Abstract

The effects of heating duration on digestibility of the muscle powder of three fish (pollock [WP], yellowtail [YT], mackerel [CM]) and the whole-body powder from mackerel (WM) were assessed in vitro using a digestive enzyme complex (EC) extracted from yellowtail pyloric caeca. This research will contribute to establishing a theoretical basis for feed processing conditions for yellowtail. Transcriptomic analysis showed that the most dominantly expressed genes in the pyloric caeca examined were those for trypsin and that their activity was well maintained in the EC. To assess heating effects, the powders were heated at 99 °C for 0, 3, 20, 72 and 240 min, followed by hydrolysis with the EC. After 3 min of heating the WP, YT and CM, the average production of essential amino acids (EAAs) decreased to 81.3%, 72.0% and 66.9%, respectively, compared to that detected in controls without heating. The production further decreased with increased heating duration from 3 to 240 min, but much of the decrease was within the first 3 min in WP, YT and CM. The decreasing rate of EAA production was higher in WM than CM, and increased with heating time. These results suggest that WP is the most suitable feed material for yellowtail of the four samples tested and that the shortening of heating time and removal of viscera are also important factors.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Digestibility is one of the important factors that determine the feed value of animal feed. Fish meal, which is a major protein source in aquaculture fish feed, is obtained by boiling/steaming, drying, pressurizing or otherwise treating fish or fish waste and is used extensively to feed carnivorous fish. During the fish meal production process, high-temperature treatment may initially increase the digestibility of proteins by unfolding the polypeptide chain, which renders the protein more susceptible to digestive enzymes; however, as temperature or heating time increases, the digestibility of these proteins may be reduced due to reactions between amino acid residues and other compounds that cannot be split by digestive enzymes (Opstvedt et al. 2003). When fish meal is processed, proteins in fish materials are heated at high temperature, which may be > 100 °C. This processing results in aggregation, denaturation, degradation and modification of the proteins (Ovissipour et al. 2017; Bhat et al. 2021). Such reactions are accelerated with increasing temperature, and they reduce feed digestibility in fish and land animals (Myklestad et al. 1972; Wang and Parsons 1998; Opstvedt et al. 2003; Abraha et al. 2018). Aksnes and Mundheim (1997) showed that fish meal processing conditions during feed production affect the growth of Atlantic halibut that later consume the feed, despite the crude protein level being the same among the tested feeds. Specifically, during fish meal processing, treatment time and temperature during boiling and drying affect feed value. In a study of tuna, Ji et al. (2008) reported that heavy steam-boiling and heat-drying during processing reduce the digestibility of fish meal.

Processing at high temperature during fish meal production provides the following advantages relative to raw fish materials: (1) the weight of the product is reduced to approximately one quarter of the initial weight by drying, and the final volume is small; (2) the raw fish material’s initial microbial load is drastically reduced owing to thermal treatment, and the dried final product is less likely to deteriorate even if microbial contamination occurs given that microorganisms do not grow under such low water activity conditions; and (3) there is no need to refrigerate the product during storage. These advantages are important for reducing the risk of feed-related infection or disease in fish, simplifying the handling and commercial trafficking processes and preserving of feed and controlling its water content. In addition (4) heating inactivates thiaminases (Zajicek et al. 2005), which destroy thiamine and are contained in raw fish, and (5) during processing, the denaturation of proteins by heating facilitates protein separation (as fish meal cake) from the liquid component of the product.

Traditional fish meal processing methods were developed in the 1940s up to the 1960s, and there has been little improvement in these methods since (Hilmarsdottir et al. 2020) in many countries, including Japan. For example, the general cooking temperature for fish meal has been set at 95–100 °C (FAO 1986; Ariyawansa 2000). Conversely, fish meal cooked at lower temperatures (LT; e.g., 70 °C, LT-fish meal) are commercially available from at least two companies in the European region (Sevgili et al. 2015), but not worldwide. Higher fish meal digestibility in LT-fish meal compared to standard fish meal was shown in mink (Opstvedt et al. 2003). Lower cooking temperatures (70–80 °C) are preferred for improved fat separation for some fish (e.g. capelin; Nygard 2010). Thus, clarifying the relationship between heating and feed digestibility in fish meal processing is considered to be important for the development of heating and digestibility compatibility methods.

In addition to fish meal processing, it is common worldwide to use extruders when mixing various ingredients to form feed. Extruders are used to control feed floatability, improve shape retention and also allow for sterilization, but have the disadvantage of exposing feedstuffs with a carbohydrate binder (starch) to temperatures exceeding 100 °C, which can easily cause Maillard reactions and reduce protein digestibility. For example, yellowtail fed extruded feed during the winter months showed a reduced growth rate (Satoh et al. 2003) and digestibility (Satoh et al. 2000) compared to yellowtail-fed raw fish, although a significant difference was not observed in the summer months.

