Abstract

Silver nanowires were prepared by polyol process and doped to the system containing conventional micro-scaled sphere or flake silver particles. It is found that the conductance of doped system is much better than the undoped system with the same quantity silver. A plausible mechanism is described as that these nanowires are favor to act as bridges to establish perfect linkage among particles, and the chance of contact and contact area become more than the cases without wires. This development will be meaningful for the preparation of advanced electrically conductive adhesive (ECA) with high conductivity and good adhesive strength.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Electrically conductive adhesive (ECA) has wide application in surface mount, flip chip and electronic component [1]. A typical ECA contains conductive fillers and polymer matrix, which play the roles as electrical conduction and mechanical interconnection, respectively. It is expected at all times that there will be an advanced and novel ECA which perform both high electrical conductance and good adhesive strength. But these two fundamental properties are always conflicting unless the decrease of content of fillers does not cause the decrease of conductance of ECA, and then we can increase the content of polymer matrix to enhance the adhesive strength. One feasible approach to this problem is the establishment of perfect conductive networks under low content of conductive fillers. Maybe developing novel filler is the effective and simple method.

Silver is the most wide applied conductive filler in ECA because of its highest electrical conductivity and stable chemical properties. Silver nanowires prefer to establish perfect networks rather than common silver particles, because slender fillers are capable of forming a continuous network at a lower loading level of the filler than sphere fillers [2]. Nowadays, these one dimension (1D) silver nanostructures have been prepared by a variety of chemical methods [3], including: polyol process [4], wet chemical synthesis without surfactant and seed [5], solvothermal method [6], ultraviolet irradiation photoreduction technique [7], electrodeposition in a micellar phase [8], sol–gel coating method [9], DNA template [10], molecular wires template [11], porous materials template [12, 13] and so on. Furthermore, the researches on the field of conductance of carbon nanotubes/nanowires filled composites also supplied some evidences for the application of 1D structure in ECA. Windle et al. have fabricated carbon nanotube/poly(vinyl alcohol) composites and indicated that these tubes were good modifier for ECA [14]. This method was also applied in other polymer composites like poly(3-octythiophene) [15], polyimide [16], and their electrical characters have been reinforced markedly. But nanoparticles, a typical quasi-spherical structures, could not play the roles of interconnects or functional units as well as wires performed in ECA. Many studies on silver nanoparticles filled [17] or doped [1, 18] ECA showed that these nanoparticles could not assemble as bridges to link particles efficiently, and the resistivity of these resulted composites often increased with an increasing content of nanoparticles, because the electrical conductive modes of nanoparticle-systems changed and interfacial resistance increased [1]. Therefore we believe that introducing silver nanowires into the common silver particles will develop an efficient and economical filler for ECA.

In this paper, we prepare the silver nanowires by polyol process developed by Xia et al. [4] and attempt to understand the influence of doping these nanowires into commercial silver particles (sphere or flake) on the bulk conductance. The related conduction mechanism and formation process are also discussed.

Experimental

Silver nitrate (AgNO3, 99.8%), poly(vinyl pyrrolidone) (PVP, MW ≈ 40,000) were purchased from Shanghai Chemical Factory, China; ethylene glycol (EG), acetone and ethanol were purchased from Hangzhou Chemical Factory, China. All chemical solvent and reagents were of analytical grade and used without further purification.

Preparation of silver nanowires

Polyol synthesis of uniform silver nanowires was carried out by reducing of silver nitrate with EG in the presence of silver seeds and PVP as the capping agent [4]. In a typical process, 1 mL of AgNO3 solution (1.5 × 10−4 M, in EG) was added to 1 mL of EG in a round-bottom flask at ∼160 °C. After 12 min, 5 mL of AgNO3 solution (0.12 M, in EG) was added to flask within 20 s, then 10 mL of PVP solution (0.36 M, in EG) was dropwise added into flask in 12 min subsequently. Silver nanowires would be obtained after keeping magnetic stirring for 2 h. Centrifugation was an effective method to get purified nanowires. Untreated product solution was diluted with acetone (5× by volume), and centrifuged at 3,000 rpm for 30 min, most of the nanowires and PVP could be deposited, supernatant contained residuary EG could be removed by syringe easily. This method could be repeated by using ethanol instead of acetone as dilution to remove residuary PVP in solution. Finally, we obtained Ag nanowires dispersing in ethanol solution (about 1.1 mg silver nanowires/mL), with few PVP capped on the side faces.

