Abstract

The recovery of rhenium from waste acid is an urgent issue due to low rhenium concentration and high sulfuric acidity. To solve the problem, novel coated solvent-impregnated resins consisting of inert resins LS-300, Alamine 304-1 and the PVA film (304-CSIRs) were prepared for the separation of Re(VII) from high sulfuric acid solutions. It was shown that the PVA film coated completely on the surfaces of LS-300 resins with a thickness of 5 μm, and Alamine 304-1 distributed completely inside the porous of LS-300 resins. The adsorption fitted well with Langmuir model and pseudo-second-order model with the saturation adsorption capacity of 139.40 mg·g−1. The maximum separation factor of Re(VII) versus Cu (II) was up to 483, and 304-CSIRs had no adsorptions for As(V). The adsorption capacity of Re(VII) onto 304-CSIRs maintained in 97.79% at the fifth adsorption–desorption cycle. 99.87% of rhenium was recovered by 304-CSIRs from waste acid generated from a copper smelter.

Graphic abstract

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

Rhenium has a wide range of applications in many industries due to its high temperature resistance and excellently catalytic properties [1]. Superalloys consume about 80% of rhenium for the manufacture of aeronautic turbines [2]. In addition, it is also found that ReS2 is a promising anode material in recent studies [3, 4]. On the contrary, it is predicted that the demand for rhenium will have an annual growth rate of 7% in the following 3 years [2, 5], while the world reserves and annual production of rhenium have been evaluated to be about 2500 and 50 tons, respectively [2, 5].

Molybdenum and copper deposits are the main sources of rhenium, and rhenium is usually extracted as a by-product from waste acid generated from copper or molybdenum smelters, where rhenium exists as ReO4− [6, 7]. Solvent extraction [8, 9], ion exchange [10,11,12] and chemical precipitation [6] have been investigated for the recovery of rhenium from waste acid. However, due to the disadvantages of high energy consumption, high costs and long time, a new method is urgent to be developed from the environment and economics point of view [6]. In addition, waste acid generated from copper smelters consists of about 30 kinds of metallic ions, especially As(V/III), Cu(II), Ni(II), Zn(II) and Fe(III) [13]. Therefore, the selective separation of rhenium from waste acid should be considered.

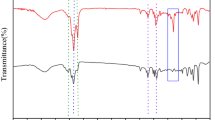

As a promising method, adsorption has been used for the recovery of metallic ions from aqueous solutions with the benefits of high efficiency, excellent selectivity and low consumption, where researchers have done lots of works [14,15,16,17,18,19,20]. Among the family of adsorbents, solvent-impregnated resins (SIRs) have been considered as an alternative adsorbent for the efficiently selective recovery of metallic ions from high acidity solutions with the benefits of easy preparation and high selectivity [21]. SIRs have been used in recent years for the adsorption of various metallic ions, such as In(III) [22], Sc(III) [23], Pd(II) [24], V(V) [25], Dy(III), Nd(III) [26], Pb(II) [27], U(VI) and Pu(IV) [28]. However, the loss of extractant impregnated in resins has limited SIRs in practical application [21]. However, coating a thin film on the surfaces of SIRs is an effective method to minimize the loss of extractant. It has been observed that the cross-linked PVA is a suitable material for the preparation of coating film with the benefits of simple operation and environmentally friendly [29, 30]. Alamine 304-1 (its structure is shown in Fig. 1) has been used for the liquid–liquid extraction of Re(VII) from sulfuric acid solutions [31], and it was chosen as the extractant impregnated in LS-300 resins.

In this study, the coated solvent-impregnated resins containing Alamine 304-1 (304-SCIRs) were prepared for the selective adsorption of Re(VII) from high sulfuric acidity solutions. 304-SCIRs were characterized by scanning electron microscopy (SEM) and energy-dispersive spectrometry (EDS). The optimal Alamine 304-1 concentration for the preparation of 304-SCIRs was observed. In addition, the adsorption behaviors of 304-SCIRs on Re(VII) were investigated comprehensively. The regenerative ability of 304-SCIRs and the recovery of rhenium by 304-SCIRs from waste acid were also performed. The results showed that 304-SCIRs might be used for the recovery of rhenium from waste acid generated from copper smelters.

