Abstract

The monitoring of leaks in pipelines is an important issue to be addressed by researchers and the public. This is due the fact that they can have a great impact both economically and environmentally. In recent years, the effect of leakages of pipelines carrying oil, gas and nuclear fluids have posed a threat on humans as well as marine life. This paper provides a survey of recent methods of detecting pipeline leaks with special focus on software based methods. These methods include negative pressure wave, mass/volume balance, pressure point analysis, real time transient modeling, statistical methods as well as methods that employing digital signal processing. This paper also surveys some of the recent research attempts that focus on the employment of wireless sensor networks for leak detection and present research challenges that can be encountered in such environments.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

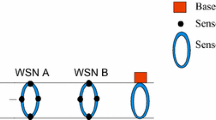

Pipelines have continued to be one of the most dominant ways of transporting large amount of fluids (e.g., oil and water) through long distances. Thus, monitoring pipelines for leaks is vital considering the huge amount of economic losses as well as environmental pollution caused by leakage of pipelines (Ostfeld 2008). Generally, leakages could be as a result of wear and tear of pipeline infrastructure, natural disasters or human sabotage. Traditional methods employed for leak detection involves a maintenance personnel who periodically monitoring the pipelines. The disadvantage of this method is the huge human involvement and its slow response in the event of leakage. Because of the advancements provided by micro-electro-mechanical systems (MEMS) (Ho and Tai 1998), inexpensive smart sensors have been developed. Smart sensors are low power devices equipped with one or more sensors, a processor, memory, a power source, communication interface, and an actuator. Smart sensors with wired and wireless communication interfaces have been developed real-time detection of leaks (Carrano et al. 2014; Jawhar et al. 2007; Stoianov et al. 2007). The wired system makes use of the wires to transmit the data to remote admin center. This method suffers from damage in the infrastructure and the huge cost incurred during installation, especially in underground pipeline monitoring. Wireless sensor networks (WSN) on the other hand employ the use of radio communication to transmit sensed signals (Akyildiz et al. 2002; Elmazi et al. 2015; Matsuo et al. 2015; O’Reilly et al. 2014). However, one of the major deployment issues of WSN is the energy consumption (Karim et al. 2014). Since the sensors are mostly battery powered, other methods employ both wired and wireless transmissions in a hybrid mode (Sportiello 2013).

The design of wireless sensor networks for pipeline leakage detection usually depends upon the fluid that the pipeline is transporting as well as the environment in which the pipeline is placed or embedded (Maglaras and Katsaros 2012). Typical fluids that the pipeline carries include water, oil and gas, sewage and thermal fluids. Pipelines are normally placed underground, underwater, or aboveground (Chen et al. 2014). The fluid transported by the pipeline and the surrounding environment plays an important role in the sensor type and its placement (whether the sensor will be placed within or outside the pipeline), as well as the architecture of the overall WSN for the pipeline monitoring for leakage detection (Abdallah 2011). Sensors for leakage detection could be broadly classified based on whether the sensors are in contact with the fluid within the pipeline or otherwise (Mustafa and Chou 2012). The invasive sensors are in contact with the fluid, while the non-invasive sensors are not in contact with the fluid.

The rest of the paper is organized as follows. Section 2 presents the classification criteria for leak detection technologies and the criteria adopted. In Sect. 3, the software based methods are discussed in detail. In Sect. 4, recent novel methods for leak detection that employ hybrids of sensors are discussed and analyses are made on their performance. Finally, Sect. 5 concludes the paper.

2 Classifying leak detection technologies

There is numerous numbers of criteria for classifying leak detection techniques. Some of these are the technical nature of the methods, physical quantity measured and the degree of human involvement required (Murvay and Silea 2012). If the degree of human involvement is chosen as the basis for classification, then the methods can fall into fully automated, semi-automated or manual in increasing order of human involvement. However, if the physical quantity measured is taken as the basis for the classification, then the methods fall into flow rate, acoustics pressure, optics, gas sampling and some hybrids of them. Due to the large number of methods under this category, they are often categorized into optical and non-optical methods (Sivathanu 2003). In contrast, other researchers considered these techniques falling into the categories of direct and indirect or inferential methods (Folga 2007). In direct detection methods, the pipeline is monitored by using hand-held devices that measure gas emissions or by visual inspection. In indirect or inferential methods, leaks are detected by measuring the variations of specific pipeline parameters such as a flow rate and pressure. In this paper, we adopt the famous classification of leak methods based on their technical nature (Scott and Barrufet 2003). Therefore, two main categories can be identified which are hardware based methods and software based methods, as shown in Fig. 1. Hardware based methods generally employ the use of specialized sensing instruments for leakage detection. Considering the type of equipment employed in the detection, these hardware methods are further classified into: acoustic, cable sensor, vapor sampling, optical, soil monitoring and ultrasonic flow meters. On the other hand, non-technical methods do not employ the use of any device and most often depend on natural senses of humans or animals. This paper duels upon the software based techniques. As the name posits, they have some software at their core. In this method, algorithms are implemented which constantly observe the state of flow rate, temperature, pressure or other pipeline parameters. Also, this method is able to determine if a leak has occurred based on the evolution of these quantities. The software based techniques shown by the shaded region in Fig. 1 include the following methods: acoustic/negative pressure wave, mass/volume balance, pressure point, real time transient modeling, analysis, statistical and digital signal processing.

