Abstract

Greenish glauconitic sandstones from the Middle Member of the Godula Formation of the Outer Western Carpathians flysch belt represent traditional building stone used in the north-eastern part of the Czech Republic and adjoining part of south Poland for about a thousand years. Despite the longstanding history of their utilisation in constructions and monuments, the amount of information about properties, durability and places of use is given in the existing literature only to a very limited extent. The Godula sandstones under study exhibit a high bulk density (up to 2610 kg/m3), relatively low water absorption capacity (0.7–3.0 wt%) and total porosity (1.7–9.4%), high values of P-wave velocity within psammitic rocks (3120–4290 m/s), and high to very high strength (uniaxial compressive strength 102.7–155.8 MPa, splitting tensile strength 4.0–10.0 MPa). However, in contrast to high quality of stone properties, the degree of their durability especially in the case of exterior use may often be very low, and stone deterioration can frequently advance very rapidly. Godula sandstones are characterised by a significant dominance of pores with diameter smaller than 1 μm. The character of pore space represents the principal and general reason of Godula sandstone deterioration susceptibility. Deterioration rate and specific weathering forms are subsequently strongly affected, in detail, by the heterogeneity of the mineralogical composition and anisotropy of rock texture within the individual sandstone bed. The data about composition, properties and stability of the Godula sandstones published in this paper could help architects or designers to understand the decay causes experienced by these types of sandstones and how to prevent them and may also serve as a guide for restoration and conservation works.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Sandstones represent the most common and, especially in the past, the most widely used building, decorative and sculpture stones in the Czech Republic. In view of the extent of quarrying and the range of construction uses, the Upper Cretaceous sandstones of the Bohemian Cretaceous Basin were and still are critically important. These light-coloured, quartz to arkosic sandstones are traditionally quarried, in particular, in the Eastern Bohemia near the towns of Hořice, Dvůr Králové-nad-Labem and Broumov (Hanisch and Schmid 1901; Rybařík 1994; Přikryl et al. 2004).

Greenish glauconitic sandstones are also quarried, to a lesser extent, and may have a local significance for building and architectural purposes. In the Czech Republic, glauconitic sandstones are currently quarried at two sites, namely in the Záměl quarry in Eastern Bohemia (Záměl sandstone, Martinec et al. 2010) and in two quarries in the Řeka municipality (Godula sandstones) close to the Czech–Polish border. The clay-rich Zápy sandstone largely applied, for instance, in the Gothic part of St. Vitus Cathedral in Prague belongs among currently unexploited glauconitic sandstones of the Czech Republic (Šrámek 2005; Rybařík 2011). In the past, the so-called malnický řasák (in Czech řasa = green algae), glauconitic sandstone from the vicinity of the Malnice municipality (about 55 km NW from Prague) was also known and locally used in a limited way. In general, glauconitic sandstones are relatively less encountered in Europe (Banerjee et al. 2016) and that is why the usage of these sandstones in constructions is not common here. Apart from the Eastern Bohemia and the Western Carpathian regions, the green glauconitic sandstones have been used, for example, in West Switzerland in the Lausanne and Bernese regions (Bläuer 1985).

Greenish glauconitic Godula sandstones of the Campanian age represent a traditional building and decorative stone, which have been widely used in the areas of Czech Silesia, the Polish part of Teschen Silesia and the Cracow region for about a thousand years. Despite the longstanding history of their utilisation, the knowledge about properties, resources, exploitation and usage for building and artistic purposes is highly fragmentary. This paper therefore aims to bring together an overview of recent knowledge about composition, material properties, geological situation of Godula sandstone deposits, quarrying history and building and sculptural utilisation of Godula sandstones on Czech as well as Polish territory.

One of characteristic feature of the Godula sandstones is their susceptibility for weathering. A lot of considerable problems with their durability especially when used in exterior have occurred recently. In contrast to the primarily high quality of physical and mechanical properties of the Godula sandstones, stone deterioration can frequently advance very rapidly. This paper contributes to the explanation of the basic causes of this phenomenon. A detailed analysis of green glauconitic Godula sandstones from the Řeka quarry (approximately 30 km SE from Ostrava, Moravian-Silesian Region, Czech Republic) has been performed, in particular with regard to their mineralogical composition, physical and mechanical properties, porosity and grain size distribution. The present study summarises the results of the first, more than 15-year exceeding stage of the study of the Godula sandstones covering their basic material characterisation and explanation of main causes of stone deterioration. Because these sandstones are typical gravity-flow sediments, the further research will be focused mainly on a detailed study of the relationship between stone durability and its vertical position within specific rock bed. The methods of the study for this forthcoming research stage are therefore indicated in the discussion.

Exploitation and use of Godula sandstones

History of quarrying

The beginning of the exploitation and utilisation of green glauconitic Godula sandstones in the Moravian-Silesian Beskids Mountains in the Czech Republic and in Beskid Śląski, Beskid Mały and Pogórze Lanckorońskie Mountains in Poland has not been precisely determined yet. With regard to the foundation of the castellan fortification of Teschen as a significant administrative and economic centre of the Upper Silesia at the turn of the tenth and eleventh centuries (Jirásek et al. 2012), the local sandstone resources had already been discovered and quarried during the early medieval times. The assumption of the long-term exploitation and use of these sandstones agrees with the findings of Rajchel (2002); Godula sandstones, together with other Outer Carpathians sandstones of the Istebna Formation, represent the earliest stones used in the architecture of Cracow since the pre-Romanesque times.

The huge expansion of the quarrying of the Godula sandstones and their use as building and decorative stones notably began at the end of the nineteenth century. For example, Hanisch and Schmid (1901) describe, in their inventory of quarries of the Austro-Hungarian monarchy, 11 quarries only in the relatively small area around Biała, Straconka, Wilkowice, Brenna, Wisła and Ustroń in the current Polish territory, and four quarries in the close vicinity of the Řeka village on the adjacent Czech side. Rajchel (2002) quotes the figure of Bolewski (1954) of about 50 large quarries working at the end of nineteenth century in the Cracow (Małopolska) region, producing annually about 20,000 m3 of stone blocks from the Godula and Istebna sandstones.

