Abstract

Sweet sorghum stalks energy recovery is one of the most interesting alternatives to meet the current challenge of energy security. The usual ethanol production process from this biomass proves to be less profitable due to very expensive juice extraction step. This study aims to improve the performance and efficiency of this process experimenting new processing techniques of direct whole stem fermentation combined with enzymatic hydrolysis. Fermentation tests were carried out on shredded whole stem and pith (particle size ≤ 1 mm) and enzymatic process efficiency was compared to fermentation of juice obtained after mechanical pressing. Saccharification treatments of biomass fractions (whole stem and pith with particle size ≤ 0.5 mm) were performed using Celluclast 1.5 L and Viscozyme L, with three different enzymatic loads (15, 30 and 45 U/g DM; and 15, 30 and 45 FBGU/g DM) combined to three different biomass loadings (2, 5 and 10% w/v). Fermentation was carried out using Saccharomyces cerevisiae. Fermentation yields were 0.45; 0.50 and 0.49 g Eth/g of consumed sugars respectively for juice, marrow and whole stem. Saccharification with Viscozyme at 45 FBGU/g DM enzymatic load and 10% (w/v) of biomass load allowed an increase of 39.63% and 28.14% in ethanol production yield; and 27.50% and 26.42% for biomass conversion efficiency, respectively between treated and untreated whole stem fractions and between treated and untreated pith fractions. Sweet sorghum stalk is a viable and sustainable source of alternative energy feedstock. Direct fermentation of the whole stem treated with cellulolytic enzyme makes it possible to dispense the juice extraction step, improving energy bioconversion performance and efficiency.

Graphical Abstract

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Statement of Novelty

This study presents an improvement in the performance and profitability of the ethanol production process from sweet sorghum stalks. This through a new operating mode combined with enzymatic treatment. Contrary to the usual process which consists to extract and ferment the sweet juice from the lignocellulosic fraction (bagasse), this study proposes a direct fermentation of the crushed whole stem, improving the process profitability considering lower water and energy consumptions. The study presents also an optimization of ethanol production yield after enzymatic hydrolysis of the whole stem. The bioconversion yields into ethanol rates of increase were 27.50% and 26.42% respectively between treated and untreated whole stem fractions, and between treated and untreated pith fractions.

Introduction

The growing demand for energy lead to the drastic reduction of fossil resources and climate changes caused by greenhouse gas emissions. So, energy security is a major concern requiring us to seek sources of alternative energies [1, 2]. As mitigation measures, it is imperative to adopt policies to minimize the use of fossil reserves, maintaining environmental sustainability and reducing greenhouse gas emissions [3]. Biofuels development is one of the most sustainable and clean energy source emerging strategies. Green biomass, in particular crop residues, is one of the best sources of raw materials for alternative energies. Ethanol production from lignocellulosic material as a strategy to mitigate global warming and improve global energy security has attracted worldwide attention [4]. However, the raw material should come from inedible agricultural residues to avoid direct competition between the production of bioethanol and foods [5]. Sweet sorghum (Sorghum bicolor (L) moench), a cereal grass producing both starchy seeds and stalks with high contents of fermentable sugars has been identified as a plant with interesting and promising potential to meet this challenge. Indeed, sorghum is the fifth most cultivated cereal in the world due to its ability to adapt to marginal agronomic conditions but also for its high yield of green biomass with juicy and sweet stalks [6,7,8]. Sorghum green biomass yield has been estimated between 20 and 120 tonnes/ha depending on the cultivation conditions and the botanical characteristics of the plant material [9]. In 2020, its world and African estimated production were 58.70 and 27.47 million tonnes over an area of 40.25 and 27.29 million hectares, respectively [10]. Generally, ethanol production process from sweet sorghum stalks consists of extracting juice from fresh stalks to ferment it. In this process, liquid fraction and the solid residues (bagasse) are processed separately [11,12,13,14]. However, this process turns out to be economically unprofitable because of the extraction techniques that consume a lot of water and energy. Mechanical pressing using two or three rolls press leads to low juice extraction yields, often below 50% of stem mass [13, 15]. Development of multi-stage press technologies combined with the diffusion extraction technique allows sugar extraction yields of around 90% [16]. Adding distilled water to bagasse followed by their incubation at temperatures ≤ 45 °C significantly improved extraction yields and achieved fermentescible sugar extraction rates in the order of 99% [17, 18].

Faced with these extraction processes which consume significative quantities of water and energy, the uses of chemical or enzymatic hydrolysis of bagasse before ethanol production by fermentation have been experimented [19]. The objective was to hydrolyse cellulose and hemicellulose into fermentable sugars and to co-ferment them with those of the juice. Chemical hydrolysis takes place under acid or alkaline conditions with often high temperatures, generally leading to the degradation of a part of fermentable sugars and the formation of numerous toxic and corrosive compounds, as well as inhibitors (furfural, hydroxymethylfurfural, acetic acid, etc.) of fermentation [20, 21]. It is not a green process and it is restricted by the neutralization steps before hydrolyzate fermentation. Dilute acid hydrolysis (0.7–3.0%) requires high operating temperatures (180–240 °C) whereas concentrated acid hydrolysis requires huge amounts of acid and therefore is less economical [4, 22]. Enzymatic hydrolysis, on the other hand, has relatively low utility costs, except that of biocatalyst, it is generally carried out under middle conditions (pH 4.8–5 and temperatures 45–50) and does not present any problem of materials corrosion [23]. It offers the opportunity of carrying out both the simultaneous saccharification and fermentation (SSF) and separate hydrolysis and fermentation (SHF).

Regarding to these properties, this study experiments an enzymatic hydrolysis of shredded sweet sorghum whole stalks aiming to overcome the very costly sugar extraction step and to increase the amount of fermentable sugars in this biomass with the objective of improving its bioconversion into ethanol. Two enzymes (Celluclast 1.5 L and Viscozyme L) were tested on shredded whole stem and pith and the fermentation was carried out using Saccharomyces cerevisiae.

This study presents an improvement in the performance and efficiency of the ethanol production process from sweet sorghum stems and its economic profitability. The aim was to prove that it is possible to dispense the expensive juice extraction step. Unlike to the usual process which consists to extract and ferment the sweet juice separately from the biomass lignocellulosic fraction (bagasse), this study proposes a direct fermentation of the crushed whole stem, improving the process profitability considering lower water and energy consumptions. The study presents also an optimization of ethanol production yield after enzymatic hydrolysis of the whole stem.

