Abstract

Purpose

This study was conducted to investigate the potential of watermelon rind as a source of nutrients for the value addition of noodles.

Methods

Three different varieties of watermelon with yellow, dark green, and pale green rind were separately dried to produce rind powder and studied for their proximate composition, phenol content, and antioxidant activity. The effect of the substitution of wheat flour with different levels of watermelon rind powder (WRP) (10–20%) on the cooking and sensory attributes of noodles was investigated.

Results

The results showed that the rind powder of the pale green rind watermelon (PGRW) contained the maximum amount of protein (19.74%), whereas the highest amount of fiber (13.35%) was present in that of the dark green rind watermelon (DGRW). In contrast, the rind powder of the yellow rind watermelon (YRW) had a higher amount of fat (13.00%) than DGRW (8.37%) and PGRW (5.83%). However, the total phenol content in terms of gallic acid equivalent (GAE) was the maximum in PGRW (166.88 GAE/g), which resulted in greater antioxidant activity (13.28%). Furthermore, the incorporation of WRP affected the cooking yield of the noodles. Both the cooking yield and cooking loss were at maximum with the incorporation of 15% rind powder. Sensory evaluation indicated that the control sample was the most acceptable, followed by the noodles with 10% WRP, among the value-added noodles.

Conclusion

Considering the nutritional potential, 10% WRP can be incorporated with wheat flour for the large-scale production of noodles.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Watermelon (Citrullus lanatus) is a medium to large, oval, round, or oblong tropical fruit from the family Cucurbitaceae; it contains substantial amounts of lycopene, carotenoids, and phenolic substances (Brat et al. 2006). The consumption of watermelon pulp and juice has been reported to reduce blood pressure and prevent stroke, heart attacks, and cancer as well as reinforce the sex drive (Slavin and Lloyd 2012). However, the watermelon rind and seeds are solid wastes that constitute 30% of the total weight of watermelon. Research shows that watermelon rind is a potential source of dietary fiber and phytochemicals such as citrulline, which shows antioxidant effects against free radical damage (Al-Sayed and Ahmed 2013).

Food waste with a high moisture content requires an extended drying process, even with the use of steam heat from an incineration plant. In this approach, a steam heat exchanger from an incineration plant is used to generate heated air, which is then injected into the heating jacket installed at the bottom of the dryer. Subsequently, drying is performed for approximately 50 h at a temperature lower than 165 °C (Song et al. 2019). It has been reported that direct steam instead of heated air from the steam generator of an incineration plant is effective for drying high-moisture food waste. Additionally, biogas generation from organic waste is a promising technique; however, high-moisture food waste has not received much attention for anaerobic digestion (Vats et al. 2020). Consequently, the inedible portions of fruits from the processing area are generally discarded for open-field dumping, which causes severe environmental pollution owing to greenhouse gas emission (Garcia-Garcia et al. 2017; Tonini et al. 2018). Instead of discarding watermelon rind as waste, its powder may serve as a nutrient source for developing food products with wheat flour.

Furthermore, dehydrated watermelon rind is less susceptible to spoilage during storage and is more convenient for the substitution of wheat flour in the development of food products (noodles, cake, and cookies). As an excellent source of dietary fiber and antioxidants, WRP has been utilized for the value addition of flour-based food products. For instance, cookies prepared with up to 20% of WRP have high amounts of dietary fiber and total phenols, resulting in a decrease in the glycemic index and an increase in the antioxidant effect with acceptable sensory attributes (Naknaen et al. 2016). Additionally, the incorporation of WRP enhanced the volume and specific volume of cakes. Furthermore, WRP supplementation retarded staling and lipid oxidation owing to the greater antioxidant activity (Al-Sayed and Ahmed 2013). Adegunwa et al. (2019) prepared a composite flour of plantain and WRP in varying proportions to produce sponge cakes. WRP supplementation significantly increased the crude protein and ash content, whereas the textural properties, including the stickiness, springiness, and cohesiveness of the cake, decreased significantly.

