Abstract

Purpose

Shallot (Allium cepa var. aggregatum) expels peel, stalk and petiole as major waste streams during harvesting and industrial processing. The study investigates effect of pre-treatments and process parameters on extraction of α-cellulose and subsequently Microcrystalline Cellulose (MCC).

Method

The extraction of cellulose and MCC was carried out by two pre-treatments such as hot water (60 °C) and autoclave method (121 °C) along with combined hydrolysis of alkali-bleaching-acid. The efficiency of pre-treatment with time, temperature and concentration of NaOH were evaluated.

Result

The recovery yield of MCC from cellulose was high in stalks and peel (autoclave pre-treated) and petiole (hot water pre-treated) with 79.39, 59.23 and 55.63% respectively. The FTIR spectra of samples showed that removal of lignin and hemicellulose was better in autoclave pre-treated samples. Scanning electron micrograph showed the morphological modifications in both pre-treatments. Crystallinity of extracted MCC was analysed with X-ray diffraction method and found high in hot water assisted petiole and autoclave assisted samples of petiole and stalk with 83.74, 79.93 and 76.75% respectively. The thermal resistance of extracted samples was analysed with DSC. The results of various parameters were compared with commercial MCC and showed close proximity.

Conclusion

The autoclave assisted pre-treatment was better for the effective transformation of cellulose to MCC with combined chemical hydrolysis which was technically easier, economical with less energy consumption. In a nutshell, selected shallot wastes proved to be source of superior quality microcrystalline cellulose with potential for commercialization.

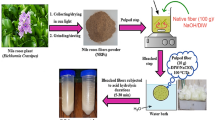

Graphical Abstract

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Statement of Novelty

Shallots have been used as a source of seasoning and bioactive components across the food and pharmaceutical sectors. Shallot processing leaves the large portion of agricultural waste directed to landfill. This further generate extreme pungent smell and phylogenetic microbial growth during decaying which cause excess environmental pollution. Therefore, exploitation of these conventionally inedible portions and conversion into profitable food-grade products will benefit the shallot producers and processors. Hence, this study has been taken up towards the utilization of shallot biowaste for the extraction and characterization of cellulose and microcrystalline cellulose by cost effective and eco-friendly techniques. The autoclaving combined with alkali, bleaching and acid hydrolysis under apt conditions help to reduce the cost and processing time, besides increasing the quality.

Introduction

Onions (Allium cepa) are extensively cultivated and consumed across the world as a culinary ingredient for its characteristic taste and pungent flavour. China and India are the major onion producing countries holding first (26 Million Tonnes) and second (24 Million Tonnes) position in world production scenario [1]. Allium cepa var. aggregatum, known as shallot or small onion is widely grown in western Asian, African and European countries [2]. Throughout the harvesting and processing of shallot, 37% of conventionally inedible portion of peel, stalk, petiole and flower along with limited quantity of roots are discarded [3]. Increased demand of onion leads to increase in production and processing subsequently leading to increase in waste generation. Dumping these wastes into landfill or feed stock are not recommended owing to the increased growth rate of opportunistic pathogens and highly pungent nature which causes adverse impact on surrounding environment [4].

As an alternative, the shallot waste streams such as peel, stalk and petiole were found to be excellent source of total polyphenols, flavonoids, glycosides, metal components, dietary fibre and oligosaccharides [3]. Moreover, flower comprises of protein and bioactive compounds that can be utilized in cosmetic, textile, pharmaceutical and food industry [5, 6]. In prior literature on Allium cepa (red onion varieties), researchers were more concentrated on the therapeutic use of phytochemicals overlooking the major component such as fibers which can either utilized directly in high fiber food or as substrate for the extraction of cellulose, hemicellulose and microcrystalline cellulose (MCC) [7, 8].

Among all the value added products, MCC is the one providing many health benefits. Conventionally, MCC could be manufactured by two stage method in which first isolation of cellulose will be carried out from the source material followed by MCC extraction. Techniques such as hydrothermal, microwave, ultrasound and combination of chemo-mechanical pre-treatments are generally applied for the synthesis of MCC from cellulose. However, the quality of the extracted MCC and its applicability depends on the substrate utilized for extraction and the treatment utilized for it (considering these aspect, the suitability of a novel source viz., shallot peel, stalk and petiole for the extraction of cellulose and consequently the MCC). MCC is a value added product which can be utilized as thickener, stabilizer, binder, filler, humectant and also serve as emulsifier [9,10,11]. According to market studies, MCC demand will pile up with 7.5% CAGR (Compound Annual Growth Rate) and estimated to 885.1 million dollars [12].

The objective of this research is effective utilization of shallot wastes such as petiole (PT), peel (P) and stalk (S) into dietary cellulose and MCC. Effect of pre-treatments, time and concentration of alkali in the extraction of cellulose and MCC yield and characteristics of MCC were studied.

Materials and Methods

Materials

Shallot bio-waste (SBW) that comprises of PT, P and S were procured from local onion processing company of Perambalur, Tamil Nadu, India. Collected samples were manually cleaned and sorted from foreign matters followed by drying in a solar hybrid drier (model) at 50 °C till it reached 5% moisture content. Dried samples were milled to powder and sieved through 0.75 mm mesh size sieve. Ground samples were packed in air tight containers and stored at refrigerated temperature till further use. Analytical grade chemicals were purchased from Sigma Aldrich and Himedia (Noida, India).

