Abstract

Lycopene was simultaneously extracted from tomato processing waste and size reduced into nano-ranges from 36 to 150 nm, via ultrasonic assisted nanoprecipitation technique. The effects of main processing parameters namely, organic to aqueous phase ratio, ultrasonic amplitude and time were evaluated on mean particle size, polydispersity (PDI) and lycopene content of produced nanodispersions, using response surface method based on central composite design. All studied parameters affected the selected responses significantly (p-value < 0.05). The studied characteristics’ changes were significantly (p-value < 0.05) fitted to second order polynomial regression models of studied independent parameters by quite high coefficients of determination (R2 > 0.9). The most desirable lycopene nanodispersions with mean particle size of 66.3 nm, PDI of 0.245 and lycopene content of 52 mg/g waste, were produced at organic to aqueous phase ratio of 0.5, and ultrasonication for 20 min at amplitude of 70%. The resulted insignificant differences between experimental and predicted data, certified the suitability of suggested response surface models.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Lycopene-rich diets have beneficial effects on human health due to its antioxidant activity as well as preventing some cancers and cardiovascular disease [1,2,3]. Since the lycopene content of tomato skin is about five times higher than in the pulp, extensive amounts of lycopene can be found in tomato processing waste or tomato pomace, compared to fresh tomato. However, the tomato processing waste is usually discarded or used as animal foods, it can be used as low-cost and sustainable source of this nutraceutical carotenoid compound [4,5,6].

Similar to other lipophilic compounds, lycopene shows very low water solubility and consequently less bioavailability. Furthermore, it is very susceptible to chemically decomposition in presence of light, heat and oxygen. Incorporating functional lipid compounds such as lycopene into nano-particulate delivery systems is one of the promising approaches for improving the mentioned problems. For example, in nanodispersions of these compounds, their solubility, stability and bioavailability would be increased, considerably, and they can be easily incorporated into water-based food, beverages, and pharmaceutical formulations [1, 7]. Their water solubility and consequently bioavailability enhancement was occurred due to considerable increase in their area to volume ratio. Moreover, the surrounding emulsifier layer of lycopene can decrease its exposure to oxygen, metal ions, heat and light, and protect its structure from degradation [8]. Nanodispersions can be prepared using either mechanical based high-energy or chemical based low energy methods such as nano-precipitation techniques [9]. Ultrasonic cavitation individually or in combination with nano-precipitation process usually offers a considerable improvement in particle size and stability of gained nanodispersions. High energy input originating from micro turbulent collapse of cavitation bubbles creates vast energy. That is enough to deform and break off dispersed phase particles into nanometer scale. But this is possible only if the Laplace pressure is prevailed. Thus, two kinds of mechanisms are involved to nanodispersion preparation in ultrasonic emulsification; an acoustic field creates combination of interfacial waves and instability causes the eruption of dispersed phase into aqueous medium, then low frequency ultrasound waves break down the particles by cavitation nearby the interface. The instability of primary particles yields the nanodispersions with very small particle sizes [10]. It was found that the particle sizes of ultrasonically-induced nanodispersions are much smaller with greater stability than those prepared nanodispersions by homogenizer [11]. Although smaller nanodispersions can be produced using microfludizers, but the ultrasonic homogenization is preferred in most cases due to its less maintain costs, more convenience uses, easier to clean and free of line blockage [12]. Therefore, ultrasonic cavitation is still the most operative and favorable method in the preparation of food or pharmaceutical incorporated nanodispersions [13, 14].

Extraction enhancement by ultrasound has also been related to the propagation of ultrasound pressure waves, and resulting cavitation phenomena. The breakdown of cavitation bubbles can produce eruptions of energy and cause extremely high temperature and pressure, that can augment the penetration of solvent into the matrix and accelerate the extraction of targeted compounds dramatically [15, 16]. Consequently, it was reported that the system homogeneity and dispersed phase particle sizes are greatly attributed to different sonication variables such as power of sonication, amplitude and temperature of sonication [13]. On the other hand, the lycopene content of nanodispersions would be positively correlated to exposure of lycopene during nanodispersion preparation resulted from extraction yield and negatively related to the possible decomposition of lycopene during ultrasound irradiation for size reduction step. Thus, this study set out to determine either the effects of ultrasonic irradiation parameters (power and amplitude) or solvent to aqueous phase ratio on mean particle size, polydispersity (PDI) and lycopene content of produced nanodispersions through simultaneous ultrasound-assisted extraction of lycopene from tomato waste and its size reduction into nano-scale ranges.

Materials and Methods

Materials

The seed free tomato processing waste was attained from Golnoosh Company (Tabriz, Iran). All reagents and trans-lycopene standard were acquired from Sigma Aldrich (Missouri, USA). Polysorbate 20 (polyoxyethylene sorbitan monolaurate), HPLC and analytical-grade solvents, were provided from Fisher Scientific (Leicestershire, UK).

