Abstract

The present work describes the sorption behavior of a newly synthesized calix[4]arene impregnated XAD-4 resin, i.e., (IV) for the amputation of As(III) from aqueous environment. Resin IV was characterized by using FT-IR spectroscopy, scanning electron microscope, elemental and thermogravimetric analyses techniques. As(III) sorption was achieved through static method to assess the As(III) removal competency of impregnated resin IV under various conditions. Batch experiments were carried out to optimize several parameters such as effect of sorbent dosage, pH effect, contact time, initial arsenic concentration and temperature effect. From results it was observed that % sorption of As(III) is highly dependent on pH of solution. The maximum sorption was achieved at pH 4.5. Equilibrium was achieved in 45 min. From different isotherm models it has been deduced that As(III) sorption behavior of resin IV can be better explained by Langmuir with Q of 100 mmol/g and Temkin isotherm models. Furthermore, thermal study reveals that sorption process is temperature dependent. Kinetic studies found to follow second order and more appropriately Moris–Weber diffusion kinetic model. Besides this, resin IV has been utilized for the removal of arsenic from surface water samples. The field studies reveal that resin IV is an effective sorbent to treat and purify As(III) contaminated water.

Graphical Abstract

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Arsenic is one of the most harmful and catastrophic pollutant found in nature. It is a slow poisoning detrimental element to human health and considered as a worldwide menace to humans because every year millions of human population across the world is victim of the venomous effects of this toxin. It is ubiquitously present in air, soil, natural and ground water in varying concentration. Two sources: natural and various anthropogenic activities bring about arsenic environmental contamination [1–3]. In water it may present in both organic and inorganic forms. Inorganic forms of arsenic mainly exist in two oxidation states, i.e., trivalent as arsenite (AsO3 3−) and pentavalent as arsenate (AsO4 3−) in natural waters and both are referred as As(III) and As(V) respectively. Both forms of arsenic are the most harmful to human health but As(III) is significantly more toxic and mobile than As(V) [1, 3].

Natural water contaminated with arsenic is a significant problem to human health since this compound is known as toxic, mutagenic and carcinogenic or arsenicosis. Short term exposure to arsenic can lead to dermal, respiratory, gastrointestinal, cardiovascular, mutagenic and carcinogenic effects and it may interfere with the immune system. Prolonged ingestion of arsenic contaminated water can cause chronic arsenicism. Symptoms of chromic level include hyper and hypopigmentation, bladder, lungs and kidney cancer. Besides this, other diseases such as pigmentation changes, skin thickening (hyperkeratosis) neurological disorders, muscular weakness, loss of appetite and nausea also examples of chronic arsenicism. Its acute intoxication can stimulate vomiting, bloody ‘‘rice water’’ diarrhea, esophageal and abdominal pain [4–6]. Due to its high toxicity to human health USEPA and WHO established an international maximum contaminant level for arsenic in drinking water of 0.001 μg L−1 [7, 8].

Environmental scientists have contributed extensive efforts for the remediation of arsenic from aqueous media. In this regard various technologies have been developed to purify water from contamination of arsenic including oxidation–precipitation [9] coagulation–flocculation filtration [10] liquid–liquid extraction, ion exchange [11, 12] membrane filtration [13] ultra and nano-filtration [14] adsorption [15]. Each of these above processes have their own advantages along with limitations such as high cost, producing high sludge, membrane fouling and constant scrutiny of the ions’ concentration. On contrary to this sorption is an economical alternative and conventional technique; it is simple to operate, environmentally benign, versatile, robust, efficient and cost-effective. Due to these characteristic features sorption technology is the most promising and a fabulous technique for arsenic removal from wastewater [16]. A variety of natural as well as synthetic materials has been tremendously utilized in sorption technology [17–20]. In this view one of the most magnificent member of macromolecules is “calixarene” has played a pivotal role for decontamination of hazardous materials. The rigidity, conformational structure and unlimited derivatization significantly determine its complexation properties [21–23]. Number of scientists has synthesized efficient calixarene derivatives possessing pyridine, amine, amide or imide functional groups have proven marvelous anions extracting receptors especially for oxoanions [24–28]. Furthermore, efficiency and stability of calixarenes due to aromatic backbone can be further strengthened by incorporation of calixarene framework onto a polymeric support. These materials are regenerable and in terms of chemical, physical/thermal point of view they are stable and widely used for purification of aqueous media [29]. Present study is an extension of our previous efforts of developing regenerable synthetic resins [30–32] which demonstrates the environmental application of newly synthesized calix[4]arene diamide derivative impregnated Amberlite XAD-4 resin to remove As(III) from aqueous media. But in this paper we first time report the synthesis of a new calix[4]arene derivative based XAD-4 resin for As(III) amputation. Although it possess different functionalities which have different criteria for As(III) removal as previously reported studies.