Methods

Pre-treatments and Extraction of Cellulose

The representation in Fig. 1 exemplify the extraction and isolation of the cellulose and MCC from P, S and PT, of the SBW. For the isolation of α-cellulose were performed with combination of time and concentration of NaOH followed by mineral acid hydrolysis. Main pre-treatments such as hot water (W) and steam assisted autoclave (A) method were applied. Detailed trial combinations are presented in supplementary Table B1.

Transformation of Cellulose to MCC

Extracted α-cellulose was mixed with concentrated hydrochloric acid (2.5 N HCl) in the ratio 1:20 (w/v) and treated at 100 °C for 15 min. The extracted MCC was further washed and filtered with excess cold distilled water to stop the reaction by eliminating the acid content [13]. Additionally, the depolymerized samples were purified by subsequent washing with different solvents including distilled water, ethyl alcohol and acetone until the end product attain the pH 7. The obtained MCC solution dried at 60 °C for 24 h in oven for further analysis.

Analysis

Chemical Characterization of Shallot Waste

Proximate analysis of the shallot waste streams was done using AOAC methods [14]. The soluble and insoluble fractions of pectin, hemicellulose and lignin components was quantified using modified gravimetric fractionation protocol [15].

Yield and Recovery %

The percentage of isolated cellulose and MCC were compared to initial mass of the shallot waste to determine the yield % [16] by following formulae detailed Eqs. (1) and (2)

where, WC is the isolated shallot cellulose and Wb is the initial weight of the SBW.

where, WC is the initial weight of the extracted cellulose isolated and Wm is the MCC content.

Colour Analysis

Colour determination is done by hunter lab colorimeter (ColorFlex EZ, Hunter Associates Laboratory Inc., Virginia, USA) [17]. The ΔE gives the total colour difference of samples and is calculated as given in Eq. (3).

where, ΔE is total colour difference and L1, a1, b1 were extracted samples.

Characterization of Microcrystalline Cellulose

Fourier Transform Infrared Spectroscopy (FTIR)

Samples were uniformly mixed with potassium bromide and pelletized to disk. The transmittance (%) determination was carried out by Spectrum two FTIR (TESCAN, VEGA 3, model no. 99065) instrument in the spectral range of 4000–400 cm−1 with resolution of 4 cm−1 with 32 scans using NIOS2 software identify the position of wavenumber in each samples [18].

Scanning Electron Microscopy (SEM)

Scanning was carried out beneath the specific distance (5 mm) and accelerating voltage of 5 kV using VEGA 3 TESCAN model with different magnifications. Throughout analysis, each samples were sputter coated with gold. Micrographs of each MCC samples magnified in 500 μm and 1000 μm. The particle size distribution examined through SEM micrograph were measured by imagej (1.52 V, USA). Image screens containing 100 particles per screen were taken for quantification of particle dimension.

X-ray Diffraction Analysis (XRD)

The crystallinity of the isolated MCC samples were examined by powder X-ray diffractometer (Malvern pAnalytical-XPERT3). In this, powdered samples were analysed with Ni-filtered Cu-Kα radiation (λ = 0.15406 nm) under certain angular incidence from 10° to 50°(2θ) generated at 45 kV and 40 mA with a ramp rate of 1 °C min−1 [19]. The quantification of crystallinity index (CI) was calculated by peak-height ratio and peak deconvolution method [20,21,22]. The peak-height or segal method is mainly expressed by the ratio among the crystalline planes (200) and amorphous planes (110) using the given Eq. (4) from PANalytical software 2019 program [22, 23] Similarly, crystalline and amorphous peaks were deconvoluted by integrating the area of crystalline and amorphous peaks by fitting the Gaussian curve using Origin pro 2018 software (SR1, origin lab Corporation, USA) by given Eq. (5)

where, I200 and IAm are the peaks corresponding to crystalline and amorphous regions respectively.

where, Ac and AAm are the integrated area of crystalline and amorphous peaks.

Crystalline size (D)was calculated by using Scherrer’s equation

where, D is the crystalline size, K is Scherrer’s constant (0.9), λ is wavelength of X-ray, β is full width at half maximum in radians and θ is Bragg angle.

Thermal Analysis

The thermal resistance of extracted MCC from the SBW was conducted by Differential Scanning Calorimeter (DSC3, Mettler Toledo, Switzerland). About 6 mg of powdered sample was kept in an aluminium pan and heat was applied at 40–350 °C at the rate of 20 °C min−1. Nitrogen flushing was maintained at 20 ml min−1 [24].

Statistical Analysis

In this study the statistical significance of pre-treatments for the extraction of the cellulose and MCC was evaluated by one-way ANOVA using Minitab 17 software (LLB, USA) with the help of Tukey modelling through significant difference (p < 0.05).