2 Experimental

2.1 Materials

Reagent Alamine 304-1 and LS-300 resins which were made of polystyrene with surface area 600-700 m2·g−1, pore diameter of 10 nm and bead size of 250–840 μm were purchased from BASF (Germany) and Lanshen, Shanxi (China), respectively. Ammonium perrhenate, PVA, boric acid and other metallic sulfates were supplied by Sigma-Aldrich. All reagents were of analytical grade without any further purification. Feed solutions were prepared by dissolving metallic sulfates into deionized water. Waste acid was supplied by a copper smelter located in Henan Province, China. The chemical composition of the waste acid is shown in Table 1.

2.2 Preparation of the 304-CSIRs

LS-300 resins were washed by ethanol followed by washing with dilute sulfuric acid solutions. Subsequently, the resins were further washed by deionized water until reaching the neutral. After drying to a constant weight, the solvent-impregnated resins containing Alamine 304-1 (304-SIRs) were prepared by the following processes. The pretreated LS-300 resins were added into the mixed solutions containing Alamine 304-1 and ethanol (liquid-to-solid ratio of L/S = 20:1, ml·g−1) and shaking in a water bath oscillator for 24 h at 40 °C. Subsequently, 304-SIRs were washed with deionized water until the filtrated was clear.

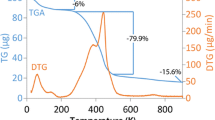

30 g of 304-SIRs was added into 300 ml 3 wt% PVA solutions with slow shaking speed for 18 h at 40 °C. After that, the PVA film was coated on the surfaces of 304-SIRs. To enhance the stability of the PVA film, 300 ml saturated boric acid solutions were used for the cross-linking of the PVA film under slow shaking speed for 10 h at 25 °C. The impregnation ratio (n, %) is calculated as Eq. 1.

where m2 is the mass of 304-CSIRs (g) and m1 is the mass of the pretreated LS-300 resins (g).

2.3 Adsorption experiment

All adsorption experiments were operated in the 500-ml conical flask. In each batch experiment, 100 mg of 304-CSIRs was added into 250 ml feed solutions, and the conical flasks shook with the speed of 250 r·min−1 for a certain time. The sulfuric acidity concentration was 0.5 mol·L−1, and the temperature was 25 °C unless specified otherwise. The adsorption capacity (Qe) and separation coefficient (β) were calculated via Eqs. (2) and (3), respectively:

where C0 is the initial concentration and Ce is the equilibrium concentration of metallic ion (mg·L−1); V is the volume of feed solutions (L); m is the mass of 304-CSIRs (mg); and X represents the element of Cu, As, Bi, Cd, Mo, Fe, Zn or Ni, respectively.

2.4 Analysis and characterization

Inductively coupled plasma optical emission spectrometry (ICP-OES, Spectro Blue Sop, Germany) was used to measure the concentration of metallic ion to calculate the adsorption capacity. The morphologies of different 304-CSIRs were observed by field emission scanning electron microscope (FESEM, TESCAN MIRA3, The Czech Republic).

3 Results and discussion

3.1 Characterization of 304-CSIRs

To confirm the existence of the PVA film on the surfaces of 304-CSIRs, the samples were evaporated for 2 h at 120 °C, and then they were sliced. It is found that scratches distribute all over the surfaces of the uncoated resins (Fig. 2a–c), while the surfaces of the coated resins are smooth at the magnification of 1000× (Fig. 2d, e) and the surfaces keep compact even at the magnification of 8000× (Fig. 2f). It is also found that the circle of boundary exists at the sectional edge of 304-CSIRs, which attributes to the PVA film (Fig. 2g, h). In addition, the thickness of the PVA film is estimated to be about 5 μm (Fig. 2i). The results suggest that 304-CSIRs are completely packaged by the PVA film with the thickness of 5 μm.