Experimental

Instrumentation

Melting points were determined on a Gallenkamp melting point apparatus (model MFB 595. 010M, England). Elemental analyses were performed using a CHNS instrument model Flash EA 1112 elemental analyzer (20090. Rndano, Milan, Italy). IR spectra were recorded on a Thermo Nicollet 5700 FT-IR spectrometer (WI. 53711, USA) as KBr pellets. UV–Vis spectra were obtained with Perkin Elmer (Shelton, CT06484, USA) Lambda 35 through UV–Vis spectrophotometer. Scanning Electron Microscopic (SEM) studies were performed using JSM-6490 instrument. The pH measurements were made with pH meter (781-pH/Ion meter, Ω Metrohm, Herisau Switzerland) with glass electrode and Ag, Ag/Cl internal reference electrode. A Gallenkamp thermostat automatic mechanical shaker (model BKS 305-101, UK) was used for batch study. Atomic absorption spectra were obtained using Perkin–Elmer Analyst 700 atomic absorption spectrometer.

Chemicals

All the chemicals and reagents of synthetic grade used in this study were obtained from Merck (Darmstadt, Germany) and used without further purification. Analytical grade arsenic trioxide (As2O3) was supplied by Merck (Darmstadt, Germany). Arsenic stock solution of 1 g L−1 was prepared on weekly basis. The pH of the solution was adjusted by mixing appropriate amount of HCl and NaOH (0.1 N). Analytical TLC was performed on precoated silica gel plates (SiO2, Merck PF254, Darmstadt, Germany). Amberlite XAD-4 resin (styrene–divinylbenzene copolymer), surface area 725 m2 g−1, pore diameter 4 nm and bead size 20–50 mesh were supplied by Fluka (Buchs, Switzerland). Nitric acid solution (5 M) was used for soaking all glassware and polyethylene bottles. Before use, all these bottles were washed with deionized water. All aqueous solutions were prepared with deionized water that had been passed through a Milli-Q system (Elga Model Classic UVF, UK). (0.05 %) aqueous solution of Rhodamine-B, potassium iodate (2 %) and (0.4 M) solution of HCl were prepared by dissolving the reagents in deionized water.

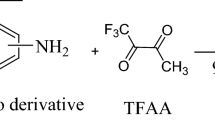

Synthesis

Synthesis of calix [4] arene I and its derivatives (II, and III) were carried out according to the previously published literature [33–35]. Resin IV employed in this work (Fig. 1) has been synthesized as follow:

Impregnation of diamide derivative of calix[4]arene onto Amberlite XAD-4™

Impregnation of (III) onto Amberlite XAD-4™ was carried out by following the same strategy as in our previously reported method [36]. 1.5 g of XAD-4 resin was taken in a 100 mL round-bottom flask. 0.0521 g (6.6 × 10−3 M) solution of compound III in 25 mL of ethanol was added and the mixture was continuously stirred for 120 h at room temperature. After that the resin was filtered off though sintered glass funnel washed with ethanol and water to remove unimpregnated compound III. The maximum amount of compound III impregnated onto dry resin was 0.0124 g that is (6.321 × 10−4 M). The elemental analysis found as C, 79.36; H, 8.55; N, 4.38 %. FT-IR: 3,436, 1,663, 1,609, 1,517, 1,356 cm−1.

