Abstract

Batch fermentation of molasses for l(+) lactic acid production using corn steep liquor (CSL) as nitrogen source by immobilized Lactobacillus (Lb.) casei MTCC 1423 has been studied. Among different tested immobilizing matrices, sodium alginate has been observed to be the best matrix for l(+)-lactic acid production. Significant reduction in cell release with double layer coated (chitosan and alginate, ACA) beads in comparison to uncoated alginate beads as well as with single layer of chitosan coated beads was observed. Stability of beads in reusability process as a function of l(+)-lactic acid production was tested and found that double layer coated alginate beads containing Lb. casei MTCC 1423 with chitosan and alginate was effective for reducing its porosity, effective l(+)-lactic acid production, enhancing stability and cell entrapment efficiency. Process conditions influence on the production of the l(+)-lactic acid production using immobilized cell system has been studied and maximum lactic acid was obtained with beads having diameter: 2.5 mm, biomass concentration: 40 g (cell dry weight, CDW)/L, shaking speed: 150 rpm, substrate concentration: 175 g/L, CSL concentration: 25 mL/L, at incubation temperature of 37 °C after incubation time of 72 h and pH 7.0.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

l(+)-Lactic acid (LA) is an organic acid and belongs to carboxylic acid family. Lactic acid naturally exists as two optical isomers that result in three types of lactic acid: l-LA, d-LA, and recemic dl-LA [1]. Chemical synthesis of lactic acid produces a recemic mixture (d&l-lactic acid) from petrochemical resources while sterio-specific lactic acid can be produced from renewable resources by fermentation process while choosing the appropriate microorganism (fungi and lactic acid bacterium, LAB) provides an alternative to the escalating environmental pollution due to petrochemical industry and inadequate petrochemical resources [2]. Lactic acid producing bacteria (LAB) have received prevalent attention worldwide among the investigators due to their ability of high growth rate and product yield. However, due the limited ability of LAB towards synthesizing amino acids and B-vitamins, there is a complex requirement of nutrient supplimenatation [3]. Over 90% of commercial lactic acid is produced by LAB through fermentation route [4].

Over the years, lactic acid has been applied in many processes of chemical, food, cosmetic, Pharmaceutical industry primarily as neutralizers, flavor enhancer, preservative etc and as a chemical feedstock for propylene oxide, acetaldehyde, biodegradable poly lactic acid (PLA) etc. [5].

Refined sugars, a conventional substrate had been utilized for the fermentive LA production, but it is expensive [6]. Currently research efforts are being focused to develop new economical and effective nutritional sources as well as new progressive sustainable fermentation techniques for achieving effective conversion of substrates to high lactic acid production [7]. Economical and efficient lactic acid fermentation is still a challenging task on many fronts and the identification of economic substrate plays an important role towards up-gradation of such processes [8]. Lactic acid manufacturing cost could be possibly reduced by using renewable raw materials like molasses, starch and lignocellulose as a cheap substrate for fermentive lactic acid production. A byproduct like molasses has been recognized as cost effective raw material for the lactic acid production as it contains sufficient nitrogen, vitamins and high sugar content [9].

Another most important nutrient for lactic acid bacteria is nitrogen. Generally, complex nitrogen addition to the fermentation broth is ensured in achieving a proper C/N (carbon to nitrogen) ratio [8]. Nitrogen sources can be organic substances, like corn steep liquor (CSL), yeast extract, peptone etc. and inorganic salts, such as ammonium nitrate and ammonium sulfate [10]. An inexpensive nitrogen sources, CSL contains high amount of amino acids and polypeptides and significant quantity of B-complex vitamins.

Immobilized LAB exhibits significant economic advantages compared to the application of free cells as it helps to reduce the production cost by coupling fermentation and separation processes and organize the lactic acid biosynthesis by non-growing cells over a longer period of time [11, 12] It also enables reutilization of cells by recycling operations, improvement in handling characteristics of microbes, attainment of higher volumetric productivities, reduction of the contamination possibilities and product/substrate inhibition etc. [12, 13]. Generally, cell entrapment, cell attachment or cell pellets formation are employed for immobilization of microbial cells [14]. Among the different fermentation conditions, immobilization matrix selection is one of the vital parameter to get sustained/improved biosynthesis of lactic acid without cell loss. Different natural matrix like agar, carrageenan, alginate, cellulose and its derivatives etc. and synthetic matrixes such as polyester, polyacrylamide, polyurethane, polystyrene etc. have been utilized for immobilization of many microbial species capable of producing lactic acid [15].

The cells may leak from the pellet due to the heterogeneous growth of the biomass immobilized inside the membrane leading to formation of a dense biofilm composed by a large number of cells in the outer surfaces near the membrane-solution interfaces and show a pseudohyphal morphology, which is capable of extending into the liquid medium [16,17,18]. Coating of the beads with the additional layer of cell free alginate can cause reductions in cell release [19, 20].

Keeping in view the above, present work was carried out for obtaining the process conditions for the development of an economical and efficient process of l(+)-lactic acid production using low cost agro-industrial waste as carbon and nitrogen source by immobilized cell system.

Materials and Methods

Materials

Sugarcane molasses was obtained from Bhagwanpura Sugar Mill Limited Dhuri, Punjab, India. CSL, waste water was obtained from Sukhjeet Industries, Phagwara, Punjab, India. Sugarcane molasses and corn steep liquor were maintained and stored at 4 °C. All the chemicals used during present experimental investigations were of analytical grade (HPLC grade for HPLC analysis) and procured from HiMedia Laboratories Pvt. Limited, Mumbai (India), Merk India Ltd., Mumabi (India), Fluka Goldie Chemika-Biochemica, Mumbai (India) and Sigma-Aldrich (USA).

Microorganism

Homofermentive, Lactobacillus (Lb.) casei MTCC 1423, was procured from Microbial Type Culture Collection (MTCC), Institute of Microbial Technology (IMTECH), Chandigarh, India. Sterile MRS (de Mann Rogosa Sharpe) broth was utilized for culturing the freeze-dried microbes for 20 h at 37 °C (0.1 g/L). The obtained culture was sub-cultured (37 °C, 20 h) twice in sterile growth medium (MRS) using 0.1 g/L of inoculums for activation and adaptation. During the experimentation, after every week the stock culture (250 mL) was sub-cultured in MRS growth medium and maintained at 4 °C.

