Abstract

Turkish red pine (Pinus brutia Ten.) is an economically and ecologically important tree species that is widely grown in the Mediterranean and Aegean regions of Türkiye, with its bark (RB) serving as waste material in the forest industry. The current study aims to quantify the phenolic composition of RB extract (RBE) and to investigate the effects of incorporating RBE into pasta at ratios of 0, 0.25, 0.50, and 1.00% (w: w) on in vitro starch digestibility, mineral composition, bioactive properties (including TPC, DPPH, and FRAP antioxidant activities), in vitro bioaccessibility of bioactive compounds, and sensory attributes. Gallic acid (2.30 mg/ 100 g) and hydroxybenzoic acid (3.80 mg/ 100 g) were the two predominant phenolic acids in RBE. Enrichment of the pasta with RBE (0.25%, 0.50%, and 1% w/w) resulted in higher mineral content, antioxidative properties, lower glycemic index and higher sensory scores as compared to the control pasta. Enrichment of pasta with 1% RBE resulted in a significant reduction in the hydrolysis index (HI) and predicted glycemic index (pGI), with HI values decreasing from 28.67 to 45.65% and pGI reductions ranging from 27.18 to 40.04%, indicating a notable negative impact on starch degradation and glucose release. Enrichment of pasta with RBE significantly increased the total phenolic content from 4.12 to 31.29 mg GAE/100 g and enhanced antioxidant activities, with FRAP values rising from 7.45 to 99.46 µmol TEAC/100 g and DPPH activities ranging from 11.45 to 70.36 µmol TEAC/100 g. Bioaccessibility index values for TPC, FRAP, and DPPH activities in pasta samples enriched with 1% RBE were determined to be 25.51%, 27.33%, and 43.03%, respectively, indicating a significant enhancement in the in vitro bioaccessibility and antioxidant potential of bioactive compounds as compared to the control sample. Enrichment with 1% RBE significantly increased calcium, potassium, magnesium, sodium, zinc, copper, iron, and manganese content of pasta, and contributed substantial percentages of the recommended dietary allowances for these minerals. Overall, the findings showed that RBE could be used as a functional ingredient in pasta formulation for increasing its nutritional and health beneficial properties.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

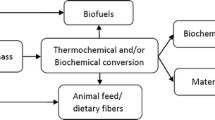

In wood-based work, debarking removes the bark from living trees. Bark is considered an economical feedstock, and millions of cubic meters of bark waste are produced worldwide each year. In addition, the fact that the barks are renewable contributes to the food availability [1]. However, common waste incineration practices restrict the proper disposal of the majority of barks, despite some being repurposed for fuel and agricultural use [2]. Scientific communities that focus on the green chemistry standards search for more environmentally friendly procedures [3]. Therefore, the evaluation of these by-products is a vital requirement in order to promote new products with high added value that prevent their stockpiling, landfilling and burning through waste disposal. They can also provide an important potential for reducing costs in the food industry [4]. In recent years, forest wastes have attracted great attention due to their high content of bioactive compounds. The use of these eco-friendly by-products increases the potential for use both in the development of functional foods and in pharmacology applications. It is crucial to investigate the presence of nutraceutical compounds in inedible plants because destroying one food source to enrich another is nonsensical [5]. Turkish red pine (Pinus brutia Ten.), extensively cultivated in Türkiye’s Mediterranean and Aegean regions, is a commercially significant tree species that constitutes 15% of the nation’s total forest acreage [6].

The optimization of extraction yield and bioactive characteristics of numerous medicinal plants has been the focus of numerous recent scientific studies. Ulukanlı et al. [7] investigated the phytotoxic, antibacterial, insecticidal, and antioxidant properties of the essential oils extracted from the resin of Pinus brutia and Pinus pinea in the Mediterranean region. Moreover, Ucar et al. [8] conducted a study on tannins extracted from Pinus brutia bark using MALDI-TOF MS and 13 C NMR techniques. Furthermore, in a study by Ince et al. (2009) [9], the impact of Pycnogenol® and Pinus brutia bark extract was investigated in a rat model of inflammation induced by carrageenan. Additionally, Cretu et al. [10] conducted an in vitro study investigating the antioxidant properties of a polyphenol-rich extract derived from the bark of Pinus brutia and its various fractions. A review on antimicrobial properties of Pinus brutia was also conducted [11]. However, to the best of our knowledge, no study has assessed the identification and measurement of RBE’s phenolic profiles using tandem mass spectrometry and liquid chromatography, as well as RBE’s application on pasta. In our earlier work [12], we thoroughly examined the process parameter optimization and the in vitro antioxidant, anticancer, antidiabetic, and antibacterial effects of RBE. Therefore, the aim of this work was: (i) to quantify their phenolic composition of RBE (iii) prepare four different pasta supplemented with RBE in the ratio of 0, 0.25, 0.50 and 1% (w: w) and specify their estimated glycemic index, mineral, bioactive properties (TPC, FRAP and DPPH radical scavenging activity), in vitro bioaccessibility of the bioactive compounds as well as sensory characteristics.

Materials and Methods

Collection and Processing of Bark Samples

The bark (Pinus brutia Ten.) samples were obtained from the Burdur-Bucak region in Türkiye, located at coordinates (37.49048332717283, 30.562099099382593). Collection of bark samples, processing of bark and extraction were conducted as described by Erol et al. [12]. For this aim, bark samples were collected from uniform masses in the same locality, initially cleaned by pre-shredding, and subsequently cut into small pieces. The bark underwent lyophilization (Martin Christ, Beta 1–8 LSC plus, Osterode am Harz, Germany) followed by grinding to particles smaller than 1 mm using a Wiley mill as illusrated in Fig. 1. Subsequently, the powdered samples (bark flour) were subjected to Soxhlet extraction with hexane for 12 h to remove lipophilic extracts. The remaining residue was dissolved in water, frozen at -80 °C, and then subjected to a second drying process in the lyophilizer to ensure the bark samples were fully dried. The obtained powdered bark samples for extraction were stored in plastic bags wrapped in aluminum foil at -18 °C until analysis. The extraction process utilized the following parameters: a temperature of 38 °C, a duration of 6 min, and an ultrasonic power of 150 W, resulting in an extraction yield of 14.46%. In this study, an 80% methanol solution was utilized as the extraction solvent at a sample-to-solvent ratio of 1:15 (w/v). Following the extraction, the RBE was lyophilized and powdered for further analyses.