SEM image and elemental mapping of Re for 304-CSIR-loaded Re(VII) are shown in Fig. 3. It is found that rhenium distributes densely over the entire cross section of 304-CSIRs after the adsorption of Re(VII) (Fig. 3a), indicating that Re(VII) can be migrated to the deepest porous of 336-CSIRs. In addition, it is further suggested that the entire porous of LS-300 resins is filled with Alamine 304-1.

3.2 Effect of Alamine 304-1 concentration on adsorption

The effect of Alamine 304-1 concentration on the adsorption of Re(VII) was investigated (Fig. 4). It is found that the adsorption capacity of Re(VII) onto Alamine 304-1 increases from 82.38 to 101.70 mg·g−1 with the concentration of Alamine 304-1 increasing from 20% to 40%, while the impregnation ratio of Alamine 304-1 in resins increases from 41.00 to 56.30%. Alamine 304-1 absorbed on the microporous walls of LS-300 resins is supposed to form the monolayer, which leads to the increase in impregnation ratio as well as adsorption capacity [32, 33]. However, the adsorption capacity decreases when the Alamine 304-1 concentration is more than 40%. For example, the adsorption capacity decreases to 93.51 mg·g−1 when the Alamine 304-1concentration is 60%, while the impregnation ratio of Alamine 304-1 increases from 56.30 to 64.27%. It is the fact that the excess Alamine 304-1 forms the multilayers, which will lead to the failure in the adsorption of Re(VII) onto Alamine 304-1 at the lower layers, and it will reduce the availability of Alamine 304-1 [32, 33]. Therefore, the optimal Alamine 304-1 concentration for the preparation of 304-CSIRs is 40%.

3.3 Adsorption isotherms

Adsorption isotherm models, namely Langmuir (Eq. (4)), Freundlich (Eq. (5)) Temkin (Eq. (6)) and Redlich–Peterson (Eq. (7)), were as follows: [16, 34]:

where Qe (mg·g−1) is the equilibrium adsorption capacity, Ce (mg·L−1) is the equilibrium concentration of ReO4−, Qm (mg·g−1) is the theoretical maximum adsorption capacity and KL (L·g−1) is the Langmuir adsorption constant. KF and n are the adsorption equilibrium constant and concentration index, respectively. AT and BT (J·mol −1) are the adsorption constants of Temkin model, respectively. KR (L·g−1), αR (mg·L−1) and g (0 < g < 1) are the adsorption constants of Redlich–Peterson model [16, 34].

The effect of operating temperatures and the initial concentration of Re(VII) on the adsorption of Re(VII) onto 304-CSIRs was investigated from 298 to 318 K at the initial concentration of Re(VII) from 25 to 300 mg·L−1 (Fig. 5). It is found that the adsorption capacity increases with the increase in operating temperature at the same conditions, indicating that higher temperature can promote the adsorption. For example, the adsorption capacity increases from 123.20 to 135.62 mg·g−1 with the operating temperatures from 298 to 318 K. In addition, the adsorption data can be described best by Langmuir model (the R-square value is 0.990, 0.982 and 0.976, respectively, as shown in Fig. 5a–c and Table 2), suggesting that the adsorption sites distribute evenly in the pores of 304-CSIRs, and the adsorption sites are independent [34]. It is also suggested that the adsorption is in the form of monolayer [34]. Furthermore, the Langmuir adsorption constant (KL) increases from 0.060 to 0.085 L·g−1 with the increase in operating temperatures from 298 to 318 K, suggesting that a higher operating temperature will promote the adsorption capacity of Re(VII) onto 304-CSIRs, which is consistent with the experimental results. In addition, the maximum adsorption capacity values of Re(VII) onto 304-CSIRs are 123.20, 130.02 and 135.62 mg·g−1 at the operating temperatures of 298, 308 and 318 K, respectively, which are close to the experimental adsorption capacities.

To further investigate the adsorption behaviors of Re(VII) onto 304-CSIRs, the Redlich–Peterson model, a three-parameter model, is used to fit the experimental data (Fig. 5d and Table 2) [34]. It is found that the R-square values of Redlich–Peterson model are the highest among the four adsorption isotherm models, suggesting that the adsorption of Re(VII) onto 304-CSIRs is dominated by the monolayer adsorption (Fig. 5 and Table 2) [34]. Therefore, the adsorption of Re(VII) onto 304-CSIRs is mainly in the form of the monolayer adsorption with endothermic reaction, and the maximum saturation adsorption capacity of Re(VII) onto 304-CSIRs is 139.40 mg·g−1.

