Abstract

The aim of this study was to develop conductive adhesive using silver nanowires prepared via solvothermal method as conductive fillers and epoxy-modified organosilicone resin as matrix resin. Effect of the addition of silver nanowires/flakes on the conductive adhesive’s electrical and mechanical properties was investigated. Compared with conventional conductive adhesive with silver flakes fillers, the percolation threshold of conductive adhesive with silver nanowires fillers is 10 % lower approximately. However, further rise of the content of silver nanowires has no obvious influence on improvement of the electrical conductivity of conductive adhesive. Both conductive and mechanical properties of conductive adhesive can be compatible by adding silver nanowires, which traditional silver conductive adhesives cannot reach.

Graphical Abstract

Silver nanowires with a pleasurable morphology prepared via alcohothermal method were introduced into the conductive adhesive compositions. It can be found find that silver nanowires are overlapped fairly in the conductive adhesive, though existing crosslinking to some extent, yet silver nanowires do not appear the phenomenon of agglomeration. The conductive adhesive with silver nanowires as conductive fillers can exhibit favorable electrical and mechanical properties.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

The conductive adhesive, for its intensively promoted properties, has been widely employed in many fields, and each year its utilization also increases on account of the continuous work in recent years [1–3], whereas, in terms of the current researches, the most challenging problem of conductive adhesive is that the conductive properties and the shear strength can be hardly compatible [4–6]. Though the addition of conductive fillers can improve the conductivity efficiently, yet it decreases the mechanical properties [7, 8]. Among all the methods of improving the mechanical properties of conductive adhesive, using nanomaterials to enhance the bonding strength is one of the most effective ways [9–11]. Silver nanowires not only exhibit excellent electrical conductivity themselves, but also have the effect of strengthening mechanical property due to the linear structure. Furthermore, silver nanowires have low sintering temperature, which can bring the contact resistance down, form the metallic bonding effect that is similar to the low-melting-point alloys and enhance the adhesive properties [12–16]. In this work, silver nanowires with a pleasurable morphology were prepared via an alcohol thermal method. By introducing these nanowires into the conductive adhesive compositions, a positive conductive adhesive with low fillers content but exhibiting favorable electrical and mechanical properties was produced. In an attempt to understand the conduction mechanism and the contact condition, the sliver flakes were also used as conductive fillers to develop conductive adhesive in comparison with silver nanowires.

2 Experimental

2.1 Synthesis of conductive fillers

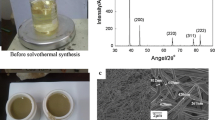

Silver nanowires were prepared by alcohothermal method. In a typical synthesis procedure, 40 ml polyvinylpyrrolidone (PVP) solution (0.4 mol·L−1 in glycerol, containing some control agents) was added into a three-necked round-bottomed flask; meanwhile, 40 ml AgNO3 solution (0.2 mol·L−1 in glycerol) was poured into an acid buret. Then, the AgNO3 solution was added to the flask slowly drop by drop with vigorous stirring, and at the same time, the mixture was heated to 210 °C from room temperature in an oil bath. When the reaction was stopped, the flask cooled down naturally to room temperature. The product was washed with distilled water several times to remove most of the impurities and then dried to get the target product. Silver flakes were purchased from HENGDA Technology Company, Kunming, China. Morphology of the as-synthesized silver nanowires and silver flakes is shown in Fig. 1. Figure 1a shows that the diameters of the silver nanowires are in the range of 50–60 nm, and lengths are up to ~15 µm; Fig. 1b shows that the average size of silver flakes is 1–10 µm.

2.2 Design of conductive adhesive

Epoxy-modified organosilicone resin, phenol formaldehyde epoxy resin, reactive diluent D-669 and silane coupling agent KH-550 were mixed in a certain proportion and grinded for 10 min. After that, silver nanowires/flakes, curing agent MeHHPA and curing promoting agent DMP-30 were added and grinded for 20 min. At last, a certain amount of defoaming agent was also added into the mixtures, which need to be grinded for another 10 min to prepare the conductive adhesive.

2.3 Characterization or measurements

Field scanning electron microscope (SEM, Hitachi S4700) was used to observe the microstructure of the fundamental materials. The bulk resistivity test samples were prepared by coating conductive adhesive on two bare glasses, with copper as testing electrode, and HK3540-1 DC resistance measuring instrument was used to measure its resistivity. Tensile shear strength testing was mainly based on ISO 4587:2003.

