Abstract

Bioactive molecules, with health-beneficial effects and functional activity on the human, are called “postbiotics”, produced by probiotic bacteria. In this study, co-production of conjugated linoleic acid (CLA), exopolysaccharides (EPSs), and bacteriocins (BACs) by Bifidobacterium lactis BB12 in supplemented cheese whey was optimized using Box–Behnken design. Yeast extract concentration had a significant effect on all responses except EPSs. The temperature significantly affected the production of CLA and the inhibition zone (p < 0.05). The incubation time had significant effects on CLA, EPSs, and BACs production (p < 0.05). Desirability functions performed to the optimization of multiple responses by maximization of CLA, EPSs and inhibition zone. Optimum conditions of CLA, EPSs, and BACs co-production were as follows: incubation temperature 38 °C, incubation time 28 h, and yeast extract concentration 2.5%. Fourier transform infrared spectroscopy was used to analyze functional groups of postbiotics. Gas chromatography, thin-layer chromatography, and SDS-PAGE were used to analyze CLA isomers, EPSs monosaccharides composition, and BACs molecular weight, respectively. Co-production of CLA, EPSs, and BACs by B. lactis BB12 in dairy effluent, as a cultivation medium, optimized successfully in this study.

Graphic Abstract

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Statement of Novelty

Postbiotics are bioactive metabolites, produced by probiotics during fermentation bioprocess, which have health-promoting effect on the consumer. Cheese whey and milk permeate, dairy by-product or effluents, are suitable as a cultivation media for fermentation. This study aimed to use these effluents as a model food-grade medium for milk and optimize fermentation variables for in situ co-production of postbiotics (conjugated linoleic acids, exopolysaccharides, and bacteriocins) by Bifidobacterium lactis BB12. The results showed that B. lactis BB12 could co-produce conjugated linoleic acid, exopolysaccharides, and bacteriocins during fermentation bioprocess in supplemented industrial cheese whey.

Introduction

Probiotic bacteria secrete water-soluble bioactive molecules with functional effects called “Postbiotics”. Bioactive lipids like conjugated linoleic acid (CLA), antimicrobial peptides such as bacteriocins (BACs), and exopolysaccharides (EPSs) are examples of these metabolites [1]. CLA is a term to define a set of linoleic acid (LA; C18:2) isomers with conjugated bonds. These bioactive lipids are biosynthesized by microorganisms during the exponential phase. Among the CLA isomers, cis 9-trans 11, trans 10-cis 12, and trans 9- trans 11 are very important. The adequate health benefits of CLA, such as anti-inflammatory, anti-diabetic, anti-cancer, immunomodulatory, anti-atherosclerotic, and anti-obesity activities reported by literature in recent years [2, 3]. Bacterial EPSs are polysaccharides molecules and these primary metabolites are secreted by some bacteria into the culture media. Due to EPSs textural and rheological properties, most studies in the food area focused on the technological applications of them. In recent years, EPSs have attracted much attention because of their functional properties. Most researches demonstrated that EPSs have immunomodulatory potential, anti-inflammatory, anti-biofilm, and antioxidant activities [4, 5]. BACs are primary metabolites of some bacteria which bio-synthesized ribosomally. These small bacterial peptides have antagonistic activity against closely related BACs producer species and some food-borne pathogens as well as spoilage bacteria. In food products, BACs are used as natural food bio-preservatives, for biological control of spoilage and pathogenic bacteria. Nonetheless, in recent years BACs have been considered due to their bioactive properties like anticancer and antiviral agents [6,7,8].

Probiotics are defined as live microorganisms that have health promoting effects on the host when consumed in adequate quantities. Bifidobacterium lactis BB12 is one of the common probiotics that are commercially used in the production of fermented dairy products. Bifidobacterium genus is rod-shaped, gram-positive, non-gas-producing, non-spore-forming, non-motile, catalase-negative, and anaerobic microorganisms. There is an increasing interest in the research to use probiotic Bifidobacteria as a producer of bioactive fatty acids such as CLA, antimicrobial peptides (BACs and bacteriocin-like compounds), and EPSs [9, 10].

Applications of agro-industrial effluents in industrial microbiology as low-cost suitable media for fermentation have received much attention in the last decades. Whey is a greenish-yellow liquid that remains after the formation and separation of the crude in the cheese production process, and permeate is the remaining liquid result of ultrafiltration of milk or whey. These dairy effluents have high biological oxygen demand and chemical oxygen demand content. Therefore, whey and permeate are a potent environmental pollutant, and their elimination is a problem with the dairy industry, since it requires extensive pre-treatment before disposal, resulting in increased operating costs in the dairy factory [11]. Generally, whey and permeate have limited applications and are often used in the production of protein concentrates, lactose, whey, and permeate powders, as well as livestock feed. Due to the high lactose content as a carbon source and appropriate nutrient content, these by-products are a perfect cultivation medium for fermentative microorganisms [12].

CLA [2, 13], EPSs [5], and BACs [7, 14, 15] production by different Bifidobacterium strains, especially Bifidobacterium lactis BB12, has been investigated. However, there is no report about the co-production of these postbiotic metabolites. Therefore, the main objectives of this study were to investigate the significant factors that affect the co-production of CLA, EPSs, and BACs and optimization of these postbiotics co-production. Consequently, the aim of this study was the optimization of their co-production to obtain a model to each postbiotics synthesize during fermentation in dairy effluent.