In addition to bakery products, noodles are a popular wheat-based food in Asia owing to its low cost, cooking convenience, and palatable taste (Tan et al. 2016). It is a prime candidate for the addition of nutrients since dietary fiber is lacking in wheat. In addition, the demand for nutrient-enriched food products has increased in recent years. Several studies have focused on the preparation of value-added noodles by partially replacing wheat flour with banana flour (Choo and Aziz 2010), kenaf seed flour (Zawawi et al. 2014), fiber from kimchi (Kim et al. 2017), and sweet potato flour (Ginting and Yulifianti 2015). In a study of wet noodle preparation involving WRP (Ho and Che Dahri 2016), it was observed that the incorporation of rind powder did not significantly affect the lightness and cooking yield. The results revealed that the firmness, cooking loss, and pH value of the wet noodles decreased but the fiber, carbohydrate, ash, and total phenols increased gradually with the increasing proportion of rind powder.

The nutritional quality assessment of different varieties of WRP should be performed before its application in product development. However, research pertaining to the value addition of noodles incorporating WRP is limited. Hence, this study was performed to investigate the nutritional profiles of three varieties of WRP and their use in the value addition of noodles.

Materials and Method

Equipment and chemicals

The equipment used in this study included an electric balance (ML204, Mettler Toledo, OH, USA), a hot plate (SB162–3, Stuart, NY, USA), a vortex mixture (SA8, Camlab, Cambridge, UK), a hot-air oven dryer (MOV-112, Sanyo, Osaka. Japan), a muffle furnace (SYD-508, Westtune, Zhejiang, China), and a spectrophotometer (UV-1800 UV/Vis, Shimadzu, Kyoto, Japan). Chemicals, including sulfuric acid, sodium hydroxide, ethanol, methanol, sodium carbonate, sodium thiosulfate, boric acid, petroleum ether, and carboxymethyl cellulose (CMC), were obtained from Merck (Merck India Ltd., Mumbai, India). Gallic acid and 2,2-diphenyl-1-picrylhydrazyl (DPPH) were purchased from Sigma–Aldrich (St. Louis, MO, USA).

Sample collection and preparation of WRP

Fresh watermelons with yellow, dark green, and pale green rind were purchased from a local market in Dhaka, Bangladesh. The watermelons were thoroughly washed using tap water to remove adhered dirt particles and sand; subsequently, they were sliced, and the pulp was scraped off to obtain the watermelon rind. The watermelon rind was further sliced into thin pieces using a slicer and spread onto trays for hot-air oven drying. The drying parameters—60 °C for 24 h—were selected based on published literature to obtain WRP for product development (Al-Sayed and Ahmed 2013; Ho and Che Dahri 2016; Naknaen et al. 2016). The dehydrated rind slices were ground to a fine powder for physicochemical analyses and the preparation of value-added noodles.

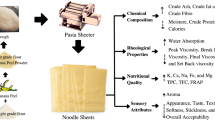

Preparation of noodles

The composition of the noodles is presented in Table 1. The noodles were prepared using commercial wheat flour, whole egg, salt, CMC, and water, whereas wheat flour was partially substituted by WRP at 0% (control), 10%, 15%, and 20%. Initially, wheat flour was mixed with rind powder and then salt and CMC were added to the mixed flour. After thorough mixing, a suspension of egg and water was added to prepare a dough. To obtain the desired noodle thickness, the dough was stored at room temperature for 10 min before being sheeted on a noodle machine. The wet noodles were dried at 60 °C for 8 h using a hot-air oven dryer.

Proximate compositions

The proximate compositions of the WRP, including moisture, ash, crude protein, and fat, were determined using standard methods described by the association of official analytical chemists (AOAC) (1995). The total amount of carbohydrate in the WRP was calculated as follows:

The energy value of the WRP was calculated by multiplying the amounts of carbohydrate, protein, and fat by their factorial values as follows:

The crude fiber of the WRP was determined according to the method described by the AOAC (1995), where the defatted sample after soxhlet extraction was subjected to acid–base digestion with 200 mL of 1.25% H2SO4 and 1.25% NaOH for 30 min. After digestion, the mixture was filtered to separate the residue, which was then washed with 25 mL of ethanol. The remaining residue was dried at 130 °C for 2 h in an oven dryer and then incinerated at 550 °C for 2 h. The weight loss of incineration was used to determine the crude fiber as follows:

The sugar content of the WRP was determined using the Luff–Schoorl titration method (Marrubini et al. 2017).