3 Results and discussion

3.1 Characterization of conductive fillers

Figure 2a, b shows the cross-sectional images of silver flakes with different densities on conductive adhesive. From these two pictures, it can be known that silver flakes disperse uniformly in the conductive adhesive; from the cross-sectional images of silver nanowires conductive adhesive as indicated in Fig. 2c, d, it can be found that silver nanowires overlap fairly in the conductive adhesive. Though there is crosslinking to some extent, the phenomenon of agglomeration does not appear in silver nanowires.

3.2 Electrical properties of conductive adhesive

As shown in Fig. 3, when the fillers content is too low, the fillers are so dispersed in the resin that continuous conductive path is hardly formed. Herein, the conductive adhesive is non-conducting. When the contents of silver nanowires and silver flakes increase to 20 wt% and 30 wt%, respectively, the conductive adhesive begins to achieve electrical conductivity. Thus, it can be judged that the percolation threshold of silver nanowires conductive adhesive is between 30 wt% and 40 wt%, while that of the silver flakes is about 40 wt%–50 wt%. When the fillers content is lower than 52 wt%, the silver nanowires conductive adhesive is lower than the micro-silver flakes conductive adhesive but not vice versa.

3.3 Mechanical properties of conductive adhesive

Figure 4 shows that the tensile shear strength of silver nanowires conductive adhesive increases when more silver nanowires were added to the sample, while that of the silver flakes conductive adhesive tends to increase at first and then starts to drop and reaches the maximum value at 60 wt%. Besides, the tensile shear strength of silver nanowires conductive adhesive is always higher than that of the silver flakes conductive adhesive.

3.4 Conductive mechanism study

The bulk resistivity of conductive adhesive is greatly dependent on the species, morphology and size. According to the “percolation threshold theory”, the conductive fillers need to form a conducting path in order to establish the conductivity. When the proportion of the fillers content in insulating polymer matrix reaches a critical value, at which all conductive fillers are supposed to contact each other and form more sufficient three-dimensionally interconnected conductive network from simple conductive path, a dramatical decrease will occur [17, 18]. At low fillers content, roughly above 30 % but below 50 %, the specific surface area of silver nanowires is larger, which means that they might more easily contact each other to form conductive networks; furthermore, on the basis of “tunneling effect theory”, silver nanowires containing some nanometer-sized Ag particles can penetrate the potential barrier and reach the next particle at some distance to form a conductive channel in some area where silver nanowires cannot contact [19], so the electrical property of silver nanowires conductive adhesive is better than that of silver flakes. As the fillers content is high, the fillers connect more closely to each other. The conductive networks in conductive adhesive filled with silver flakes have less contact points and more contact areas than that filled in silver nanowires, which have more contact lines and contact points that result in a higher constriction resistance. Therefore, silver flakes conductive adhesive has a better electrical conductivity at high filler content. Figure 5 shows the contact state of different morphologies of conductive fillers.

3.5 Mechanical properties study

Since silver nanowires have a fibroid shape, they could more easily contact with the resin and be wetted by the resin [20] and do not break the succession of the resin matrix. Moreover, in a certain range, the addition of nanometer-sized Ag particles can enlarge the contact area efficiently, which implies that it can decrease the bulk resistivity and enhance the tensile shear strength simultaneously. Meanwhile, the small size effect of nanomaterials plays a significant role as well. It is well known that nanomaterials have a large interface whose atomic arrangement is rather disordered, making atoms transfer much more easily under the circumstance of the deformation of external force. This without doubt will endow the conductive adhesive with a particular toughness and ductility. Therefore, the tensile shear strength of silver nanowires conductive adhesive increases with the increase in silver nanowires content. However, when there are too many silver flakes, they cannot be wetted by the resin, which can generate gaps or air holes on the fillers interface, leading to discontinuity of the resin matrix. The stress caused by external load on the composite materials do not arrange uniformly, which would give rise to the craze of the conductive adhesives once the local stress concentrates. As a consequence, the tensile shear strength of silver flakes conductive adhesive has a tendency to increase at first and then start to drop.

