Abstract

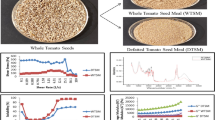

Capia pepper seeds are the mass waste of pepper utilization, and they have not commonly utilized as raw materials. In this study, the defatted press cakes (or meals) of cold oil pressed capia pepper seeds were evaluated. The pepper seeds were previously roasted and treated with enzymes (hemicellulase and protease) against control, before pressing. The compositional and functional properties of the defatted meals were determined. Moisture, protein, remaining oil, ash, L, a*, b* values and viscosity of the meals were measured by basic physicochemical analyses. Phytic acid, tannins and mineral contents were also determined. As functional properties, water-holding capacity, oil-holding capacity, emulsion activity, emulsion stability, foaming capacity, foam stability and the least gelation concentration were measured. The meals were shown to contain nutritionally important amounts of protein and minerals. For most functional properties, seed roasting caused some enhancements in the meals. Hence, defatted capia pepper seed meals can be utilized in food formulations due to their good nutritional and functional properties. This study points out the possibility and advantages of pepper seed meal valorization.

Graphical Abstract

(1) Capia pepper seed press cakes (meals) were used in this study. (2) Functional and physicochemical properties of the meals were measured. (3) The meals included good levels of proteins and some minerals. (4) The meals had functionalities for water and oil holding, emulsification and foaming. (5) The meals could be used in food formulations for enhanced functionalities.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Valorization of agro-food processing by-products and wastes has been gaining more attention recently as research area due to the increasing food demand of fast-growing world population, deficiencies in the feed supply and global bioenergy demands. It was estimated that up to 39 % of food waste occurs during food manufacturing, and 5 % occurs within food distribution systems. Hence, valorization of food processing wastes is actually a necessity for sustainable agriculture and economy [1, 2].

In Turkey, the world second largest (2.300.000 tons in 2013) pepper (Capsicum annuum L.) producer, at least half of the annual harvested peppers, are processed to sauces, canned peppers, smoked peppers, etc. [3]. During processing, the pepper seeds are removed and produced as clean and semidry solid waste. Pepper seeds are flat, disklike materials with 2.5–6.5 mm length, 0.5–5.0 mm width and 0.1–1.0 mm thickness. Usually, seeds comprise about 20 % of dry fruit weight. Thousand seeds weight varies from 5.0 to 8.0 g depending on the variety [4]. The only current valorization of pepper seeds in Turkey is cattle feeding, and in fact due to transportation problems, most seeds are discarded as waste. Hence, more efficient utilization of this waste is important from economic and environmental point of view [5]. Compositions of various red pepper seeds were reported as 3.0–4.8 % ash, 13.0–19.0 % protein, 18–30 % crude lipid, 40–65 % total dietary fiber, 0.09–5.32 mg capsaicin, 0.01–2.17 mg dihydrocapsaicin, 1.6–5.0 % organic acids, 2.88 g/100 g phytic acid, 2.89 g/100 g tannins and 2.20 mg/g trypsin inhibitors [5–7].

There are very limited numbers of studies about valorization of pepper seeds. In a previous study [8], response surface methodology was used to determine the optimum protein extraction conditions from red pepper seeds, and 12.24 g protein from 100 g defatted red pepper seed flour was obtained at 31 °C temperature, 8.8 pH, 20 min extraction time and 21:1 (v/w) solvent/meal ratio extraction conditions. In another study [9], capia pepper seeds were used to produce oil by cold pressing technique. The effects of pre-roasting and enzyme treatments of seeds on oil yield and oil quality parameters were determined. The press cakes (meals) obtained during that study were used as the material subjects of this study. Since the seeds were very clean and pure, and cold pressing conditions were not harsh, the meals (or press cakes) could be utilized as human food source.

Oilseed meals and proteins extracted from meals have been considered as good materials for human food sources [10–14]. In most of these studies, the main physicochemical properties for both meals and protein extracts were determined, but only limited number of studies reported the functional properties of the oilseed meals. In only one study [15], some functional properties of red pepper seed flour and protein were reported.

Hence, the objectives of this study were to characterize the physicochemical and functional properties of cold-pressed capia pepper seed meals to evaluate their possible food applications. This study is the first one for pepper seeds meals, while similar studies exist for various oilseed and kernel meals. Hence, the results of this study may aid valorization of pepper seed meals for human food usages.

