Abstract

Purpose

The process of removing sediments from the bottom of dams generates large amounts of dredged sediments, which are considered waste. The purpose of this research was to present the results of testing conducted on dredged sediment stabilized with ordinary Portland cement (OPC) and fly ash (FA) for reuse as pavement materials.

Materials and methods

The base sediment was high plasticity silt (MH) based on the Unified Soil Classification System (USCS). The experiments in this study consisted of unconfined compression (UC), California bearing ratio (CBR), and resilient modulus (Mr) tests on stabilized dredged sediment. A combination of scanning electron microscopy (SEM) and energy-dispersive X-ray spectroscopy (EDX) was used to investigate the microstructures of the stabilized specimens. Finally, a simple comparative cost analysis between roads using conventional earthen materials and stabilized dredged sediment was performed.

Results and discussion

The results showed that the unconfined compressive strength (qu), CBR, and Mr improved the pavement materials from unsuitable to suitable, and a 10% FA content provided the optimal strength enhancement. The SEM images showed that the calcium silicate hydrate (CSH) product, which was formed by hydration and pozzolanic reactions, attached to the clay clusters and filled the pore spaces between clay particles, resulting in a denser sediment structure. The EDX analyses showed that the calcium weight proportion and the silica-aluminum ratio were important factors in improving the strength of the dredged sediment treated with OPC and FA. These EDX results agreed with the qu, CBR, and Mr results. For the studied situation, roads using stabilized sediment were 1.5 times more economical than roads using conventional earthen pavement materials.

Conclusions

Dredged sediments treated with OPC and FA can be sustainably reused as pavement materials based on the Department of Highways of Thailand standard, as well as the recommendations of Austroads (2017). Thus, for suitable sediments, reuse in road and pavement construction may be considered with appropriate treatment and conditioning.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

Sediments may be characterized as a combination of loose particles consisting of clay, silt, and sand produced by the erosion and weathering processes of soils, rocks, and organics and by human activities (Dubois et al. 2011). The deposition of sediments in many water sources creates problems in transportation and shipping due to river shoaling; almost a billion cubic meters of sediments are dredged yearly to maintain navigable river channels and sufficiently deep harbors in Thailand. These dredged sediments, which are considered waste materials, are dumped in the sea or at a land disposal site (Kamali et al. 2008). A large amount of sediment has accumulated behind the Mae Sab hydropower dam, which is located in Samoeng District, Chiang Mai, Thailand, reducing the water storage capacity of the reservoir. Sediments are dredged to maintain the water storage capacity of the reservoir. However, the large amount of dredged sediments removed is a major problem because it is difficult to identify proper storage sites and disposal methods.

To relieve such problems, the reuse of dredged sediments as pavement materials, such as subgrade, selected material subbase and base courses, is considered and highly encouraged. However, most of the dredged sediments are classified as fine-grained materials such as silts and clays with high void ratios and compressibilities, weak strengths, and low bearing capacities. Consequently, dredged sediments that do not undergo stabilization cannot be reused directly as pavement materials. Chemical stabilization with type I ordinary Portland cement (OPC) is one of the most traditional techniques for improving the properties of problematic soils in various applications, resulting in high unconfined compressive strengths (qu), high bearing capacities and low compressibilities (Horpibulsuk et al. 2010; Horpibulsuk et al. 2011; Mohammadinia et al. 2015; Tongwei et al. 2014; Voottipruex and Jamsawang 2014; Güllü et al. 2017; Jamsawang et al. 2017; Yoobanpot et al. 2017).

Ordinary Portland cement can also be mixed with waste material from the coal combustion process of power plants, such as fly ash (FA), to reduce costs (via the replacement of OPC) and environmental problems (because a high level of CO2 is released during cement production) associated with the use of OPC alone (Wen et al. 2010; Güllü 2014). Class C FA has been shown to be effective for soil stabilization in civil engineering works (Horpibulsuk et al. 2009; Jongpradist et al. 2010; Wen et al. 2010; Tastan et al. 2011; Kogbara et al. 2013; Shaheen et al. 2014; Suksiripattanapong et al. 2015). Fly ash is able to increase the performance of the soil stabilization process by increasing the reactive surface area (Horpibulsuk et al. 2009) for hydration and pozzolanic reactions.

The resilient modulus (Mr) and California bearing ratio (CBR) are important factors in the determination of pavement thickness and the selection of pavement construction materials, as explained in the AASHTO (1993) Guide for the Design of Pavement Structures and Austroads (2017). Over the last decade, several studies have focused on evaluating the factors affecting the Mr and CBR of OPC-stabilized subgrade soils (Osinubi et al. 2011; Solanki et al. 2011; Tastan et al. 2011; Agapitus 2014; Voottipruex and Jamsawang 2014; Abu-Farsakh et al. 2015; Jiang et al. 2015). These factors include the stress state, additive content, curing time, curing temperature, moisture content, compaction delay, and soil properties. In general, Mr of stabilized soil increases as the binder content increases, whereas the permanent deformation of stabilized soil decreases as the binder content increases (Solanki et al. 2011; Abu-farsakh et al. 2015).

Scanning electron microscopy (SEM) has been widely used to investigate the microstructural changes resulting from the stabilization process (Shaheen et al. 2014; Kang et al. 2015; Ahmed 2015; Jiang et al. 2015; Jamsawang et al. 2017; Yoobanpot et al. 2017). Scanning electron microscopy is commonly coupled with energy-dispersive X-ray spectroscopy (EDX) to describe the microstructural changes in stabilized samples. Most previous studies focused on the mechanical and microstructural properties of subgrade soils stabilized with cementitious materials. However, a limited number of studies focused on the reuse of dredged sediments stabilized with OPC and FA as pavement materials.

This paper investigates the development of qu, CBR and Mr of dredged sediment stabilized with OPC and FA. The microstructural changes in the stabilized dredged sediment were observed via SEM, whereas the changes in chemical composition were investigated using EDX. The prediction of the stabilized dredged sediment Mr was determined via the qu and CBR values. Finally, the properties of dredged sediments stabilized with OPC and FA were assessed for reuse as pavement materials based on the Department of Highways of Thailand standards and Austroads (2017) recommendations, and a road construction site was evaluated to compare the costs between roads using stabilized sediment and roads using conventional earthen pavement materials.

