

Sharma RK, Hymavathi J (2016) Effect of fly ash, construction demolition waste and lime on geotechnical characteristics of a clayey soil—a comparative study. Environ Earth Sci 75(377):1–11. https://doi.org/10.1007/s12665-015-4796-6

Shit PK, Bhunia GS, Maiti R (2016) Spatial analysis of soil properties using GIS-based geostatistics model. Earth Syst Environ 2(2):1–6. https://doi.org/10.1007/s40808-016-0160-4

Singh AK, Sahoo JP (2021) Undrained cyclic loading response of lignosulfonate treated high plastic clay. Soil Dyn Earthq Eng 150:106943. https://doi.org/10.1016/j.soildyn.2021.106943

Sujatha ER, Geetha AR, Jananee R, Karunya SR (2018) Strength and mechanical behaviour of coir reinforced lime stabilized soil. Geomech Eng 16(6):627–634

Sujatha ER, Sivaraman S, Subramani AK (2020) Impact of hydration and gelling properties of guar gum on the mechanism of soil modification. Arab J Geosci 13:1278. https://doi.org/10.1007/s12517-020-06258-x

Tastan EO, Edil TB, Benson CH, Aydilek AH (2011) Stabilization of organic soils with fly ash. J Geotech Geoenviron Eng 137(9):819–833

Tripathi R, Nayak AK, Shahid M, Raja R, Panda BB, Mohanty S, Kumar A, Lal B, Gautam P, Sahoo RN (2015) Characterizing spatial variability of soil properties in salt-affected coastal India using geostatistics and kriging. Arab J Geosci. https://doi.org/10.1007/s12517-015-2003-4

Vinod JS, Indraratna B, Mohamud MAA (2010) Stabilization of an erodible soil using a chemical admixture. Proc Inst Civ Eng Ground Improv 163(1):43–51. https://doi.org/10.1680/grim.2010.163.1.43

Wang D, Abriak NE, Zentar R (2013) Strength and deformation properties of Dunkirk marine sediments solidified with cement, lime and fly ash. Eng Geol 166:90–99

Wang D, Zentar R, Abriak NE (2018) Durability and swelling of solidified/ stabilized dredged marine soils with class-F fly ash, cement, and lime. J Mater Civ Eng 30(3):04018013

Yoobanpot N, Jamsawang P, Simarat P, Jongpradist P, Likitlersuang S (2020) Sustainable reuse of dredged sediments as pavement materials by cement and fly ash stabilization. J Soils Sedim 20(10):3807–3823. https://doi.org/10.1007/s11368-020-02635-x

Yu H, Yin J, Soleimanbeigi A, Likos WJ (2017) Effects of curing time and fly ash content on properties of stabilized dredged material. J Mater Civ Eng 29(10):1–11. https://doi.org/10.1061/(ASCE)MT.1943-5533.0002032

Zhang W, McCabe BA, Chen Y, Forkan TJ (2018) Unsaturated behaviour of a stabilized marine sediment: a comparison of cement and GGBS binders. Eng Geol 246:57–68

Zhang T, Liu S, Zhan H, Ma C, Cai G (2020) Durability of silty soil stabilized with recycled lignin for sustainable engineering materials. J Clean Prod 248:119293. https://doi.org/10.1016/j.jclepro.2019.119293

Funding

No funding was received for the research presented in this manuscript.

Author information

Authors and Affiliations

Contributions

The authors gratefully acknowledge the financial support by the AICTE under the National Doctoral Fellowship (NDF) scheme.

Corresponding author

Ethics declarations

Conflict of interest

On behalf of all authors, the corresponding author states that there is no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Athira, S., Subaida, E.A. & Vinod, P. A framework for geotechnical characterization of dredged reservoir sediments and its sustainable reuse after stabilization. Environ Earth Sci 83, 152 (2024). https://doi.org/10.1007/s12665-024-11448-x

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s12665-024-11448-x