Materials and methods

Preparation of Probiotic Inoculum

The B. lactis BB12 (BB12) was obtained from Chr. Hansen, DK-2970 Hørsholm, Denmark and weighted according to the manufacturer’s recommendation. After that, it was grown in MRS broth with 0.1% Tween 80, 0.05% l-cysteine (AppliChem, Darmstadt, Germany), and 0.1% lithium chloride (Sigma-Aldrich, St. Louise, Missouri, USA) for 24 h at 37 °C. The cell cultures were centrifuged at 5000 × g for 15 min and washed twice in 0.85% w/v NaCl solution. The pellet was resuspended in the normal saline solution to obtain probiotics suspension containing approximately 1 × 109 CFU/mL [16].

Preparation of Food-grade Cultivation Medium

Cheese whey and milk permeate were obtained from Sahar and Aynaz dairy industries (local dairy plants of Urmia, Iran). First, the pH of cheese whey and milk permeate adjusted to 4.5 by 5 N HCl, then they were heated at 121 °C for 15 min, and the precipitates were removed by centrifugation at 2360× g for 5 min. After that, the pH of supernatants adjusted according to the experimental design and sterilized at 121 °C for 15 min. Next, linoleic acid (99% purity; Sigma-Aldrich, St. Louise, Missouri, USA) in 2% Tween 80, and yeast extract (Sigma-Aldrich, St. Louise, Missouri, USA) added depending on the statistical design using cellulose acetate membrane filters with 0.45 µm pore size. The Fermentation bioprocess was performed in 200 mL Erlenmeyer flasks with 50 mL media inoculated by 1 × 109 CFU/mL probiotics. Finally, according to the experimental design, they were incubated in different temperature and time conditions [17].

Enumeration of BB12

For this purpose, a viable-cell count procedure was used to determine the counts of BB12 in samples. At the end of incubation time (according to the excremental design), samples were homogenized by vortex (model Genius 3 (IKA® WERKE GMBH & CO.KG, Germany) and 1 mL of each fermented media added to 9 mL of sterile peptone water (1 mg/100 g) and serially diluted (up to 10–10) using the same diluent. Subsequently, a 1 mL of each dilution was added into Reinforced Clostridia agar medium (RCM, Merck, Germany) using the pour-plate method, and the plates were incubated for 72 h at 37 °C under anaerobic conditions (Anaerocult® A gas pack, Merck, Darmstadt, Germany). The counts were expressed as the log of the colony-forming units per milliliter of fermentation media (log CFU/mL) [18].

Extraction and Quantitative Determination of CLA

In order to extract CLA from culture media, 10 mL of culture media were centrifuged at 7500 × g for 5 min at 4 °C. Then, 3 mL of the supernatant were added to 6 mL of isopropanol and vortexed for 1 min. After that, 5 mL of hexane was added and vortexed for 1 min and centrifuged at 2000× g for 5 min at 4 °C. Finally, total CLA measurements were carried out in triplicate for 2 mL of the CLA extract in quartz cuvettes by hexane as a blank at 233 nm, using a UV–Vis spectrophotometer (80-2088-64, Pharmacia LKB Biochrom, Cambridge, UK). The concentration of CLA was calculated using a calibration curve. The standard curve was constructed for 0–30 (mg/mL in 2% tween 80) concentration of CLA (99%, Sigma-Aldrich, St. Louise, Missouri, USA) at 233 nm [19].

Isolation and Quantitative Determination of EPSs

First, 5 mL of culture media were centrifuged at 5000× g for 30 min at 4 °C. Then, 5 mL of trichloroacetic acid was added to the supernatant in order to inactivate EPSs-degrading enzymes, while cold ethanol was added for the precipitate proteins and concentrate the polysaccharides. After that, EPSs were dissolved in deionized water and then dialyzed in distilled water. Measurements of total EPSs were carried out in triplicate by the phenol–sulfuric acid method, widely used for this purpose. The concentration of EPSs was calculated using a calibration curve. The standard curve was constructed for 0–150 mg/L concentrations of glucose (Merck, Darmstadt, Germany) at 500 nm [7].

Purification and Determination of BACs’ Inhibitory Activity

In order to purify the BACs, one ml of culture medium was centrifuged at 10,000 × g for 10 min at 4 °C. The supernatant was filtered through syringe filters with 0.45 µm pore size (Supor® membrane, Paul Co. Ltd., Ann Arbor, MI). Then, the activity of BACs was estimated using the agar well diffusion method as described below. First, Brain heart infusion agar (Merck, Darmstadt, Germany) was cooled to 47 °C and inoculated with 1 ml overnight culture containing 107 CFU/mL of Listeria monocytogenese ATCC 19113 as an indicator strain. Then, it was poured into a sterile plate at room temperature. After solidification, wells with 6 mm in diameter were cut and filled with 50 µL of supernatant neutralized to pH 7 with 1 N NaOH solution. The plates were kept in the refrigerator (4 °C) for 2 h to diffuse supernatant and then incubated at 37 °C for 24 h. Finally, the inhibition zone diameters were determined [8].

Fourier Transform Infra-red (FTIR) analysis

Major functional groups of purified EPSs, BACs, and CLA were investigated by Bruker TENSOR 27, FTIR spectrometer (Bruker Optik, Ettlingen, Germany). For this purpose, the freeze-dried EPSs and BACs samples (5 mg) and methyl ester of CLA (1 mL) were ground with 200 mg of KBr powder and were pressed into tablets by a hydraulic press. The tablets were scanned within the range of 4000–400 cm−1 for EPSs and BACs, as well as 3500–650 cm−1 for CLA [20, 21].