2 Materials and methods

2.1 Dredged sediment and admixtures

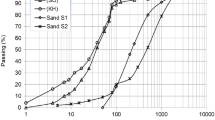

The studied sediments were dredged from the Mae Sab hydropower dam in Samoeng District, Chiang Mai, Thailand. The basic physical and engineering properties of the untreated dredged sediment were assessed in accordance with the ASTM standards. The raw sediment was sieved through sieve no. 40 (finer than 0.425 mm) and then tested using three samples for each test. Therefore, the test results were presented in terms of an average value. The specific gravity of the dredged sediments is 2.55, and the natural moisture content of the dredged sediments, which is defined as the ratio of the weight of the water to the weight of the dry sediment and presented as a percentage, is 55%. The liquid and plastic limits are 57 and 39%, respectively. The dredged sediment is classified as inorganic high plasticity silt (MH) according to the Unified Soil Classification System. The maximum dry unit weight and the optimum moisture content were obtained from a modified Proctor compaction test according to ASTM D1557 (2015) and were found to be 16.6 kN m−3 and 18.5%, respectively. The SEM images in Fig. 1a show that the dredged sediment comprises a nonuniform distribution of silt and clay fractions with large pores. The OPC particles have rough surfaces and sharp corners and are nonuniformly shaped, whereas most of the FA particles are spherical, as shown in Fig. 1b and c, respectively.

Based on the X-ray fluorescence analysis presented in Table 1, the untreated dredged sediment consisted of 66.20% silicon dioxide (SiO2), 19.30% aluminum oxide (Al2O3), 6.67% ferric oxide (Fe2O3), 1.01% calcium oxide (CaO), and 0.91% magnesium oxide (MgO). All the components of the dredged sediments are considered to be relatively inert and unreactive relative to OPC and FA. The cement utilized in this study was type I OPC with a specific gravity of 3.15, fineness of 2900 cm2 g−1, and high CaO content of 62.81%. The FA was from the Mae-Moh power plant in northern Thailand. The total amount of the three main components (SiO2, Al2O3, and Fe2O3) in the FA is 69.14%, which is between 50 and 70%. Thus, the FA used in this study is classified as class C based on ASTM C 618 (2012).

2.2 Molding and curing of the specimens

Cylindrical specimens 50 mm in diameter and 100 mm in height were used for the unconfined compression (UC) and Mr tests, whereas cylindrical specimens 152 mm in diameter and 116 mm in height were used for the CBR tests. The raw dredged sediment was sieved (passing 0.425 mm) and then dried in an oven for 24 h to ensure that its initial moisture content was zero before mixing with OPC, FA and additional water. A series of UC, CBR, and Mr tests was performed using exclusively OPC, exclusively FA, and a combination of OPC and FA. In this study, OPC contents of 1.5, 2.5, 5, and 7.5% (by dry weight of sediment) and FA contents of 5, 10, 15, and 20% (by dry weight of sediment) were mixed with the sediment. The water content in the mixture achieves the optimum moisture content of 18.5%, as determined by modified Proctor tests. The descriptions of all the mixture proportions are shown in Table 2.

The unstabilized and stabilized compacted specimens used in the tests were prepared by hand-mixing dry sediment, OPC, FA, and water. The uniformity and homogeneity of the specimen were satisfied by visual observation, and three samples of the mixtures were taken to determine the moisture content. For the UC and Mr tests, each specimen was contained in a cylindrical mold, which could split into two parts and was greased by lubrication oil and was then statically compacted in three layers using a compression machine so that each layer attained the specified dry unit weight. The top of each layer was slightly scarified. After the molding process was completed, the specimen was instantly demolded. The specimen was considered appropriate for testing when it met the following criteria: dry unit weight, moisture content, diameter, and height within 1, 0.5%, 0.5 mm, and 1 mm of the design values, respectively. The specimens passing these criteria were covered with a plastic sheet to avoid moisture loss from the sample (Güllü 2014) and were then cured for 7, 14, 28, 60 and 120 days inside a controlled room with a temperature of 25 ± 2 °C and humidity of 95 ± 5%.

For this study, the CBR values of the unstabilized and stabilized compacted specimens were determined at the maximum dry unit weight and optimum water content obtained from the modified Proctor tests, which were the same values used for specimen preparation for the UC and Mr tests. The specimen was contained in a standard cylindrical steel mold and was compacted in five layers. Each layer was given 56 blows with a 44.5 N metal hammer falling 457 mm according to ASTM D1557 (2012). The criteria for considering the appropriate specimen and curing condition for the CBR test are similar to those for the UC and Mr tests.

2.3 Unconfined compression test

The unconfined compressive strength (qu) of pavement material is an important parameter used in pavement design (Silitonga et al. 2009). The UC tests were conducted in accordance with ASTM D 2166 (2016a) to illustrate the influences of the OPC and FA contents on the strength development in the stabilized sediment. When the assigned curing time of the specimen was achieved, the UC tests were then performed on the specimen using an automatic loading machine with a capacity of 50 kN under a strain rate of 0.01 min−1 until the specimen failed. qu was taken to be the maximum compressive stress or the compressive stress at 15% axial strain, whichever occurred first during the test. The acceptance criterion of this study was designated as follows: a deviation of each qu result of three specimens with the same mixture proportion must be less than 10% from the mean qu.

2.4 California bearing ratio test

The CBR value is extensively used in designing pavement courses, and the CBR test is the most traditional test utilized to evaluate pavement materials. All CBR tests in this study were conducted based on ASTM D1883 (2016b). After the required curing time of the specimen was reached, the surcharge with a weight of 44.5 N was placed on the top of the specimen in the mold. The mold with surcharge was immersed in water, allowing water to access the top and bottom of the specimen to soak the specimen for 96 h. After soaking, the CBR tests were then performed on the specimen using an automatic loading machine with a capacity of 50 kN. The load on the penetration piston with a cross-sectional area of 1935 mm2 was applied with a penetration rate of approximately 1.27 mm min−1. The stress values at penetrations of 2.54 and 5.08 mm were recorded. The bearing ratios were calculated for each specimen by dividing the stresses at penetrations of 2.54 and 5.08 mm by the standard stresses of 6900 and 10,300 kN m−2, respectively, and multiplying by 100. The CBR value reported is normally the one at 2.54 mm penetration. When the CBR at 5.08 mm penetration is greater than the CBR at 2.54 mm penetration, the CBR test was repeated. If the repeated test provides the same result, the CBR at 5.08 mm penetration is reported.