4 Conclusion

In this work, silver nanowires were prepared with a high slenderness ratio via an alcohothermal method. Using these silver nanowires as conductive fillers, a novel conductive adhesive was developed. The preliminary results show that silver nanowires conductive adhesive has a percolation threshold lower about 10 % than that of micro-silver flakes, which is beneficial to saving materials and lowering the costs. In addition, the mechanical properties of silver nanowires conductive adhesive are better than those of silver flakes conductive adhesive, and the tensile shear strength of silver nanowires conductive adhesive increases with the increase in silver nanowires’ content. Electrical conductivity and mechanical properties can be guaranteed. In contrast, as for silver flakes conductive adhesive, when the fillers content exceeds 60 wt%, its tensile shear strength will decrease, which means that it cannot have both good electrical conductivity and mechanical properties.

References

He YC. The study and development of electrically conductive adhesive. Chem Adhes. 2008;30(1):47.

Ni XJ, Liang TX. Progress in research on electrically conductive adhesives. Electron Compon Mater. 2002;21(1):1.

Li Y, Wong CP. Recent advances of conductive adhesives as a lead-free alternative in electronic packaging: materials, processing, reliability and applications. Mater Sci Eng. 2006;51(1–3):1.

Ho LN. Copper-filled electrically conductive adhesives with enhanced shear strength. J Mater Eng Perform. 2014;23(9):3371.

Qin YC, Qi SH, Yang YQ, Zhang Y. Research progress of improving ECA’s properties. Chin Adhes. 2011;9(20):53.

Wang YH, Xiong NN, Xie H, Zhao YZ, Li JZ. New insights into silver nanowires filled electrically conductive adhesives. Mater Electron. 2015;26(2):621.

Liang TX, Guo WL, Yan YH. Electroless plating of silver on graphite powders and the study of its conductive adhesive. Int J Adhes Adhes. 2008;28(1):55.

Wu HP, Wu XJ, Ge MY. Properties investigation on isotropical conductive adhesives filled with silver coated carbon nanotubes. Compos Sci Technol. 2007;67(6):1182.

Dai K, Zhu GP, Lu LH. Easy and large scale synthesis silver nanodendrites: highly effective for isotropic conductive adhesives. J Mater Eng Perform. 2012;21(3):353.

Xiao JY, Wei H, Shou XW, Guo YZ, Yao T. Preparation and properties of a novel electrically conductive adhesive using a composite of silver nanorods, silver nanoparticles, and modified epoxy resin. Mater Electron. 2012;23(1):108.

Chen C, Wang L, Li RL. Effect of silver nanostructures on the resistivity of electrically conductive adhesives composed of silver flakes. J Mater Sci. 2010;21(5):486.

Wu HP, Liu JF, Wu XJ. High conductivity of isotropic conductive adhesives filled with silver nanowires. Int J Adhes Adhes. 2006;26(8):617.

Wu HP, Wu XJ, Liu JF, Zhang GQ, Wang YW, Zeng YW, Jing JZ. Development of a novel isotropic conductive adhesive filled with silver nanowires. J Compos Mater. 2006;40(21):1961.

Hai PW. Development of a novel isotropic conductive adhesive filled with silver nanowires. J Compos Mater. 2006;40(21):1961.

Chen C, Wang L, Li RL, Jiang GH, Yu HJ, Chen T. Effect of silver nanowires on electrical conductance of system composed of silver particles. J Mater Sci. 2007;42(9):3172.

Qin J, Du YG, Wang X, Zhang WJ, Liu Y. Preparation and application of 1D silverwires for conductive adhesives. Precious Met. 2012;33(1):10.

Morris JE, Lee JJ. Liu J. Isotropic conductive adhesives: Future trends, possibilities and risks. In: International Conference on Polymers and Adhesives in Microelectronics and Photonics, Polytronic. Poland; 2005. 328.

Pike E, Seager CH. Percolation and conductivity: a computer study I and II. Phys Rev. 1974;10(4):1435.

Ye L, Lai Z, Johan L, Tholen A. Effect of Ag particle size on electrical conductivity of isotropically conductive adhesives. IEEE Tran Electron Packag Manuf. 1999;22(4):299.

Madaria AR, Kumar A, Ishikawa FN, Zhou C. Uniform, highly conductive, and patterned transparent films of a percolating silver nanowires network on rigid and flexible substrates using a dry transfer technique. Nano Res. 2010;3(8):564.

Acknowledgments

This study was financially supported by the Shenzhen Innovation and Technology Commission under the Strategic Emerging Industries Development Project (No. ZDSY20120612094418467).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Li, XS., Xiang, XZ., Wang, L. et al. Conductivity and mechanical properties of conductive adhesive with silver nanowires. Rare Met. 37, 191–195 (2018). https://doi.org/10.1007/s12598-016-0747-y

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12598-016-0747-y