GC Analysis of CLA Isomers

First, 3 mL Methanolic HCl solution (1 N) was added to a screw-cap test tube containing 3 mL sample, and vortexed for the 30 s. After that, the test tube was held in a water bath for 55 °C for 5 min and then cooled to room temperature. CLA methyl esters were extracted with 3 mL n-hexane by vortex for 1 min. The n-hexane extract was washed with 3 mL NaOH (1.0 N)-ethanol (50%) solution and 3 mL distilled water. The sample was dried over anhydrous sodium sulfate for GC analysis. A gas chromatography instrument (Agilent7890 A, Wilmington, DE, USA) with flame ionization detector (GC-FID) equipped by silica capillary column (30 m) was used for the analysis of CLA isomers. The carrier gas was N2, the oven temperature was increased from 180 to 200 °C at 2 °C/min and kept for 30 min, injection volume was 1 mL, injector and detector temperature were 240 and 260 °C, respectively [22].

TLC Analysis of EPSs Composition

Thin-layer chromatography (TLC) was used to analyze the monosaccharide compositions of the purified EPSs. For this purpose, 10 mg of the EPSs dissolved in 2 mL trifluoroacetic acid (TFA) (2 mol/L) at 100 °C for 4 h. Then, the samples were dried with nitrogen and 6 mL methanol added to eliminate TFA. After that, hydrolyzed EPSs samples were dissolved in double distilled water for further study. The silica gel (n-butanol: ethyl acetate: pyridine: acetic acid: distilled water at 4:4:1:5:1 v/v/v/v/v ratio) plates (20 cm × 20 cm) were used to investigate the EPSs hydrolysates. Additionally, the mixture of seven different monosaccharides, including glucose, fructose, mannose, rhamnose, galactose, xylose, and arabinose (5 mg/mL) used as standards. EPSs spots were detected after spraying urea—sulphuric acid at 105 °C for 5 min [23].

SDS Page Analysis of BACs Fractions

Tricine-sodium dodecyl sulfate–polyacrylamide gel electrophoresis (Tricine-SDS-PAGE) (Mini-PROTEAN® Tetra Cell, Bio-Rad Laboratories, USA) was used to estimate the molecular weight of partial purification BACs at 120 V for 3 h. Then the gel was stained by the Coomassie brilliant blue R-250 (Sigma Aldrich, USA) [24]. The molecular weight of the BACs was determined by comparison with the protein molecular size marker 11–180 kDa (Cina Clon, Tehran, Iran) using the gel documentation system BIOMATE.

Experimental Design, Statistical Analysis, and Optimization

In order to select the significant factors responsible for the co-production of CLA, EPSs, and BACs, a factorial experimental design with 38 experiments was applied to investigate the effects of 7 independent variables, including five numerical variables (initial pH, temperature, incubation time, linoleic acid and yeast extract concentrations), as well as one categorical variable (types of culture media) (Supplementary Table 1). ANOVA statistical analysis was utilized to evaluate the statistical significance of the different independent variables and their interactions, using Fisher’s F-test and P-value at α = 0.05. The results of the factorial design showed the significant factors and were subjected for optimization design by response surface methodology.

After that, a Box–Behnken design (BBD) was performed to optimize and obtain a quadratic model for the co-production of CLA, EPSs, and BACs. The experiment consisted of three variables A: incubation temperature (℃), B: incubation time (h) and C: yeast extract concentration (%) at 3 coded levels (−1, 0, + 1) and had 16 experiments with 4 center points and 12 IBfact points (Supplementary Table 2). Subsequently, data were fitted to a second-order polynomial Eq. (1) for each dependent variable (Y).

where Y = predicted response, β0 = a constant, βi = linear coefficient, βii = squared coefficient and βij = interaction coefficient.

Finally, the desirability function was used to find the optimal fermentation condition of postbiotics co-production. In this method, each response (Yi) was converted into an individual desirability function (di) which varies from 0 to 1, which the variables were selected to maximize the total desirability as the following equation:

where m = the number of responses, di = 1 indicates that Yi is at its target value, and di = 0 shows that it is not in an acceptable state.

The design, statistical analysis, and optimization, as well as charting, were done by Design-Expert Version 12 (Stat-Ease, Minneapolis, USA).

Results

The results of the factorial design showed that the significant factors were incubation temperature and time, as well as yeast extract concentration. Furthermore, cheese whey was a better medium to co-produce CLA, EPSs, and BACs. In addition to, the best initial pH and free linoleic acid concentration for co-production of CLA, EPSs, and BACs were 5 and 200µL, respectively. To determine the optimal condition, effects of different levels of significant variables were evaluated with constant values of initial pH and free linoleic acid concentration by BB12 in cheese whey. Therefore, the BBD experiment was designed to optimize the co-production of postbiotics.

Viable Cell Count of BB1

Figure 1a, b shows the effects of investigated parameters on the viability of B. lactis BB12 during the fermentation bioprocess in cheese whey. According to the results, yeast extract concentrations, the interaction of incubation temperature with incubation time, and interaction of incubation temperature with yeast extract concentration had a significant effect on the viable cell count of BB12 (p < 0.05). However, the viable cell count of BB12 was not significantly affected by the incubation temperature and incubation time (p > 0.05). Increasing the concentration of yeast extract from 2 to 6% caused an increase in the viability of BB12 (Fig. 1a). This Fig. illustrates that increasing temperature with adding 2% yeast extract caused an increase in the viability of BB12, but increasing temperature with adding 6% yeast extract caused a decrease in the viability of BB12. Furthermore, the viable cell count of BB12 in 34 °C and supplementation with 6% yeast extract was higher than that of supplementation with 2% yeast extract. As shown in Fig. 1b, increasing temperature at 12 h caused a decrease in the viability of BB12, even though the viability of BB12 increased by the rising temperature at 60 h of incubation time. In the other word, the viable cell count of BB12 was increased by increasing incubation temperature and time, from 34 to 42 °C and 12 to 60 h, respectively. According to sequential model sum of squares, the quadratic model was significant (p < 0.05), and the coefficient of determination (R2) and the Adjusted R2 of the quadratic polynomial model (Eq. 3) were 0.822 and 0.723, respectively.