During the twentieth century, the number of active quarries situated in the middle part of the Godula Formation has been gradually decreasing together with the stone production in the territory of Czechoslovakia or the Czech Republic, respectively (Menčík et al. 1983; Rybařík 1994; Pospíšil 2004). From a range of historical localities (Procházka 1910; Jahn 1917; Kühnel 1958; Roth et al. 1962; Rybařík 1994) where the Godula sandstones were exploited in the course of the twentieth century, only two quarries in the Řeka village are continuously active. Another one quarry in Trojanovice municipality works only episodically.

Different situations exist in Poland where the centuries-old tradition of the production of Godula sandstones blocks has remained unchanged for the last hundred years (Figarska-Warchoł and Matlak 2012). In the 1950s and 1960s, more than 20 quarries in the immediate surroundings of Brenna were active. From 2000 to 2010, eight quarries (e.g. Głębiec, Tokarzówka, Cisowa, etc.) in this critical Polish area of Godula sandstones production were still open (Jonczy 2000; Łukasiak 2010, 2013; Figarska-Warchoł and Matlak 2012).

Documented uses and monuments built of Godula sandstones

Godula sandstones have been used as building, decorative and sculpture stones for about a thousand years. Their application in civil engineering and architecture is limited exclusively to the areas situated near the quarrying sites, i.e., they represent the typical local stone of the Ostrava region, Teschen Silesia and western and southern parts of the modern Lesser Poland Voivodeship (Małopolska). According to the unpublished data of Tyrowicz cited by Rajchel (2002), the Godula sandstones are included in the pre-Romanesque and Romanesque structures of the Wawel castle, the Rotunda of the Virgin Mary and the first two Romanesque cathedrals at Wawel Hill in Cracow. The greenish Godula sandstones can also be found in the structures of the finest Renaissance Sigismund chapel and Vasa chapel of the Wawel cathedral (Rajchel 2008). During the so-called Wallachian colonisation of the Beskids Mountains in the sixteenth to eighteenth centuries, the Godula sandstones became a commonly used building material also in rural architecture. However, the use of the Godula sandstones in constructions expanded significantly in the course of the second half of the nineteenth and the twentieth century. During this period, they were used in many places in Poland, e.g., Warszawa, Wrócław, Cracow, Wadowice, Kalwaria Zebrzydowska, Chorzów, Bielsko-Biała, Skoczów, Ustroń, Wisła and Cieszyn (Kamieński et al. 1968; Rajchel 2002; Buciak 2012), and in the territory of the Czech Republic, especially in Ostrava, Karviná, Třinec, Český Těšín, Petřvald and Frýdek (Hanisch and Schmid 1901; Rybařík 1994). Their use in construction elsewhere in the Czech Republic (e.g. in Brno, Zlín, Pardubice and Cheb) is rarer (Bretfeld 1956; Rybařík 1994). Since the 1990s, the Godula sandstones have been widely used in the Moravian-Silesian Region of the Czech Republic, mainly for reconstruction purposes (e.g. railway stations in Ostrava, squares and pedestrian zones in Frýdek-Místek and Opava). They have also been utilised for the construction of new structures, for example, the complex of the Regional Research Library and Jewish cultural centre with a new synagogue in Liberec built in 2000. Outside the Czech Republic or Poland, the Godula sandstones were used, for example, as a cladding material in the Škoda Pavilion at Autostadt near Wolfsburg in Germany, consisting of the sandstone from the Řeka quarry (Pospíšil 2004) or the coating of the facade of the theatre and library complex in St. Quentin-en-Yvelines near Paris in France, which was made from the sandstone from the Głębiec quarry in Brenna (Czyżewski 1998).

Contrary to, for example, the sandstones of the Czech Cretaceous Basin, the Godula sandstones do not represent a typical and widely used stone for sculptural purposes due to the physical and mechanical properties. However, it has been recently confirmed by petrographic and chemical analyses (Šrámek 2002) that fine-grained glauconitic sandstone, which is very similar in mineralogical and chemical composition and in texture to the currently mined sandstones in the Řeka quarry, was used as sculptural material for the unique statue of Madonna of Teschen (or Madonna from Old Market Square, according to Kwaśny (2002)). This Gothic sculpture, discovered unexpectedly in 2000, has been recognised as the oldest stone Madonna statue made by Peter Parler’s workshop. According to the similarity with the stone busts of the four wives of the emperor Charles IV in the choir triforium of the St. Vitus Cathedral in Prague, it has been assumed that its origins date back to the mid-1370s (Kwaśny 2002; Hlobil 2002). The Gothic tombstone of Premyslaus I Noszak, Duke of Teschen from 1358 to 1407, situated in the Dominican church of Teschen (Cieszyn), which is probably the work of Peter Parler’s workshop too, was made from the Godula sandstones as well (Kwaśny 2002; Šrámek 2002). In the nineteenth century, the Godula sandstones were used, for example, for the manufacture of the altar and pulpit of the St. Albrecht´s church in Třinec, built in the Neo-Gothic style from 1882 to 1885. Works of Vladislav Gajda made in the 1960s and 1970s installed in Ostrava, Orlová, Opava and Zubří cities are examples of the use of the Godula sandstones in modern Czech sculpture.

Materials and analytical methods

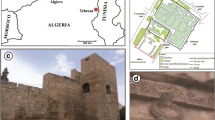

To prepare test specimens as well as thin sections, rock blocks of glauconitic Godula sandstones were extracted from the Řeka quarry (Fig. 1).

Properties of the above-mentioned material were studied using the following methods and equipment:

-

Optical microscopy Petrographic analyses were performed on thin sections using an optical polarising microscope NIKON Eclipse LVDIA-N with the aid of the NIS-Elements microscope imaging software platform (Nikon Metrology NV). Planimetry of the Godula sandstone thin sections was performed using a point counter of Eltinor type. In total, about 1500 point measurements were taken on each thin section.