Categorization of leak detection methods based on their technical nature (Murvay and Silea 2012)

3 Software based methods

This section provides additional explanation on each of the software-based-methods outlined in Sect. 2. Recent research works that employ each of these methods are outlined and general discussion is provided based on their merits.

3.1 Negative pressure wave method

In the negative pressure wave method, once a leak occurs the pressure of the fluid drops. This is due to the sudden decrease of liquid density at the position of the leak. Subsequently, pressure wave source propagates outwards for the point of leakage towards the opposite sides of the leak. Considering the pressure of the fluid before and after the leak as a reference, the wave produced by such leakage is termed the negative pressure wave. As this negative pressure wave travels towards the terminal ends of the pipeline section, pressure sensors stationed at the terminal ends are able to measure the pressure reduction signal. This can be achieved because when the wave reaches the terminal ends, it causes a drop first at the station inlet pressure and then the station outlet pressure. Since the leakage can be at any random point on the pipeline section, different time difference of the negative pressure wave is obtained at the terminal ends. From the knowledge of the different time difference that the pressure sensors on both sides of the leak detect, the pipeline section length and negative pressure wave velocity, the position of the leak can be obtained (Ge et al. 2008; Ma et al. 2010).

From Fig. 2, assume the distance between the sensors is \( L \), propagation velocity of negative pressure wave in pipeline is \( v \), the velocity of natural gas in the pipeline is \( u \), the distance between the leak point and the upstream sensor is x, and the times when the wave is detected by the two sensors is \( t_{1} \) and \( t_{2} \) respectively. However, it should be noted that the velocity of gas in the pipeline gas is ignored because it is negligible when compared to the velocity of the negative pressure wave (Ma et al. 2010; Peng et al. 2011; Tian et al. 2012). In contrast, researchers in (Hou et al. 2013) do not neglect the velocity of the gas in the pipeline. Thus, by considering the velocity of the gas in the pipeline u, the relationship between the length and time variable can be developed. This is because it affects the propagation of the negative pressure wave in the pipeline (Hou et al. 2013).

A schematic of the negative pressure wave method (Tian et al. 2012)

The distance x between the leak point and the sensor can be obtained using Eq. 1 (Hou et al. 2013).

Equation 2 is termed as the traditional leak location formula (Hou et al. 2013) and (Shuqing et al. 2009) presented a modification of the traditional leak location.

The limitation of Eq. 2 is that it assumes the propagation velocity of the negative pressure wave \( v \) and the velocity of natural gas in the pipeline \( u \) are constant (Hou et al. 2013; Shuqing et al. 2009). However, in practice \( v \) and \( u \) are dependent upon the temperature, pressure, density and specific heat capacity of the surrounding medium. Equation 3 represents the modified version of Eq. 2, which is given by (Hou et al. 2013):

where \( Z \) is the compression factor of gas, \( R \) is the constant value (8.3143 J/(mol K)), \( T \) is the temperature of gas, \( P \) is the pressure of gas, \( m \) is the quality of molar gas, \( D \) is the diameter of pipeline, \( C \) is the pipe restraint coefficient, \( E \) is the elastic modulus of pipe material, \( e \) is the thickness of pipe wall.

Consequently, using the thermal and hydraulic analysis, the formula of these two velocities can be obtained. Considering the velocity of natural gas and negative pressure wave as variables, the leak location can be re-written as follows (Hou et al. 2013):

Since, both equations for \( u\left( x \right) \) and \( v\left( x \right) \) are complex to solve deterministically and the integrals in Eq. 4 are not manageable definite integrals, numerical methods are employed to solve for \( t_{1} \) and \( t_{2} \) (Hou et al. 2013; Shuqing et al. 2009). (Hou et al. 2013) employ the use of compound Simpson (a numerical technique for approximating definite integrals) to solve the variable integrals in Eq. 4. In contrast, (Shuqing et al. 2009) employ the compound trapezoid formula (another numerical method for approximating definite integrals) to solve the integrals. Moreover, another difference between the work proposed by (Shuqing et al. 2009) and (Hou et al. 2013) is that (Shuqing et al. 2009) ignored the velocity of gas in the pipelines in their analyses, while the velocity of gas is not assumed to be negligible by (Hou et al. 2013).