The digestibility of fish feed has been evaluated using two methods involving in vivo and in vitro assays. In vivo methods are considered to be indirect methods and include tests on live fish in which the nutritional composition of feed is compared using data collected before feeding and at the end of an experiment (in feces or the content of the rectum via indigestible metal markers). This method involves fish rearing and is time consuming (lasting several weeks), and the digestibility results are termed “apparent digestibility” (Greaves 1963) because it is difficult to distinguish the remaining proteins from the secreted proteins in the intestine. In vitro methods are considered to be direct methods. In these assays, the digestibility of test feeds is evaluated using enzymes or extracts from fish in vitro. Such methods allow rapid evaluation of protein samples under reproducible and defined conditions, such as temperature, ionic strength and pH, without variation. Analysis of digestion products using such tests can clarify enzyme hydrolysis efficiency without the influence of mechanisms specific to digestion in live animals, including, for example, the interaction among organs, peristaltic movement of the intestine and nervous system effects. In vitro methods are effective for analyzing proteins or peptides in terms of the relationship between their digestibility by enzymes and biochemical characteristics, but they are performed in simplified buffers that do not completely reflect the inner intestinal environment of live fish. The effectiveness of evaluating feed digestibility in fish in vitro has advanced over the years, and results have been validated using extracts of the stomach and small intestine from barramundi Lates calcarifer (Lewis et al. 2019). In a study on white trevally, the authors reported a strong positive correlation between the in vitro protein digestibility of diet using extracts of the stomach and the pyloric caeca, with specific growth rate and feed conversion efficiency (Takakuwa et al. 2022).

Yellowtail Seriola quinqueradiata is an important aquaculture fish in Japan and is commercially produced at a level much high than all other aquaculture fish. Feed pellets processed at high temperature and containing a high percentage of fish meal are the first-choice feed for yellowtail. However, a recent increase in fish meal costs has impacted yellowtail aquaculture; thus, feed processing techniques that help reduce this cost are required. In particular, it remains necessary to determine the relationship between feed digestibility and heating conditions in feed processing to establish the best conditions for fish meal processing, which will then be applied in yellowtail aquaculture.

In line with these research needs, the aims of this study were: (1) to evaluate the digestibility of fish muscle proteins according to heating time in vitro using an enzyme complex (EC) extracted from yellowtail pyloric caeca containing pancreatic tissue, with confirmation of the most dominant proteases in it and preservation level of their activities during separation of EC; (2) to compare the digestibility of proteins under such conditions among phylogenetically different fish species; and (3) to compare digestibility according to heating time between muscle-only feed and feed containing muscle and other organs. This research will contribute to establishing a theoretical basis for the protein processing conditions used to produce fish meal designed to feed aquacultured yellowtail.

Material and methods

Preparation of fish homogenate

Pieces of white muscle were taken from between the lateral line and dorsal fin of walleye pollock Gadus chalcogramma, yellowtail and chub mackerel Scomber japonicus. Quick frozen fillets of walleye pollock (10 individual fish, each with an approximate body weight of 1.5 kg) were purchased from Yamato Co., Ltd. (Shiogama, Japan). Yellowtail (10 individuals, each with a body weight of approx. 3 kg) were produced at the Goto Field Station, Japan Fisheries Research and Education Agency; after being cut into small pieces, the pieces were frozen at − 25 °C with forced air circulation. Chub mackerel (6 individuals, with an average body weight of 200 g) were purchased from Nagasaki Fish Market Co., Ltd. (Nagasaki, Japan) The white muscles from four chub mackerel were used to produce chub mackerel (CM)-type fish powder, whereas the whole bodies of the remaining two chub mackerel, including the head, skin, viscera, fins and bones, were used for the whole body chub mackerel (WM)-type fish powder. Specifically, the muscles and the whole bodies of chub mackerel were first cut into small pieces and the pieces frozen under the same conditions as those used for yellowtail. All muscles and the whole bodies of the fish were lyophilized using a freeze-dryer (model 25EL; Virtis, Los Angeles, CA, USA). After lyophilization, the materials were ground into powder, first in a food processor (model SKF-G100; Tiger Corp., Osaka, Japan) with dry ice for 3 min, then by manual milling with a pestle for 20 min. The whole bodies of mackerel were also lyophilized and ground into powder in a motor-driven mill for 1 min (High-Speed-Mill; Labonect, Sakai, Japan). Thus, four types of fish powder were produced, and these were homogenized in a 20-fold volume of distilled water (v/w) for 1 min using a Polytron homogenizer (model PT-1200E; Kinematica AG, Luzernerstrasse, Switzerland) equipped with a 5.5-mm shaft. The final four powders were those of walleye pollock (WP), yellowtail (YT), CM and WM.

Preparation of a digestive EC from yellowtail pyloric caeca

The pyloric caeca from five individual yellowtails were frozen with dry ice, lyophilized and ground into powder with dry ice using a food processor. Powdered pyloric caeca (706 mg) was added to 7.06 mL of 50 mM borate–KCl–NaOH (BKS) buffer (pH 8.2), and the mixture was homogenized for 1 min using a Polytron homogenizer with a 5.5-mm shaft (Kinematica AG). The homogenate was centrifuged at 20,000 g and 0 °C for 5 min, and the fat-free supernatant was filtrated using a syringe filter (diameter 13 mm; pore size 1 μm; Advance Microdevices Pvt. Ltd., Tepla, Haryana, India). The filtrate was incubated for 6 h at 25 °C with pancreatic proteases to digest proteins and peptides other than digestive enzymes in the tissue. After a second centrifugation at 20,000 g and 0 °C for 5 min, the supernatant was removed from the small molecules by collecting void fractions following elution through a gel filtration column (Superdex Peptide HR10/30; Pharmacia A.B., Uppsala Sweden) on a SMART system (Pharmacia) at 10 °C, a flow rate of 300 μL/min, with monitoring of the elution at 278 nm. From 6.5 to 12.5 mL, eluted fractions were collected every 500 μL (with fractions denoted no. 1 to no. 12); after pooling, these fractions were used as the digestive enzyme complex from yellowtail pyloric caeca (hereafter denoted “EC”).