Preparation of Lycopene Nanodispersions

A ternary solvent system composed of 31% acetone, 38% ethyl acetate and 31% hexane, was selected as organic phase in either extraction or size reduction stages in preparation of lycopene nanodispersions [17]. 5 g seed less dry tomato waste was added to various volumes of selected solvent (Table 1) and the extraction of lycopene was performed under ultrasound irradiation (Prob-sonicator, UP200H, Hielscher, Germany) for 15 min, amplitude of 80% and cycle of 0.8, at 25 °C water bath in a screw-top vial. 0.2 g polysorbate 20 was then added to double deionized water to form aqueous phase. While the total volume of aqueous plus solvent phases in homogenization step was set at 100 ml, the volume ratio of solvent to double deionized water has been adjusted as Table 1. The aqueous phase was added to solvent phase, under ultrasound homogenization at various amplitude and irradiation time (according to Table 1). The produced emulsions were filtered in vacuum filter (Whatman filter paper, no. 4) and simultaneously heated and stirred magnetically at 50 °C, in 900 rpm for 10 min, in order to eliminating of solvent from system. The solvent residual was then totally removed in vacuum rotary evaporator (Heidolph, Germany) at 55 °C, 10 min and 100 rpm. The prepared nanoemulsions were converted to nanodispersions after solvent elimination. Finally, all samples (nanodispersions) were volume up to 200 ml by addition of deionized water.

Particle Size and PDI Analysis

The average particle size and PDI of lycopene nanodispersions were measured based on dynamic light scattering mechanism using size analyzer (Nano Wave, Microtrac., Montgomeryvill, PA, US), on diluted samples (1:100) in order to prevent the effects of manifold scattering. The measurements were performed at 25 °C and the refractive index of 1.456. Information about the average particle size of nanodispersions was obtained based on a best fit between Mie theory and measured light scattering pattern. The PDI is a dimensionless quantity of the size distribution width established from the cumulant analysis and ranging from 0 to 1, in which smaller PDI values shows higher similarity in sizes of produced dispersed nanoparticles [18]. The data were reported as mean of three replications with two readings.

Lycopene Content Measurement in Nanodispersions

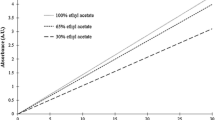

A mixture of acetone and n-hexane (33% v/v acetone and 67% v/v n-hexane) was used to extract the lycopene from prepared nanodispersions. 4 ml of samples was extracted using 10 ml solvent for 15 min in triplicate [4]. The volume of samples was brought up to 20 ml by adding the acetone. Then, a sample aliquot was filtered using nylon syringe filter (4 mm, 0.45 mm). The HPLC analysis was performed in a high pressure liquid chromatography system (Shimadzo, CT10A VP, Shimadzu, Kyoto, Japan), with SPD10AV UV–Vis detector, C18 Nova-Pak column (300 mm, 3.9 mm, Waters) and LC-10AT pump system. The injection volume and flow rate were set at 50 µl, and 1.2 ml/min, respectively. The methanol: Methyl tert-butyl ether:ethyl acetate (30:60:10, v/v/v) was used as isocratically mobile phase and detection wavelength was set at 503 nm [19]. The various concentrations of trans-lycopene were used as standard to provide the calibration curve which was linear at used concentrations’ range (R2 = 0.9977, n = 5).

Experimental Design and Statistical Analysis

The multivariate statistical response surface methodology (RSM) is a set of mathematical and statistical procedures based on the fit of a polynomial model to the experimental data, defining the changes of a data set with the aim of providing statistical previsions. It can be used if a response or a set of responses are influenced by several independent variables. Despite one-variable-at-a-time technique, the RSM, include the interactive effects among the variables studied. Therefore, this technique illustrate the complete effects of the parameter on the response. Furthermore, the experiments time and costs along with consumption of reagents and materials are considerably decreased by reducing the number of necessary experiments to conduct the research. The central composite design was used as experimental design pattern, represents a specific set of combinations for the levels of variables that must be applied experimentally to gain the responses. This design consists of a full factorial or fractional factorial design as well as a supplementary design, known as star design, in which the experimental points locate at the distance of α from centre; and the central point which should be replicated various times. The number of experiments can be obtain according to

where k is the number of factors and (cp) is the number of central point replication. Moreover, α can be calculated by

and for three variables, it equals to 1.68. All independent variables are considered in five levels namely, −α, − 1, 0, + 1, +α. For selected large experimental domains, or in the cases of processing limitation out of the selected domain, the star points are replaced by factorial ones in order to place all points within the selected ranges for each factors which has been applied for current study. Two ultrasonic parameter namely ultrasonic time and amplitude, as well as the organic to inorganic phase ratio, as formulation parameter, were selected based on screening procedure of more effective parameters (unpublished data) as independent factors. Then, the effects of them were studied on mean particle size, size distribution (PDI) and lycopene content of prepared nanodispersions using Mimitab14 (Minitab, Inc. Version 14, PA, USA) (Table 1). By selecting the default condition of software, the centre point are suggested to be replicated five times in order to evaluate the pure error related to repetitions.

