Abstract

This research examines traceability and its model in industry 4.0. Hence, this paper introduces the main design features of this model. The fourth industrial revolution is an environment that combines manufacturing with the Internet of Things and cyber-physical Systems. In such an environment, various sources (i.e., smart products, intelligent agents, and sensors) generate an increasing amount of data, which is essential for effective traceability. However, due to these heterogeneous sources, a traceability system should face the interoperability challenge and overcome the data integration issue. Moreover, the incorporation of this information in a traceability tool is motivated by the requirement to have access to a maximum amount of accurate product data. Thus, this article proposes to take advantage of industry 4.0 information. Also, the present study advocates that traceability should not only allow trace and track but also ensure product safety and quality. Accordingly, the proposal includes an intelligent traceability description, an ontology-based modeling, and a cloud-based application. This system provides users with a common knowledge base to access and represent data. Also, this model enables users to share and query remotely the traceable information using the cloud.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

In manufacturing, the trend is towards the smart factory and more automation of processes (Zhong et al. 2017). This environment puts together a series of cooperative technologies (Xu et al. 2018) that involve cyber-physical systems (CPS), the Internet of Things (IoT), and cloud computing. CPS refer to an implementation where physical data drives computation. This implementation combines real-world objects with computers and enables to deploy the Internet of Things technologies (Chaâri et al. 2016; Trappey et al. 2017).

IoT refers to a set of devices and technologies that could share resources and intelligence. Accordingly, García et al. (2019) provided a review of the use of Artificial Intelligence within the IoT, including examples in machine learning, computer vision, fuzzy logic, and natural language processing. Further, cloud computing provides technologies to ensure the connection between these resources, which generates heterogeneous, distributed, and ever-growing data volume, namely big data.

The combination of the mentioned technologies leads indeed to the Industrial Internet of Things (IIoT). In this context, Molano et al. (2018) detailed the different aspects of such a deployment, including an architecture proposal for the Internet of things applied to the industry and a meta-model of integration (Internet of Things, social networks, cloud, and industry 4.0). Also, the authors presented a five-layer prototype of IIoT platform for the manufacturing processes monitoring.

The present paper addresses industry 4.0 from a supply chain perspective (Pfohl et al. 2015). This perspective involves logistics operations (Strandhagen et al. 2017a, b) and promotes the emergence of logistics 4.0 (Hofmann and Rüsch 2017). Thus, these advancements have contributed to improving the supply chain efficiency, which requires, among other things, an effective traceability system. Olsen and Borit (2013) provided a detailed overview of traceability definitions and concepts. Consequently, traceability is the ability to access any or all information relating to that which is under consideration throughout its entire life cycle by means of recorded identifications. Moreover, traceability is driven by regulations (i.e., food and health sectors) and has several requirements and properties (Mania et al. 2018; Karlsen et al. 2011).

In industry 4.0, various sources (i.e., smart products, intelligent agents, and sensors) generate an increasing amount of data, which is essential for effective traceability. Due to these heterogeneous sources, a traceability system should face the interoperability challenge and overcome the data integration issue. This paper outlines the need for modeling the industrial 4.0 concepts and incorporating intelligent traceability functions into the same model to meet the mentioned challenges.

Therefore, this article proposes an intelligent, ontology-based, and cloud-based traceability. The proposal aims to ease reasoning on traceability data and provide users with a common knowledge base to access and represent data. It might enable users to share and query remotely the traceable information. Thus, this article adopts the ontology-based approach to integrating heterogeneous data. This method is a part of the broad research field of data integration (Ziegler and Dittrich 2007). Also, this work uses semantic and cloud computing techniques to design a traceability cloud-based platform.

The second section reviews some related works on traceability and industry 4.0. The third section introduces the principal concepts of ontology, semantic web, and cloud computing. The fourth section details the proposed traceability model. In the fifth section, the proposed model is evaluated, focusing on the accuracy of the system and its benefits. The sixth section discusses this proposal. Finally, the last section summarizes conclusions.

2 Related works

During the last 10 years, many works have introduced intelligent traceability systems. Wang (2014) meant by intelligent traceability a real-time view into the production processes. The solution provided instant visibility into manufacturing. However, Xiao et al. (2015, 2016) applied statistical control, fault-tree analysis, and wireless sensors network to implement an intelligent traceability system. In other propositions, authors developed a traceability tool using IoT technologies (Chen 2015; Wang et al. 2017a). The devices collect product information, and fuzzy rules are used to support decisions. Yongjun et al. (2019) presented an intelligent traceability system in the domain of seafood. This solution tried to ensure automatic monitoring of live fish and traceability management using the HACCP (Hazard Analysis Critical Control Point) and wireless monitoring design. Most of these solutions are intended to ensure quality management. Note that the cited references are from the food industry. Other examples are available in different sectors. Solanki and Brewster (2014) examined traceability in the pharmaceutical supply chain. Also, Appelhanz et al. (2016) dealt with wood products.

In the literature, some studies have suggested specific traceability solutions for industry 4.0. Thus, Barata et al. (2018) proposed a traceability system in industry 4.0, especially ceramic products. This traceability was integrated with a cloud-based manufacturing execution systems (MES). Additionally, the cited authors used several devices like mobile devices, quick response codes, and RFID, one can see that these technologies generate heterogeneous data. In this context, an effective traceability system should properly collect and use this data. Also, Corallo et al. (2018) proposed a framework for voluntary traceability in industry 4.0, particularly in agriculture 4.0. The suggested system aimed to support the management of product data in the agri-food supply chain. The system design started with business model analysis to conceive each process task. This solution used IoT techniques for data collection and analytics methods for information processing. Hence, the recovered traceable information is accessible through IT solutions and mobile applications. In contrast to traditional tag-based traceability, Sánchez et al. (2015) proposed a cyber-physical traceability system. The system comprises a cybernetic glove, a cybernetic table, an execution engine, and a visualization platform for system and process execution. This architecture allows managers to monitor both workers’ actions and products movement.

According to Salampasis et al. (2012) and Alonso-Rorís et al. (2016), semantics can play a key role in developing effective traceability. Both publications have proposed traceability systems using semantic web technology. The first solution (TraceALL) provided formal means to represent knowledge and model information on pasteurized milk. The second work used a holistic and reusable platform for tracing products and controlling processes. Also, Pizzuti et al. (2017) used an ontology-based system, which is customized to represent the meat data. Therefore, the suggested ontology depends on the processes and actors involved in the meat supply chain. Context-modeling also can be used in industry 4.0. Therefore, a series of recent studies has introduced a context handling for industry 4.0. For example, Giustozzi et al. (2018) adopted a knowledge-driven approach, precisely the ontology-based one. Hence, the cited authors tried to represent the execution of industrial processes, their internal state, the context of their execution, and users’ interactions. This design depends on three elements, including process, situation, and resource ontologies. Also, Miragliotta et al. (2018) introduced an industry 4.0 modeling using a data-driven approach. The suggested method tried to define and measure data productivity in industry 4.0. The approach subdivided data into availability, quality, and performance and included technical and organizational factors to support the decision-making process.