Results and Discussion

Proximate Characterization of Shallot Wastes

Table 1 exhibits the proximate estimation of untreated bio waste from shallot as given in the study by Bhosale et al. [3], as a part of the preliminary work conducted for the current study. As compared with PT, lesser quantity of carbohydrate and protein content was found in P and S with 17.93, 5.18 and 4.58, 5.6% respectively. However, the total ash content was relatively high in P, S and PT with 7.79, 15.89 and 9.21% respectively. The increased ash content can interfere the chemical reaction during alkali hydrolysis. It is also an important indicator of contaminants. The high fibre content of the biowaste sources indicate the feasibility of extracting cellulose and MCC for the purpose of valorisation. This was further confirmed by the high crude cellulose content in all the samples. Relatively high was found in peel along stalk and petiole with 54.76, 49.51 and 40.73% respectively.

Table 2 elaborately gives an insight about the structural composition of crude fibre. Consequently, this proximate estimation may vary from parts to part of SBW. In untreated SBW fiber, highest cellulose present in P fibre with 31.41% along with lowest lignin (6.047) content as compared to S and PT The soluble fibre was relatively high in PT sample along with P and S (9.09, 8.11 and 4.29%) respectively.

Extraction of Cellulose and MCC Isolation

The extraction of MCC mainly liable on source, pre-treatments, time, temperature, chemical hydrolysis and cellulose yield %. Through hot water pre-treatment, the yield % of α-cellulose was relatively high in WP followed by WS and WPT with values of 31.58, 34.48 and 30.41% along with high ash content of 3.11, 3.64 and 2.74% respectively showed in Fig. 2a. However, in Fig. 3a. autoclave assisted pre-treated cellulose samples which were treated at 120 °C for 30 min and 15psi and 2.0 N NaOH showed relatively good quality of cellulose yield of 29.31, 27.94 and 25.70% in AP, AS and APT as comparing with ash content with 0.54, 3.32 and 0.77% respectively. In untreated SBW, ash content is too high in each parts which causes negative impact on various processing and product development. Among these pre-treatments, 21.98, 17.36and 16.92% of MCC was extracted from AS, AP and WPT with lower ash content of 0.065, 0.185 and 1.195% respectively. While in selected MCC samples of C, APT, AP and AS, the lightness index (L*) were much better than hot water pre-treatment of 91.81 ± 0.037, 82.41 ± 0.005, 73.82 ± 0.008 and 77.5 ± 0.269 respectively. In hot water assisted samples, more time needed for the solubilisation of protopectin, pigment matter and lignin. After the pre-treatment, chemical hydrolysis will take place. As the NaOH concentration increases with longer time will cleave the glycosidic and ether bonding of lignin and hemicellulose. Also, the elongated penetrations of NaOH affect the structural deformations, stability, polymerization and crystalline phase of MCC. Demineralization and contaminants were diminished highly in 2 N NaOH for 60 min in hot water treated samples which was indicated by relatively low ash content [25, 26].

Variations of time, temperature and concentration of NaOH factors convoluted in extraction of cellulose with respect to a ash content and b MCC yield versus ash content and lightness (L*) index through 2.5 N HCl hydrolysis from shallot wastes pre-treated with hot water assistance. [*Results were expressed as mean ± SD (n = 3). Data in detail has been tabulated in the supplementary Table B2]. Hot water assisted extracted MCC samples from peel, stalk and petiole were denoted as WP, WS and WPT

Variation of different concentration of NaOH a on yield of cellulose with respect to ash content and b MCC versus ash content and lightness (L*) through acid hydrolysis from shallot wastes pre-treated with pressurised steam assistance. [*Results were expressed as mean ± SD (n = 3). Data in detail has been tabulated in the supplementary Table B3]. Auto clave assisted extracted MCC samples from peel, stalk and petiole were denoted as AP, AS and APT

The autoclave assisted pre-treatment activate the maximum depectinization, delignification and demineralization with minimal time consumption as compared to hot water pre-treatment. These results clearly indicate that prior to autoclave pre-treatment, cellulose expands and loosens structural binding of hemicellulose and lignin easily. Throughout the NaOH hydrolysis, the penetration of alkali might be uniform and quicker due to porous surface in autoclaved samples that dissolve the lignin and cleave ester bonding of pectin to form a complex certainly removed by dissolution more rapidly than hot water method. In bleaching process, a combination of sodium hypochlorite and acetic acid interaction at acidic condition will not only remove lignin but also breakdown the polyphenols and other pigmentation completely from cellulose surface and becomes white coloured powder. But cellulose diminishes its colour to yellowish which affect the cellulose attributes due to the longer exposure of bleaching process which was seen in hot water treated samples [27]. Owing to steam explosion, as the temperature increase to 190 °C leads to destruction of cellulose into glucose accordingly breakdown the glyosidic linkage of linear chain along with increased ash content [28].

Figure 4 exposes the MCC yield % of selected optimized condition of hot water and steam assisted pre-treatments. Overall, recovery of MCC was found comparatively high in AS followed by AP, WPT with 79.39, 59.23 and 55.63% respectively. Acid hydrolysis is an important stage involved in production of MCC. During acid hydrolysis, linear higher degree polymer of cellulose breakdown to smaller degree polymer further removal of amorphous region with increased specific surface area than commercial cellulose. The reaction starts with the vigorous interaction of 2.5 N HCl interact with extracted cellulose at 100 °C. At high temperature, increased concentration of HCL will penetrate in to the amorphous region of cellulose where Clˉ has weakens the glycosidic linkage and H+ react with β-1,4-glycosidic bonding and breaks into shorter chain MCC. The extend of pre-treatments and, alkali and bleaching hydrolysis will also affect the HCl hydrolysis such as yield, DP, crystallinity and colour attributes of MCC.