-

X-ray computed micro-tomography (X-ray CT) The X-ray CT study of the internal texture of sandstones was conducted using an XT H 225 ST industrial micro-tomographic system made by Nikon Metrology NV. It is a fully automated apparatus with a rotating scanning system equipped with a micro-focal X-ray source, which generates cone-shaped beams. Micro-tomograph is equipped with X-ray flat panel detector of area 400 × 400 mm and with number of pixels 2000 × 2000 (4 million). Studied samples were reconstructed using the CT Pro 3D software (Nikon Metrology NV). The visualisation and analysis software VGStudio MAXx 2.2 (Volume Graphics GmbH, Germany) was used for subsequent imaging.

-

Mercury intrusion porosimetry (MIP) MIP was carried out on cut samples with volumes of approximately 2000 mm3 (10 × 10 × 20 mm) using an AutoPore 9500 porosimetry analyser (Micromeritics Instrument Corporation, USA). This device is able to operate with pressures which allowed for the detection of pores with diameters between 5.5 nm and 360 μm.

-

X-ray fluorescence (XRF) analysis For XRF studies, the DELTA Premium Handheld XRF Analysers (Olympus) was used in the field. This device provides immediate results of quantitative chemical composition of rocks and therefore allows prompt identification of differences in rock chemistry within the rock body.

-

Determination of time-dependent water absorption capacity and evaporation The long-term process of saturation and evaporation of Godula sandstones was studied according to the internal methodology of the Institute of Geonics of the CAS, v. v. i. (Martinec et al. 2014, unpublished). Cylindrical specimens with a diameter of 46 mm and a height of 92 mm were drilled out of the rock blocks perpendicularly to the bedding planes. Then, the specimens were gradually saturated under stable laboratory conditions with distilled water at the level of 1/3, 2/3 and 3/3 of the specimen height until weight stabilisation occurred. At defined intervals, the weight of the specimens was measured and its increment was calculated. After full saturation by water, the mass loss due to the evaporation from the free surface of the specimen was determined at an ambient temperature of 25 ± 3 °C until weight stabilisation.

-

Determination of physical and mechanical properties of rocks Material characteristics of Godula sandstones were tested according to standard procedures represented by relevant European standards and suggested testing methods of the International Society for Rock Mechanics. Mechanical properties of Godula sandstones were determined by computer controlled mechanical presses FPZ 100 (VEB TIW Rauenstein Thüringer, Germany) and ZWICK 1494.

Geology of Godula sandstone deposits in the Czech–Polish region of the Beskids Mountains

Geological setting

Upper Cretaceous Godula sandstones represent a dominant lithological type of the Middle Member of the Godula Formation, which represents one of the well-exposed parts of the Silesian Unit of the Outer Western Carpathians flysch belt of Central Europe. The Middle Godula Member represents a medium- to thick-bedded sandstone succession and is interpreted as synorogenic, deep-marine, gravity-flow flysch (turbiditic) sediments of the Lower–Upper Campanian age (for more detail, see Skupien and Mohamed 2008; Šimíček and Bábek 2015). The greenish, glauconite-rich sandstones up to fine-grained conglomerates form clearly separated beds with a thickness of up to several metres and are regularly alternated with the layers of grey to brown-grey or green-grey sandy siltstones and claystones (shales) in the thick flysch sequence. Individual sedimentary bodies of sandstones differ from each other in terms of mineralogical composition, colour, texture and thickness. Typical positive graded bedding is often developed within the sandstone beds; thus, the base of the layer is formed by very poorly sorted, coarse-grained sandstones to conglomerates with sandy matrix. The central part of the bed is formed by fine- to medium-grained, poorly sorted glauconitic sandstone with a massive texture. At the top of the body, there is a growing content of clay matter (illite and illite–smectite). Laminated bedding at the top part of the body is frequent, and the size of clastic grains is smaller in relation to the middle part of the sedimentary body. The Godula sandstones are mostly monotonous green-grey to blue-grey, and, in the upper, fine-grained (silty) parts, even brown-grey.

Mineralogy and petrology of the Godula sandstones

The modal mineralogical composition of sandstones from the Middle Godula Member is relatively monotonous. Based on the planimetric analyses made by Šimíček and Bábek (2015), most of the sandstone samples taken from outcrops in the area of the Moravian-Silesian Beskids Mountains in the Czech territory correspond to the subarcose and/or feldspathic litharenite fields, according to Folk´s classification diagrams (Folk 1974). Samples of quartz arenite and/or arcose composition are less common. The average content of the major sandstone components are ca 72% quartz, ca 23% feldspars and 5% rock fragments (lithic clasts). A similar petrographic composition of the Godula sandstones has been determined in the Polish area (Kamieński et al. 1967, 1968; Jonczy 2000).

Studied glauconitic sandstones from the Řeka quarry are mainly formed by stable quartz grains (ca 40–60%, monocrystalline vs. polycrystalline grains = 3–5:1). The quartz grains are subangular to subrounded in shape with, usually, a low degree of sphericity (0.4–0.8). The average grain size (Md) of quartz grains ranged from 0.18 mm to 0.39 mm. The distinct bimodal distribution of the grain size of the quartz fragments is often visible, the rock is medium to poorly sorted. Non-stable fragments are formed mainly by feldspars (ca 7–15%), and less frequently by micas flakes (ca 5%, muscovite > biotite). Feldspar grains are angular to subrounded with Md = 0.17–0.32 mm. The ratio between K-feldspar and plagioclase is variable; generally, the plagioclase (polysynthetically twinned oligoclase-andesine) occurs less often than the potassium feldspar. Both feldspars are at different stages kaolinised and sericitised, rarely also glauconised. Mica flakes reach up to 0.5 mm in size, and biotite is often chloritised and baueritised. Lithic clasts (5–20%) are represented mainly by subangular to subrounded fine-grained quartzite with similar grain sizes and degrees of sphericity to the quartz grains. Other rock fragments include schists, sandstones, cherts, volcanic rocks and limestone. In some samples, the microfossils are relatively common.

