Abstract

Formation damage due to clay minerals swelling and migration is one of the major challenges in shaly reservoirs. The main objective of this study was to explore the potential of nanoparticles application as clay swelling inhibitor and investigate the effect of various parameters on nanoparticles performance. The experiments were designed using Taguchi orthogonal array and the impact of the main factors, including pH value, salinity, and temperature, and the presence of nanoparticles with concentrations of 0.05–1 wt% was inspected on the clay swelling. Zeta potential measurements were used to determine the surface charge of nanoparticles at different pH values. XRD and XRF analyses were carried out to characterize the nanoparticles and bentonite powder. The experimental results showed that after solution salinity, the most effective parameter on the clay swelling is the concentration of nanoparticles. The minimum clay swelling index was obtained in the presence of silica nanoparticles at 0.1 wt% concentration. It was observed that higher concentrations of nanoparticles not only have no effect on reducing the clay swelling but also increase the volume due to nanoparticles agglomeration. The presence of alumina nanoparticles showed an inverse effect on the clay swelling and increased the swelling index. The results of zeta potential measurements indicated that nanoparticles with negative surface charge help to decrease the clay swelling as the result of similar charge repulsion. The low swelling index detected in samples containing silica nanoparticles shows the potential of nanoparticles to prevent the formation damage due to clay swelling.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Formation damage in petroleum formations is known as rock permeability impairment and reduction in the natural capability of a reservoir to produce hydrocarbon fluids. Damage can occur near the wellbore region or deep into the reservoir rock during different steps of drilling, workover, production, and enhanced oil recovery operations. Fines migration and clay swelling are the main reasons for permeability reduction and formation damage in oil reservoirs. Therefore, prediction and inhibition of formation damage during different operations performed in hydrocarbon reservoirs is vital (Valadbeygian et al. 2023; Hajipour et al. 2023; Mohan et al. 1993).

Clay minerals that are characterized as swelling and non-swelling are available in approximately 97% of petroleum reservoirs. Swelling clays like montmorillonite expand when exposed to water-based fluids and non-swelling clays may migrate during water injection and plug pore throats of the reservoir rock. Both these effects decrease pore spaces and permeability of the reservoir rock (Lalji et al. 2022a; Movahedi et al. 2022; Cong et al. 2018; Sharifipour et al. 2017). In shaly sand reservoirs, one of the significant reasons for formation damage is the expansion of clay particles in contact with fluids, specifically water. The types and amounts of clay minerals affect the swelling and migration characteristics of a particular shale. Sodium-saturated smectites have high swelling potential and are abundant in hydrocarbon formations, so they should be given special attention. In drilling operations, various additives are used to adjust the properties of water-based drilling fluids among which KCl is commonly used as a clay expansion inhibitor. But the high concentration of additives is undesirable for the environment (Cheraghi et al. 2022; Khan et al. 2021; Hajipour 2020; Balaban et al. 2015).

Clays are crystalline particles made up of two main structural units, including tetrahedral silicone and hexagonal aluminum sheets. The ions, cations, hydroxylic groups, water molecules, and organic compounds can be placed in free space between structural layers. The negative surface charge of clay particles participates in hydrogen bonds between water molecules and clay, which makes a thin layer of water on the internal surfaces and interlayers, leading to clay swelling. The presence of exchangeable cations such as Ca2+, Mg2+, and H+ strengthens the integrity of clay particles and affects the thickness of the formed water layer. Kaolinite, smectite, illite, and chlorite are important clay particles that play critical roles in the decreased permeability of sandstone reservoirs. The permeability reduction and pore blockage, particle migration and accumulation, and entrapment of large amounts of fluid are the main problems that follow the clay swelling (Mao et al. 2021; Sruthi and Reddy 2019).

The main approaches that can reduce clay swelling are ion exchange, modification of clay surface affinity toward water, and use of stabilizers for coating the clay particles (Asaad et al. 2021; Zaitoun and Berton 1992). These treatments are divided into permanent and temporary methods. Temporary clay stabilizers are additives that avoid swelling and movement of clay particles but are easily detached by the produced reservoir fluids after the treatment. Inorganic salts, including sodium chloride, calcium chloride, and potassium chloride, are the most common temporary clay stabilizers (Yin et al. 2018). Recent research has addressed permanent clay stabilizers like quaternary amine polymers which tightly attach to the clay surface and are not removed by the produced fluid. Different categories of clay stabilizers and their advantages and disadvantages can be found in the literature (Fu et al. 2019; Chen et al. 2017; Berry et al. 2008). However, most of the stabilizers cannot meet the actual requirements due to the inability to migrate through small voids, environmental impact, and high cost.