Moreover, the literature review shows other approaches, including the process modeling method (Pérez et al. 2015; Petrasch and Hentschke 2016; Suri et al. 2017). Such an approach attempted to use an industry 4.0 process modeling language to represent different applications and processes in an industry 4.0 environment. This language is an extension of the business process model and notation (BPMN) standard. Other studies introduced a conceptual framework for industry 4.0 (Bortolini et al. 2017; Saucedo-Martínez et al. 2018; Zheng et al. 2018). These general frameworks attempted to lay the most noticeable basis of smart manufacturing, smart design, smart machining, smart control, smart monitoring, and smart scheduling. Moreover, these tools involve key technologies such as IoT, CPS, and big data analytics.

3 Methods and material

Ontologies have been used to develop conceptual models that represent context, data, and structures (Storøy 2017). According to Gruber (1993), an ontology explicitly specifies a shared conceptualization, including concepts, relations, instances, and axioms. These primitives shape information into knowledge bases. Thus, reasoning with ontologies is an automatic procedure, and new axioms could be inferred from the elaborated ones.

The semantic web (SW) promotes a common format for data, which is represented in the Worldwide Web. The W3C organization coordinates semantic web activities and specifies SW technologies and practices. The SW’s stack includes several levels (Bratt 2007). The uniform resource identifier (URI) ensures the interaction between web resources, and the Resource Description Framework (RDF) represents information as a graphs model (Ivanova et al. 2018).

In RDF, “subject-predicate-object” describes pieces of information. Each triple expresses only one assertion (e.g., proposition or fact). “Subject” refers to the source, and the “object” denotes the target. The “predicate” designates a relationship between the source and the target. Graphs (triples) are the fundamental communication unit for exchanging information. Note that any two graphs might be combined to yield a third one (Ristoski and Paulheim 2016). When URIs and RDF are combined, a piece of data is easily identified and structured. However, this combination alone does not suffice to give semantics to data. Further technologies are required to reinforce and complete the SW stack.

First, RDF Schema (RDFS) provides metadata terms to formulate the entity’s hierarchy (classes). RDFS restricts predicates domain and range. Nevertheless, it cannot describe some models because it does not incorporate set theory elements. Second, Web Ontology Language (OWL), which is an extension of RDFS, is required. This language uses description logics principles (Horrocks et al. 2003). It can describe a more complex entity and an additional relationship. Indeed, OWL is used to construct concise and powerful ontologies. At the same time, the semantic web enables the web inclusion of the semantic content (García-Castro and Gómez-Pérez 2010).

The present work takes advantage of two remarkable ontology properties. First, ontologies own a solid base in description logics (DLs). Second, ontologies support standard languages, promote knowledge exchange, and ease the reusability of models. Moreover, this article proposes to represent traceability functionalities as a service, which are designed according to cloud computing service models. According to the National Institute of Standards and Technology (NIST), cloud computing is a model for enabling ubiquitous, convenient, and on-demand access (Zissis and Lekkas 2012). Manageability, scalability, and availability are the main cloud characteristics. Also, it has properties like ubiquitous, multi-tenant, elasticity, and stability. Cloud computing proposes three models, including Infrastructure as a service (IaaS), platform as a service (PaaS), and software as a service (SaaS) (Hashizume et al. 2013). Other publications also introduced anything as a service (AaaS) (Singh et al. 2016).

4 Traceability proposal

In a nutshell, the proposal describes intelligent traceability, which might ensure product monitoring alongside its tracing and tracking. This system seeks to improve the supply chain decision-making process. Also, this paper depicts a context modeling ontology, which describes and relates different entities existing in the Industry 4.0 environment. Finally, this model is the core part of a developed prototype. This is an intelligent traceability as a service (ITaaS). The following subsections describe this proposed model in detail.

4.1 Intelligent traceability

Traceability systems should support product monitoring within industry 4.0. This article advocates that a solution should not only ensure “tracing’’ and “tracking” but also “controlling” products. Hence, it should provide tools to monitor situations and assist with decisions (Bougdira et al. 2016c). Basically, traceability systems can retrieve information and localize position. Therefore, including additional activities (i.e., supervising product’s environment) could enhance products quality and safety. A part of this claim has been discussed as active traceability (Jansen-Vullers et al. 2003).

The trace function indeed enables recording and retrieving product properties. This function should keep following all product data. It should include information that comes from using an analytical method or instrument. The track function should give access to product location at a given time. This paper estimates that these functions are only one traceability aspect. If one introduces more aspects, a traceability system would have a significant impact on the supply chain. Consequently, this study proposes to add a control aspect to promote intelligent traceability.

As mentioned in Sect. 2, there is no consensus on what the term “intelligent traceability” means. Several conflicting models and descriptions exist, and there is confusion when using it. Also, publications do not mention the difference between smart traceability and ordinary ones. As one can see, there is no explicit explanation or characterization of what is intelligent traceability.

Therefore, our suggested description includes three principles. Intelligent traceability is represented as a set of activities. Next, each activity uses a specified procedure. Finally, users should incorporate these activities into the functioning processes. If one conducts a process (e.g., manufacturing process and logistics process), one can report it using the corresponding activity. The proposed activities involve collecting activities, retrieving activities, and monitoring ones.

Collecting activities ensure that all product information is correctly captured and arranged. These activities should gather not only immediate product properties but also information about the origin, owners, and history. Information can include the owner’s identity, processing conditions, and task description in various stages of the chain. Other data are relevant to traceability, although this information did not directly influence the product properties (i.e., information from entities that exist in the product’s surroundings).

In practice, if collecting activities were appropriately executed, the retrieving activities would provide reliable and fruitful information. These activities guarantee that a product is properly identified, traced, and located. The information about identification should be accessible to the user anytime and anywhere. Therefore, the system can retrieve information about the product ID, name, origin, and the owner contact information. In the food industry, this type of information cannot be analytically verified. Therefore, introducing an identification activity is needed and useful. The tracing information could include ingredients, part of a product, and properties. The tracking activity enables users to follow the product geographically. Hence, one could see exactly where a product and all its ingredients came from and went.