Technical challenges faced in the NPWM of leak detection localization are presented (Tian et al. 2012). They have identified three areas where reliability and accuracy can be enhanced. These areas include data quality, adaptive thresholding and reduction of false alarm rates. Missing data and data duplication are two factors that limit the quality of data. The missing data can be solved by employing interpolation algorithms (algorithms used in estimating an intermediate value from two known values) to repopulate data. On the other hand, data duplication can be solved by data processing to remove redundant data. Furthermore, noise can be removed using filtering techniques.

Adaptive thresholding can be employed to accurately detect anomalies in the slope curve of a given pressure transducers (Tian et al. 2012). Since the slope varies over different working conditions, adaptive thresholding is more desirable than using a constant threshold. Statistical process control (SPC) (Oakland 2008) is one of the dominant methods in adaptive thresholding.

There is another challenge in the negative pressure wave method, which is the high false alarm rate. This false rate results due to the fact that normal transient of the pipeline can also cause pressure drops at pressure transducers. In some cases, these normal transients such as opening or closing pump valves can cause larger pressure drops than those caused by leakages (Tian et al. 2012). Thus, there is a need to adopt schemes that eliminates or reduces the false alarm rates. Some of the identified techniques include the following:

-

Hybridizing the NPWM with other leak detection approaches for cross validation (Sun et al. 2011).

-

Employment of flow meters. In order to address the problem of high false alarm rates of the negative pressure wave method (NPWM), it can be integrated with the flow balance method (Ma et al. 2010; Peng et al. 2011; Tian et al. 2012). Determining accurately whether the negative pressure wave is caused by normal transient behavior of the pipeline or due to a leak cannot be accomplished by pressure analysis alone. Hence, the flow balance method is incorporated. In the flow balance method, as can be seen in Fig. 3 (Peng et al. 2011), ultrasonic sensors are stationed at both ends of the pipe section. These flow meters continuously measure the gas flow signal at the inlet and outlet of the pipeline. In normal operation, there is no significant difference between flow readings obtained at both terminal ends. However, in the presence of leakage, the flow upstream will increase and the flow downstream will decrease. Thus, the differential flow rate gets significantly large. Hence, by studying the normal transients of the pipeline operation we can set a certain threshold for this differential value and once the value exceeds this threshold a leak alarm is raised.

Fig. 3 Negative pressure wave method with flow meters (Peng et al. 2011)

-

Another method of reducing false alarm rates is using pattern-matching algorithms. This can be helpful since in most cases there are multiple oscillations in leak pressure drop curves while in the case of pump pressure curve, the drop curve is smooth. Thus, with this knowledge we can distinguish between pressure drops caused by leak and that caused by normal transients of pipeline.

-

Use of multiple-sensor pairing can also be used to reduce false alarm rates (Tian et al. 2012).

-

Time synchronization of monitoring devices is another factor that affects the accuracy of the leak localization. Ma et al. employ the use of GPS to achieve accurate time synchronization (Ma et al. 2010). This is essential, because a small time deviation in monitoring can cause a very large location error (Tian et al. 2012).

The wavelet transform is a powerful computational tool for a variety of signals and image processing applications. It is also an effective tool for signals noise reductions (Selesnick 2007). Wavelets transform solves the short time Fourier transform in the analysis of non-stationary signals, because it possesses the time localization property making it the best choice for analyzing non-stationary phenomena (Barford et al. 1992). The basic idea behind the wavelet transform is the decomposition of a time-domain signal into frequency range components called wavelets so that analyses can be concentrated on certain range of frequencies of the original signal. Since the useful signals obtained from the pressure sensors are of lower frequency than that of the noise which is of high frequency, the wavelet transform is applied to decompose the signal into low and high frequency ranges. This causes the noise signal to be isolated from useful signal; thus, analysis can be centered on the useful data (Hou et al. 2013; Peng et al. 2011; Shuqing et al. 2009; Tian et al. 2012).

Some NPWMs have the ability to approximate the size of leakages, such as ATMOS wave (De Joode and Hoffman 2011). Another way of employing the NPWM is to intentionally produce transient pressure waves by opening and closing valves periodically (Elaoud et al. 2010; Mpesha et al. 2001). In the presence of leak, these pressure waves are partly reflected. Consequently, the leakage can be detected as well as localized. An advantage of this method is that it does not involve the building of a mathematical model including many calculations. Moreover, the system does not depend on system hardware. However, this method requires that the leak be quick and sudden, and is more suitable for small leaks. In case where the leak is not abrupt as the case of slow leaks, negative pressure waves are not generated or they naturally die out before reaching the pressure sensors at terminal ends of the leak. Another drawback of this method is its low accuracy in detecting leaks in long range pipelines (El-Shiekh 2010).