Total phenol content and free radical–scavenging activity

Briefly, 40 mg of each dried rind powder sample was mixed with 20 mL of methanol in a conical flask and transferred to a shaking water bath at 40 °C for 3 h. The solution was filtered to separate the methanol extract and solid residues.

The total phenol content of the WRP was determined using the Folin–Ciocalteu method described by Alhakmani et al. (2013). The methanol extract (0.5 mL) was gently mixed with 2.5 mL of Folin–Ciocalteu reagent (diluted 10 times with water) and 2.0 mL of Na2CO3 (7.5% w/v) solution, and the mixture was then incubated for 20 min at room temperature (25 °C). The absorbance was measured at 760 nm using a UV spectrophotometer with methanol as the blank. A standard curve was prepared using gallic acid solution at concentrations of 0.2 to 1 mg/L.

The free radical-scavenging activity of WRP in terms of DPPH was determined according to the method described by Brand-Williams et al. (1995). The methanol extract (2.0 mL) was mixed with 3.0 mL of a DPPH solution (200 μg/mL). After a 30-min reaction period at room temperature, the absorbance was measured at 515 nm against pure methanol (blank) using a UV spectrophotometer. The free radical–scavenging activity was expressed as inhibition and calculated as follows:

Color analysis

Color analysis of the WRP in terms of L*, a*, and b* values was performed using a chroma meter (Minolta, CR-300, Osaka, Japan), where L* indicates the lightness value (0 = black, 100 = white), a* the red/green value (+ value = redness, − value = greenness), and b* the yellow/blue value (+ value = yellowness, −value = blueness). The hue angle and chroma (C) were calculated as hab = tan−1 − (b/a) and C = (a2 + b2), respectively.

Cooking properties of the noodles

The cooking properties of the noodles were measured in terms of cooking yield and cooking loss according to the method described by Zawawi et al. (2014). Approximately 10 g of noodles and 150 mL of distilled water were placed in a beaker and cooked for 10 min with continuous stirring; the beaker was covered with aluminum foil to prevent evaporation. After cooking, the noodles were separated and allowed to cool for 15 min. The cooking yield was calculated as follows:

After the noodles were separated, the filtrate was transferred into a 250-mL volumetric flask, and distilled water was added up to the mark. The mixture was subjected to vortex mixing for 15 min. Subsequently, a 10-mL aliquot was placed in a crucible and subjected to oven drying at 105 °C until a constant weight was attained. Cooking loss was measured using the following equation:

Sensory evaluation of the noodle samples

Sensory evaluation was conducted using the hedonic test on a nine-point scale to evaluate the overall acceptability of the noodles (Wichchukit and O'Mahony 2015). In the sensory evaluation, 10 expert panelists were asked to score the quality attributes of the cooked noodles (appearance, flavor, mouth feel, taste, and overall quality) based on their degree of preference, where 1 = dislike extremely, 2 = dislike very much, 3 = dislike moderately, 4 = dislike slightly, 5 = neither like nor dislike, 6 = like slightly, 7 = like moderately, 8 = like very much, and 9 = like extremely.

Statistical Analysis

Data are presented as mean values of three individual replicates ± standard deviation. One-way analysis of variance was conducted using SPSS version 20 software (IBM, Armonk, NY, USA). A significant difference between the means was measured using Duncan’s multiple range test at a significance level of p < 0.05.

Results and Discussion

Physicochemical analysis of WRP

Proximate compositions

The proximate compositions of the three WRPs (YRW, DGRW, and PGRW) are presented in Fig. 1. As shown, the moisture content did not differ significantly among the samples. The highest moisture content was 10.50% for both the YRW and DGRW powders, whereas that for the PGRW powder was 9.92%. However, the initial moisture content of the watermelon rind was higher than 95.63%. The YRW and DGRW powders had a slightly higher moisture content (0.58%) than the PGRW powder, which may result in an increased moisture content and deteriorate the quality of the end product. The moisture content of the WRP should be ≤ 10% to facilitate long-term storage and further use in product development (Al-Sayed and Ahmed 2013). Meanwhile, the PGRW powder had the highest amount of ash (15.14%), followed by the YRW (14.53%) and DGRW (11.33%) powders. The ash content can be ascribed to the amount of minerals present in the sample (Ismail 2017); therefore, the addition of WRP can increase the mineral content of noodles.