It is relevant to have access to all the mentioned information. Further, it would be perfect that this information is incorporated into a monitoring tool. In this context, monitoring activities try to exploit this data to ensure product safety and quality. With the help of recorded data and the sensors ones, a user can supervise the product environment, makes the proper diagnosis, and take the right decisions (Matkovic et al. 2014; Bougdira et al. 2016a). These activities could certify product security. During processing, they could also adjust pro-actively parameters.

The description above sets some properties and characteristics of intelligent traceability. Accordingly, this research proposes a definition that might enhance the understanding of intelligent traceability. This characterization paraphrases some aspects presented by other works, including Olsen and Borit (2013), ISO 8402 and ISO 9000. Thus, intelligent traceability is a set of activities that can record identifications, collect data, in different stages from heterogeneous sources, and retrieve any or all object’s information that is processed not only to trace and track but also to ensure object safety within its environment.

This definition takes into consideration the importance of recording information. Furthermore, it stresses the need for keep-recording other information like information about processing, logistics operations, and any other events that affect the product life cycle. This property is needed each time a product is transformed from input to output. Further, it includes data captured in product surroundings. Additionally, it underlines the importance of linking this information to the product through identifiers. Collecting and retrieving acts aim at tracing information, tracking position, and supervising the product’s surroundings. Furthermore, the safety means that one can supervise and control different parameters to ensure the physical security and the quality of objects (i.e., temperature in storage and processing conditions). In this case, intelligent traceability is a part of the decision-making process, and it helps to ensure product security and quality. Intelligent traceability is the first part of the proposed model. The next subsection details the second one, which is ontology-based modeling.

4.2 Ontology-based modeling

The proposal takes an activity-centric perspective and revolves around Object, Surroundings, PhysicalContext, and DataElement. It highlights the relationships between industry 4.0 components and traceability activities.

In this paper, an object is a traceable unit resource (TRU). This concept has been detailed in several articles (Moe 1998; Pizzuti et al. 2014; Olsen and Borit 2018). An object could be a product, pallet, container, or ingredient. Surroundings refer to entities that surround, affect, or interact with an object, including persons, sensors, plants, machines, and processes, and operations. The physical context denotes the time and location (Bettini et al. 2010; Topcu 2011). This aspect provides a spatiotemporal meaning to statements. Hence, it is primordial to include the location and the time of each entity. The data element involves all useful information that helps with traceability.

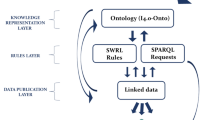

So far, activities and industry 4.0 components are the proposal’s pillars and are the starting point category of our ontology-based modeling. These comprise a small set of classes and properties that can promote simple and initial descriptions. Our design-approach urges that all the mentioned components are under traceability. Hence, the object property “isUnder” denotes the relation between industry 4.0 and traceability. Activities cooperate as well this paper introduces a reflexive property “cooperatesWith” at the same time each element could be “composedOf” another element. Figure 1 depicts this primitive description.

The next step details the main concepts of industry 4.0 and the relationships between its classes. Each class has reflexive and other object properties. The following figure (Fig. 2) summarizes the core classes and properties of industry 4.0 modeling. Thus, an object could contains another one. For instance, a container contains products and a product contains some ingredients. Each data element isConnectedTo another one. In traceability case, information about the product’s owner and its ingredients are directly bound and combined to provide accurate information. A surroundings element can constitute another one (isPartOf). Similarly, Machine isPartOf WorkStation, WorkStation isPartOf Line, and Line isPartOf ManufacturingPlant. Time and Location, each one referTo the other. A location is determined in a specific time and vice versa. “interactsWith” designates the relation between an object and its Surroundings. Hence, each object has a kind of interaction at least with one element of industry 4.0. This property could encompass several relationships and have sub-properties. Likewise, an Operator handles Object at the same time a Process transforms Object from input to new output.

The relation “has” links Object and DataElement. Thus, an object possesses data useful for traceability. “isDescribedIn” is a connection between Surroundings and DataElement. Each surroundings element assigns or provides data necessary for traceability.

Object evolvesWithin PhysicalContext: such a relation aims to follow object’s transformations in terms of time and location. This aspect is indispensable for traceability efficiency. This link might include sub-properties and generates statements, like Object isInLocation Location and Object isAtTime Time.

Simultaneously, surroundings elements need a context description. “isWithin” property and its sub-properties fulfill this role. For example, Process occursIn Location and Process occursAt Time. Data element relates to the time and location thanks to “isCreatedWithin” property. It helps to know the source of each data piece in terms of time and location.

In this context, Lorezo et al. (2010) discussed the issues of geographic context and geographic information. Thus, the authors proposed a computer application for topological relationships by applying the Douglas–Peucker algorithm and Bézier curves. Also, regarding the location, Nighot et al. (2017) proposed a novel technique to find a randomly moving target where the target’s location and searching space are unknown. The authors used a hybrid method of wireless sensor network (WSN) that combines static sensor node (SSN) with mobile sensor node (MSN).

Figure 3 details other aspects of the above modeling and provides additional semantics. Surroundings comprise Operator, Resource, and Occurrence. An operator is an agent (i.e., software, manager, or technician). It operates a facility, a platform, a manufacturing plant, or another resource. Resource generates occurrence.

An occurrence could be a production process, a human’s operation, or an assessment situation. If the property “operates” relates an operator (o) to a manufacturing plant (mp) and this one generates an occurrence (oc), one can deduce that o involvedIn oc.

In addition, if a product (p) interacts with its surroundings, i.e., p interactsWith oc, a user can draw an inference from this evidence. Consequently, one can know; the manufacturing (mp) that has transformed the product (p); the operator (o) that has been involved in this transformation; and the identity of this transformation (oc). Information about o, oc, mp isDescribedIn DataElement. This latter includes subclasses such as OwnerInformation, OccurenceInforamtion, and OperatorInformation.

Hence, p has OwnerInformation(mp), p has OccurenceInformation(oc), and p has OperatorInformation(o). Typically, each data element possesses data properties, which refer to a piece of information (i.e., OwnerInfroamtion(mp) hasName, hasAdress, hasOrigin), (i.e., OccurenceInformation(oc) hasDetails, hasStepDescription, hasProcessingHistory) and (i.e., OperatorInformation hasFirstName, hasLastName, hasRole).

Statements provide inferential evidence about the product (p) information. This paper provides further examples that are based on the semantic web rule language (SWRL).

The following expression stands for a Container ?c that contains some Products ?p. The interaction between the container and its surroundings is interpreted as; Container carries a Tag ?t; and Reader ?r reads a Tag. The tag is part of a Platform ?pt and Operator ?o operates the platform. This manipulation generates an Identification ?id (occurrence). The container’s identification is described in data element (IdentityInformation).