Materials and Methods

Collection and Pretreatment of Sorghum Stalks

The sorghum stalks from sorghum (bicolor) were collected on November 05, 2020 at “KODEK” (10° 39′ 19″N; 14° 24′ 42″E; 880 m), a locality of DIAMARE department, located in the Far North region of Cameroon. Stem samples were immediately cut up and stored in a -20 °C freezer for further analysis. To study the performance and efficiency of the ethanol production process from this biomass, fermentation tests were carried out on different stalk fractions (whole stem, marrow, and juice). Indeed, the stem was deleafed, cut up, dried and ground. The marrow was separated from the bark by peeling, then dried and ground. Juice extraction was carried out by mechanical pressing of the marrow. Figure 1 shows the different biomass pretreatment operations.

Figure 2 presents the overall implementation process as well as the intermediate products resulting from the different process unit operations. The first operation consisted of collecting biomass (sorghum stalks) in sufficient quantity after having identified it (species, cultivar, GPS coordinates, etc.). It was then subjected to a physico-chemical characterization, in particular the determination of the contents of extractable sugars, total fibres, cellulose, hemicelluloses, lignin, phenolic compounds, dry matter, organic matter, etc. The fermentation was tested on different biomass fractions in order to study and compare the efficiency of the process.

According to itinerary 1 in Fig. 2, the collected stems were pretreated to remove leaves and panicles before the pressing step [11]. The pith was separated from the bark by peeling in order to optimize the juice and sugars extraction yields. The juice was extracted from the marrow by crushing and mechanical pressing using a mill, then characterized and fermented. Following route 2 in Fig. 2, the direct fermentation of ground marrow (untreated and treated) was tested. During itinerary 3, the direct fermentation of shredded whole deleafed stems (treated and untreated) was tested. The objective is to limit as much as possible the fractionation steps that consume a lot of energy and water.

Physicochemical Characterization of Sorghum Stem

The dry matter was determined according to the AFNOR method [24], by stoving biomass samples at 105 °C until a constant mass was obtained. The dry matter content, expressed as a percentage of fresh matter, was calculated according to Eq. (1) after cooling the samples in a desiccator.

where DMC is the dry matter content (%); Mf is the mass of the crucible and residual dry sample (g); Mi is the initial mass of the crucible and its wet contents (g); T is the empty crucible tare (g).

The samples moisture content (MC), expressed in (%) was deducted from the dry matter value according to Eq. (2):

Mineral matter was determined from residual dry samples by electric muffle furnace incineration at 550 °C for 6 h, and its value was calculated according to the Eq. (3) after cooling.

where MMC is the mineral content compared to DM (%); Mf is the final mass of the crucible and residual sample after incineration (g); Mi is the initial mass of the crucible and dry sample before incineration (g); T is the empty crucible tare (g).

The tests were carried out in three repetitions and the result is the average of the repetitions.

The sorghum stem biochemical composition, namely total fibers content, hemicellulose, cellulose, and lignin was determined by the method described by Van Soest [25].

The total fibers content (%), expressed as a percentage of dry matter, was calculated according to Eq. (4):

where S is the initial sample mass (g) and W1 is the mass of residual sample insoluble in neutral detergent (g).

The hemicellulose content was determined from the dry residues of neutral detergent insoluble fiber (W1). It is expressed as a percentage (%) of dry matter and calculated according to Eq. (5):

where W2 is the mass of residual sample insoluble in acid detergent (g).

Cellulose and lignin contents were determined after sulphuric acid (72%) digestion of the cellulosic fraction of the residual mass of acid detergent insoluble fibers (W2). They are expressed as a percentage (%) of dry matter and are calculated according to Eqs. (6) and (7) respectively.

where W3 is the residual mass of sample after sulphuric acid digestion (g).

Determination of Biomass Sugars Contents

The water-soluble and total sugars contents were determined according to the method of Dubois et al. [26] using phenol and sulfuric acid. The soluble sugars were extracted with hot water (90 °C for 90 min) from different biomass fractions powders. For this purpose, 1 g of biomass powder was mixed with 50 mL of milli-Q water and heated in a water bath at 90 °C for 90 min and then filtered under vacuum using a size 3 frit (40–90 μm). The filtrate was used for soluble sugars analysis as well as for biomass reducing sugars content determination. The reducing sugar content was determined by method described by Waffenschmidt and Jaenicke [27], using biquinchoninic acid. The fibrous residues from the filtration were dried by stoving at 60 °C until a constant mass was obtained. They were then hydrolyzed to extract the insoluble structural sugars. For this purpose, 0.2 g of dry fibrous residues were mixed with 5 mL of sulfuric acid (0.75 M) and heated in a water bath at 100 °C for 90 min. The hydrolyzate was then centrifuged at 13 000 g for 10 min and the supernatant was recovered and neutralized (pH = 7 ± 0.1) with a NaOH solution, then used for the determination of total structural sugars.

Determination of Total Phenolic Compounds Content

The phenolic compounds were extracted by mixing 1 g of biomass powder in 40 mL of diluted acetone solution (50% v/v of acetone/water) and stirred at room temperature (20–22 °C) for 60 min. The solution was then filtered under vacuum through a Whatman 1 filter paper and the filtrate was recovered. It was then separated from the solvent by evaporation under vacuum using a rotavapor and the lost volume was replaced by milli-Q water. The extracts of the phenolic compounds were assayed with Folin Ciocalteu’s reagent according to the protocol described by Gutfinger [28]. Biomass total phenolic compounds contents were expressed as grams of gallic acid equivalent / kilogram DM of sample (g GAE/Kg DM sample).

Fermentation Test of Different Biomass Fractions

The fermentation was carried out using Saccharomyces cerevisiae ATCC 7754. It was taken up in sterile water and spread on YM-agar agar (yeast Medium, Difco 0712–01-8) before to be incubated at 28 °C for 24 h. The strain was then stored at 4 °C and subcultured on a petri dish for 24 h before being used in the culture vessels [29].

Preliminary fermentation trials were tested on different biomass fractions (whole stalks, marrow and juice) in order to study and compare the efficiency and performance of the bioethanol production process from sweet sorghum stalks. For this purpose, part of the stem was peeled and the juice was extracted from the pith by mechanical pressing. The whole stem and the pith were then cut up and dried by stoving at 60 °C until a constant mass was obtained, then ground to a particle size ≤ 1 mm. The fermentation was carried out in 500 mL Erlenmeyer flasks, with 200 mL working volume. The different culture media were composed of 10% (w/v) of the corresponding biomass fraction or sufficiently diluted stem sorghum juice, enriched with additional nutrients as described by Kristiansen [30], except glucose. The culture media were then autoclaved at 121 °C for 20 min and inoculated with 10% (v/v) of Saccharomyces cerevisiae preculture in exponential phase of growth. They were then incubated at 30 °C with 200 rpm stirring speed. The media samples were taken every 2 h to monitor the fermentation kinetics.