Identification and Quantification of Phenolic Profiles of RBE

Phenolic Acids Determination of RBE by Liquid Chromatography–Tandem Mass Spectrometry (LC–MS/MS)

The qualitative and quantitative analyses of phenolic compounds were carried out based on the previously reported procedure of Pelvan et al. [13] with minor modification. LC–MS/MS (AB SCIEX API 4000 QTrap, Framingham, MA, USA) and Q-OT-MS (Q-exactive hybrid quadrupole-orbitrap, Thermo Scientific, Bremen, Germany) were employed in order to analyse the phenolic compounds of RBE. A AB SCIEX API 4000 QTrap mass spectrometer (MS) with as electrospray ionization (ESI) interface was equipped with a ultra high liquid chromatography (Shimadzu Corporation, Kyoto, Japan) including an autosampler (SIL-20 A HT XR), two pumping modules (LC-20AD XR), two solenoid valve units (FCV-11AL), a system controller (CBM-20 A), a degasser (DGU-20A5), and a column oven (CTO-20AC). The injection volume was 10 µl, and the gradient flow rate was 0.5 mL min− 1. The column (ZORBAX Eclipse Plus Phenyl–hexyl 4.6 × 150 mm 3.5 μm, Agilent Technologies, Santa Clara, CA, United States) was used for all separations. The mobile phase consisting of formic acid-water (0.1:99.9, v/v) (A) and methanol (65:35, v/v) (B) was used as follows: 0–1 min; 5% B, 1–30 min; 5–100% B, 30–31 min; 5% B, 31–40 min; 5% B. The operating parameters were as follows: 3500 V for the ion spray; 20 PSI for the curtain gas; 45 PSI for the nebulizer gas; and 550 °C for the turbo spray.

Determination of Phenolic Profiles of RBE by Q-OT-MS

Phenolic profiles of RBE was specified tentatively employing Q-OT-MS. The column (ZORBAX Eclipse Plus Phenyl–hexyl 4.6 × 150 mm 3.5 μm, Agilent Technologies, Santa Clara, CA, United States) was used. The gradient eluent at an injection volume of 10 µL and a gradient flow of 0.8 mL/min (0.1% formic acid in water is mobile phase A; methanol is mobile phase B) was set as follows: t [min]/B [%] 5–16/0–9, 16–35/9 − 2, 35–50/2–18, 50–65/18–20, 65–80/20–30, and 80/30. Additionally, the following was the programming for MS source conditions: Temperatures of the gas 1 and gas 2 are 50 °C, the ion source is 550 °C, and the ion spray voltage is -4500 V.

Pasta Production

Pasta samples were prepared using durum wheat semolina adding different percentages of RBE (0, 0.25, 0.50 and 1.0% (w/w)) under the conditions earlier described by Vignola et al. [14]. For this purpose, 100 g of durum wheat semolina and 50 mL tap water were mixed. To ensure the homogeneous incorporation of the RBE, the appropriate amount of RBE was first dissolved in the 50 mL of tap water. This solution was then gradually added to the semolina while continuously mixing to ensure even distribution of the extract throughout the mixture. The mixture was allowed to knead for 3 min using a kneading device (Kitchen aid, Model 5 K SM 150). Afterwards, a pasta roller machine was employed in order to get the dough to a thickness of 2 mm and cut into pieces of 5 cm length x 1 cm wide. Pasta samples were firstly dried at 30 °C for 30 min without humidity control, then they were placed under the following conditions: 45 °C of drying temperature, 17.5 h of drying time and 75% of relative humidity. The moisture content of dried pasta was measured as 10.01 ± 0.41%.

Hydrolysis Index (HI) and Predicted Glycemic Index (GI Predicted) of Cooked Pasta

Samples were cut into 0.5 cm × 0.5 cm pieces, and 30 mL of distilled water was added to 2.5 g of the sample. This mixture was stirred in a shaking water bath (Daihan Wisd Wisebath, South Korea) at 37 °C and 130 rpm. The digestion process consisted of three phases: oral, gastric, and pancreatic. The oral phase began by adding 0.1 mL of 10% α-amylase and 0.8 mL of 1 M HCl. After 1 min, the reaction was halted by adding 0.5 mL of the mixture to 2 mL of ethanol. For the gastric phase, 1 mL of 10% pepsin and 0.05 M HCl were added, and the mixture was incubated at 37 °C in a shaking water bath for 30 min. At the end of this period, the gastric digestion was stopped by adding 2 mL of 1 M sodium bicarbonate and 5 mL of 0.2 M sodium maleate buffer (pH 6). The final digestion step involved adjusting the mixture to 55 mL with distilled water. Pancreatic digestion was initiated by adding 1 mL of 5% pancreatin (prepared with 0.2 M maleate buffer) and 0.1 mL of amyloglucosidase. This digestion was performed at 37 °C in the shaking water bath. At 0, 20, 60, 90, 120, and 180 min, 0.5 mL of the liquid sample was removed and mixed with 2 mL of ethanol to halt the reaction. The released reducing sugars were then analyzed using the modified dinitrosalicylic acid (DNS) colorimetric method. Samples were centrifuged at 6000 rpm for 10 min at 24 °C, and 25 µL of the supernatant was mixed with 0.25 mL of acetate buffer containing 1% amyloglucosidase. The mixtures were vortexed and incubated at room temperature for 30 min to assess monosaccharide formation. DNS solution (glucose at 0.5 mg/mL, 4 M NaOH, and DNS reagent in a 1:1:5 ratio) was added to the samples, which were then heated at 95–100 °C for 15 min and rapidly cooled. After adding 4 mL of distilled water, the absorbance of the samples, standards, and blanks was measured spectrophotometrically at 530 nm at 25 °C. To determine the amount of glucose recommended by Goni et al. [15], starch analysis was performed. The following equation was utilized to calculate the starch fraction:

where RDS is rapidly digestible starch, RAG is glucose liberated from starch and sugars after 20 min of incubation, FG is free glucose.

where SDS is slowly digestible starch, AG is available glucose, glucose liberated from starch and sugars after 120 min of incubation, RAG is glucose liberated from starch and sugars after 20 min of incubation.

where RS is resistant starch, TS is total starch, RDS is rapidly digestible starch, SDS is slowly digestible starch.

where TG is total glucose, TS is total starch, and FG is free glucose.