Electrical measurements

The resistances of various silver particles were measured by Linear Sweep Voltammetry (LSV). Four series of silver particle systems were studied in this paper: (I) Micro-sized sphere particles with a diameter of ∼0.4 μm; (II) Flake silver; (III) Sphere silver doping of silver nanowires; (IV) Flake silver doping of silver nanowires.

For series I, 31.5 mg of sphere silver particles was added into 2.3 mL ethanol. For series II, sphere silver particles was replaced by flake silver, other operations were similar. For series III/IV, 0.3 mL of series I/II was mixed with 0.1 mL of silver nanowires solution (about 2.6wt% in all silver fillers).

The samples of these four series for resistance measurements were prepared by placing the droplets (contained ∼0.5 mg silver each) on the gold interdigitated electrode. This electrodes which consisted of an interdigitated finger pattern was prepared by liftoff of gold on a silicon dioxide substrate, the finger width and separation was 200 and 400 μm, respectively. In order to assure the deposition of silver particle on the face of electrode, ethanol should be removed by drying at 120 °C for 5 min. LSV measurement was operated on the Electrochemical Analyzer (CHI-600B), the potential was scanned in appropriate range to avoid overflow of current.

Characterization

The transmission electron microscopic (TEM) images were taken using a JEOL model 1200EX microscope operated at 160 kV, the samples for TEM observation were prepared by placing small droplets of the diluted (by ∼10× with ethanol) suspension of silver nanowires/particle on copper grids coated with amorphous carbon film. The scanning electron microscopic (SEM) images were obtained by using a field emission microscope (SIRION) at an acceleration voltage of 20 kV. The samples were dispersed in ethanol and dropped on the smooth copper substrate, drying in open ambience.

Results and discussion

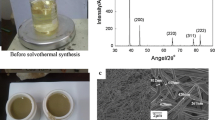

Characterization of silver nanowires

The morphology and size of synthesized silver nanowires is directly observed by TEM as shown in Fig. 1. These nanowires without any treatment exhibit high slenderness ratio (100∼1000) and some assemble to the bundles (as shown in Fig. 1a), but they are also easy to break into several segments (10∼50 μm) by centrifugation, and the average diameter of these nanowires is about 100 nm (as shown in Fig. 1b). In order to realize the conductance of silver nanowires, one droplet of nanowires sample treated by centrifugation was placed on the electrode, and the resistance of nanowires deposit (containing ∼0.05 mg silver) was 160 ohms. So it is demonstrated that these nanowires could establish conductive networks by assembly, and the few residual PVP adsorbed on the surface of silver nanowires does not act as obstacles to the conductance of electrons.

Transmission electron microscopic (TEM) images of silver nanowires synthesized by polyol method [4] without centrifugation, the length and diameter of these nanowires is between 20∼100 μm and ∼100 nm. (a) Nanowires assemble to the bundles; (b) the end of single nanowire, inset image is the corresponding convergent beam electron diffraction pattern

Conductance of undoped and doped systems

In a vacuum filtering method, the density of deposit can be controlled accurately with the volume of suspension [19], so in our experiments. The density of deposit on the face of electrode can also be controlled with the volume (number of drop) of silver-contained droplets (one droplet contains ∼0.1 mg silver). The conductance of this silver deposit is increased along with the evaporation of ethanol as the conductive networks are formed gradually by the volume shrinkage of droplet within drying process. The conductance of these four series silver deposit is also increased with the increasing quantity of droplets placed on the electrodes. The plots made of the deposit conductance vs. volume of silver-contained droplets are depicted in Fig. 2. Flake silver deposit is much more conductive than sphere one (as shown by curve I and curve III in Fig. 2). Sphere silver deposit does not exhibit conductance until the fourth droplet being deposited, it just resembles the insulator-to-conductor transition mentioned in percolation theory [20], then the conductance keeps increasing with addition of more droplets. However, flake silver deposit exhibits high conductance even only one droplet is placed on, and addition of more droplets are not quite effective for the enhancement of conductance yet. It is interpreted that flake particle which provides face contacts exhibits higher conductance than micro-sized sphere particle that provides point contacts.