Over the past decade, several studies have been performed on the use of nanoparticles for the control of clay swelling (Lalji et al. 2022b; Abdullah et al. 2022; Swai 2020; Jain et al. 2015; Akhtarmanesh et al. 2013; Hoelscher et al. 2012). Nanoparticles (NPs), which are less than 100 nm in at least one dimension, are known as influential materials able to inhibit the fine migration in hydrocarbon formations. Due to the small particle size and high surface activity, the effective working area is greatly increased (El-Diasty and Ragab 2013). Sameni et al. (2015) showed that the presence of NPs has no significant effect on the swelling and migration of clay particles. They used bentonite as the clay sample, the swelling ratio of which was calculated in distilled water and KCl solution as controls. The effect of three NPs, including aluminum oxide, magnesium oxide, and silica, on the swelling mechanism was evaluated. Their results demonstrated no impact of NPs, in different concentrations, on the clay swelling inhibition. Habibi et al. (2013) evaluated the effect of various NPs on the migration of clay particles. Their findings showed that MgO resulted in the most controlled migration of particles. Sensoy et al. (2009) studied the impact of NPs on the migration and swelling of clay particles due to the invasion of water-based drilling muds. Their study showed the positive influence of NPs in decreased water penetration in shales, which may be a suitable solution for unstable wells. Pham and Nguyen (2014) investigated the dispersion of silica NPs with polyethylene glycol coating in NaCl and KCl aqueous solutions for clay swelling control. Their results revealed that the clay swelling is reduced by a factor of approximately 2 at low nanoparticle concentration in 1 wt%. NaCl and KCl solutions.

Although the potential of NPs in clay swelling control was investigated in previous studies, but still a specific mechanism was not reported and a fundamental understanding of NPs’ influence on clay swelling is still lacking. Considering problems like wellbore instability and decreased permeability due to clay swelling, a precise evaluation of parameters influencing the swelling index is essential. Therefore, in the current study, the interaction between NPs and bentonite was explored and the impact of effective factors including pH value, aqueous solution salinity, temperature, and the concentration of NPs on clay swelling was investigated. Taguchi L-16 orthogonal array was applied as the experimental design method to reduce the number of experimental tests. Moreover, the effect of NPs’ surface charge was explored by the application of silica and alumina NPs with negative and positive surface charges, respectively. Our findings confirm that NPs’ surface charge has a determining effect on controlling the clay swelling behavior and should be considered for the selection of the proper nanoparticle type.

Materials and methods

Materials

Two types of metal oxide NPs, i.e., silica (20 nm, > 98% purity) and alumina (20 nm, > 98% purity) with different surface charges were provided from US Research Nanomaterials, Inc. Laboratory grade Na-bentonite from Dr. Mojallali Industrial Chemical Complex Co. (density 2.5 g/cm3) was used as the clay sample to evaluate the swelling index. Bentonite is composed mainly of montmorillonite which has excellent adsorption properties and high swelling in aqueous solutions. To adjust pH value, hydrochloric acid (0.1 M) and sodium hydroxide (99.99%) were prepared from Merck company. Sodium chloride with 99.99% purity (from Merck) was used to adjust the brines salinity.

Zeta potential analysis was used to determine the surface charge of NPs at different pH values. X-ray diffraction (XRD) and X-ray fluorescence (XRF) analysis were carried out to ensure the composition of bentonite (Table 1). Moreover, XRD analysis was used for the characterization of NPs.

Design of experiments

Numerous experimental tests are needed to investigate the effect of solution salinity, pH value, temperature, and the concentration of NPs on clay swelling index (SI). Instead of performing numerous experimental tests for all possible combinations of parameters, the Taguchi method was used to design experiments to obtain the optimal conditions and save time and expenses (Davis and John 2018; Ackah et al. 2022). Taguchi L-16 orthogonal array for four factors and four levels was selected to reduce the number of experiments. Table 1 shows the details of factors and levels used in the design of experiments. Ranges of each factor are determined based on previous studies and preliminary tests.

ASTM standard method

The measurement of the swelling index was performed based on ASTM D5890-11 which is a standard method for the evaluation of clay swelling (Scalia et al. 2019). First, 2 g of bentonite that passed through an 80-mesh sieve and retained on a 100-mesh sieve was separated using a sieve shaker (Retsch, German). Different aqueous solutions were prepared based on the values of designed factors specified by the design of the experiment in the graduated cylinder. In experiments involving nano-suspension, NPs were dispersed and homogenized using ultrasonic bath sonication (ELMA, German).

When the solution was prepared, four parts of bentonite (each containing 0.5 g) were added in 10 s with 1 min intervals. In the next step, the graduated cylinder was sealed to avoid evaporation of the solution. After 24 h, the volume changes due to bentonite swelling were recorded and the swelling index was calculated using the following equation (Sameni et al. 2015):

where Vf and Vi are final volume of bentonite after hydration and initial volume of bentonite, respectively. Bentonite particles naturally swell when exposed to water, and the presence of salt in water reduces this expansion (Barast et al. 2017; Wan et al. 2020). A salinity test was performed by the ASTM method to evaluate the authenticity of bentonite and its swelling performance in contact with salt water (without the presence of NPs, at a constant temperature of 25 °C and pH 7).