The predicted glycemic index (pGI) values for each sample were determined using the HI values. These figures were computed by dividing each pasta sample’s area under the hydrolysis curve by the comparable area of freshly baked white bread (a reference sample). The following equation was used for the estimation of the pGI values previously reported by Goni et al. [15].

where GI is in vitro glycemic index, HI is the hydrolysis index.

Determination of Optimum Cooking Time

The optimal cooking time of pasta samples was measured using the American Association of Cereal Chemists (AACC) authorized technique 66 − 50 [16]. For this aim, pasta samples weighing 10 g were cooked until the white center of the pasta was completely removed. The samples were then compressed between two glass plates and their cooking time was recorded. The cooking time was recorded as 12.50 min for the control samples, while it was 11.5 min for the other samples supplemented with RBE.

Bioactive Constituents and Antioxidant Activity

Preperation of Extracts

After draining the cooking water of pasta cooked according to the optimum cooking times, the pasta samples were finely chopped into small cubes using the fine brunoise technique. A sample mixture at a ratio of 1:5 (w/v) was prepared in a beaker and mixed with a magnetic stirrer at 300 rpm for 30 min. The pH of this mixture was then adjusted to 4.6 using a buffer solution. The mixture was centrifuged at 4000 rpm for 5 min and the clear supernatant was collected. The clear supernatant was then mixed with ethanol in a 1:1 (v: v) ratio. The resulting solution was used to determine various bioactive properties of the samples.

TPC, FRAP and DPPH Antioxidant Activities

TPC, FRAP and DPPH antioxidant activities of pasta samples were specified by Atlar et al. [17], Erol et al. [12], and Kutlu [18] according to the methods as described above, respectively. TPC results were expressed as mg GAE/100 g determined using the standard curve equation y = 9.579x + 0.0162, with R2 = 0.9986. DPPH antioxidant activity was expressed as µmol TEAC /100 g using the following equation based on the calibration curve: y = 1.629x – 0.001, R2 = 0.9994), trolox solutions at concentrations between 0.25 and 0.6 mg/mL. FRAP contents were determined following equation based on the calibration curve: y = 5.3823x + 0.0235, R2 = 0.9997, where y refers the absorbance and x refers the milligrams of Trolox per gram dry weight of the bark samples. The results were expressed as µmol TEAC/100 g.

Mineral Composition

Major (Ca, K, Mg and Na) and minor minerals (Zn, Cu, Fe and Mn) of pasta samples were analyzed according to the method noted by Bremner [19] utilizing an atomic absorption spectrophotometer (Perkin Elmer-Analyst 800, Norwalk, CT). Initially, app. 0.3–1.0 g of the sample was treated with 6.5 mL of 69% nitric acid (HNO3) and 1.5 mL of 30% hydrogen peroxide (H2O2), after which it was subjected to microwave digestion. Blank solution was prepared using only digestion acid without adding any sample. Microwave conditions (220 PSI, 180 ºC, ramp time 15–25 min, hold time 10–15 min) were utilized with an acceleration time of 15–25 min and a holding time of 10–15 min at 180 °C temperature and 220 psi pressure. After being allowed cooling to room temperature, it was diluted to 50 mL with ultrapure water (Milli-Q water, Millipore, Bedford, MA, USA). Following the microwave digestion process, major and minor minerals were determined. Standard stock solutions of minerals at 1000 µg/mL were prepared, and the relevant standard calibration curve was drawn.

Sensory Evaluation

Before the sensory test, pasta samples were cooked and coded with three-digit numbers before being presented to 16 panelists (8 female, 8 male, aged 18–40). The panelists were trained prior to the evaluation, which included familiarization with the scoring system and sample attributes through several practice sessions. A rating form ranging from 1 to 10 (1: dislike extremely, 5: fair, 10: like extremely) was used. Each pasta sample was presented in a randomized order to avoid bias, and panelists were instructed to cleanse their palate with water between each sample to ensure accurate evaluation. Panelists were non-smokers and were instructed not to consume any food, coffee, or strong-flavored beverages at least one hour before the evaluation to ensure their palate was not influenced. The sensory evaluations were conducted in a well-lit, odor-free room with individual booths to prevent communication between panelists. The evaluations were performed over a period of 30 min to ensure sufficient time for through the assessment. Panelists evaluated the cooked samples for color, odor, taste, appearance, texture, and overall acceptability [20].

In Vitro Bioaccesibility Tests

In vitro bioaccessibility testing was performed on pasta samples with added extracts of RBE at different ratios, based on the three-stage method summarized by Minekus et al. [21]. The effects of in vitro digestion conditions on TPC, DPPH radical scavenging capacities, and FRAP activities of the post-digestion samples were determined.

To simulate oral digestion, 3 mL of ultrapure water, 4 mL of simulated salivary fluid (SSF), α-amylase solution (75 U/mL), 25 µL of 0.3 M CaCl2(H2O)2, and 975 µL of ultrapure water were added to 5 g of pasta sample. The mixture was incubated in a shaking water bath at 37 °C for 2 min. After simulated oral digestion, 2 mL of liquid was taken for each sample. Moreover, to simulate gastric digestion, 8 mL of simulated gastric fluid (SGF), 5 µL of 0.3 M CaCl2(H2O)2, and pepsin solution (2000 U/mL) were added and adjusted to pH 3 with 3 M HCl, and the amount of HCl used was recorded. Then, 1 mL of pepsin solution was added, followed by the addition of 0.3 mol/L CaCl2, and the pH was adjusted to 3 using 1 mol/L HCl. The total volume was brought to 20 mL with the addition of ultrapure water, and the mixture was incubated in a shaking water bath at 37 °C for 2 h. After simulated gastric digestion, 4 mL of liquid was taken for each sample. Furthermore, to simulate intestinal digestion, the remaining mixture was adjusted to pH 7 with 1 M NaOH after adding 8 mL of simulated intestinal fluid (SIF) and pancreatin solution (100 U/mL), bile fluid (10 mM), and the amount of NaOH used was recorded. Then, 5 mL of pancreatin, 2.5 mL of bile solution (160 mM), and 40 µL of 0.3 M CaCl2(H2O)2 were added, and ultrapure water was added to reach a final volume of 40 mL. The remaining mixture was distributed into three intestinal tubes, with a total volume of gastric fluid: simulated intestinal fluid at a ratio of 1:1 (v/v). Each tube was equipped with dialysis tubing with a molecular weight cut-off of 12,000 daltons, representing the portion that can pass from the microvilli of the small intestine into the bloodstream. The tubes were washed with a 0.09% NaCl solution both internally and externally, and the necessary amount of NaHCO3 (0.1 M) was added before sealing both ends tightly. They were then immersed in the remaining three centrifuge tubes and incubated in a shaking water bath at 37 °C for 2 h. After simulated intestinal digestion, 4 mL of liquid was taken for each sample.