FT-IR Spectra

The FT-IR spectra is given in supplementary Fig. C1 with major and minor resultant peaks specified in spectral images of A and B. A broadened peak bending was found in all pre-treated MCC samples in the range of 3500–3000 cm−1 detected the of O–H absorption due to the intra and intermolecular interaction between cellulose. The distinctive spectral range of polysaccharide was found in between 1800 and 650 cm−1 represent the structural confirmation of presence or absence of pectin, hemicellulose and cellulose. The hot water pre-treated samples revealed the minor peak stretching at 1740 cm−1 was shifted to 1735–1720 cm−1 due the partial removal of hemicellulose quantity by alkali and acid hydrolysis whereas in autoclave pre-treated not showed significant peak. Furthermore, peak assigned in 1615, 1264, 1043, 1093 and 1091 cm−1 assigned to weak asymmetric stretching of C–O and C–H2 (methyl group) in pectin and its derivatives. C–O vibration of derivative pectic acid was observed significantly in both WP and WS while in autoclave assisted pre-treated samples this band was disappeared. Finally, aromatic ring structure with C=C stretch vibration of lignin in 1520–1510 cm−1 was completely removed in autoclave pre-treated samples by subsequent NaOH and chlorite hydrolysis. In MCC samples of WPT and WS, C=C stretching of lignin traces were found. Whereas in autoclave assisted samples, 1734–1720, 1615, 1596, 1512, 1520,1344, 1269 1244, 1094, 1091 and 1043 cm−1 are the absorption spectra of hemicellulose and lignin was completely ceased by the autoclave assisted pre-treatment and chemical hydrolysis [29]. Absence of C=O in region of 1510, 1523 and 1413 peaks stretching was mainly due aromatic ring of lignin evidenced the degradation of lignin in previous research [30]. Utmost, characteristic band identified in between 1430 and 1429, 1364, 1157, 895 cm−1 showed a sharp peak bending symmetric CH2 and asymmetric C1–H represents pure crystalline cellulose band in many agro-industrial wastes like tea waste [31] Aforementioned sharp peak stretching at 900–895 cm−1was found in all MCC samples with varying sharpness in peaks intensity depending on the extend of process conditions. Overall, MCC samples isolated from autoclave assisted pre-treatments showed tremendous reduction in number peaks with increased spectrum resolution as compared to hot water assisted MCC samples [32]. Table 3 elucidate resultant peak bands shifting and presence or absence of functional groups in each MCC samples ranged from 4000 to 400 cm−1. Almost all MCC samples extracted from autoclave assisted method showed similarity in FTIR spectra by commercial MCC with slight shift in peak positions according to the extent of time, temperature, pre-treatments and chemical hydrolysis.

SEM and Particle Size Distribution

Figure 5 shows structural features of extracted MCC through hot water and autoclave pre-treatments along with C-MCC through SEM micrographs. The selected micrographs in 100 × along with magnified 2000 × micrographs were portrayed through black arrows (and shapes), labelled as a, b, c, d, e, f and g of each MCC samples.

Induced pre-treatment and chemical hydrolysis plays an important role in transformation from cellulose to MCC. As compared to hot water treatment, autoclave assisted pre-treated samples showed well defined cleavage, porous, smooth surfaces [33]. The petiole part depicted in (a) and (d) micrographs has the individual rod shaped structures in both the MCC samples of WPT and APT. Due to the prolonged reaction time, temperature and chemical penetration, structural damages were observed to be higher in MCC samples of WPT but non-cellulosic components were removed and converted cellulose fibrils to individual short micro fibrils of MCC by acid hydrolysis [34]. More damage and irregularity were showed in hot water pre-treated samples because of extended chemical hydrolysis. While in the MCC samples of APT, the surface became more porous by the removal of amorphous region by acid hydrolysis, but crystalline structures were more intact and maintained its slender, smooth and rod like in each particle. The autoclave treated samples of e and f (AP & AS) became more expanded and smooth surfaced with clear and fibrous irregular shaped structures which showed similarity to that of g sample.

The particle size and agglomerations are mainly reliant on raw material nature, pre-treatments and hydrolysis procedures. More the reaction time, larger will be the agglomerates and, surface area and internal area of particle thus increased in micro-fibrils [35]. The particle size distribution was illustrated in supplementary Fig. C2a, b and c was plotted by histograms of MCC samples. The average particle size mean varies from 16.14 to 36.34 μm from sample to sample. In comparison to the C-MCC (17.56), AS, APT and WS had the mean average particle diameter of 16.14 ± 0.84, 21.82 ± 0.22 & 24.84 ± 0.76 μm respectively as plotted in Fig. 6. Similar studies on rice husk and soya husk MCC exhibited the particle diameter of 255–342 and 396-615 μm respectively [36]. The average L/D ratio of AP-MCC samples were 1.366 which means they are almost spherical. Whereas for APT and AS, the L/D ratio was found to be 2.591 and 2.106 respectively. These ratios indicate that the length is double that of diameter which means that the particles are more longitudinal in nature. This data can be backed up by the similar trend shown by SEM images of the respective samples in Fig. 3a.