Moreover, the effect of contact time of bentonite and brine was assessed. The designed experiments without and with NPs were performed and the volume changes of bentonite were recorded after passing different times.

Results and discussion

Characterization of bentonite and nanoparticles

XRD analysis was used to evaluate the crystallography and purity of clay samples and metal oxide NPs used in this study. Figure 1 illustrates the XRD pattern of bentonite and NPs against the reference patterns using X’Pert HighScore Plus software. The blue patterns show the characteristic peaks for the standard reference samples and the red curves show the XRD patterns for the samples used in the experiments. In Fig. 1a, the characteristic peaks were observed in the region 4.9° < 2θ < 10° for the pattern of Na-bentonite sample which coincides with the reference pattern. The position of the peaks in Fig. 1a indicates that the bentonite sample is mainly composed of montmorillonite.

The XRD patterns of NPs in Fig. 1b, c show the consistency of the characteristic peaks with the reference pattern and confirm the purity of NPs. For silica NPs, the main characteristic peak occurs at 2θ = 22.3°. For alumina NPs, the pattern peaks are identified as γ-Al2O3 peaks at diffraction angles of 19.4°, 37.6°, 45.8°, and 67.0° (Wang et al. 2016; Madsen et al. 2011).

XRF analysis was also carried out to determine the composition of bentonite. Table 2 shows the percentage of chemical constituents in the bentonite sample. As shown, the total content of SiO2 and Al2O3 is 79.27%, and the ratio of SiO2 to Al2O3 is 4.8 which indicates relatively high-silica montmorillonite. The contents of CaO and Na2O reveal interlayer cations in bentonite samples. The higher content of Na2O compared to CaO indicates that the bentonite sample can be classified as Na-bentonite.

Clay swelling

The ASTM method was used to calculate the volume changes of clay particles in three cases, without NPs, in the presence of SiO2 NPs, and the presence of Al2O3 NPs. First, to find the appropriate contact time for maximum clay swelling, the volume change of the bentonite sample was measured after two different time intervals while other parameters were kept constant. Figure 2a, b illustrates the volume change of clay particles in contact with a solution with salinity of 4000 mg/l, pH equal to 9, and without NPs at ambient temperature after 24 and 72 h, respectively. As can be seen, the changes in bentonite volume were the same after 24 and 72 h which shows that the contact time more than 24 h does not affect on the swelling index. Based on the obtained results, the main volume changes of clay particles occur at initial times of contact with brine. The findings of our experiments were in agreement with the study carried out by Aksu et al. (2015). Accordingly, all the measurements were carried out after 24 h contact time. The results of the experiments performed based on the L-16 orthogonal array are given in Table 3.

Clay swelling without nanoparticles

To compare the impact of NPs on the clay swelling, initially a series of experiments were carried out without NPs. As shown in Table 3, in the absence of NPs, the minimum and maximum swelling index were calculated equal to 0.5 and 4.5 for the suspension of clay particles in solution with the highest salinity and distilled water, respectively.

It is widely known that montmorillonite swelling is decreased by increasing the solution salinity (Hu et al. 2016; Sameni et al. 2015; Anderson et al. 2010). In Fig. 3, the macroscopic swelling of the bentonite samples is shown while the concentration of NaCl is increased from left to right. It was observed that the increase of solution salinity by increasing NaCl concentration results in the reduction of the volume of clay particles. The increase in NaCl concentration leads to the compression of the diffuse double layer and a decrease in the electrostatic repulsion between the clay particles. The increase in cation concentration neutralizes the negative clay surface charge and leads to the deposition of clay particles with low permeability (Shirazi et al. 2011). Clay swelling decreases greatly when sodium ions are replaced by other interlayer cations. This is possibly due to cation fixation and lattice collapse, rendering the interlayer region relatively inaccessible to water penetration (Yotsuji et al. 2021; Chen et al. 2022).

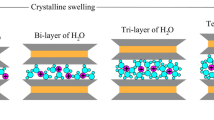

Figure 4(a), demonstrates the influence of pH value on the clay swelling index. As pH changes from the neutral value i.e., pH = 7, the clay swelling tends to increase. The clay swelling results from increased space between structural molecules of clay particles, which depends on the composition of the solution exposed to the clay particles (Sun et al. 2019). Clay swelling occurs based on crystalline and osmotic swelling mechanisms (Wangler 2023). Crystalline swelling is followed by an increase in internal layers’ distance in clay particles, while osmotic swelling is the result of an increase in the distance between clay particles. The hydration capacity of the clay particles and the concentration of cations affects the mentioned mechanisms. The contact of clay particles with a solution containing high amounts of divalent or monovalent cations leads to crystalline swelling. In contrast, osmotic swelling occurs as a result of clay contact with diluted solutions due to the formation of an electrical double layer on the surface of clay particles. Moreover, when the concentration of cations in the interlayer is higher than that of the surrounding water, water molecules diffuse into the interlayer to dilute its ion concentration, restoring cation equilibrium. This phenomenon creates an osmotic repulsive pressure between the clay particles. The osmotic pressure is mainly related to the difference in the ion concentrations between the interlayer and surrounding water. In this way, the distance between clay particles increases greatly, and then the clay swelling is carried out. The osmotic swelling is much more severe and leads to higher clay swelling and, consequently, extensive formation damage (Wilson and Wilson 2014; Anderson et al. 2010). A critical salt concentration is introduced based on which the higher concentrations lead to crystalline swelling, and lower concentrations are accompanied by osmotic swelling (Butscher et al. 2016).