The fermentation kinetic was monitored through three parameters: ethanol production, fermentable sugars consumption and microbial growth. The consumption of fermentable sugars was monitored by the colorimetric total sugars assay method of Dubois et al. [26]. Microbial growth was monitored measuring A600 (Biomate 3S, UV–visible spectrophotometer, Thermo Scientific, Lyon, France). Ethanol production was quantified by HPLC device (1260 Infinity Quaternary LC system, Agilent Technology, Palo Alto, CA, USA). It was equipped with two ionic exclusion columns (Rezex ROA 300 × 7.8 mm, Phenomenex, Torrance, CA, USA) connected in serial in an oven (50 °C) and coupled to a refractometer as detector. The mobile phase consisted of 2 mM sulfuric acid solution, in ultrapure water (Millipore, MilliQmore), pumped at 0.7 mL/min flow rate and 70 bars (7000 kPa). Ethanol was detected using a refractometer (HP 1100 series, Agilent Technologies, USA). Samples were previously deproteinized before injection in order to avoid clogging of the column. To do this, 125 μL of barium hydroxide solution (0.3 M) and 125 μL of zinc sulphate solution (5% w/v) were added to 1 mL of sample and centrifuged at 10 000 g for 10 min then the supernatant was filtered using a 0.2 μm cellulose acetate filter (Chromafil, Steinheim, Germany) before analysis.

Enzymatic Hydrolysis of Biomass

Two liquefaction enzymatic cocktails were tested for the saccharification of different fractions of biomass fibers. The first one was Viscozyme L. It is a cellulolytic enzymes mixture composed of arabinase, cellulase, β-glucanase, hemicellulase, and xylanase from Aspergillus sp. with an enzymatic activity ≥ 100 Fungal Beta-Glucanase Units (FBGU)/g. The second one was Celluclast 1.5 L. It is a liquid complete cellulase mixture from Trichoderma reesei containing exo- and endocellulases, β-glucosidases, and hemicellulases with an enzyme activity ≥ 700 units (U)/g. To determine the optimal hydrolysis conditions, three different biomass loads were studied, 2%, 5% and 10% (w/v) from different biomass powders with particle size ≤ 0.5 mm. Different enzymatic loads were also tested in combination with different biomass loads: Celluclast at 15, 30 and 45 U/g DM of biomass; and Viscozyme at 15, 30 and 45 FBGU/g DM of biomass. Hydrolysis was carried out in 250 mL Radleys reactor (Carousel 6 Plus Reaction Station) with 200 mL of working volume. The reactors were agitated with a rotational mixing speed of 500 rpm and the temperatures were set at 44 °C and 50 °C respectively for the Viscozyme and the celluclast assays. A control sample without enzyme was carried out in parallel under the same conditions. In order to follow the hydrolysis kinetics, samples were taken every 2 h for the first 10 h, then at 24 h and after 48 h. The samples taken were subjected to an instantaneous thermal shock at 100 °C for 10 min in a dry bath to stop the hydrolysis. Samples were then centrifuged (13 000 g, 10 min) and the supernatants were collected and used for total and reducing sugars analyses.

Enzymatic Saccharification and Fermentation

Biomass enzymatic hydrolysis was performed using Vicozyme under optimal hydrolysis conditions with 45 FBGU/g DM of biomass of enzymatic load and 10% (w/v) biomass load. Viscozyme was chosen because of its high yield compared to Celluclast. Hydrolysis was carried out in 250 mL Radleys reactor (Carousel 6 Plus Reaction Station) with 200 mL of working volume and under the same hydrolysis conditions of 44 °C and 500 rpm stirring speed. The samples were incubated for 24 h and the hydrolysates obtained after biomass hydrolysis step were transferred into 500 mL Erlenmeyer flasks, then autoclaved at 121 °C for 20 min and inoculated with a volume of 10% (v/v) of Saccharomyces cerevisiae preculture in exponential growth phase. The fermentation was carried out under the conditions described in section (I.5) against a non-pretreated biomass control. The culture medium samples were taken every 2 h to monitor the fermentation kinetics according to the methods described in section (I.5).

The statistical analysis of the data was carried out using the Excel spreadsheet of the Microsoft office software version 2013. The tests were carried out in triplicate and the results were expressed as mean ± standard deviation.

Results and Discussions

Physicochemical Characteristics of Sorghum Stem

Biomass Dry Matter and Ash Content

The stalk of S. bicolor ecotype studied had a dry matter content evaluated on average at 31.74% for the whole deleafed stem (consisting of bark and marrow). This result is similar to those of Almodares and Hadi [31] and Gutjahr et al. [32], who also reported dry matter content evaluated at 30% of the fresh mass of the studied varieties of sorghuh stalks. This content was evaluated at 21.90% and 47.89% respectively for the marrow and the bark (Table 1). The analysis of these results revealed that the moisture content, representing the juice content of the stem, is essentially contained by the marrow, i.e. 78.1% against 52.11% for the bark. These results are in line with those of Billa et al. [33] and Djomdi et al. [18] who also worked on the stalks of sweet sorghum varieties and reported that the moisture content was higher in the marrow (77%) than in the bark (56%).

The biomass ash content was quantified at 3.34% of DM for the whole deleafed stem. It was estimated at 2.90% of DM in the bark, and at 5.69% of DM in the marrow, i.e. 1.96 times higher than that of the bark. These ash content values are much higher and in contradiction with those of Billa et al. [33], who reported ash contents values of 0.3%, 0.2% and 0.5% of DM, respectively for the whole stem, marrow and bark. They indicated that bark contains 2.5 times more ash than marrow. This variation of ash content as well as its distribution in different biomass fractions could be explained by the genotypic characteristics of the varieties, the specificities of the cultivars studied and the agronomic conditions.

Biochemical Composition of Biomass

The biochemical composition analysis of the whole deleafed stem of S. bicolor revealed that it contained 63.50% DM of total fibers, 16.96% DM of hemicellulose, 18.25 DM of cellulose and 28.60% DM of lignins. This composition validated the potential of the fibers from these stems as a source of fermentable sugars accessible after their hydrolysis. This fibers content is similar to that of certain varieties of sweet sorghum studied by Amer [34] (62.6% DM), Amélia [35] (74.7 to 75.5% DM) and Tremblay et al. [36] (56.6% DM). However, the hemicellulose and cellulose contents are much closer to those of the varieties studied by Khalil et al. [37] (11.7 – 17.2 and 20.1–26.1% DM, respectively). Similar studies carried out by several authors indicated that the distribution of total fibers into hemicellulose, cellulose and lignin varies enormously according to the sorghum varieties studied. It was evaluated on average at 10.2; 12.4 and 4.8% DM respectively in hemicellulose, cellulose and lignin according to variety studied by Billa et al. [33]. It was evaluated on average at 21.2–41.2; 21.9–35.6 and 18.2–21.5% DM respectively in hemicellulose, cellulose and lignin, according to those studied by Jolanta et al. [38]. Kim and Day [39] and Nasidi et al. [40] reported that it was composed mainly of cellulose (30 to 45% DM), hemicelluloses (16 to 30% DM) and lignins (15 to 20% DM). This biochemical composition of sorghum stalk is comparable to that of rice straw whose average composition reported by some authors in the literature is 28–40%; 22–35% and 12–18% respectively in cellulose, hemicellulose and lignins [41, 42].