Crystalline Characterization by X-ray Diffraction (XRD) Analysis

Increase or decrease in crystalline Index is mainly dependent on variables such as process condition, structural modification and compositional deformation happens in extracted MCC samples. The diffractogram of isolated MCC samples have been displayed in a and b represents the patterns of hot water assisted and autoclave assisted extraction process respectively (see Fig. 7).

X-ray diffraction patterns exhibited by MCC isolated from different pre-treatments (a) hot water and (b) autoclave assisted samples. (i) Hot water assisted extracted samples from the peel, stalk, and petiole were indicated as WP, WS, and WPT. (ii) Autoclave assisted extracted MCC samples from peel, stalk, and petiole were labelled as AP, AS, and APT. (iii) Commercial microcrystalline cellulose standard (C-MCC)

Major three peaks of the MCC samples of C, WP, AP & AS that showed at 2θ = 15°, 22° and 34° were related to the crystallographic planes of 110, 200 and 040. The lattice shifting mainly happened in planes of 200 were 2θ = 21.53°–22.6° was observed in Alfa fibres. The earlier experiments on sago seed shell [37] and sorghum stalks [38], also showed similar major plane in 110, 200, 040 with 2θ = 16°, 22.8° and 34.5°. During extraction of MCC, pre-treatments and chemical hydrolysis cause hydrolytic breakdown of β-1,4-glucopyranose linkage and released the individual crystallites from the cellulose fibres as well as reduction of the amorphous components. These leads to an increment of CI in isolated MCC samples. This had happened in the MCC samples of WPT and APT where position of same peak had shifted to 2θ = 14.9° and 21.9°. The peaks observed in 2θ = 15°, 14.9° represent the amorphous peaks of monoclinic cellulose I. The major peak examined at 2θ = 21, 22° confirms the presence of crystalline cellulose II which is linked by Vander Vaal force which can break due to the excess energy. In MCC sample of WS, the doublet peak in the plane of ͞200 and 200 at 2θ = 21.3 and 22.2° were formed by cellulose I and cellulose II allomorphs [39]. These may also be due to the transformation of cellulose I to cellulose II type by the swelling or renewed cellulose due to the alkali hydrolysis [32]. In previous literature, researchers found same similarity in oxy-MCC isolated from rice husk which also found doublet peaks in 2θ = 20°, 22° which related to the co-occurrence of cellulose I and II which transform to unique hybrid MCC structure with 84.8% CI [40]. In all pre-treated samples, isolated MCC contains notable two peaks which positioned at 2θ = 43° and 44° which might be an extra crystal lattices. Formation of these peaks may relate to new crystalline planes atomic interface by the degradation of cellulose I.

Typically, higher degree of crystallinity of standard MCC were ranging from 55 to 80%. Using peak intensity method given in Eq. (5), CI was significantly high in C along with APT, AS and WPT with 78.28, 79.93, 76.75 and 83.74% respectively. Compared with the control (C) MCC, APT, AS, WP, WPT has excellent CI of 83.68, 82.50 and 81.53% respectively using peak area or convulsion method through Eq. (6). Similarly, CI of waste source such as cotton, sugar bagasse groundnut husk, corncob, rice husk, palm stalk, palm spikelet stands at 84.46, 87.4, 64, 78, 68.46, 76.2 and 81.3% respectively [29, 32].

The crystallite size is also an important factor which is interrelated to the CI. It is calculated by the Scherrer’s Eq. (6) and was schemed in the Table 4. elucidates the average crystallite size in crystallographic planes of cellulose I and II of extracted MCC. The CI and crystallite size of the autoclave assisted pre-treated samples showed better results as compared to C-MCC. The crystallite size was non-uniform in extracted MCC samples because of different source and nature, pre-treatments, extent of NaOH and bleaching agent interaction, HCl hydrolysis, reaction time and temperature, and extraction procedure [30].

Thermal Characteristics by DSC Method

The DSC thermogram (see supplementary Fig. C3) of the extracted MCC samples showed two noticeable endothermic peaks in varying temperatures of differently pre-treated samples. The endothermic peaks were formed by the volatilization and charring due to the thermal decomposition [41, 42]. The changes which occurs in MCC during heat decomposition was because of loss of moisture content, damage of intermolecular hydrogen bonding between the monomers as well as melting of crystals present in the sample. The presence of crystals resists the heat decomposition depending upon on the nature of cellulose I and II in present samples. DSC thermographs of the extracted samples illustrated in Table 5 showed that, initially first endothermic peak event happened in 80°–145° in extracted MCC from different samples. In the first endothermic peak, MCC samples of AS, C, WS showed highest temperature with 144, 123.3, and 121℃ respectively. Subsequently, second event examined in between 200 and 300 °C caused mass destruction of crystalline cellulose. In this event, highest thermal resistance was found in MCC samples of AS, AP and WPT with 263, 259 and 255 respectively. Prior studies of biomass from wheat, soybean, banana and rice indicated the TM of 296, 290, 301 and 268 °C respectively supporting the above results [43, 44]. The ΔHf was lower in MCC samples extracted from SBW compared to control samples. Lower ΔHf showed in AP, WPT, APT of 16.49, 25.82 and 47.47 Jg−2.