3.2 Mass balance method

The mass balance method for leak detection is straightforward (Burgmayer and Durham 2000; Martins and Seleghim 2010). It is based on the principle of mass conservation. The existence of leak causes an unbalance between the output and input mass flow rate as well as the line pack variable rate (Liou 1996; Parry et al. 1992). This is variable that defines the actual amount of gas in a pipeline or distribution system. A leak alarm is raised once the difference between the volume of fluid entering a section of the pipeline and the volume of the fluid leaving the section exceeds some pre-set threshold. (Liu 2008) presented a detailed theory and the implementation issues that are encountered in this method. In their work, they further pointed out that the volume or mass can be obtained by using readings of commonly used process variables such as temperature, pressure and flow rate. (Rougier 2005) presented a hybrid mass balance method, which incorporates probabilistic method to the mass balance method. The main drawback of this method is that the probabilistic method requires a substantial amount of computational power. One of the advantages of the mass balance method however is the ease with which it can be implemented on existing pipeline infrastructure. It is also able to rely on existing instrumentation already available on the pipeline; thus, resulting in low cost implementation (Murvay and Silea 2012; Wan et al. 2011). However, its performance relies on the size of the leak, frequency at which balance measurements are obtained as well as on the overall accuracy of measuring instruments. Another limitation of the mass balance method is its inability to detect small leak in real-time. Thus, resulting in loss of significant amount of fluid before an alarm is raised. A further limitation is that the mass balance method easily affected by random disturbances around the pipeline as well as the pipe dynamics. Thus, unless the threshold values are adapted, high false alarm rates will be recorded during transient periods of the pipeline. Moreover, unless a localization technique is attached to the method, it cannot localize the actual location of the leak on its own.

3.3 Pressure point analysis

pressure point analysis (PPA) is among the dominant methods of leak detection systems (Wan et al. 2011). The PPA method requires constant measurements of pressure in various locations along the pipe. Subsequently, by obtaining statistical evaluation of these measurements, a leak alarm is raised when the mean value of pressure measurements obtained falls below a preset threshold. (Bin Md Akib et al. 2011) presented mathematical derivations for calculating the pressure before and after leakage. This mathematical derivation is able to save huge amount of time in sample collection as well as analyses. The mathematical derivation presented shows the relationship between the temperature and pressure with leakage. Thus, from this relationship the temperature drop and pressure drop can be used to locate the actual point of leakage. Since the PPA requires only pressure signals to be obtained from one or many detection points, the advantage of the method is its low cost and ease of maintenance. Moreover, it has the ability to detect small leaks, which is not achievable by other techniques (Wan et al. 2011). PPA is also able to perform well in underwater and cold environments (Murvay and Silea 2012). One of the disadvantages of the PPA is its unreliability when it comes to detecting leaks in transient flows. In addition, leak localization is difficult using the PPA method and therefore limiting its application.

The pressure transducer shown in Fig. 4 is able to covert a hydraulic pressure to a proportional electrical signal (Farmer 1989). The statistical analyzer block is meant to make statistical analysis of pressure readings obtained from each point on the pipeline. The additional qualifying logic block is responsible for eliminating false alarms. Next, the display device is able to display the analyzed results. The optional actuator device is able to make corrective measures on the pipeline should there be a leakage (Farmer 1989).

3.4 Real time transient modeling

This method depends on pipe flow models developed to employing equations such as: conservation of momentum, mass and energy as well as the equation of state of the fluid. The presence of leakage is determined by the estimated value and measured value of the flow. Continuous monitoring noise levels and transient events minimize false alarm rate. Billmann and Isermann (1987) designed an observer with friction adaptation that in the event of leakage it generates a different output from one obtained from measurements. Thus, from this difference leakage can be detected.

Verde and Visairo (2001) proposed a method, which uses a linearized, discretized pipe flow model on an N-node grid and a bank of observers. The observers are modeled in such a way that when leakage occurs, all observers are reset except one. Localization of the leakage is obtained by the location of the non-responsive observer. Meanwhile, the quantity the leak can be obtained from the output of the other observers. Moreover, a detection system that utilizes an adaptive Luenberger-Type observer, based on a set of two-coupled one dimensional first order non-linear hyperbolic partial differential equation, is proposed by (Aamo et al. 2006; Hauge et al. 2007). Although this method is able to detect tiny leaks [less than 1 % of flow (Scott and Barrufet 2003)], it has the drawback of having high cost, as it requires huge instrumentation for obtaining data in real time. Moreover, another disadvantage of this method is the complexity of models employed that can be handled only by an expert.

3.5 Statistical methods

Statistical method is one of the simple methods for detecting gas leakages (Murvay and Silea 2012), which does not require the development of a mathematical model. In this method, the analysis is carried out on measured parameters such as flow rate and pressure at several points along the pipe. A leakage alarm is raised if the system comes across some patterns that show significant changes in pressure and flow rates (Zhang 1993). The leak thresholds are determined after a calibration period during which the parameter variance is examined, when leakage is absent, under several working conditions. However, the tuning needs to be carried out over a lengthy period of time—this is needed in order to avoid high false alarms (Zhang and Di Mauro 1998). One of the challenges of this method is that if there is a leak in the system during calibration period, the leaks will influence the preliminary measurements collected. Thus, the system behavior will be wrongly regarded as normal. As a consequence, this initial leakage is not detected until it increases in size enough to go above the set threshold. The method is able to detect small leaks with a detection of 0.5 % of flow as reported by (Zhang and Di Mauro 1998). Moreover, leak localization can also be achieved using this method. In addition, the method is robust, easy to deploy and easily adapted to diverse pipeline infrastructure. On the other hand, the main disadvantage of this method is the difficulty associated with estimating leak volume and its high cost of implementation.