Samples obtained after oral, gastric, and intestinal digestion were centrifuged at 4000 rpm for 10 min. The supernatants were filtered through filter paper, and the remaining supernatant was transferred to 15 mL Falcon tubes and stored at -4 °C. TPC determination, DPPH radical scavenging activity, and FRAP antioxidant analyses were performed on the liquids obtained at each stage. Finally, percentage bioaccesibility was calculated by dividing the amount of material in the IN phase (the part that can be dialysed in intestinal digestion) by the amount of material in the OUT phase (the part that cannot be dialysed in intestinal digestion).

Statistical Analysis

Measurements were conducted in triplicate with replicates in each, and the results were presented as the mean value along with its standard deviation. Statistical analyses were performed using the SPSS program (Statistics Software, IBM version 20, USA). Statistical differences between the samples were determined using one-way ANOVA (p < 0.05).

Results and Discussion

Phenolic Profile

The detailed LC-MS/MS conditions and their retention times for RBE are listed in Table 1. Based on the findings, four hydroxybenzoic acids (4-hydroxybenzoic acid, gallic acid, gentisic acid, and vanillic acid), four hydroxycinnamic acids (caffeic acid, ferulic acid, coumaric acid, and T-3-OH cinnamic acid), and three organic acids (oxalic acid, succinic acid, and tartaric acid) were determined. But, chlorogenic acid, cinnamic acid, sinapic acid, and syringic acid didn’t quantify in RBE. Gallic acid (2.30 mg/ 100 g) and hydroxybenzoic acid (3.80 mg/ 100 g) were the two predominant phenolic acids in RBE. On the other hand, RBE was rich sources of organic acids related to succinic acid (17.35 mg/ 100 g), oxalic acid (5.25 mg/ 100 g), and tartaric acid (0.44 mg/100 g). Hydroxybenzoic acid was known its antioxidant and estrogenic acitivities [22]. Gallic acid possessed antioxidant, antiviral, antifungal, anti-hyperlipidemic and anti-hyperglicemic activities [23, 24]. Gentisic acid exhibited important effects on the inhibition of cancers and angiogesis-dependent diseases [25]. Syringic acid had antioxidant [26] and antidiabetic features [27] and played an important role as inhibitor of LDL oxidation [28]. Vanillic acid had been noted to show antioxidant [29], antihyperinsulinemia [30], antihyperglycemia [30] and protective effects against lipid oxidation and cardioprotective properties [31]. Cinnamic acid, chlorogenic acid and sinapic acids have been reported to antioxidant and antimicrobial properties [32,33,34]. Caffeic acid had antioxidant, antitumor anticancer, antibacterial activities [35]. Ferulic acid has been observed to exhibit role as anti-inflamory, anti-oxidant, antimicrobial, anticancer, antidiabetic [36]. Coumaric acid has been known to possess antioxidant and anticancer characteristics (Bommegowda Rashmi & Singh Negi et al., 2020) [37]. Oxalic acid, succinic acid and tartaric acid were responsible for antioxidant activities (Zhang et al., 2020) [38].

Hydrolysis Kinetics and Estimated Glycemic Index

HI determined by the ratio of starch hydrolysis over time and the related pGI of cooked pasta samples are demonstrated in Table 2. The hydrolysis curves of the pasta samples enriched with RBE in the proportion of 0, 0.25, 0.50 and 1.00% (w: w) are illustrated in Fig. 2. The samples enriched with RBE possessed lower HI values than the control sample. The lowest HI values were observed in samples enriched with 1% RBE, whereas the highest HI values were found in the reference samples. It had been previously reported that presence of phenolic compounds could exhibit inhibitory activity against carbohydrate digestive enzyme [39, 40]. The pGI showed the same trend as parameter of HI, such that, a significant diminishment in pGI was specified in all the enriched samples with RBE (0.25, 0.50 and 1.00% (w: w)) as compared to the reference pasta (from 27.18 up to 40.04) (p < 0.05), which was almost equivalent to declines in the pGI with 14.65 to 32.10% as compared to the reference. These results were in accordance with previous reports [40, 41]. Based on the pGI classification (low GI = less than or equal to 55; medium GI = 56–69; High-GI = equal to or higher than 70) [42], all pasta samples could be classified as foods with a low GI. Overall, it could be infered with the results that RBE supplementation into the pasta samples may exhibit hindering influences on starch degradation and glucose release.

TPC, FRAP and DPPH Antioxidant Capacities

Table 3 demostrates the TPC and the antioxidant activities determined by DPPH and FRAP methods of cooked pasta samples enriched with RBE in proportions of 0, 0.25, 0.50 and 1% (w: w). TPC content of the cooked pasta samples significantly increased from 4.12 to 31.29 mg GAE/100 g with increasing levels of incorporation of RBE (p < 0.05). DPPH and FRAP antioxidant activity contents of tested samples also followed a similar trend with TPC values. The supplementation of pasta with RBE caused a significant increase in FRAP activities from 7.45 µmol TEAC /100 g to 99.46 µmol TEAC /100 g (p < 0.05). The FRAP antioxidant activity in reference pasta was found as 7.45 µmol TEAC/100 g, and the gradual supplementation of RBE led to an increase in this activity. DPPH scavenging activities of pasta samples ranged between 11.45 and 70.36 µmol TEAC /100 g. Enrichment of RBE at 0.25-1.00% significantly increased the DPPH radical scavenging ability of pasta samples (p < 0.05). Increase in antioxidant and antiradical potential of pasta by the incorporation of RBE could be attributed to the high abundance of phenolic compounds in RBE with antioxidant potential. These compounds could synergistically enhance TPC, FRAP and DPPH antiradical activities in RBE-fortified pasta as their ratio increased. Similar findings were reported for pasta with orange peel [43], noodles with pomegranate peel extract [44], noodles with watermelon peel [45], fresh noodles with artichoke waste extract [46], and pasta with moringa sprouts [47].