Materials and Methods

Materials

In this study, the defatted meals obtained from cold-pressed capia pepper seed (Capsicum annuum L.) samples were used. The meals were obtained in the previous study [9] of capia pepper seeds cold pressing to produce oil, and the meals were immediately used for this study. All chemicals and standards used for the analyses were of analytical grade and purchased from Merck (Darmstadt, Germany) and Sigma-Aldrich (St. Louis, USA).

Defatting of the Press Cakes

The meals of the cold-pressed capia pepper seeds were used as the starting material for this study. Briefly, the seeds were roasted at 150 °C in a conventional oven (Ecocell Drying Oven, Germany) for 25 min for roasting treatment, and incubated with 100 U/g meal hemicellulase and 0.25 U/g meal protease which were dissolved in phosphate-citrate buffer (pH 6.0) at 60 °C for 3 h. Cold pressing of the seeds was carried out with a laboratory-scale cold press machine (Koçmaksan ESM 3710, İzmir, Turkey), and the collected press cakes or meals were used for this study [9]. The control sample was obtained by applying no pretreatment to the seeds prior to cold pressing. The remaining oil from the pepper seed meals was removed according to Manamperi et al. [16] with some modifications. The meal was mixed with hexane (1:4, w/v) and stirred at 150 rpm for 1 h at room temperature (25 °C), before decantating the solvent. The same procedure was repeated three times. Then, hexane in the wet meal was removed in forced-air oven at 60 °C for 1 h. Finally, the oil-free meals were stored under fume hood for 24 h to remove traces of the solvent by providing natural air flow. Defatted pepper seed meals (DPMs) were then ground to pass through 75 mesh screen and filled in brown-colored glasses and capped. The samples were labeled and kept at −20 °C until and during analysis.

Physicochemical Analyses

Proximate Composition

Ohaus MB45 moisture analyzer was used for moisture content determination (1 g sample, 110 °C, 30 min). Crude protein was determined by the Kjeldahl technique (method Aa 5–38) [17]. Oil contents of the DPM samples were determined by Soxhlet technique of AOAC 920.39 [18]. Total ash of the DPM samples was measured according to the Ba 5a–49 method [17].

Color Measurement

The color parameters (L, a* and b*) of the DPM samples were measured with a Minolta CR-400 Reflectance colorimeter (Osaka, Japan) calibrated with white tile, and analysis was performed on several different points of samples placed in a glass petri.

Viscosity Measurement

The technique of Khalid et al. [19] was followed for the apparent viscosity measurement of DPM dispersions. DPM dispersions (20 %, w/v) were prepared, and pH was adjusted to 7.0 by 1 N HCI or NaOH. Then, the viscosity of the dispersions was measured at 25 °C set by a water bath circulating around the sample holder with 30 rpm speed of the spindle. Brookfield DV II. Pro viscosimeter with Rheocalc software (Brookfield Eng. Lab., Inc., MA, USA) equipped with no. 18 spindle was used for the measurements, and apparent viscosities were recorded as centipoise (cP) values.

Phytic Acid Contents

The AOAC method 986.11 [20] was followed for phytic acid measurements. Two grams of DPM was extracted with 40 ml of HCI (2.4 %, v/v) and shaken at 150 rpm for 3 h at 25 °C, before filtrating the slurry through Whatman no. 1 filter paper. The extract was diluted with 25 ml Na2EDTA–NaOH solution (1:1, v/v). An ion-exchange column was prepared with Dowex® AG 1 × 4 chloride resin (100–200 μm) and washed with 15 ml of 0.7 M NaCl solution and 15 ml of water. Then, the diluted extract was transferred to the column. The first two elutions were done with 15 ml water and 15 ml 0.1 M NaCl, and the eluates were discarded. The final elution with 15 ml 0.7 M NaCl was collected. Finally, 0.5 ml H2SO4 + 3 ml HNO3 was added to the final eluate containing phytate and wet ashing was applied according to Kjeldahl method. The phytate salts were dissolved in 100 °C water bath after adding 10 ml distilled water. Then, 2 ml molybdate and 1 ml sulfonic acid solutions were added and completed to 25 ml with distilled water to complete the reaction in 15 min. After the reaction, spectrophotometric analyses were performed at 640 nm (Agilent 8453 UV–visible spectrophotometer, Waldbronn, Germany). Standard curve was prepared with potassium acid phosphate, and phytate content (mg P/g) was calculated.