3.6 Digital signal processing

Digital signal processing is one of the alternative methods for leak detection (USDT 2007). In the set-up stage, the output obtained from the system due to a known alteration in flow is obtained. Subsequently, digital signal processing is carried on the obtained measurements in order to detect variations in system response. The application of digital signal processing helps in isolation of original leak responses from noisy data. Encouraging results have been obtained from the application of this method for both gas and liquid pipelines (Golby and Woodward 1999; USDT 2007).

The main advantage of this method is that the mathematical model of the pipeline is not needed. However, just like the statistical method, if there is a leak in the set-up phase, it will not be detected until its size grows substantially. An additional disadvantage of this method is its high cost and complexity when it comes to installation and testing.

4 Recent novel methods

This section presents some recent methods of leak detection. Most of the methods employ hybrids of other techniques. Brief discussions are also provided on each of these methods.

Sun et al. (2011) proposed a robust means of applying WSN in underground pipeline leakage detection and localization. This method is magnetic induction-based and targets underground pipelines. The method involves the use of variety of sensors which are either stationed within or outside the pipeline. Conse-quently, these sensors collaboratively work together in order to accurately detect and localize leakages in the pipeline. The system consists of pressure and acoustic sensors placed in the pipelines at check points or pump stations. Acoustic sensors complement the pressure sensors at the check points. The pipeline is divided into segments by checkpoints with each segment having two checkpoints with soil property sensors stationed along each segment. Pressure sensors measure the flow pressure during the transient event and send out the measurements to the remote admin center. The admin center compares the data with the steady state readings. Subsequently in the second phase, if there is a deviation that exceeds some threshold value, the admin center notifies the pressure sensors along the suspicious area. The pressure sensors in the area then send out data requests to the soil property sensors along the segment. Measurements are then gathered in a multi-hop fashion at the processing hub. In the third phase, adjacent processing hubs along each segment exchange measurements through aboveground wireless channel. Subsequently, they determine collaboratively whether there is a leakage. The processing hubs also determine the location of the leakage. The results are then sent to the remote admin center to notify operating personnel. Communication between the processing hubs and remote admin center is accomplished using existing wireless communication such as ad-hoc network, cellular or satellite network. Due to the location of the soil property sensors, communication amongst the sensors cannot be realized reliably with exiting wireless communication methods. This is due to the fact that electromagnetic waves suffer high attenuation in underground applications (Akyildiz and Stuntebeck 2006; Li and Liu 2007; Vuran and Akyildiz 2010). As a consequence, magnetic induction based communication is employed between the soil property sensors. Magnetic wave-guide is used to guide the magnetic waves to target sensors. The wave guide is implemented by relay coils and with this architecture, the number of sensors needed for the communication is reduced. This method comes with research challenges. The first challenge is that of placement of devices. Since the pressure and acoustic sensors are to be placed at pump station due to energy requirements, the challenge is whether the existing pipeline has pump stations at short intervals for enhanced detection or not. Another challenge is that of designing collaborative leakage detection and localization algorithms. Moreover, a further challenge is that of employing in-network processing and light weight protocols to lower the power consumption of sensors. How the magnetic coils could be used to recharge the battery of the soil property sensors is another design problem. Additionally, due to the real-time detection and localization requirements putting all the soil property sensors in sleep mode and waking them up arbitrarily might pose a challenge. A better option would have been randomly keeping few sensors awake all the time for quick system response. Also, an experimental work needs to be done in order to test and evaluate the underground Magnetic Induction communication for robustness. On the other hand, (Mustafa and Chou 2012) proposed a distributed real-time detection algorithm for rapture events in pipelines. Their method is non-invasive as sensors are not in contact with fluid but rather placed on the surface of the pipeline. They make use of accelerometers to measure the speed of the fluid, and once the readings deviate from the certain set threshold, a rapture alarm is raised at the admin center. Moreover, their method has significant savings in energy consumption without losing on specificity (measures the proportion of negatives which are correctly identified) and sensitivity (measures the proportion of actual positives which are correctly identified).

The system employs a three tier approach for the detection process. Firstly, the sensing tier is responsible for sensing acceleration readings from the pipelines. Secondly, the aggregation tier collects statistical data of time stamped mean and media of accelerometer readings. Finally, the back-end server, which is at the tail of the chain, is responsible for making final decisions on the rapture event.

