Abstract

In this work, metal–semiconductor–metal solar-blind ultraviolet photoconductors were fabricated based on the β-Ga2O3 thin films which were grown on the c-plane sapphire substrates by molecular beam epitaxy. Then, the effects of β-Ga2O3 annealing on both its material characteristics and the device photoconductivity were studied. The β-Ga2O3 thin films were annealed at 800, 900, 1000, and 1100 °C, respectively. Moreover, the annealing time was fixed at 2 h, and the annealing ambients were oxygen, nitrogen, and vacuum (4.9 × 10−4 Pa), respectively. The crystalline quality and texture of the β-Ga2O3 thin films before and after annealing were investigated by X-ray diffraction (XRD), showing that higher annealing temperature can result in a weaker intensity of \(\left( {\bar{4}02} \right)\) diffraction peak and a lower device photoresponsivity. Furthermore, the vacuum-annealed sample exhibits the highest photoresponsivity compared with the oxygen- and nitrogen-annealed samples at the same annealing temperature. In addition, the persistent photoconductivity effect is effectively restrained in the oxygen-annealed sample even with the lowest photoresponsivity.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Nowadays, solar-blind ultraviolet photoconductors can be used in wide application fields, such as flame detection, ultraviolet leakage inspection, and combustion process monitoring. Moreover, β-Ga2O3 has been considered as one of the most promising materials for the fabrication of solar-blind deep ultraviolet photodetector due to its wide bandgap energy of 4.8 eV, high saturation velocity, good thermal stability, and large mechanical strength [1–4]. Recently, it was reported that the β-Ga2O3 thin film grown on c-plane sapphire substrate by molecular beam epitaxy (MBE) can be adopted for the fabrication of metal–semiconductor–metal (MSM) solar-blind ultraviolet photoconductors [5, 6]. However, the device performance was degraded by the lattice mismatching between β-Ga2O3 thin film and sapphire substrate. It was reported that annealing may improve the quality of β-Ga2O3 thin film and accordingly the device performance [7, 8]. In this study, the β-Ga2O3 thin films with different annealing conditions were monitored by X-ray diffraction (XRD). Then, all the films were fabricated into MSM solar-blind ultraviolet photoconductors to investigate both current-voltage (I–V) characteristics and transient photoresponse. Finally, the annealing effects on photoelectrical properties of β-Ga2O3 thin film were discussed.

2 Experimental

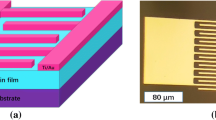

Firstly, the β-Ga2O3 thin films with a thickness of 100 nm were grown on c-plane sapphire substrates by MBE with a base pressure of 6.6 × 10−6 Pa and a substrate temperature of 660 °C. On the one hand, gallium with a purity of 99.99999 % as the source of Ga was evaporated from an effusion cell, and the temperature of effusion cell was fixed at 940 °C. On the other hand, oxygen with a purity of 99.999 % as the source of O was sprayed via a radio-frequency (RF) plasma source, and the flow rate of oxygen gas and the input RF power of plasma source were maintained at 1 ml·min−1 and 300 W, respectively. Then, the β-Ga2O3 thin films were annealed at 800, 900, 1000, and 1100 °C, respectively. Moreover, the annealing time was fixed for 2 h, and the annealing ambients were oxygen, nitrogen, and vacuum (4.9 × 10−4 Pa), respectively. The crystalline quality and texture of the β-Ga2O3 thin films before and after annealing were tested through a high-resolution XRD system (Bede-D1) with a Cu Kα line (λ = 0.1542 nm) as the radiation source. Finally, an interdigital Ti/Al (20 nm/20 nm) electrode with an area of 0.024 mm2 was deposited on each β-Ga2O3 thin film by conventional electron beam evaporation and lift-off process, and accordingly, a photoconductor was fabricated. Then, a rapid thermal annealing was carried out at 500 °C for 5 min in nitrogen ambient in order to reduce the contact resistance. The electrode fingers were 3 µm in width, 80 µm in length, and 3 µm in spacing gap. In order to measure the I–V characteristics and transient photoresponse of the fabricated devices, a HP-4155B semiconductor parameter analyzer was utilized. Moreover, an ultraviolet lamp with a wavelength of 254 nm, combined with a time shutter, acted as the light source, whose illumination intensity was 85 μW·cm−2. In addition, the measurement of transient photoresponse was taken at a constant voltage of 20 V.