2.5 Resilient modulus test

The resilient modulus (Mr) of unstabilized and stabilized soils is a significant factor in determining the pavement thickness and material selection. The Mr values of the pavement materials were determined using the Mr test conducted in accordance with the AASHTO T307 (2012) standard test method. The specimens were initially conditioned by the application of five hundred stress cycles with a cyclic stress of 23.1 kN m−2 and a confining stress of 103.4 kN m−2. When the conditioning stage was completed, a series of steps was performed that consisted of the application of one hundred cycles with a haversine-shaped stress pulse under various levels of confining pressures and deviatoric stresses. In this study, the stress pulse had a load duration of 0.1 s and a rest period of 0.9 s. Mr was determined from the cyclic stress divided by the recoverable strain. The equipment of the Mr test included two vertical electric displacement transducers that were symmetrically placed on top of the sample to measure the vertical displacements. The applied axial stress was measured by a load cell with a capacity of 10 kN attached on the loading plunger. The air pressurized chamber (which provided a confining pressure) was utilized to accommodate the sample during the test. The samples used in the Mr tests were similar to those used in the UC tests. The Mr tests were performed on the specimens after curing. Before testing, the plastic wrap was removed from the samples, and the dimensions and unit weights of the samples were measured. The acceptance criteria for the CBR and Mr values were similar to that for the qu value.

2.6 Scanning electron microscopy and energy-dispersive X-ray spectroscopy

Scanning electron microscopy (SEM) and energy-dispersive X-ray spectroscopy (EDX) were performed to investigate the microstructural changes in the stabilized dredged sediments caused by the stabilization process. Small block-shaped samples were collected from the failure plane of the tested specimens after the UC tests were completed. The collected samples were approximately 3 to 7 mm long and were placed in a box with desiccant to dry. A selected sample was coated with platinum for 30 s at a current of 50 mA before SEM micrographs were obtained with a Do SEM JSM-5410 LV scanning electron microscope, and the EDX analysis was performed with a Do SEM Link ISIS300.

3 Results and discussion

3.1 Unconfined compressive strength

The increase in the strength of dredged sediment due to stabilization with OPC and FA can be simply explained by using chemical equations of the OPC hydration reaction and the pozzolanic reaction, as presented in Eqs. 1 and 2, respectively.

Once the OPC, FA, and water are mixed with the dredged sediment, the OPC hydration reaction occurs immediately. High concentrations of CaO dissociating from the OPC and FA dissolve SiO2 and Al2O3, producing cementitious calcium silicate hydrate, CSH, gel and calcium hydroxide, Ca(OH)2. Ca(OH)2 can be considered a byproduct of the OPC hydration reaction. Then, the pozzolanic reaction occurs. SiO2, which is a compound in FA, slowly sequesters Ca(OH)2 from the OPC hydration reaction, creating a new pozzolanic reaction product or new CSH induced by the pozzolanic reaction. The increase in strength depends on the type and quantity of reaction products induced by the OPC hydration reaction products (e.g., CSH improves the short-term strength at curing times of 7, 14 and 28 days), and the pozzolanic reaction products (e.g., CSH improves the long-term strength at curing times of 60 and 120 days) (Horpibulsuk et al. 2009; Shon et al. 2010; Tastan et al. 2011; Kang et al. 2015). The rate of reaction and the strength contribute to the consumption of Ca(OH)2. Principally, the pozzolanic process is rather slow and is slowed further by the creation of a crust of CSH gel around particles of FA (Kang et al. 2015). This phenomenon can be observed via SEM.

The mean values of qu obtained from the UC tests are shown in Table 1. qu of the unstabilized specimen was 386 kN m−2, and the qu values of the stabilized specimens for all the mixture proportions increased steadily with the curing time. The qu of the specimens stabilized with exclusively OPC and exclusively FA increased with the OPC and FA contents, respectively. Unlike for stabilization with a combination of OPC and FA, qu increased as the content of exclusively FA increased from 5 to 10%, and qu decreased as the content of exclusively FA increased above 10%. Considering the short-term strength of the curing period of 28 days, the qu values of the specimens stabilized with exclusively 7.5% OPC (C7.5F0), exclusively 20% FA (C0F20) and a combination of OPC and 10% FA (C7.510) were 1866, 846 and 2365 kN m−2, respectively. When the curing time increased to 120 days, the long-term strengths increased to 2519, 1454 and 3529 kN m−2 for C7.5F0, C0F20 and C7.510, respectively.

It can be concluded that the use of a combination of OPC and FA was the most effective for dredged sediment stabilization, followed by the use of exclusively OPC and exclusively FA. Most of the CSH was induced from only the OPC hydration reaction due to the lack of SiO2 from FA, as expressed in Eqs. 1 and 2. The utilization of FA exclusively provided the lowest strength due to the lack of CaO from OPC, which is the main chemical component in CSH, causing the lowest amount of CSH to form (e.g., lowest strength). For specimens stabilized with a combination of OPC and FA, the total amount of CSH was the sum of the portions of CSH products induced by OPC hydration and pozzolanic reactions due to the existence of SiO2 in the FA, resulting in a greater amount of CSH than using exclusively OPC or exclusively FA.

However, the 10% FA content provided the highest qu for all samples (C1.5FA10, C2.5FA10, C5FA10, and C7.5FA10), as the 10% FA content provided the most suitable proportions of SiO2 and CaOH2 from the FA and the OPC hydration reaction, respectively, yielding an optimal performance of the pozzolanic reaction caused by the increased formation of CSH. qu tended to decrease when the FA content was greater than 10%. An FA content in excess of 10% may occlude the OPC grains and prevent the chemical reaction between water and OPC, which reduces the degree of the hydration reaction, resulting in a decrease in the amount of hydration products (Horpibulsuk et al. 2011).

Figure 2a presents the qu values of the dredged sediments stabilized with OPC and FA after 7, 14, 60, and 120 days of curing versus those at 28 days of curing. The correlation between qu at d days, qu(d), and qu at 28 days, qu(28d), was represented by a fitting curve determined through a linear regression. This correlation indicated that the qu values of the stabilized sediments at 7, 14, 60, and 120 days were approximately 0.78, 0.86, 1.24, and 1.60 times the qu(28d), respectively. The qu(28d) was used to calculate normalized strength, qu(d)/qu(28d), as was suggested by Horpibulsuk et al. (2009, 2011, 2012). Figure 2b shows the qu(d)/qu(28d) with respect to the curing time, d, for the stabilized specimens. The generalized strength development for the stabilized dredged sediment can be expressed on a natural logarithmic scale as a linear variation, as shown in Eq. 3; the correlation coefficient (R2) of this equation is 0.9095. The equation determined in this study is close to the previously reported equations for cement kiln dust (CKD) and FA residue mixed with soft clay (Yoobanpot et al. 2017), OPC mixed with soft Bangkok clay (Horpibulsuk et al. 2011) and OPC mixed with saline clay (Horpibulsuk et al. 2012) due to similar strength development characteristics caused by the hydration and pozzolanic processes, which were major and minor reactions, respectively.