At high salinities, pH value does not have a significant impact on cation exchange capacity and clay swelling index (Baik and Lee 2010; Zhou et al. 2012). The electrical charge on the surfaces and edges of the clay particles may be dissimilar at different pH values. The charge of the clay edges is dependent on pH value due to the aluminol groups (i.e., Al–OH). The attachment of hydrogen ions to the oxygen atoms causes the clay edges to become positively charged at low pH values, while the particles’ surface charge is negative. At higher pH values, the separation of hydrogen ions from the oxygen atoms makes the charge of the clay edges negative i.e., the same as the clay surface charge. Therefore, clay particles arrangement may vary due to the differences in electrical charge on the edges and surfaces of particles. As the pH value decreases, the charge on the edges of clay particles increases, which leads to electrostatic attraction between the edges and surfaces. Therefore, clay platelets are no longer parallel and arranged so that the negative surfaces of one particle are in the vicinity of the positive edges of other particles resulting in particles aggregates and volume increase (Butscher et al. 2016; Chen et al. 2022).

The influence of temperature on the clay swelling was also evaluated. As depicted in Fig. 4b, as the temperature increases the swelling index increases slightly in the absence of NPs. The obtained result is in agreement with previous studies available in the literature. Ishimori and Katsumi (2012) demonstrated that temperature affects more on samples containing electrolytes with higher salinities. Although the interlayer spacing is independent of temperature, higher temperatures cause the clay volume to increase due to an increase in internal and kinetic energy and growth in the frequency of interlayer cations and water molecules (Ishimori and Katsumi 2012; Pham and Nguyen 2014).

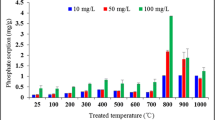

Effect of silica nanoparticles

The values of the clay swelling index at different concentrations of silica NPs are reported in Table 3. The lowest SI was detected for the bentonite samples in contact with solutions that have a salinity of 40,000 ppm in experiments 10, 8, and 1. As expected, the most effective factor on the clay swelling and particles volume change is the electrolyte salinity. The higher the salinity is, the lower the clay swelling index. However, the lowest clay volume change was observed in the presence of 0.1 wt% silica NPs. In terms of cost saving, a lower concentration of NPs with acceptable clay swelling control would be beneficial, while higher concentrations would not provide any additional benefits in terms of SI.

The experimental results revealed that silica NPs have a positive impact on the reduction of clay swelling. A reverse effect was observed only in experiment 4, and the SI increased 42.5% in the presence of 1 wt% NPs compared to the absence of NPs. This observation can be justified by the fact that at higher concentrations, NPs aggregation and sedimentation occur which causes NPs clusters to settle down and finally separate out of the nanofluid. Therefore, high concentrations of NPs not only have no effect on reducing the clay swelling, but also NPs agglomeration causes an increase in volume.

The percentage of clay volume change in the presence of silica NPs compared to the absence of NPs is presented in Table 5. The negative sign indicates a decrease in the clay volume. As can be seen, the highest reduction in SI and the clay volume was detected at a concentration of 0.1 wt% of silica NPs in experiment 10.

To investigate the factors’ impact on the response variable i.e., clay swelling index, ANOVA and main effect plots were used. The experimental results based on the Taguchi orthogonal array were evaluated by analysis of variance to demonstrate the degree of importance of each factor. The mathematical equations applied in ANOVA are as follows (Lee et al. 2013):

where yi is the measured value of the response, t is the number of experiments repetition, n is the number of experiments in the orthogonal array, and m is the number of factors’ levels. (S/N) is the signal-to-noise ratio used to indicate the impact of noise factors on the response variable. The sum of squares (SS) is calculated using Eq. (3) and the percentage contribution of each factor on the response variable is obtained by Eq. (4).

The results of ANOVA for clay swelling index in the presence of SiO2 NPs are reported in Table 6. The percentage contributions of pH, NPs concentration, solution salinity, and temperature are found to be 9.59%, 15.66%, 63.82%, and 3.71%, respectively, and the error is 7.22%. The value of percentage contribution is used to determine the significant influencing factors. The higher the value of the percentage contribution is, the greater the effect of the factor on the response variable.