The results revealed that crude protein was one of the most abundant constituents of the rind powder. In this study, the amount of crude protein in the WRP was in the range of 17.01 to 19.74%, which is relatively higher or lower than the values found in previous studies (Adegunwa et al. 2019; Al-Sayed and Ahmed 2013; Naknaen et al. 2016). The results also revealed that the crude protein content differed significantly among the different watermelons (Fig. 1). In addition to variety, soil nutrients in terms of the nitrogen-phosphorous-potassium fertilizer applied are vital in improving fruit quality (Li et al. 2019). Furthermore, protein is an excellent source of amino acids for humans. It is well known that amino acids are important for metabolic health, tissue repair, and the synthesis of hormones and neurotransmitters (Jonker et al. 2012; Yoon 2016). Hence, the incorporation of WRP will increase the protein content of noodles.

The YRW powder contained a higher amount of fat (13.00%) than the DGRW (8.37%) and PGRW (5.83%) powders. A high fat content is undesirable in noodle preparation because upon rancidification during storage, the fat imparts an unpleasant taste and odor to the end product (Gotoh et al. 2007). In this context, the DGRW and PGRW powders appear more suitable for the value addition of noodles than the YRW powder (Fig. 1). Notably, the DGRW powder had the highest amount of crude fiber (13.35%), followed by the PGRW (12.78%) and YRW (3.75%) powders. Several studies have shown that fiber intake is essential for modulating and supporting gut microbiota (Desai et al. 2016; Makki et al. 2018). Other health benefits of fiber intake include a reduced risk of colorectal cancer, diabetes, and inflammation (Riva et al. 2019). Therefore, noodles partially substituted with WRP represent a good option for fiber-rich diets.

Table 2 shows the carbohydrate content and energy value of the WRPs. The carbohydrate content did not differ significantly between the DGRW and PGRW powders. Although the YRW powder had the lowest carbohydrate content, it secured the highest energy value of 384.87 kcal/100 g because of its higher proportion of fat compared with the other two samples. In this study, the PGRW powder had the lowest energy value of 328.93 kcal/100 g. The sugar content, including reducing and non-reducing sugars, of the WRP samples is presented in Fig. 2. The sugar content did not differ significantly among the samples. However, the YRW powder had the highest amount of total sugars (11.71 mg/g), whereas the DGRW powder had the lowest sugar content (11.01 mg/g). The results revealed that the amount of reducing sugars was higher than that of non-reducing sugars in all samples. The YRW powder contained a high amount of reducing and non-reducing sugars (7.16 and 4.81 mg/g, respectively), compared with those in the DGRW (6.67 and 4.34 mg/g, respectively) and PGRW (6.68 and 4.64 mg/g, respectively) powders. In food, sugar is hydrophilic and causes an increase in the water absorption capacity. Hence, an appropriate amount of sugar in WRP would enhance the hydration properties of dough prepared using wheat flour (Chandra et al. 2015).

Total phenol content and antioxidant activity

The amount of total phenols and the antioxidant activity of the WRPs are shown in Table 3. The total phenol content differed significantly among the three samples. The highest and lowest phenolic content was present in the PGRW and DGRW powders, respectively. In a previous study, 10 phenolic compounds were identified in watermelon rind extract, with 4-hydroxybenzoic acid, vanillin, sinapinic acid, and P-anisic acid being the most abundant compounds (Al-Sayed and Ahmed 2013). Furthermore, the PGRW powder demonstrated greater free radical–scavenging activity than the other powders. Additionally, the antioxidant capacities of the DGRW and YRW powders were the same. Therefore, WRP can be used as a good source of phenolic compounds with high antioxidant activity.

Color analysis

The color analysis results in terms of the L*, a*, and b* values of the different WRP samples are presented in Table 4. The results show that the YRW powder had the highest L* value (51.77), signifying more whiteness compared with the DGRW and PGRW powders. The a* value was positive only for the YRW powder and negative for both the DGRW and PGRW powders. The negative value of a* for both the DGRW and PGRW powders was indicated by the color green and the presence of a chlorophyll-like pigment in the rind. Meanwhile, the positive value of b* was indicated by the color yellow, and the highest value of 20.28 was obtained for the YRW powder. The hue angle was only positive for the YRW powder owing to the positive values of a* and b*. Similarly, the maximum value of chroma was 429.7 for the YRW powder; the lowest value of 225.48 was obtained for the DGRW powder. It can be concluded that the substitution of wheat flour with the DGRW and PGRW powders resulted in a slight green color in the finished product.