Conclusions

Allium cepa var. aggregatum is produced biennially and the huge agro-industrial waste generated can be the potential source of cellulose for the production of MCC. The current research summarizes the extraction of MCC through the hydrothermal pre-treatments in which the low concentrated bleaching and alkali-acid hydrolysis proved to be effective for transformation of cellulose to MCC. Autoclave assisted extracted MCC (2 N NaOH, 4% NaClO and 2.5 N HCl) from stalk (AS) and peel (AP) showed better recovery of MCC with 79.39 and 59.23% than hot water pre-treatments. Further characterization through FTIR, morphological distributions, crystalline properties (XRD) and thermal analysis (DSC) also point out the process conditions through autoclave assisted extracted MCC from shallot bio-waste showed functional groups and morphological configuration similar to commercial MCC mainly meeting international specifications. The crystallinity index of MCC was also showed on par with C-MCC through XRD. Crystallinity of extracted MCC was observed to be 83.74 and 79.93% in autoclave assisted petiole (APT) and stalk (AS) respectively through peak intensity method. As compared to C-MCC, AP, WS and APT showed smaller crystallite size with 28.54, 31.05 and 33.23 nm respectively. The crystallinity of the extracted MCC samples were dependent on sample and cellulose nature, and process conditions and independent from crystallite size. DSC results also revealed improved thermal resistance in autoclave-assisted pre-treated samples, particularly MCC samples from stalk and peel, which supported crystallinity properties. However further investigation needed for the crystallinity peaks involved in 2θ = 43° and 44° and also to find out techno-functionality properties in different industrial applications. Hence, it can be concluded that autoclave assisted pre-treatment along with other optimized conditions were better when compared to water assisted pre-treatment for the MCC extraction from shallot bio-waste and shallot bio wastes are potential cheap sources for cellulose and MCC which is eco-friendly too.

References

Food and Agriculture Organization of the United Nations (FAO): FAOSTAT. http://www.fao.org/faostat/en/#rankings/countries_by_commodity. Accessed 22 July 2020

Bede, D., Zaixiang, L.: Dietary polysaccharides from allium species: a critical review in dietary polysaccharides from allium species: extraction, characterization, bioactivity and potential utilization. Acta Sci. Agric. 4, 01–15 (2020). https://doi.org/10.31080/asag.2020.04.0780

Bhosale, Y.K., Varghese, S.M., Thivya, P., Hema, V., Sinija, V.R.: Studies on assessment of safety and nutritional quality of shallot waste fractions. J. Food Process. Preserv. (2020). https://doi.org/10.1111/jfpp.15147

Bello, M.O., Olabanji, I.O., Abdul-Hammed, M., Okunade, T.D.: Characterization of domestic onion wastes and bulb (Allium cepa L.): fatty acids and metal contents. Int. Food Res. J. 20, 2153–2158 (2013)

Benítez, V., Mollá, E., Martín-Cabrejas, M.A., Aguilera, Y., López-Andréu, F.J., Cools, K., Terry, L.A., Esteban, R.M.: Characterization of industrial onion wastes (Allium cepa L.): dietary fibre and bioactive compounds. Plant Foods Hum. Nutr. 66, 48–57 (2011). https://doi.org/10.1007/s11130-011-0212-x

Benítez, V., Mollá, E., Martín-Cabrejas, M.A., Aguilera, Y., Esteban, R.M.: Physicochemical properties and in vitro antidiabetic potential of fibre concentrates from onion by-products. J. Funct. Foods. 36, 34–42 (2017). https://doi.org/10.1016/j.jff.2017.06.045

Reddy, J.P., Rhim, J.W.: Extraction and characterization of cellulose microfibers from agricultural wastes of onion and garlic. J. Nat. Fibers. 15, 465–473 (2018). https://doi.org/10.1080/15440478.2014.945227

Choi, I.S., Cho, E.J., Moon, J.H., Bae, H.J.: Onion skin waste as a valorization resource for the by-products quercetin and biosugar. Food Chem. 188, 537–542 (2015). https://doi.org/10.1016/j.foodchem.2015.05.028

Nsor-Atindana, J., Chen, M., Goff, H.D., Zhong, F., Sharif, H.R., Li, Y.: Functionality and nutritional aspects of microcrystalline cellulose in food. Carbohydr Polym (2017). https://doi.org/10.1016/j.carbpol.2017.04.021

Winuprasith, T., Khomein, P., Mitbumrung, W., Suphantharika, M., Nitithamyong, A., McClements, D.J.: Encapsulation of vitamin D3 in pickering emulsions stabilized by nanofibrillated mangosteen cellulose: impact on in vitro digestion and bioaccessibility. Food Hydrocoll. 83, 153–164 (2018). https://doi.org/10.1016/j.foodhyd.2018.04.047

Yohana Chaerunisaa, A., Sriwidodo, S., Abdassah, M.: Microcrystalline cellulose as pharmaceutical excipient. Pharm. Formul. Des. Recent Pract. (2020). https://doi.org/10.5772/intechopen.88092

Microcrystalline Cellulose Market- Industry Research Report https://www.quincemarketinsights.com/industry-analysis/microcrystalline-cellulose-mcc-market. Accessed 3 Feb 2021

Katakojwala, R., Mohan, S.V.: Microcrystalline cellulose production from sugarcane bagasse: Sustainable process development and life cycle assessment. J. Clean. Prod. 249, 119342 (2020). https://doi.org/10.1016/j.jclepro.2019.119342