Fermentation Media

Without pretreatment, corn steep liquor and the molasses have been diluted with deionized H2O to achieve the required sugar concentration for fermentation. Fermentation medium was prepared with molasses sugar concentration of (25–400 g/L), MnSO4 (0.02 g/L), CaCO3 (0.25 g/g sugar content) and CSL (0–35 mL/L). The pH was adjusted with 4.0 N NaOH and conc. H2SO4. Before the onset of fermentation, sterilization (121 °C, 15 psi for 20 min) of 50 mL medium contained in Erlenmeyer flasks was carried out.

Screening of Matrixes

Lb. casei MTCC 1423 cells were cultivated in MRS broth for 24 h at a controlled temperature of 37 °C. Cells were harvested aseptically after centrifuging (6700 rpm × 12 min at 4 °C) and washing with phosphate buffer (0.1 M, pH 7.0) twice. Different matrixes namely sodium alginate, chitosan, k-carrageenan, PVA-alginate and PEG-alginate were used for immobilization of Lb. casei MTCC 1423 cells. All the experiments were conducted in triplicate.

The procedure as adopted by Idris and Wahidin [21] and Kaleem et al. [22] has been utilized for entrapping Lb. casei MTCC 1423 cells in sodium alginate (20 g/L) solution which was sterilized (121 °C, 20 min) and the cells were mixed with this solution. The beads of appropriate size were formed by the dropwise addition of resultant mixture into a sterile solution of calcium chloride (0.2 M) with the help of sterilized syringe followed by hardening of beads for 30 min and washing with sodium chloride solution (8.5 g/L) and stored at 4 °C.

Lactobacillus casei MTCC 1423 cells were encapsulated in k-carrageenan (20 g/L) using the method as described by Kashipeta et al. [23]. k-carrageenan solution (20 g/L) was prepared by heating at 60 °C to dissolve k-carrageenan. Lb. casei MTCC 1423 cells were mixed with molten k-carrageenan at 40 °C and beads were formed with the help of sterilized syringe by dropping into a potassium chloride solution (20 g/L).

Lactobacillus casei MTCC 1423 cells were immobilized by entrapping into chitosan as described by Liang et al. [19]. The harvested cells were mixed with sterilized chitosan solution (20 g/L) obtained by dissolving in acetic acid solution (10 mL/L) and beads were prepared from this mixture with the help of sterilized syringe by dropping into Na5P3O10 (20 g/L) (pH 5.7) and continuously stirred. Beads were allowed to stand for 2 h to harden in a Na5P3O10 solution (20 g/L). Then beads were recollected and washed with sterile deionized water.

Lactobacillus casei MTCC 1423 cells were entrapped in poly vinyl alcohol (90 g/L)—sodium alginate (10 g/L) by following the procedure as described by Idris et al. [24] and Zain et al. [25]. The Lb. casei MTCC 1423 cells were mixed with a solution containing PVA (90 g/L) and sodium alginate (10 g/L) solution and dropped using a sterilized syringe into a solution (100 mL) obtained by mixing of calcium chloride (20 g/L) and boric acid (30 g/L) and stirred for 30–50 min. The beads were stored at 4 °C. After 24 h the beads were then the transferred into boric acid solution (10 g/L) and stirred for 30 min and afterwards beads were put into 0.5 M sodium sulphate solution for another 30 min. The beads were kept at 4 °C for further use.

The Lb. casei MTCC 1423 cells were mixed with a solution containing polyethylene glycol (200 g/L) and calcium chloride (20 g/L) and were immobilized by microencapsulation using the method as described by Sarote et al., [26]. The resulting suspension was extruded drop wise using sterilized syringe on the surface of a sterile solution containing sodium alginate (5 g/L) and Tween 80 (1 mL/L) and agitated. The beads were screened and washed with sterile deionized water and resuspended for hardening in a mildly stirred solution of CaCl2 (10 g/L), pH 6.0 for 30 min. These beads were used during lactic acid production.

Bead Coating

To study the effect of different matrices for bead coatings on cell release and production of lactic acid by Lb. casei MTCC 1423, alginate beads were coated with chitosan (AC), or sequentially with chitosan/alginate (ACA) or chitosan/alginate/chitosan (ACAC). The bead coating was carried out as described by Klinkenberg et al. [20].

A chitosan (4 g/L) solution was prepared by dissolving appropriate quantity of chitosan in acetic acid solution (10 mL/L) using magnetic stirrer and a pH of 5.6 was adjusted for coating the beads with chitosan. This solution was sterilized and then cooled. The alginate beads were immersed in it and stirred to apply a chitosan coat. After 45 min, the beads were washed with sterile distilled water after sieving off from the chitosan solution. To apply another additional alginate layer, these chitosan coated beads were transferred to a sterilized solution of sodium chloride (0.2 M) and calcium chloride (0.05 M) and stirred for 15 min. The beads were then immersed in a sodium alginate solution (5 g/L), stirred for 10 min and then washed with sterile deionized water. Afterwards these beads were put in back to a solution of sodium chloride (0.2 M) and calcium chloride (0.05 M). For applying another layer of chitosan same procedure as described above was adopted. The bead coating processes were carried out at ambient temperatures and the finished beads were stored in peptone solution (7.5 g/L) until utilized.

Process Parametric Effect on Lactic Acid Production Using Immobilization Cell System

To obtain the efficient lactic acid production by immobilized Lb. casei MTCC 1423, the effect of the molasses sugar content (25–250 g/L), effect of nitrogen source i.e. CSL (15–35 mL/L) in the fermentation media and sodium alginate concentrations (10–30 g/L) for bead formation, bead size (1.5–3.4 mm), biomass loads (6.5–55 g (CDW)/L (20 g/L sodium alginate solution)), shaking speed (0–200 rpm), incubation temperatures (23–45 °C) and pH (3.5–7.5) were investigated. All the experiments were conducted in triplicate.