Cooking properties of the noodles

Considering the nutritional potential of watermelon rind, wheat flour was partially substituted with the PGRW powder for noodle preparation. According to the substitution percentage, the noodle samples were marked as control, 10% PGRW, 15% PGRW, and 20% PGRW. The cooking properties of the noodles in terms of cooking yield and cooking loss are presented in Fig. 3. The increase in the noodle weight after cooking can be defined as the cooking yield, which is also an indicator of the water absorption ability of the noodles during cooking. A high cooking loss of noodles indicates poor structural integrity (Wandee et al. 2014). Therefore, a high cooking yield and a low cooking loss are desirable for good-quality noodles. In this study, the highest cooking yield of 311.48% was observed with 15% WRP, whereas the lowest cooking yield (237%) was found in the control sample. Meanwhile, the cooking loss of the value-added noodles was higher than that of the control sample. It was observed that the cooking loss increased progressively with the amount of PGRW powder added. The leaching out of WRP during cooking because of low binding properties might have contributed to the cooking loss of the value-added noodles.

Sensory evaluation

The sensory evaluation of the noodles with PGRW is presented in Fig. 4. The results revealed that the sensory parameters were affected by the incorporation of WRP. The control sample received a superior score in appearance. Noodles with 10% and 15% PGRW were moderately accepted, whereas the S4 sample (20% PGRW) was considered slightly similar. The score for flavor decreased with the incorporation of WRP. With regard to mouth feel and taste, the control sample received the highest scores, whereas these scores decreased with the increasing proportion of rind powder. With regard to the overall quality, the control sample received the highest score of 8.03, whereas the noodles with different proportions of WRP received a score ranging from 7 to 7.43. Furthermore, the results revealed no significant difference in sensory attributes except for taste between the control and S2 samples (noodles with 10% PGRW). Combining the sensory attributes and health benefits of WRP, a substitution level of 10% is applicable for the production of value-added noodles.

Conclusion

In this study, the nutritional potential of watermelon rind, which is typically treated as waste, was investigated for the value addition of noodles. Proximate composition analysis of three different WRPs demonstrated that the DGRW powder contained lower amounts of ash and protein than the YRW and PGRW powders. Meanwhile, the YRW powder contained a high amount of fat, but its desirable fiber was significantly less than those of the DGRW and PGRW powders. The highest amount of crude fiber (13.35%) was found in the DGRW powder, followed by the PGRW powder (12.78%). Among the three samples, the PGRW powder demonstrated greater antioxidant activity against DPPH. In the preparation of noodles, the incorporation of WRP resulted in an increase in the cooking yield of the value-added noodles. However, the cooking loss of the value-added noodles was slightly higher than that of the control sample. Based on the sensory evaluation, it was discovered that the control sample was the most preferred and that noodles with 10% WRP had better acceptability among the value-added noodle samples. Thus, noodles supplemented with 10% watermelon rind may be a convincing option for the public in terms of a food product based on nutritional value rather than taste. In conclusion, the energy demand for longer drying times indicated the necessity of solar drying for the commercial-scale production of WRP, which showed significant nutritional potential for the further development of flour-based products for human consumption.

Change history

23 February 2021

A Correction to this paper has been published: https://doi.org/10.1007/s42853-020-00068-5

References

Adegunwa, M., Oloyede, I., Adebanjo, L., & Alamu, E. (2019). Quality attribute of plantain (Musa paradisiaca) sponge-cake supplemented with watermelon (Citrullus lanatus) rind flour. Cogent Food & Agriculture, 5(1), 1631582. https://doi.org/10.1080/23311932.2019.1631582.

Al-Sayed, H. M. A., & Ahmed, A. R. (2013). Utilization of watermelon rinds and sharlyn melon peels as a natural source of dietary fiber and antioxidants in cake. Annals of Agricultural Science, 58(1), 83–95. https://doi.org/10.1016/j.aoas.2013.01.012.