3.2 California bearing ratio

The results derived from the CBR tests conducted on the unstabilized and stabilized dredged sediment specimens were similar to the UC test results, as presented in terms of the mean CBRs in Table 1. The CBR for the unstabilized dredged sediment was 6%. At a curing time of 28 days, the CBRs of the stabilized specimens C7.5F0, C0F20, and C7.5F10 increased to 47, 20, and 52%, respectively. For the curing time of 120 days, the CBR increased to 63, 36, and 88% for C7.5F0, C0F20, and C7.510, respectively. Thus, the unstabilized specimens could be improved via 8-, 3-, and 9-fold CBR increases at a short-term curing time of 28 days and via 11-, 6-, and 15-fold CBR increases at a long-term curing of 120 days for C7.5F0, C0F20, and C7.510, respectively. The CBR values of C7.5F10 were higher than those of C0F20 and C7.5F0, similar to the results of the UC tests, as discussed in Sect. 3.1. For specimens stabilized with a combination of OPC and FA, when the FA content increased from 10 to 20%, the CBR values of C7.5F20 decreased to 49 and 75% after 28 and 120 days, respectively. Thus, 10% FA is also optimal for improving the CBR of unstabilized sediment.

The correlation between CBR and the qu value of dredged sediment stabilized with OPC and FA found in this study is illustrated in Fig. 2c and was modeled by a linear equation, as expressed in Eq. 4. This correlation has been studied by other researchers for various types of stabilized soil. Jaritngam et al. (2008) attempted to improve soft clay with OPC to reduce the postconstruction settlement of road construction on soft clay and found that the CBR was approximately 0.034qu. Osinubi et al. (2011) improved black cotton soil with OPC mixed with locust bean waste ash, and the result was a CBR of 0.022qu. Agapitus (2014) enhanced the strength and durability of soil subgrade with cement kiln dust and presented that CBR = 0.064qu. Voottipruex and Jamsawang (2014) studied OPC and FA stabilization of expansive soils and showed that CBR = 0.018qu for both 3–7% exclusively cement and a combination of 1% cement and 10–20% FA. Jiang et al. (2015) used calcium carbide residue as a stabilizer to improve soft subgrade soil highway materials and investigated the subgrade at the microscale and macroscale in the laboratory. Their results showed that CBR = 0.042qu. The correlation between qu (in kPa) and CBR (in %) of stabilized sediment in the current study is within range of general cementitious material-stabilized soil.

3.3 Resilient modulus

Various types of prediction models have been proposed to estimate Mr. To reduce the cost and time of advanced laboratory experiments used for determination of the Mr, Mr predictions for stabilized sediments were performed in this study. Figure 3a shows examples of the Mr values at each cycle for C7.5F0, C7.5F5, C7.5F10, C7.5F15, and C7.5F20 at curing times of 7, 28, and 120 days. Table 1 shows the mean values of Mr after 15 cycles for all the specimens used in this study at curing times of 7, 14, 28, 60, and 120 days. The results showed that the Mr results of the stabilized dredged sediment exhibited similar trends to those of the qu and CBR values. The Mr value of the unstabilized dredged sediment was 52 MN m−2. After stabilization with OPC and FA, the Mr values increased to 271, 131, and 308 MN m−2 at a curing time of 28 days and increased to 430, 246, and 494 MN m−2 at a curing time of 120 days for C7.5F0, C0F20, and C7.510, respectively. The Mr values of the unstabilized specimens could be improved 5-, 3-, and 6-fold at short-term curing of 28 days and 8-, 5-, and 10-fold at long-term curing of 120 days for C7.5F0, C0F20, and C7.510, respectively. C7.5F10 was most effective in developing Mr. However, the Mr values of C7.5F20 increased to 284 and 437 at curing times of 28 and 120 days, respectively.

Figure 3b shows the relationship between Mr and qu. The trend could be modeled by linear regression. Based on the linear regression equation, Mr of the stabilized dredged sediment is 149 times qu, as expressed by Eq. 5. The similar linear Mr–qu relationship reported in previous studies is compared to the results proposed in this study, as shown in Fig. 3b. Kang et al. (2015) utilized 10–20% FA and 4–20% lime kiln dust for stabilizing soft clay used in roadbase construction, whereas Tastan et al. (2011) studied the effect of various types of FA (10–20% FA contents) on the stabilization of three soft organic soils with different organic contents. Kang et al. (2015) and Tastan et al. (2011) found that Mr–qu correlations could be expressed as Mr = 393qu and Mr = 270qu, respectively, which overestimates the MR values obtained from this study by approximately 1.8–2.6 times. However, the proposed linear relationship (Mr = 70qu) by Arora and Aydilek (2005) for silty soils stabilized by 2–8% quick lime for use in highway subgrade underestimates the Mr–qu correlation of this study by 2.1 times. The correlation (Mr = 128qu) reported by Ardah et al. (2017) for clayey soils treated by 2–8% OPC, 2–11% lime and 10–15% FA is close to that derived from the current study.

Figure 3c shows the Mr–CBR results of this study. The trend of the correlation was modeled by a linear equation, as expressed in Eq. 6. The Mr–CBR relationships suggested by other researchers are also illustrated in Fig. 3c for comparison purposes. Garber and Hoel (2015) proposed the linear equation Mr = 10CBR for subgrade soils, which overestimates the MR values obtained from this study by approximately 1.7 times. However, the suggested linear relationship (Mr = 3CBR) by Arora and Aydilek (2005) for silty soils stabilized by 2–8% quick lime underestimates the Mr-CBR correlation of this study by half. The linear Mr-CBR correlation (Mr = 5CBR) proposed by Razouki and Kuttah (2004) for clayey gypsiferous soil is very close to that obtained from this study. However, the nonlinear Mr-CBR correlation (Mr = 148CBR0.34) reported by Razouki and Ibrahim (2017) for a gypsum sand roadbed improved by an increased degree of compaction significantly overestimates the MR values found in this study.