The reusability of Lb. casei MTCC 1423 cells immobilized in sodium alginate without coating (SA) and with single (AC), double (ACA) and triple layer coating (ACAC) on lactic acid production was examined as per the procedure described by Reyed [27]. The fermentation media was aseptically decanted after every 72 h from each flask. Then after the addition of fresh medium the process was again continued by running the subsequent batches for 72 h intervals for the next cycle. The performance of immobilized cells was also compared with free Lb. casei MTCC 1423 cells for lactic acid production by recycling them after every 72 h.

Analytical Methods

Lactic Acid and Sugar Concentration Measurement

The fermentation broth samples were centrifuged (6700 rpm × 12 min at 4 °C) by using Eppendorf centrifuge and the supernatant thus obtained was once filtered using Whatman filter paper and then twice through a membrane filter (0.22 µm) using vacuum pump (Millipore filtration assembly) and further utilized for lactic acid concentration and sugar concentration measurement. Lactic acid concentration measurement (in triplicate) by the HPLC method [28] was carried out using Shimadzu LC 2010 CHT (Shimadzu Corporation, Kyoto, Japan) equipped with column oven, dual wavelength UV–Visible detector and low pressure quaternary gradient pump. The LC solution software was utilized for recording the chromatographic data and processing. The column oven temperature was maintained at 25 °C. The phosphate buffer (10 mM, pH 3.0) and acetonitrile at 95:5% (v/v) ratio as mobile phase was used for performing the isocratic elution. The flow rate of 1 mL/min was maintained and injection volume was 50 μL. The effluent was monitored at a wavelength of 210 nm. The internal standard curve was developed for quantification of lactic acid concentration in fermentation broth. The calibration standards were prepared using known lactic acid concentrations (10–100 mg/L) obtained by serial dilution method from a lactic acid solution (100 mg/L). The concentration of molasses total sugar was determined (in triplicate) as per the phenol sulfuric acid method [29] using the UV–visible spectrophotometer (DR 5000, HACH USA).

Biomass and Cell Leakage Determination

Both biomass in freely suspended cultures and cells leaked from the immobilizing matrix as cell dry weight (CDW) were determined by monitoring absorbance with a UV–visible spectrophotometer (DR 5000, HACH USA) of 1/10 to 1/105 dilutions of the fermentation broth samples. Cell dry weight was calculated through calibration curve relating the optical density at 660 nm to CDW (g/L) following centrifugation and washing of cells. The cell dry weight was determined by centrifuging (6700 rpm × 12 min at 4 °C) broth (MRS/molasses) sample as well blank sample of equal quantity followed by re-suspension of pallets obtained twice in phosphate buffer (0.1 M, pH 7.0) and re-centrifugation. Then these were kept in an oven (65 °C, 72 h) before weighing. The difference in the masses obtained from the broth and blank samples were taken as cell dry weight.

A series of dilutions of samples obtained after fermentation was used to establish a linear OD660 to biomass concentration (CDW) relationship. This correlation was used to convert all OD660 values to biomass concentration (CDW).

Calculation of Fermentative Parameter

Product yield (YP/S, g/g) was calculated as a slope of the curve obtained by plotting lactic acid production against total sugar consumption [30].

Results and Discussion

Screening of Matrix for the Lactic Acid Production

The efficiency of different immobilizing matrixes has been studied for lactic acid production using Lb. casei MTCC 1423. Among different immobilizing matrix, alginate was found to be the best matrix to be utilized. (Fig. 1). Result showed that at different incubation time (24, 36, 48 and 72 h), the highest lactic acid (43.23 ± 1.58, 78.76 ± 1.67, 106.75 ± 2.12 and 124.78 ± 2.34 g/L respectively) was produced by Lb. casei MTCC 1423 cells immobilized in alginate matrix compared to others (Fig. 1). The highest yield (0.928 ± 0.0232 g/g) after 72 h was also obtained by using alginate matrix. This may be due to the fact that alginate barrier constitutes a transparent semi-permeable spherical fine coat around the bacterial cells through which nutrients and metabolites readily permeate [30, 31]. Therefore alginate had been considered as best immobilization matrix to encapsulate Lb. casei MTCC 1423 cells for the lactic acid production during this study.

Effect of immobilizing matrix on lactic acid production using immobilized Lb. casei MTCC 1423 (Experimental conditions: Sugar content: 175 g/L; corn steep liquor: 25 mL/L; MnSO4: 0.02 g/L; pH 6.75; incubation temperature: 37 °C; CaCO3: 0.25 g/g sugar; bead size: 2.5 mm; 40 g (cell dry weight)/L (sodium alginate solution: 20 g/L); agitation speed: 150 rpm; incubation time: 24, 36, 48, 72 h)

Effect of Alginate Concentration

The pore size of the beads depends upon the degree of cross linking of the gelling agent. The effect of various sodium alginate concentrations (10–40 g/L) utilized for the entrapping the Lb. casei MTCC 1423 cells for the lactic acid production has been studied (Fig. 2). The lactic acid production first increased with the enhancement in sodium alginate concentration upto 20 g/L and further increment in alginate concentration had resulted in a fall in lactic acid production. It had been observed that cell leakage after 72 h of incubation time had decreased (0.72–0.21 g/L, CDW) with the increase in sodium alginate concentration (20–40 g/L). Actually, alginate concentration is also directly related with the effective diffusivity of the substrate and at its higher concentration, the bead surface become stronger and denser, causing a decrease in mass transfer diffusivity of substrate, nutrients and products transported across the bead. This may be due to the fact that the binding sites for Ca2+ ions has increased with the enhancements of biopolymer molecules per unit volume of solution, as the sodium alginate concentration increases forming probably a more densely cross-linked gel structure, which results in the formation of thinner walls [21]. There was a prominent cell leakage (2.12 g/L, CDW) from the beads formulated with low sodium alginate concentration (10 g/L), because of the production of too soft beads and thus low mechanical strength make it susceptible to be easily broken hence resulted in cell leakage from the beads when it was employed in a shaking incubator or a stirred tank reactor [31, 32]. Beads with 20 g/L alginate concentration had been noticed to produce higher amount of lactic acid (124.34 ± 2.12 g/L) and yield (0.9434 ± 0.0212 g/g) after 72 h of incubation time. Probably this may be owing to the less cross linking of the alginate molecules at this alginate concentration. Therefore it may have formed less densely packed three-dimensional lattices structure throughout the bead including the outermost layer. This could have resulted in easy transportation of nutrients and substrate into the permeable beads thus facilitates Lb. casei MTCC 1423 growth leading to increased productivity [21]. So taking into consideration, the most effective balance for permeation and strength, the polymer concentration of 20 g/L (alginate) to prepare the beads for immobilizing cells had been chosen for further study. These results were also in agreement with the previous studies, where optimum sodium alginate concentration was found to be 20 g/L [21].