In Vitro Bioaccesibility

In vitro gastrointestinal digestion was conducted to determine the bioaccessible polyphenol potential and antioxidant activity of pasta samples and the findings were tabulated in Table 4. The TPC values were determined to be in the range of 0.11–2.93 mg GAE/100 g for the control samples, and 17.67–51.58 mg GAE/100 g for the pasta samples enriched with 1% RBE across the oral, gastric, and intestinal IN and OUT phases.The highest TPC values for both samples were observed in the OUT phase of the small intestine, followed by the gastric phase. On the other hand, FRAP values were 2.97–65.95, 4.38–83.73, 1.53–39.74, and 9.71-105.64 µmol TE/100 g for the oral, gastric, intestinal IN, and OUT phases in control and 1% RBE-enriched pasta samples, respectively. Regarding FRAP values, in control samples, the highest values were observed in the OUT phase of the small intestine, followed by gastric, oral, and intestinal IN phases. In enriched pasta, the highest FRAP values were determined in the OUT phase of the small intestine, followed by gastric, oral, and intestinal IN phases. Additionally, DPPH activities were 2.23–21.29, 4.83–40.46, 2.55–26.98, and 16.04–35.71 µmol TE/100 g for the oral, gastric, intestinal IN, and OUT phases in control and 1% RBE-enriched pasta, respectively. According to the findings, the highest DPPH activity in control samples was observed in the OUT phase of the small intestine, followed by gastric, intestinal IN, and oral phases, respectively. On the other hand, in enriched pasta, the highest DPPH activity was determined in the gastric phase, followed by the OUT phase of the small intestine, intestinal IN phase, and oral phase, respectively. The enrichment of pasta with RBE led to an increase in TPC, ABTS, and FRAP activities in all phases compared to control samples. When the results were compared with the data in Table 3, in vitro gastrointestinal digestion conditions led to a decrease in TPC values for control samples. However, in the enriched pasta, higher TPC content was determined in the gastric and intestinal OUT phases. Moreover, in control samples, FRAP values decreased except for the OUT phase of the small intestine. In enriched pasta, while FRAP activity values remained higher levels in the intestinal IN phase (Table 3), a decrease occurred in the other phases. Furthermore, the DPPH antiradical activity values of the control samples followed a similar trend with the FRAP antioxidant activity results of the control samples. Compared to the results in Table 3, lower DPPH activity was determined in the mouth, stomach and the IN phases of the small intestine as a result of in vitro gastrointestinal digestion. On the other hand, DPPH activity of the enriched samples was lower in all phases compared to Table 3.

A high bioaccessibility index indicates that a greater proportion of a component becomes liberated and available for absorption during the digestion process, thereby enhancing its usability within the body. Moreover, the bioaccessibility of TPC, FRAP, and DPPH activities in the pasta sample enriched with 1% RBE was determined to be 25.51%, 27.33%, and 43.03%, respectively. The calculated BI values for DPPH, TPC, and FRAP in the enriched pasta samples were higher as compared to the control sample. This suggests that the enrichment of pasta with RBE not only improves the overall antioxidant capacity but also enhances the availability of these bioactive compounds during in vitro digestion, potentially increasing their beneficial effects on health.

The relatively low levels of phenolics observed in control pasta samples during the oral phase (following 2 min of digestion with α-amylase) may be attributed to the limited solubility of these compounds in saliva and the duration of this phase. The rise in phenolic content under gastric conditions indicates that the acidic pH and digestive enzymes might aid in the liberation of phenolics bound within the plant matrix [48]. The correlation between phenolic characteristics and bioaccesibility has been noted to be affected by factors such as chemical structure (degree of polymerization and molecular size), glycosylation, conjugation with other phenolics, and solubility [49]. As an example, isoflavones, phenolic acids, quercetin glycosides and catechins demonstrate high absorption rates, whereas larger polyphenols exhibit lower absorption rates. Overall, the results demonstrated that the digestion phases had varying effects on these parameters, with the highest activities were generally observed in the OUT phase of the small intestine. The findings indicated that RBE-enriched pasta offered improved functional properties and higher bioaccessibility of phenolic compounds, which could be beneficial for developing health-oriented food products.

Mineral Content Evaluation

The mineral content of RBE and the pasta samples fortified with RBE in the ratios of 0, 0.25, 0.50 and 1.00% RBE (w: w) were tabulated in Table 5. Regarding to the findings, RBE had higher mineral content compared to the control pasta samples as expected. Regarding mineral composition of RBE, the predominant minerals were sodium (1986 mg/kg), followed by calcium (1786 mg/kg), potassium (1679 mg/kg), magnesium (354.64 mg/kg), zinc (22.54 mg/kg), manganese (10.73 mg/kg), copper (1.75 mg/kg), and iron (< 2.5 mg/kg). Moreover, pasta samples formulated with 1% RBE presented the higher Ca, K, Mg, Na, Zn, Cu, Fe and Mn contents when compared to the pasta samples incorporated with 0, 0.25 and 0.50% RBE (w: w). It was previously reported that Mn, Cu, and Zn acted as antioxidants. For that reason, these minerals may contribute the antioxidant properties of RBE [50]. According to the data provided in the table, 100 g of RBE corresponded to the following percentages of the recommended dietary allowance (RDA) values for the elements: zinc (225.4%), copper (175.0%), iron (< 7.1%), calcium (223.3%), magnesium (94.6%), potassium (83.9%), and manganese (536.5%).