Furthermore, this study shows that the stem total fibers are much more concentrated in the bark, with a content estimated on average at 75.71% DM, i.e. 2.55 times higher than that of the marrow which was evaluated at 29.59% DM. On the other hand, most of the sorghum stem lignin was concentrated in the bark with contents evaluated on average at 24.25% DM, against 3.03% DM in the marrow. Billa et al. [33] also reported in their study that the bark contains almost all of the stem lignin content, with 8.8% DM against 0.6% DM in the marrow. The hemicellulose and cellulose contents were evaluated on average respectively at 14.01 and 12.53% DM and at 17.78 and 33.75% DM, respectively in the marrow and the bark. The biochemical composition of the shredded whole stem, in particular its high total fibers content (63.50% DM), is a major asset making it suitable to be used as feedstock for the production of additional bioethanol. Hemicellulose (16.96% DM) and cellulose (18.25% DM) can be hydrolyzed into simple sugars that can be fermented into ethanol after a hydrolysis step. However, its relatively high lignin content (28.60% DM) can affect the hydrolysis process and would require a prior delignification operation in order to optimize the hydrolysis yield and therefore the bioconversion yield of this biomass into ethanol. These results and others physicochemical characteristics of different sorghum stem fractions are summarized in Table 1.

Biomass Sugars Content

The whole deleafed stem sugars content is evaluated on average at 731.69; 538.22 and 377.68 g/Kg DM, respectively for total sugars, soluble sugars and reducing sugars (Table 1). The stem total sugars content of the S. bicolor ecotype studied in this work was higher than that of the varieties studied by Crépeau et al. [43] and Crépeau [44]. Indeed, these authors reported total sugars contents between 56.4 and 104.7 g/Kg DM. It was also higher than those of the varieties studied by Noura Saϊed [45] (249.3–256.1 g/Kg DM) and Djomdi et al. [18] (497.8 g/Kg DM). This study reveals that the sweet sorghum stem carbohydrate content is mainly concentrated in the marrow, with contents estimated on average at 780.44; 628.80 and 326.20 g/Kg DM respectively in total sugars, soluble sugars and reducing sugars, against 384.12; 183.74 and 61.05 g/Kg DM, respectively in the bark. This observation was also reported by Djomdi et al. [18], who studied the stem sugars content of a sweet sorghum cultivar from the Far North region of Cameroon, and found sugars contents much higher in marrow (228.7 and 55.4 respectively for soluble and reducing sugars) than in the whole deleafed stem (176.5 and 41.9 respectively). Furthermore, the results of this study show that the soluble sugars content of S. bicolor is much higher than that observed by Almodares and Hadi [31], in Quebec with CSSH 45 hybrid sorghum variety (145–298 g/kg DM) or by Noura Saϊed [45] on the same hybrid variety (129.39 g/kg DM). These variations of stem sugars content, observed in sweet sorghums, could be explained not only by specific genotypic characters of the races, varieties and cultivars studied, but also by the difference in agronomic and environmental conditions. Due to its high content of fermentable free sugars, sweet sorghum stalk constitutes a viable and sustainable source of raw material for 2G fuel bioethanol production. This sugar content could be further enhanced by a hydrolysis operation of the fibrous part of this biomass, thus improving ethanol productivity.

Biomass Phenolic Compounds Content

The S. bicolor stalks studied has total phenolic compounds contents evaluated on average at 5.2; 4.2 and 3.95 g/Kg DM, respectively for the whole stem, pith and bark. These phenolic compounds values are much lower than those reported by Hao et al. [46], who studied the BJ0602 variety of sweet sorghum grown in China and obtained stalks phenolic compounds contents evaluated on average at 2.21 mg/g. Ring et al. [47] also studied the evolution of phenolic compounds on different sorghum tissues (caryopes, glumes, stems, and leaves) during its growth, and reported that the phenolic compounds of the stem, quantified at 4.8 mg/g, varied very little during its growth and after its physiological maturation. Similar observations were also reported by Sereme et al. [48] who indicated phenolic compound contents < 2% DM in sorghum caudatum stems and also noticed very small variations of stem phenolic compounds compared to other tissues (sheaths, leaves and roots) during sorghum growth. These low contents of sorghum stem phenolic compounds observed in this study are a major asset, since phenolic compounds have a negative impact on microbial growth and metabolism and at high concentrations, can act as an antimicrobial compounds [46, 49, 50] and therefore negatively impact the ethanol production from microbial fermentation. As a result, the productivity of bioethanol from the stems of the S. bicolor variety studied would not be significantly impacted with regard to the low levels of phenolic compounds observed.

Bioethanol Production from Different Biomass Fractions

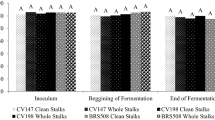

Traditionally, the process for producing ethanol from sweet sorghum stalks involves the extraction stage followed by juice filtration and fermentation. Several research works have made it possible to improve the performance and yield of fermentable sugars extraction. However, extraction techniques remain laborious and consuming a lot of water and energy [51]. This study aims to do the proof of concept of eliminating this juice extraction in order to improve the performance of ethanol production process from this biomass. The fermentation of whole stem and marrow crushed (particle size ≤ 1 mm) was tested and compared to that of corresponding juice extracted by mechanical pressing. Fermentation kinetics of different biomass fractions were shown in Fig. 3.

The fermentation yields evaluated on average at 0.45; 0.50 and 0.49 g of ethanol/g of consumed sugars were obtained respectively for juice, marrow and whole stem (Fig. 4). The direct fermentation of ground whole stem and marrow yields slightly higher than that of juice fermentation. These results show that the fibrous particles (contained in the whole stem and marrow samples) did not impact the yield of ethanol production by Saccharomyces cerevisiae. These results are in line with the observations of Jia et al. [17], who reported that the fibrous particles contained in sweet sorghum juice did not impact the fermentation yield (0.428 – 0.437 and 0.429–0.434 g of ethanol/g of consumed sugars, respectively for filtered and unfiltered juice). Authors concluded that the juice filtration step was not necessary. A similar observation was also reported by Bálint et al. [11], who noticed that there was no significant difference in the yields of ethanol production from sorghum stalk juice extracted with or without leaves, the yields were 0.42–0.45 g Eth/g consumed sugars. On the other hand, they noticed a significant difference in sugar content between the samples of juice extracted in different ways, the extracts without leaves had sugar contents about 20% higher.