Preliminarily, damage is detected when acceleration measured in one window exceeds the optimal threshold value. The detection is further refined when the median reading deviates from the expected median. Once the threshold unit detects a divergence, it sends interrupts to sensing nodes. Sensing nodes starts sampling and evaluating median values. These values are compared against the standard time-stamped median. Damage is confirmed if deviation exceeds a predetermined threshold. Experimental analyses are carried out at pipe installations at Pacific Advanced Civil Engineering in Canada. Accelerometers are installed on the exterior of pipelines. Opening control valves along the pipeline simulates raptures. The system builds upon a previous work (Shinozuka et al. 2010) and is able to achieve huge performance in terms of energy conservation compared. Also, the system employing time stamped values to solve the problem of readings being affected by background noise within pipeline environment. The authors however were not clear on the leakage localization scheme they adopt. Another novel method is that of (Stoianov et al. 2007), which presents an application of wireless sensor networks for collecting real-time operational data from pipeline structures for monitoring and control. Their work focuses on large diameter water distribution pipelines. Moreover, the authors are able to develop a system that is able to collect hydraulic and acoustic/vibration data at high sampling rates and at the same time present an algorithm for detecting and localizing leakages. The developed architecture is able to address challenges such as high sampling rates for data, maintaining aggressive duty cycles and ensuring time synchronized data collection at very low power consumption. The method employs the use of sensors, which captures pressure transients, mass velocity flow as well as acoustic/vibrations of the pipeline. With these sensors, the system is able to monitor the pipeline more effectively. Moreover, it is able to self-organize itself in the event of failure of few nodes. The pressure transients and flow velocity sensors are invasive, while the acoustic and vibration sensors are non-invasive. The design issue of the invasive sensors is that they limit sensor installation to areas with outlets; thus, leading to poor localization of leakages. On the other hand, the non-invasive methods employ the use of vibration sensors placed around the surface of the pipelines to detect leaks. Despite the fact that the proposed system is able to determine small leaks in water pipelines, the developed algorithm was computationally expensive, which requires (O (N log(N)) operations to compute the frequency spectrum for N-samples. Another limitation of this method is that it requires off-line processing. Furthermore, (Meribout 2011) designed a secure WSN (Mahshid and Eslamipoor 2014) based detection infrastructure for fast and accurate detection of leakages that occur in multi-phase pipelines (i.e., pipelines that carry more than one fluid). The design consists of an inner pipeline that is surrounded by an outer pipeline. The outer pipeline houses the electronic monitoring devices while the inner pipeline carries the multi-phase fluid. The design consists of an air-ultrasonic sensor that continuously monitors the presence of leakage of the inner pipe into the outer pipe. The localization is carried out by a bi-directional microphone, which senses the sound of the fluid in the outer pipeline. Both of these sensors are interfaced to a WSN, which performs control, signal processing and transmission task. The author also designed a secure and reliable communication protocol. The advantage of this method over other methods is that the sensors devices are not placed in the fluid; hence, they do not suffer corrosion. Another advantage is the fact that the outer pipe can be made of any particular material and can serve to protect the inner pipeline. A drawback of the method is that it involves the design of new pipeline system and can hardly be implemented on an existing pipeline structure. Moreover, (Sportiello 2013) presented a hybrid wired-wireless distributed network for monitoring infrastructures such as pipelines. The wireless system serves as a back-up in case the wired system fails. The system is able to automatically re-configure itself and provides an energy aware routing using duty cycling. Although the system employs duty cycling to enhance energy efficiency, incorporating more aggressive means of energy conservation such as data aggregation and compression and also in-network processing will further enhance the energy awareness of the scheme.

5 Conclusions and future work

In this paper, we presented the general categorization of leak detection methods based on their technical nature. According to this classification, the methods fall into hardware and software techniques. The hardware techniques include acoustic, cable sensor, vapor sampling, optical, soil monitoring and ultrasonic flow meters. Unlike other surveys, we focused our discussions around software detection methods, which are negative pressure wave, mass/volume balance, pressure point analysis, real time transient modeling, statistical methods as well as digital signal processing. Moreover, we presented recent methods involving wireless sensor networks that employ hybrids of these techniques to enhance the detection and localization of leakages. In the future, we attempt to develop a new robust approach to leak detection that overcomes the challenges of the methods we have reviewed in this paper.