3.4 Adsorption kinetics

Adsorption kinetic data models, namely pseudo-first order (Eq. 8), pseudo-second order (Eq. 9) and Elovich (Eq. 10) model, were as follows [16, 34, 35]:

where Qt is the adsorption capacity at time t min (mg·g−1), k1 is the adsorption constant of pseudo-first-order model (min), k2 is the adsorption constant of pseudo-second-order model (mg·g−1·min), and α represents the initial adsorption rate constant (mg·g−1·h−1), respectively [16, 34, 35].

The effect of operating time and the initial concentration of Re(VII) on the adsorption of Re(VII) onto 304-CSIRs was investigated at the initial concentration of Re(VII) from 25 to 75 mg·L−1 at 298 K (Fig. 6). It is found that the adsorption rates are fast during the first 90 min with the adsorption capacity of 31.87, 51.71 and 64.68 mg·g−1, respectively. During the following 350 min, the adsorption rates decrease due to the minor concentration difference of Re(VII) between the adsorption sites of 304-CSIRs and feed solutions. The adsorption rates gradually approach constant values when the operating time exceeds 420 min. The maximum adsorption capacities of Re(VII) onto 304-CSIRs are 44.50, 71.50 and 88.82 mg·g−1 at the initial Re(VII) concentrations of 25, 50 and 75 mg·L−1, respectively. The adsorption kinetic data fitted by the kinetic models are shown in Fig. 6, and the kinetic parameters are reported in Table 3. It is found that the pseudo-second-order kinetic model fits best with the highest correlation coefficient (the R-square values are 0.996, 0.992 and 0.972, respectively), indicating that the adsorption might in the form of chemisorption [34, 35]. In addition, the saturation adsorption capacities calculated according to Eq. (9) are 47.17, 74.70 and 90.64 mg·g−1, respectively, which are close to the experimental data. The results suggest that the adsorption of Re(VII) onto 304-CSIRs might be a chemisorption process, and the adsorption equilibrium time is 420 min.

3.5 Effect of sulfuric acidity on selectivity

The effect of sulfuric acidity on the selective adsorption of Re(VII) onto 304-CSIRs was investigated with the sulfuric acidity ranging from 0.5 to 4.0 mol·L−1 at the metallic ions concentration of 50 mg·L−1 (Fig. 7). It is found that Re(VII) can be separated from the mixed aqueous solutions consisting of Re(VII), As(V), Cu(II), Fe(III), Zn(II) and Ni(II), indicating that 304-CSIRs have the ability of selective adsorption for Re(VII). The adsorption capacity of Re(VII) onto 304-CSIRs decreases from 71.89 to 30.56 mg·g−1 in single Re(VII)-containing solutions, while that decreases from 70.67 to 27.54 mg·g−1 in the mixed aqueous solutions at the sulfuric acidity from 0.5 to 4.0 mol·L−1. It is the fact that the adsorption sites are occupied by SO42− [36]. The adsorption reactions could be expressed below in two steps: protonation of the amine (Eq. (11)) and exchange of counterion (Eq. (12)) [33]:

The adsorption capacity of Re(VII) onto 304-CSIRs rarely decreases in the mixed aqueous solutions compared with the single Re(VII)-containing solutions, which indicates that the existence of impurity elements has slight effects on the adsorption capacity of Re(VII) onto 304-CSIRs. The maximum adsorption capacities of Cu (II) and Fe(III), which exist in abundance in waste acid, onto 304-CSIRs are 0.66 and 0.82 mg·g−1, respectively. In addition, 304-CSIRs had no adsorptions for As(V), Zn(II) and Ni(II). It is the fact that As(V) mostly forms HAsO3 at the high sulfuric acidity solutions [36]. As for Cu (II), Fe(III), Zn(II) and Ni(II) mostly exist as the cations in the sulfuric acid solutions, which will not be adsorbed by the adsorption sites. The highest separation coefficients of Re(VII) versus Cu (II) and Fe(III) are 483 and 1401, respectively (Table 4). Therefore, Re(VII) can be selectively separated from the mixed aqueous solutions by 304-CSIRs.