3 Results and discussion

Figure 1 shows XRD patterns of β-Ga2O3 thin films annealed at different conditions. Figure 1a–c shows that the peak location of diffraction is almost unchanged for each annealing condition, indicating that annealing has no significant effect on the crystal orientation of β-Ga2O3 film. Moreover, there are four obvious peaks in each XRD pattern. Among them, the peak located at 41.7° is corresponding to (0006) of the sapphire substrate, and the peaks located at 18.9°, 38.4°, and 59.1° are corresponding to \(\left( {\bar{2}01} \right)\), \(\left( {\bar{4}02} \right)\), and \(\left( {\bar{6}03} \right)\) of β-Ga2O3 thin film, respectively. Furthermore, the intensity of each diffraction peak was normalized based on the \(\left( {\bar{2}01} \right)\) diffraction peak. In addition, Fig. 1d shows that the relative intensity of \(\left( {\bar{4}02} \right)\) diffraction peak reduces with the increase in annealing temperature for each annealing ambient, which is possibly attributed to recrystallization of β-Ga2O3 thin film during the annealing process. For example, the crystalline texture could be deteriorated when increasing annealing temperature [9], resulting in a lower relative intensity of \(\left( {\bar{4}02} \right)\) diffraction peak. In addition, the relative intensities of diffraction peaks are almost unchanged for different annealing ambients if the annealing temperature is fixed. In other words, the annealing ambient has no significant influence on the crystalline texture of β-Ga2O3 thin film.

As shown in Fig. 2, the I–V characteristics of all the devices were measured in illumination and dark, respectively. It is found that the photoresponsivities of photoconductors decrease with the increase in annealing temperature. For example, both the photocurrents and the dark currents of photoconductors decrease significantly with the increase in annealing temperature at a voltage bias of 20 V. In particular, the photocurrents are reduced to about 1.2 × 10−12 A, close to the dark current, when the annealing temperature rises up to 1100 °C, and thus, the photoresponsivities of photoconductors are close to zero. It indicates that a higher annealing temperature can lead to a larger resistivity of β-Ga2O3 thin film. As discussed previously, the relative intensity of \(\left( {\bar{4}02} \right)\) diffraction peak will decrease while increasing the annealing temperature, which means that the β-Ga2O3 thin film with a stronger relative intensity of \(\left( {\bar{4}02} \right)\) diffraction peak should have lower resistivity and better photoresponsivity. The degradation of the photoresponsivity of photoconductor with the increase in annealing temperature is possibly due to the recrystallization effect as well, which makes the deterioration of the crystalline texture of β-Ga2O3 thin film.

Furthermore, Fig. 3 shows the I–V characteristics of the photoconductors based on the β-Ga2O3 thin films annealed at 800 °C. It is found that the photoconductor without any annealing exhibits the highest photocurrent and dark current compared with all the annealed samples. In addition, the vacuum-annealed photoconductor performs higher photocurrent and dark current than the oxygen- and nitrogen-annealed ones, and the lowest values of both parameters are observed in the oxygen-annealed one. It indicates that either nitrogen or oxygen annealing can increase the resistivity of β-Ga2O3 thin film, thus degrading the photoresponsivity of photoconductor. It was reported that the oxygen vacancies in β-Ga2O3 thin film normally act as donors and accordingly can release electrons to the conduction band [7, 10]. As for the vacuum-annealed sample, the concentration of the oxygen vacancies in β-Ga2O3 thin film is almost unchanged. However, the annealing for β-Ga2O3 thin film in oxygen increases the oxygen concentration and accordingly reduces the oxygen vacancies, resulting in a high resistivity and a low photoresponsivity. As for the nitrogen-annealed sample, the doping of nitrogen atoms, acting as acceptors, can be caused during the annealing process [11]. As a result, the recombination of the electrons and holes which are from oxygen vacancies and nitrogen doping, respectively, is induced, reducing the carrier concentration of β-Ga2O3 thin film and accordingly the photoresponsivity of the photoconductor based on such a material. In addition, the slow relaxation of photoconductor, which means that the signal cannot respond quickly enough to the switching on or off of the light source, often appears in its practical applications [12–14]. After removing the ultraviolet light source, the decay of the persistent photoconductivity (PPC) follows the exponential model expressed as follows:

where i ph(t) is the instantaneous current at time (t), i ph0 is the current at the onset of decay, and it is the relaxation time. According to this equation, the time which elapses before i ph(t) decreasing to 1/e of i ph0 is called the falling time, and the time which elapses before i ph(t) rising to (e − 1)/e of i ph0 is called the rising time [15]. As shown in Fig. 4, the transient photoresponses of the photodetectors based on the β-Ga2O3 thin films before and after annealing at 800 °C in different ambients were measured. Meanwhile, both rising and falling time for each sample is listed in Table 1. It shows that the annealing for β-Ga2O3 thin film in oxygen can effectively improve the transient photoresponse and thus reduce the falling time of device. It could be attributed to the increase in the oxygen concentration in β-Ga2O3 thin film during oxygen annealing, which may lead to the decrease in the oxygen vacancies and point defects in β-Ga2O3 and reduce the PPC effect as a result.