Nielsen, S.S.: Food science text series food analysis laboratory manual. Springer, New York (2017)

Collazo-Bigliardi, S., Ortega-Toro, R., Chiralt Boix, A.: Isolation and characterisation of microcrystalline cellulose and cellulose nanocrystals from coffee husk and comparative study with rice husk. Carbohydr. Polym. 191, 205–215 (2018). https://doi.org/10.1016/j.carbpol.2018.03.022

Ilyas, R.A., Sapuan, S.M., Ishak, M.R.: Isolation and characterization of nanocrystalline cellulose from sugar palm fibres (Arenga Pinnata). Carbohydr. Polym. (2017). https://doi.org/10.1016/j.carbpol.2017.11.045

Karaman, E., Yılmaz, E., Tuncel, N.B.: Physicochemical, microstructural and functional characterization of dietary fibers extracted from lemon, orange and grapefruit seeds press meals. Bioact. Carbohydrates Diet. Fibre. 11, 9–17 (2017). https://doi.org/10.1016/j.bcdf.2017.06.001

Liu, Y., Liu, A., Ibrahim, S.A., Yang, H., Huang, W.: Isolation and characterization of microcrystalline cellulose from pomelo peel. Int. J. Biol. Macromol. 111, 717–721 (2018). https://doi.org/10.1016/j.ijbiomac.2018.01.098

Li, J., Wang, D., Xing, X., Cheng, T.J.R., Liang, P.H., Bulone, V., Park, J.H., Hsieh, Y.S.Y.: Structural analysis and biological activity of cell wall polysaccharides extracted from Panax ginseng marc. Int. J. Biol. Macromol. 135, 29–37 (2019). https://doi.org/10.1016/j.ijbiomac.2019.05.077

Ju, X., Bowden, M., Brown, E.E., Zhang, X.: An improved X-ray diffraction method for cellulose crystallinity measurement. Carbohydr. Polym. 123, 476–481 (2015). https://doi.org/10.1016/j.carbpol.2014.12.071

Ahvenainen, P., Kontro, I., Svedström, K.: Comparison of sample crystallinity determination methods by X-ray diffraction for challenging cellulose I materials. Cellulose 23, 1073–1086 (2016). https://doi.org/10.1007/s10570-016-0881-6

Agarwal, U.P., Ralph, S.A., Reiner, R.S., Baez, C.: New cellulose crystallinity estimation method that differentiates between organized and crystalline phases. Carbohydr. Polym. 190, 262–270 (2018). https://doi.org/10.1016/j.carbpol.2018.03.003

Segal, L., Creely, J.J., Martin, A.E., Conrad, C.M.: An empirical method for estimating the degree of crystallinity of native cellulose using the X-ray diffractometer. Text. Res. J. 29, 786–794 (1959). https://doi.org/10.1177/004051755902901003

Alotabi, M.D., Alshammari, B.A., Saba, N., Alothman, O.Y., Kian, L.K., Khan, A., Jawaid, M.: Microcrystalline cellulose from fruit bunch stalk of date palm: isolation and characterization. J. Polym. Environ. 28, 1766–1775 (2020). https://doi.org/10.1007/s10924-020-01725-8

Bicu, I., Mustata, F.: Optimization of isolation of cellulose from orange peel using sodium hydroxide and chelating agents. Carbohydr. Polym. 98, 341–348 (2013). https://doi.org/10.1016/j.carbpol.2013.06.009

Bicu, I., Mustata, F.: Cellulose extraction from orange peel using sulfite digestion reagents. Bioresour. Technol. 102, 10013–10019 (2011). https://doi.org/10.1016/j.biortech.2011.08.041

Jacquet, N., Maniet, G., Vanderghem, C., Delvigne, F., Richel, A.: Application of steam explosion as pretreatment on lignocellulosic material: a review. Ind. Eng. Chem. Res. 54, 2593–2598 (2015). https://doi.org/10.1021/ie503151g

Hu, F., Ragauskas, A.: Pretreatment and lignocellulosic chemistry. Bioenergy Res. 5, 1043–1066 (2012). https://doi.org/10.1007/s12155-012-9208-0

Shao, X., Wang, J., Liu, Z., Hu, N., Liu, M., Xu, Y.: Preparation and characterization of porous microcrystalline cellulose from corncob. Ind. Crops Prod. 151, 1–6 (2020). https://doi.org/10.1016/j.indcrop.2020.112457

Kunusa, W.R., Isa, I., Laliyo, L.A.R., Iyabu, H.: FTIR, XRD and SEM analysis of microcrystalline cellulose (MCC) fibers from corncorbs in alkaline treatment. J. Phys. Conf. Ser. 1028, 012199 (2018). https://doi.org/10.1088/1742-6596/1028/1/012199

Gao, Y., Zhou, Y., Zhang, Q., Zhang, K., Peng, P., Chen, L., Xiao, B.: Hydrothermal extraction, structural characterization, and inhibition HeLa cells proliferation of functional polysaccharides from Chinese tea Zhongcha 108. J. Funct. Foods. 39, 1–8 (2017). https://doi.org/10.1016/j.jff.2017.09.057