As shown in Table 6, solution salinity and NPs concentration have the highest impacts on the clay swelling index, followed by pH and temperature. Based on the values of calculated statistical parameters, the electrolyte salinity is the most effective factor on the clay swelling while temperature does not have a significant influence on the volume change of clay particles. In ANOVA, p < 0.05 was considered to be statistically significant, with a 95% confidence level. The values of F and p parameters shown in Table 6, confirm that salinity, NPs concentration, and pH value are three significant factors affecting clay swelling among which salinity is the most effective factor.

The optimal values of factors are those that minimize the clay swelling index. According to the analysis performed in this study, the lowest clay swelling occurs at ambient temperature in the presence of 0.1 wt% silica NPs in a solution with salinity and pH values equal to 40,000 ppm and 7, respectively. To confirm the obtained result, a sample with the optimal values of factors was made and the clay swelling index was calculated at 0.15. Figure 5 illustrates the clay volume change for two different concentrations of silica NPs while other factors were at optimal values. The observed increase in clay volume by increasing NPs concentration was in agreement with the study of Sameni et al. (2015).

The main effect plots for clay swelling in the presence of silica NPs are illustrated in Fig. 6. Since this study is aimed to minimize the clay swelling index, the experiments target was selected to achieve that the smaller is the better. Therefore, the lowest values of SI at all levels were assessed to define the optimal values of affecting factors. The same results as ANOVA were obtained and the optimum combination was determined as A2B2C4D1 (A2 = 7, B2 = 0.1 wt%, C4 = 40,000 ppm, and D1 = 25 °C).

As shown in Fig. 6, similar trends were observed for clay swelling variations against pH value, salinity, and temperature in the presence and absence of silica NPs. However, in the presence of silica NPs, the magnitude of clay swelling is lower relative to brines without NPs at constant values of pH, salinity, and temperature. As can be seen in Fig. 6a, the clay swelling index first decreases and then increases by increasing the concentration of silica NPs. In fact, NPs are effective in clay swelling control at certain concentrations. Increasing the concentration of NPs more than the optimal value has a negative impact on the clay swelling due to the particle’s agglomeration.

The negatively charged clay particles attract a high concentration of cations close to the clay surfaces which is called the diffuse layer. The more cations in the diffuse layer, the more water surrounds the clay particles due to cations hydration and therefore more swelling occurs. Moreover, the repulsion forces between the clay particles increase due to the interaction of diffuse layers, whenever clay particles are close to each other. In a colloidal suspension, attraction forces between particles prevail at short distances regardless of the particles surface charges. The presence of silica NPs with a negative surface charge in the brine compels the clay particles to become close to each other, therefore the attractive forces prevail over the repulsive forces, and particles flocculation occurs.

According to Fig. 6b, as the pH value changes from the neutral value (i.e., pH 7), the clay swelling index increases in the presence of silica NPs. In fact, both acidic and basic pH values increase the clay volume. At low pH values, the critical diameter of silica NPs increases which makes the nanofluid unstable. At high pH values, there are two competing mechanisms affecting the clay swelling. On one hand, an increase in pH value causes the negative surface charge of silica NPs to increase which has a positive effect on reducing clay swelling (Metin et al. 2011). On the other hand, like electrical charges on the edges and surfaces of clay particles promote the clay swelling. However, by comparing Fig. 4a with Fig. 5b, the positive impact of silica NPs in reducing the clay swelling can be found.

Figure 6c, d depicts the impact of salinity and temperature on the clay swelling index in the presence of silica NPs, respectively. As stated before, the trend of SI variations is similar in the presence and absence of NPs. Limited studies on the effect of temperature on clay swelling in the presence of NPs are available in the literature. At elevated temperatures, the increase of kinetic energy and Brownian motion of NPs leads to an increase in particles collision and a further increase in the volume of particles. Increasing the temperature in the presence of NPs caused a significant increase in solution turbidity which can be the result of increased rate of NPs aggregation due to greater kinetic energy at higher temperatures.

Effect of alumina nanoparticles

The values of SI in the presence of alumina NPs at various concentrations are presented in Table 3. As can be seen, the volume change of clay particles exposed to alumina NPs suspensions shows the opposite trend of that in the presence of silica NPs. The percentage of clay volume change in the presence of alumina NPs relative to the solution without NPs is reported in Table 5. The obtained results indicate that minimal change in the clay volume was in experiment 1, where solution salinity has the maximum value and the concentration of NPs has the lowest value. Similar to the results achieved in the presence of silica NPs, the highest increase in SI was observed at a concentration of 1 wt% of alumina NPs in experiment 4. Therefore, the adverse effect of high concentrations of NPs on clay swelling was confirmed.

The obtained results from the analysis of variance for experiments performed in the presence of alumina NPs are given in Table 7. According to ANOVA results, solution salinity and temperature are the most and least effective factors on clay swelling, respectively. The percentage contributions of pH, NPs concentration, solution salinity, and temperature are found to be 8.04%, 19.98%, 57.46%, and 2.89%, respectively, and the error is 11.62%. Similar to the results obtained for silica NPs, the values of F and p parameters reveal that salinity, NPs concentration and pH value are three significant factors affecting the clay swelling in the presence of alumina NPs. According to the results, the lowest clay swelling occurs for a sample containing 0.05 wt% alumina NPs at ambient temperature with salinity and pH values equal to 40,000 ppm and 11, respectively.