3.4 Microstructural analyses

3.4.1 Scanning electron microscopy

Figure 4a–f show the microstructural changes in the samples. The observation of C7.5F0 depicted in Fig. 4a, b illustrated that after 28 days of curing, many hydration products were present, including CSH gels and ettringite crystals (Jamsawang et al. 2017), and rough surfaces of the specimens were found. The pozzolanic reaction products, which are cementitious compounds, improve the intercluster bonding strength and fill the void spaces. After 120 days of curing, the CSH products form a fabric on the sediment clusters and filled the void spaces between particles of the sediments, causing the sediment structure to densify. Cementitious products were also detected on the surfaces of the sediment particles.

Figure 4c and d illustrate SEM images of C7.5F10. The particles of FA interspersed with the CSH fabric and filled the voids between the particles of the sediments. Consequently, this impact reduced the void volume in the sediment structure, resulting in an increase in the overall density. In general, SEM revealed that the FA particles were hollow spheres of various sizes, and most of the FA particles were smooth. After 120 days of curing (Fig. 4d), some glassy irregularly shaped pieces can be seen among the FA particles. When FA added to the sediment, the mixture started setting, and the hydration products around the particles of FA could be easily detected via SEM. As the curing period increased, a crust of hydration gel formed that tightly bound the sediment particles and adjacent FA particles. Eventually, the hydration crust connected the sediment and FA particles, and the strength of the mixture was improved by the curing time. The products obtained from the hydration and pozzolanic reactions filled the voids in the mixture, and the particles aggregated and connected. The connection and aggregation of the stabilized dredged sediments improved the stress-strain behavior at the macroscale. The stabilized dredged sediments had smaller pores and denser microstructures than those of the unstabilized dredged sediments (Fig. 1a). Thus, the stabilized sediments had high qu, CBR and Mr properties and low compressibilities (low plastic strain) (Kang et al. 2015). The advantage of including FA to produce cementitious products has been previously suggested, and former studies have found that FA is beneficial for reducing the void spaces in sediment particles and enhancing sediment strength in long-term curing conditions (Wang et al. 2013; Shaheen et al. 2014; Yoobanpot et al. 2017).

The SEM images of C7.5F20 in Fig. 4e, f are similar to those of C7.5F10, but C7.5F20 has a larger void space than that of C7.5F10 because C7.5F20 produced less CSH that could fill the voids in the mixture. Moreover, some FA particles in C7.5F20 were only partially covered by a crust of CSH gels, unlike the FA particles found in C7.5F10, which were fully encased by CSH.

3.4.2 Energy-dispersive X-ray spectroscopy

The chemical composition of the stabilized dredged sediment was investigated by EDX analysis of C7.5F0, C7.5F10, and C7.5F20 after 28 and 120 days of curing; the results are shown in Fig. 5a–f. The observations show that calcium (Ca), silica (Si), aluminum (Al), iron (Fe), and oxygen (O) are present in all the specimens (Al-Homidy et al. 2017; Li and Poon 2017; Bilondi et al. 2018). High amounts of Ca, Si, O, and Al, especially Ca, provided suitable conditions for the formation of CSH gel in the stabilized specimens, whereas the Si/Al ratio is significantly important to the bond strength of the stabilized specimens. Therefore, the main parameters affecting the strength of the stabilized specimens were both the weight proportion of Ca and the ratio of Si/Al; additionally, an increase in the Si/Al ratio, which is expected to control the amount of Ca, increases the strength of the stabilized specimens due to the associated increase in the formation of the CSH gels and bond strength (Bilondi et al. 2018).

Figure 5a shows the analysis of C7.5F0 after 28 days of curing. The weight proportion of Ca and the Si/Al ratio were 4.16 and 1.70, respectively, and these parameters increased with curing time due to the hydration and pozzolanic reactions to 10.56 and 1.97 after 120 days of curing, respectively (Fig. 5b). Similar results were observed for C7.5F10 and C7.5F20, as shown in Figs. 5c, d and e, f, respectively. The weight proportion of Ca and the Si/Al ratio for C7.5F10 were 6.34 and 2.07 at a curing period of 28 days and 13.07 and 2.25 at a curing period of 120 days, respectively, and for C7.5F20, these results were 4.59 and 1.90 at a curing period of 28 days and 11.54 and 2.12 at a curing period of 120 days, respectively. The trend of the Ca content and Si/Al ratio versus FA content charts, as shown in Fig. 5g and h, respectively, is similar to results of the qu, CBR and Mr, and the maximum weight proportion of Ca and the maximum value of Si/Al ratio were exhibited by C7.5F10, which can be explained by C7.5F10 having the greatest amount of CSH gel formation and highest bond strength compared to those of C7.5F0 and C7.5F20. The findings obtained from SEM and EDX confirmed that 10% FA is optimal for improving the performance of sediment stabilized with a combination of OPC and FA and suggested that an excessive amount of FA may block the interaction between the water and OPC, decreasing the degree of cement hydration reaction and the amount of cementitious products. These results confirm the finding of the highest qu for specimens stabilized with a combination of OPC and FA at an optimal content of 10% in Sect. 3.1. Therefore, FA could effectively stabilize dredged sediments in terms of enhancing its strength and resilience characteristics as an effect of pozzolanic reactions, which improve the properties and bonding between the sediments and FA particles (Horpibulsuk et al. 2009; Shon et al. 2010).

3.5 Summary of the potential use of dredged sediments as pavement materials

The criteria of suitable pavement materials based on the Department of Highways of Thailand classify highway materials into four categories: soil cement base, soil cement subbase, selected material and subgrade material. These classifications are listed together with the corresponding standard designations in Table 3. The specifications of the soil cement base and soil cement subbase require the minimum qu of stabilized soil at 7 days to be 1724 and 689 kN m−2, respectively. If the qu requirement at 7 days is not met, the stabilized soil is classified as selected material or subgrade material by considering only the CBR values. A consideration of stabilized sediment as a pavement material for all mixture proportions is presented in Fig. 6a and b. Note that the unstabilized dredged sediment is suitable for use as only a subgrade material because the CBR values exhibited by the unstabilized dredged sediment are higher than the subgrade material requirement but lower than the requirements for other materials listed in the standard. Table 3 also summarizes the optimum mixture proportions of the tested stabilized dredged sediments in this study for potential use as soil cement base, soil cement subbase, selected material and subgrade material based on the Department of Highways of Thailand.

Alternatively, Austroads (2017) also provided presumptive values of Mr for unbound granular materials under thin bituminous surfacing, as shown in Table 4; these values should be considered by pavement designers. Thus, the results in this study, as presented in Fig. 6c, compared to Table 4, also show that the stabilized dredged sediment with the optimum mixture proportions can be used as pavement materials, including high standard crushed rock base course, normal standard crushed rock base course, base quality gravel, and subbase quality materials.