Deposit conductance vs. volume (number of drop) of silver-contained droplets on the electrode. Curve I: sphere silver dispersed in ethanol (series I); curve II: flake silver dispersed in ethanol (series II); curve III: sphere and nanowires silver dispersed in ethanol (series III); curve IV: flake and nanowires silver dispersed in ethanol (series IV)

However, when silver nanowires are introduced into the systems mentioned above, the conductance of as-obtained mixed wire-sphere/flake deposits increases immediately (as shown by curve II and curve IV in Fig. 2). The transition of conductance of sphere silver deposit before and after introduction of nanowires is very exciting. The one undoped of nanowires is an insulator, but the one doped of nanowires is a conductor (538 ohms). From Fig. 2, it is clearly indicated that conductance of flake silver deposit with and the one without nanowires have the same magnitude, and there seems to be a threshold for both of them, except series IV just needs fewer qualities of sample to reach this threshold than series III.

These silver particles modified by silver nanowires would be meaningful for the ECA industry. It implies that the same amount of sphere particles filled in adhesive will exhibit higher conductivity, while to reach the same conductance of flake silver filled adhesive only need fewer amount of particle. These characters are very useful to prepare advanced ECA with good performance to contact fine devices.

Mechanism of conductive behavior

Silver particles dispersed in solution do not show any conductance, as they are separated by the insulative ethanol molecules. The suspension dropped on the electrode would shrink to form more compact structure by evaporation of ethanol, if this structure contacts as a bridge between the fingers of electrode, the conductive pathway forms. Gold nanowires have been demonstrated to form alignment on the interdigitated electrode under alternating electric field by the polarization of the wires [21]. However, the polarization herein is too weak to drive nanowires align orderly, the van der waals interaction and solution transport drive the wires to assemble possibly. During the evaporation of ethanol, larger particles are deposited immediately, while smaller ones are carried by ethanol and tend to be adsorbed on the surface of larger particles or assemble on the edge of droplet which could be observed by eyes. So the conductive networks established by only nanowires between fingers of electrode are disorder and localized, it lacks some junctions to reinforce the linkages, and indubitably results with high resistance.

In the system composed with silver particles and nanowires, these slender wires are excellent materials to contact the particles together, while the particle could supply junctions for wire-build networks, therefore the number of conductive pathways could be increased and the effective contact area could be larger. From Fig. 3a, it is apparent that the nanowires are spanning over the gap between two flake silver particles and forming a conductive pathway. However, depended on the flat and thin properties of flake silver itself, this type of filler itself is much easier to form conductive networks than the nanowires which only play limited and auxiliary effect here (as shown in Fig. 3b). Therefore the conductance of doped flake silver is improved slightly compared with the undoped one, and the performance of both silver flake and doped one after seven drops seems to be the same. Correspondingly, the conductance of sphere silver particles doped of nanowires is much more conductive than the undoped one. This situation is undoubtedly different with the flake case, though the nanowires also act as bridges among particles (as shown in Fig. 3c). Since the poor chance of the sphere silver particles to contact with each other in limited quantity and the good capability of nanowires to form a continuous linkage, the dominant conductive networks are built by silver nanowires rather than spheres (as shown in Fig. 3d). The conductance of both single pathway and whole networks is enhanced due to the dramatic improvements on contact mode, chance, and area. Additionally, the linkage between wire and sphere is face-point contact, better than the point–point contact between spheres. The increased number of conductive pathways and the improved quality of conductive networks results perfect conductive networks and high conductance. Furthermore if these improved multicomponent silver fillers are preserved in certain environment, such as dark, airless cabinet, the nanowires will not be corroded to fragments even after one year. This is meaningful to minimize the damage of corrosion described before [22].

The schematic formation process of conductive networks of sphere particles with and without nanowires is shown in Fig. 4. The silver particles are depositing gradually (as shown in Fig. 4a), but no useful conducting pathway forms (as shown in Fig. 4b); the conductive pathways only form when more quality of silver dripped on the electrode (as shown in Fig. 4c), but the conductance is still poor anyway because of the point–point contacts of spheres. After doping nanowries (as shown in Fig. 4d), the contact mode changes to the face-point contact, the interfacial resistance between wires and particles may be also quite high, but the chance to establish conductive pathways and the number of conductive pathways are much more, so the same quality of doped system could also exhibit conductibility (as shown in Fig. 4e). However, if this type of doped silver fillers used in ECA, more details should be studied, and these are under way in our group.