Sorption methods

The sorption efficiency of the synthesized calix[4]arene diamide impregnated resin toward oxoanion As(III) was estimated through static and dynamic sorption methods.

Static method (batch method)

Batch equilibrium sorption studies were exercised with aqueous solutions of As(III). Sorption measurements were carried out with 10 mL volume of (30 mg L−1) concentration and constant amount of 0.5 g in 50 mL stoppered Erlenmeyer flasks; the mixture was agitated in a thermostatic shaker at 175 rpm, 25 °C for equilibration (shaking) time of 1 h. After that, the mixture was filtered off and sorbent was separated before measurement. The residual arsenite ion concentration remaining in aqueous phase was determined spectrophotometrically at 553 nm by a reported method [32, 37]. The effect of pH was studied by adjusting the pH of aqueous solutions using diluted HCl and NaOH solutions at 25 °C. The % sorption of As(III) was calculated as:

Where C i (mol L−1) is initial concentration of solution before sorption and C f (mol L−1) final concentration of As(III) after sorption.

Results and discussion

Characterization of resin IV

SEM analysis

The morphology and surface characteristics of sorbent material are generally characterized by SEM. In this approach SEM is used to study the morphological changes on the surface of impregnated resin which are shown in (Fig. 2a–c). From SEM images it can be observed that the surface of impregnated resin IV has been totally covered of with the impregnation of calixarene molecules evident from the formation of white layer (cloud) of uniform thickness and coverage.

Thermo gravimetric (TGA) analysis

Thermogravimetric analysis (TGA) was used to examine the thermal stability of the impregnated resin IV as shown in (Fig. 3). This study was carried out in an inert atmosphere of N2 gas. Thermal degradation curve of impregnated resin IV shows two main steps. The first very small step ranging from (36 to 100 °C) was attributed due to the loss of physically sorbed moisture content. During this step only 14 % weight was lost. The second very sharp decreasing downward curve ranging from (370 to 490 °C) has been recognized to the combustion of impregnated resin IV. Here 60 % more weight was reduced. From these results it has been concluded that resin IV is very much stable up to 490 °C.

Sorption studies

Effect of sorbent dosage

Dosage study parameter was carried out using varying amount of impregnated resin IV (0.25–1.25 g) at shaking speed of 125 rpm for 1 h. Figure 4 demonstrates the percent sorption of As(III) increased very rapidly when amount of sorbent was increased from (0.25 to 0.50 g) after that percent removal of As(III) remains almost constant up to 1.25 g of sorbent dosage.

Effect of pH

The most effective and important parameter is pH effect which not only affects sorption efficiency but also explains the sorption mechanism and determines the nature of the sorption process as well. In this study effect of pH on sorption capacity of impregnated resin IV toward As(III) was examined through static method at pH range of 2.5–7.5 using initial concentration of As(III) as 30 mg L−1 and a contact time of 1 h. The results are presented in (Fig. 5) which indicates that sorption capacity of resin IV significantly depends on solution pH. The maximum percentage sorption of As(III) was determined as 82 % at pH 4.5. Similarly percentage sorption decreases to 44 % when pH of the aqueous solution increased to neutral range, i.e., 6.5. It signifies that best interaction between ligand and arsenite ions occurs at this acidic pH range. These interactions include electrostatic interaction and hydrogen bonding between protonable amine and the oxygen atoms of arsenate anions [38].

Effect of contact time

As(III) removal capacity of resin was determined in terms of contact time. The equilibrium time was examined by agitating the solution for 1 h at optimized pH 4.5 and fixed concentration using 0.5 g of resin at the shaking speed of 125 rpm. Figure 6 reveals that with the passage of contact time percentage removal of As(III) increases. Equilibrium was observed at 30 min but sorption efficiency of resin remains almost constant after 30 min. Hence further study was done for 60 min to avoid any kind of error.

Effect of temperature

To explain the thermodynamic behavior of As(III) sorption by resin IV experiments were conducted at different temperature ranges, i.e., 298–318 K with intervals of 10 K at optimum conditions. Figure 6 shows that with the rise of temperature As(III) sorption also increases which reflects that the nature of As(III) sorption onto resin IV is temperature dependent.