CLA Production

According to results, the effects of temperature, incubation time, yeast extract concentrations, and the interaction of temperature with incubation time and temperature with yeast extract concentrations on the CLA production, were statistically significant (p < 0.05). According to the obtained results, the CLA production decrease by increasing the temperature, incubation time, and yeast extract concentrations. Although CLA production by supplementing 2 and 6% of yeast extract had no statistically difference at 34 °C, rising temperature from 34 to 42 °C, its production decreased and increased by adding 6 and 2% yeast extract, respectively (Fig. 2a). However, at 34 °C, by increasing incubation time from 12 to 60 h, CLA biosynthesize increased, but at 42 °C, its production decreased by increasing incubation time (Fig. 2a). The coefficient of determination (R2) and the adjusted R2 values for the obtained model (Eq. 4) were 0.902 and 0.853.

EPSs Production

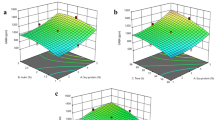

According to the results, incubation time and interaction of incubation time with yeast extract concentration significantly affected EPSs production (p < 0.05). Nonetheless, temperature and yeast extract concentration had no significant effect on EPSs production (p > 0.05). Results showed that EPSs production was increased significantly by increasing incubation time. According to Fig. 3a, which illustrates the interaction of incubation time with yeast extract concentration, at 12 h, increasing yeast extract concentration from 2 to 6% caused an increase in the production of EPSs. As confirmed by this Fig., an increase in incubation time resulted in a decrease and increase in the production of EPSs by adding 6 and 2% yeast extract, respectively. From Fig. 3b, although the amount of EPSs 12 h decreased by increasing temperature, its amount increased at 60 h by increasing temperature. The coefficient of determination (R2) and the adjusted R2 values for the obtained model (Eq. 5) were 0.924 and 0.838.

BACs’ Inhibitory Activity

The results showed that the temperature, incubation time, yeast extract concentration, and interaction of incubation time with yeast extract concentration had a significant effect on BACs production (p < 0.05). The temperature and yeast extract concentration had a positive effect i.e., increasing these parameters led to increased BACs activity. On the other hand, incubation time had a negative effect i.e., the BACs activity decreased by increasing the incubation time. Figure 4a shows that the inhibition zone increased by increasing temperature. As shown in Fig. 4b, inhibition zone (BACs activity) at 12 h after fermentation bioprocess inhibition zone had no difference by adding 2 and 6% yeast extract. Although at 60 h after fermentation, bioprocess inhibition zone in diameter increased by increasing with supplementing 6% yeast extract, its amount decreased with supplementation by 2% yeast extract (Fig. 4b). The coefficient of determination (R2) and the Adjusted R2 of the quadratic polynomial model (Eq. 6) were 0.933 and 0.888, respectively.

Optimization

Optimization was based on maximization of viable cell count, CLA, EPSs, and inhibition zone. The optimal condition was found to be incubation temperature 38 °C, incubation time 28 h, and yeast extract concentration 2.5%, by the desirability value equal to 0.63. At this point, viable cell count, CLA, EPSs and inhibition zone were 7.06 × 109 CFU/mL, 95.54 µg/mL, 130.35 mg/mL and 11.14 mm, respectively.

FTIR Analysis

Figure 5a shows the result of FTIR analysis for the bio-produced CLA. The CLA showed a peak at 2900 cm−1, which was due to the hydrocarbon chain asymmetric fatty acids − CH2. A peak at 1759 cm−1 was due to the carbonyl ester. Bio-produced CLA had an absorption at 1100 cm−1, which was caused by the C–O [25]. According to the results of Kadamne et al. (2011), the peaks at the 1100 − 1300 cm−1 range were caused by the C = O and C = C bonds. The cis and trans bonds, are separated by more than one methylene group, showed the absorption at 1000 cm−1 [25]. At 973 cm−1 the peak was created by cis and trans isomers [21]. CLA had a peak at 775 cm−1, which was related to the methylene vibrations and showed the high chain fatty acids [25].

Figure 5b shows the results of FT-IR analysis for the EPSs. The stretched peak at 3435 cm−1, was created by the OH (hydroxyl) groups. According to Zhou et al. (2016), the peaks at the 3200–3600 cm−1 range were created by OH groups [23]. A peak at 2909 was due to the vibration of C-H groups in the carbohydrates and showed the methyl groups of EPSs [26]. The C–C groups had a peak at 1603 cm−1. Imran et al. (2016) reported that the peak at 1700–1498 cm−1 was due to stretching the C–C bond. This peak is typical for EPSs and is known as the fingerprint region of EPSs. Carboxyl groups (COO −) had a peak at 1343 cm−1. The peak at 1082 cm−1, was created by the C–O bonds. Imran et al. (2016) reported that the peaks at 1300–1000 cm−1 were due to the C–O bonds. The peak at 891 cm−1, was due to the C − O and C − O − C bands and showed the presence of carbohydrates because the 1200 − 800 cm−1 area is another fingerprint region of EPSs [26].