Container(?c)∧Product(?p)∧contains(?c,?p)∧Tag(?t)∧carries(?c,?t)∧Reader(?r))∧reads(?r,?t)

∧Platform(?pt)∧isPartOf (?r,?pt)∧Operator(?o) ∧operates(?o,?pt)∧Identification(?id)

∧generates(?pt,?id)∧ IdentityInformation(?i)∧isDescribedIn(?id,?i)

As an example of how to represent time and location, the following expression stands for a Specialist ?s operates a ProcessingMachine ?pm in order to cut raw meat into pieces. The cutting is the occurrence ?c the raw meat is the object ?rm. This process occurs in a location ?l and at a time ?t.

ProcessingMachine(?pm)∧Specialist(?s)∧ operates(?s,?pm)

Cutting(?c)∧generates(?pm,?c)∧Location(?l)∧occursIn(?c,?l)∧Time(?t)∧occursAt(?c,?t)

In this example, one draws inferential from this information. One could know the location and the time of the raw meat. If RawMeat usedBy Cutting and Cutting occursIn l and occursAt t, then RawMeat isInLocation l and isAtTime t. This assertion can be expressed, in OWL case, with Super-Property of Chain.

Information about location could be more detailed using spatial relations (Kontchakov et al. 2014) like existsWith and existsNearBy. Similarly, information about time could include startedAt, endedAt, hasLast. These relations enrich traceable information. Since this paper aims to give a general overview, it does not detail spatial–temporal relations. Sensors generate a stream of time-stamped and heterogeneous data. This stream is a great asset in our proposed modeling. It enriches knowledge about an object and enhances the monitoring aspect of traceability. Sensor ontology annotates heterogeneous data with formalized semantics.

In this article, measurements are related to sensing and observations from the semantic sensor network ontology (SSN) (Compton et al. 2012). Hence, the following statement stands for a surroundings element ?s that possesses a sensor ?se which makes an observation ?ob. SSN introduces two kinds of results; hasResult; and hasSimpleResult (rdfs). “DataElement” describes this information using sub-classes and their data properties. Therefore, MeasurementsInformation represents the observation and their values.

Surrounding(?s)∧Sensor(?se)∧hasSensor(?s,?se)∧snn:Observation(?ob)∧madeObservation(?se,?ob)∧

MeasurementsInformation(?m)∧hasResult(?ob,?m)

Supposing a product exists in a storage facility. Surroundings information (storage facility) isDescribedIn MeasurementsInformation. Product interactsWith Surroundings and Product has DataElement. Inferring from these statements, one can know the object storage conditions (e.g., temperature and humidity). This information helps to supervise the product quality and enhance system efficiency. Figure 4 illustrates the relation with sensor ontology.

The last step addresses the modeling of traceability activities. This current paper conceives intelligent traceability as activities that result in information being generated or a change in the surrounding environment (adjusting parameters). Thus, alignment of activities modeling to prov-ontology is an obvious choice. Timothy et al. (2013) detailed the provenance ontology. Figure 5 illustrates the general description of activities.

CollectingActivity includes Recording, Capturing, Acquiring, and Stamping. The recording activity ensures that all data elements are properly stored and arranged. It guarantees to link all properties with an object identifier. The capturing activity enables data capture. Data could refer to the process’s execution, operations step, and an event’s history through which an object has been passed. Both activities intend to ensure data recording and keep-recording information. Traceability systems should keep tracking all data. Acquiring activity is data acquisition and tries to involve information from the object surroundings like sensors’ observation. Time-stamped and location-stamped are essential for the accuracy of traceable information. Hence, the last activity aims to identify where and when an object exists, or an event occurs. Collecting activities concerns all industry 4.0 elements.

RetrievingActivity involves Identifying, Tracing, and Tracking. These activities describe the sequence of information retrieval. This organization attempts to provide traceable information in a meaningful way. It might enhance information accuracy. For instance, if a user needs only to locate a product, one can directly use the tracking activity without retrieving all the other information. Note that all these activities pertain to the object (TRU).

MonitoringActivity comprises Supervising, Diagnosing, and Adjusting. These activities follow a sequence to assist users in the decision-making process. If a system user supervises an object’s environment, based on the acquired information and the retrieved one, one could make an instant diagnosis of the situation status. If the situation needs adjustments, one makes the appropriate decision. Otherwise, one assigns this task to the right operator (i.e., person or actuator). In the case of processing, these cooperative actions permit pro-actively to adjust production processes and optimize production characteristics and results.

Activities cooperate, and each activity uses a specified procedure. For instance, a sensor’s observation is conducted according to its procedure. The acquiring activity uses this procedure and its result. A user can collect, correlate, and retrieve data as an object moves throughout the entire supply chain. This collaboration might guarantee object safety qualitatively and physically. The key purpose of activities modeling is to facilitate activity integration into different processes. This aspect is essential to capture the different step’s information.

This ontology-based modeling helps to construct meaningful ontologies. It could be used as a core part of a semantic web application. Accordingly, the next subsection details a prototype that results from the ontology-based proposal and cloud concepts. This traceability application, namely, intelligent traceability as a service (ITaaS) uses a lightweight ontology to provide the application’s user with tools for traceability purpose.

4.3 Intelligent traceability as a service

The proposal should meet the challenges of system implementation. In this setting, a system should merge information from different suppliers. Moreover, it should allow to track an object in real-time and monitor situations remotely. This study considers that the cloud-based approach fits with this context. Therefore, the proposed platform uses principles of cloud services models (SaaS and AaaS). Hence, this paper outlines the modeling principals and addresses only the system implementation in terms of the application layer. Details about storage organization (multi-tenancy), deployment model (e.g., private or public), and security issues are beyond the scope of this article.

This implementation uses a development-ecosystem that comprises tools like OWL and the software protégé. Also, this work uses the Jena API to manipulate the ontology. The prototype is developed in a J2EE environment. For the sake of readability, the following paragraphs introduce ITaaS using examples-driven description.

Figure 6 depicts an ontology example using the suggested context modeling. It represents the most noticeable information needed for efficient traceability. However, that does not mean the ontology includes all the information. Although this case belongs to the food sector, the proposal is likely to be applicable to other sectors. The ontology formalizes the object and its surroundings. It contains information about interactions, location, and time. In addition, this ontology integrates measurements that result from sensors existing in the object’s surroundings.