Comparative study

The maximum sorption capacity of impregnated resin for As(III) has been compared with other sorbents already reported in the literature [1, 39–47]. It can be noticed from data as given in (Table 1) that sorption capacity of impregnated resin is much higher than previously reported studies. It may also be demonstrated that resin IV is more effective as compared with other sorbent materials as amount of sorbent dosage that only 0.5 g of resin IV is sufficient to sorb 86 % of As(III) from sample solution. The superiority of this impregnated resin over other sorbents could be explained on the basis of economical viewpoint. Efficient capability for As(III) along with regeneration and reusability of the resin makes its cost negligible.

Sorption isotherms

The chemistry of As(III) onto resin IV enlightened using sorption isotherms. Equilibrium experimental data have been evaluated using Langmuir, Freundlich D–R and Temkin isotherm models. Langmuir isotherm assumes that Sorption rate is directly proportional to the number of active sites of sorbent and sorbate concentration but sorption limited to monolayer coverage only [48].

Favorability of sorption behavior can be determined using dimensionless equilibrium parameter, i.e., separation factor (R L ) can be calculated using the following relationship:

The Freundlich sorption model [49] is based on surface heterogeneity of the sorbent, i.e., multilayer sorption. Thus unlimited surface coverage is demonstrated mathematically and signifying physisorption. This isotherm was tested in the following form:

Dubinin–Radushkevich (D–R) isotherm is more general to differentiate physico-chemical sorption phenomena [50]. This isotherm is more common than Langmuir isotherm model. It assumes heterogeneity of energies over the surface. The linear form of D–R equation can be examined as:

Polanyi proposed the difference in free energy between the sorbed phase and saturated liquid phase is referred to as sorption potential. The saturation limit(X m) may represent total specific micropore volume of the sorbent. The value of sorption energy E can be correlated by using Eq. 7 which has calculated as 9.85 KJ mol−1.

Temkin equation gives information about a relationship between heat of sorption and the sorbent–sorbate interaction on surfaces. It suggests that heat of adsorption of all molecules decreases linearly as the completion of sorption sites of sorbent is increased [51]. The Temkin isotherm equation is given as below;

From results as shown in (Table 2) can be concluded that the experimental constant values were calculated from Langmuir, Freundlich, D–R and Temkin isotherm equations. Relatively regression coefficient (R 2) values are significant (0.99) for Langmuir and Temkin isotherm models which are higher than Freundlich and D–R isotherm models. The value of correlation coefficient indicates that this sorption process is feasible, compatible and equilibrium data follow the Langmuir and Temkin isotherm models. The value R L calculated was less than 1 and the adsorption capacity (1/n) of resin IV was evaluated to be 0.65 which supports that the sorption process is favorable. D–R isotherm was used to ascertain the nature of As(III) sorption. Value of energy of sorption for As(III) onto resin IV is calculated as 9.85 KJ mol−1 which suggests the As(III) sorbed ionic interactions/chemisorption. Data show applicability of Langmuir and Tempkin isotherms which explain surface monolayer coverage of As(III) and best maximum interaction with sorbent sites on the surface of resin IV.

Sorption kinetics

In kinetic studies the rate of sorption of As(III) onto resin IV was determined by utilizing four kinetic models that are (Lagergren) pseudo-first-order, (Ho and Mckay) pseudo-second-order and intraparticle diffusion using (Moris–Waber) [52–54].

From results as shown in (Table 3) that sorption of As(III) onto resin IV follows the pseudo-second-order kinetic model. Sorption process do not comply with pseudo-first-order model in spite of having significant q e value. While in case of pseudo-second-order model the experimental data fit significantly well and provide better correlation coefficients (R 2 = 0.99, 0.99, 0.92) than pseudo-first-order model for As(III) sorption behavior. Rate constant values for pseudo-first-order increase while for pseudo-second-order model tends to decrease with the rise of temperature. Moreover the pseudo-first-order model is based on the assumption that the rate limiting step may be chemical sorption involving hydrogen bonding between sorbate and sorbent. Hence it can be concluded that the sorption of As(III) was predominated by pseudo-second-order kinetic model and hence sorption data of present study support the chemisorption nature of As(III). Diffusion model depicts the solute mass transfer from bulk of solution to solid surface. The value of R d and rate constant of intraparticle transport were estimated as described in (Table 3). However linear plot in this study did not pass through the origin. This indicates that degree of boundary layer controls the As(III) sorption onto resin IV and intraparticle diffusion was not the only rate controlling step.