Effect of alginate concentration on lactic acid production using immobilized Lb. casei MTCC 1423 (Experimental conditions: sugar content: 175 g/L; corn steep liquor: 25 mL/L; MnSO4: 0.02 g/L; pH 6.75; incubation temperature: 37 °C; CaCO3: 0.25 g/g sugar; bead size: 2.5 mm; biomass: 40 g (cell dry weight)/L (sodium alginate solution); agitation speed: 150 rpm; incubation time: 30, 48, 72 h)

Effect of Bead Coating

The effect of chitosan and alginate coatings of alginate beads enclosing/entrapping Lb. casei MTCC 1423 on the lactic acid production were studied in batch fermentations (Fig. 3). Though, lactic acid production and yield had decreased with each additional coating layer but the cell leakage was observed to decrease with the increase in the coating layers. The lactic acid produced and yield after 72 h incubation time were observed to be 127.23 ± 2.25 (g/L) and 0.92 ± 0.02 (g/g) using uncoated (SA), 124.23 ± 2.15 (g/L) and 0.906 ± 0.193 g/g using chitosan (AC) coated, 122.56 ± 2.34 (g/L) and 0.8956 ± 0.0166 (g/g) using chitosan/alginate (ACA) coated and 117.12 ± 2.02 (g/L) & 0.8645 ± 0.145 (g/g) using the chitosan/alginate/chitosan (ACAC) coated beads respectively. The decrease in lactic acid production and yield with the addition of coating layer may be owing to the decrease in the mass transfer of substrate and essential nutrients, since the electrostatic interactions between alginate carboxylate groups and divalent cations form a mechanically stable network. The cell release of 0.87 ± 0.076, 0.36 ± 0.035, 0.25 ± 0.30 & 0.15 ± 0.028 (g/L, CDW) was observed from the uncoated, chitosan, chitosan/alginate and chitosan/alginate/chitosan coated beads respectively after 72 h of incubation time. Alginate beads containing calcium carbonate microparticles are pH-sensitive beads and in the acidic conditions cavities in the matrix can be formed due to leaching out of calcium carbonate and hence leading to the possible promotion of release of cells. While alginate beads coated with chitosan results in an strong electrostatic interaction between negatively charged alginate and positively charged chitosan. Due to this interaction chitosan formed a dense coat with the surface of alginate beads in acidic condition, leading to a suppressed release [33]. Significant reduction in cell release with beads coated with chitosan and alginate in comparison to uncoated alginate beads as well as with beads coated with a single layer of chitosan had been also reported [20].

Effect of bead coating on lactic acid production using immobilized Lb. casei MTCC 1423 (Experimental conditions: Sugar content: 175 g/L; corn steep liquor: 25 mL/L; MnSO4: 0.02 g/L; pH 6.75; incubation temperature: 37 °C; CaCO3: 0.25 g/g sugar; bead size: 2.5 mm; biomass: 40 g (cell dry weight)/L (sodium alginate solution: 20 g/L); agitation speed: 150 rpm; incubation time: 36, 48, 72 h)

Lactic Acid Production Using Immobilized Cell System

The process conditions such as substrate concentration, CSL concentration, bead size, biomass concentration, shaking speed, pH, and incubation temperature and incubation time have been optimized to enhance the lactic acid production.

Effect of Substrate Concentration

Increase in lactic acid production by the immobilized Lb. casei MTCC 1423 cells and yield had been noticed with the increase in substrate concentration upto 175 g/L (Fig. 4), however with further increase in substrate concentration had caused a decrease in the lactic acid production and yield owing to the substrate inhibition [34] and moreover the high concentration of sugar concentration (molasses) makes the viscosity of the media high, imposing diffusional resistance to transport of essential nutrients as well as the product across the beads [35]. The heighest lactic acid production and yield have been obtained as 124.21 ± 1.87 g/L and 0.924 ± 0.023 g/g respectively after 72 h of incubation time and 175 g/L sugar concentration.

Effect of sugar content on lactic acid production using immobilized Lb. casei MTCC 1423 (Experimental conditions: corn steep liquor: 25 mL/L; MnSO4: 0.02 g/L; pH 6.75; incubation temperature 37 °C; CaCO3: 0.25 g/g sugar; bead size: 2.5 mm; biomass: 40 g (cell dry mass)/L (sodium alginate solution: 20 g/L); agitation speed: 150 rpm; incubation time; 24, 36, 72 h)

Effect of Nitrogen Content

Without the supplementing the media with CSL, 98.7 g/L of lactic acid was produced by immobilized Lb. casei MTCC 1423 after 72 h (Fig. 5) indicating that molasses is fortified with enough nitrogen sources necessarily required for the growth of such a fastidious organisms. The addition of CSL upto 25 mL/L tends to enhance the lactic acid production. 25% increase in the lactic acid production after 72 h of fermentation had been observed with the supplementation fermentation media with 25 mL/L CSL (Fig. 5). However further increase in CSL had decreased the amount of lactic acid produced after 72 h of fermentation. Yield (0.926 ± 0.021 g/g) had also been found to be maximum at 25 mL/L CSL.