Tannin Contents

Condensed tannins present in the DPM samples were measured by the modified methods of Price et al. [21] and Hagerman [22]. DPM sample (0.5 g) and 10 ml methanol were stirred at 150 rpm for 30 min at room temperature (25 °C) and centrifuged at 2291×g for 10 min. The extracts were collected and placed into tubes, before addition of 5 ml 1 % vanillin solution (dissolved in 8 % HCI). The tubes were incubated in 30 °C water bath at dark place for 20 min. Finally, the absorbance was measured at 500 nm by spectrophotometer (Agilent 8453 UV–visible spectrophotometer, Waldbronn, Germany). A standard curve was prepared with catechin. Tannin content was calculated as catechin equivalents per gram sample.

Mineral Contents

Wet ashing was applied to prepare the DPM samples for mineral analysis. Half gram DPM sample was heated gradually with 100 ml HNO3 (65 %) on hot plate (90 °C—30 min, 100 °C—30 min, 150 °C—30 min, 200 °C—30 min, 300 °C until a clear solution was obtained) under fume hood. Then, the clear solution was diluted to 25 ml with distilled–deionized (DI) water. Finally, the mineral contents were determined by ICP-AES (Varian Liberty II AX Sequential, Australia) with appropriate dilutions of AccuTrace reference standards (New Haven, USA) for curve calibration.

Functional Properties

Water-Holding Capacity

Water-holding capacity (WHC) of the samples was determined according to Moure et al. [23] and Manamperi et al. [16]; 5.0 g sample and 20 ml DI water (pH 7.0) were mixed for 30 min and centrifuged at 2291×g for 15 min. After draining the supernatant, the tubes were inverted and weighed after 30 min. The initial weight and the final weight difference of the samples were calculated, and the WHC was expressed as g water/g sample.

Oil-Holding Capacity

Oil-holding capacity (OHC) of the samples was measured by the technique of Manamperi et al. [16]. 2.0 g sample and 10 ml sunflower oil were vortexed for 1 min and centrifuged at 2291×g for 15 min. After draining the oil phase, the tubes were inverted, left for 60 min, and weighed. The difference between the initial weight and the final weight of the sample was determined as the OHC and was expressed as g oil/g sample.

Emulsifying Activity and Emulsion Stability

The method of Wu [24] was used for these measurements. DPM, water and sunflower oil were (7:100:100, w:v:v) weighed and homogenized at 10.000 rpm for 1 min. Then, the tubes were centrifuged at 2291×g for 5 min. Emulsifying activity (EA) was calculated by the following formula;

The emulsion stability (ES) was determined through keeping the emulsion which was prepared as above at 80 °C water bath for 30 min, and then rapidly cooled with running tap water and ice. Finally, the tubes were centrifuged at 2291×g for 5 min and emulsion stability (ES) was determined by the following formula;

Foaming Capacity and Foam Stability

Foaming capacity (FC) and foam stability (FS) were measured according to Cano-Medina et al. [25] and Kanu et al. [26] methods; 3.0 g DPM sample was mixed with 100 ml DI water, and pH was adjusted to 7.0 with 1 N HCI or 1 N NaOH. After shaking with Waring blender at highest speed for 3 min at room temperature (25 °C), the mixture was poured into a 250-ml volumetric cylinder. The foaming liquid volume capacity (FC) was reported by the formula;

The tubes were left at room temperature (25 °C) for 30 min, and then the remaining foam was recorded again to calculate the foam stability (FS) by the formula;

Least Gelation Concentration

The method of Moure et al. [23] was modified for the least gelation concentration (LGC) measurement; 40 % (w/v) dispersions of DPM samples in DI water were prepared, and pH was adjusted to 7.0 with 1 N HCI or 1 N NaOH. From this stock solution, dilution series of 38, 34, 32, 28, 24, 20, 18, 16, 14, 12 and 10 % (w/v) were prepared. The pH values of the solutions were adjusted again to pH 7.0 and vortexed for 2 min. The liquid portions of the dispersion (5 ml) were taken into tubes, and the tubes were kept in water bath at 100 °C for 1 h. Finally, the tubes were cooled under running tap water and visually examined for solid gel structure that remained fixed in the tube wall. Solid gel, liquid gel and clot structures were defined according to Moure et al. [23].

Statistical Analysis

The capia meals obtained from the previous study as the two replicates were the two sample replicates in this study. For each replicate sample, all analyses were accomplished at least twice in this study. The data were reported as mean ± standard deviation. Data analysis was performed by two-way analysis of variance (ANOVA) and Tukey’s multiple comparison tests. Statistical analyses were performed with Minitab v. 16.1 [27] and SPSS software [28] programs. The level of confidence was at least 95 % for all tests.