The full quadratic polynomial equations (Eq. 1) were considered as the most suitable models, describing the response characteristics of samples;

where β0 is a constant and β1, β2, β3, are the coefficients of linear effects, β11, β22, β33 are the coefficients of quadratic effects and β12, β13, β23 are the coefficients of binary interaction effects and finally the β123 is the coefficient of ternary effects of chosen independent parameters. Moreover, Y was used for response variable. The quality of models were evaluated using coefficients of determinations or R2 and R2-adj values. The models with R2 > 0.8, were consider as acceptable since more than 80% of experimental points would be follow the suggested models. For evaluating the significant terms, ANOVA testing was performed and the obtained p-values and (t-value or F-ratio) of terms were compared. The terms with p-values < 0.05 were considered as significant, in which the significancy of terms would be increased by decreasing the p-values or increasing the net t-values or F-ratios. The 3D graphs were also provided using software to evaluate the interaction behavior of independent parameters on studied responses [20, 21].

Optimization and Validation

The single as well as the multiple optimizations were performed to find the best processing conditions leading to attain the most desirable lycopene nanodispersions with the smallest mean particle size, PDI and the highest lycopene content, using either numerical or graphical optimization techniques. The desirability values were also reported to evaluate the either synergistically or antagonistic effects of variables to get the most desirable product, as the higher overall desirability indicates the more synergistic effects of variables. Therefore, the overall desirability decreases by the antagonistic changes of responses with selected variables. A three-component solvent system composed of 31% hexane, 31% acetone and 38% ethyl acetate, which has been previously obtained as optimum solvent phase composition (unpublished data), was used as organic phase in this study.

The adequacy of models were also checked by comparison the experimental and predicted data for each responses in suggested points. Moreover, the optimum suggested sample were also prepared, and their measured characteristics were compared to the predicted ones using statistical comparison Tukey test at significant level of 0.05 [7, 22].

Results and Discussions

Since in ultrasonic assisted solvent displacement technique, the ultrasound irradiation as well as the solvent phase were used in either extraction or size reduction steps, it can be expected that the ultrasonic process parameters and applied initial solvent content have the most significant effects on particle size characteristics and lycopene contents of produced nanodispersions. Consequently, the optimum lycopene nanodispersions can be produced with minimum mean particle size, PDI and maximum lycopene contents from tomato processing wastes by tuning the time and amplitude of ultrasound irradiation as well as initial organic to aqueous phase ratio.

The ANOVA analysis were performed to evaluate the significance of either linear or quadratic and interaction effects of processing variables on responses’ variations. Moreover, the multiple regression of analysis were used to present the most suitable second order polynomial models for prediction the lycopene nanodispersion characteristics’ as a function of independent factors. The regression coefficients of suggested models, as well as the coefficients of determinations (R2 and R2-adj) of each models were shown in Table 2. As stated before, the terms with less p-value and greater F-ratio were considered as more significant terms of model suggested for prediction of corresponded response. As pointed to Table 2, the obtained almost high coefficients of determinations of each model confirm the excellence and suitability of proposed models. The significance of each linear, quadratic and interaction terms (p-value and F-ratio) were also indicated in Table 3.

Mean Particle Size

It was reported that the particle sizes of functional lipid nanodispersions are affected by ultrasound parameters, considerably [13]. The similar dependency has also been observed between the particle sizes of mentioned systems and solvent to aqueous phase ration used [21].

In preparation of nanodispersions using ultrasonication, cavitation occurs as the pressure amplitude of the applied aquatic irradiation reaches a definite minimum, known as the cavitation threshold. The emulsification subsequently initiates when this threshold of cavitation reaches, and it can offer an additional energy for new interface formation and broken down of liquid in the form of small bubbles. These bubbles and their sequential collision, collapse the larger particles into smaller ones [23].

From the data of Tables 2 and 3, it can be concluded that all selected processing variables in either linear or quadratic and interaction forms, except for quadratic effect of ultrasound time, had influenced the mean particle size changes of produced nanodispersions, significantly (p-value < 0.05). Furthermore, the negative signs of linear and positive signs of quadratic terms of all independent factors, illustrated that by increasing the solvent to aqueous phase ratio, ultrasound amplitude or time up to certain levels the particle size of produced nanodispersions would be decreased, while, further increases of them passing this threshold, they affected inversely and increased the sizes of nanodispersions. Therefore, it would be an optimum level for each factor leading to production of nanodispersions with the smallest average particle size. These trend can be clearly observed in Fig. 1. The inspection of the interactions effects also indicated that parallel increase/decrease of processing parameters also caused the production of lycopene nanodispersions with larger particle sizes.

As clearly shown in Fig. 1a, at less uses of organic solvents, increasing the amplitude up to 85%, reduced the dispersed phase sizes of products, but applying additional pressures acted reversely. On the other hand, at high levels of solvent used, the size of nanodispersions increased by enhancing the ultrasound amplitudes.

The particle sizes of prepared nanodispersions also decreased by increasing the ultrasound time at less solvent to aqueous uses. However, this tendency was changed at high solvent to aqueous ratios (Fig. 1b). It can be also seen that, at high ultrasonic amplitudes or times, increasing the solvent to water ratio, led to an increase in particle size. Though, this effect became negligible at low levels of applied ultrasonic time and amplitude.