As depicted above, one could infer data from statements, which represent interactions between a product and its surroundings. For instance, affectedBy refers to a situation in which an object is part of an occurrence. The link notifiedBy denotes an operator that takes part in an occurrence. If a product is affectedBy occurrence, it is important to capture the data describing this occurrence. Accordingly, the information could describe the processing, labeling information, quality, and safety instructions. If the same product is notifiedBy an operator, the data, describing this operator, are required for efficient traceability. Note that the product location, at a specific time, could be inferred from these mentioned statements. The occurrence has two links occursIn and occursAt, which refer to a location at a specific time. Also, the product location could be obtained through sensors observations.

The activities are split into interacting services. Each service provides access to a well-defined functionality. This design is inspired by service-oriented architecture (SOA) (Erl 2005). In this setting, users can separate traceability services physically. Afterward, one can executes and reuses these services for other purposes. Thanks to SOA, a designer could easily reconfigure a service into a new one. If a business process evolves or changes, the designer has not to remake the design. A service provides users with an interface that manipulates the value object. A user can invoke services via cloud infrastructure. Figure 7 describes an example at a design level. It implements functionalities for capturing traceable information during product transformation.

This figure shows two interfaces published by the proposed component. A user can create tasks and detail information about them. These interfaces manipulate some value objects like the step duration and number. Moreover, one can assign operation and describe the operator’s role. Therefore, the user can capture data about the role’s name and description. “ProcessingCapturing” service permits recording and collecting information about production steps and entities involved in each step. These data are integrated into the ontology-based model. This integration enriches the knowledge base and reinforces retrieving and monitoring efficiency. The mentioned example is useful to give a brief overview of the expected design manner.

The following traceability example concerns the canned fish industry. The cannery supply chain comprises fishing units, intermediaries, processing units, and distributors. In morocco, the canneries are the main fish processing units, and the distributors are responsible for tasks like import, export, distribution, and retailing. The Canning units involve several products type (i.e., Sardine, Tuna, Salmon). Fishes are canned in many ways. For instance, in the tuna cannery, the fish are washed, sized, and cooked (deep-frying or steam-cooking). Then, they are packed in other ingredients like olive and tomato sauce. In the case of canned sardines, after the reception step, a sequence of activities starts, including fish handling, pre-treatment phase, which prepares the fish for canning (i.e., bringing the raw material closer to the size required for retorting), and juicing in which the cans are filled with the fish and juice (i.e., adding oil or order ingredients). After that, the cans are sealed during crimping. The post-process phase involves sterilization and cooling. These processing units produce several products like the whole sardines in vegetable oil, the skinless and boneless sardines in tomato sauce. Other preparations can include other commodities such as olive oil, pimento, salt, and Moroccan spices. The finished products could have different characteristics regarding label information, weight (i.e., fish weight: 277 g, 120 g, 84 g, 78 g), types, and size of cans.

This paper uses the suggested lightweight ontology to represent this case. In addition, this article introduces a scenario when a food crisis occurs due to several fish cans. A medical unit reports that several intoxicated persons have eaten a canned fish. Authorized person elaborates data querying via ITaaS. The following paragraphs describe the functioning scenario of the proposed system.

The first reasoning operation performed is oriented to the identification of owners. Thus, authorities launch an identifying activity using ITaaS interfaces. Users can enter a product ID, a name, or a SPARQL query. Figure 8 shows the query result, which contains information about the owner. Accordingly, the data includes the identity of owners, addresses, and contact information. Supplier information is essential for recognizing the steps followed by the contaminated products. This operation facilitates product recall. In addition, the prototype interfaces enable a user to track product location, which would be useful in such a situation. In this work, note that results are coded into the JSON format, which is a minimal and readable format for structuring data. However, one can present these data in tables using other transformation (i.e., JavaScript or jQuery).

During the investigation, responsible for food safety finds two results. Some cans are not produced by the same company. Moreover, those produced by the same company do not belong to the same lots. As a consequence, authorities use the tracing activity. They try to know ingredients, quality conditions, and production dates. Figure 9 depicts the obtained data. This procedure reveals the presence of a common ingredient (tomato sauce) involved in all cans production. Hence, this ingredient could be responsible for this contamination. Thus, the user can easily identify the supplier that provided the sauce. Based on these results, authorities can intervene to manage this food crisis.

5 System evaluation

This paper assesses the model effectiveness in terms of performance and benefits. Thus, this evaluation focuses on the system functioning, and it depends on two factors: the accuracy of the system and its benefits.

Our suggested model focuses on integrating different data types and using valuable information to ensure traceability efficiency. Also, our modeling uses a unique concept (occurrence) to represent the process and situation in an industry 4.0 environment. This utilization facilitates the context-modeling, increases the modeling consistency, and decreases the ontology weight (complexity). Moreover, the current paper has a traceability-centric vision. Thus, our context modeling separately represents the resource, the operator, and the object. This separation between these elements helps to enable an accurate description of manufacturing knowledge in a machine-interpretable way. Also, our modeling seeks to enable better integration of traceable data from different sources, an easy transformation from a context-modeling to a context-aware, and better reasoning on context-related semantics and information.

The current proposal recognizes the potential of the cloud to facilitate traceability. Therefore, the cloud is a main part of the proposed model. Hence, our system is expected to provide not only internal traceability but also to share the traceable information among all the supply chain stakeholders (external traceability). Thus, the proposal is expected to enable users with interfaces to manage and retrieve traceability information. Accordingly, cloud computing has the potential and flexibility to provide such services. These specifications depend on shared resources by local servers or individual devices. Note that in industry 4.0, applications, entities, and machines evolve into distributive environments. These resources should communicate and share information to achieve consistency. Further, the suggested platform ensures the main traceability functions (i.e., identifying, tracing, and tracking) and can be also extended to other functions like supervising and diagnosing product status.

Thus, the current study urges that the model is generic enough and can extend to other attributes, including different traceability cases and customizable requirements. Consequently, although different technologies and devices are used in industry 4.0 and traceability, one can see that the proposed model would promote the development of an effective traceability system that properly collects and use these heterogeneous data. Accordingly, our modeling tried to underline and overcome this issue. Hence, one can benefit from all the collected information using the proposed ontology modeling, which allows users to collect the most noticeable product data and provides added-value information to improve the monitoring of operations and their performance.

Practically, our proposal attempts to provide a general traceability solution. It is independent of the product’s sector. Therefore, ontology-based traceability can be easily specialized or extended to various environments. Thus, the present study, in a way, strives to enrich traceable information using industry 4.0. Further, traceability data can be exchanged easily in a scheme of data web (Trillo et al. 2011). Therefore, our proposed solution takes a general-purpose perspective. It aims to integrate traceability activities into enterprise processes regardless of the manufacturing process and the industrial sector specifications. Thus, the suggested model emphasizes the importance of organizing traceability into a set of activities. These activities are in line with the standards described by prov-ontology. For example, a business operator would implement collecting activities as a part of the industrial process. In this way, users can keep following the data as an object moves through the supply chain. Also, these activities might use the procedures already implemented by industrial instances. These procedures specify how to carry out activities using instructions and rules.