Results and Discussion

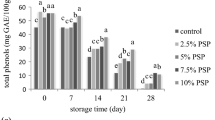

Physicochemical Properties

The physicochemical properties of the defatted capia pepper seed meals are presented in Table 1. There are some statistically significant differences among the samples for the measured properties. The highest moisture content was in the enzyme (hemicellulase and protease)-treated sample meal. It might be caused by the high remaining water after enzyme slurry incubation of the seeds. Moisture content of meals could be very important for storage stability. For long-term storage, drying should be done. The moisture level of both oilseeds and their meals must be lower than their critical moisture level, and for most seeds it is below 10–12 % by weight [29]. There is only one similar study in the literature completed with red pepper seed. Red pepper seed flour was reported to contain 10.78 % moisture [15]. In a recent study [30], cold press by-products from almonds, walnuts, pomegranate seeds and grape seeds were shown to contain 6.29 to 9.45 % moisture. Usually, the reported results in the literature concur with our findings.

Around 20 % protein was measured in the capia pepper seed meals (Table 1). Previous studies about pepper seed proximate compositions have indicated that these seeds may contain around 20–30 % protein depending on the seed type [4–7]. Similarly, red pepper seed flours were found to contain 26.02 % protein [15]. Hence, our findings agree with the literature. Total protein content of oilseed meals would be very important quality parameter when evaluating its nutritional and feed value [23, 31]. Defatted hybrid hazelnut meals were shown to contain between 41.3 and 54.4 % crude protein [12]. Similarly, defatted meals of pumpkin seeds had around 64.13 % crude protein [13]. Clearly, the protein level of the meals greatly depends on the initial seed composition and oil yield during pressing may affect the proportion of the components after pressing.

The oil contents remaining in the defatted meals were statistically different among the samples, and the control sample had the lowest oil content. Even though the same defatting process was applied, this difference was detected. Clearly, the amount of oil remaining in the meals depends on the total oil content of the raw material and efficiency of the defatting procedure. On larger scales of production, oil contents of meals could be reduced below 1 % by industrial solvent extraction procedures. Not as harsh, the defatting procedure applied in this study yielded the results shown in Table 1. Oil remaining in the meals could be important for two factors: energy value (nutritional quality) and oxidative stability. In a previous study [9], the fatty acid composition of capia pepper seed oil was determined. The oil consisted mainly of 70 % linoleic, 11 % oleic and 11 % palmitic acids. Furthermore, some important levels of γ-tocopherol and sterols were present in the capia pepper seed oil. Hence, the oil is nutritionally very valuable and could contribute to the nutritional value of the meal for either food or feed usage. Similarly, defatted pumpkin seed meals had around 7 % oil [13], while defatted hazelnut meals had 1.93–4.34 % crude oil remaining [12]. It would be possible to extract more oil during pressing, but usually in this case, as heat increases, cold press conditions are violated. Hence, it would be acceptable if some oil remains in the meals, even after the defatting process.

Total ash in the meals ranged from 4.22 to 6.28 %, and the control sample had the highest content. Total ash of red pepper seed flour was 4.10 % [15], and similar amounts were reported for various pepper seeds [4, 6, 7]. Clearly, total ash of the seeds was not affected by the cold pressing and meal defatting processes.

The instrumental color values of the meals are presented in Table 1. There are some significant differences among the samples. Color of meals can be very important in determining the food application type. Darker colors may cause some compatibility problems for food applications. Hence, during cold pressing, excessive heat must be avoided to prevent darkening of the meals. Although the pepper seeds were naturally beige in color, the meal after cold pressing was red-brown. Since the wholesomeness of the seed tissue was disrupted, some enzymatic and chemical reactions might have occurred unavoidably. Roasted seed meals had the highest luminosity (L value) among the others. In the CIE color system, the color terms are L value (0 = black to 100 = white), a* value (+a* = red, −a* = green) and b* value (+b* = yellow, −b* = blue) [32]. Furthermore, the total color difference (∆E) between the control and roasted sample was 3.76, and between the control- and enzyme-treated sample was 2.19. These values indicate that there are some differences between the samples in terms of color. According to the findings (Table 1), capia pepper seed meals are reddish browny-colored samples. This color would be compatible for most bakery and processed meat products. Defatted pumpkin seed meals had similar color values [13]. Colors of the meals usually depend on the color of the original seed material and processing parameters.