Furthermore, the conversion yields obtained were evaluated at 165.44; 252.62 and 184.87 g of ethanol/Kg DM, respectively for juice, marrow and whole stem. These results show that the direct fermentation of shredded stem and pith presents much higher biomass conversion yields compared to that of corresponding juice extracted by mechanical pressing. This could be explained by the fact that the mechanical pressing extraction process presents a low yield of fermentable sugars extraction. On the other hand, direct fermentation uses almost all the sugars. These conversion yield values obtained in this study are higher than those obtained by Khalil et al. [37], who evaluated the efficiency of ethanol production from the juice and bagasse of five sweet sorghum varieties and obtained maximum overall production of 160 mL/g DM with SS-301 variety. The results of this study show that the juice extraction step, which consumes a lot of water and energy, could be dispensed.

Biomass Enzymatic Hydrolyse

Two enzymatic cocktails were tested on different stem fractions (whole stalk and pith) in order to determine the best suited to the saccharification of this biomass. Enzyme load is one of the most important factors influencing the efficiency of enzymatic hydrolysis process [52]. To compare the effectiveness of the enzyme cocktails, three different enzymatic loads were studied for each of the two enzymes studied (15, 30 and 45 U/g DM of biomass; and 15, 30 and 45 FBGU/g DM of biomass) respectively for Celluclast and Viscozyme. The hydrolysis kinetics, studied through the evolution of reducing sugar content, are summarized in Figs. 5 and 6.

Influence of Enzyme Load on Saccharification

The saccharification efficiency was influenced by the enzyme load. The reducing sugar content increased logically with increasing enzymatic load for a fixed biomass (Fig. 5). For example, at 5% of biomass load, the concentration of reducing sugars, initially evaluated at 62 g/Kg DM, reached 109.03 and 136.01 g/Kg DM, respectively for celluclast enzymatic loads of 15 and 45 U/g DM (Fig. 5C). These concentrations reached 116.16 and 142.22 g/Kg DM respectively for Viscozyme using 15 and 45 FBGU/g DM with the same biomass concentration of 5% (Fig. 5D). A similar observation was reported by Zeghlouli et al. [53], who experimented ethanol production via enzymatic hydrolysis of argan pulp using Celluclaste 1.5 L and Viscozyme L. These authors obtained reducing sugars concentrations of 700.36 and 723.36 g/Kg DM, respectively for Celluclaste and Viscozyme with a biomass load of 2% (w/v). Jin et al. [42], also tested the production of ethanol after the enzymatic hydrolysis of rice straw pretreated with NaOH. Enzyme loading in a range of 50 to 200 FPU/mL were studied and the maximum yield of reducing sugars (529.90 g/Kg) was obtained after 20 h of hydrolysis with an enzymatic load of 200 FPU/mL. Deliana et al. [54], also studied the enzymatic hydrolysis of empty fruit bunch and indicated that the enzyme concentration strongly influences the speed and yield of hydrolysis (6.2% against 10.67% concentrations in glucose equivalent were obtained after 72 h of hydrolysis at 10 FPU and 40 FPU respectively). This study reveals that Viscozyme has better saccharification yields with a maximum concentration of reducing sugars evaluated at 188.68 g/Kg DM after 24 h of hydrolysis with an enzymatic load of 45 FBGU/g DM and 10% (w/v) biomass concentration (Fig. 5F). The maximum concentration of reducing sugars was 170.37 g/Kg DM after 48 h of hydrolysis using Celluclast at 45 U/g DM and 10% (w/v) biomass load (Fig. 5E).

Similar results were obtained testing the impact of the enzymatic load on the marrow saccharification (Fig. 6). However, a significant difference in hydrolysis speed and yield was observed between the two enzymatic cocktails studied. At 2% of biomass for example, the concentrations of reducing sugars initially evaluated at 4.5 g/Kg DM, reached 15.91 and 109.41 g/Kg DM after 2 h of hydrolysis respectively with Celluclast at 45 U/g DM and Viscozyme at 45 FBGU/g DM (Fig. 6A and B) for maximum concentrations of 42.08 and 158.01 g/Kg DM respectively, after 24 h of hydrolysis. This indicates that Viscozyme has the best marrow hydrolysis yield with a higher hydrolysis rate compared to Celluclast. This phenomenon could be explained by largest diversity of polysaccharide hydrolases in Viscozyme compared to Celluclast which is mainly composed of cellulases [53]. Furthermore, this could also be explained by the fact that the pith contains a relatively low lignin content compared to the whole stem (28.60 ± 1.49 against 3.03 ± 0.18 respectively for the whole stem and marrow (Table 1)), which could accelerate the marrow enzymatic digestibility.

Effect of Biomass Load on Saccharification

The influence of biomass concentration was studied by monitoring the evolution of total soluble sugar content during the enzymatic hydrolysis of different biomass fractions. Figure 7 shows that for the two biomass fractions studied (whole stem and pith), the total soluble sugar content increased with increasing biomass concentration for both Celluclast and viscozyme. For example from 5 to 10% (w/v) of whole stem hydrolysis with Celluclast at 45 U/g DM, total sugars increased from 6.22 to 16.07 g/L respectively (Fig. 7A) and from 7.30 to 23.08 g/L respectively, for hydrolysis with Viscozyme at 45 FBGU/g DM (Fig. 7B). The same result was observed with other fractions. For example from 2 to 5% (w/v) of marrow an increase of total sugars from 0.8 to 4.93 g/L respectively was observed with Celluclast at 30 U/g DM (Fig. 7C) and from 4.98 to 9.68 g/L with Viscozyme at 30 FBGU/g DM. Similar observations were reported by Qiu et al. [55], who studied the influence of substrate load during the enzymatic hydrolysis of wheat straw pretreated with phosphoric acid and hydrogen peroxide. Four substrate loadings were tested, and the results showed that the higher glucose concentrations were correlated with the higher biomass concentrations. However, contrary to these observations, some authors have reported in the literature that high substrate concentrations resulted in hydrolysis inhibition with low hydrolysis yields [56]. The extent of substrate inhibition depends on total substrate/total enzyme ratio [57, 58].

Improving Ethanol Production Yield: Hydrolysates Fermentation

In order to improve the yield of ethanol production, Viscozyme, presenting better saccharification yields compared to Celluclast, was used to carry out the enzymatic hydrolysis of different fractions of sorghum stalks. The optimal conditions (Viscozyme at 45 FBGU/g DM and 10% (w/v) of substrate concentration) were used and the hydrolysates were fermented by Saccharomyces cerevisiae against a corresponding untreated biomass fraction control. The fermentation kinetics followed through the production of ethanol and the consumption of total sugars in the reaction media are presented in Figs. 8 and 9.