Potassium had been reported to support heart and bone health [51] and found in the range of 2.93 to 14.32 mg/100 g in pasta samples. The contribution of the RBE addition into the pasta were less than 25% of the potassium RDA. Calcium was essential for healthy bones and teeth [52] and 100 g of the pasta contributed 1.20–3.22% of the calcium RDA. Additionally, sodium had a different fundamental roles in the body regarding to regulation of the normal cellular homeostasis, maintenance of fluid and electrolyte balance and blood pressure [53]. Moreover, iron was a fundamantal mineral for almost all living organisms since it found in a lot of metabolic processes [54]. Iron content was less than 2.5 mg/100 g for all tested samples, supplying about less than 17.9% of the iron RDA. Additionally, zinc deficiency was a global public health problem encountered in the developing countries, the rural areas and in the poorest communities as cereal-based diets decreased the absorption of zinc from the intestine [55]. Zinc content of samples were less than 2.5 mg/100 g, supplying about less than 25% of the zinc RDA. Furthermore, manganese is a crucial biological element in order to have roles on enzyme systems related to the carbohydrates, fats, and proteins metabolism [56]. Manganese content in pasta samples were less than 2.5 mg/100 g, providing about 125% of the RDA of the manganese. As well, copper was a cofactor in many enzymes [57] and were less than 2.5 mg/100 g in all pasta samples, providing about 250% of the copper RDA.

Sensory Properties

The sensory scores regarding to color, odor, taste, appearance, texture and overall acceptability parameters of cooked pasta samples were given in Table 6. Higher scores indicated greater sensory acceptability of the pasta samples. Appearance, texture and overall acceptability received markedly lower scores in the pasta enriched with 1% RBE (w: w) compared with the other pasta samples. Hence, increasing RBE level progressively changed the taste, appearance, texture and overall acceptability of the end product. Suprisingly, the pasta samples prepared with 1% RBE (w: w) received significantly higher taste and odour scores than the pasta fortified with 0.50 RBE (w: w) (p < 0.05). These findings indicated that while higher levels of RBE could impact certain sensory attributes negatively, they may enhance specific qualities such as taste and odor. Therefore, incorporating RBE into pasta formulations could improve functionality and offered a desirable sensory profile if balanced carefully. Further optimization of RBE levels and additional sensory evaluations could help in achieving the optimal balance between functionality and sensory acceptance.

Conclusion

This study presents a comprehensive analysis of the identification and quantification of phenolic and organic compounds in RBE. The research further investigates pasta samples enriched with RBE at concentrations of 0%, 0.25%, 0.50%, and 1% (w: w), evaluating their biological activities (TPC, FRAP, and ABTS antioxidant activities), mineral compositions, in vitro starch digestibility properties, sensory attributes, and the in vitro bioaccessibility of bioactive compounds. Based on the findings, gallic acid and hydroxybenzoic acid were identified as the predominant phenolic acids in RBE, while RBE was also found to be a rich source of organic acids such as succinic acid, oxalic acid, and tartaric acid. Enrichment of pasta with RBE at concentrations of 0.25%, 0.50%, and 1% (w: w) resulted in a lower glycemic index, increased mineral content, enhanced antioxidant activity, and higher odor and taste scores compared to the control pasta. The forest industry has the potential to generate substantial income by developing high-value functional food products from these alternative, eco-friendly by-products. This approach not only contributes to sustainable practices but also leverages underutilized resources to create innovative food solutions.

Data Availability

The authors assert that the data underpinning the conclusions of this study can be accessed from the corresponding author upon a reasonable request.

References

Sillero, L., Prado, R., Welton, T., Labidi, J.: Energy and environmental analysis of flavonoids extraction from bark using alternative solvents. J. Clean. Prod. 308, 127286 (2021)

Nemli, G., Gezer, E.D., Yıldız, S., Temiz, A., Aydın, A.: Evaluation of the mechanical, physical properties and decay resistance of particleboard made from particles impregnated with Pinus brutia bark extractives. Bioresour Technol. 97(16), 2059–2064 (2006)

Sillero, L., Prado, R., Andrés, M.A., Labidi, J.: Characterisation of bark of six species from mixed Atlantic forest. Ind. Crops Prod. 137, 276–284 (2019)

Andrew, J., Masetlwa, J., Tesfaye, T., Sithole, B.: Beneficiation of eucalyptus tree barks in the context of an integrated biorefinery–optimisation of accelerated solvent extraction (ASE) of polyphenolic compounds using response surface methodology. Sustain. Chem. Pharm. 18, 100327 (2020). https://doi.org/10.1016/j.scp.2020.100327

Gascón, S., Jiménez-Moreno, N., Jiménez, S., Quero, J., Rodríguez-Yoldi, M.J., Ancín-Azpilicueta, C.: Nutraceutical composition of three pine bark extracts and their antiproliferative effect on Caco-2 cells. J. Funct. Foods. 48, 420–429 (2018)

Icgen, Y., Kaya, Z., Cengel, B., Velioğlu, E., Öztürk, H., Önde, S.: Potential impact of forest management and tree improvement on genetic diversity of Turkish red pine (Pinus brutia Ten.) Plantations in Turkey. Ecol. Manage. 225(1–3), 328–336 (2006)

Ulukanli, Z., Karabörklü, S., Bozok, F., Ates, B., Erdogan, S., Cenet, M., Karaaslan, M.G.: Chemical composition, antimicrobial, insecticidal, phytotoxic and antioxidant activities of Mediterranean Pinus brutia and Pinus pinea resin essential oils. Chin. J. Nat. Med. 12(12), 901–910 (2014)

Ucar, M.B., Ucar, G., Pizzi, A., Gonultas, O.: Characterization of Pinus brutia bark tannin by MALDI-TOF MS and 13 C NMR. Ind. Crops Prod. 49, 697–704 (2013)

Ince, I., Yesil-Celiktas, O., Karabay-Yavasoglu, N.U., Elgin, G.: Effects of Pinus brutia bark extract and Pycnogenol® in a rat model of carrageenan-induced inflammation. Phytomedicine. 16(12), 1101–1104 (2009)

Cretu, E., Karonen, M., Salminen, J.-P., Mircea, C., Trifan, A., Charalambous, C., Miron, A.: In Vitro Study on the antioxidant activity of a Polyphenol-Rich Extract from Pinus brutia Bark and its fractions. J. Med. Food. 16(11), 984–991 (2013)

Dığrak, M., İlçim, A., Hakkı Alma, M.: Antimicrobial activities of several parts of Pinus brutia, Juniperus oxycedrus, Abies Cilicia, Cedrus libani, and Pinus nigra. Phytother Res. 13(7), 584–587 (1999)