The monitoring of ultrasonic time and amplitude at certain level of used organic phase (middle level), illustrated that middle levels of these parameters, as well as short time applying of high ultrasonic amplitude and longtime exposure of samples to low amplitude ultrasound process, could produce more desirable lycopene nanodispersions in term of their average particle sizes (Fig. 1c). Decreasing the size of nanodispersions by increasing the ultrasound amplitude and time has also been resulted through nanoprecipitation of some other active compounds in several studies, which can be related to promoting the nucleation rate and breaking down the agglomerated particles, due to increase in interfacial instabilities resulted by augmented cavitation. Moreover, the temperature of system raised up due energy dissipation, resulting a considerable decrease in viscosity and interfacial tension, which improved the dispersion of one phase to other [23,24,25].

In anti-solvent nanoprecipitation technique, the ultrasound affects all mixing (in both extraction and size reduction steps), crystallization, crystal size growth, crystal habit and agglomeration in preparation of nanodispersions. In mixing step, ultrasound increased the energy dissipation rate and consequently, decrease the mixing time. It was reported that the mixing time can be decrease 10 times during ultrasonic irradiation compared to mechanically or magnetically ones [25]. The ultrasound increases the mixing rate and mass transfer during precipitation step of organic nanodispersions’ process [26]. It also resulted that the ultrasound significantly reduced the time among the supersaturation creation and crystals appearance, known as induction time, due to enhanced diffusion of solute molecules. Ultrasound also decreased the variability in the spread of initiation times at different supersaturation levels. Moreover, ultrasound decreased the width of metastable zone that directly related to induction time. Consequently, shorter metastable zone width led to less induction time and greater nucleation rate, and as a result, smaller particle size [25,26,27,28]. Decreasing the particle size by increasing ultrasound amplitude or time can also be related to accelerated diffusion of solute due to sonication energy applied. Therefore, the ultrasound can decrease the size of produced nanodispersions through increasing the supersaturation, enhancing the nucleation time and increasing the diffusion coefficient of solute [19, 23]. Furthermore, some previous researches reported that the moderate power applied by sonication, can increase the crystallization rate in uses of higher solvent to aqueous phase ratio, which was also be seen in the results of current study.

In moderate levels of ultrasonic amplitudes, increasing the ultrasonic exposure time provides adequate time for mixing (either in macro or meso and micro scale), and consequently sufficient contact time and collaboration of the organic and aqueous phases.

However, increasing the size of nanodispersions by simultaneous increasing the ultrasound amplitude and time can be related to over-processing mechanism due to extra production of cavitation creating mechanical turbulences in liquids and increasing mass transfer and consequently, rate of movement of solute to the surface of growing crystal [25, 26, 28].

Increasing the solvent or organic to aqueous phase ratio the size, promoted the Ostwald ripening and caused an increase in mean particle size of produced nanodispersions particularly at high ultrasonic exposure time or amplitudes. Additionally, the temperature of system increased due to high input at great ultrasonic time and amplitude, and caused the organic system, mainly acetone, to evaporate. Hence, before the production of nanoparticles, the optimum organic phase composition would be interrupted, causing the production of greater particles through nanodispersions preparation process [20, 23, 26].

As indicated in Tables 2 and 3, the ultrasound amplitude was the most affective parameter on the variation of mean particle sizes of prepared nanodispersions (according to obtained higher F-ratio values for the linear and quadratic effects of this variable). The attained high coefficient of determination (R2 > 90%) confirms the suitability of suggested model for predicting the particle size changes by ultrasound amplitude and time, as well as, solvent to aqueous phase ratio (v/v).

The individual optimization of independent variables to obtain the nanodispersions with the least particle sizes, predicted that using organic to aqueous phase ratio of 0.11, and exposure them to ultrasound irradiation with the amplitude of 90% and for 10 min, would produce the lycopene nanodispersions with minimum mean particle sizes (23.7 nm).

PDI

The results of analysis of regression for size distribution or PDI of prepared nanodispersions indicated that all selected process parameters also influenced this characteristic significantly (p-value < 0.05), as well (Tables 2, 3). Therefore, according to obtained R2 for this response (R2 > 94%), more than 94% of PDI variation of prepared nanodispersions could be predicted by suggested polynomial regression model (Table 2). The ANOVA analysis for this characteristics revealed that the linear effect of ultrasonic amplitude, the quadratic effect of organic to aqueous phase and the interaction effect of organic to aqueous phase with ultrasonic time, retained the highest F-ratio values and were the most affective linear, quadratic and interaction terms, respectively, in suggested model. It was shown that at higher used solvent concentrations, increasing the ultrasound amplitude or time caused a considerable increase in PDI of prepared nanodispersions up to certain levels. However, extra increasing of these ultrasonic parameters, affected the PDI, contrariwise.

On the other hand, using less either amplitude or time of ultrasound exposure, caused the preparation of lycopene nanodispersions with less homogeneity (high PDI), while increasing the levels of these parameters would improve the homogeneity of system and decrease the PDI of produced nanodispersions, mainly at high solvent used. Contrary, at a reduced amount of used solvent to aqueous phase ratio, increasing the amplitude and time of ultrasonic irradiation, enhanced the PDI of obtained nanodispersions, noticeably.

The observed curvature in Fig. 2a, b, confirmed the significance of the interaction effects of solvent to aqueous phase ration with ultrasonic amplitude and time, as indicated in Table 3, as well. Then, simultaneous increase of x1 and x2 or x1 and x3, reduced the PDI of system. It meant that in the uses of greater solvent to aqueous phase ratios, more power was needed to production of the homogenous nanodispersions with less PDI, which can be provided at either high levels of amplitude or exposure time of ultrasound.