The ethanol conversion yields, evaluated on average at 212.01 and 270.32 g Eth/Kg DM were obtained respectively for the untreated and treated whole stem (Fig. 10A). This indicates that the fermentation of the hydrolyzate of the whole stem treated with Viscozyme made it possible to increase bioconversion in ethanol of the order of 27.50% compared to the fermentation of the untreated stem (Fig. 10B). The same bioconversion yields were evaluated at 276.74 and 349.86 g Eth/Kg DM, respectively for the untreated and treated marrow (Fig. 10A). This also indicates a rate of increase in the order of 26.42% between fermentation of untreated and treated marrow (Fig. 10B). These results show that enzymatic hydrolysis makes it possible to obtain a significant increase in the rate of biomass bioconversion. These results also indicate that expressed in terms of rate of increase in ethanol production yield, it would be more beneficial and profitable to treat the whole stem (richer in total fiber (Table 1)) which releases more additional sugars compared to the pith.These ethanol yields increases compared to the consumption of total sugars in hydrolyzates were evaluated at 39.63% and 28.14% respectively for the treated and untreated whole stem fractions and between the fractions of treated and untreated marrow (Fig. 10B). These conversion efficiencies are significantly higher than those reported by Sudiyani et al. [59], who also experimented ethanol production after enzymatic hydrolysis (at 30 FPU of Cellic®Ctec2 and Cellic®Htech2 enzymes) of sweet sorghum stalk bagasse pretreated with 10% (w/v) NaOH. The bioconversion yields after fermentation of the hydrolyzate by S. cerevisiae were 178.34 and 110.66 L/ton respectively by the process of simultaneous saccharification and fermentation (SSF) and separate hydrolysis and fermentation (SHF). Similarly, Jin et al. [42] experimented the production of ethanol after enzymatic hydrolysis (20 FPU/mL) of rice straw pretreated with 1% NaOH and obtained a maximum yield of 189 g Eth/Kg DM after fermentation of the hydrolyzate by Saccharomyces tanninophilus. Bahry et al. [29] also experimented the production of ethanol from carob waste hydrolyzed by sulfuric acid. They reported that the fermentation yield of waste in solid state by S. cerevisiae, was evaluated at 155 g/Kg and was higher than that of the fermentation of waste extract in liquid phase which, was limited to 78 g/Kg.

These results show that the process for ethanol production tested by this study makes it possible to significantly improve the yield of conversion of sorghum stalks into ethanol. It is a green and environmental friend process, efficient and more suitable for sustainable development policy compared to other ethanol production methods from lignocellulosic feedstock.

Conclusion

This study aimed to improve the bioconversion of sweet sorghum stalks into ethanol. The direct fermentation process (without juice extraction) of ground whole stem experimented in this study significantly improved the efficiency of the ethanol production process. The conversion yields were 165.44; 252.62 and 184.87 g Eth/Kg DM of biomass respectively for juice, marrow and whole stem. Enzymatic hydrolysis applied to different shredded (particle size ≤ 0.5 mm) biomass fractions (whole stem and marrow) showed that Viscozyme led to better biomass saccharification yield compared to Celluclast. The optimal conditions (Viscozyme at 45 FBGU/g DM and 10% (w/v) of biomass concentration) made it possible to obtain increases in total sugar concentrations evaluated at 23.08 and 21.39 g/L after 24 h of hydrolysis, respectively for whole stem and pith hydrolysates. The fermentation of the subsequent hydrolysates by S. cerevisiae made it possible to significantly increase the biomass conversion yields. The bioconversion yields were 212.01 and 270.32 g Eth/Kg DM respectively for the untreated and treated whole stem fractions, i.e. a rate of increase of 27.50%. They were 276.74 and 349.86 g Eth/Kg DM, respectively for the untreated and treated marrow fractions, i.e. a rate of increase of 26.42%. Contrary to the usual process, this study reveals that the juice extraction step, which consumes a lot of water and energy could be dispensed improving the performance and efficiency of the ethanol production process from sweet sorghum stalks. The performance of this new process was further enhanced by a saccharification treatment of the biomass lignocellulosic fraction using cellulolytic enzymes. However, since xylose, which is one of the main sugars obtained after saccharification of the lignocellulosic fraction of this biomass, is not consumed by S. cerevisiae, it would also be relevant for the future studies to explore the fermentation of biomass hydrolyzate in mixed culture between S. cerevisiae and Z. mobilis, or by other strains of microorganisms such as Pachysolen tannophilus, Clostridium thermohydrosulfuricum, S. tanninophilus, etc., capable of fermenting pentoses.

Data Availability

All data generated and analyzed during this study are included in this published article.

References

Phoon, B.L., Lai, C.W., Juan, J.C., Show, P.L., Pan, G.: Recent developments of strontium titanate for photocatalytic water splitting application. Int. J. Hydro. Energy. (2019). https://doi.org/10.1016/j.ijhydene.2019.01.166

Rubin, E.M.: Genomics of cellulosic biofuels. Nature 454, 841–845 (2008)

Phwan, C.K., Ong, H.C., Chen, W., Ling, T.C., Ng, E.P., Show, P.L.: Overview: comparison of pretreatment technologies and fermentation processes of bioethanol from microalgae. Energy Convers. Manage. 173, 81–94 (2018). https://doi.org/10.1016/j.enconman.2018.07.054

El-Zawawy, W.K., Ibrahim, M.M., Abdel-Fattah, Y.R., Nadia, A., Soliman, N.A., Mahmoud, M.M.: Acid and enzyme hydrolysis to convert pretreated lignocellulosic materials into glucose for ethanol production. Carbohyd. Polym. 84, 865–871 (2011)

Sakai, S., Tsuchida, Y., Okino, S., Ichihashi, O., Kawaguchi, H., Watanabe, T., Yukawa, H.: Effect of lignocellulose-derived inhibitors on growth of and ethanol production by growth-arrested Corynebacterium glutamicum R. Appl. Environ. Microbiol. 73, 2349–2353 (2007)

Wang, Y., Chen, C.J., Cai, D., Wang, Z., Qin, P.Y., Tan, T.W.: The optimization of L-lactic acid production from sweet sorghum juice by mixed fermentation of Bacillus coagulans and Lactobacillus rhamnosus under unsterile conditions. Bioresour. Technol. 218, 1098–1105 (2016). https://doi.org/10.1016/j.biortech.2016.07.069

Wang, Y., Chang, J.Q., Cai, D., Wang, Z., Qin, P.Y., Tan, T.W.: Repeated-batch fermentation of L-lactic acid from acid hydrolysate of sweet sorghum juice using mixed neutralizing agent under unsterilized conditions. J. Chem. Technol. Biot. 92, 1848–1854 (2017). https://doi.org/10.1002/jctb.5195

Zhang, C.W., Wen, H., Zheng, J., Fu, C.H., Chen, C.J., Cai, D., Qin, P.Y., Wang, Z.: A combination of evaporation and chemical preservation for long-term storage of fresh sweet sorghum juice and subsequent bioethanol production. J. Food Process. Pres. 42, 13825 (2018). https://doi.org/10.1111/jfpp.13825