Erol, K.F., Kutlu, G., Tornuk, F., Guzel, M., Donmez, I.E.: Determination of antioxidant, anticancer, antidiabetic, and antimicrobial activities of Turkish red pine (Pinus brutia Ten.) Bark ultrasound-assisted extract as a functional food additive. Acta Aliment. 52(1), 102–112 (2023)

Pelvan, E., Olgun, E., Karadağ, A., Alasalvar, C.: Phenolic profiles and antioxidant activity of Turkish Tombul hazelnut samples (natural, roasted, and roasted hazelnut skin). Food Chem. 244, 102–108 (2018)

Vignola, M.B., Bustos, M.C., Pérez, G.T.: Comparison of quality attributes of refined and whole wheat extruded pasta. LWT. 89, 329–335 (2018)

Goñi, I., Garcia-Alonso, A., Saura-Calixto, F.: A starch hydrolysis procedure to estimate glycemic index. Nutr. Res. 17, 427–437 (1997)

AACC: American Association of Cereal Chemistry Approved Methods 10th ed. St. Paul. Available online: (2022). http://methods.aaccnet.org/toc.aspx Accessed 29 June 2022

Atlar, G.C., Kutlu, G., Tornuk, F.: Design and characterization of chitosan-based films incorporated with summer savory (Satureja hortensis L.) essential oil for active packaging. Int. J. Biol. Macromol. 254, 127732 (2024)

Kutlu, G.: Valorization of various nut residues grown in Turkey: Antioxidant, anti-cholinesterase, anti-diabetic, and cytotoxic activities. Food Sci. Nutr. (2024). https://doi.org/10.1002/fsn3.4103

Bremner, J.: Nitrogen-total. Methods soil. Analysis: Part. 3 Chem. Methods. 5, 1085–1121 (1996)

Kutlu, G., Yılmaz, S., Karabulut, A.E.: Development of a new vegan muffin formulation: Assessing its quality and sensory characteristics. Eur. Food Sci. Eng. 5(1), 26–34 (2024)

Minekus, M., Alminger, M., Alvito, P., Ballance, S., Bohn, Bourlieu, C., Brodkorb, A.A.: Standardised static in vitro digestion method suitable for food–an international consensus. Food func. 5(6), 1113–1124 (2014)

Manuja, R., Sachdeva, S., Jain, A., Chaudhary, J.: A comprehensive review on biological activities of p-hydroxy benzoic acid and its derivatives. Int. J. Pharm. Sci. Rev. Res. 22(2), 109–115 (2013)

Kahkeshani, N., Farzaei, F., Fotouhi, M., Alavi, S.S., Bahramsoltani, R., Naseri, R., et al.: Pharmacological effects of gallic acid in health and diseases: A mechanistic review. Iran. J. Basic. Med. Sci. 22(3), 225 (2019)

Xiang, Z., Guan, H., Zhao, X., Xie, Q., Xie, Z., Cai, F., Wang, C.: Dietary gallic acid as an antioxidant: A review of its food industry applications, health benefits, bioavailability, nano-delivery systems, and drug interactions. Food Res. Int. 114068 (2024)

Fernández, I.S., Cuevas, P., Angulo, J., López-Navajas, P., Canales-Mayordomo, A., González-Corrochano, R.: Gentisic acid, a compound associated with plant defense and a metabolite of aspirin, heads a new class of in vivo fibroblast growth factor inhibitors. J. Biol. Chem. 285(15), 11714–11729 (2010)

Sabahi, Z., Khoshnoud, M.J., Khalvati, B., Hashemi, S.S., Farsani, Z.G., Gerashi, H.M., Rashedinia, M.: Syringic acid improves oxidative stress and mitochondrial biogenesis in the liver of streptozotocin-induced diabetic rats. Asian Pac. J. Trop. Biomed. 10(3), 111–119 (2020)

Vinayagam, R., Jayachandran, M., Xu, B.: Antidiabetic effects of simple phenolic acids: A comprehensive review. Phytother Res. 30(2), 184–199 (2016)

Mabile, L., Meilhac, O., Escargueil-Blanc, I., Troly, M., Pieraggi, M.T., Salvayre, R., Nègre-Salvayre, A.: Mitochondrial function is involved in LDL oxidation mediated by human cultured endothelial cells. Arterioscler. Thromb. Vasc Biol. 17(8), 1575–1582 (1997)

Sharma, N., Tiwari, N., Vyas, M., Khurana, N., Muthuraman, A., Utreja, P.: An overview of therapeutic effects of vanillic acid. Plant. Arch. 20(2), 3053–3059 (2020)

Chang, W.C., Wu, J.S.B., Chen, C.W., Kuo, P.L., Chien, H.M., Wang, Y.T., Shen, S.C.: Protective effect of vanillic acid against hyperinsulinemia, hyperglycemia and hyperlipidemia via alleviating hepatic insulin resistance and inflammation in high-fat diet (HFD)-fed rats. Nutrients. 7(12), 9946–9959 (2015)

Ashokkumar, N., Vinothiya, K.: Protective impact of vanillic acid on lipid profile and lipid metabolic enzymes in diabetic hypertensive rat model generated by a high-fat diet. Curr. Drug Discov. Technol. 20(3), 66–73 (2023)

Nimse, S.B., Pal, D., Mazumder, A., Mazumder, R.: Synthesis of cinnamanilide derivatives and their antioxidant and antimicrobial activity. J. Chem. 208910 (2015) (2015)

Miao, M., Xiang, L.: Pharmacological action and potential targets of chlorogenic acid. Adv. Pharmacol. 87, 71–88 (2020)

Nićiforović, N., Abramovič, H.: Sinapic acid and its derivatives: Natural sources and bioactivity. Compr. Rev. Food Sci. Food Saf. 13(1), 34–51 (2014)

Espíndola, K.M.M., Ferreira, R.G., Narvaez, L.E.M., Silva Rosario, A.C.R., Silva, D., Silva, A.H.M.: Chemical and pharmacological aspects of caffeic acid and its activity in hepatocarcinoma. Front. Oncol. 9, 541 (2019)

Kumar, N., Pruthi, V.: Potential applications of ferulic acid from natural sources. Biotechnol. Rep. 4, 86–93 (2014)

Bommegowda Rashmi, H., Singh Negi, P.: Phenolic acids from vegetables: A review on processing stability and health benefits. Food Res. Int. 109298 (2020)