Notably, the results in this study were based on the stabilization of dredged sediment without contaminants; thus, only the strength of the stabilized dredged sediment was considered for use as pavement materials. However, OPC and FA can also stabilize highly contaminated dredged sediment, but in addition to the strength, the leachability rate of heavy metals is primary concern regarding the final judgment of the use of stabilized dredged sediment as pavement materials. Previous studies by Dermatas and Meng (2003), Yin et al. (2006), Scanferla et al. (2009), Tomasevic et al. (2013), Wang et al. (2015), and Gupta et al. (2017) confirmed that highly contaminated soil and sediment stabilized by OPC and FA exhibited high strength and low leachability that never exceeded regulatory limits due to the existence of hydration and pozzolanic reaction products, similar to the findings in this study.

The results obtained by this study are generally applicable in all climes. However, the application of stabilized sediment for road materials in cold climes and tropical wet–dry climes requires additional test results of the freeze–thaw durability and wetting–drying durability, respectively, to ensure that the stabilized sediment has a sufficient residual strength for maintaining the service life of the road, as recommended by COE (2004) and Tripathy and Rao (2009). Previous studies by Tebaldi et al. (2016), Wang et al. (2018) and Yilmaz and Fidan (2018) confirmed that stabilized pavement materials can resist freeze–thaw cycles, whereas Tang et al. (2011), Kampala and Horpibulsuk (2013) and Kampala et al. (2014) reported that stabilized soils exhibit durability against wetting–drying cycles and can thus be considered durable pavement materials, resulting in reduced maintenance costs.

3.6 A comparative cost analysis

Typical sections of pavement structures using conventional earthen materials and cement-stabilized soil materials in accordance with the standard of the Department of Highways of Thailand, as shown in Fig. 7a and b, respectively, were used for the comparative cost analysis. The typical pavement structures consisted of wearing surface (asphaltic concrete), base, subbase, selected material, and subgrade layers. The dredged sediments stabilized with OPC and FA in optimum mixture proportions, as shown in Table 4, were used instead of cement-stabilized soil materials, as shown in Fig. 7b, to perform a simple comparative cost analysis between roads using conventional earthen pavement materials and roads using dredged sediment stabilized with OPC and FA, considering the material, hauling, and transportation costs only. The detailed comparative cost analysis is summarized in Table 5. The road construction site was near the Mae Sab hydropower dam in Samoeng District, Chiang Mai, Thailand, at the future site of a 1-km-long rural road connecting the dam and the local community center. The costs of the asphaltic concrete were the same for the roads with conventional earthen pavement materials and stabilized sediment. There was no material cost for the dredged sediment, but a hauling cost was required to obtain the dredged sediment for the roads using stabilized sediment. Although the hauling cost for the road using earthen materials was zero, the material cost of earthen materials was high. The distance from the material source to the construction site for the road using stabilized sediment was only approximately 1 km, whereas that for the road using earthen materials was approximately 10 to 30 km. However, the additional costs of the road using stabilized sediments compared to the costs of conventional roads were attributed the material and transportation costs of the FA and OPC. The material cost of the FA was lower than that of the OPC by approximately 30 times, and the distance from the supply source of the OPC and FA was 30 km. The summarized comparative cost analysis in Table 5 indicates that the use of dredged sediment stabilized with OPC and FA as pavement materials in a roadway application has a clear advantage over the use of conventional earthen pavement materials. The main factor affecting the total cost is the distance from the material source to the construction site. In this study, the total transportation cost of roads using stabilized sediment was 2.5 times cheaper than that of roads using conventional earthen pavement materials, resulting in a total cost of using stabilized dredged sediment that was 1.5 times more economic than using conventional earthen materials.

4 Conclusions

This research evaluated the engineering properties of dredged sediments stabilized with OPC and FA for use as road construction materials. The laboratory testing program included UC, CBR, and resilient modulus tests. Correlations used for estimation of Mr from CBR and qu were proposed. The changes in the microstructure and chemical composition due to hydration and pozzolanic reactions of cement and FA were investigated via SEM and EDX analyses. An assessment of the stabilized dredged sediments for reuse as pavement materials was performed. Finally, the cost between roads using conventional earthen materials and stabilized dredged sediment was analyzed. Based on the results of this study, the following conclusions can be drawn:

-

1.

The developments of qu, CBR and Mr of the stabilized dredged sediment were similar. The stabilization of dredged sediments with a combination of OPC and FA is most effective because of the highest amount of CSH products induced via the sum of the CSH products from the hydration reaction (induced by the presence of OPC during short-term curing) and the CSH products from the pozzolanic reaction (induced by the presence of SiO2 in FA during long-term curing). Utilization of exclusively OPC creates CSH products from only the hydration reaction due to the absence of SiO2 from the FA. The use of exclusively FA is the least effective due to the absence of CaO from the OPC, creating the lowest amount of CSH.

-

2.

An FA content of 10% was the most effective for increasing the qu, CBR, and Mr results of the samples using a combination of OPC and FA because 10% FA provided the most suitable proportions of SiO2 and CaOH2 for creating the greatest amount of CSH products. When the FA content exceeded 10%, qu, CBR and Mr gradually decreased. An excess FA content of 10% may occlude the OPC grains and hinder the interaction between the water and OPC, which significantly reduces the degree of the hydration reaction, leading to a reduction in the cementitious products.

-

3.

The correlations between Mr and qu and between Mr and CBR were represented by linear regression equations, which can be expressed as Mr = 149qu and Mr = 6CBR, respectively. The correlations are useful in terms of cost and time reduction for determining the parameter Mr by using advanced laboratory experiments.

-

4.

The SEM results confirmed that samples stabilized with a combination of OPC and 10% FA had a larger amount of CSH products than samples stabilized with either a combination of OPC and 20% FA or exclusively OPC. A larger amount of CSH products can enhance the intercluster bonding strength and can fill more pore spaces in the sediment. This effect reduces the void volume in the sediment structure, thereby increasing the overall structural densification and increase in strength, which agreed well with the results of the UC, CBR and Mr tests.

-

5.

The EDX analysis showed that the samples stabilized with a higher weight proportion of Ca and a high Si/Al ratio had greater strengths due to the more suitable conditions for the formation of the CSH gel and higher bond strength. The EDX analysis also confirmed that the sediment stabilized with a combination of OPC and 10% FA exhibited the optimal performance because it had the highest weight proportion of Ca and Si/Al ratio. Therefore, the pozzolanic reactions induced by the existence of FA can enhance the strength and resilience characteristics by improving the bonds between the sediments and FA particles.