Alhakmani, F., Kumar, S., & Khan, S. A. (2013). Estimation of total phenolic content, in-vitro antioxidant and anti-inflammatory activity of flowers of Moringa oleifera. Asian Pacific Journal of Tropical Biomedicine, 3(8), 623–627. https://doi.org/10.1016/S2221-1691(13)60126-4.

AOAC. (1995). Official methods of analysis (16th Ed.). Association of Official Analytical Chemists International, Washington, DC, USA.

Brand-Williams, W., Cuvelier, M. E., & Berset, C. (1995). Use of a free radical method to evaluate antioxidant activity. LWT - Food Science and Technology, 28(1), 25–30.

Brat, P., Georgé, S. P., Bellamy, A., Chaffaut, L. D., Scalbert, A., Mennen, L., Arnault, N., & Amiot, M. J. P. (2006). Daily polyphenol intake in France from fruit and vegetables. The Journal of Nutrition, 136(9), 2368–2373. https://doi.org/10.1093/jn/136.9.2368.

Chandra, S., Singh, S., & Kumari, D. (2015). Evaluation of functional properties of composite flours and sensorial attributes of composite flour biscuits. Journal of Food Science and Technology, 52(6), 3681–3688. https://doi.org/10.1007/s13197-014-1427-2.

Choo, C. L., & Aziz, N. A. A. (2010). Effects of banana flour and β-glucan on the nutritional and sensory evaluation of noodles. Food Chemistry, 119(1), 34–40. https://doi.org/10.1016/j.foodchem.2009.05.004.

Desai, M. S., Seekatz, A. M., Koropatkin, N. M., Kamada, N., Hickey, C. A., Wolter, M., Pudlo, N. A., Kitamoto, S., Terrapon, N., Muller, A., Young, V. B., Henrissat, B., Wilmes, P., Stappenbeck, T. S., Núñez, G., & Martens, E. C. (2016). A dietary fiber-deprived gut microbiota degrades the colonic mucus barrier and enhances pathogen susceptibility. Cell, 167(5), 1339–1353.e21. https://doi.org/10.1016/j.cell.2016.10.043.

Garcia-Garcia, G., Woolley, E., Rahimifard, S., Colwill, J., White, R., & Needham, L. (2017). A methodology for sustainable management of food waste. Waste and Biomass Valorization, 8(6), 2209–2227. https://doi.org/10.1007/s12649-016-9720-0.

Ginting, E., & Yulifianti, R. (2015). Characteristics of noodle prepared from orange-fleshed sweet potato, and domestic wheat flour. Procedia Food Science, 3, 289–302. https://doi.org/10.1016/j.profoo.2015.01.032.

Gotoh, N., Iwasawa, A. I., Watanabe, H., Osato, R., & Wada, S. (2007). Oxidation of fats and oils in instant noodles stored under various conditions. Journal of Food Lipids, 14(4), 350–365. https://doi.org/10.1111/j.1745-4522.2007.00091.x.

Ho, L.-H., & Che Dahri, N. (2016). Effect of watermelon rind powder on physicochemical, textural, and sensory properties of wet yellow noodles. CyTA Journal of Food, 14(3), 465–472. https://doi.org/10.1080/19476337.2015.1134672.

Ismail, B. P. (2017). Ash content determination. In S. S. Nielsen (Ed.), Food Analysis Laboratory Manual (pp. 117–119). Cham: Springer International Publishing.

Jonker, R., Engelen, M. P. K. J., & Deutz, N. E. P. (2012). Role of specific dietary amino acids in clinical conditions. British Journal of Nutrition, 108(S2), S139–S148. https://doi.org/10.1017/S0007114512002358.

Kim, B.-R., Kim, S., Bae, G.-S., Chang, M. B., & Moon, B. (2017). Quality characteristics of common wheat fresh noodle with insoluble dietary fiber from kimchi by-product. LWT- Food Science and Technology, 85, 240–245. https://doi.org/10.1016/j.lwt.2017.07.027.

Li, Z., Zhang, R., Xia, S., Wang, L., Liu, C., Zhang, R., Fan, Z., Chen, F., & Liu, Y. (2019). Interactions between N, P and K fertilizers affect the environment and the yield and quality of satsumas. Global Ecology and Conservation, 19, e00663. https://doi.org/10.1016/j.gecco.2019.e00663.