The apparent viscosity values of the meal dispersions (20 % in water) have revealed that roasting and enzyme treatment of the seeds caused some increases (Table 1). Heating the seeds might have caused some protein denaturation and/or some starch gelatinization to enhance the viscosity. Likewise, enzyme treatment may have partially denatured seed proteins to change their folded structure. In a previous study [33], viscosities of 1 and 10 % defatted sesame flour were reported as 2.5 and 7.0 cP, respectively. Apparently, concentration of dispersion might be very effective on the viscosity measured.

Phytic acid content of the meals was in the range of 10.3–11.5 mg P/g sample (Table 1). Enzyme treatment might aid phytates to be released, and roasting may degrade some of the phytates. In a previous study [34], the phytate-P content of rapeseed, sunflower seed and niger seed was reported as 6.89, 8.80 and 8.35 mg/g, respectively. Embaby and Mokhtar [7] reported phytic acid content of whole sweet pepper seed as 2.88 g/100 g on dry basis. This amount is higher than our measurement in the meals, but during the previous processes (cold pressing and defatting), some phytate loss might have occurred. Erdman [35] indicated that most oilseeds contain around 1.5 % phytate on dry basis, and due to the chelation ability of phytate, mineral bioavailability can be reduced. Similarly, defatted hazelnut meals had 18.5–33.0 mg/g phytates [12]. Generally, our findings concur with the literature. The other anti-nutritional factor, tannin content of the samples, was also measured. Defatted capia pepper seed meals contained around 1.54–1.66 mg/g tannins (Table 1). No difference was evident among the samples in terms of tannin content. Previously, tannins content of sweet pepper seed was reported as 2.89 mg/g [7]. Like the phytic acid content, the tannins content of our meals was lower than that of the sweet pepper seeds. Clearly, during cold pressing and defatting of press cakes, some tannin is lost. From nutritional point of view, this situation is rather beneficial for human food applications of the meals. Sharma et al. [11] measured the tannin contents of meals as 0.7 mg/g for almond, 0.3 mg/g for Brazil nut, 0.3 mg/g for chestnut, 0.9 mg/g for hazelnuts, 0.3 mg/g for the macadamia nut, 0.0 mg/g for the pine nuts, 1.3 mg/g for the pistachio and 0.2 mg/g for soybean variety W82. Defatted hazelnut meals had 5.56–9.46 mg/g tannins and 0.25–1.53 % condensed tannins [12]. Our results are usually in agreement with the literature.

Mineral Content

Mineral composition of the meal samples was analyzed by the ICP-AES technique, and out of 16 minerals analyzed, 10 of them were detected in the samples (Table 2). Amounts of Zn, Fe, Mn, Ca, Al, Na and K were statistically higher in the enzyme-treated samples. Heavy metals such as Pb, Co, Cd, Ni and Cr were analyzed, but luckily not detected in the samples. Significantly higher sodium content in the enzyme-treated sample could be due to the added enzyme slurry during the seed pre-treatment. Although the mineral composition data were not available for the enzymes used, the solid dust enzyme preparates may contain some sodium. In one study [7], the mineral composition of sweet pepper seed was reported. Out of analyzed 7 minerals (K, Na, P, Fe, Cu, Zn and Mn), the most abundant were potassium and phosphorous (687.14 and 74.97 mg/100 g sample). In terms of abundancy, our results concur with theirs for K and Na findings. In another recent study [30], mineral compositions of walnut, pomegranate, grape and almond seed meals were reported. Compared with our results, amounts of Ca, Mg, Fe, Mn, Al and Zn were fairly similar, but contents of K and Na were significantly higher in our samples. Generally, capia pepper seed meals can be accounted as good sources for K, Na and Mg, but poor for Fe. Hence, the meals can be used safely as food or feed ingredients.

Functional Properties

Functional properties of the capia pepper seed meals are reported in Table 3. WHC of enzyme-treated meal was significantly higher than the others. WHC could be an important functional parameter in processed foods such as bakery products, sauces, soups and meat products [10–31]. Hence, if these meals are incorporated into similar products, they could have beneficial effects on quality and yield. There is no study reported in the literature for capia pepper seed flours or meals; therefore, comparison with other similar materials would be meaningful. WHC of six different mucuna bean varieties were reported to be between 1.40 and 2.20 g/g [36]. Similarly, WHC of crude and heat-treated linseed flours was 3.45 and 4.43 g/g, respectively [37]. With respect to WHC, capia pepper seed meal samples are very similar to the other oilseed and kernel meal materials and could be credited as moderate water-holding capacity samples.