-

6.

Based on the qu and CBR values according to the standard of the Department of Highways of Thailand, unstabilized dredged sediment was determined to be suitable for use as a subgrade material. The inclusion of only 5%FA with improved the dredged sediment enough to meet the requirements of selected material. To meet the requirements of soil cement subbase and soil cement base, combinations of 7.5% OPC with 10% FA and 1.5% OPC with 5% FA were required.

-

7.

Based on the Mr value according to recommendations of Austroads (2017), stabilization with the combinations of 7.5% OPC with 10% FA and 5% OPC with 5% FA improved dredged sediment to meet the requirements of high standard crushed rock base course and normal standard crushed rock base course, respectively. In addition, the use of 1.5% OPC with 10% FA and 1.5% OPC with 5% FA stabilized the dredged sediment to meet the requirements of base quality gravel and subbase quality materials, respectively.

-

8.

A simple cost comparative analysis showed that the road using dredged sediment stabilized with OPC and FA was approximately 1.5 times more economic than the road using conventional earthen materials because the total transportation cost of materials used in the road using stabilized sediments was 2.5 times cheaper than that of the road using conventional earthen pavement materials.

References

AASHTO (1993) Guide for design of pavement structures. AASHTO, Washington, DC

AASHTO (2012) Standard method of test for determining the resilient modulus of soils and aggregate materials. AASHTO, T 307, Washington, DC

Abu-farsakh M, Dhakal S, Chen Q (2015) Laboratory characterization of cementitiously treated/stabilized very weak subgrade soil under cyclic loading. Soils Found 55(3):504–516

Agapitus AA (2014) Enhancing durability of quarry fines modified black cotton soil subgrade with cement kiln dust stabilization. Transport Geotech 1:55–61

Ahmed A (2015) Compressive strength and microstructure of soft clay soil stabilized with recycled bassanite. Appl Clay Sci 104:27–35

Al-Homidy AA, Dahim MH, Abd El Aal AK (2017) Improvement of geotechnical properties of sabkha soil utilizing cement kiln dust. J Rock Mech Geotech Eng 9(4):749–760

Ardah A, Chen Q, Abu-farsakh M (2017) Transportation geotechnics evaluating the performance of very weak subgrade soils treated / stabilized with cementitious materials for sustainable pavements. Transp Geotech 11:107–119

Arora S, Aydilek AH (2005) Class F fly-ash-amended soils as highway base materials. J Mater Civ Eng 17(6):640–649

ASTM (2012) Standard specification for coal Fly ash and raw or calcined natural pozzolan for use in concrete. Standard C 618. ASTM, west Conshohocken, USA

ASTM (2015) Standard test methods for laboratory compaction characteristics of soil using modified effort. Standard D 1557. ASTM, west Conshohocken, USA

ASTM (2016a) Standard test method for unconfined compressive strength of cohesive soil. Standard D 2166/D 2166M. ASTM, west Conshohocken, USA

ASTM (2016b) Standard Test Method for California Bearing Ratio (CBR) of Laboratory-Compacted Soil. Standard D 1883. ASTM, west Conshohocken, USA

Austroads (2017) Guide to pavement technology part 2: pavement structural design. Austroads, Sydney

Bilondi MP, Toufigh MM, Toufigh V (2018) Experimental investigation of using a recycled glass powder-based geopolymer to improve the mechanical behavior of clay soils. Constr Build Mater 170:302–313

COE (U.S. Army Corps of Engineers) (2004) Soil stabilization for pavements. TM 5–822-14/AFJMAN 32/1019. http://www.wbdg.org/ccb/DOD/UFC/ufc_3_250_11.pdf

Dermatas D, Meng X (2003) Utilization of fly ash for stabilization / solidification of heavy metal contaminated soils. Eng Geol 70:377–394

Dubois V, Zentar R, Abriak NE, Grégoire P (2011) Fine sediments as a granular source for civil engineering. Eur J Environ Civ Eng 15:137–166

Garber NJ, Hoel LA (2015) Traffic and highway engineering, 5th edn. Cengage Learning, Stamford

Güllü H (2014) Factorial experimental approach for effective dosage rate of stabilizer: application for fine-grained soil treated with bottom ash. Soils Found 54(3):462–477

Güllü H, Canakci H, Al Zangana IF (2017) Use of cement based grout with glass powder for deep mixing. Constr Build Mater 137:12–20

Gupta A, Arora VK, Biswas S (2017) Contaminated dredged soil stabilization using cement and bottom ash for use as highway subgrade fill. Int J Geo-Engineer 8:20

Horpibulsuk S, Rachan R, Raksachon Y (2009) Role of fly ash on strength and microstructure development in blended cement stabilized silty clay. Soils Found 49(1):85–98

Horpibulsuk S, Rachan R, Chinkulkijniwat A, Raksachon Y (2010) Analysis of strength development in cement-stabilized silty clay from microstructural considerations. Constr Build Mater 24(10):2011–2021

Horpibulsuk S, Rachan R, Suddeepong A (2011) Assessment of strength development in blended cement admixed Bangkok clay. Constr Build Mater 25(4):1521–1531

Horpibulsuk S, Phojan W, Suddeepong A, Chinkulkijniwat A, Liu MD (2012) Strength development in blended cement admixed saline clay. Appl Clay Sci 55:44–52

Jamsawang P, Poorahong H, Yoobanpot N, Songpiriyakij S, Jongpradist P (2017) Improvement of soft clay with cement and bagasse ash waste. Constr Build Mater 154:61–71

Jaritngam S, Swasdi S, Tonnayopas D, Thongchim P (2008) Improvement for subsoil by cement column - a case study in Thailand. Proceedings of the 13th International Conference of Hong Kong Society for Transportation Studies of two-day duration (Hong Kong, 13th – 15th December 2008)

Jiang NJ, Du YJ, Liu SY, Wei ML, Horpibulsuk S, Arulrajah A (2015) Multi-scale laboratory evaluation of the physical, mechanical, and microstructural properties of soft highway subgrade soil stabilized with calcium carbide residue. Can Geotech J 52:1–11

Jongpradist P, Jumlongrach N, Youwai S, Chucheepsakul S (2010) Influence of fly ash on unconfined compressive strength of cement-admixed clay at high water content. J Mater Civ Eng 22:49–58