Heating of fish homogenates and in vitro hydrolysis

First, 100 μL of fish homogenate was dispensed into a 2-mL plastic tube with a round bottom (2.0 mL Safe-Lock tubes; Eppendorf AG, Eppendorf, Hamburg, Germany) using a positive displacement pipette (Microman E [M100E]; Gilson, Middleton, WI, USA) and vigorously mixed with 100 μL of distilled water. The homogenates were then heated in tubes with cap locks (Thermo Fisher Scientific; Waltham, MA, USA) at 99 °C for 0 (no heating), 3, 20, 72 and 240 min using a preheated (for > 30 min) aluminum block shaker (WSC-2630; ATTO Co., Ltd., Tokyo, Japan) without shaking. After heating, the tubes were immediately cooled and stored in an aluminum block cooled on ice. After cooling, 400 μL of EC or BKS buffer and 10 μL of 0.6% NaN3 (as a preservative) in BKS were added to each tube, and the mixture was incubated at 25 °C for 14 h with continuous mixing (1500 rpm) using the same aluminum block shaker mentioned above. In addition, two controls were established: (1) EC without fish homogenate and (2) fish homogenate without EC. After incubation, the homogenates were centrifuged at 20,000 g and 0 °C for 5 min, and 190 μL of the supernatants was added to 10 μL of 100% trichloroacetic acid for 1 h at room temperature to achieve protein precipitation. The samples were centrifuged once again at 20,000 g and 0 °C for 5 min. The resultant supernatants were diluted to 25% using the first buffer (P-21; JEOL Ltd., Tokyo, Japan) of an amino acid analyzer (JLC-500/V; JEOL Ltd.), and amino acid concentrations were measured in 50 μL of the solution using the amino acid analyzer at the highest resolution mode, which involved the use of a postcolumn derivatization method with ninhydrin as the analysis reagent and LiOH buffers as elution buffers. The detection limit for amino acids was 5 μM.

The amount of amino acids produced by in vitro hydrolysis with EC was calculated using the following equation:

where AAa is the amount of proteinogenic amino acids produced by in vitro hydrolysis, TAAa is total amount of proteinogenic amino acids in the reaction mixture, ECAAa is the amount of proteinogenic amino acids in the reaction mixture of the EC without fish homogenate and HAAa is the amount of proteinogenic amino acids in the homogenate without EC. The average rate of decrease (ADR; %/min) of amino acids produced by in vitro hydrolysis was calculated using AAa at heating times of 0, 3 and 240 min according to the following equation:

Evaluation of the catalytic activity of proteases in chromatographic elutions of yellowtail pyloric caeca

The catalytic activities of four proteases were measured in the fractions of the chromatographic elutions of the EC. The substrates for trypsin, chymotrypsin and elastase were t-butyloxycarbonyl-L-glutaminyl-L-alanyl-L-arginine 4-methylcoumaryl-7-amide (Kawabata et al. 1988), succinyl-L-alanyl-L-alanyl-L-prolyl-L-phenylalanine 4-methylcoumaryl-7-amide (Sawada et al. 1983) and succinyl-L-alanyl-L-alanyl-L-alanine 4-methyl-coumaryl-7-amide (Mumford et al. 1980), respectively, and L-alanine 4-methylcoumaryl-7-amide was used for aminopeptidase. Elution volumes were fractionated every 500 μL, and the fractions were diluted at 1:50 for trypsin, chymotrypsin and aminopeptidase using a protein-free blocker solution (EzBlock Chemi; ATTO Co., Ltd.); measurements were made on 10 μL of the diluted solution. In contrast, the activity of elastase was measured without dilution. The measuring procedure for the catalytic activity of enzymes followed that of Andoh (2020), with EzBlock Chemi used to ensure that a linear relationship existed between the catalytic activity of an enzyme and the dilution rate (Andoh 2020). The catalytic activities of the enzymes were calculated by measuring the increase in 7-amino-4-methylcoumarin fluorescence intensity per minute, which was produced during catalysis at 30 °C using fluorescence wavelengths of 380 nm for excitation and 485 nm for emission (Andoh 2020). A multimode microplate reader (model Spark 10M; Tecan Trading AG, Männedorf, Switzerland) was used to take measurements. The intensity was designated as relative fluorescence units per minute. The total activities of enzymes were calculated as the integration of the activities from fractions no. 1 to no. 12 in each enzyme.

Transcriptomic analysis of the pyloric caeca

Pieces of pyloric caeca were collected from three individual adult yellowtails and preserved in RNAlater (Thermo Fisher Scientific). Total RNA was extracted using a Maxwell RSC Simply RNA Kit (Promega, Madison, WI, USA), and messenger RNA (mRNA) was purified using a Gene Read Pure mRNA Kit (Qiagen, Hilden, Germany). Transcriptomic analysis was performed using an Ion Proton platform (Life Technologies, Thermo Fisher Scientific) as previously described (Yasuike et al. 2018). Sequencing libraries were constructed using an Ion Total RNA-Seq Kit v2, and these were sequenced using Ion Proton (Life Technologies, Thermo Fisher Scientific). The raw RNA-Seq datasets created here have been deposited at the DDBJ Sequence Read Archive under accession nos. DRR337802–DRR337804. RNA-Seq data analysis was conducted using CLC Genomics Workbench 9.5.2 software (CLC Bio, Aarhus, Denmark) as follows: low-quality sequences were filtered using the default parameters (quality limit = 0.05; ambiguous limit = 2), and the filtered sequence reads were mapped to the yellowtail reference genome (GenBank assembly accession: GCA_003402435.1) using the default parameters (mismatch cost = 2; insertion cost = 3; deletion cost = 3; length fraction = 0.8; and similarity fraction = 0.8). Subsequently, transcripts per million (Wagner et al. 2012) values were calculated for each gene.