A clay matrix (10–20%) is formed by dominant illite (cf. Plevová et al. 2011), as well as very low content of kaolinite and a varying content of illite–smectite mixed-layers with a low content of smectite phase (mainly in thin laminas at the top of the sedimentary body). Small subrounded to rounded pellets of authigenic glauconite (up to 0.7 mm, 1–5% vol, see Fig. 2) occur frequently. There are no signs of glauconite oxidation in the thin sections. Rock cement includes early diagenetic quartz, a very variable content of authigenic calcite and dolomite (up to 5–10% vol.), and traces of fine-grained pyrite. Fe oxyhydroxides (“limonite”) are very finely dispersed in the intergranular space or rarely fill the pores. Accessories in the form of heavy minerals are mainly represented by zircon, tourmaline and apatite.

Rock texture is psammitic, subangular and poorly sorted, with long (flattened) to partly sutured grain contacts. A fine-grained matrix fills, in particular, the pores between touching sandy clasts. In general, these types of grain-to-grain contacts, and the low degree of sorting and textural maturity, determine the high compactness, low total porosity and high strength of the Godula sandstones, which has been already stated by Kühnel (1958).

Geochemistry

The chemical composition of the Godula sandstones published by several authors, presented in Table 1, reflects their modal mineralogy. The values of SiO2 are lower than 80% and are associated with the lower content of detrital quartz to the detriment of non-stable fragments. Conversely, the higher values of Al2O3 (ca 5–8%) and alkali metal oxides (Na2O and K2O) are in accordance with the presence of feldspars and white micas (muscovite, sericite and illite) identified by mineralogical analyses. The Na2O/K2O ratio, which is generally lower than 1.0, simultaneously shows the predominance of the potassium feldspars over the plagioclases within feldspars. The content of CaO is varying and corresponds, in particular, to the presence of calcite in the rock cement and/or limestone fragments. Fe oxides are concentrated in glauconite, fine-grained pyrite and “limonite”. The Godula sandstones can be classified as subarkoses to litharenites, according to the geochemical classifications of Pettijohn et al. (1972) and Herron (1988), based on the relations between the SiO2/Al2O3 ratio vs. the Na2O/K2O ratio, and the SiO2/Al2O3 ratio vs. the Fe2O3/K2O ratio, respectively. The low values of the SiO2/Al2O3 ratio (from 10.40 to 17.11) simultaneously confirm the relatively lower degree of chemical maturity of the Godula sandstones. The weathering potential index (WPI) calculated according to Reiche (1943) with values of 4.00 and 10.30% indicates the medium to high reactivity of the Godula sandstones during weathering.

Physical and mechanical properties of the Godula sandstones

Basic physical and mechanical properties of the Godula sandstones were tested on blocks of irregular shape and size from 0.4 to 0.7 m taken from the active Řeka quarry (49.6438972 N, 18.5743436 E). The results determined in the laboratories at the Institute of Geonics of the Czech Academy of Sciences, v. v. i., are shown in Table 2. The table also presents their comparison with the properties of the Godula sandstones exploited in the Głębiec quarry (municipality of Brenna, Poland), which were previously published in the Polish literature (Kamieński et al. 1968; Jonczy 2000). The great circle distance between both quarries is approximately 25 km.

Cylindrical samples were subsequently drilled from the blocks in the laboratory. The drilling was carried out perpendicular to the bedding planes. The ends of the cylindrical cores were finally cut perpendicularly to the length, so that the length-to-diameter ratio (slenderness ratio) was about 4, 2 and 0.5, respectively. The cylindrical specimens (48 mm in diameter, 96 mm high) were used to determine the index physical properties (specific and bulk densities, water absorption capacity and porosity) and uniaxial compressive strength (UCS). Tensile splitting strength, determined by the Brazilian test, was measured on disc-like specimens (48 mm in diameter, 24 mm thick). Flexural strength and fracture toughness were measured on long-cylindrical specimens (48 mm in diameter, 192 mm long).

In terms of the physical and mechanical properties given in Table 2, the Godula sandstones can be characterised as sandstones having a high value of bulk density, a relatively low absorption capacity and total porosity, high abrasion resistance in laboratory conditions, high to very high values of strength properties and high fracture toughness. Due to the high compactness (see Figs. 3, 4) and strength, they are polishable in relatively good quality, as one of few types of sandstones currently mined in the Czech Republic. Based on the data presented in Table 2, the similarity of physical and mechanical properties of the Godula sandstones taken from both the Czech and Polish localities is obvious. However, it is important to consider the scattering of measured values of some properties, which often ranged in wide intervals (see, e.g. values of the bulk density from ca 2270 to 2610 kg/m3 in the sandstones from the Řeka quarry or the UCS ranging from ca 60 to 200 MPa in the sandstones from the Głębiec quarry). This is because the Godula sandstones are typical rhythmical flysch sediments with frequent graded bedding. Therefore, their properties vary not only within individual beds, but they are, first of all, significantly affected by the position of tested samples in a particular sandstone bed.