Figure 5c shows the FTIR spectrum of the produced BACs. The sharp peak at 3288 cm−1, revealed the stretching of the N–H bond. Perumal and Venkatesan (2017) reported that a broad peak at 3000–3600 cm−1 was due to the N–H group [27]. Additionally, they stated that peaks at the 3200–3500 cm−1 range were due to the existence of the amide group. Produced BACs had absorptions at 1713 and 1600 cm−1, which were due to carbonyl stretching in amide I, respectively. BACs showed a peak at 1503 cm−1 that was related to amide II and agrees with the result of Senbagam et al. (2013) [28].

Isomers of Produced CLA

The GC analysis is the formal method for the determining the produced CLA and its isomers based on methyl ester of fatty acid. Figure 6a shows the result of isomers of produced CLA by BB12 under the optimized conditions. As can be seen, this commercial probiotic produced both isomers of CLA (CLA 1: c9, t11 C18:2 methyl ester; CLA 2: t10, c12 C18:2 methyl ester). However, the quantities of these isomers were different. Rodríguez-Alcalá et al. (2011) reported that Bifidobacteria could produce both isomers of CLA [19]. The results of this study were in agreement with the previous studies [16, 19, 29].

Monosaccharides Composition of Produced EPSs

The TLC analysis for purified EPSs showed that the produced EPSs by BB12 mainly consisted of glucose, galactose, glucuronic acid, rhamnose, and xylose which was in agreement with the result of the previous study by Amiri et al. (2019) [5].

Molecular Weight of Produced BACs

Figure 6b shows the result of the SDS-Page analysis for the partially purified BACs produced by BB12. This analysis indicated that produced BACs by BB12 had three bands with estimated molecular mass 26, 45, and 95 KD.

Discussion

Incubation temperature and time are important factors in fermentation bioprocess, which have a significant effect on the growth of bacteria and the biosynthesis of metabolites. In a combination of these factors, yeast extract concentration is one of the best organic nitrogen sources with a vibrant effect on probiotics growth and metabolites production [30, 31].

The coefficient of determination value (0.822) for Eq. 3 indicated that the sample variation for a viable cell count of 82.2% was attributed to the independent variables, and 17.8% of the total variations were not explained by this equation. The optimal temperature for the growth of Bifidobacterium strains is around 37 °C [33]. Khosravi-Darani et al. (2014) supposed that parallel with an increase in temperature due to a suitable condition for the growth of BB12, which have an optimum temperature for growth at 37 °C, enhance the production of CLA [13, 33]. According to the similar results reported by Van Nieuwenhove et al. (2007), cell growth has not been significantly affected by linoleic acid concentration. The results demonstrated that the conversion bioprocess was dependent on the free linoleic acid concentration. However, numerous authors reported that the bacterial growth inhibition effect of linoleic acid with diverse tolerance for different strains. Recently studies reported that common probiotic strains were able to grow in low concentrations of linoleic acid [34]. The growth of BB12 can be improved by supplementing the culture medium by nitrogen sources (including peptone, yeast extract, and beef extracts) and Tween 80, sodium acetate, and magnesium salts [32]. Generally, based on cell growth studies, an increase in nitrogen supplementation of the culture medium caused increase the biomass of bacterial culture. According to the literature, the nitrogen source generally improves biological changes in the fermentation bioprocess [3]. Alonso et al. (2003) investigated the effect of yeast extract on the growth of lactic acid bacterial strains in the commercial cheese whey as a culture medium and reported that in yeast extract supplemented culture media cell density was found to be higher (about 1.8 g/L), compared with non-supplemented medium (1.2 g/L) [35]. Dey et al. (2012) showed that among the various nitrogen sources, yeast extract had the highest effect on biomass increase due to having high nitrogen content and including amino acids and vitamins [30]. Moreover, some researchers reported that among the various complex sources of nitrogen, yeast extract is the best choice for high biomass growth [15, 34].

The R2 value of 0.902 gives 90.8% variability in the production of CLA, and about 9.2% total variation cannot explain by the model. The results demonstrated that the bioconversion process was extremely dependent on the free linoleic acid concentration [34]. According to Ye et al. (2013), the total amount of CLA production was significantly affected by temperature [31]. Khosravi-Darani et al. (2014) reported that CLA production increased by adding 4% whey powder, which could be due to the role of proteins in the oxidation of linoleic acid and the formation of its radical. This result is similar to the previous report demonstrating that the production of CLA increased by the addition of skim milk. The role of proteins can be as hydrogen donors, increasing the isomerization of linoleic acids in bio-hydrogenation [33]. Based on the results of bibliographic studies, the highest CLA production by probiotics, especially Bifidobacterium strains, is done in the first 24 h of incubation time, in the exponential phase [13, 33, 34]. The findings are in good agreement with the results of this study. The main reason for the bioconversion of linoleic acid to CLA by bacteria is unclear. However, some researchers proposed that it may be due to the inhibitory effect of linoleic acid and the detoxification mechanism of bacteria for growth [34, 36]. Earlier researches reported that many compounds of culture media, such as proteins, could neutralize the harmful effects of fatty acids on probiotics metabolism. Also, bacterial growth in the milk-based media, like cheese whey, was not affected by added linoleic acid and produced CLA. The results of this study are consistent with the findings of other authors who reported on the CLA production in the milk-based media [13]. Similar results were reported by Terán et al. (2015) [29] and Macouzet et al. (2009) [13] on the effect of linoleic acid concentration on CLA production. Terán et al. (2015) claimed that the highest percentages of conversion of linoleic acid to CLA were determined by adding linoleic acid concentrations lower than 500 µg/mL; nevertheless, these percentages decreased with higher concentrations of linoleic acid [29]. Khosravi et al. (2015) reported the linear effect of linoleic acid content on CLA production [36]. Considering all reported results, generally, there is a direct relationship between the CLA bio-synthesis and the concentration of free linoleic acid in the cultivation medium [33]. Khosravi et al. (2015) demonstrated that the CLA productions were positively affected by yeast extract concentration. The high buffering capacity of yeast extract with complex nutritional factors, consisting of free amino acids, small peptides, nucleotides, some carbohydrates, trace elements, and Group-B vitamins, is the most-frequently-used nitrogen source for microbial fermentation. Some researchers reported on the linear effect of yeast extract concentration on CLA production [36]. Earlier researches reported that many compounds of culture media, such as proteins, could neutralize the negative effects of fatty acids on probiotics metabolism. Also, bacterial growth in the milk-based media, like cheese whey, was not affected by added linoleic acid and produced CLA. The results of this study are consistent with the findings of other authors who reported on the CLA production in the milk-based media [13]. Terán et al. (2015) reported that the B. animalis subsp. lactis INL2 strain showed a high CLA production, depending on the substrate's concentration present in the culture medium [29]. Ye et al. (2013) reported that CLA production increased from 54.17 μg/mL at pH 4.5–110.70 μg/mL at pH 6.5 in skim milk [31].