Generally, in nanodispersions systems, uniform energy apply causes the production of homogeneous dispersions with less PDI. Thus, if the particles experience similar power, they will be broken down consistently into smaller particles. Therefore, despite of mean particle size, the PDI of product are influenced mainly by the applied power changes, instead of the power strength [7, 22, 29, 30]. At less solvent uses, increasing either ultrasound amplitude or time, caused an intensive rise in energy input of system. Therefore, the dispersed phase particles were broken up, rapidly. However, the sufficient time for even and completely attaching of stabilizer molecules onto the newly created smaller particles could not be provided in system, led to re-attaching of some incomplete stabilized particles and production the dispersed phase with various mean particles sizes and broad size distribution [20, 29, 31]. It has also been reported that at less solvent uses, the shock waves generated due to cavitation led to shortening of the crystals contact time, prevent their agglomeration and size growth [25].

On the other hand, increasing the solvent quantity, or dispersed phase volume in preparation of lycopene nanodispersions, enhance the energy need of system for complete mixing and homogenization of the phases. Therefore, less ultrasonic time or amplitude are not sufficient for disintegration of all particles and some of them remained unbroken, which leading the production of particles with different sizes [22, 29, 32]. Moreover, at high levels of solvent used, the collisions of the dispersed phase particles were increased, which raised the chance of their association together and production of uneven particles. The PDI of system will be improved by intensive upsurge of ultrasonic amplitude or time, at high solvent uses. Therefore, long time exposure of ultrasound or using high ultrasonic amplitude can provide adequate energy need for disruption of all fresh particles and re-arrange the insufficient stabilized particles. Previous researches also concluded that more energy dissipation caused a uniformity in system [26], which was opposed by most current study results for PDI changes.

Furthermore, the enhanced PDI of produced nanodispersions at certain organic phase concentrations and long time exposure of ultrasound with less amplitude levels or using short time ultrasound with higher amplitudes, revealed the unevenness of applied ultrasound power in these cases.

The individual optimization predicted that using equal volumes of organic and aqueous phases, and ultrasonic process with amplitude of 90% for 30 min, would produce the most homogeneous lycopene nanodispersions with the least PDI.

Lycopene Content

Since the ultrasonic irradiation effect in homogenization step is mostly appear on particle size and PDI characteristics of produced nanodispersions, its effect in extraction step, is typically reflected on lycopene content of prepared nanodispersions. The lycopene content of product is also affected by the chemical stability of extracted lycopene during size reduction process. As stated before, like other carotenoids, the chemical structure of lycopene is liable to heat and light and is declined in presence of oxygen in environment [20].

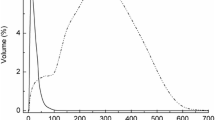

The selected independent process parameters had significant effect on lycopene content of gained lycopene nanodispersions. The high coefficient of determination (R2 = 0.9271) of suggested regression model for prediction this response can confirm the suitability of obtained model. The obtained positive linear and negative quadratic coefficients of suggested models, indicated that increasing all process variables to certain threshold, increased the lycopene content of produced nanodispersions. However, further rise of them affected inversely, and decreased the active compound content in products (Table 2).

The ANOVA analysis also indicated that linear effect of phases’ ratio is the most affective term on lycopene content of products. Moreover, all interaction terms are insignificant in confidence level of 95% (p-value > 0.05, Table 3). Generally, increasing the solvent content, as well as ultrasound time and amplitude, can increase the lycopene content in prepared nanodispersions. These effects are predictable, since increasing all these operation parameters can improve the extraction yield of lycopene from plant cells of waste [4, 19, 24, 33]. For example, Konwarh et al. [24] resulted similar trend for changing the yield of extracted lycopene from tomato peels for ultrasound amplitude and time. Increasing the extracting solvent normally caused an increase in extraction yield due to a considerable rise in equilibrium concentration of extracted component in media [4, 15, 34]. The cavitation intensity also increased by surge of the solvent content in system, since the used solvent system has less vapor pressure compared to aqueous phase [35]. The increase of the ultrasonic amplitude or time also increased the energy input to system and strengthened the cavitation leading to efficient plant cell collapse and increased mass transfer of lycopene from cells into extracting solvent [4, 15, 35]. However, extra increase of solvent, caused a considerable increase on duration of the solvent removal step, which decreased the chemical stability of extracted lycopene and promoted its deterioration through the process due to long time exposure to heat, light and oxygen (Fig. 3). Also, as observed in Fig. 3, the severe increase of ultrasonic amplitude or time, degraded the active compound chemically due to production of highly reactive radicals and oxygen derivatives, and decrease the size of nanoparticles [20].

The single optimization resulted that using organic to aqueous phase with the volume ratio of 0.93, and ultrasonic process in amplitude of 65 and 18 min, would give the lycopene nanodispersions with the highest lycopene content (59.8 mg/100 g dry waste).