X-ray CT image (XY plane) and pore size analysis of the internal texture of Godula sandstone illustrating the presence of small, more frequently isolated, intergranular pores. Pores are highlighted in white colour. a Projection of pores in one layer of voxels (12 μm). b Projection of pores in eight layers of voxels (ca 0.1 mm)

Generally, the strength properties of building stone are one of the most significant factors influencing its resistance against weathering. According to Ruedrich et al. (2011), there is a close relationship between the pore size distribution in the rock, the saturation degree, the intensity of moisture swelling and the strength reduction. Strength decrease in sandstone can be remarkable after only 1% water saturation as was concluded by Vásárhelyi and Ván (2006). It is well known that the natural stones show a decrease in strength at the water-saturated state which was already mentioned by Hirschwald (1908) and is referred to as softening. According to, e.g., Morales Demarco et al. (2007) or Siedel (2010), this effect can reach a strength decrease of up to 50% in sandstones. From the Czech literature (Rybařík 1994), the decrease exceptionally up to 60% in the case of Hořice sandstones is known. From this point of view, the values of strength softening of the Godula sandstones (28% in the case of Řeka quarry and 14% published by Kamieński et al. 1968 for the Głębiec quarry) can be described as moderate. These differences within the Godula sandstones (28 and 14%, respectively) can be attributed to the structural anisotropy and heterogeneity of gravity-flow sediments both in vertical and lateral direction. Morales Demarco et al. (2007) described a positive correlation between the reduction of UCS and the moisture expansion in sandstones. For that reason, the detail evaluation of hygric expansion of the Godula sandstones will be one of the objectives of further research.

Godula sandstones stability observed in buildings

In the past, glauconite-rich sandstones from the Beskids Mountains were used, in particular, as stone blocks for the bases of buildings (Hanisch and Schmid 1901). Since the second half of the twentieth century, the Godula sandstones have been used for various interior and exterior purposes, predominantly as cut, split, grinded or polished cladding and paving slabs, as well as in garden architecture. They are more rarely used as inner windows sills, steps, risers, columns and sets.

In contrast to the high quality of the physical and mechanical properties of the Godula sandstones, the degree of their durability in the case of exterior use is often very low and stone deterioration can advance very rapidly. The historical use of these stones in civil engineering and architecture shows that the glauconitic sandstones are stable only if they are not in direct and long-term contact with water and, moreover, in an environment affected by temperature changes. This means that the good stability of the Godula sandstones in construction can only be guaranteed in “dry” conditions. Only differential erosion and surface roughening are observed, and sedimentary structures are accentuated in this case. When the rocks are influenced by capillary water, e.g., at the base of the building, the partial sanding of rocks is observed.

The glauconitic sandstones in buildings exposed to outdoor conditions can be used only if the exchange between moisture in rock pores and water vapour in the air is not restricted. Otherwise, already, after less than 10 years of exposure to weather (in combination with road salting), almost total surface decay of the stone can occur. Road salting in the winter, thus, represents the second factor affecting the rate of stone decay. The other case is the direct chemical corrosion of sandstones due to the oxidation of pyrite and the dissolution of carbonates in an acidic environment. A specific feature of deterioration of the Godula sandstones is the exfoliation of stone in thin laminas rich in illite–smectite clay matter, pyrite and carbonate, and with a lower quartz content (see below). Therefore, the central parts of the sandstone beds with massive structures, excluding parallel bedded thin layers with higher contents of clay matter in the upper parts of the beds, are the most appropriate for the production of stone elements. Some typical forms of Godula sandstones deterioration in constructions are given in Fig. 5.

Illustrative examples of Godula sandstone deterioration in buildings. a Blistering and crust formation on surface of sandstone block in the base of building (Jiří Myron Theatre in Ostrava built in 1892–1893; photograph taken in 2016). b Demonstration of extreme exfoliation of Godula sandstones after only ca 10 years of exposition in exterior (pavement at the entrance to the Ostrava–Svinov railway station; photograph taken in 2016). c Sandstone cladding showing phenomena of salt efflorescence and blistering (Zámecké (Castle) square in Frýdek-Místek; photograph taken in 2008). d Splitting and contour scaling developed on a tile made from Godula sandstone (approximately 60-year-old construction, Military Academy in Brno; photograph taken in 2015)

Reasons for Godula sandstones deterioration in exterior conditions

In order to determine the reasons for the degradation of the Godula sandstones in exterior conditions, the pore space, the interaction of rocks with water, the mineralogical composition and the grain size distribution together with their variability in the vertical motion within the sandstone bed were studied. Potential oxidative changes in glauconite due to rock weathering were also estimated.

Pore size distribution and interaction of rock with water

Size distribution and shape parameters of rock pore space were determined using MIP and X-ray CT. Also, the long-term, time-dependent water saturation and evaporation were observed to simply describe the character of rock pore space and the process of the rock-water interaction.

According to MIP, pores with diameter smaller than 1 μm significantly dominate (Fig. 6). The average pore diameter (r) ranges from ca 50 to 85 nm and the bulk porosity of the Godula sandstones determined by MIP extends from 4.7 to 9.3% (18.6–38.1 mm3/g) as shown in Table 3. While respecting the IUPAC terminology (IUPAC 1976; Rouquerol et al. 1994), all studied sandstone samples show a relatively high content of mesopores (11.3–27.3% from all measured pores), in which drastic reduction in water flux due to the interactions of the water molecules with the pore walls occurs. Identified pore size distribution of the Godula sandstones has a significant impact on the rate of exchange of moisture between rock and its surrounding (see below). The rock exhibited a relatively closed pore structure with touching sand-sized particles. Space among the sandy grains was filled with clay minerals, glauconite pellets, calcite and rare pyrite. The high compactness of the Godula sandstones due to the presence of small, frequently isolated, intergranular pores was also observed using the X-ray CT (Figs. 4, 7). Total porosity calculated using the X-ray CT was 1.7% (at a voxel resolution of 12 μm) and 2.2% (at a voxel resolution of 8 μm), respectively. Although these values were within a determined interval of the total porosity of the Godula sandstones (see Table 2), low degree of the X-ray CT distinctiveness, in case of the Godula sandstones, was proven. The pores with volumes between 0.0001 and 0.0005 mm3 were the most common according to the visualisation and interpretation of the X-ray CT scanning results (Fig. 7).

Mercury intrusion porosimetry of the Godula sandstone from the Řeka quarry (sample No. 13316). Pore’s nomenclature and boundaries between the individual pore size categories were adopted from the IUPAC (1976) terminology

Experiments with long-term water absorption and evaporation provided important information about rock behaviour during its interaction with water, which enabled the estimation of the stone’s durability. The timing of the processes of the three-step water saturation and subsequent evaporation of the Godula sandstones in laboratory conditions are illustrated in Fig. 8. The dynamics of water saturation and evaporation indicate relatively slow moisture exchange between the rock and the surrounding environment.