Figure 7 illustrates the main effect plots for clay swelling in the presence of alumina NPs. The mean values of four affecting factors including pH value, NPs concentration, salinity, and temperature at each level were evaluated. Similar to ANOVA results, the optimum condition for minimum clay swelling was determined as A4B1C4D1 (A4 = 11, B1 = 0.05 wt%, C4 = 40,000 ppm, and D1 = 25 °C).

Figure 7a shows that SI increases in the presence of alumina NPs. In fact, alumina NPs with positive surface charge in a wide pH range (i.e., pH values lower than 10), attract the negatively charged clay particles and increase the clay particles’ dispersion. Therefore, increasing the concentration of alumina NPs increases the clay swelling. The impact of pH value on the clay swelling in the presence of alumina NPs is illustrated in Fig. 7b. Similar results to silica NPs were detected. The clay swelling index increases in the presence of alumina NPs by deviation of pH from neutral value except for pH values higher than 9. The decrease in clay swelling at high pH values can be justified by changing the surface charge of alumina NPs.

Zeta potential measurements for NPs at different pH values are reported in Table 8. As can be seen, the positive surface charge of alumina NPs changes to negative at high pH values. The presence of NPs with negative surface charge in the solution helps to decrease the clay particles swelling due to similar charge repulsion. This effect is clear in Fig. 7b at a pH value of 11. Figure 7c shows the salinity effect on the clay swelling in the presence of alumina NPs. As expected, the increase of solution salinity results in the reduction of clay swelling due to the increase of cations concentration. The variations of the clay swelling index in Fig. 7d indicate the minor impact of temperature on the clay volume change in alumina nanofluid.

Figure 8 compares the effect of NPs on the clay swelling index at different values of affecting factors. It can be seen that the presence of silica NPs has a positive effect on the reduction of the clay swelling index. As stated before, the minimum SI is achieved at maximum salinity, neutral pH value, and ambient temperature. The variations of clay swelling at different amounts of NPs indicated that there is an optimum concentration in which the clay swelling index is minimum, and 0.1 wt% were determined as the optimum value for silica NPs. The findings would help to optimize the conditions for a lower risk of formation damage due to clay swelling.

Conclusions

In this study, the impact of NPs as clay swelling inhibitor for reducing and preventing water sensitivity damage in clayey formations was investigated. The influence of effective factors including pH value, aqueous solution salinity, temperature, and the concentration of two types of metal oxide NPs on the clay swelling was studied. Taguchi experimental design was applied to decrease the number of experimental tests and optimize the conditions for minimal clay swelling. The main findings of this study are as follows:

-

Silica NPs with negative surface charge reduce the clay swelling up to an optimum value of NPs concentration which was found to be 0.1 wt%. It was confirmed that high concentrations of NPs not only have no effect on reducing the clay swelling but also cause an increase in volume due to NPs agglomeration.

-

In the presence of alumina NPs with a positive surface charge, an inverse effect was detected and the clay swelling index increased compared to the electrolyte alone.

-

Zeta potential measurements for alumina NPs indicated that as the positive surface charge of alumina NPs changes to negative at high pH values, clay swelling decreases as a result of similar charge repulsion.

-

According to ANOVA results, solution salinity and NPs concentration have the highest impacts on the clay swelling, followed by pH and temperature.

-

In the presence of NPs, the influence of pH on the swelling index was found due to changes in the NPs’ surface charge.

-

The swelling inhibition effect of NPs decreases by increasing the temperature due to higher NPs collision and aggregation.

Our findings confirm the inhibition effect of NPs at low concentrations on clay swelling. However, the type of NPs should be further studied in the future.

Data availability

The data that support the findings of this study are available within the article.

References

Abdullah AH, Ridha S, Mohshim DF, Yusuf M, Kamyab H, Krishna S, Maoinser MA (2022) A comprehensive review of nanoparticles: effect on water-based drilling fluids and wellbore stability. Chemosphere 308:136274

Ackah FS, Hailiang W, Huaiping F, Cheng L, Feng LZ (2022) Use of Taguchi method to evaluate the unconfined compressive strength of quicklime stabilized silty clayey subgrade. Case Stud Constr Mater 17:e01417

Akhtarmanesh S, Shahrabi MA, Atashnezhad A (2013) Improvement of wellbore stability in shale using nanoparticles. J Petrol Sci Eng 112:290–295

Aksu I, Bazilevskaya E, Karpyn ZT (2015) Swelling of clay minerals in unconsolidated porous media and its impact on permeability. GeoResJ 7:1–13

Anderson R, Ratcliffe I, Greenwell C, Williams P, Cliffe S, Coveney P (2010) Clay swelling—a challenge in the oilfield. Earth Sci Rev 98(3):201–216