3.6 Regeneration and recovery of rhenium from waste acid

In order to investigate the stabilities of 304-CSIRs and 304-SIRs, the adsorption–desorption tests were carried out. In each batch test, 5 mol·L−1 ammonium sulfate solutions were selected as the stripping solutions, and over 97% Re(VII) loaded on both 304-CSIRs and 304-SIRs were stripped at the L/S ratio of 30. As shown in Fig. 8, the adsorption capacity of 304-CSIRs for Re(VII) decreases from 71.84 to 70.25 mg·g−1 after five cycles, while the adsorption capacity of 304-SIRs for Re(VII) decreases from 69.34 to 65.27 mg·g−1 (Fig. 8). The results suggest that the PVA film effectively minimizes the loss of Alamine 304-1.

In addition, the recovery of rhenium by 304-CSIRs from waste acid was carried out for 12 h at 298 K, and the results are reported in Table 5. It is found that 99.87% of rhenium is recovered, while only 0.19% arsenic, 0.98% copper, 0.97% zinc, 1.11% cadmium and 0.51% molybdenum are adsorbed by 304-CSIRs. In addition, the separation coefficients of Re versus As, Cu, Zn, Cd, Fe and Mo are up to 3.85 × 105, 0.75 × 105, 0.86 × 105, 0.67 × 105, 1.86 × 105 and 2.41 × 105, respectively. The 304-CSIR-loaded Re(VII) were washed by deionized water until it reaches neutral, and then Re(VII) loaded onto 304-CSIRs were striped by 5 mol·L−1 ammonium sulfate solutions. Chemical analysis of the desorption aqueous solutions is reported in Table 5, and the enrichment ratio of rhenium after the desorption is 7.9. The results suggest that 304-CSIRs might be used for the adsorption of rhenium from waste acid generated from copper smelters.

4 Conclusion

Novel coated solvent-impregnated resins consisting of inert resins LS-300, Alamine 304-1 and the PVA film were prepared for the adsorption of Re(VII) from high sulfuric acidity solutions. It was found that the optimal Alamine 304-1 concentration for the preparation of 304-CSIRs was 40%. The PVA film was successfully coated on the surfaces of the absorbent with the thickness of 5 μm, and Alamine 304-1 distributed completely inside the porous of LS-300 resins. The adsorption was mainly in the form of monolayer with the maximum saturation adsorption capacity of 139.40 mg·g−1. The adsorption of Re(VII) onto 304-CSIRs was a chemisorption process, and the adsorption equilibrium time was 420 min, respectively. High sulfuric acidity was disadvantageous for the adsorption of Re(VII) onto 304-CSIRs. 304-CSIRs showed excellently selective adsorption for Re(VII). The PVA film could enhance the stability of Alamine304-1 inside the LS-300 resins. The adsorption capacity of Re(VII) onto 304-CSIRs was maintained in 97.79% of the first cycle after five adsorption–desorption cycles. 99.87% of rhenium was recovered from waste acid generated from a copper smelter by 304-CSIRs.

References

Millensifer TA. Rhenium and rhenium compounds. In: Othmer K, editor. Encyclopedia of Chemical Technology. London: Wiley; 2010.1.

Kesieme U, Chrysanthou A, Catulli M. Assessment of supply interruption of rhenium, recycling, processing sources and technologies. Int Refract Met Hard Mater. 2019;82:150.

Dhakal KP, Kim H, Lee S, Kim Y, Lee JD, Ahn JH. Probing the upper band gap of atomic rhenium disulfide layers. Light Sci Appl. 2018;7:98.

Sim S, Lee D, Trifonov AV, Kim T, Cha S, Sung JH, Cho S, Shim W, Ho MJ, Choi H. Ultrafast quantum beats of anisotropic excitons in atomically thin ReS2. Nat. Commun. 2019;9:351.

Wang Y, Wang CY. Recent advances of rhenium separation and enrichment in China: industrial processes and laboratory trials. Chin Chem Lett. 2018;29:345.