References

Aamo OM, Salvesen J, Foss B (2006) Observer design using boundary injections for pipeline monitoring and leak detection. IFAC Symp. Adv. Control Chem. Process, pp 2–5

Abdallah S (2011) Generalizing unweighted network measures to capture the focus in interactions. J Soc Netw Anal Min 1(4):255–269

Akyildiz IF, Stuntebeck EP (2006) Wireless underground sensor networks: research challenges. Ad Hoc Netw 4(6):669–686

Akyildiz IF, Su W, Sankarasubramaniam Y, Cayirci E (2002) Wireless sensor networks: a survey”. Comput Netw 38(4):393–422

Barford LA, Fazzio RS, Smith DR (1992) An introduction to wavelets. Hewlett-Packard Laboratories, Technical Publications

Billmann L, Isermann R (1987) Leak detection methods for pipelines. J o Autom 23(3):381–385

Bin Md Akib A, Bin Saad N, Asirvadam V (2011) Pressure point analysis for early detection system. In: IEEE 7th international colloquium on signal processing and its applications (CSPA), pp 103–107

Burgmayer PR, Durham VE (2000) Effective recovery boiler leak detection with mass balance methods. In: TAPPI engineering conference, pp 1011–1025

Carrano R, Passos D, Magalhaes L, Albuquerque C (2014) Survey and taxonomy of duty cycling mechanisms in wireless sensor networks”. J IEEE Commun Surv Tutor 16(1):181–194

Chen K, Ma M, Cheng E, Yuan F, Su W (2014) A survey on mac protocols for underwater wireless sensor networks. J IEEE Commun Surv Tutor 16(3):1433–1447

De Joode AS, Hoffman A (2011) Pipeline leak detection and theft detection using rarefaction waves. In: 6th pipeline technology conference

Elaoud S, Hadj-Ta¨ıeb L, Hadj-Ta¨ıeb E (2010) Leak detection of hydrogen–natural gas mixtures in pipes using the characteristics method of specified time intervals. J Loss Prev Process Ind 23(5):637–645

Elmazi D, Kulla E, Ta Oda, Spaho E, Sakamoto S, Barolli L (2015) A comparison study of two fuzzy-based systems for selection of actor node in wireless sensor actor networks. J Ambient Intell Humaniz Comput 6(5):635–645

El-Shiekh T (2010) Leak detection methods in transmission pipelines. J Energy Sources Part A Recovery Util Environ Eff 32(8):715–726

Farmer E (1989) System for monitoring pipelines. US Patent 4,796,466

Folga S M (2007) Natural gas pipeline technology overview. Technical Report, Argonne National Laboratory (ANL)

Ge C, Wang G, Ye H (2008) Analysis of the smallest detectable leakage flow rate of negative pressure wave-based leak detection systems for liquid pipelines. J Comput Chem Eng 32(8):1669–1680

Golby J, Woodward T (1999) Find that leak [digital signal processing approach. IEE Rev 45(5):219–221

Hauge E, Aamo OM, Godhavn JM (2007) Model based pipeline monitoring with leak detection. In: 7th IFAC Symp. on nonlinear control systems, 2007

Ho CM, Tai YC (1998) Micro-electro-mechanical-systems (MEMS) and fluid flows. Annu Rev Fluid Mech 30(1):579–612

Hou Q, Ren L, Jiao W, Zou P, Song G (2013) An improved negative pressure wave method for natural gas pipeline leak location using fbg based strain sensor and wavelet transform. J Mathematical Problems in Engineering, Article ID 278794, 8 pages. http://dx.doi.org/10.1155/2013/278794

Jawhar I, Mohamed N, Shuaib K (2007) A framework for pipeline infrastructure monitoring using wireless sensor networks. In: IEEE Wireless Telecommunications Symposium, pp 1–7

Karim L, Nasser N, Sheltami T (2014) A fault-tolerant energy-efficient clustering protocol of a wireless sensor network. J Wirel Commun Mob Comput 14(2):175–185

Li M, Liu Y (2007) Underground structure monitoring with wireless sensor networks. In: ACM 6th international conference on Information processing in sensor networks, pp 69–78

Liou JL (1996) Leak detection by mass balance effective for Norman wells line. Oil Gas J 94(17):69–74

Liu A (2008) Overview: pipeline accounting and leak detection by mass balance, theory and hardware implementation. Quantum Dynamics Inc., Woodland Hills

Ma C, Yu S, Huo J (2010) Negative pressure wave-flow testing gas pipeline leak based on wavelet transform. In: IEEE international conference on computer, mechatronics, control and electronic engineering (CMCE), vol 5, pp 306–308

Maglaras LA, Katsaros D (2012) New measures for characterizing the significance of nodes in wireless ad hoc networks via localized path-based neighborhood analysis. J Soc Netw Anal Min 2(2):97–106

Mahshid MK, Eslamipoor R (2014) An efficient and secure authentication for inter-roaming in wireless heterogeneous network. J Soc Netw Anal Min 4(1):1–10

Martins JC, Seleghim P (2010) Assessment of the performance of acoustic and mass balance methods for leak detection in pipelines for transporting liquids. J Fluids Eng 132(1):011401. doi:10.1115/1.4000736

Matsuo K, Elmazi D, Liu Y, Sakamoto S, Barolli L (2015) A multi-modal simulation system for wireless sensor networks: a comparison study considering stationary and mobile sink and event. J Ambient Intell Humaniz Comput 6(4):519–529