Makki, K., Deehan, E. C., Walter, J., & Bäckhed, F. (2018). The impact of dietary fiber on gut microbiota in host health and disease. Cell Host & Microbe, 23(6), 705–715. https://doi.org/10.1016/j.chom.2018.05.012.

Marrubini, G., Papetti, A., Genorini, E., & Ulrici, A. (2017). Determination of the sugar content in commercial plant milks by near infrared spectroscopy and Luff-Schoorl total glucose titration. Food Analytical Methods, 10(5), 1556–1567. https://doi.org/10.1007/s12161-016-0713-1.

Naknaen, P., Itthisoponkul, T., Sondee, A., & Angsombat, N. (2016). Utilization of watermelon rind waste as a potential source of dietary fiber to improve health promoting properties and reduce glycemic index for cookie making. Food Science and Biotechnology, 25(2), 415–424. https://doi.org/10.1007/s10068-016-0057-z.

Riva, A., Kuzyk, O., Forsberg, E., Siuzdak, G., Pfann, C., Herbold, C., Daims, H., Loy, A., Warth, B., & Berry, D. (2019). A fiber-deprived diet disturbs the fine-scale spatial architecture of the murine colon microbiome. Nature Communications, 10(1), 4366. https://doi.org/10.1038/s41467-019-12413-0.

Slavin, J. L., & Lloyd, B. (2012). Health benefits of fruits and vegetables. Advances in nutrition (Bethesda, Md.), 3(4), 506–516. https://doi.org/10.3945/an.112.002154.

Song, D. B., Lim, K. H., & Jung, D. H. (2019). Developing heated air dryer for food waste using steam generated from incineration plant. Journal of Biosystems Engineering, 44(2), 112–119. https://doi.org/10.1007/s42853-019-00021-1.

Tan, T. C., Phatthanawiboon, T., & Mat Easa, A. (2016). Quality, textural, and sensory properties of yellow alkaline noodles formulated with salted duck egg white. Journal of Food Quality, 39(4), 342–350. https://doi.org/10.1111/jfq.12203.

Tonini, D., Albizzati, P. F., & Astrup, T. F. (2018). Environmental impacts of food waste: Learnings and challenges from a case study on UK. Waste Management, 76, 744–766. https://doi.org/10.1016/j.wasman.2018.03.032.

Vats, N., Khan, A. A., & Ahmad, K. (2020). Options for enhanced anaerobic digestion of waste and biomass-a review. Journal of Biosystems Engineering, 1–15. https://doi.org/10.1007/s42853-019-00040-y.

Wandee, Y., Uttapap, D., Puncha-arnon, S., Puttanlek, C., Rungsardthong, V., & Wetprasit, N. (2014). Enrichment of rice noodles with fibre-rich fractions derived from cassava pulp and pomelo peel. International Journal of Food Science & Technology, 49(11), 2348–2355. https://doi.org/10.1111/ijfs.12554.

Wichchukit, S., & O'Mahony, M. (2015). The 9-point hedonic scale and hedonic ranking in food science: some reappraisals and alternatives. Journal of the Science of Food and Agriculture, 95(11), 2167–2178. https://doi.org/10.1002/jsfa.6993.

Yoon, M.-S. (2016). The emerging role of branched-chain amino acids in insulin resistance and metabolism. Nutrients, 8(7), 405. https://doi.org/10.3390/nu8070405.

Zawawi, N., Gangadharan, P., Ahma Zaini, R., Samsudin, M. G., Karim, R., & Maznah, I. (2014). Nutritional values and cooking quality of defatted kenaf seeds yellow (DKSY) noodles. International Food Research Journal, 21(2), 603–608.

Acknowledgments

The authors wish to thank the Post-Harvest Technology Department of the Bangladesh Agricultural Research Institute and the Department of Agroforestry & Environment of Bangabandhu Sheikh Mujibur Rahman Agricultural University (BSMRAU) for providing technical support. We would like to thank Editage (www.editage.co.kr) for English language editing.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of Interest

The authors declare that they have no conflicts of interest.

Rights and permissions

About this article

Cite this article

Chakrabarty, N., Mourin, M.M., Islam, N. et al. Assessment of the Potential of Watermelon Rind Powder for the Value Addition of Noodles. J. Biosyst. Eng. 45, 223–231 (2020). https://doi.org/10.1007/s42853-020-00061-y

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s42853-020-00061-y