4 Conclusion

In summary, the photoelectric properties of β-Ga2O3 thin film, which mainly depend on crystalline texture and oxygen vacancy, are influenced significantly by the annealing temperature and ambient in this work. It is found that the relative intensity of \(\left( {\bar{4}02} \right)\) diffraction peak is weakened with the increase in annealing temperature. Accordingly, the photoresponsivity of photoconductor decreases since the crystalline texture of β-Ga2O3 thin film is deteriorated. Moreover, the vacuum-annealed sample exhibits a higher photoresponsivity than the oxygen- and nitrogen-annealed samples even at the same annealing temperature, which is possibly attributed to a higher concentration of oxygen vacancies in β-Ga2O3 thin film. Furthermore, the oxygen annealing reduces the PPC effect of photoconductor significantly though the photoresponsivity is sacrificed.

References

Suzuki R, Nakagomi S, Kokubun Y. Solar-blind photodiodes composed od a Au Schottky contact and a β-Ga2O3 single crystal with a high resistivity cap layer. Appl Phys Lett. 2011;98(13):131114.

Weng WY, Hsueh TJ, Chang SJ, Huang GJ, Hsuch HT. A β-Ga2O3/GaN hetero-structured solar-blind and visible-blind dual-band photodetector. IEEE Sens J. 2011;11(6):1491.

Wuu DS, Ou SL, Horng RH, Ravadgar P, Wang TY, Leed HY. Growth and characterization of Ga2O3 on sapphire substrates for UV sensor applications. Proc SPIE. 2012;8263(17):826317.

Oshima T, Okuno T, Fujita S. Ga2O3 thin film growth on c-plane sapphire substrates by molecular beam epitaxy for deep-ultraviolet photodetectors. Jpn J Appl Phys. 2007;46(11):7217.

Víllora EG, Shimamura K, Kitamura K, Aoki K. Rf-plasma-assisted molecular-beam epitaxy of β-Ga2O3. Appl Phys Lett. 2006;88(3):031105.

Wang W, Chu FT, Yue C, Liu XZ. Preparation of β-Ga2O3 thin films by MBE method and ultraviolet-photoresponse study. Electron Compon Mater. 2013;32(5):17.

Huang CY, Horng RH, Wuu DS, Tu LW. Thermal annealing effect on material characterizations of β-Ga2O3 epilayer grown by metal organic chemical vapor deposition. Appl Phys Lett. 2013;102(1):011119.

Su XQ, Wang L, Lu Y, Gan YL, Wan RP. The effect of thermal annealing on (In2O3)(0.75)(Ga2O3)(0.1)(ZnO)(0.15) thin films with high mobility. Vacuum. 2014;107(S):191.

Ou SL, Wuu DS, Fu YC, Liu SP, Horng RH, Liu L, Feng ZC. Growth and etching characteristics of gallium oxide thin films by pulsed laser deposition. Mater Chem Phys. 2012;133(1):700.

Qu F, Zhang T, Gu HW, Qiu QQ, Ding FZ, Peng XY, Wang HY. Electrical and optical properties of ZnO: Al films with different hydrogen contents in sputtering gas. Rare Met. 2015;34(3):173.

Song YP, Zhang HZ, Lin C, Zhu YW, Li GH, Yang FH, Yu DP. Luminescence emission originating from nitrogen doping of β-Ga2O3 nanowires. Phys Rev B. 2004;69(7):075304.

Seghier D, Gislason HP. Characterization of photoconductivity in AlxGa1−xN materials. J Phys D Appl Phys. 2009;42(9):095103.

Ghaffarzadeh K, Nathan A, Robertson J, Kim S, Jeon S. Persistent photoconductivity in Hf–In–Zn–O thin film transistors. Appl Phys Lett. 2010;97(14):143510.

Bayan S, Mohanta D. ZnO nanorod-based UV photodetection and the role of persistent photoconductivity. Philos Mag. 2012;92(32):3909.

Li J. Research and test on performance of MSM ultraviolet detectors. Chengdu: University of Electronic Science and Technology of China; 2010. 17.

Acknowledgments

This study was financially supported by the National Natural Science Foundation of China (No. 61223002) and the Research Foundation for the Doctoral Program of Higher Education of China (No. 2012018530003).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Sheng, T., Liu, XZ., Qian, LX. et al. Photoelectric properties of β-Ga2O3 thin films annealed at different conditions. Rare Met. 41, 1375–1379 (2022). https://doi.org/10.1007/s12598-015-0575-5

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12598-015-0575-5