Bhandari, K., Roy Maulik, S., Bhattacharyya, A.R.: Synthesis and characterization of microcrystalline cellulose from rice husk. J. Inst. Eng. Ser. E. 101, 99–108 (2020). https://doi.org/10.1007/s40034-020-00160-7

Luo, X., Wang, Q., Fang, D., Zhuang, W., Chen, C., Jiang, W., Zheng, Y.: Modification of insoluble dietary fibers from bamboo shoot shell: structural characterization and functional properties. Int. J. Biol. Macromol. 120, 1461–1467 (2018). https://doi.org/10.1016/j.ijbiomac.2018.09.149

Guo, Y., Liu, W., Wu, B., Wu, P., Duan, Y., Yang, Q., Ma, H.: Modification of garlic skin dietary fiber with twin-screw extrusion process and in vivo evaluation of Pb binding. Food Chem. 268, 550–557 (2018). https://doi.org/10.1016/j.foodchem.2018.06.047

Lin, Y., Wang, H., Rao, W., Cui, Y., Dai, Z., Shen, Q.: Structural characteristics of dietary fiber (Vigna radiata L. hull) and its inhibitory effect on phospholipid digestion as an additive in fish floss. Food Control 98, 74–81 (2019). https://doi.org/10.1016/j.foodcont.2018.11.016

Owolabi, A.F., Haafiz, M.K.M., Hossain, S., Hussin, M.H., Fazita, M.R.N.: International journal of biological macromolecules Influence of alkaline hydrogen peroxide pre-hydrolysis on the isolation of microcrystalline cellulose from oil palm fronds. Int. J. Biol. Macromol. 95, 1228–1234 (2017). https://doi.org/10.1016/j.ijbiomac.2016.11.016

Naduparambath, S., Purushothaman, E.: Sago seed shell: determination of the composition and isolation of microcrystalline cellulose (MCC). Cellulose 23, 1803–1812 (2016). https://doi.org/10.1007/s10570-016-0904-3

Ren, H., Shen, J., Pei, J., Wang, Z., Peng, Z., Fu, S., Zheng, Y.: Characteristic microcrystalline cellulose extracted by combined acid and enzyme hydrolysis of sweet sorghum. Cellulose 26, 8367–8381 (2019). https://doi.org/10.1007/s10570-019-02712-6

Fawcett, T.G., Crowder, C.E., Kabekkodu, S.N., Needham, F., Kaduk, J.A., Blanton, T.N., Petkov, V., Bucher, E., Shpanchenko, R.: Reference materials for the study of polymorphism and crystallinity in cellulosics. Powder Diffr. 28, 18–31 (2013). https://doi.org/10.1017/S0885715612000930

Ahmed-Haras, M.R., Kao, N., Ward, L., Islam, M.S.: Insights into the production and physicochemical properties of oxycellulose microcrystalline with coexisting crystalline forms. Int. J. Biol. Macromol. 146, 150–161 (2020). https://doi.org/10.1016/j.ijbiomac.2019.12.083

Amaro, C., Alves, L.P., Malheiro, T., Rafaela, A., Barros, A., Lima, G.: De: an alternative source of cellulose for production of pharmaceutical dosage forms and biomaterials: extraction and characterization. Polymers (Basel). (2019). https://doi.org/10.3390/polym11071124

Trilokesh, C., Uppuluri, K.B.: Isolation and characterization of cellulose nanocrystals from jackfruit peel. Sci. Rep. 9, 1–8 (2019). https://doi.org/10.1038/s41598-019-53412-x

Chai, S.Y., Abbasiliasi, S., Lee, C.K., Ibrahim, T.A.T., Kadkhodaei, S., Mohamed, M.S., Hashim, R., Tan, J.S.: Extraction of fresh banana waste juice as non-cellulosic and non-food renewable feedstock for direct lipase production. Renew. Energy. 126, 431–436 (2018). https://doi.org/10.1016/j.renene.2018.03.050

El-sayed, S., Mahmoud, K.H., Fatah, A.A., Hassen, A.: DSC, TGA and dielectric properties of carboxymethyl cellulose/polyvinyl alcohol blends. Phys. B Phys. Condens. Matter. 406, 4068–4076 (2011). https://doi.org/10.1016/j.physb.2011.07.050

Acknowledgements

We would like to acknowledge the Ministry of Food Processing Industry (MoFPI), Government of India for all financial aid provided under project and also grateful for all lab facilities provided by Indian Institute of Food Processing Technology (IIFPT).

Funding

The present work was conducted with the funding received from Ministry of Food Processing Industries, Government of India (Grant No. Q11/14/2018-R&D).

Author information

Authors and Affiliations

Contributions

SVR: Mentorship, supervision, methodology, resources and validation, reviewing and editing. SMV: Investigation, formal analysis, data curation, writing—research draft preparation and data interpretation. BYK: Conceptualization, editing, software and supervision. ANUK: Reviewing and editing, formal analysis, conceptualization. HV: Mentorship.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Ethical Approval

Not applicable.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Varghese, S.M., Bhosale, Y.K., Aruna Nair, U.K. et al. Valorisation and Characterization of Allium cepa var. aggregatum Biowastes for the Production of Microcrystalline Cellulose. Waste Biomass Valor 13, 1931–1944 (2022). https://doi.org/10.1007/s12649-021-01625-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12649-021-01625-5