Thermodynamics of sorption

The thermodynamic parameters change in enthalpy (ΔH), entropy (ΔS), and Gibbs free energy (ΔG) describe the spontaneity, nature and randomness of the sorption process [55]. Thermodynamics parameters are estimated from the equations below:

Where K c is the equilibrium constants for sorption, R is an ideal gas constant (8.314 KJ mol−1 K−1) and T is the temperature in Kelvin. Thus, the effect of temperature on sorption As(III) onto impregnated resin IV was studied at different temperatures, i.e., (298, 308 and 318 ± 1 K) at optimum conditions. The thermodynamic parameters ΔH, ΔS and ΔG were calculated from the slope and intercept of the linear plot of ln (q e /C e ) vs 1/T.

From (Fig. 6) it has been concluded that As(III) percent sorption onto resin IV increases with increasing the temperature. The values of three parameters are given in (Table 4). The negative value of ΔG suggests that As(III) sorbed spontaneously onto resin IV under applied conditions. Moreover endothermic nature of sorption can be analyzed form positive value of ΔH. With the rise of temperature values of ln K c increased from 0.47–0.92. Furthermore increasing percent uptake with temperature shows that sorption of As(III) onto resin IV is a temperature dependant process. It can be suggested that the driving force for sorption process is an entropy effect and slightly positive value of entropy (ΔS) implies the increased randomness at the solid/solution interface during the sorption of As(III) onto resin IV.

Field application of resin IV

An effort has made to ensure that resin IV is an efficient sorbent for the removal of As(III) from aqueous environment. The field study of resin IV for real waste water samples has been carried out by spiking method. The real samples were collected as ground water samples from different sites of the outskirts of Hyderabad city in Pakistan. Their conductivity, salinity and total dissolved solids (TDS) contents were determined before and after the treatment with resin. Batch experiments were performed with 50 mg of resin IV and 10 mL of real sample of Arsenic contaminated effluent that has been stirred at 160 rpm for 1 h at room temperature. The arsenic concentration was investigated before and after the treatment of waste effluent with resin IV through the UV–visible spectrophotometer at its particular wavelength, i.e., 553 nm. The results obtained are summarized in (Table 5).

From results shown in (Table 5) it has been observed that resin IV shows quite remarkable efficiency for the removal of total arsenic from different real samples and was determined up to 76 %. In addition to this other parameters like conductivity, salinity and TDS drastically decreased. It can be concluded that resin IV is an efficient sorbent for arsenic remediation from aqueous environment.

Regeneration of resin IV

The resin IV was regenerated and reused for times for As(III) sorption. The resin was agitated for 10 min and basified with only 10 mL of 4 % NaOH basic solution. After this, the resin was washed thoroughly with deionized (mili-Q) water until the pH of water reached at neutral. The efficiency of regenerated resin was remained almost same.

Conclusion

This study highlights the synthesis of calix[4]arene based resin IV and its sorption ability toward As(III). Synthesis was confirmed by using different analytical techniques. The characteristics sorption of As(III) onto resin IV was studied under static and dynamic modes of sorption. Maximum removal of As(III) occurred at pH of 4.5. Equilibrium sorption data showed excellent fit to Langmuir and Tempkin isotherm models with an adsorption capacity of 100 mmol g−1 which indicate monolayer sorption on the homogeneous surface of the sorbent. Thermodynamic studies concluded that the sorption process for As(III) was feasible, spontaneous and endothermic in nature because of the positive ΔH 0 0.034 KJ mol−1 and negative ΔG value. The pseudo-second-order kinetic model was found to best correlate to the experimental data for As(III) sorption. The rate determining step was found to be controlled by both surface sorption as well as film diffusion mechanism. In addition, it also reduces other water quality parameters of pH, TDS, conductivity and salinity of waste water. Hence results of this study signify that resin IV has high capacity to remove As(III) from contaminated waste water.