Kamali S, Bernard F, Abriak NE (2008) Marine dredged sediments as new materials resource for road construction. Waste Manag 28:918–928

Kampala A, Horpibulsuk S (2013) Engineering properties of silty clay stabilized with calcium carbide residue. J Mater Civ Eng 25(5):632–644

Kampala A, Horpibulsuk S, Prongmanee N, Chinkulkijniwat A (2014) Influence of wet-dry cycles on compressive strength of calcium carbide residue–fly ash stabilized clay. J Mater Civ Eng 26(4):633–643

Kang X, Kang G-C, Chang K-T, Ge L (2015) Chemically stabilized soft clays for road-base construction. J Mater Civ Eng 27(7):04014199

Kogbara RB, Al-Tabbaa A, Yi Y, Stegemann JA (2013) Cement-fly ash stabilization / solidification of contaminated soil: performance properties and initiation of operating envelopes. Appl Geochem 33:64–75

Li J, Poon CS (2017) Innovative solidification/stabilization of lead contaminated soil using incineration sewage sludge ash. Chemosphere 173:143–152

Mohammadinia A, Arulrajah A, Sanjayan J, Disfani MM, Bo MW, Darmawan S (2015) Laboratory evaluation of the use of cement-treated construction and demolition materials in pavement base and subbase applications. J Mater Civ Eng 27:04014186-1-10

Osinubi KJ, Oyelakin MA, Eberemu AO (2011) Improvement of black cotton soil with ordinary Portland cement - locust bean waste ash blend. EJGE 16:619–627

Razouki SS, Ibrahim AN (2017) Improving the resilient modulus of a gypsum sand roadbed soil by increased compaction. Int J Pavemet Eng 20(4):432–438

Razouki SS, Kuttah DK (2004) Effect of soaking period and surcharge load on resilient modulus and California bearing ratio of gypsiferous soils. Quart J Engineer Geol Hydrogeol 37:155–164

Scanferla P, Ferrari G, Pellay R, Ghirardini AV, Zanetto G, Libralato G (2009) An innovative stabilization/solidification treatment for contaminated soil remediation: demonstration project results. J Soils Sediments 9:229–236

Shaheen SM, Hooda PS, Tsadilas CD (2014) Opportunities and challenges in the use of coal fly ash for soil improvements – a review. J Environ Manag 145:249–267

Shon C-S, Saylak D, Mishra SK (2010) Combined use of calcium chloride and fly ash in road base stabilization. Transp Res Rec J Transp Res Board 2186(1):120–129

Silitonga E, Levacher D, Mezazigh S (2009) Effects of the use of fly ash as a binder on the mechanical behaviour of treated dredged sediments. Environ Technol 30(8):799–807

Solanki P, Zaman MM, Dean J (2011) Resilient modulus of clay subgrades stabilized with lime, class C fly ash, and cement kiln dust for pavement design. Transp Res Rec J Transp Res Board 2186(1):101–110

Suksiripattanapong C, Horpibulsuk S, Boongrasan S, Udomchai A (2015) Unit weight, strength and microstructure of a water treatment sludge–fly ash lightweight cellular geopolymer. Constr Build Mater 94:807–816

Tang CS, Cui YJ, Shi B, Tang AM, Liu C (2011) Desiccation and cracking behaviour of clay layer from slurry state under wetting-drying cycles. Geoderma 166:111–118

Tastan EO, Edil TB, Benson CH, Aydilek AH (2011) Stabilization of organic soils with fly ash. J Geotech Geoenviron Eng 137(9):819–833

Tebaldi G, Orazi M, Orazi US (2016) Effect of freeze–thaw cycles on mechanical behavior of lime-stabilized soil. J Mater Civ Eng 06016002

Tomasevic DD, Dalmacija MB, Prica DM, Dalmacija BD, Kerkez DV, Becelic-Tomin MR, Roncevic SD (2013) Use of fly ash for remediation of metals polluted sediment – green remediation. Chemosphere 92:1490–1497

Tongwei Z, Xibing Y, Yongfeng D, Dingwen Z, Songyu L (2014) Mechanical behaviour and micro-structure of cement-stabilised marine clay with a metakaolin agent. Constr Build Mater 73:51–57

Tripathy S, Rao SSK (2009) Cyclic swell-shrink behavior of a compacted expansive soil. Geotech Geol Eng J 27(1):89–103

Voottipruex P, Jamsawang P (2014) Characteristics of expansive soils improved with cement and fly ash in Northern Thailand. Geomech Eng 6:437–453

Wang D, Edine N, Zentar R (2013) Strength and deformation properties of Dunkirk marine sediments solidified with cement, lime and fly ash. Eng Geol 166:90–99

Wang L, Tsang DCW, Poon C (2015) Green remediation and recycling of contaminated sediment by waste-incorporated stabilization / solidification. Chemosphere 122:257–264

Wang D, Zentar R, Abriak NE (2018) Durability and swelling of solidified/stabilized dredged marine soils with class-F fly ash, cement, and lime. J Mater Civ Eng 30(3):04018013

Wen H, Warner J, Edil T, Wang G (2010) Laboratory comparison of crushed aggregate and recycled pavement material with and without high carbon fly ash. Geotech Geol Eng 28:405–411

Yilmaz F, Fidan D (2018) Influence of freeze-thaw on strength of clayey soil stabilized with lime and perlite. Geomech Eng 14(3):301–306

Yin CY, Mahmud HB, Shaaban MG (2006) Stabilization/solidification of lead-contaminated soil using cement and rice husk ash. J Hazard Mat 137:1758–1764

Yoobanpot N, Jamsawang P, Horpibulsuk S (2017) Strength behavior and microstructural characteristics of soft clay stabilized with cement kiln dust and fly ash residue. Appl Clay Sci 141:146–156

Funding

This research was funded by King Mongkut’s University of Technology North Bangkok under Contract No. KMUTNB-61-KNOW-008 and King Mongkut’s University of Technology Thonburi (KMUTT) under Research Grant No. CE-KMUTT 6401. The last author would like to acknowledge the Ratchadapisek Sompoch Endowment Fund (2019), Chulalongkorn University (762003-CC).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Human participant and/or animal rights and informed consent

None.

Additional information

Responsible editor: Victor Magar

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Yoobanpot, N., Jamsawang, P., Simarat, P. et al. Sustainable reuse of dredged sediments as pavement materials by cement and fly ash stabilization. J Soils Sediments 20, 3807–3823 (2020). https://doi.org/10.1007/s11368-020-02635-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11368-020-02635-x