Proximate analysis of four types of fish powder

Crude protein levels were calculated by measuring total nitrogen according to the Kjeldahl method using a Super Kjel 1400 (Velp Scientifica Srl, Lombardy, Italy). To calculate crude protein from the nitrogen content, a nitrogen–protein conversion factor of 6.25 was used. Crude fat was analyzed using the Soxhlet extraction method and a SER148 Solvent Extractor (Velp Scientifica Srl). Diethyl ether was used as the solvent for extraction.

Statistics

All measurements were taken in triplicate except for the catalytic activity of digestive enzymes, which were measured in duplicate. Data in graphs are presented as the mean ± standard deviation (SD) of replicates. One-way analysis of variance and Tukey’s post-hoc test were performed to compare amino acid amounts. The level of significance was set at P < 0.05. GraphPad Prism Ver.9 (GraphPad Software Inc., San Diego, CA, USA) was used to conduct all statistical analyses.

Results

Chromatographic separation of the digestive EC from yellowtail pyloric caeca

Chromatographic profiling of the elutions of the EC before and after incubation at 25 °C for 6 h are shown in Fig. 1 . The highest absorbance peak was at around 8 mL of elution volume, which was just after the void, before incubation (Fig. 1a); following incubation, this peak had almost disappeared (Fig. 1b). Four peaks, from 17.5 to 24.0 mL, were substantially higher after incubation; this volume range corresponded to the elution volume of amino acids.

Gel chromatography of the EC before (a) and after (b) incubation at 25 °C for 6 h. Short vertical lines ticks on the x-axis from 6.5 to 12.5 mL indicate the 500-μL intervals of the fractions collected. Arrows on the graph indicate elution volumes of blue dextran (1), bovine serum albumin (2), insulin (3), leucine (4), phenylalanine (5) and tyrosine (6) on the column (Superdex Peptide HR10/30; Pharmacia A.B.). EC Digestive enzyme complex separated from yellowtail pyloric caeca extract

The catalytic activities of trypsin, chymotrypsin, elastase, and aminopeptidase in the eluted fractions of the EC before and after incubation are shown in Fig. 2. Before incubation, the highest peaks for trypsin and chymotrypsin activity are at fraction no. 6; after incubation, the highest peaks are at fraction no. 8. In contrast, the highest peaks for the activities of elastase and aminopeptidase did not change before and after incubation. The total enzyme activity ratios of “after” to “before” incubation in the 12 fractions were 110.9%, 100.1%, 59.0% and 122.8% for trypsin, chymotrypsin, elastase and aminopeptidase, respectively.

Transcriptomic analysis of the pyloric caeca

A total of 23,981 transcripts were detected. The top 30 transcripts accounted for > 75% of all transcripts (Table 1), with 20 of these 30 transcripts originating from genes encoding digestive enzymes: eight trypsins, seven chymotrypsins, two elastases and three carboxypeptidases. The transcript with the highest expression level was trypsin-1 precursor (16.9% of all transcripts), followed by chymotrypsin A-like. The amount of integrated expression in the top 30 transcripts was 38.2% (of all transcripts) for trypsins, 22.0% for chymotrypsins, 2.4% for elastases and 3.8% for carboxypeptidases. Trypsins and chymotrypsins accounted for > 60% of the amount of all transcript expression. Aminopeptidases, including one aminopeptidase and four aminopeptidase N-like, were expressed in the pyloric caeca, but the expression level was < 0.05% of all transcripts.

Amino acid amounts produced by in vitro hydrolysis of fish powders

The crude protein and fat contents of the four fish powders are summarized in Table 2. The crude protein values were used in the calculations given below.

The average percentage of the amount of integrated amino acids in ECAAa to that in TAAa was 1.45%, 1.37% and 1.35% for WP, YT and CM, respectively. In the EC analysis, the concentrations of most amino acids were close to the detection limit of the amino acid analyzer. Alanine (Ala), methionine (Met), cystine (Cys2), tryptophan (Trp) and proline (Pro) were not detected in the ECAAa.

In all muscle powders, lysine (Lys) was the dominant amino acid in the reaction mixture at 0 min (no heating) followed by leucine (Leu), Ala and arginine (Arg) (Fig. 3). The AAa of all amino acids in the three muscle powders decreased with increasing heating time, but the reduction rate differed among amino acids and fish species. Of the top five essential amino acids (EAAs) with the highest rates of decrease at 3 min, the most common amino acids in the three muscle powders were Leu, valine (Val) and threonine (Thr) (Table 2). The other two EAAs were isoleucine (Ile) and Trp in WP, phenylalanine (Phe) and Trp in YT and Ile and histidine (His) in CM. For non-essential amino acids (NEAAs), glutamic acid (Glu), aspartic acid (Asp) and Pro decreased clearly from 0 to 3 min of heating for all three muscle powders. When heating was > 3 min, the amount of all amino acids gradually decreased. The changes in the integrated AAa of all amino acids with heating time are shown in Fig. 4a, b . The AAa of EAAs (Fig. 4a) in CM and WP were the joint highest at 0 min, with those of YT and WM second highest. After 3 min of heating, the integrated AAa of both EAAs and NEAAs decreased significantly in the three muscle powders (Fig. 4a, b). When heating time was > 3 min, the integrated AAa of EAAs decreased gradually. In CM, the mean (± SD) integrated AAa of EAAs decreased from 1001.1 ± 17.1 nmol/mg at 0 min to 675.2 ± 5.0 nmol/mg at 3 min; in WP and YT, it decreased from 1036.1 ± 19.6 to 968.3 ± 11.1 nmol/mg and from 854.7 ± 9.1 to 716.0 ± 11.4 nmol/mg, respectively. After 3 min of heating, NEAA was significantly decreased (Fig. 4b).