References

A. Goswami, P.K. Raul, M.K. Purkait, Chem. Eng. Res. Des. 90, 1387 (2012)

A.I. Zouboulis, I.A. Katsoyiannis, Ind. Eng. Chem. Res. 41, 6149 (2002)

D.K. Nordstrom, Science 296, 2143 (2002)

C.K. Jain, I. Ali, Water Res. 34, 4304 (2000)

A. Chatterjee, D. Das, B.K. Mandal, T.R. Chowdhury, G. Samanta, D. Chakraborty, Analyst 120, 643 (1995)

USEPA (United States Environmental Protection Agency). Inorganic chemical pollution of fresh water in Water Quality Criteria Data Book, vol. 2, (US Government Printing Office, Washington, DC. Pub. No. 18010, DPV 07/71, Litton Inc. 1971)

U.S. Environmental Protection Agency (USEPA), Quality Criteria for Water 1986. Office of Water, Regulation and Standard. (Washington, DC 20460. EPA 440/5-86-001. 1986)

WHO. Guidelines for drinking-water quality, health criteria and other supporting information, vol 2, 2nd edn. (World Health Organization, 1996), p. 940

O.X. Leupin, S.J. Hug, Water Res. 39, 1729 (2005)

H.K. Hansen, P. Núñez, R. Grandon, Miner. Eng. 19, 521 (2006)

S. Sayin, F. Ozcan, M. Yilmaz, J. Hazard. Mater. 178, 312 (2010)

S. Sayin, M. Yilmaz, M. Tavasli, Tetrahedron 67, 3743 (2011)

T. Dutta, C. Bhattacherjee, S. Bhattacherjee, Int. J. Eng. Res. Technol. 1, 9 (2012)

D.H. Kim, K.W. Kim, J. Cho, J. Water Health 4, 215 (2006)

I. Qureshi, S. Memon, M. Yilmaz, Clean Soil Air Water 41, 258 (2013)

M. Jang, S.H. Min, T.H. Kim, J.K. Park, Environ. Sci. Technol. 40, 3248 (2006)

C. Chiing-Chang, C. Ying-Chien, J. Environ. Sci. Health Part A 41, 645 (2006)

T.D. Ciftçi, O. Yayayürük, E. Henden, Environ. Technol. 32, 341 (2011)

M. Bissen, T. Gremm, U. Koklu, F.H. Frimmel, Acta Hydrochim. Hydrobiol. 28, 41 (2000)

M.A. Barakat, S. Ismat-Shah, Arab. J. Chem. 6, 307 (2013)

E. Ghidini, F. Ugozzoli, R. Ungaro, S. Harkema, A. Abu El-Fadl, D.N. Reinhoudt, J. Am. Chem. Soc. 112, 6979 (1990)

S. Shinkai, T. Otsuka, K. Fujimoto, T. Matsuda, Chem. Lett. 19, 835 (1990)

T. Tuntulani, P. Thavornyutikarn, S. Poompradub, N. Jaiboon, V. Ruangpornvisuti, N. Chaichit, Z. Asfari, J. Vicens, Tetrahedron 58, 10277 (2002)

S. Memon, D.M. Roundhill, M. Yilmaz, Collect. Czech. Chem. Commun. 69, 1231 (2004)

S. Sayin, F. Ozcan, S. Memon, M. Yilmaz, J. Incl. Phenom. Macrocycl. Chem. 67, 385 (2010)

S. Sayin, F. Ozcan, M. Yilmaz, Desalination 262, 99 (2010)

S. Sayin, F. Ozcan, M. Yilmaz, A. Tor, S. Memon, Y. Cengeloglu, Clean Soil Air Water 38, 639 (2010)

I. Qureshi, S. Memon, Appl. Water Sci. 2, 177 (2012)

A.A. Bhatti, A.A. Bhatti, I.B. Solangi, S. Memon, Desalination. Water Treat. 51, 4666 (2013)