It was concluded that pore space with the domination of aforementioned small pores of configurative and cemented types in the matrix with the gradual saturation of pores with water and subsequent retardation of water evaporation from the rock surface were typical for the Godula sandstones. This may lead to water retention in the rock pore system with severe consequences for rock stability (cf. Ruedrich and Siegesmund 2007; Ruedrich et al. 2011), especially due to freezing and thawing in combination with road salting. Rocks with pore space containing the vast majority of pores with size between 0.1 and 10 μm are significantly susceptible to salt weathering (see, e.g. Ruedrich and Siegesmund 2007; Benavente 2011); therefore, it is reasonable to assume that this form of stone damage will strongly apply also in the case of the Godula sandstones.

Glauconite in the Godula sandstones

Green, grey-green to blue-green colours of the Godula sandstones are caused by glauconite content in amounts up to 5% vol. Using 57Fe Mössbauer spectrometry, the Fe2+/Fe3+ ratio close to 1:1 in the crystal structure of glauconite separated from the Godula sandstones was estimated (Martinec and Maslan 2006, unpublished). In glauconite from the Godula sandstones, there was, thus, a sufficient quantity of Fe2+ that could be transformed to Fe3+ via the oxidation process. Therefore, it was originally assumed that this Fe2+/Fe3+ ratio in glauconite caused the instability of this mineral under oxidative outdoor conditions, which might be one of the reasons for the exterior deterioration of Godula sandstones (Vavro et al. 2009). However, as was found via microscopic study of the weathered Godula sandstones from natural outcrops and constructions, there were no significant signs of the glauconite limonitisation due to degradation under normal atmospheric conditions. Therefore, the crystallochemistry of glauconite should be, regarding the low content of glauconite in the rock, of lesser importance in stone decay than expected. It should be noted that two types of glauconite occurred in the Godula sandstones. The first was represented by sand-sized glauconite pellets and was much more resistant against weathering. The second was glauconised micas or, rarely, feldspars, which degraded faster, and their grass green colour changed to yellow-green due to weathering.

Variability of mineralogical composition and grain size distribution in the vertical motion within the rock bed

Structural features of rock represent other risk factors that influence weathering. Godula sandstones are deep-marine turbiditic sediments that often present positive graded bedding and associated anisotropy of mineralogical composition and probably also physical and mechanical properties. Therefore, it could be reasonable assumed that the scope, intensity and forms of stone deterioration depend on the position of the stone block within the sandstone layer, as well.

To describe the mineralogical heterogeneity of Godula sandstone beds, the samples from the base, central area and top of the selected sandstone layer, as well as from the laminated aleuropelites in the hanging wall of the layer, were taken (Fig. 9). Thin sections from all samples were prepared. The results of the optical microscopic analysis are presented in Table 4. As is evident from this table, the grain size of quartz and feldspars as the main rock components decreased towards the top of the bed. For the base, the bimodal grain size distribution was typical. Contrarily, the content of clay minerals, micas and pyrite generally increased towards the top of the bed. Described variability in mineralogical composition in vertical profile through the sandstone bed was confirmed by in situ X-ray fluorescence (XRF) analysis using DELTA Premium Handheld XRF Analysers (Olympus). The results are shown in Table 5.

Documentation of sampling points for the initial study of mineralogical and textural variability of Godula sandstone depending on the position within the bed and microscopic character of rocks from individual positions (cross-polarised light). Photograph of the quarry face taken in 2015. Compare with Tables 4 and 5

Problematic parts were, thus, represented by thin laminas rich in clay matter with dominant illite and/or illite/smectite mixed-layers in upper parts of mined sedimentary bodies. Therefore, it would be highly desirable to select appropriate raw stone blocks in the quarry with regard to the specific application of the stones in a building. However, in practical terms, selective mining does not appear to be possible due to a further increase in the already high quantity of mining waste represented by fine-grained aleuropelite intercalated sandstone beds.

The process of stone weathering can also be encouraged by the presence of authigenic carbonates (calcite, dolomite and eventually siderite) in the rock cement and by the presence of very fine-grained framboidal pyrite localised especially in the upper and more lutitic parts of sedimentary bodies. According to observations of Kühnel (1958) carried out on natural outcrops of the Godula sandstones, the dissolution of carbonates, which occurred as the first step of weathering, led to an increase in sandstones porosity. This facilitated the penetration of solutions rich in oxidation pyrite products (“limonite”).

The study of Godula sandstones deterioration phenomena in relation to the specific position of the rock sample in the sandstone bed is an entirely new approach of research which is currently under preparation.

Conclusions

Glauconitic Godula sandstones represent a traditional local building stone of the north-eastern part of the Czech Republic and adjacent territory of south Poland with a long-lasting history of their construction use. In view of a relatively very little information about these sandstones, particularly those that are quarried on the area of the Czech Republic, this paper gives an original comprehensive overview on their mineralogical and geochemical composition, geology of deposits, physical, mechanical and durability properties, as well as history of quarrying and use.

Due to their unusual colour, texture and ability to be polished, the Godula sandstones from the Czech Řeka quarry are currently used as an interesting material for the interior and exterior of buildings. However, it has been shown via the example of the Godula sandstones that the high quality of material properties does not necessarily indicate substantial stone resistance against weathering. The Godula sandstones have a closed pore space, overwhelmingly formed by pores with a diameter between 0.01 and 1 μm, which results in gradual and relatively slow water absorption and evaporation. Therefore, there is a high probability of water storage in the pore system, which may lead, especially due to periodic freezing and thawing in combination with road salting, to rapid and large-scale stone deterioration. The long-term stability of the Godula sandstones is guaranteed in the case of interior use or when a well-made waterproofing system is present, e.g., at the base of a building. The character of the pore space is, thus, the main reason for stone deterioration in an environment affected by temperature and moisture changes.