Amino acid amounts produced by hydrolysis with the digestive enzyme complex separated from yellowtail pyloric caeca extract (EC) in four types of fish samples. Amino acids are expressed as one-letter notation, with essential amino acids shown on the left graphs (K lysine, L leucine, R arginine, V valine, I isoleucine, F phenylalanine, M methionine, T threonine, H histidine, W tryptophan) and non-essential amino acids shown on the right graphs (A Alanine, E glutamate, S serine, Y tyrosine, D aspartate, G glycine, Q glutamine, N asparagine). Order of presentation of amino acids (from left to right) follows the descending order of prevalence in walleye pollack. Times indicate the duration of heating at 99 °C. Measurements were taken in triplicate. Error bars show standard deviations. CM Muscle powder homogenate of chub mackerel, EAA essential amino acids, NEAA non-essential amino acids, WM whole body powder homogenate of chub mackerel, WP muscle powder homogenate of walleye pollack, YT muscle powder homogenate of yellowtail

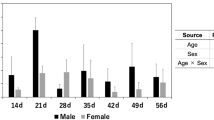

Changes in the integrated essential amino acids in proteinogenic amino acid amount produced by hydrolysis (AAa) (a), in integrated non-essential amino acids in AAa (b) and in integrated amino acids in proteinogenic amino acid amount in the homogenate (HAAc) in the reaction mixture (c). Measurements were taken in triplicate. Error bars indicate standard deviations. Different lowercase letters indicate significant differences at P < 0.05

The average (± SD) 3 min:0 min ratio of AAa in EAAs was 81.3% ± 1.5%, 72.0% ± 1.6% and 66.9% ± 1.3% for WP, YT and CM, respectively (Table 3). For the 3 min/0 min ratio in WP, EAAs at < 70% were not detected. In contrast, amino acids at < 70% were observed for the 3 min/0 min ratio for four EAAs (Leu, Val, Thr and Trp) in YT and six EAAs (Leu, Val, Ile, Thr, His and Trp) in CM. In particular, Val, Ile and Thr in CM were detected at < 60%. Thus, with heating for > 3 min, the AAa in the EAAs of WP was better maintained than those of YT and CM. The AAa of NEAA in WP, with the exception of Asp and glycine (Gly) at 3 min/0 min in YT, was also higher than those of YT and CM following heating for > 3 min (Table 3).

Even with heating for > 3 min, WP had higher AAa in the hydrolysis. The average 240 min/0 min ratio of EAA was 67.4% ± 2.3%, 33.7% ± 1.4% and 44.6% ± 1.7% in WP, YT and CM, respectively; for the 240 min/3 min ratio, these values were 83.1% ± 1.3%, 46.6% ± 2.8% and 67.3% ± 3.8%, respectively. The ADR of EAAs slowed down in the three fish muscle powders over 3 min; for example, in WP, it was 6.241% ± 0.508%/min from 0 to 3 min but 0.07% ± 0.006%/min from 3 to 240 min. The rates from 0 to 3 min in YT and CM were 9.329% ± 0.548%/min and 11.023% ± 0.425%/min, respectively, whereas those from 0 to 240 min were 0.276% ± 0.006%/min and 0.231% ± 0.007%/min, and those from 3 to 240 min were 0.225% ± 0.012%/min and 0.138% ± 0.016%. These rates were 1.5-fold higher than the rates detected in WP. The digestibility of muscle powder changed substantially in the first 3 min with heating for all three fish species. The statuses in EAAs were also common in NEAAs (Table 4).

The integrated HAAa of all amino acids was < 160 nmol/mg (YT at 0 min) in all samples except for WM at 0 min, and these values did not change drastically with duration of heating time (Fig. 4c). The integrated HAAa of all amino acids in WM at 0 min was 866.1 ± 8.0 nmol/mg, which was greater that the integrated AAa of EAA (701.0 ± 12.4 nmol/mg; Fig. 4a), but this decreased to 121.1 ± 0.6 nmol/mg after 3 min of heating. The percentage of integrated HAAa to integrated AAa for EAAs and NEAAs in WP, YT and CM was 3.2%, 9.2% and 5.0% at 0 min, respectively. However, His accounted for > 95% and > 72% of the integrated HAAa in YT and CM without heating. In contrast, His in WP at 0 min was < 1.3% of TAAa.

The AAa of WM at 0 min was significantly lower than that at 3 min for all EAAs except Val, Ile, Met and Trp (Fig. 3), and the integrated AAa of EAAs at 0 min was lower than that at 3 min (Fig. 4a, c). In contrast, the ADRs of 240 min/3 min for the integrated AAa of EAAs in CM and WM were 0.125 ± 0.011%/min and 0.203 ± 0.017%/min, respectively, whereas that of WM was significantly higher (t-test). The statuses in EAAs were similar to those in NEAAs. The ADRs in CM and WM were 0.089 ± 0.004%/min and 0.191 ± 0.002%/min, respectively.