The R2 value (0.924) for Eq. 5 indicates that the sample variation of 92.4% for EPSs was attributed to the independent variables, and 7.6% of the total variation cannot be explained by the model. According to the result of Deepak et al. (2015), the temperature had no significant effect on the production of EPSs, which is in agreement with the finding of this study [37]. Deepak et al. (2015) reported that EPSs biosynthesis was increased when the incubation time was increased, which is in agreement with this study. The result of Deepak et al. (2015) showed that the production EPSs was found to increase by increasing the concentration of yeast extract due to increase growth of producer bacterium. Nonetheless, according to the result of this study, the yeast extract concentration had no significant effect on EPSs production. Suresh Kumar et al. (2007) stated that EPSs production was improved by adding organic nitrogen sources into culture media [4]. According to Macedo et al. (2002), nitrogen source supplementation of whey permeate-based medium increased EPSs production by Lactobacillus rhamnosus RW-9595M, in agreement with data presented in this study [38]. Haj-Mustafa et al. (2015) investigated the effect of fermentation conditions on EPSs production by Lactobacillus rhamnosus 519 in skimmed milk base media and reported on the significant effect of pH and yeast extract interaction on the production of EPSs. The findings of the current study are consistent with those of Haj-Mustafa et al. (2015), who demonstrated that EPSs production increased with increasing pH, considering that the maximum EPSs were obtained around pH 5.8 and decreased at higher pH [39]. Furthermore, it has been reported that EPSs production in continuously-growing cultures with controlled pH is more productive than that in acidified batch cultures. Considering the fact that pH has a direct effect on both cell growth and bacteriocins production and bacteriocins production is associated with cell growth, it can be concluded that both cell growth and bacteriocins production stop at lower pH due to the accumulation of lactic acid in the medium [40].

The model's *tness (Eq. 6) was analyzed by determination coefficient (R2 = 0.933), which implied that the sample variation 93.3% was attributed to the variables and only 6.7% of the total variance could not be explained by the model. Previous researchers demonstrated differences between optimal incubation temperature for growth and BACs production [40]. Suresh Kumar et al. (2007) reported, the optimal temperature for BACs production was 35 °C using Lactobacillus casei LA-1 and Micrococcus sp. GO5 is close to the optimum temperature obtained in this study. However, differences in optimal temperatures were reported for organisms producing nisin [4]. As primary metabolites, BACs, produced during the exponential phase, reach the maximum at the end of this phase or at the beginning of the stationary phase. Therefore, the maximum activity of bacteriocins can usually be observed at the time interval of 10–12 h of fermentation and decreased after that [40]. According to the previous study, which used cheese whey as an alternative substrate for BACs production, BACs produced in a medium only after supplementing it with yeast extract [14]. Because yeast extract provides a large proportion of free amino acids and short peptides and enhances bacterial growth [40, 41].

Conclusion

Previously the ability of different probiotic bacteria investigated and optimized the production of CLA, EPSs, and BACs, but there was no report on the co-producing capacity of these bioactive metabolites by probiotics. To the best of our knowledge, the present work is the first study to investigate and optimize the co-production of postbiotic metabolites by BB12 in supplemented cheese whey as a food-grade medium. The optimal condition was found to be incubation temperature 38 °C, incubation time 28 h, and yeast extract concentration 2.5%, by the desirability value equal to 0.63. At this point, viable cell count, CLA, EPSs, and inhibition zone were 7.06 × 109 CFU/mL, 95.54 µg/mL, 130.35 mg/mL, and 11.14 mm, respectively. However, co-production potential of CLA, EPSs, and BACs by BB12 in cheese whey optimized successfully in this work, produced values were lower than their individually production at optimal condition. Further studies are suggested to investigate and optimize in situ co-production of postbiotics by BB12 in fermented dairy products such as yogurt, kefir, etc.