Effect of corn steep liquor concentration on lactic acid production using immobilized Lb. casei MTCC 1423 (Experimental conditions: Sugar content: 175 g/L; MnSO4: 0.02 g/L; pH 6.73; incubation temperature 37 °C; CaCO3: 0.25 g/g sugar; bead size: 2.5 mm; biomass: 40 g (cell dry mass)/L (sodium alginate solution: 20 g/L); agitation speed: 150 rpm; incubation time: 24, 48, 72 h)

Effect of pH

At initial pH 6.5–7, the metabolic activities of immobilized Lb. casei MTCC 1423 cells were observed to be at best since the microbes had started utilizing molasses sugar earlier at a faster rate compared to other initial pH (Fig. 6) Further increase has caused a decrease in lactic acid production as well as in yield. The organism metabolic abilities may be got too much stressed at higher initial pH [21]. The product inhibition enhances as the medium pH is farther away from the internal pH maintained by the bacteria. Though the dissociated as well as undissociated lactic acid had inhibitory effect on its production but the undissociated lactic acid cause more inhibition in comparison to dissociated one. As the pKa for lactic acid is 3.86, so at low pH the high fraction of undissociated lactic acid resulted in low cell growth hence low lactic acid production [36]. It had been observed from the data that the immobilized Lb. casei MTCC 1423 seems to grow well and perform efficiently in a neutral environment having initial pH range of 5.5–7.5, with best lactic acid production (125.23 ± 2.67 g/L) at around initial pH 7. Different microbes have different pH optima [34]. For a homofermentative process in a recycle batch reactor, lactic acid production by immobilized Lb. casei at pH of 6.0 was found to be optimal [37].

Effect of pH on lactic acid production using immobilized Lb. casei MTCC 1423 (Experimental conditions: Sugar content: 175 g/L; corn steep liquor: 25 mL/L; MnSO4: 0.02 g/L; temperature: 37 °C; CaCO3: 0.25 g/g sugar; bead size: 2.5 mm; biomass: 40 g (cell dry weight)/L (sodium alginate solution: 20 g/L); agitation speed: 150 rpm; incubation time: 24, 48, 72 h)

Effect of Bead Size

The effect of bead size (1.5–3.4 mm) on the lactic acid production and yield by immobilized Lb. casei MTCC 1423 cells has been revealed in Fig. 7. Maximum lactic acid concentration (123.67 ± 2.1 g/L) and the yield (0.918 ± 0.02 g/g) were attained after 72 h with the 2.5 mm bead diameter. Increasing the bead size beyond 2.5 mm had not improved lactic acid production. The beads of 3.4 mm diameter with immobilized cells had resulted in a decrement in the production of lactic acid (112.34 ± 2.19 g/L) and yield (0.851 ± 0.021 g/g). The results were in agreement with the previously reported work where the maximum phenol removal rate was observed for smallest particle (0.2 cm) since the diffusional limitations got enhanced with the increase in bead size [34]. Maximum lactic acid concentration using Lb. bifermentans immobilized in Ca-alginate was obtained with the 2 mm bead diameter [38].

Effect of bead size on lactic acid production using immobilized Lb. casei MTCC 1423 (Experimental conditions: sugar content: 175 g/L; corn steep liquor: 25 mL/L; MnSO4: 0.02 g/L; pH 6.75; CaCO3: 0.25 g/g sugar; incubation temperature: 37 °C; bead size: 2.5 mm; biomass: 40 g (cell dry weight)/L (sodium alginate solution:20 g/L); agitation speed: 150 rpm; incubation time: 36, 48, 72 h)

The bead size of 2.41–2.79 mm had been reported to be optimum for the peak level of lactose consumption and lactic acid production from whey [39]. The density of S. cerevisiae encapsulated in alginate–chitosan–alginate microcapsules with smaller diameter (200 μm) was found to reach the highest and had fewer aggregates and higher cell growth rate [40]. Therefore bead size of 2.5 mm was considered for lactic acid production using double layer coated (ACA) sodium alginate beads for lactic acid production.

Effect of Biomass Concentration

The effect of biomass concentration loaded in the beads on the lactic acid production and yield was investigated by incorporating 6.5–55 g (cell dry weight) biomass of Lb. casei MTCC 1423 cells in 1 L of sodium alginate (20 g/L) solution. The maximum lactic acid production of 128 ± 2.03 g/L and 0.922 ± 0.022 g/g yield was observed with a biomass of 40 g (CDW)/L after 72 h of incubation time (Fig. 8). Further enhancement in biomass concentration had led to decrease in lactic acid production as well as the yield. The increase in biomass beyond a threshold value may affect the cell growth rate due to space limitation within the matrix causing arrest of growth and hence decrease in lactic acid production [17].

Effect of immobilized biomass loading (Lb. casei MTCC 1423) on lactic acid production (Experimental conditions: sugar content: 175 g/L; corn steep liquor: 25 mL/L; MnSO4: 0.02 g/L; pH 6.75; incubation temperature: 37 °C; CaCO3: 0.25 g/g sugar; bead size: 2.5 mm; sodium alginate: 20 g/L; agitation speed: 150 rpm; incubation time: 48, 72 h)

Effect of Agitation

The lactic acid production as well as the yield has been observed to increase with increase in agitation (Fig. 9). Since the efficiency of immobilized system depends upon the transport capability and the metabolic activity within the beads. The diffusional activity becomes the rate limiting step as soon as the rate of substrate consumption and production reaches at a certain level. The diffusion process is controlled by the fluid film formed around the beads. It offers resistance to mass transfer and is affected by the bead diameter, viscosity and agitation. Agitation increases the external mass transfer coefficient causing enhanced diffusion of substrate and other essential nutrients through the immobilized beads and it also act synergistically with the CaCO3 added in the fermentation medium resulting in highest lactic acid production (128.45 ± 2.2 g/L) and yield (0.935 ± 0.023 g/g) at 150 rpm after 72 h. Agitation of the fermentation media causes more efficient uniform distribution of substrate and lactic acid produced in the fermentation broth leading to better mass transfer between solid particles of CaCO3 and the fermentation media, hence enabling efficient neutralization of lactic acid produced during the fermentation [41]. The increase in agitation beyond 150 rpm, where mass transfer is dominated by mechanical shaking didn’t improve the lactic acid production as well as yield. Hence agitation was controlled at 150 rpm for lactic acid production by immobilization Lb. casei MTCC 1423, with a consideration to maintain minimum possible shear stress on the beads containing cells.