The integrated AAa of NEAAs in WM was higher than that in CM at 3, 20 and 72 min (Fig. 4b); this trend was not observed for the EAA relationship between CM and WM (Fig. 4a). In WM, the amounts of some NEAAs were clearly higher following these heating periods (e.g. Glu, Asp and Gly in WM; Fig. 3).

Discussion

In the current study, the high absorbance peak for proteins in the EC at an 8-mL elution volume had almost disappeared after incubation at 25 °C for 6 h, indicating that the combined method of incubation plus gel filtration is an effective method for removing protein and amino acid contamination from the EC. This result was confirmed by the integrated ECAAa of all amino acids, which was < 1.5% that of the integrated TAAa in the three fish species. Thus, background noise from contamination introduced by digestive enzymes in the EC was reduced, as was possible exhaustion of digestive enzyme activity in the EC due to competitive hydrolysis between proteins in the sample and contaminated proteins in the EC. In addition, ECAAa without chromatographic separation in the EC from yellowtail was sometimes > 50% that of TAAa (data not shown). Thus, the separation of contaminated proteins and amino acids in the EC is an essential step for in vitro estimation of the digestibility of protein samples.

The digestive enzyme activities of trypsin, chymotrypsin, elastase and aminopeptidase were well-maintained after incubation at 25 °C for 6 h, with total activity of trypsin, chymotrypsin and aminopeptidase, respectively, of > 100% and that of elastase of 59%, suggesting that the incubation method effectively maintained sufficient activity levels for a simple reproduction of intestinal status in yellowtail. In the pyloric caeca of yellowtail, > 60% of all transcripts detected in transcriptomic analysis encoded trypsins and chymotrypsins, suggesting that these proteases are the most dominant digestive enzymes in pyloric caeca of yellowtail. Pepsin is expressed in the stomach of yellowtail (Yasuike et al. 2018), but the pH in the stomach is close to 6 for several hours after feeding (Kofuji et al. 2004), and fish pepsin loses its catalytic activity when pH is > 6 (Zhao et al. 2011). Thus, pepsin activity is unlikely to contribute to feed digestion in the stomach of yellowtail, whereas trypsins and chymotrypsins in the intestinal phase play the most important leading roles in this process. Therefore, the method described here, which only reproduces the intestinal digestive system and uses EC that is considered to be properly processed without reproducing the digestive system in the stomach, is appropriate for digestibility evaluation of feed materials in vitro in yellowtails. It is also groundbreaking in that it identified the most dominant enzymes in the digestive system of the yellowtail and constructed an in vitro digestive system while maintaining the activity of these enzymes.

In the intestine, plural digestive enzymes recognize various amino acid sequences; thus, protein complexes with various amino acid sequences and structures in feed can be digested cooperatively. In the present study, the EC functioned as an enzyme complex that included yellowtail pyloric caeca and pancreatic tissue. Amino acid composition analysis of feed materials can be conducted using hydrolysis with hydrochloric acid under high temperature and high pressure. Using this method, Trp, Ser and Thr are decomposed partially or completely, Met is oxidized and peptides containing Ile and Val are partially hydrolyzed. In addition, Asp and Glu are converted to asparagine (Asn) and glutamine (Gln). Therefore, this amino acid composition analysis method does not always reflect the actual hydrolysis taking place in the fish intestine. While no hydrolysis method can accomplish quantitative liberation of all amino acids (Fountoulakis and Lahm 1998) and given that the present method cannot enable hydrolysis of all amino acid sequences, it is still expected that it better reflects the in vivo situation in yellowtail as it includes partial reproduction of the in vivo situation using a fish EC rather than hydrolysis at high temperature and high pressure with hydrochloric acid.

The integrated HAAa of all amino acids except His was < 3.2% of the integrated TAAa of all amino acids in the three muscle powders. This is an important factor for lowering the background noise of the reaction mixture and thereby improving amino acid analysis in the EC. Moreover, the ratio of fish powder and EC amount used in the present study was shown to be effective for determining muscle powder digestibility in vitro.

Amino acid production by enzyme hydrolysis was reduced with increasing heating time in the present study. Heating during processing can reduce the digestibility of proteins in mink fed fish meal and soybean meal heated > 120 °C (Ljøkjel et al. 2000) and in pig fed over-heated fish meal (Wiseman et al. 1991). However, to our knowledge, the study is the first to report the quantitative relationship between heating time and amino acid production from fish protein by enzyme hydrolysis while also including methodological validation. Specifically, we prepared a digestive EC from the pyloric caeca of yellowtail for in vitro hydrolysis, and the efficiency of the assay was confirmed using gel filtration and by measuring the activities of four major digestive enzymes. Major proteases in the pyloric caeca were characterized by transcriptome analysis. Contaminating proteins and amino acids from the EC and free amino acids in HAAa (i.e. background noise) were also confirmed quantitatively.

The muscle powders used in the present study were prepared from white muscle; they did not contain bone, skin, red muscle or other organs. During processing, denaturation of proteins was minimized by rapid freezing followed by lyophilization; consequently, it was possible to analyze the relationship between heat-induced denaturing and digestibility in muscle proteins. The integrated HAAa in the three muscle powders did not change under different heating conditions (Fig. 4c), suggesting that self-digestion and degradation during heating were at minimal levels or did not occur at all. Therefore, our method better reflects the actual difference in the digestibility of muscle among fish species according to heating time.