References

Aguilar-Toalá, J.E., Garcia-Varela, R., Garcia, H.S., Mata-Haro, V., González-Córdova, A.F., Vallejo-Cordoba, B., Hernández-Mendoza, A.: Postbiotics: an evolving term within the functional foods field. Trends Food Sci. Technol. 75, 105–114 (2018)

Dahiya, D.K., Puniya, A.K.: Isolation, molecular characterization and screening of indigenous lactobacilli for their abilities to produce bioactive conjugated linoleic acid (CLA). J. Food Sci. Technol. 54, 792–801 (2017)

Dubey, V., Ghosh, A.R., Mandal, B.K.: Appraisal of conjugated linoleic acid production by probiotic potential of Pediococcus spp. GS4. Appl. Biochem. Biotechnol. 168, 1265–1276 (2012)

Suresh Kumar, A., Mody, K., Jha, B.: Bacterial exopolysaccharides–a perception. J. Basic Microbiol. 47, 103–117 (2007)

Amiri, S., Mokarram, R.R., Khiabani, M.S., Bari, M.R., Alizadeh, M.: Optimization of food-grade medium for co-production of bioactive substances by Lactobacillus acidophilus LA-5 for explaining pharmabiotic mechanisms of probiotic. J. Food Sci. Technol. 20, 1–12 (2021)

Amiri, S., Aghamirzaei, M., Mostashari, P., Sarbazi, M., Tizchang, S., Madahi, H.: The impact of biotechnology on dairy industry. In: Microbial Biotechnology in Food and Health, pp. 53–79. Academic Press (2021)

Amiri, S., Mokarram, R.R., Khiabani, M.S., Bari, M.R., Alizadeh, M.: Optimization of food-grade medium for co-production of bioactive substances by Lactobacillus acidophilus LA-5 for explaining pharmabiotic mechanisms of probiotic. J. Food Sci. Technol. 20, 1–12 (2021)

Amiri, S., Rezazadeh Bari, M., Alizadeh Khaledabad, M., Rezaei Mokarram, R., Sowti Khiabani, M.: Co-production of parabiotic metabolites by Lactobacillus acidophilus LA5 and Bifidobacterium animalis subsp. lactis BB12 in dairy effluents. Chem. Rev. Lett. 4, 66–76 (2021)

Gholam-Zhiyan, A., Amiri, S., Rezazadeh-Bari, M., Pirsa, S.: Stability of Bacillus coagulans IBRC-M 10807 and Lactobacillus plantarum PTCC 1058 in Milk Proteins Concentrate (MPC)-Based Edible Film. J. Package. Technol. Res. 5, 11–22 (2021)

Cheikhyoussef, A., Pogori, N., Chen, W., Zhang, H.: Antimicrobial proteinaceous compounds obtained from bifidobacteria: from production to their application. Int. J. Food Microbiol. 125, 215–222 (2008)

Parashar, A., Jin, Y., Mason, B., Chae, M., Bressler, D.C.: Incorporation of whey permeate, a dairy effluent, in ethanol fermentation to provide a zero waste solution for the dairy industry. J. Dairy Sci. 99, 1859–1867 (2016)

Pescuma, M., de Valdez, G.F., Mozzi, F.: Whey-derived valuable products obtained by microbial fermentation. Appl. Microbiol. Biotechnol. 99, 6183–6196 (2015)

Macouzet, M., Lee, B.H., Robert, N.: Production of conjugated linoleic acid by probiotic Lactobacillus acidophilus La-5. J. Appl. Microbiol. 106, 1886–1891 (2009)

Schirru, S., Favaro, L., Mangia, N.P., Basaglia, M., Casella, S., Comunian, R., Fancello, F., de Melo Franco, B.D., de Souza Oliveira, R.P., Todorov, S.D.: Comparison of bacteriocins production from Enterococcus faecium strains in cheese whey and optimized commercial MRS medium. Ann. Microbiol. 64, 321–331 (2014)

Rodríguez-Pazo, N., Vázquez-Araújo, L., Pérez-Rodríguez, N., Cortés-Diéguez, S., Domínguez, J.M.: Cell-free supernatants obtained from fermentation of cheese whey hydrolyzates and phenylpyruvic acid by Lactobacillus plantarum as a source of antimicrobial compounds, bacteriocins, and natural aromas. Appl. Biochem. Biotechnol. 171, 1042–1060 (2013)

Amiri, S., Mokarram, R.R., Khiabani, M.S., Bari, M.R., Khaledabad, M.A.: In situ production of conjugated linoleic acid by Bifidobacterium lactis BB12 and Lactobacillus acidophilus LA5 in milk model medium. LWT. 132, 109933 (2020)

Rezazadeh-Bari, M., Najafi-Darmian, Y., Alizadeh, M., Amiri, S.: Numerical optimization of probiotic Ayran production based on whey containing transglutaminase and Aloe vera gel. J. Food Sci. Technol. 56, 3502–3512 (2019)

Moghanjougi, Z.M., Bari, M.R., Khaledabad, M.A., Almasi, H., Amiri, S.: Bio-preservation of white brined cheese (Feta) by using probiotic bacteria immobilized in bacterial cellulose: Optimization by response surface method and characterization. LWT. 117, 108603 (2020)

Rodríguez-Alcalá, L.M., Braga, T., Malcata, F.X., Gomes, A., Fontecha, J.: Quantitative and qualitative determination of CLA produced by Bifidobacterium and lactic acid bacteria by combining spectrophotometric and Ag+-HPLC techniques. Food Chem. 125, 1373–1378 (2011)

Maleki, O., Khaledabad, M.A., Amiri, S., Asl, A.K., Makouie, S.: Microencapsulation of Lactobacillus rhamnosus ATCC 7469 in whey protein isolate-crystalline nanocellulose-inulin composite enhanced gastrointestinal survivability. LWT. 126, 109224 (2020)

Kadamne, J.V., Castrodale, C.L., Proctor, A.: Measurement of conjugated linoleic acid (CLA) in CLA-rich potato chips by ATR-FTIR spectroscopy. J. Agric. Food Chem. 59, 2190–2196 (2011)

Gurovic, M.S., Gentili, A.R., Olivera, N.L., Rodríguez, M.S.: Lactic acid bacteria isolated from fish gut produce conjugated linoleic acid without the addition of exogenous substrate. Process Biochem. 49, 1071–1077 (2014)