Another factors which will most likely affect, in particular, the rate and forms of Godula sandstones deterioration are the heterogeneity of the mineralogical composition and anisotropy of turbiditic sediment texture within the sandstone bed. One can assume that these sandstones may be highly representative of decay patterns and mechanisms that other building stones of similar origin suffer and therefore be used as a good example in the pursuit of understanding them. For this reason, a detail laboratory study on durability and deterioration of samples taken from different parts of sandstone layer (base, central part, top) is currently being prepared. The mineralogical and chemical composition and pore space characteristics using MIP in relation to the sample position in vertical cross section of the sandstone layer will be studied more deeply. Strength softening, measurements of hygric expansion, salt crystallisation tests and freeze/thaw testing will be used for detailed characterisation of sandstone sensitivity to weathering.

References

Adamová M (1986) Geochemické zhodnocení sedimentů slezské jednotky. Sbor geol Věd Geol 41:167–245

Banerjee S, Bansal U, Thorat AV (2016) A review on palaeogeographic implications and temporal variation in glaucony composition. J Palaeogeogr (English Edition) 5(1):43–71

Benavente D (2011) Why pore size is important in the deterioration of porous stones used in the built heritage. Macla 15:41–42

Bläuer C (1985) Weathering of Bernese sandstones. In: Félix G (ed) Proceedings of the 5th international congress on deterioration and conservation of stone, Lausanne, pp 381–390

Bolewski A (1954) Exploatation of the Carpathian cut sandstones. Przegl Geol 5:182–183

Bretfeld Z (1956) Technické použití beskydského pískovce. Stavivo 34:141–143

Buciak R (2012) Wietrzenie piaskowców w środowisku miejskim na przykładzie obserwacji okładzin ścian w wyjściach z metra warszawskiego. Przegl Geol 60(10):554–562

Czyżewski A (1998) Mediateka pod Paryżem. Dom i Biuro, Człowiek – Wzornictwo – Architektura 1(17):26–31

Figarska-Warchoł B, Matlak E (2012) Ograniczenia przyrodnicze górnictwa surowców skalnych między Cieszynem a Skoczowem w ostatnim stuleciu. Gospodarka Surowcami Mineralnymi 28(2):43–66

Folk RL (1974) Petrology of sedimentary rocks, 2nd edn. Hemphill Press, Austin

Hanisch A, Schmid H (1901) Österreichs Steinbrüche. Verzeichnis der Steinbrüche, welche Quader, Stufen, Pfĺastersteine, Schlief- und Mühlsteine oder Dachplatten liefern. Verlag von Carl Graeser & Co., Wien

Herron MM (1988) Geochemical classification of terrigenous sands and shales from core or log data. J Sediment Petrol 58(5):820–829

Hirschwald J (1908) Die Prüfung der natürlichen Bausteine auf ihre Wetterbeständigkeit. Z prakt Geologie 16:257–264

Hlobil I (2002) Těšínská madona. Objev vzácné sochy z huti Petra Parléře. In: Dáňová H, Hlobil I (eds) Těšínská Madona a vzácné sochy Petra Parléře - Cieczyńska Madonna i cenne rzeźby Piotra Parlera - Die Teschener Madonna und wertvolle Statuen von Peter Parler. Národní galerie v Praze, Ústav dějin umění AV ČR, Artefactum, Prague, pp 13–34

IUPAC (1976) Manual of symbols and terminology for physicochemical quantities and units—appendix II. Definitions, terminology and symbols in colloid and surface chemistry. Part II. Heterogeneous catalysis. Pure Appl Chem 46(1):71–90

Jahn JJ (1917) Pamětný spis o nerostných pokladech Moravy. Brno

Jirásek Z, Antonín R, Čapský M, Janák V, Kouřil P, Prix D (2012) Slezsko v dějinách českého státu I. Od pravěku do roku 1490. Nakladatelství Lidové noviny, Praha

Jonczy I (2000) Uwagi o charakterystyce petrograficznej piaskowców godulskich ze zloz w Brennej. Zeszyty Naukowe Politechniki Śląskiej w Gliwicach. Górnictwo 246:195–211

Kamieński M, Peszat C, Rutkowski J (1967) Zmienność petrograficzna piaskowców karpackich i zagadnienie ich klasyfikacji. Rocz Pol Tow Geol 37(4):499–508

Kamieński M, Peszat C, Rutkowski J, Skoczylas-Ciszewska K (1968) O wykształceniu i własnościach technicznych piaskowców godulskich. Zeszyty Naukowe Akademii Górniczo-Hutniczej w Krakówie, Geologia 12:1–86

Kłopotowska A, Łukasiak D (2011) Zmienność wytrzymałościowa piaskowców w warunkach krystalizacji siarczanu sodu oraz oddziaływania dwutlenku siarki. Biul Państw Inst Geol 446(2):143–148

Kühnel RA (1958) Příčiny větrání godulských glaukonitických pískovců. Věst Ústř Úst geol 33:75–79

Kwaśniewski M, Rodríguez-Oitabén P (2012) Study on the dilatancy angle of rocks in the pre-failure domain. In: Qian Q, Zhou Y (eds) Harmonising rock engineering and the environment. Proceedings of the 12th ISRM International Congress on Rock Mechanics, Beijing, pp 681–686

Kwaśniewski M, Takahashi M (2010) Strain-based failure criteria for rocks: State of the art and recent advances. In: Zhao J, Labiouse V, Dudt J-P, Mathier J-F (eds) Rock mechanics in civil and environmental engineering. Proceedings of the European Rock Mechanics Symposium EUROCK 2010, Lausanne, pp 45–56