Anderson CD, Taylor PR, Anderson CG. Extractive metallurgy of rhenium: a review. Miner Metall Process. 2013;30:59.

Helbiga T, Gilbrichtb S, Lehmannc F. Oxidative leaching of a sulfidic flue dust of former copper shale processing with focus on rhenium. Miner Eng. 2018;128:168.

Lou ZN, Cui XX, Zhang SQ, Feng XD, Shan WJ, Xiong Y. Extraction of Re(VII) from hydrochloric acid medium by N263/TBP/n-heptane/NaCl microemulsion. Hydrometallurgy. 2016;165:329.

Cheema HA, Ilya S, Masud S, Mushan MA, Mahnood I, Lee JC. Selective recovery of rhenium from molybdenite flue-dust leach liquor using solvent extraction with TBP. Sep Purif Technol. 2018;191:116.

Laatikainen M, Virolainen S, Paatero E, Sainio T. Recovery of ReO4− by weakly basic anion exchangers: modeling of sorption equilibrium and rate. Sep Purif Technol. 2015;153:19.

Fathi MB, Rezai B, Alamdari EK. Competitive adsorption characteristics of rhenium in single and binary (Re–Mo) systems using Purolite A170. Int J Miner Process. 2017;169:1.

Liu HZ, Zhang B, Jing XJ, Wang W, Wang LJ. Adsorption and desorption properties for rhenium using a kind of weak-base anion resin. Rare Met. 2018;37(8):707.

Wang A, Zhou KG, Zhang XK, Zhou DC, Peng CH, Chen W. Reductive removal of arsenic from waste acid containing high-acidity and arsenic levels through iodide and copper powder synergy. Chem Eng J. 2019;373:23.

Xiong Y, Cui XR, Zhang P, Wang YJ, Lou ZN, Shan WJ. Improving Re(VII) adsorption on diisobutylamine-functionalized graphene oxide. ACS Sustain Chem Eng. 2017;5:1010.

Xiong Y, Song Y, Tong Q, Zhang P, Wang YJ, Lou ZN, Zhang F, Shan WJ. Adsorption-controlled preparation of anionic imprinted amino-functionalization chitosan for recognizing rhenium(VII). Sep Purif Technol. 2017;177:142.

Lou ZN, Xing SS, Xiao X, Shan WJ, Xiong Y, Fan Y. Selective adsorption of Re(VII) by chitosan modified with imidazolium-based ionic liquid. Hydrometallurgy. 2018;179:141.

Sun ZH, Chen DY, Chen BD, Kong LJ, Su MH. Enhanced uranium(VI) adsorption by chitosan modified phosphate rock. Colloid. Surf. A Physicochem. Eng. Aspects. 2018;547:141.

Chen JX, Liu KL, Jiang MH, Han J, Liu ML, Wang CB, Li CL. Controllable preparation of porous hollow carbon sphere@ZIF-8: novel core-shell nanomaterial for Pb2+ adsorption. Colloid. Surf. A Physicochem. Eng. Aspects. 2019;568:461.

Liu YC, Gao MH, Zheng L, Zhao J, Wang H, Han K, Zhou YH. Understanding the high adsorption-reduction performance of triethanolamine modified graphene oxide for silver ions. Colloid. Surf. A Physicochem. Eng. Aspects. 2019;567:96.

Xu X, Zou J, Zhao XR, Jiang XY, Jiao FP, Yu JG, Liu Q, Teng J. Facile assembly of three-dimensional cylindrical egg white embedded graphene oxide composite with good reusability for aqueous adsorption of rare earth elements. Colloid. Surf. A Physicochem. Eng. Aspects. 2019;570:127.

Kabay N, Cortins JL, Trochimczuk A. Solvent-impregnated resins (SIRs)-Methods of preparation and their applications. React Funct Polym. 2010;70:484.

Wei SL, Liu JS, Zhang SX, Chen XL, Liu QQ, Zhu LL, Guo L, Liu XY. Stoichiometry, isotherms and kinetics of adsorption of In(III) on Cyanex 923 impregnated HZ830 resin from hydrochloric acid solutions. Hydrometallurgy. 2016;164:219.