Another important functional property, oil-holding capacity (OHC), was also measured (Table 3). There was no significant difference among the samples. OHC is a preferred property in emulsified products; especially in emulsified meat products, it would be better if any added ingredient enhances the OHC or emulsifying activity [31]. Unfortunately, the literature lacks for this property of pepper seed meal samples, as well. On the other hand, Adebowale et al. [36] reported the OHCs of 6 mucuna beans between 2.1 and 2.6 g/g. Likewise, the OHC of linseed flour samples was between 2.36 and 1.37 g/g [37]. Effect of heat treatment was evaluated by Abbey and Ibeh [38], and it was found out that WHC and OHC of chickpea flour increased from 2.4 to 3.6 g/g and from 2.9 to 3.2 g/g, respectively. Clearly, compared to the literature, OHC values of our samples are lower.

Emulsifying activity (EA) and emulsion stability (ES) of the samples are also shown in Table 3. For both values, the enzyme-treated samples had significantly higher values than those of the control and roasted samples. In the only available literature [15] for red pepper seed flour and protein samples, emulsion activity values were reported as 49.3–54.7 and 48.4–70.4 %, respectively. These data concur with ours, but it is obvious that enzyme pre-treatment of the seeds enhanced the value quite significantly. This might be due to the partial unfolding or hydrolysis of seed proteins, since one of the enzymes was protease. It was indicated that protein unfolding may increase the emulsification activities due to the enhancement of hydrophobic domain and developing flexibility [10]. Narayana and Narasinga Rao [39] reported a decrease in emulsion and foaming capacity of bean flour by heat treatment from 35 to 18 %. The emulsion stability (ES) exhibited similar trends of changes with EA values (Table 3). For the red pepper seed flour and protein samples, ES was reported as 52.9–54.33 and 47.19–64.9 %, respectively [15]. These data are in agreement with our results. In one study [37], heat treatment was reported to reduce emulsion and foaming capacities of flax seed flour. Generally, different measurement techniques were used in different studies, and EA and ES values of meals varied greatly, possibly due to the material source differences. Overall, enzyme pre-treatment of the seeds might have caused some protein unfolding, and this led to significant increase in the EA and ES values to increase significantly. It can be suggested that if meals are intended for emulsion type products, protease pre-treatment may enhance their emulsion properties.

Foaming capacity (FC) and foam stability (FS) data of the samples (Table 3) revealed that the lowest values were in the enzyme-treated sample and the highest values were in the control samples, contrary to the results of EA and ES values. No data were found in the literature for these two functional properties of pepper seed flour or protein extracts. Hrčková et al. [40] treated commercial defatted soy flour with Flavourzyme (exopeptidase and endoprotease complex), Novozym (proteolytic enzymes) and Alcalase (endopeptidases), and found that enzyme treatment caused increment in FC but significant reduction in FS. Sharma et al. [11] measured foaming capacities of almonds, chestnut, Brazil nuts, hazelnuts, macadamia nuts, pine nuts, pistachio nuts, soybeans W82 variety and found them above 40 %, and indicated that foaming capacity and stability are quite dependent on the material source. Hence, capia pepper seed meals can be considered as moderate capacity materials compared to the literature for FC and FS values for different food applications.

The least gelling concentrations (LGCs) of the meals were also measured (Table 4). LGC is commonly used as functional property for extracted seed proteins [10–31], but could also provide some insights for the meal samples. While in the control sample, solid gel occurred at 24 % dispersion concentration, roasted samples gelled at 32 % concentration. Up to 38 % dispersion concentrations, enzyme-treated meals did not gel at all. Eventually, this result may suggest that protein damage in the meals prevented solid gel formation under the test conditions. Hence, for any food application regarding gel formation, especially protease treatment would not be appropriate. There are no data in the literature for pepper seed meals for this property, but six mucuna bean flours were reported to have LGC at 14–20 % [36]. In another study [11], the LGCs for almonds, Brazil nuts, chestnuts, hazelnuts, macadamia nuts, pine nuts, pistachios and soy protein concentrates were reported to be 6, 8, 8, 12, 20, 12, 10 and 16 %, respectively. Hrčková et al. [40] treated commercial defatted soy flour with Alcalase and measured LGC value of 2 %, but the gel was sliding on the tube wall. A weak gel was formed with 6 % Novozym, and solid gel structure at 2 % concentration with Flavourzyme was apparent. Hence, capia pepper seed meal samples can be credited as low gelling materials.