Based on the literature on intelligent traceability systems, it seems that these solutions attempted primarily to ensure product quality. If one accepted this claim, intelligent traceability would be simply another tool of quality control. However, experiences and common practices indicate that intelligent traceability should have a much broader picture. The suggested design urges that it should have the means to strengthen the safety, security, and quality of products throughout the entire supply chain. Therefore, besides identifying, tracing, and tracking functions, our system allows stakeholders to supervise the product, diagnose the product status, and make decisions. This continuous monitoring of products enables the control of a significant part of the product life cycle. Also, our suggested model does not depend on specific tools, but it builds a sequence of activities to assist the users in the decision-making process. Therefore, one can choose tools without being conditioned by a specific tool. Consequently, one can adapt to different traceability cases.

6 Discussion

The functioning scenario shows that ITaaS helps to conduct a backward analysis. It results in identifying a product, its owner, and food commodities in a finished product. Activities arrangement is helpful, especially with a disease outbreak. This arrangement operates as a reasoning stream to perform a detailed analysis. It starts with identifying an object and supplier identities. Next, it permits exploring components, elements, instructions, and information about each entity. The tracking activity determines entities’ position and can support product recalls. This activity completes and improves crisis analysis accuracy. Hence, the users could see exactly where a product and all its ingredients came from and went. Therefore, this system might help to combat counterfeiting, ease products recall, supervise product life cycle, and assist in product withdrawal.

The flow of activities is a rapid instrument for accurate analysis. ITaaS could conduct the main analysis steps even if a non-specialist third-party leads the investigation since the main activities are pre-programmed (i.e., identifying, tracing, and tracking). This model facilitates reasoning on product information and eases the incorporation of traceability activities along with the processing activities. Hence, the suggested model permits collecting data from heterogeneous sources designates means to store data, relates data to the product identifier (ID), and implements mechanisms to share the collected information among different stakeholders.

ITaaS could also be used as a valuable tool to monitor the product’s life cycle. For example, tracing activity shows values of quality conditions in terms of temperature and humidity. One can compare these values with the sensors’ observations. ITaaS could use these measurements thanks to the acquiring activity. Thus, during a storage situation, a user can supervise and diagnose storage status. Consequently, one can recommend adjustments to ensure product safety and quality. This functionality allows for continuous monitoring. It helps users to make proactive corrections in processing. If one managed indeed to combine with ITaaS other tools [i.e., quality control (Bougdira et al. 2019)], ITaaS would have a positive impact on the decision-making process. In addition, these additional tools could enhance system effectiveness.

This decision-making process is an important feature of an intelligent traceability system. This mechanism might help stakeholders to enhance supply chain visibility, provide supply chain sustainability benchmarks, and test supply chain indicators (Carter and Liane Easton 2011; Bougdira et al. 2016b). The suggested model helps not only to achieve product tracing and tracking but also to monitor the product’s situations. Therefore, it should promote both backwards and forwards analysis.

Activities handle another aspect, which is information continuity. Olsen and Borit (2013) stressed the need for systematic recordings and record-keeping to ensure effective traceability. Accordingly, collecting activities are arranged to ensure this functionality. In manufacturing, products result from several conversions. Hence, our system tries to identify entities and operations involved in these transformations. Consequently, the capturing activity seeks to collect all traceable information at various stages. This activity could be directly combined with the acquiring activity, particularly in the case of production monitoring. This combination is useful during processing operations, which need permanent control (i.e., food and pharmaceutical production). The recording activity allows users to store traceability data. In addition, it enables the linkage between all traceability data coming from different actors. The stamping activity grants actor permission and means to assign for each piece of data time and location, which adds meaningful information to deal with systematic data storing and retrieving.

This article tries to represent product information and its surroundings in the same context-modeling. Several publications proposed to model traceability data using ontology (Salampasis et al. 2012; Pizzuti et al. 2014). Also, some ontologies represent surroundings in many contexts; IoT (Wang et al. 2017b); sensors and actuators (Janowicz et al. 2018); and industry 4.0 (Giustozzi et al. 2018). Instead of being separately expressed, the suggested model seeks to link both parts. This association could yield a valuable traceability model. It attempts to represent and bring together information about an object and its surroundings.

This association ensures interoperability and data integration. Thus, it offers the most traceable information without pretending to establish an exhaustive list of all possible data. In addition, the suggested work attempts to be independent regarding identification, localization, and recording means. The identification mechanism depends on the type (e.g., RFID and bar code) and structure (e.g., numeric, alphanumeric, and GS1 number). Localization technology could be indoor, outdoor, or GPS transponders. The recording of properties and transformations could be manual or computerized.

The suggested model does not pretend to give a new traceability definition or replace the existing ones. It should be improved and enriched in collaboration with supply chain experts. This paper seeks to put under the spotlight other traceability aspects, but it is not the only possible representation in industry 4.0. It could be an opportunity to explore traceability deeply, especially within industry 4.0. Although the proposal could be useful for some cases, it should learn lessons from existing models. In this context, Olsen and Borit (2018) provided a structure for describing a traceability system in which the authors emphasized the need for three system components.

The noticed results would be a powerful asset to the suggested model enhancing. These enhancements should take into consideration other aspects. For example, how can one construct, send, and receive traceability messages.

7 Conclusions

In this paper, a traceability model for industry 4.0 has been proposed. In such a context, traceability systems should participate in the decision-making process. Therefore, the suggested model involves a description of intelligent traceability. Moreover, this design aims to represent the object and its surroundings in the same context-modeling instead of being separately represented. This association provides more interoperability and yields a valuable traceability model. Also, this paper has developed an application prototype for traceability purposes. This platform uses semantic technologies and cloud computing techniques. It also aims to ease reasoning on traceability data. This application provides users with a common knowledge base to access and represent traceable information. According to a simulated scenario, users can share and query remotely this knowledge base.