Effect of agitation on lactic acid production using immobilized Lb. casei MTCC 1423 (Experimental conditions: sugar content: 175 g/L; corn steep liquor: 25 mL/L; MnSO4: 0.02 g/L; pH 6.75 incubation temperature 37 °C; CaCO3: 0.25 g/g sugar; bead size: 2.5 mm; biomass: 40 g (cell dry weight)/L (sodium alginate solution: 20 g/L); incubation time: 36, 48, 72 h)

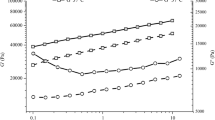

Effect of Incubation Temperature

The effect of temperature (23–45 °C) on the lactic acid production and yield by immobilized Lb. casei MTCC 1423 cells has been presented in Fig. 10. The highest lactic acid production of 126.56 ± 2.53 g/L and 0.92 ± 0.024 g/g, yield after 72 h fermentation from 175 g/L molasses sugar content was obtained at 37 °C. These immobilized cells were showing variable ability to produce lactic acid from 23 to 45 °C as most species have a characteristic temperature range in which they have the ability but not at same growth rate over the whole range of temperature. The performance of immobilized Lb. casei MTCC 1423 cells seems to be reasonably good at the temperature range of 33 to 42 °C. Since the microbial growth hence the production is chemical reaction rate controlled and is catalyzed by enzymes within cell which in turn depends upon temperature [21]. Goranov et al. [11] had reported that lactic acid was more accumulated at 42°С with encapsulated Lb. casei ssp. rhamnosus ATCC 11979 cells in alginate/chitosan complexes.

Effect of temperature on lactic acid production using immobilized Lb. casei MTCC 1423 (Experimental conditions: sugar content: 175 g/L; corn steep liquor: 25 mL/L; MnSO4: 0.02 g/L; pH 6.75; CaCO3: 0.25 g/g sugar (w/w); bead size: 2.5 mm; biomass: 40 g (cell dry weight)/L (sodium alginate solution: 20 g/L); agitation speed: 150 rpm, incubation time: 24, 48, 72 h)

Reusability of Alginate Beads for Lactic Acid Production

During the reusability tests, the lactic acid production had been observed to be consistent till fourth (SA), seventh (CA) and ninth cycle (ACA) and decreased by 52, 25 and 7%, after ninth cycle with immobilized uncoated, chitosan-coated and chitosan-alginate coated sodium alginate beads respectively (Fig. 11).

Reusability of alginate beads for lactic acid production by immobilized Lb. casei MTCC 1423 (Experimental conditions: Sugar content: 175 g/L; corn steep liquor: 25 mL/L; MnSO4: 0.02 g/L; pH 6.75; CaCO3: 0.25 g/g sugar; incubation temperature 37 °C; bead size: 2.5 mm; biomass: 40 g (CDW)/L (sodium alginate solution: 20 g/L); agitation speed: 150 rpm; incubation time: 72 h)

In comparison to the lactic acid production by free cells, immobilized cells provide operational stability high productivity, and decreased product contamination by free cells (Fig. 11). The higher production with immobilized cells could be attributed to the minimal cells growth in the matrix and also to the retention of enzymatic activity at the higher level in immobilized cells as compared to in free cells [42]. Hence double layer coating with chitosan and alginate had been utilized for coating alginate beads for reducing its porosity, effective lactic acid production, enhancing stability and cell entrapment efficiency [43,44,45]. As evident from Fig. 7, an elevated immobilization efficiency by double layer coated (chitosan and alginate) calcium alginate beads for entrapping the Lb. casei MTCC 1423 cells and for lactic acid production from molasses had been exhibited in comparison to the traditional without coated calcium alginate, single coated (chitosan) beads and by free cells. The lactic acid production as investigated by Zijjan et al. [46] has been observed to be decreased after three batches from the calcium alginate beads owing to the decreased concentration of cells in beads due to gradual disintegration of calcium alginate beads leading to liberation of Lb. rhamnosus cells into media. Three to four time reused saccharomyces cerevisiae immobilized in calcium alginate beads has been reported to provide the best result in terms of fermentation time and ethanol yield [47]. Alginate beads entrapping B. succiniciproducens for succinic acid production were reported to be reused in four sequential fed-batch fermentations producing totally 64.7 g acid from 114.55 g sugar consumed and reduction in yield as well as productivity was observed due to significant rupture of the beads after fourth cycle by Alexandri et al. [48].

Conclusion

Among different immobilizing matrices studied using Lb. casei MTCC 1423, alginate (20 g/L) was found to be the best matrix to be utilized for lactic acid production. Significant reduction in cell leakage from double layer coated beads (coated with chitosan and alginate) in comparison to uncoated alginate beads as well as with chitosan a coated beads (single layer) was observed. Stability of beads in reusability process as a function of lactic acid production was tested and found that double layered coated alginate beads containing Lb. casei MTCC 1423 with chitosan and alginate was effective upto ninth cycle for reducing its porosity, effective lactic acid production from molasses an agro-industrial waste, enhancing stability and cell entrapment efficiency. The optimal process conditions featured beads diameter (2.5 mm), biomass concentration (40 g(CDW)/L), shaking speed (150 rpm), substrate concentration (175 g/L), CSL concentration (25 mL/L), incubation temperature (37 °C) at incubation time of 72 h and pH (7.0) were obtained.