Kwaśny I (2002) Madona ze Starého trhu v Těšíně. Těšínsko 45(1):10–15

Łukasiak D (2010) Zmienność wytrzymałościowa piaskowców godulskich z Brennej w warunkach jednoosiowego ściskania Kwartalnik Akademii Górniczo-Hutniczej im. Stanisława Staszica w Krakowie. Górnictwo i Geoinżynieria 34(2):435–441

Łukasiak D (2013) Wpływ wybranych procesów niszczących na trwałość piaskowców godulskich z Brennej. Górnictwo Odkrywkowe 54(1):56–61

Martinec P, Vavro M, Scucka J, Maslan M (2010) Properties and durability assessment of glauconitic sandstone: a case study on Zamel sandstone from the Bohemian Cretaceous Basin (Czech Republic). Eng Geol 115(3–4):175–181

Menčík E, Adamová M, Dvořák J et al (1983) Geologie Moravskoslezských Beskyd a Podbeskydské pahorkatiny. Ústřední ústav geologický, Academia, Prague

Morales Demarco M, Jahns E, Ruedrich J, Oyhantcabal P, Siegessmund S (2007) The impact of partial water saturation on rock strength: an experimental study on sandstone. Z dt Ges Geowiss 158(4):869–882

Pettijohn FJ, Potter PE, Siever R (1972) Sand and sandstone. Springer-Verlag, New York

Plevová E, Vaculíková L, Kožušníková A, Daněk T, Pleva M, Ritz M, Simha Martynková G (2011) Thermal study of sandstones from different Czech localities. J Therm Anal Calorim 103(3):835–843

Pospíšil P (2004) Cretaceous sandstones in Moravia and Silesia and their application as building and ornamental stones. Bull Geosci 79(3):183–193

Přikryl R, Svobodová J, Siegl P (2004) Historical dimension stone resources in the Czech Republic. Roc Maquina 53:28–31

Procházka VJ (1910) Horniny průmyslové a užitečné Moravy. Brno

Rajchel J (2002) Rocks of the Carpathians and the Carpathian Foredeep in the architecture of Cracow. Geologica Carpathica, 53: special issue on CD-ROM Proceedings of the 17th Congress of Carpathian-Balkan Geological Association, Bratislava

Rajchel J (2008) The Stony Cracow: geological valors of its architecture. Przegl Geol 56(8/1):653–662

Reiche P (1943) Graphic representation of chemical weathering. J Sediment Petrol 13:58–68

Roth Z, Cicha I, Bubík K et al (1962) Vysvětlivky k přehledné geologické mapě ČSSR 1:200000 M – 34 – XIX Ostrava. Geofond, Nakladatelství Československé akademie věd, Praha

Rouquerol J, Avnir D, Fairbridge CW, Everett DH, Haynes JM, Pernicone N, Ramsay JDF, Sing KSW, Unger KW (1994) Recommendations for the characterization of porous solids (Technical Report). Pure Appl Chem 66(8):1739–1758

Ruedrich J, Siegesmund S (2007) Salt and ice crystallisation in porous sandstones. Environ Geol 52(2):225–249

Ruedrich J, Bartelsen T, Dohrmann R, Siegesmund S (2011) Moisture expansion as a deterioration factor for sandstone used in buildings. Environ Earth Sci 63(7–8):1545–1564

Rybařík V (1994) Ušlechtilé stavební a sochařské kameny České republiky. Nadace Střední průmyslové školy kamenické a sochařské v Hořicích v Podkrkonoší, Hořice

Rybařík V (2011) Povaha a původ kamenů v gotické části katedrály sv. Víta. Kámen 17(3):7–13

Siedel H (2010) Historic building stones and flooding: changes of physical properties due to water saturation. J Perform Constr Facil 24(5):452–461

Šimíček D, Bábek O (2015) Assessing provenance of Upper Cretaceous siliciclastics using spectral γ-ray record. Geol Carpath 66(4):311–329

Skupien P, Mohamed O (2008) Campanian to Maastrichtian palynofacies and dinoflagellate cysts of the Silesian Unit. Outher Western Carpathians. Bull Geosci 83(2):207–224

Šrámek J (2002) Průzkum kamene Těšínské madony. In: Dáňová H, Hlobil I (eds) Těšínská Madona a vzácné sochy Petra Parléře - Cieczyńska Madonna i cenne rzeźby Piotra Parlera - Die Teschener Madonna und wertvolle Statuen von Peter Parler. Národní galerie v Praze, Ústav dějin umění AV ČR, Artefactum, Prague, pp 73–75

Šrámek J (2005) Zápský pískovec. Zpr geol Výz v r. 2005(38):167–169

Vásárhelyi B, Ván P (2006) Influence of water content on the strength of rock. Eng Geol 84(1–2):70–74

Vavro M, Martinec P, Ščučka J (2009) Green sandstones of the Czech Republic and parameters influencing their durability in buildings. In: Žižková N (ed) Proceedings of the 12th international scientific conference, Brno, pp 207–210

Acknowledgements

Authors wish to thank the three anonymous reviewers for their critical and inspiring comments which helped to improve significantly the article quality.

This article was written in connection with the project of the Institute of Clean Technologies for Mining and Utilization of Raw Materials for Energy Use—Sustainability programme (ICT-PU, identification code: LO1406). This project was supported by the National Programme for Sustainability I (2013–2020) and financed by the Government of the Czech Republic. The presented work was also supported by a project on the long-term conceptual development of research organisations (RVO: 68145535).

Author information

Authors and Affiliations

Corresponding author

Additional information

This article is part of a Topical Collection in Environmental Earth Sciences on “Geomaterials used as construction raw materials and their environmental interactions” guest edited by Richard Přikryl, Ákos Török, Magdalini Theodoridou and Miguel Gomez-Heras.

Rights and permissions

About this article

Cite this article

Vavro, M., Vavro, L., Martinec, P. et al. Properties, durability and use of glauconitic Godula sandstones: a relatively less known building stone of the Czech Republic and Poland. Environ Earth Sci 75, 1437 (2016). https://doi.org/10.1007/s12665-016-6248-3

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s12665-016-6248-3