References

Alonso-Rorís VM, Álvarez-Sabucedo L, Santos-Gago JM, Ramos-Merino M (2016) Towards a cost-effective and reusable traceability system. A semantic approach. Comput Ind 83:1–11

Appelhanz S, Osburg VS, Toporowski W, Schumann M (2016) Traceability system for capturing, processing and providing consumer-relevant information about wood products: system solution and its economic feasibility. J Clean Prod 110:132–148

Barata J, da Cunha PR, Gonnagar AS, Mendes M (2018) Product traceability in ceramic industry 4.0: a design approach and cloud-based MES prototype. In: Paspallis N, Raspopoulos M, Barry C, Lang M, Linger H (eds) Advances in information systems development (lecture notes in information systems and organization), vol 26. Springer, Cham, pp 187–204. https://doi.org/10.1007/978-3-319-74817-7

Bettini C, Brdiczka O, Henricksen K, Indulska J, Nicklas D, Ranganathan A, Riboni D (2010) A survey of context modelling and reasoning techniques. Pervasive Mobile Comput 6(2):161–180

Bortolini M et al (2017) Assembly system design in the industry 4.0 era: a general framework. In: IFAC-PapersOnLine, vol 50(1), pp 5700-5705

Bougdira A, Ahaitouf A, Akharraz I (2016a) Cloud of things-based decision-making process using product’s traceability. IEEE Proc. https://doi.org/10.1109/CloudTech.2016.7847701

Bougdira A, Ahaitouf A, Akharraz I (2016b) An intelligent traceability system: efficient tool for a supply chain sustainability. AIP Proc. https://doi.org/10.1063/1.4959406

Bougdira A, Ahaitouf A, Akharraz I (2016c) Towards an intelligent traceability system. IEEE Proc. https://doi.org/10.1109/it4od.2016.7479280

Bougdira A, Ahaitouf A, Akharraz I (2019) Fuzzy approach to enhance quality control within intelligent traceability systems. IEEE Proc. https://doi.org/10.1109/wits.2019.8723764

Bratt S (2007) Semantic web, and other technologies to watch. https://www.w3.org/2007/Talks/0130-sb-W3CTechSemWeb/0130-sb-W3CTechSemWeb.pdf. Accessed 6 Mar 2019

Carter CR, Liane Easton P (2011) Sustainable supply chain management: evolution and future directions. Int J Phys Distrib Logist Manag 41(01):46–62

Chaâri R, Ellouze F, Anis K, Basit Q, Nuno P, Habib Y, Eduardo T (2016) Cyber-physical systems clouds: a survey. Comput Netw 108:260–278 (issn 1389-1286)

Chen RY (2015) Autonomous tracing system for backward design in food supply chain. Food Control 51:70–84

Compton M et al (2012) The SSN ontology of the W3C semantic sensor network incubator group. J Web Semant 17:25632

Corallo A, Latino ME, Menegoli M (2018) From industry 4.0 to agriculture 4.0: a framework to manage product data in agri-food supply chain for voluntary traceability. Int J Nutr Food Eng 12(5):146–150

Erl T (2005) Service-oriented architecture (paperback): concepts, technology, and design. Prentice Hall International, Upper Saddle River. https://www.arcitura.com/wp-content/uploads/2017/09/Erl_SOABook2_Ch07-2.pdf

García CG, Núñez-Valdez ER, García-Díaz V, Pelayo G, Bustelo C, Cueva-Lovelle JM (2019) A review of artificial intelligence in the Internet of Things. Int J Interact Multimed Artif Intell 05(04):9–20

García-Castro R, Gómez-Pérez A (2010) Interoperability results for semantic web technologies using OWL as the interchange language. Web semantics: science, services and agents on the World Wide Web. J Web Semant 8(4):278–291. https://doi.org/10.1016/j.websem.2010.08.008

Giustozzi F, Saunier J, Zanni-Merk C (2018) Context modeling for industry 4.0: an ontology-based proposal. Procedia Comput Sci 126:675–684. https://doi.org/10.1016/j.procs.2018.08.001

Gruber TR (1993) A translation approach to portable ontology specifications. Knowl Acquis 5(2):199–220

Hashizume K, Rosado DG, Fernández-Medina E, Fernandez EB (2013) An analysis of security issues for cloud computing. J Internet Serv Appl 4(1):1–13

Hofmann E, Rüsch M (2017) Industry 4.0 and the current status as well as future prospects on logistics. Comput Ind 89:23–34

Horrocks I, Patel-Schneider PF, van Harmelen F (2003) From SHIQ and RDF to OWL: the making of a web ontology language. Web semantics: science, services and agents on the World Wide Web. J Web Semant 1(1):7–26. https://doi.org/10.1016/j.websem.2003.07.001

Ivanova V, Lambrix P, Lohmann S, Pesquita C (2018) Visualization and interaction for ontologies and linked data-editorial, web semantics: science, services and agents on the World Wide Web. J Web Semant. https://doi.org/10.1016/j.websem.2018.10.001

Janowicz K, Haller A, Cox SJD, Le Phuoc D, Lefrançois M (2018) SOSA: a lightweight ontology for sensors, observations, samples, and actuators. J Web Semant. https://doi.org/10.1016/j.websem.2018.06.003

Jansen-Vullers M, van Dorp CA, Beulens AJ (2003) Managing traceability information in manufacture. Int J Inf Manag 23(5):395–413

Karlsen K, Donnelly KA-M, Olsen O (2011) Granularity and its importance for traceability in a farmed salmon supply chain. J Food Eng 102(1):1–8

Kontchakov R, Pratt-Hartmann I, Zakharyaschev M (2014) Spatial reasoning with RCC8 and connectedness constraints in Euclidean spaces. Artif Intell 217:43–75

Lorezo W, Gonzalez-Crespo R, Castillo-Sanz A (2010) A prototype for linear features generalization, International Journal of interactive multimedia and artificial. Intelligence 01(03):60–66

Mania I, Delgado AM, Barone C, Parisi S (2018) Food traceability system in Europe: basic and regulatory requirements. In: Traceability in the dairy industry in Europe: theory and practice. https://doi.org/10.1007/978-3-030-00446-0_1

Matkovic P, Tumbas P, Pavlicevic V (2014) Decision making in logistics processes supported by cloud computing. Int Sci J Manag Inf Syst 09(01):11–20

Miragliotta G, Sianesi A, Elisa C, Distante R (2018) Data driven management in industry 4.0: a method to measure data productivity. IFAC-PapersOnLine 51(11):19–24

Moe T (1998) Perspectives on traceability in food manufacture. Trends Food Sci Technol 9:211–214

Molano JIR, Lovelle JMC, Montenegro CE, Granados JJR, Crespo RG (2018) Metamodel for integration of internet of things, social networks, the cloud and industry 4.0. J Ambient Intell Humaniz Comput 09(03):709–723

Nighot M, Ghatol A, Thakare V (2017) Self-organized hybrid wireless sensor network for finding randomly moving target in unknown environment. Int J Interact Multimed Artif Intell 05(01):16–28