Asaad A, Hubert F, Ferrage E, Dabat T, Paineau E, Porion P, Savoye S, Gregoire B, Dazas B, Delville A, Tertre E (2021) Role of interlayer porosity and particle organization in the diffusion of water in swelling clays. Appl Clay Sci 207:106089

Baik MH, Lee SY (2010) Colloidal stability of bentonite clay considering surface charge properties as a function of pH and ionic strength. J Ind Eng Chem 16(5):837–841

Balaban RC, Vidal ELF, Borges MR (2015) Design of experiments to evaluate clay swelling inhibition by different combinations of organic compounds and inorganic salts for application in water base drilling fluids. Appl Clay Sci 105:124–130

Barast G, Razakamanantsoa A, Djeran-Maigre I, Nicholson T, Williams D (2017) Swelling properties of natural and modified bentonites by rheological description. Appl Clay Sci 142:60–68

Berry SL, Boles JL, Brannon HD, Beall BB (2008) Performance evaluation of ionic liquids as a clay stabilizer and shale inhibitor. In: SPE international symposium and exhibition on formation damage control, Lafayette, Louisiana, USA

Butscher C, Mutschler T, Blum P (2016) Swelling of clay-sulfate rocks: a review of processes and controls. Rock Mech Rock Eng 49:1533–1549

Chen G, Yana J, Lili L, Zhang J, Gu X, Song H (2017) Preparation and performance of amine-tartaric salt as potential clay swelling inhibitor. Appl Clay Sci 138:12–16

Chen WL, Grabowski RC, Goel S (2022) Clay swelling: role of cations in stabilizing destabilizing mechanisms. ACS Omega 7(4):3185–3191

Cheraghi M, Hajipour M, Emamzadeh A (2022) Enhancement of the heat capacity of water-based drilling fluids for deep drilling applications. Braz J Chem Eng 39:77–86

Cong M, Zhao B, Long G, Sang X, Xie Y (2018) Quantitative study on strength development of earth-based construction prepared by organic clay and high-efficiency soil stabilizer. Constr Build Mater 174:520–528

Davis R, John P (2018) Application of taguchi-based design of experiments for industrial chemical processes. In: Valter Silva (ed) Statistical approaches with emphasis on design of experiments applied to chemical processes. IntechOpen

El-Diasty AI, Ragab AM (2013) Applications of nanotechnology in the oil and gas industry: latest trends worldwide and future challenges in Egypt. In: North Africa technical conference and exhibition, Cairo, Egypt

Fu L, Liao K, Ge J, Zhang G, He Y, Wang X, Zhang S, Deng S (2019) Study of ethylenediammonium dichloride as a clay stabilizer used in the fracturing fluid. J Petrol Sci Eng 179:958–965

Habibi A, Ahmadi M, Pourafshary P, Ayatollahi S, Al-Wahaibi Y (2013) Reduction of fines migration by nanofluids injection: an experimental study. SPE J 18:309–318

Hajipour M (2020) CFD simulation of turbulent flow of drill cuttings and parametric studies in a horizontal annulus. SN Appl Sci 2:1146

Hajipour M, Movahedi H, Jamshidi S (2023) Evaluation of the effect of metal oxide nanoparticles in combination with polyacrylamide on improving the filtration and rheological properties of drilling fluids. J Miner Resour Eng 8(1):1–16

Hoelscher KP, De Stefano G, Riley M, Young S (2012) Application of nanotechnology in drilling fluids. In: SPE international oilfield nanotechnology conference and exhibition. Society of Petroleum Engineers

Hu X, Hu S, Jin F, Huang S (eds) (2016) Physics of petroleum reservoirs. Springer mineralogy. Springer, Berlin

Ishimori H, Katsumi T (2012) Temperature effects on the swelling capacity and barrier performance of geosynthetic clay liners permeated with sodium chloride solutions. Geotext Geomembr 33:25–33

Jain R, Mahto V, Sharma VP (2015) Evaluation of polyacrylamide-grafted-polyethylene glycol/ silica nanocomposite as potential additive in water based drilling mud for reactive shale formation. J Nat Gas Sci Eng 26:526–537

Khan MA, Haneef J, Lalji SM et al (2021) Experimental study and modeling of water-based fluid imbibition process in Middle and Lower Indus Basin Formations of Pakistan. J Petrol Explor Prod Technol 11:425–438

Lalji S, Ali S, Ahmed R et al (2022a) Study the effects of mineral content on water diffusion mechanism and swelling characteristics in shale formations of Pakistan. Arab J Geosci 15:864

Lalji SM, Ali SI, Ahmed R et al (2022b) Influence of graphene oxide on salt-polymer mud rheology and Pakistan shale swelling inhibition behavior. Arab J Geosci 15:612

Lee DH, Park JS, Ryu MR, Park JH (2013) Development of a highly efficient low-emission diesel engine-powered cogeneration system and its optimization using Taguchi method. Appl Therm Eng 50(1):491–495