Meribout M (2011) A wireless sensor network-based infrastructure for real-time and online pipeline inspection. IEEE Sens J 11(11):2966–2972

Mpesha W, Gassman SL, Chaudhry MH (2001) Leak detection in pipes by frequency response method. J Hydraul Eng 127(2):134–147

Murvay PS, Silea I (2012) A survey on gas leak detection and localization techniques. J Loss Prev Process Ind 25(6):966–973

Mustafa H, Chou PH (2012) Embedded damage detection in water pipelines using wireless sensor networks. In: IEEE 9th international conference on high performance computing and communication & IEEE 14th international conference on embedded software and systems, pp 1578–1586

O’Reilly C, Gluhak A, Imran M, Rajasegarar S (2014) Anomaly detection in wireless sensor networks in a non-stationary environment. J IEEE Commun Surv Tutor 16(3):1413–1432

Oakland JS (2008) Statistical process control. Routledge

Ostfeld A, Uber JG, Salomons E, Berry JW, Hart WE, Phillips CA, Watson JP, Dorini G, Jonkergouw P, Kapelan Z (2008) The battle of the water sensor networks (BWSN): a design challenge for engineers and algorithms. J Water Resour Plan Manag 134(6):556–568

Parry B, Mactaggart R, Toerper C, (1992) Compensated volume balance leak detection on a batched lpg pipeline. International conference on offshore mechanics and arctic engineering, pp 501–501

Peng Z, Wang J, Han X (2011) A study of negative pressure wave method based on haar wavelet transform in ship piping leakage detection system. In: IEEE 2nd international conference on computing, control and industrial engineering (CCIE), 2:111–113

Rougier J (2005) Probabilistic leak detection in pipelines using the mass imbalance approach. J Hydraul Res 43(5):556–566

Scott SL, Barrufet MA (2003) Worldwide assessment of industry leak detection capabilities for single & multiphase pipelines. Offshore Technology Research Center, College Station

Selesnick IW (2007) Wavelet transforms a quick study. Polytechnic University, Brooklyn

Shinozuka M, Chou PH, Kim S, Kim HR, Yoon E, Mustafa H, Karmakar D, Pul S (2010) Nondestructive monitoring of a pipe network using a mems-based wireless network. In: SPIE smart structures and materials + nondestructive evaluation and health monitoring, pp 76490P–76490P-12

Shuqing Z, Tianye G, Hong X, Guangpu H, Zhongdong W (2009) Study on new methods of improving the accuracy of leak detection and location of natural gas pipeline Measuring. IEEE Int Conf Technol Mech Autom 1:360–363

Sivathanu Y (2003) Naturalgas leak detection in pipelines. Technology Status Report, EnUrga Inc., West Lafayette, IN

Sportiello L (2013) A methodology for designing robust and efficient hybrid monitoring systems. Int J Crit Infrastruct Prot 6(3):132–146

Stoianov I, Nachman L, Madden S, Tokmouline T, Csail M (2007) Pipe net: A wireless sensor network for pipeline monitoring. In: IEEE 6th international symposium on information processing in sensor networks, pp 264–273

Sun Z, Wang P, Vuran MC, Al-Rodhaan MA, Al-Dhelaan AM, Akyildiz IF (2011) Mise-pipe: magnetic induction-based wireless sensor networks for underground pipeline monitoring. J Ad Hoc Netw 9(3):218–227

Tian CH, Yan JC, Huang J, Wang Y, Kim DS, Yi T (2012) Negative pressure wave based pipeline leak detection: Challenges and algorithms. In: IEEE international conference on service operations and logistics, and informatics (SOLI), pp 372–376

USDT (2007) “Leak detection technology study for pipes act.” Tech. report, U.S. Department of Transportation

Verde C, Visairo N (2001) Bank of nonlinear observers for the detection of multiple leaks in IEEE International conference on a pipeline in control applications, pp 714–719

Vuran MC, Akyildiz IF (2010) Channel model and analysis for wireless underground sensor networks in soil medium. J Physical Commun 3(3):245–254

Wan J, Yu Y, Wu Y, Feng R, Yu N (2011) Hierarchical leak detection and localization method in natural gas pipeline monitoring sensor networks. Sensors 2(1):189–214

Zhang XJ (1993) Statistical leak detection in gas and liquid pipelines. Pipes Pipelines Int 38(4):26–29

Zhang J, Di Mauro E (1998) Implementing a reliable leak detection system on a crude oil pipeline. In: Advances in pipeline technology, Dubai, UAE

Acknowledgments

The authors would like to acknowledge the support of King Fahd University of Petroleum and Minerals for this research.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Sheltami, T.R., Bala, A. & Shakshuki, E.M. Wireless sensor networks for leak detection in pipelines: a survey. J Ambient Intell Human Comput 7, 347–356 (2016). https://doi.org/10.1007/s12652-016-0362-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12652-016-0362-7