Zhou, K., Zeng, Y., Yang, M., Chen, S., He, L., Ao, X., Zou, L., Liu, S.: Production, purification and structural study of an exopolysaccharide from Lactobacillus plantarum BC-25. Carbohydr. Polym. 144, 205–214 (2016)

Sarikhani, M., Kermanshahi, R.K., Ghadam, P., Gharavi, S.: The role of probiotic Lactobacillus acidophilus ATCC 4356 bacteriocin on effect of HBsu on planktonic cells and biofilm formation of Bacillus subtilis. Int. J. Biol. Macromol. 115, 762–766 (2018)

Roach, J.A., Mossoba, M.M., Yurawecz, M.P., Kramer, J.K.: Chromatographic separation and identification of conjugated linoleic acid isomers. Anal. Chim. Acta 465, 207–226 (2002)

Wang, J., Zhao, X., Tian, Z., Yang, Y., Yang, Z.: Characterization of an exopolysaccharide produced by Lactobacillus plantarum YW11 isolated from Tibet Kefir. Carbohydr. Polym. 125, 16–25 (2015)

Perumal, V., Venkatesan, A.: Antimicrobial, cytotoxic effect and purification of bacteriocin from vancomycin susceptible Enterococcus faecalis and its safety evaluation for probiotization. LWT. 78, 303–310 (2017)

Senbagam, D., Gurusamy, R., Senthilkumar, B.: Physical chemical and biological characterization of a new bacteriocin produced by Bacillus cereus NS02. Asian Pac. J. Trop. Med. 6, 934–941 (2013)

Terán, V., Pizarro, P.L., Zacarías, M.F., Vinderola, G., Medina, R., Van Nieuwenhove, C.: Production of conjugated dienoic and trienoic fatty acids by lactic acid bacteria and bifidobacteria. J. Funct. Foods 19, 417–425 (2015)

Dey, P., Sikder, J., Roy, S., Pal, P.: Fermentative lactic acid production from a renewable carbon source under response surface optimized conditions without alkali addition: a membrane-based green approach. Clean Technol. Environ. Policy 14, 827–835 (2012)

Ye, S., Yu, T., Yang, H., Li, L., Wang, H., Xiao, S., Wang, J.: Optimal culture conditions for producing conjugated linoleic acid in skim-milk by co-culture of different Lactobacillus strains. Ann. Microbiol. 63, 707–717 (2013)

Amado, I.R., Vázquez, J.A., Pastrana, L., Teixeira, J.A.: Cheese whey: a cost-effective alternative for hyaluronic acid production by Streptococcus zooepidemicus. Food Chem. 198, 54–61 (2016)

Khosravi-Darani, K., Reihani, F.S., Feili, R.: Bioproduction of conjugated linoleic acid in yogurt by probiotic bacteria. Int. J. Biotech. Well. 3, 62–68 (2014)

Van Nieuwenhove, C.P., Oliszewski, R., Gonzalez, S.N., Pérez Chaia, A.B.: Conjugated linoleic acid conversion by dairy bacteria cultured in MRS broth and buffalo milk. Lett. Appl. Microbiol. 44, 467–474 (2007)

Alonso, L., Cuesta, E.P., Gilliland, S.E.: Production of free conjugated linoleic acid by Lactobacillus acidophilus and Lactobacillus casei of human intestinal origin. J. Dairy Sci. 86, 1941–1946 (2003)

Khosravi, A., Safari, M., Khodaiyan, F., Gharibzahedi, S.M.: Bioconversion enhancement of conjugated linoleic acid by Lactobacillus plantarum using the culture media manipulation and numerical optimization. J. Food Sci. Technol. 52, 5781–5789 (2015)

Deepak, V., Ram Kumar Pandian, S., Sivasubramaniam, S.D., Nellaiah, H., Sundar, K.: Optimization of anticancer exopolysaccharide production from probiotic Lactobacillus acidophilusby response surface methodology. Prep. Biochem. Biotechnol. 46, 288–297 (2016)

Macedo, M.G., Lacroix, C., Champagne, C.P.: Combined effects of temperature and medium composition on exopolysaccharide production by Lactobacillus rhamnosus RW-9595M in a whey permeate based medium. Biotechnol. Prog. 18, 167–173 (2002)

Haj-Mustafa, M., Abdi, R., Sheikh-Zeinoddin, M., Soleimanian-Zad, S.: Statistical study on fermentation conditions in the optimization of exopolysaccharide production by Lactobacillus rhamnosus 519 in skimmed milk base media. Biocatal. Agric. Biotechnol. 4, 521–527 (2015)

Zamfir, M., Callewaert, R., Cornea, P.C., De Vuyst, L.: Production kinetics of acidophilin 801, a bacteriocin produced by Lactobacillus acidophilus IBB 801. Microbiol. Lett. 190, 305–308 (2000)

Sohrabpour, S., Rezazadeh Bari, M., Alizadeh, M., Amiri, S.: Investigation of the rheological, microbial and physicochemical properties of developed synbiotic yogurt containing Lactobacillus acidophilus LA‐5, honey and cinnamon extract. J. Food Process. Preserv. e15323 (2021)

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Amiri, S., Rezazadeh-Bari, M., Alizadeh-Khaledabad, M. et al. Fermentation Optimization for Co-production of Postbiotics by Bifidobacterium lactis BB12 in Cheese Whey. Waste Biomass Valor 12, 5869–5884 (2021). https://doi.org/10.1007/s12649-021-01429-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12649-021-01429-7