References

Cuong, M.N., Gyung, J.C., Yong, H.C., Kyoung, S.J., Jin-Cheol, K.: d- and l-lactic acid production from fresh sweet potato through simultaneous saccharification and fermentation. Biochem. Eng. J. 81, 40–46 (2013)

Niju, N., Pradip, K.R., Aradhana, S.: L(+) lactic acid fermentation and its product polymerization. Electron. J. Biotechnol. 7(2), 167–179 (2004)

Abdurahman, H.N., Nuraini, M.: Chemical destabilization on water in crude oil emulsions. World Acad. Sci. Eng. Technol. 38, 700–703 (2010)

Jinglan, W., Yanan, H., Jingwei, Z., Wenbin, Q., Xiaoqing, L., Yong, C., Xiaochun, C., Jingjing, X., Jianxin, B., Hanjie, Y.: Separation of d-lactic acid from aqueous solutions based on the adsorption technology. Colloids Surf. A 407, 29–37 (2012)

Young, J.W., Kim, J.N., Ryu, H.W.: Biotechnological production of lactic acid and its recent applications. Food Technol. Biotechnol. 44(2), 163–172 (2006)

Mohammad, A.B., Janakiram, N., Gopal, R.: Screening of inexpensive nitrogen sources for production of L(+) lactic acid from starch by amylolytic Lactobacillus amylophilus GV6 in single step fermentation. Food Technol. Biotechnol. 43(3), 235–239 (2005)

Ali, H.J., Abbas, F.M.A., Ogugbue, C.J., Azhar, M.E., Norulaini, N.A.N.: Production of the lactic acid from mango peel waste: factorial experiment. J. King Saud. Univ. Sci. 25, 39–45 (2013)

Ying, W., Yukihiro, T., Kenji, S.: Fermentative production of lactic acid from renewable materials: recent achievements, prospects, and limits. J. Biosci. Bioeng. 119(1), 10–18 (2015)

Anjana, D.N., Surendra, K.: Kinetic modeling of lactic acid production from molasses using Enterococcus faecalis RKY1. Biochnol. Eng. J. 38(3), 277–284 (2008)

Zhan, Y.Z., Bo, J., Joan, M.K.: Production of lactic acid from renewable materials by Rhizopus fungi. Biochem. Eng. J. 35(3), 251–263 (2007)

Goranov, B., Blazheva, D., Kostov, G., Denkova, Z., Germanova, Y.: Lactic acid fermentation with encapsulated Lactobacillus casei ssp. rhamnosus ATCC 11979 (NBIMCC 1013) in alginate/chitosan matrices. Bulg. J. Agric. Sci. 19(2), 101–104 (2013)

Mohamed, A.A.-R., Yukihiro, T., Kenji, S.: Recent advances in lactic acid production by microbial fermentation processes. Biotechnol. Adv. 31, 877–902 (2013)

Zijian, Z., Xiaona, X., Zhi, W., Yanchun, T., Xuedun, N., Xuri, H., Li, L., Zhengqiang, L.: Immobilization of Lactobacillus rhamnosus in mesoporous silica-based material: an efficiency continuous cell-recycle fermentation system for lactic acid production. J. Biosci. Bioeng. 121(6), 645–651 (2016)

Min-Tian, G., Takashi, S., Nobuhiro, I., Haruo, T.: Fermentative lactic acid production with a metabolically engineered yeast immobilized in photo-crosslinkable resins. Biochem. Eng. J. 47, 66–70 (2009)

Chaganti, S.R., Reddy, S.P., Adari, B.R., Jhillu, S.Y.: Production of L(+) lactic acid by Lactobacillus delbrueckii immobilized in functionalized alginate matrices. World J. Microbiol. Biotechnol. 24, 1411–1415 (2008)

Jerome, L., Jean-Claude, V.: Diffusion-reaction-growth coupling in gel-immobilized cell systems: model and experiment. Enzyme Microbiol. Technol. 17, 276 – 284 (1995)

Greenberg, N., Tartakovsky, B., Yirme, G., Ulitzur, S., Sheintuch, M.: Observations and modeling of growth of immobilized microcolonies of luminous E.coli. Chem. Eng. Sci. 51(5), 743–756 (1996)

Perez-Bibbins, B., Salgado, J.M., Torrado, A., Aguilar-Uscanga, M.G., Dominguez, J.M.: Culture parameters affecting xylitol production by Debaryomyces hansenii immobilized in alginate beads. Process Biochem. 48, 387–397 (2013)

Liang, Z.P., Feng, Y.Q., Meng, S.X., Liang, Z.Y.: Prepration and properties of urease immobilized onto cross-linked chitosan beads. Chin. Chem. Lett. 16, 135–138 (2005)

Klinkenberg, G., Lystad, K.Q., Levine, D.W., Dyrset, N.: Cell release from alginate immobilized Lactococcus lactis ssp. lactis in chitosan and alginate coated beads. J. Dairy Sci. 84, 1118–1127 (2010)

Idris, A., Wahidin, S.: Effect of sodium alginate concentration, bead diameter, initial pH and temperature on lactic acid production from pineapple waste using immobilized Lactobacillus delbrueckii. Process Biochem. 41, 1117–1123 (2006)

Kaleem, I., Shen H., Lv., B.L., Wei, B., Rasool, A., Li, C.: Efficient biosynthesis of glycyrrhetic acid 3-O-mono-β-d-glucuronide (GAMG) in water-miscible ionic liquid by immobilized whole cells of Penicillium purpurogenum Li-3 in alginate gel. Chem. Eng. Sci. 106, 136–143 (2014)

Kashipeta, R., Tadimalla, P., Katikala, P., Nalli, V.: Immobilization of cyclodextrin glycosyltransferasevfrom newly isolated, mutated Bacillus sp. TPR71HNA6 by entrapment technique. Adv. Appl. Sci. Res. 3(4), 2288–2298 (2012)

Idris, A., Zain, N.A.M., Suhaimi, M.S.: Immobilization of Baker’s Yeast in PVA-alginate matrix using innovative immobilization technique. Process Biochem. 43, 331–338 (2008)

Zain, N.A.M., Suhaimi, M.S., Idris, A.: Hydrolysis of liquid pineapple waste by invertase immobilized in PVA-alginate matrix. Biochem. Eng. J. 50, 83–89 (2010)