Optimization and Validation Process

The multiple optimization in order to get the lycopene nanodispersions with the least mean particle size, PDI and the highest lycopene content were also performed either graphically or numerically. The acceptance level of these characteristics were set from minimum to first quarter of measured data for mean particle size and PDI and from third quarter to maximum for lycopene contents of samples. The results for graphical optimization are shown in Fig. 4. The white area in each contour plot shows the operation conditions resulting the production of the most desirable nanodispersions. It can be seen that using organic to aqueous phase with the ratio ranged from 0.5 to 0.6, ultrasonication with the amplitude ranges of 65–75% and time ranges of 15–20 min would give the best products.

The numerical optimization also indicated that setting organic to aqueous phases ratio on 0.5, and ultrasonic amplitude and time on 70% and 20 min, respectively, would produce the best lycopene nanodispersions (66.3 nm, PDI of 0.245 and 52 mg/g waste lycopene), with overall desirability of 0.854.

The suitability of suggested models were also checked by comparison the measured characteristics with the data obtained from model using two sample t-test. All acquired p-values are 1 with the F-ratio of 0, meaning that there are no significant difference (p-value < 0.05) between the experimental and calculated data for characteristics of produced nanodispersions. Thus, the suitability of models can be established.

Moreover, the suggested optimum lycopene nanodispersions were prepared at three replications and their mean particle sizes, PDI and lycopene contents were measured and compared to predicted values, as well. The data are shown in Table 4. It can be concluded that the experimental values do not differ from calculated ones significantly due to more than 0.05 values of obtained p-values of comparison tests. Therefore, the accuracy of all three suggested models can be re-confirmed.

Physical and Chemical Stability of Optimum Lycopene Nanodispersions

The mean particle size, PDI and lycopene contents of optimum lycopene nanodispersion were measured after 30 days storage at either 4 or 25 ± 1 °C in order to evaluate its physical and chemical stabilities. The results are presented at Table 5. It can be seen that regardless of lycopene content, the particle size and PDI of stored optimum lycopene nanodispersions remained constant at 4 °C. Thus, they show good physical, but less chemical stabilities. However, the increasing of particle size and PDI of stored nanodispersions at 25 °C and decreasing of their lycopene content, unveiled their neither physical nor chemical stabilities at room temperatures. Previous studies resulted first order kinetic model for degradation of carotenoids in nanodispersion systems. Moreover, their reported degradation rate constant (k) augmented by increasing the storage temperatures, according to Arrhenius equation. Therefore, the current study outcome agreed to the earlier ones [36]. The lycopene content of stored nanodispersions at 25 °C decrease twofold quickly compared to 4 °C. Therefore, the lycopene content of stored nanodispersions at 25 °C are approximately 50% of stored ones at 4 °C. Then, decreasing the storage temperature, as well as oxygen content and light of environment can improve the chemical stabilities of nanodispersions considerably, as the lycopene is greatly liable to these conditions [1, 36]. Moreover, the less physical stability of produced nanodispersions at room temperature can be related to lycopene degradation reactions in system leading to disturbing the stabilizer molecules by produced radicals as well as their action as connecting agents of nanoparticles in systems [1, 36, 37].

Conclusion

Lycopene nanodispersions were successfully fabricated using ultrasound assisted simultaneously extraction and size reduction of lycopene from tomato wastes. The effects of main processing parameters, namely, organic to aqueous phase ratio, ultrasonic time and amplitude, were studied on mean particle size, PDI and lycopene content of products, response surface method based on central composite design of experiments. The empirical second order polynomial models were presented to predict the variations of studied responses, with quite high coefficients of determinations (R2 > 0.9). The results clearly showed that the main effect of ultrasound amplitude, the quadratic effect of phases’ ratio and also its main effect are the most significant terms on mean particle size, PDI and lycopene content of lycopene nanodispersions, respectively. Furthermore, the optimization procedures suggested that using organic to aqueous phases at ratio of 0.5, and ultrasonic process at amplitude and time of 70% and 20 min, respectively, would lead to production the most desirable lycopene nanodispersions with particle size of 66.3 nm, PDI of 0.245 and 52 mg/g waste lycopene content. The prepared nanoparticles had acceptable physical stability, especially at less temperature storage, but relatively less chemical stability due to observed lycopene content decrease in optimum sample during 30-day storage at either 4 or 25 °C. The formulated lycopene nanodispersions can be successfully used in various food, cosmetic and pharmaceutical applications.

References

Tan, C.P., Nakajima, M.: β-Carotene nanodispersions: preparation, characterization and stability evaluation. Food Chem. 92(4), 661–671 (2005). https://doi.org/10.1016/j.foodchem.2004.08.044

Santini, A., Novellino, E.: Nutraceuticals—shedding light on the grey area between pharmaceuticals and food. Expert Rev. Clin. Pharmacol. 11(6), 545–547 (2018). https://doi.org/10.1080/17512433.2018.1464911

Santini, A., Tenore, G.C., Novellino, E.: Nutraceuticals: a paradigm of proactive medicine. Eur. J. Pharm. Sci. 96, 53–61 (2017). https://doi.org/10.1016/j.ejps.2016.09.003

Poojary, M.M., Passamonti, P.: Extraction of lycopene from tomato processing waste: kinetics and modelling. Food Chem. 173, 943–950 (2015). https://doi.org/10.1016/j.foodchem.2014.10.127