Zhang, D., Nie, S., Xie, M., Hu, J.: Antioxidant and antibacterial capabilities of phenolic compounds and organic acids from Camellia oleifera cake. Food Sci. Biotechnol. (2019)

Hanhineva, K., Törrönen, R., Bondia-Pons, I., Pekkinen, J., Kolehmainen, M., Mykkänen, H., Poutanen, K.: Impact of dietary polyphenols on carbohydrate metabolism. Int. J. Mol. Sci. 11(4), 1365–1402 (2010)

Lalegani, S., Gavlighi, A., Azizi, H., Sarteshnizi, M.H.A.: Inhibitory activity of phenolic-rich pistachio green hull extract-enriched pasta on key type 2 diabetes relevant enzymes and glycemic index. Food Res. Int. 105, 94–101 (2018)

Armellini, R., Peinado, I., Asensio-Grau, A., Pittia, P., Scampicchio, M., Heredia, A., Andres, A.: In vitro starch digestibility and fate of crocins in pasta enriched with saffron extract. Food Chem. (2019)

Similä, M.E., Valsta, L.M., Kontto, J.P., Albanes, D., Virtamo, J.: Low-, medium-and high-glycaemic index carbohydrates and risk of type 2 diabetes in men. Br. J. Nutr. 105(8), 1258–1264 (2011)

Crizel, T., de Rios, M., de Thys, A., Flôres, R.C.S.: Effects of orange by-product fiber incorporation on the functional and technological properties of pasta. Food Sci. Technol. (Brazil). 35(3), 546–551 (2015)

Kazemi, M., Karim, R., Mirhosseini, H., Hamid, A.A., Tamnak, S.: Processing of parboiled wheat noodles fortified with pulsed ultrasound pomegranate (Punica granatum L. var. Malas) peel extract. Food Bioproc Technol. 10(2), 379–393 (2017)

Chakrabarty, N., Mourin, M.M., Islam, N., Haque, A.R., Akter, S., Siddique, A.A., Sarker, M.: Assessment of the potential of watermelon rind powder for the value addition of noodles. J. Biosyst Eng. 45(4), 223–231 (2020)

Pasqualone, A., Punzi, R., Trani, A., Summo, C., Paradiso, V.M., Caponio, F., Gambacorta, G.: Enrichment of fresh pasta with antioxidant extracts obtained from artichoke canning by-products by ultrasound-assisted technology and quality characterisation of the end product. Int. J. Food Sci. Technol. 52(9), 2078–2087 (2017)

Coello, K.E., Peñas, E., Martinez-Villaluenga, C., Elena Cartea, M., Velasco, P., Frias, J.: Pasta products enriched with moringa sprout powder as nutritive dense foods with bioactive potential. Food Chem. 360, 130032 (2021)

Kilicli, M., Erol, K.F., Toker, O.S., Tornuk, F.: Production of tomato powder from tomato puree with foam-mat drying using green pea aquafaba: Drying parameters and bioaccessibility of bioactive compounds. J. Sci. Food Agric. 103(7), 3691–3700 (2023)

Barba, F.J., Mariutti, L.R., Bragagnolo, N., Mercadante, A.Z., Barbosa-Cánovas, G.V., Orlien, V.: Bioaccessibility of bioactive compounds from fruits and vegetables after thermal and nonthermal processing. Trends Food Sci. Technol. 67, 195–206 (2017)

Akwu, N.A., Naidoo, Y., Singh, M.: A comparative study of the proximate, FTIR analysis and mineral elements of the leaves and stem bark oF Grewia Lasiocarpa E.Mey. Ex Harv.: An indigenous southern African plant. S Afr. J. Bot. 123, 9–19 (2019)

Weaver, C.M.: Potassium and health. Adv. Nutr. 4(3), 368S–377S (2013)

Theobald, H.E.: Dietary calcium and health. Nutr. Bull. 30(3), 237–277 (2005)

Bernal, A., Zafra, M.A., Simón, M.J., Mahía, J.: Sodium homeostasis, a balance necessary for life. Nutrients. 15(2), 395 (2023)

Crichton, R.: Iron Metabolism: From Molecular Mechanisms to Clinical Consequences. Wiley (2016)

Gupta, S., Brazier, A.K.M., Lowe, N.M.: Zinc deficiency in low- and middle-income countries: Prevalence and approaches for mitigation. J. Hum. Nutr. Diet. 33(5), 624–643 (2020)

Campbell, L.C., Nable, R.O.: Physiological functions of manganese in plants. In: Manganese in Soils and Plants: Proceedings of the International Symposium on ‘Manganese in Soils and Plants’ held at the Waite Agricultural Research Institute, The University of Adelaide, Glen Osmond, South Australia, August 22–26, 1988 as an Australian Bicentennial Event, pp. 139–154 Dordrecht: Springer Netherlands. (1988)

Tsang, T., Davis, C.I., Brady, D.C.: Copper biology. Curr. Biol. 31(9), R421–R427, Weaver, C.M.: Potassium and health. Adv. Nutr. 4(3), 368S–377S (2013) (2021)

Anonymous Turkish Food Codex Regulation on Food Labelling and Informing Consumers, Issue: 29960: (2017)

Acknowledgements

There are no acknowledgements.

Funding

Kubra Feyza EROL received support from the Council of Higher Education (CoHE) through the 100/2000 Ph.D. scholarship program and from The Scientific and Technological Research Council of Türkiye (TUBITAK) under grant 2211-C.

Author information

Authors and Affiliations

Contributions

Kubra Feyza EROL: Writing – original draft, methodology, visualization, validation, investigation. Gozde KUTLU: Investigation, Writing – original draft, review & editing. Elmas Oktem Olgun: Methodology. Fatih TORNUK: Validation, conceptualization, supervision, resources, review & editing.

Corresponding author

Ethics declarations

Ethical Approval and Consent to Participate

Not Applicable.

Consent for Publication

Not applicable.

Competing Interests

The authors have disclosed that they have no conflicts of interest.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Erol, K.F., Kutlu, G., Olgun, E.O. et al. A Sustainable Innovation: Functionalization of Pasta with Methanol Extract of Turkish Red Pine (Pinus brutia Ten.) Barks. Waste Biomass Valor (2024). https://doi.org/10.1007/s12649-024-02702-1

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s12649-024-02702-1