Conclusion

Cold pressing of edible oilseeds to get special oils is gaining popularity in recent years. Since the seeds must be very clean, healthy and pure for product specifications of cold-pressed (unrefined) oils, the meals obtained after cold pressing are usually of high quality. Due to the mild processing conditions and absence of solvent or any other chemicals, cold press meals or press cakes are safe materials to be utilized as human food source. This study showed that capia pepper seed meals are good sources of protein and some minerals. Although anti-nutritional factors such as phytic acid and tannins are present, they are not in high amounts compared to other similar meals. Most importantly, the meals exhibited some functional properties, such as water-holding capacity, emulsification and foaming abilities. In fact, for most functional properties, roasting of seeds has shown to enhance the properties. In conclusion, this study suggests that capia pepper seed meals are safe, nutritionally beneficial and functional materials for food applications. Further studies of capia pepper seed meals for food applications are needed.

References

Galanakis, C.M.: Recovery of high added-value components from food wastes: conventional, emerging technologies and commercialized applications. Trends Food Sci. Technol. 26, 68–87 (2012)

Mirabella, N., Castellani, V., Sala, S.: Current options for the valorization of food manufacturing waste: a review. J. Clean. Prod. 65, 28–41 (2014)

TUİK: http://www.tuik.gov.tr/PreTablo.do?alt_id=1001 (2016). Accessed 03 May 2014

Bosland, P.W., Votava, E.J.: Peppers: Vegetable and Spice Capsicums. CABI Publishing, New York (2000)

Aybak, H.Ç.: Biber Yetiştiriciliği (Pepper Cultivation). Hasad Publishing Co., Istanbul (2002)

Bok, P.J.: Chemical component analysis of red pepper (Capsicum Annuum L.) seeds with various cultivars. J. Korean Soc. Food Sci. Nutr. 37, 1084–1089 (2008)

Embaby, H.E., Mokhtar, S.M.: Chemical composition and nutritive value of lantana and sweet pepper seeds and nabak seed kernels. J. Food Sci. 76, C736–C741 (2011)

Firatligil Durmus, E., Evranuz, O.: Response surface methodology for protein extraction optimization of red pepper seed (Capsicum frutescens). LWT-Food Sci. Technol. 43, 226–231 (2010)

Yılmaz, E., Arsunar, E.S., Aydeniz, B., Güneşer, O.: Cold pressed capia pepper seed (Capsicum Annuum L.) oils: composition, aroma and sensory properties. Eur. J. Lipid Sci. Technol. 117, 1016–1026 (2015)

Moure, A., Sineiro, J., Dominguez, H., Parajo, J.C.: Functionality of oilseed protein products: a review. Food Res. Int. 39, 945–963 (2006)

Sharma, G.M., Su, M., Joshi, A.U., Roux, K.H., Sathe, S.K.: Functional properties of select edible oilseed proteins. J. Agric. Food Chem. 58, 5457–5464 (2010)

Xu, Y., Hanna, M.A.: Nutritional and anti-nutritional compositions of defatted Nebraska hybrid hazelnut meal. Int. J. Food Sci. Technol. 46, 2022–2029 (2011)

Rodriguez-Miranda, J., Hernandez-Santoz, B., Herman-Lara, E., Vivar-Vera, M.A., Carmona-Garcia, R., Gomez-Aldapa, C.A., Martinez-Sanchez, C.E.: Physicochemical and functional properties of whole and defatted meals from mexican (Cucurbita pepo) pumpkin seeds. Int. J. Food Sci. Technol. 47, 2297–2303 (2012)

Hojilla-Evangelista, M.P., Selling, G.W., Berhow, M.A.: Extraction, composition and functional properties of pennycress (Thlaspi arvense L.) press cake protein. J. Am. Oil Chem. Soc. 92, 905–914 (2015)

Fıratlıgil Durmuş, E., Evranuz, O.: Kırmızı biber tohum unu ve proteininin çözünürlük ve emülsiyon özellikleri. ITU J. Eng. 9, 33–44 (2010)

Manamperi, W.A., Pryor, S.W., Chang, S.K.C.: Separation and evaluation of canola meal and protein for industrial bioproducts. An ASABE Section Meeting Presentation Paper Number: RRV-07116 (2007)

AOCS: Official Methods and Recommended Practices of the American Oil Chemists Society, 3rd edn. AOCS Press, Champaign (1984)

AOAC: Official methods of analysis of AOAC International, 17th edn. AOAC International, Gaithersburg (2002)

Khalid, E.K., Babiker, E.E., El Tinay, A.H.: Solubility and functional properties of sesame seed proteins as influenced by ph and/or salt concentration. Food Chem. 82, 361–366 (2003)