Naviglio, D., Pizzolongo, F., Ferrara, L., Aragòn, A., Santini, A.: Extraction of pure lycopene from industrial tomato by-products in water using a new high-pressure process. J. Sci. Food Agric. 88(14), 2414–2420 (2008). https://doi.org/10.1002/jsfa.3334

Gervasi, T., Pellizzeri, V., Benameur, Q., Gervasi, C., Santini, A., Cicero, N., Dugo, G.: Valorization of raw materials from agricultural industry for astaxanthin and β-carotene production by Xanthophyllomyces dendrorhous. Nat. Prod. Res. 32(13), 1554–1561 (2018). https://doi.org/10.1080/14786419.2017.1385024

Anarjan, N., Jafarizadeh-Malmiri, H., Nehdi, I.A., Sbihi, H.M., Al-Resayes, S.I., Tan, C.P.: Effects of homogenization process parameters on physicochemical properties of astaxanthin nanodispersions prepared using a solvent-diffusion technique. Int. J. Nanomed. 10, 1109–1118 (2015). https://doi.org/10.2147/IJN.S72835

Shi, J., Xue, S.J., Wang, B., Wang, W., Ye, X., Quek, S.Y.: Optimization of formulation and influence of environmental stresses on stability of lycopene-microemulsion. LWT Food Sci. Technol. 60(2), 999–1008 (2015). https://doi.org/10.1016/j.lwt.2014.10.066

Anarjan, N., Tan, C.P., Ling, T.C., Lye, K.L., Malmiri, H.J., Nehdi, I.A., Cheah, Y.K., Mirhosseini, H., Baharin, B.S.: Effect of organic-phase solvents on physicochemical properties and cellular uptake of astaxanthin nanodispersions. J. Agric. Food Chem. 59(16), 8733–8741 (2011). https://doi.org/10.1021/jf201314u

Periasamy, V.S., Athinarayanan, J., Alshatwi, A.A.: Anticancer activity of an ultrasonic nanoemulsion formulation of Nigella sativa L. essential oil on human breast cancer cells. Ultrason. Sonochem. 31, 449–455 (2016). https://doi.org/10.1016/j.ultsonch.2016.01.035

Luque de Castro, M.D., Priego-Capote, F.: Ultrasound-assisted preparation of liquid samples. Talanta 72(2), 321–334 (2007). https://doi.org/10.1016/j.talanta.2006.11.013

Kaur, K., Kumar, R., Arpita, Goel, S., Uppal, S., Bhatia, A., Mehta, S.K.: Physiochemical and cytotoxicity study of TPGS stabilized nanoemulsion designed by ultrasonication method. Ultrason. Sonochem. 34, 173–182 (2017). https://doi.org/10.1016/j.ultsonch.2016.05.037

Kaur, K., Kumar, R., Mehta, S.K.: Formulation of saponin stabilized nanoemulsion by ultrasonic method and its role to protect the degradation of quercitin from UV light. Ultrason. Sonochem. 31, 29–38 (2016). https://doi.org/10.1016/j.ultsonch.2015.11.017

Abbas, S., Bashari, M., Akhtar, W., Li, W.W., Zhang, X.: Process optimization of ultrasound-assisted curcumin nanoemulsions stabilized by OSA-modified starch. Ultrason. Sonochem. 21(4), 1265–1274 (2014). https://doi.org/10.1016/j.ultsonch.2013.12.017

Xu, Y., Pan, S.: Effects of various factors of ultrasonic treatment on the extraction yield of all-trans-lycopene from red grapefruit (Citrus paradise Macf.). Ultrason. Sonochem. 20(4), 1026–1032 (2013). https://doi.org/10.1016/j.ultsonch.2013.01.006

Naviglio, D., Caruso, T., Iannece, P., Aragòn, A., Santini, A.: Characterization of high purity lycopene from tomato wastes using a new pressurized extraction approach. J. Agric. Food Chem. 56(15), 6227–6231 (2008). https://doi.org/10.1021/jf703788c

Anarjan, N., Jouyban, A.: Preparation of lycopene nanodispersions from tomato processing waste: effects of organic phase composition. Food Bioprod. Process. 103, 104–113 (2017). https://doi.org/10.1016/j.fbp.2017.03.003

Tang, S.Y., Manickam, S., Wei, T.K., Nashiru, B.: Formulation development and optimization of a novel Cremophore EL-based nanoemulsion using ultrasound cavitation. Ultrason. Sonochem. 19(2), 330–345 (2012). https://doi.org/10.1016/j.ultsonch.2011.07.001

Eh, A.L.-S., Teoh, S.-G.: Novel modified ultrasonication technique for the extraction of lycopene from tomatoes. Ultrason. Sonochem. 19(1), 151–159 (2012). https://doi.org/10.1016/j.ultsonch.2011.05.019

Anarjan, N., Mirhosseini, H., Baharin, B.S., Tan, C.P.: Effect of processing conditions on physicochemical properties of astaxanthin nanodispersions. Food Chem. 123(2), 477–483 (2010). https://doi.org/10.1016/j.foodchem.2010.05.036