Bao SX, Hawker W, Vaughan J. Scandium loading on chelating and solvent impregnated resin from sulfate solutions. Solvent Ion Exch. 2017;36:100.

Turanov AN, Karandashev VR, Sharova Artyushin OI, Sharova EV, Genkina GK. Adsorption of palladium(II) from hydrochloric acid solutions using polymeric resins impregnated with novel N-substituted 2-(diphenylthiophosphoryl)acetamides. Sep Purif Technol. 2017;187:355.

Chen B, Bao SX, Zhang YM, Zheng RW. Ultrasound-assisted synthesis of N235-impregnated resins for vanadium (V) adsorption. R. Soc. Open Sci. 2018;5:171746.

Nishihama S, Harano T, Yoshizuka K. Silica-based solvent impregnated adsorbents for separation of rare earth metals. Sep Sci Technol. 2018;53(7):1027.

Ahmad HB, Ramzanali K, Reza HS, Abolfazl RS, Ayoob R, Zahra P, Esmaeil F. Sorption efficiency of three novel extractant-impregnated resins containing vesuvin towards Pb(II) ion: effect of nitrate and amine functionalization of resin backbone. Colloids Surf A: Physicochem. Eng. Asp. 2016;504:62.

Paramanik M, Panja S, Dhami PS, Yadav JS, Kaushik CP, Ghosh SK. Unique reversibility in extraction mechanism of U compared to solvent extraction for sorption of U(VI) and Pu(IV) by a novel solvent impregnated resin containing trialkyl phosphine oxide functionalized ionic liquid. J Hazard Mater. 2018;354:125.

Yuan YX, Liu JS, Zhou BX, Yao SY, Li HM, Xu WX. Synthesis of coated solvent impregnated resin for the adsorption of indium (III). Hydrometallurgy. 2010;101:148.

Bao SX, Chen B, Zhang YM, Tang YP. Synthesis of coated solvent impregnated resins by PVA cross-linked with vapor-phase glutaraldehyde for adsorption of vanadium (IV). React Funct Polym. 2018;128:58.

Chen B, Bao SX, Zhang YM, Zheng RW. A high-efficiency approach for the synthesis of N235-impregnated resins and the application in enhanced adsorption and separation of vanadium(V). Minerals. 2018;8:358.

Tan YP, Bao SX, Zhang YM, Liang L. Effect of support properties on preparation process and adsorption performances of solvent impregnated resins. React Funct Polym. 2017;113:50.

Kim HS, Park JS, Seo SY, Tran T, Kim MJ. Recovery of rhenium from a molybdenite roaster fume as high purity ammonium perrhenate. Hydrometallurgy. 2015;156:158.

Tan KL, Hameed BH. Insight into the adsorption kinetics models for the removal of contaminants from aqueous solutions. J. Taiwan Inst. Chem. Eng. 2017;74:25.

Tran HN, You SJ, Hosseini-Bandegharaei A, Chao HP. Mistakes and inconsistencies regarding adsorption of contaminants from aqueous solutions: a critical review. Water Res. 2017;120:88.

Shan WJ, Cheng P, Li J, Xiong Y, Fang DW, Zang SL. Solvent extraction of perrhenate from sulfuric acid medium by triisooctylamine. J Chem Eng Data. 2015;60:2843.

Acknowledgments

This research was financially supported by the Fundamental Research Funds for the Central Universities of Central South University (No. 2019zzts243), the National Natural Science Foundation of China (No. 51604303) and Hunan Natural Science Fund for Distinguished Young Scholar (No. 2019JJ20031).

Author information

Authors and Affiliations

Corresponding author

Additional information

Xue-Yi Guo and Zhong-Chen Ma have contributed equally to this work.

Rights and permissions

About this article

Cite this article

Guo, XY., Ma, ZC., Liu, GW. et al. Adsorption of Re(VII) by coated solvent-impregnated resins containing Alamine 304-1 from sulfuric acid solutions. Rare Met. 39, 942–950 (2020). https://doi.org/10.1007/s12598-020-01447-9

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12598-020-01447-9