Importantly, we found that heating at 99 °C for 3 min decreases the average production of EAAs from muscle powder by hydrolysis to < 82% in the three fish species (Table 3). In addition, the average AAa of CM decreased to 66.9%, which is equivalent to a loss of > 33%. The NEAAs of WP also decreased to < 77% on average. Moreover, all amino acid levels produced with EC hydrolysis decreased substantially by heating, and Pro was no longer detected after heating for 3 min (Fig. 3), suggesting that it is either easily denatured or not easily produced from muscle proteins with digestive enzymes under these conditions. Indeed, we found no positive effect of heating on the digestibility of fish muscle powder from 3 to 240 min, except for a decreased rate of Asn for 3 min/0 min in WP. These results suggest that fish muscle proteins are not unfolded into polypeptide chains at 99 °C or rendered more susceptible to digestive enzymes. Thus, despite fish meal processing having several benefits, resource availability is clearly lost. We suggest, therefore, that boiling and drying at high temperature during fish meal processing must be reconsidered in terms of the balance between its various benefits and the utilization efficiency of natural resources.

Although there was a positive effect of heating on Asn in WP, this amino acid is a NEAA and the improvement was only 17%; moreover, the increase in Asn may have been due to its conversion from Asp by asparagine synthetase in the EC. Transcriptomic analysis revealed that this enzyme is expressed in the pyloric caeca in yellowtail (data not shown). The mammalian pancreas is also known to synthesize Asn using asparagine synthetase, which is expressed at high levels in the pancreas (Tsai et al. 2020).

The growth performance of two LT-fish meal types was compared with flame-dried and steam-dried fish meals in growth performance evaluations using turbot (Sevgili et al. 2015). The two LT-fish meals were found to be better in terms of phosphorus retention and losses than two conventional fish meals, but there were no significant effects in terms of growth rate and feed utilization. Treating fish meal at 70 °C may still be too high to avoid any decrease in the digestibility in the fish meal during processing.

Nonthermal processing technology has led to advancements in fish-related food processing methods (Zhao et al. 2019; Cropotova et al. 2020). For example, using a high-pressure treatment > 200 MPa without heating can reduce microbial growth in raw fish material and inactivate pro-oxidative endogenous enzymes. Such novel technologies should be adopted during fish feed processing to minimize protein denaturing.

The digestibility of WP and CM at 0 min was almost identical for both EAAs and NEAAs (Fig. 4a, b); however, the ADR of 3 min/0 min for the EAAs was 81.3% in WP but only 66.9% in CM (Table 3). The ADR in YT (72.0%) was also lower than that in WP. Higher resistance to heating in WP was also observed in the AAa of NEAAs (Table 4). These results indicate that walleye pollock is a superior material for use in fish feed that is produced using fish meal processing and applied to yellowtail aquaculture.

A mixture including the viscera, head, red muscle and bones lowered the digestibility of proteins in chub mackerel. Thus, removing these tissues before processing may improve the digestibility of fish meal. Candidate factors that may influence the digestibility of fish muscle during heating are carbohydrates, which induce the Maillard reaction (Maillard 1912). As heating time increased, browning increased, which suggests that the Maillard reaction occurred in all muscles of the three fish species (data not shown). The protein content of wet fish muscle varies from 13.8% to 23.2% (Murray and Burt 1969), and fresh fish muscle frequently contains glycogen, which can be a modifier for glycation, at 0.18–0.88% (Sharp 1934; Amano et al. 1953; Miyazaki et al. 2018). Glycogen can be found at levels exceeding 10% in the livers of seabass, seabream trout and tilapia, although glycogen content varies according to physiological conditions (Enes et al. 2009). Thus, removing the liver of fish may be an effective method for minimizing glycation during heat-processing of fish meal.

In the EC, heated proteins are less likely to be recognized by the four major digestive enzymes examined in the present study, i.e. trypsin, chymotrypsin, elastase and aminopeptidase. Genes encoding carboxypeptidase are also expressed in the yellowtail intestine (Yasuike et al. 2018), and gel filtration on a Superdex Peptide column does not exclude carboxypeptidases from the EC because of their molecular weight. Trypsin recognizes the positive charge of the side chains of Lys and Arg (Olsen et al. 2004), whereas chymotrypsin recognizes the aromatic rings of Tyr, Trp and Phe (Vajda and Szabo 1976). Elastase recognizes at least Ala–Ala and Ala–Gly (Gertler et al. 1977), whereas membrane alanyl aminopeptidase recognizes the N-terminal of various amino acid residues, including Ala, Phe, Tyr and Leu (Sanz 2007). Thus, these four enzymes recognize at least nine different structures, including amino acids. Despite this wide recognition by the EC, heated proteins cannot be digested by the enzymes in the EC even though these enzymes act cooperatively. Moreover, a 14-h incubation period at 25 °C is sufficient for digestion compared with the excretion time of feed in yellowtail (Kitamikado et al. 1965). These results suggest that denaturation by heating at 99 °C is a strict processing condition for protein hydrolysis. Heating for > 3 min at 99 °C during fish meal processing may cause protein to be indigestible of protein due to the relative indigestibility when the seasonal temperature is low. Indeed, the apparent digestibility of a single moist pellet consisting of fish meal processed by heating decreases from 83% in the summer to 68% in the winter, whereas the apparent digestibility of a mainly raw fish diet is maintained at approximately 85% across seasons in yellowtail (Satoh et al. 2000).