Anarjan, N., Nehdi, I.A., Tan, C.P.: Influence of astaxanthin, emulsifier and organic phase concentration on physicochemical properties of astaxanthin nanodispersions. Chem. Cent. J. 7(1) (2013). https://doi.org/10.1186/1752-153X-7-127

Anarjan, N., Mirhosseini, H., Baharin, B.S., Tan, C.P.: Effect of processing conditions on physicochemical properties of sodium caseinate-stabilized astaxanthin nanodispersions. LWT Food Sci. Technol. 44(7), 1658–1665 (2011). https://doi.org/10.1016/j.lwt.2011.01.013

Gaikwad, S.G., Pandit, A.B.: Ultrasound emulsification: effect of ultrasonic and physicochemical properties on dispersed phase volume and droplet size. Ultrason. Sonochem. 15(4), 554–563 (2008). https://doi.org/10.1016/j.ultsonch.2007.06.011

Konwarh, R., Pramanik, S., Kalita, D., Mahanta, C.L., Karak, N.: Ultrasonication—a complementary ‘green chemistry’ tool to biocatalysis: a laboratory-scale study of lycopene extraction. Ultrason. Sonochem. 19(2), 292–299 (2012). https://doi.org/10.1016/j.ultsonch.2011.07.010

Thorat, A.A., Dalvi, S.V.: Liquid antisolvent precipitation and stabilization of nanoparticles of poorly water soluble drugs in aqueous suspensions: recent developments and future perspective. Chem. Eng. J. 181–182, 1–34 (2012). https://doi.org/10.1016/j.cej.2011.12.044

Kentish, S., Wooster, T.J., Ashokkumar, M., Balachandran, S., Mawson, R., Simons, L.: The use of ultrasonics for nanoemulsion preparation. Innov. Food Sci. Emerg. Technol. 9(2), 170–175 (2008). https://doi.org/10.1016/j.ifset.2007.07.005

Jadhav, A.J., Holkar, C.R., Karekar, S.E., Pinjari, D.V., Pandit, A.B.: Ultrasound assisted manufacturing of paraffin wax nanoemulsions: process optimization. Ultrason. Sonochem. 23(0), 201–207 (2015). https://doi.org/10.1016/j.ultsonch.2014.10.024

Leong, T.S.H., Wooster, T.J., Kentish, S.E., Ashokkumar, M.: Minimising oil droplet size using ultrasonic emulsification. Ultrason. Sonochem. 16(6), 721–727 (2009). https://doi.org/10.1016/j.ultsonch.2009.02.008

Horn, D., Rieger, J.: Organic nanoparticles in the aqueous phase—theory, experiment, and use. Angew. Chem. Int. Ed. 40(23), 4330–4361 (2001). https://doi.org/10.1002/1521-3773(20011203)40:23%3C4330::AID-ANIE4330%3E3.0.CO;2-W

McClements, D.J.: Nanoparticle- and Microparticle-Based Delivery Systems: Encapsulation, Protection and Release of Active Compounds. Taylor and Francis, Boca Raton (2014)

Jafari, S.M., Assadpoor, E., He, Y., Bhandari, B.: Re-coalescence of emulsion droplets during high-energy emulsification. Food Hydrocolloids 22(7), 1191–1202 (2008). https://doi.org/10.1016/j.foodhyd.2007.09.006

Verma, S., Burgess, D.: Solid nanosuspensions: the emerging technology and pharmaceutical applications as nanomedicine. In: Kulshreshtha, A.K., Singh, O.N., Wall, G.M. (eds.) Pharmaceutical Suspensions: From Formulation Development to Manufacturing, pp. 285–318. Springer, New York (2010)

Luengo, E., Condón-Abanto, S., Condón, S., Álvarez, I., Raso, J.: Improving the extraction of carotenoids from tomato waste by application of ultrasound under pressure. Sep. Purif. Technol. 136, 130–136 (2014). https://doi.org/10.1016/j.seppur.2014.09.008

Periago, M.J., Rincón, F., Agüera, M.D., Ros, G.: Mixture approach for optimizing lycopene extraction from tomato and tomato products. J. Agric. Food Chem. 52(19), 5796–5802 (2004). https://doi.org/10.1021/jf049345h

Vilkhu, K., Mawson, R., Simons, L., Bates, D.: Applications and opportunities for ultrasound assisted extraction in the food industry—a review. Innov. Food Sci. Emerg. Technol. 9(2), 161–169 (2008). https://doi.org/10.1016/j.ifset.2007.04.014

Anarjan, N., Tan, C.P.: Chemical stability of astaxanthin nanodispersions in orange juice and skimmed milk as model food systems. Food Chem. 139(1–4), 527–531 (2013). https://doi.org/10.1016/j.foodchem.2013.01.012

Anarjan, N., Tan, C.P.: Effects of storage temperature, atmosphere and light on chemical stability of astaxanthin nanodispersions. J. Am. Oil Chem. Soc. 90(8), 1223–1227 (2013). https://doi.org/10.1007/s11746-013-2270-8

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Anarjan, N. Evaluation the Effects of Ultrasonic Parameters on Simultaneously Extraction and Size Reduction of Lycopene from Tomato Processing Waste. Waste Biomass Valor 11, 1929–1940 (2020). https://doi.org/10.1007/s12649-018-0528-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12649-018-0528-y