I.B. Solangi, A.A. Bhatti, M.A. Kamboh, S. Memon, M.I. Bhanger, Desalination 272, 98 (2011)

A.A. Bhatti, M.A. Kamboh, I.B. Solangi, S. Memon, J. Appl. Polym. Sci. 130, 676 (2013)

I. Qureshi, M.A. Qazi, A.A. Bhatti, S. Memon, S.M. Yilmaz, Desalination 278, 98 (2011)

C.D. Gutsche, M. Iqbal, D. Stewart, J. Org. Chem. 51, 742 (1986)

E.M. Collins, M.A. McKervey, E. Madigan, M.B. Moran, M. Owens, G. Ferguson, S.J. Harris, J. Chem. Soc. Perkin Trans. 1, 3137 (1991)

X. Chen, R.P.M. Dings, I. Nesmelova, S. Debbert, J.R. Haseman, J. Maxwell, T.R. Hoye, K.H. Mayo, J. Med. Chem. 49, 7754 (2006)

F.N. Memon, S. Memon, S. Memon, N. Memon, J. Chem. Eng. Data 56, 3336 (2011)

A. Pillai, G. Sunita, V.K. Gupta, Anal. Chim. Acta 408, 111 (2000)

S. Sayin, F. Ozcan, M. Yilmaz, Mater. Sci. Eng. C 33, 2433 (2013)

D. Mohan, C.U. Pittmann, Jr. J. Hazard. Mater. 142, 1 (2007)

O.S. Thirunavukkarasu, T. Viraraghavan, K.S. Subramanian, O. Chaalal, M.R. Islam, Energy Sour. 27, 209 (2005)

C.A. Martinson, K.J. Reddy, J. Colloid Interface Sci. 336, 406 (2009)

Md. R. I. Chowdhury, C.N. Mulligan, J. Hazard. Mater. 190, 486 (2011)

J. Giménez, M. Martínez, J. de Pablo, M. Rovira, L. Duro, J. Hazard. Mater. 141, 575 (2007)

V.M. Boddua, K. Abburib, J.L. Talbottc, E.D. Smitha, R. Haasch, Water Res. 42, 633 (2008)

J. Antoniomuñoz, A. Gonzalo, M. Valiente, Environ. Sci. Technol. 36, 3405 (2002)

H. Matsunaga, T. Yokoyama, R.J. Eldridge, B.A. Bolto, React. Funct. Polym. 29, 167 (1996)

Z. Gu, B. Deng, Environ. Eng. Sci. 24, 113 (2007)

I. Langmuir, J. Am. Chem. Soc. 40, 1361 (1918)

H. Freundlich, Colloid Capillary Chemistry (Methuen, London, 1926), p. 414

M. Polanyi, Trans. Farad. Soc. 28, 316 (1932)

C. Aharon, M. Ungarish, J. Chem. Soc. Faraday Trans. 1. 73, 456 (1977)

E. Haribabu, Y.D. Upadhya, S.N. Upadhyay, J. Environ. Stud. 43, 169 (1993)

Y.S. Ho, G. McKay, Proc. Biochem. 34, 451 (1999)

W.J. Morris, J.C. Weber, J. Sanit. Eng. Div. ASCE. 89, 31 (1963)

I.B. Solangi, A.A. Bhatti, M.A. Kamboh, S. Memon, M.I. Bhanger, Sep. Sci. Technol. 46, 1113 (2011)

Acknowledgments

The authors thank the Scientific and Technical Research Council of Turkey (TUBITAK), Ministry of Science and Technology, Islamabad, [Project No—12(106-B)/2004-ASA (IL)] and the National Center of Excellence in Analytical Chemistry, University of Sindh, Jamshoro-Pakistan, for the financial support of this work.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Memon, S., Bhatti, A.A. & Bhatti, A.A. Sorption of As(III) by calix[4]arene modified XAD-4 resin: kinetic and thermodynamic approach. J IRAN CHEM SOC 12, 727–735 (2015). https://doi.org/10.1007/s13738-014-0531-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13738-014-0531-6