Saballos, A.: Development and utilisation of sorghum as a bioenergy crop. Gen. Improv. Bioenergy. Crops. (2008). https://doi.org/10.1007/978-0-387-70805-8_8

FAOSTAT. (2022) Données de l’alimentation et de l’agriculture. http://www.fao.org/faostat/fr/#home. Accessed 24 July 2022

Bálint, S., Jutka, R., Zsolt, S., Zsófia, K., Dóra, D., Kati, R.: Sweet sorghum as feedstock for ethanol production: enzymatic hydrolysis of steam-pretreated bagasse. Appl. Biochem. Biotechnol. 153, 151–162 (2009). https://doi.org/10.1007/s12010-008-8423-9

Sheehan, J., Himmel, M.E.: Enzymes, energy, and the environment: cellulose development in the emerging bioethanol industry. Biotechnol. Prog. 15, 817–827 (1999)

Husiatynska, N., Hryhorenko, N., Kalenyk, O., Husiatynskyi, M., Teterina, S.: Studying the process of extracting sugary substances from the stalks of sweet sorghum in the technology of making food syrups. Eastern-Euro J. Enterp Technol. 4, 17–24 (2021). https://doi.org/10.15587/1729-4061.2021.237785

Appiah-Nkansah, N.B., Li, J., Rooney, W., Wang, D.: A review of sweet sorghum as a viable renewable bioenergy crop and its techno-economic analysis. Renew Energy. (2019). https://doi.org/10.1016/j.renene.2019.05.066

Monroe, G.E., Nichols, R.L., Bryan, W.L., Sumner, H.R.: Sweet sorghum juice extraction with 3-roll mills. Trans ASAE. 27, 651–654 (1984). https://doi.org/10.13031/2013.32845

Grigorenko, N.A., Stangeeva, N.I. (2017) Improvement of the method of sugars extracting from stems of sorghum. Prodovolchi resursy. 9: 150–153 Available at: http://nbuv.gov.ua/UJRN/pr_2017_9_20

Jia, F., Chawhuaymak, J., Riley, M.R., Zimmt, W., Ogden, K.L.: Efficient extraction method to collect sugar from sweet sorghum. J. Biol. Eng. 7, 1 (2013). https://doi.org/10.1186/1754-1611-7-1

Djomdi, Hamadou, B., Klang, M.J., Djoulde, D.R., Christophe, G., Michaud, P.: Extraction performance of juice and bioethanol production from sweet sorghum (Sorghum bicolor (L.) Moench). Glob. J. Eng. Sci. Res. Manag. 6, 57–66 (2019)

Sriariyanun, M., Kitiborwornkul, N., Tantayotai, P., Rattanaporn, K., Show, P.L.: One-pot ionic liquid-mediated bioprocess for pretreatment and enzymatic hydrolysis of rice straw with ionic liquid-tolerance bacterial cellulase. Bioengineering 9, 17 (2022). https://doi.org/10.3390/bioengineering9010017

Shah, R.B., Clausen, E.C., Gaddy, J.L.: Production of Chemical Feedstocks from Biomass. CEP Newlt. January, 76 (1984)

Ogier, J.C., Ballerini, D., Leygue, J.P., Rigal, L., Pourquié, J.: Production d’éthanol à partir de biomasse Lignocellulosique. Oil Gas. Sci. Technol.—Revue de l’IFP. 54, 67–94 (1999)

Banerjee, S., Mudliar, S., Giri, B., Satpute, D., Chakrabarti, T., Pandey, R.A.: Commercializing lignocellulosic bioethanol: technology bottlenecks and possible remedies. Biofuels, Bioprod. Biorefin. 4, 77–93 (2010)

Duff, S.J.B., Murray, W.D.: Bioconversion of forest products industry waste cellulosics to fuel ethanol: a review. Bioresour. Technol. 55, 1–33 (1996)

AFNOR (Association Française de Normalisation): Recueil des normes françaises des produits dérivés des fruits et legumes, Jus de fruits. 1ère éd., Afnor Compétences, Paris la défense, France (1982)

Van Soest, P.J.: The use of detergents in the analysis of fibrous feeds: II. a rapid method for the determination of fiber and lignin. Off. Agric. Chem. 46, 829 (1963)

Dubois, M., Gilles, K.A., Hamilton, J.K., Roberts, P.A., Smith, F.: Colorimetric method for determination of sugar and related substances. Anal. Chem. 28, 350–356 (1956)

Waffenschmidt, S., Jaenicke, L.: Assay of reducing sugars in the nanomole range with 2,2′-bicinchoninate. Anal. Biochem. 165, 337–340 (1987)

Gutfinger, T.: Polyphenols in olive oils. J. Am. Oil Chem. Soc. 58, 966–968 (1981)

Bahry, H., Pons, A., Abdallah, R., Pierre, G., Delattre, C., Fayad, N., Taha, S., Vial, C.: Valorization of carob waste: definition of a second-generation bioethanol production process. Bioresour. Technol. Elsevier 235, 25–34 (2017). https://doi.org/10.1016/j.biortech.2017.03.056

Kristiansen, B.: Integrated design of a fermentation plant: the production of baker’s yeast. VCH, New York (1994)

Almodares, A., Hadi, M.R.: Production of bioethanol from sweet sorghum: a review. Afr. J. Agric. Res. 4, 772–780 (2009)

Gutjahr, S., Clément-Vidal, A., Soutiras, A., Sonderegger, N., Braconnier, S., Dingkuhn, M., Luquet, D.: Grain, sugar and biomass accumulation in photoperiod-sensitive sorghums. II. biochemical processes at internode level and interaction with phenology. Funct. Plant Biol. 40, 355–368 (2013)

Billa, E., Koullas, D.P., Monties, B., Koukios, E.G.: Stucture and compostion of sweet sorghum stalk components. Ind. Crops Prod. 6, 297–302 (1997)

Amer, S.M.M.: Evaluation of high water soluble carbohydrates annual forages for dairy cattle, pp. 32–87. McGill University, Québec City (2011)

Amélia, D.P.B.: Rendement en biomasse et en sucres et valeur nutritive du millet perlé sucré et du sorgho sucré en fonction de la date de récolte et du délai entre le hachage et le pressage du fourrage. Mémoire, Maîtrise en biologie végétale, p. 114. Université Laval, Québec city (2012)

Tremblay, G.F., Lefebvre, D., Petit, H., Lafrenière, C.: La valeur nutritive des fourrages. Dans : Bélanger G., Couture L. et G. Tremblay. 2005. Les plantes fourragères, pp. 154. Centre de Référence en Agriculture et Agroalimentaire du Québec, (2005)