Madsen I, Scarlett N, Kern A (2011) Description and survey of methodologies for the determination of amorphous content via X-ray powder diffraction. Zeitschrift Fur Kristallographie 226:944–955

Mao H, Huang Y, Luo J, Zhang M (2021) Molecular simulation of polyether amines intercalation into Na-montmorillonite interlayer as clay-swelling inhibitors. Appl Clay Sci 202:105991

Metin CO, Lake LW, Miranda CR, Nguyen QP (2011) Stability of aqueous silica nanoparticle dispersions. J Nanopart Res 13(2):839–850

Mohan KK, Vaidya RN, Reed MG, Fogler HS (1993) Water sensitivity of sandstones containing swelling and non-swelling clays. Colloids Surf A 73:237–254

Movahedi H, Jamshidi S, Hajipour M (2022) Hydrodynamic analysis and cake erosion properties of a modified water-based drilling fluid by a polyacrylamide/silica nanocomposite during rotating-disk dynamic filtration. ACS Omega 7:44223–44240

Pham H, Nguyen QP (2014) Effect of silica nanoparticles on clay swelling and aqueous stability of nanoparticle dispersions. J Nanopart Res 16:2137

Sameni A, Pourafshary P, Ghanbarzadeh M, Ayatollahi S (2015) Effect of nanoparticles on clay swelling and migration. Egypt J Pet 24(4):429–437

Scalia J, Benson C, Finnegan M (2019) Alternate procedures for swell index testing of granular bentonite from GCLs. Geotech Test J 42(5):20180075

Sensoy T, Chenevert ME, Sharma MM (2009) Minimizing water invasion in shale using nanoparticles. In: SPE annual technical conference and exhibition, New Orleans, Louisiana

Sharifipour M, Pourafshary P, Nakhaee A (2017) Study of the effect of clay swelling on the oil recovery factor in porous media using a glass micromodel. Appl Clay Sci 141:125–131

Shirazi SM, Wiwat S, Kazama H, Kuwano J, Shaaban MG (2011) Salinity effect on swelling characteristics of compacted bentonite. Environ Prot Eng 37(2):65–74

Sruthi PL, Reddy PHP (2019) Swelling and mineralogical characteristics of alkali-transformed kaolinitic clays. Appl Clay Sci 183:105353

Sun C, Li G, Sun Y, He J, Rong H (2019) Modelling hydration swelling and weakening of montmorillonite particles in mudstone. Processes 7(7):428

Swai RE (2020) A review of molecular dynamics simulations in the designing of effective shale inhibitors: application for drilling with water-based drilling fluids. J Petrol Explor Prod Technol 10:3515–3532

Valadbeygian V, Hajipour M, Behnood M (2023) Static and dynamic evaluation of formation damage due to barium sulfate scale during water injection in carbonate reservoirs. J Petrol Explor Prod Technol 13(8):1819–1831

Wan Y, Guo D, Hui X, Liu L, Yao Y (2020) Studies on hydration swelling and bound water type of sodium and polymer-modified calcium bentonite. Adv Polym Technol 2020:9361795

Wang Z, Wu W, Bian X, Wu Y (2016) Synthesis and characterization of amorphous Al2O3 and γ-Al2O3 by spray pyrolysis. Green Process Synth 5(3):305–310

Wangler T (2023) Mechanism of clay swelling in Villarlod molasse: a Swiss sandstone. Environ Earth Sci 82:259

Wilson MJ, Wilson L (2014) Clay mineralogy and shale instability: an alternative conceptual analysis. Clay Miner 49(2):127–145

Yin C, Zhang W, Jiang X, Huang Z (2018) Effects of initial water content on microstructure and mechanical properties of lean clay soil stabilized by compound calcium-based stabilizer. Materials 11(10):1933

Yotsuji K, Tachi Y, Sakuma H, Kawamura K (2021) Effect of interlayer cations on montmorillonite swelling: comparison between molecular dynamic simulations and experiments. Appl Clay Sci 204:106034

Zaitoun A, Berton N (1992) Stabilization of montmorillonite clay in porous media by high-molecular-weight polymers. SPE Prod Eng 7:160–166

Zhou D, Abdel-Fattah AI, Keller AA (2012) Clay particles destabilize engineered nanoparticles in aqueous environments. Environ Sci Technol 46(14):7520–7526

Funding

No funding was received for this work.

Author information

Authors and Affiliations

Contributions

Ali Kianersi and Mastaneh Hajipour wrote the main manuscript text and prepared figures. Mastaneh Hajipour and Ebrahim Biniaz Delijani interpreted the results and reviewed the manuscript.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Kianersi, A., Hajipour, M. & Biniaz Delijani, E. Experimental evaluation of bentonite clay swelling and inhibition effect of nanoparticles. Environ Earth Sci 82, 526 (2023). https://doi.org/10.1007/s12665-023-11210-9

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s12665-023-11210-9