AOAC: Official methods of analysis of AOAC International. Official method 986.11, phytate in foods. AOAC International, Gaithersburg (1986)

Price, M.L., Van Scoyoc, S., Butler, L.G.: A critical evaluation of the vanillin reaction as an assay for tannin in sorghum grain. J. Agric. Food Chem. 26, 1214–1218 (1978)

Hagerman, A.E.: Vanillin Assay. http://www.users.miamioh.edu/hagermae/Vanillin%20Assay.pdf (2002). Accessed 03 May 2016

Moure, A., Dominguez, H., Zuniga, M.E., Soto, C., Chamy, R.: Characterisation of protein concentrates from pressed cakes of Guevina avellana (chilean hazelnut). Food Chem. 78, 179–186 (2002)

Wu, Y.V.: Emulsifying activity and emulsion stability of corn gluten meal. J. Sci. Food Agric. 81, 1223–1227 (2001)

Cano-Medina, A., Jiménez-Islas, H., Dendooven, L., Herrera, R.P., González-Alatorre, G., Escamilla-Silva, E.M.: Emulsifying and foaming capacity and emulsion and foam stability of sesame protein concentrates. Food Res. Int. 44, 684–692 (2011)

Kanu, P.J., Kerui, Z., Ming, Z.H., Haifeng, Q., Kanu, J.B., Kexue, Z.: Sesame protein 11: functional properties of sesame (Sesamum indicum L.) protein isolate as influenced by ph, temperature, time and ratio of flour to water during its production. Asian J. Biochem. 2, 289–301 (2007)

Minitab: Minitab 16.1.1 Statistical Software. Minitab Inc, State College, Pennsylvania (2010)

SPSS: SPSS Professional Statistics 10.1. Spss Inc, Chicago (1994)

Nas, S., Gökalp, H.Y., Ünsal, M.: Vegetable Oil Technology (Textbook). Pamukkale Univ. Pub. No: 005, Denizli, Turkey (2001)

Karaman, S., Karasu, S., Tornuk, F., Toker, O.S., Geçgel, Ü., Sagdic, O., Ozcan, N., Gül, O.: Recovery potential of cold press byproducts obtained from the edible oil industry: physicochemical, bioactive, and antimicrobial properties. J. Agric. Food Chem. 63, 2305–2313 (2015)

Foegeding, E.A., Davis, J.P.: Food protein functionality: a comprehensive approach. Food Hydrocoll. 25, 1853–1864 (2011)

Pomeranz, Y., Meloan, C.E.: Food Analysis: Theory and Practice. Chapman & Hall Pub. Co, New York (1994)

Inyang, U.E., Nwadimkpa, C.U.: Functional properties of dehulled sesame (Sesamum indicum L.) seed flour. J. Am. Oil Chem. Soc. 69–8, 819–822 (1992)

Eklund, A.: The contents of phytic acid in protein concentrates prepared from nigerseed, sunflower seed, rapeseed and poppyseed. Upsala J. Med. Sci. 80, 5–6 (1975)

Erdman, J.W.: Oilseed phytates: nutritional implications. J. Am. Oil Chem. Soc. 56, 736–741 (1979)

Adebowale, Y.A., Adeyemi, I.A., Oshodi, A.A.: Functional and physicochemical properties of flours of six mucuna species. Afr. J. Biotechnol. 4, 1461–1468 (2005)

Madhusudhan, K.T., Singh, N.: Effect of heat treatment on the functional properties of linseed meal. J. Agric. Food Chem. 33, 1222–1226 (1985)

Abbey, B.W., Ibeh, G.O.: Functional properties of raw and heat processed cowpea (Vigna unguiculata, walp) flour. J. Food Sci. 53, 1775–1777 (2006)

Narayana, K., Narasinga Rao, M.S.: Functional properties of raw and heat processed winged bean (Psophocarpus tetragonolobus) flour. J. Food Sci. 47, 1534–1538 (1982)

Hrčková, M., Rusnakova, M., Zemanovic, J.: Enzymatic hydrolysis of defatted soy flour by three different proteases and their effect on the functional properties of resulting protein hydrolysates. Czech J. Food Sci. 20, 7–14 (2002)

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Yılmaz, E., Hüriyet, Z., Arifoğlu, N. et al. Functional Properties of the Capia Pepper Seed Defatted Press Cakes. Waste Biomass Valor 8, 783–791 (2017). https://doi.org/10.1007/s12649-016-9602-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12649-016-9602-5