Schematic diagrams of sphere particles depositing process without and with nanowires. (a) one sample droplet without nanowires spreads on the face of electrode; (b) conducting path cannot form after evaporation of solvent; (c) conductive networks of sphere form through deposition and the evaporation of solvent; (d) one sample droplet with nanowires on the face of electrode; (e) conductive networks form through the deposition and evaporation of solvent

Conclusion

We conclude that doping silver nanowires is a new route to enhance the conductance of system composed of silver particle (sphere or flake). It is demonstrated that the conductive performance of single component system (no matter sphere, flake particle or wire) is worse than multicomponent one. From TEM and SEM studies, we find that nanowires are useful to form prefect continuous linkage of particles, the contact area could be larger and the conductive pathways could be increased in number. Especially for sphere particle which could be prepared easily, doping nanowires is a good method to improve the conductance. It may be able to develop a new type of multicomponent filler which could be applied in ECA to improve the conductance and reduce the consumption of silver filler. And these developments will be in favor of interconnection technique and promote the miniaturization of electrical devices.

Note

We have developed a more effective method to synthesize silver nanowires recently. It is one-step process rather than two-step process in this paper, using Ag2S as seeds to improve the rate and stability of reaction [23]. The application example of such silver fillers in ECA can also be obtained by Chinese patent [24].

References

Fan L, Su B, Qu J, Wong CP (2004) 9th International symposium on advanced packaging materials, p 193

Grujicic M, Cao G, Roy WN (2004) J Mater Sci 39:4441

Xia Y, Yang P, Sun Y, Wu Y, Mayers B, Gates B, Yin Y, Kim F, Yan H (2003) Adv Mater 15:353

Sun Y, Yin Y, Mayers BT, Herricks T, Xia Y (2002) Chem Mater 14:4736

Caswell KK, Bender CM, Murphy CJ (2003) Nano Lett 3:667

Wei G, Nan C, Deng Y, Lin Y (2003) Chem Mater 15:4436

Zhou Y, Yu S, Wang C, Li X, Zhu Y, Chen Z (1999) Adv Mater 11:850

Huang L, Wang H, Wang Z, Mitra A, Bozhilov KN, Yan Y (2002) Adv Mater 14:61

Yin Y, Lu Y, Sun Y, Xia Y (2002) Nano Lett 2:1109

Keren K, Krueger M, Gilad R, Ben-Yoseph G, Sivan U, Braun E (2002) Science 297:72

Song JH, Wu Y, Messer B, Kind H, Yang P (2001) J Am Chem Soc 123:10397

Adhyapak PV, Karandikar P, Vijayamohanan K, Athawale AA, Chandwadkar AJ (2004) Mater Lett 58:1168

Zhong A, Tao X, Ren J, Hu L (2004) Mater Sci Eng A 371:236

Shaffer MSP, Windle AH (1999) Adv Mater 11:937

Kymakis E, Alexandou I, Amaratunga GAJ (2002) Synth Met 127:59

Ounaiesa Z, Parkb C, Wiseb KE, Siochic EJ, Harrisonc JS (2003) Compos Sci Technol 63:1637

Rong M, Zhang M, Liu H, Zeng H (1999) Polymer 40:6169

Ye L, Lai Z, Liu J, Thölén A (1999) IEEE T Electron Pack 22:299

Hu L, Hecht DS, Grulner G (2004) Nano Lett 4:2513

Stauffer D, Aharony A (1992) Introduction to percolation theory. Talor & Francis, London

Smith PA, Nordquist CD, Jackson TN, Mayer TS (2000) Appl Phys Lett 77:1399

Elechiguerra JL, Larios-Lopez L, Liu C, Garcia-Gutierrez D, Camacho-Bragado A, Yacaman MJ (2005) Chem Mater 17:6042

Chen C, Wang L, Yu H, Wang J, Zhou J, Tan Q, Deng L (2007) Nanotechnology 18:115612

Wang L, Chen C CN200610050523.2

Acknowledgements

This work is financially supported by the Science and Technology Commission of Zhejiang Province (2004C34005).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Chen, C., Wang, L., Li, R. et al. Effect of silver nanowires on electrical conductance of system composed of silver particles. J Mater Sci 42, 3172–3176 (2007). https://doi.org/10.1007/s10853-007-1594-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-007-1594-x