Khalil, S.R.A., Abdelhafez, A.A., Amer, E.A.M.: Evaluation of bioethanol production from juice and bagasse of some sweet sorghum varieties. Ann. Agric. Sci. 60, 317–324 (2015). https://doi.org/10.1016/j.aoas.2015.10.005

Jolanta, B., Jakub, F., Aleksandra, W., Agnieszka, Ł: Bioethanol production from biomass of selected sorghum varieties cultivated as main and second crop. Energies. 13, 6291 (2020). https://doi.org/10.3390/en13236291

Kim, M., Day, D.F.: Composition of sugar cane, energy cane, and sweet sorghum suitable for ethanol production at Louisiana sugar mills. J. Ind. Microbiol. Biotechnol. 38(7), 803–807 (2011)

Nasidi, M., Agu, R., Deeni, Y., Walker, G.: Improved production of ethanol using bagasse from different sorghum cultivars. Biomass Bioenerg. 72, 288–299 (2015)

Saini, J.K., Saini, R., Tewari, L.: Lignocellulosic agriculture wastes as biomass feedstocks for second-generation bioethanol production: concepts and recent developments. Biotech. 5, 337–53 (2015). https://doi.org/10.1007/s13205-014-0246-5

Jin, X., Song, J., Liu, G.: Bioethanol production from rice straw through an enzymatic route mediated by enzymes developed in-house from Aspergillus fumigatus. Energy. 190, 116395 (2020). https://doi.org/10.1016/j.energy.2019.116395

Crépeau, M., Khelifi, M., Vanasse, A., Seguin, P., Trembly, G.F.: Compressive forces and harvest time effects on sugars and juice extracted from sweet pearl millet and sweet sorghum. Trans. ASABE 56(5), 1665–1671 (2013)

Crépeau, M.: Optimisation de la récolte, de l’entreposage et du pressage du millet perlé sucré et du sorgho sucré cultivés au Québec pour la production de bioéthanol .Thèse Doctorat en sols et environnement, p. 151. Université Laval, Québec city (2017)

Noura, S.: (2016) Amélioration de l’extraction des sucres de la biomasse du millet perlé sucré et du sorgho sucré pour une éventuelle production de bioéthanol Mémoire Maîtrise en sols et environnement. Université Laval, Québec city (2015)

Hao, C., Xuejiao, T., Qunli, Y., Wei, H., Jihong, C., Libin, Z.: Sweet sorghum stalks extract has antimicrobial activity. Ind Crops Prod. 170, 113746 (2021). https://doi.org/10.1016/j.indcrop.2021.113746

Ring, A.S., Waniska, R.D., Rooney, L.W.: Phenolic compounds in different sorghum tissues during maturation. Biomass. 17, 39–49 (1988)

Sereme, A., Kuoda-Bonafos, M., Nacro, M.: Phenolic compounds in Sorghum caudatum tissues during plant development. Biomass Bioenerg. 4, 69–71 (1993)

Acosta-Estrada, B., Gutierrez-Uribe, J., Serna-Saldivar, S.: Bound phenolics in foods, a review. Food Chem. 152, 46–55 (2014)

Irvan, S.K., Khaswar, S., Erliza, N., Gumbira, S.E.: Sorghum stalk juice pre-treatment method for bioethanol fermentation process. Energy Procedia. 65, 140–145 (2015). https://doi.org/10.1016/j.egypro.2015.01.047

Teshome, H.R., Charles, S.W.: Sweet sorghum as a bioenergy crop: Literature review. Biomass Bioenerg. 64, 348–355 (2014). https://doi.org/10.1016/j.biombioe.2014.03.052

Zhu, Y., Xin, F., Chang, Y., Zhao, Y., Weichong, W.: Feasibility of reed for biobutanol production hydrolyzed by crude cellulase. Biomass Bioenergy. 76, 24–30 (2015). https://doi.org/10.1016/j.biombioe.2015.02.013

Zeghlouli, J., Christophe, G., Guendouz, A., El Modafar, C., Belkamel, A., Michaud, P., Delattre, C.: Optimization of bioethanol production from enzymatic treatment of argan pulp feedstock. Molecules. 26, 2516 (2021). https://doi.org/10.3390/molecules26092516

Deliana, D., Sri, O.T., Eka, T., Muhammad, N.: Haznan abimanyu comparison of SHF and SSF processes using enzyme and dry yeast for optimization of bioethanol production from empty bunch. Energy Procedia. 68, 107–116 (2015). https://doi.org/10.1016/j.egypro.2015.03.238

Qiu, J., Ma, L., Shen, F., Yang, G., Zhang, Y., Deng, S., Zhang, J., Zeng, Y., Hu, Y.: Pretreating wheat straw by phosphoric acid plus hydrogen peroxide for enzymatic saccharification and ethanol production at high solid loading. Bioresour. Technol. 238, 174–181 (2017)

Cheung, S.W., Anderson, B.C.: Laboratory investigation of ethanol production from municipal primary wastewater. Bioresour. Technol. 59, 81–96 (1997)

Huang, X.L., Penner, M.H.: Apparent substrate inhibition of the Trichoderma reesei cellulase system. J. Agric. Food Chem. 39, 2096–2100 (1991)

Penner, M.H., Liaw, E.T.: Kinetic consequences of high ratios of substrate to enzyme saccharification systems based on Trichoderma cellulase. In: Himmel, M.E., Baker, J.O., Overend, R.P. (eds.) Enzymatic Conversion of Biomass for Fuels Production, pp. 363–371. American Chemical Society, Washington, DC (1994)

Sudiyani, Y., Triwahyuni, E., Muryanto, Burhani, D., Waluyo, J., Sulaswaty, A., Abimanyu, H.: Alkaline pretreatment of sweet sorghum bagasse for bioethanol production. Int. J Renew. Energy Dev. 5, 113–118 (2016)

Acknowledgements

The authors would like to thank the French government which financed H.B.’s research mobility through its Eiffel scholarship program of excellence.

Funding

Author H.B. has received research support from Campus France (The French agency in charge of promoting French higher education abroad, managing scholarships from French and foreign governments and welcoming international students). Campus France, D21–0000000051, Hamadou Bakari

Author information

Authors and Affiliations

Contributions

Conceptualization: HB, D and PM; Methodology: GC, DDR and HB; Formal analysis and investigation: HB, DP and PG; Writing—original draft preparation: HB and ZF; Writing—review and editing: DC and PG; Supervision: PM and DDR] and all authors commented on previous versions of the manuscript. All authors read and approved the final manuscript.

Corresponding author

Ethics declarations

Competing interests

The authors have no relevant financial or non-financial interests to disclose.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Bakari, H., Djomdi, Falama Ruben, Z. et al. Optimization of Bioethanol Production after Enzymatic Treatment of Sweet Sorghum Stalks. Waste Biomass Valor 14, 2531–2545 (2023). https://doi.org/10.1007/s12649-022-02026-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12649-022-02026-y