Olsen P, Borit M (2013) How to define traceability. Trends Food Sci Technol 29:142–150

Olsen P, Borit M (2018) The components of a food traceability system. Trends Food Sci Technol 77:143–149

Pérez F, Irisarri E, Orive D., Marcos M, Estevez E (2015) A CPPS Architecture approach for industry 4.0. In: IEEE 20th conference on emerging technologies and factory automation (ETFA), Luxembourg, 2015, pp 1–4. https://doi.org/10.1109/etfa.2015.7301606

Petrasch R, Hentschke R (2016) Process modeling for industry 4.0 applications: ToWARDS an industry 4.0 process modeling language and method. In: IEEE 13th International joint conference on computer science and software engineering (JCSSE), Khon Kaen, 2016, pp 1–5. https://doi.org/10.1109/jcsse.2016.7748885

Pfohl HC, Yahsi B, Tamer K (2015) The impact of industry 4.0 on the supply chain. In: Kersten W, Blecker T, Ringle CM (eds) Innovations and strategies for logistics and supply chains. epubli GmbH, pp 31–58. https://www.researchgate.net/publication/288466876_The_Impact_of_Industry_40_on_the_Supply_Chain

Pizzuti T, Mirabelli G, Sanz-Bobi MA, Goméz-Gonzaléz F (2014) Food track and trace ontology for helping the food traceability control. J Food Eng 120:17–30

Pizzuti T, Mirabelli G, Grasso G, Paldino G (2017) MESCO (MEat Supply Chain Ontology): an ontology for supporting traceability in the meat supply chain. Food Control 72:123–133

Ristoski P, Paulheim H (2016) Semantic Web in data mining and knowledge discovery: a comprehensive survey, web semantics: science, services and agents on the World Wide Web. J Web Semant. https://doi.org/10.1016/j.websem.2016.01.001

Salampasis M, Tektonidis D, Kalogianni EP (2012) TraceALL: a semantic web framework for food traceability systems. J Syst Inf Technol 14(04):302–317

Sánchez BB, Alcarria R, Martín D, Robles T (2015) TF4SM: A framework for developing traceability solutions in small manufacturing companies. Sensors 15(11):78–80

Saucedo-Martínez JA et al (2018) Industry 4.0 framework for management and operations: a review. J Ambient Intell Humaniz Comput 9(3):789–801

Singh S, Jeong YS, Park JH (2016) A survey on cloud computing security: issues, threats, and solutions. J Netw Comput Appl 75:200–222

Solanki M, Brewster C (2014) EPCIS event-based traceability in pharmaceutical supply chains via automated generation of linked pedigrees. In: The semantic web—ISWC 2014, lecture notes in computer science, vol 8796. Springer, pp 82–97

Storøy VC (2017) Conceptual modeling meets domain ontology development: a reconciliation. J Database Manag 28(1):18–30

Strandhagen JO, Vallandingham LR, Fragapane G, Strandhagen JW, Stangeland ABH, Sharma N (2017a) Logistics 4.0 and emerging sustainable business models. Adv Manuf 5(4):359–369

Strandhagen JW, Alfnes E, Strandhagen JO, Vallandingham LR (2017b) The fit of industry 4.0 applications in manufacturing logistics: a multiple case study. Adv Manuf 5(4):344–358

Suri K, Cadavid J, Alferez M, Dhouib S, Tucci-Piergiovanni S (2017) Modeling business motivation and underlying processes for RAMI 4.0-aligned cyber-physical production systems. In: 22nd IEEE international conference on emerging technologies and factory automation (ETFA), Limassol, 2017, pp 1–6. https://doi.org/10.1109/etfa.2017.8247702

Timothy L et al (2013) PROV-O: the PROV ontology. https://www.w3.org/TR/prov-o/. Accessed 15 Feb 2019

Topcu F (2011) Context modeling and reasoning techniques. SNET seminar in the ST, pp 1–8

Trappey AJC, Trappey CV, Govindarajan UH, Chuang AC, Sun JJ (2017) A review of essential standards and patent landscapes for the Internet of Things: a key enabler for industry 4.0. Adv Eng Inform 33:208–229 (issn 1474-0346)

Trillo R, Po L, Ilarri S, Bergamaschi S, Mena E (2011) Using semantic techniques to access web data. Inf Syst 36(2):117–133

Wang KS (2014) Intelligent and integrated RFID (II-RFID) system for improving traceability in manufacturing. Adv Manuf 02(02):106–120

Wang J, Yue H, Zhou Z (2017a) An improved traceability system for food quality assurance and evaluation based on fuzzy classification and neural network. Food Control 79:363–370

Wang W, De S, Cassar G, Moessner K (2017b) Knowledge representation in the internet of things: semantic modelling and its applications. J Control Meas Electron Comput Commun 54(4):388–400

Xiao X, Fu Z, Qi L, Mira T, Zhang X (2015) Development and evaluation on an intelligent traceability system for frozen tilapia fillet processing. J Sci Food Agric 95(13):2693–2703

Xiao Xinqing, Fu Z, Yongjun Z, Zhaohui P, Xiaoshuan Z (2016) Developing an intelligent traceability system for aquatic products in cold chain logistics integrated WSN with SPC. J Food Process Preserv 40(06):1448–1458

Xu LD, Xu EL, Li L (2018) Industry 4.0: state of the art and future trends. Int J Prod Res 56(80):2941–2962

Zhang Y, Wang W, Yan L, Branko G, Zhang X (2019) Development and evaluation of an intelligent traceability system for waterless live fish transportation. Food Control 95:283–297

Zheng P et al (2018) Smart manufacturing systems for industry 4.0: conceptual framework, scenarios, and future perspectives. Front Mech Eng 13(2):137–150

Zhong R, Xu X, Klotz E, Newman ST (2017) Intelligent manufacturing in the context of industry 4.0: a review. Engineering 3(5):616–630 (issn 2095-8099)

Ziegler P, Dittrich K (2007) Data Integration-problems, approaches, and perspectives. In: Krogstie J, Opdahl AL, Brinkkemper S (eds) Conceptual modelling in information systems engineering. Springer, Berlin, Heidelberg, pp 39–58. https://doi.org/10.1007/978-3-540-72677-7

Zissis D, Lekkas D (2012) Addressing cloud computing security issues. Future Gen Comput Syst 28(3):583–592

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Bougdira, A., Akharraz, I. & Ahaitouf, A. A traceability proposal for industry 4.0. J Ambient Intell Human Comput 11, 3355–3369 (2020). https://doi.org/10.1007/s12652-019-01532-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12652-019-01532-7