Sarote, S., Tiyaporn, L., Wirat, V., Thongchai, S., Henry, H.C., Yusuf, C.: Optimization of lactic acid production by immobilized Lactococcus lactis IO-1. J. Ind. Microbiol. Biotechnol. 34, 381–391 (2007)

Reyed, M.R.: Biosynthesis and properties of extracellular amylase by encapsulation of Biofidobacterium bifidium in batch culture. Aust. J. Basic Appl. Sci. 1, 7–14 (2007)

Ginjupalli, K., Armugam, K., Shavi, V.G., Averineni, R.K., Mahalingam, B., Udupa, N.: Development of RP-HPLC method for simultaneous estimation of Lactic acid and glycolic acid. Der Pharma Chem. 5(4), 335–340 (2013)

Dubois, M., Gilles, K.A., Hamilton, J.K., Robers, P.A., Smith, F.: Colorimetric method for determination of sugar and related substances. Anal. Chem. 28, 350–356 (1996)

Lilina, S.C., Aida, R.D.S.: Lactic acid production by a strain of Lactococcus lactics subs lactis isolated from sugar cane plants. Electron. J. Biotechnol. 9(1), 40–45 (2006)

Suchata, K., Muenduen, P.: Bacterial cellulose-alginate composite sponge as a Yeast cell carrier for ethanol production. Biochem. Eng. J. 77, 103–109 (2013)

Xiaobei, W., Jie, L., Guocheng, D., Jingwen, Z., Jian, C.: Efficient production of l-sorbose from d-sorbitol by whole cell immobilization of Gluconobacter oxydans WSH-003. Biochem. Eng. J. 77, 171–176 (2013)

Yeon, J.H., Mi-Sun, L., Jin-Chul, K.: pH-dependent release of alginate beads coated with polylysine. J. Ind. Eng. Chem. 17, 410–414 (2011)

Arzu, Y.D., Ozlem, T.: Internal mass transfer effect of biodegradation of phenol by ca-alginate immobilized Ralstonia eutropha. J. Hazard. Mater. B126, 105–111 (2005)

Sule, B., Elibol, M., Ozer, D.: Effect of different carbon sources on l-(+)-lactic acid production by Rhizopus oryzae. Biochem. Eng. J. 21, 33–37 (2004)

Wenge, F., Mathews, A.P.: Lactic acid production from lactose by Lactobacillus plantarum: kinetic model and effects of pH, substrate, and oxygen. Biochem. Eng. J. 3, 163–170 (1999)

Appadurai, S., Vasanthe, S., Rajni, H., Bo, M.: Lactic acid production by immobilized Lactobacillus casei in recycle batch reactor: a step towards optimization. J. Biotechnol. 73, 61–70 (1999)

Sebastien, G., Vincent, P., Francis, D.: Lactic acid production from hemicellulosic hydrolyzate by cells of Lactobacillus bifermentans immobilized in Ca-alginate using response surface methodology. World J. Microbiol. Biotechnol. 24, 745–752 (2008)

Panesar, P.S., Kennedy, J.F., Knill, C.J., Kosseva, M.R.: Applicability of pectate-entrapped Lactobacillus casei cells for L(+) lactic acid production from whey. Appl. Microbiol. Biotechnol. 74, 35–42 (2007)

Qi, W., Yu, W., Xie, Y., Ma, X.: Optimization of Saccharomyces cerevisiae culture in alginate-chitosan-alginate microcapsule. Biochem. Eng. J. 25, 151–157 (2005)

Aleksandra, P., Djukic, V., Ljiljana, V.M., Maja, S.V., Marica, B.R., Svetlana, B.N., Jelena, D.P., Maja, L.B.: Effect of different fermentation parameters on l-lactic acid production from liquid distillery stillage. Food Chem. 134, 1038–1043 (2012)

Lingappa, K., Syeda, A., Vishalakshi, N., Prabhakar, M.: Immobilization of Streptomyces gulbargensis in polyurethane foam: a promising technique for L-asparaginase production. Iran. J. Biotechnol. 7(4), 199–204 (2009)

Serp, D., Cantana, E., Heinzen, C., Von, S.U., Marison, I.W.: Characterization of an encapsulation device for the production of monodisperse alginate beads for cell immobilization. Biotechnol. Bioeng. 70(1), 41–53 (2000)

Krasaekoopt, W., Bhandari, B., Deeth, H.: The influence of coating materials on some properties of alginate beads and survivability of microencapsulated probiotic bacteria. Int. Dairy J. 14(8), 37–743 (2004)

Chavarri, M., Maranon, I., Ares, R., Ibanez, F.C., Marzo, F., Villaran, M.D.C.: Microencapsulation of a probiotic and prebiotic in alginate-chitosan capsules improves survival in simulated gastro-intestinal conditions. Int. J. Food Microbiol. 142(1–2), 185–189 (2010)

Zhao, Z., Xiaona, X., Wang, Z., Tao, Y., Niu, X., Huang, X., Liu, L., Li, Z.: Immobilization of Lactobacillus rhamnosus in mesoporous silica-based material: an efficiency continuous cell-recycle fermentation system for lactic acid production. J. Biosci. Bioeng. 121(6), 645–651 (2016)

Alexandri, M., Papapostolou, H., Stragier, L., Verstraete, W., Papanikolaou, S., Koutinas, A.A.: Succinic acid production by immobilized cultures using spent sulphite liquor as fermentation medium. Bioresour. Technol. 238, 214–222 (2017)

Lee, K.H., Choi, I.S., Kim, Y.-G., Yang, D.-J., Bae, H.-J.: Enhanced production of bioethanol and ultrastructural characteristics of reused Saccharomyces cerevisiae immobilized calcium alginate beads. Bioresour. Technol. 102, 8191–8198 (2011)

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Thakur, A., Panesar, P.S. & Saini, M.S. l(+)-Lactic Acid Production by Immobilized Lactobacillus casei Using Low Cost Agro-Industrial Waste as Carbon and Nitrogen Sources. Waste Biomass Valor 10, 1119–1129 (2019). https://doi.org/10.1007/s12649-017-0129-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12649-017-0129-1