His comprised > 72% of HAAa in YT and CM at 0 min (without heating), suggesting that the muscle of yellowtail and chub mackerel contain His at higher concentrations as free amino acids compared with the levels found in WP muscle. However, free His is a minor component in hydrolysate. In agreement with our findings, high concentrations of His in the muscle of yellowtail (Suyama 1973) and chub mackerel (Sakaguchi et al. 1984) have previously been reported.

In WM, the integrated AAa of EAA at 0 min was lower than that at 3 min of heating. WM contained digestive enzymes in the viscera, and freeze-drying maintains their activity in powder. Therefore, the integrated HAAa of WM at 0 min was apparently higher than of the muscle powders (Fig. 4c). Conversely, the integrated NEAAs in WM were higher than those of CM (Fig. 4b). In previous research, the autolysis digesta of a frigate mackerel Auxis thazard head–viscera mixture were found to contain high levels of Glu, Asp and Gly (Morioka et al. 1999). Similarly, Glu, Asp and Gly were found at high levels in a viscera extract from mackerel processed using supercritical carbon dioxide (Park et al. 2008). In general, the viscera hydrolysates of many fish species contain Asp/Asn and Glu/Gln at high concentrations (Villamil et al. 2017). Therefore, the higher levels of NEAAs in WM in the present study likely originated from the viscera rather than from the muscle.

In conclusion, the quantitative relationship between the digestibility of fish muscle and heating time at 99 °C was elucidated using an in vitro method incorporating a fish digestive EC. The amounts of amino acids, both EAAs and NEAAs, produced by hydrolysis decreased with increasing duration of heating time. Most of the reduction in AAa was observed within 3 min of heating for each of three tested fish muscle powders, suggesting that heating time should be minimized during fish feed processing. The muscle of walleye pollock had the highest resistance to heating, but the digestibility was not as high as that of the unheated muscle, suggesting that nonheating sterilization techniques and feed pelleting without extruder can improve the availability and sustainability of fish protein as a natural resource in aquaculture. The likely mechanism underlying the reduction in fish muscle protein digestibility with heat treatment is the denaturation of amino acid residues involving Maillard reaction at recognition sites by the four major pancreatic digestive enzymes in yellowtail, which is highly dependent on pancreatic enzymes that function in the digestive process.

Abbreviations

- AAa:

-

Proteinogenic amino acid amount produced by hydrolysis

- ADR:

-

Average rate of decrease of amino acid amount produced by hydrolysis

- CM:

-

Muscle powder homogenate of chub mackerel

- EAA:

-

Essential amino acid

- EC:

-

Digestive enzyme complex separated from yellowtail pyloric caeca extract

- ECAAa:

-

Amino acid amount of the reaction mixture of EC without fish homogenate

- HAAa:

-

Proteinogenic amino acid amount in the homogenate

- Integrated AAa:

-

Integration of AAa for all proteinogenic amino acids

- NEAA:

-

Non-essential amino acid

- TAAa:

-

Total proteinogenic amino acid amount

- WM:

-

Whole body powder homogenate of chub mackerel

- WP:

-

Muscle powder homogenate of walleye pollock

- YT:

-

Muscle powder homogenate of yellowtail

References

Abraha B, Admassu H, Mahmud A, Tsighe N, Shui XW, Fang Y (2018) Effect of processing methods on nutritional and physico-chemical composition of fish: a review. MOJ Food Process Technol 6:376–382

Aksnes A, Mundheim H (1997) The impact of raw material freshness and processing temperature for fish meal on growth, feed efficiency and chemical composition of Atlantic halibut (Hippoglossus hippoglossus). Aquaculture 149:87–106. https://doi.org/10.1016/S0044-8486(96)01438-X

Amano K, Bito M, Kawabata T (1953) Handling effect upon biochemical change in the fish muscle immediately after catch. I. Difference of glycolysis in the frigate mackerel killed by various methods. Bull Japan Soc Sci Fish 19:487–498

Andoh T (2020) Dilution of digestive fish proteases with protein-free blocking reagents prevents loss of catalytic activity during microquantification. Fish Sci 86:543–550. https://doi.org/10.1007/s12562-020-01422-4

Ariyawansa S (2000) The evaluation of functional properties of fish meal. United Nations University, Fisheries Training Programme, Project Final, Sri Lanka, 1–25.

Bhat ZF, Morton JD, Bekhit AEA, Kumar S, Bhat HF (2021) Thermal processing implications on the digestibility of meat, fish and seafood proteins. Compr Rev Food Sci Food Safety 20:4511–4548. https://doi.org/10.1111/1541-4337.12802

Cropotova J, Mozuraityte R, Standal IB, Ojha S, Rustad T, Tiwari B (2020) Influence of high-pressure processing on quality attributes of haddock and mackerel minces during frozen storage, and fishcakes prepared thereof. Innov Food Sci Emerg Tech 59:102236. https://doi.org/10.1016/j.ifset.2019.102236

Enes P, Panserat S, Kaushik S, Oliva-Teles A (2009) Nutritional regulation of hepatic glucose metabolism in fish. Fish Physiol Biochem 35:519–539. https://doi.org/10.1007/s10695-008-9259-5

Fishery Industries Division of the Food and Agriculture Organization (FAO) of the United Nations (1986) The production of fish meal and oil. FAO Fisheries Technical Paper 142. http://www.fao.org/3/X6899e/X6899E00.HTM. Accessed 25 July 2023

Fountoulakis M, Lahm HW (1998) Hydrolysis and amino acid composition of proteins. J Chromatograph A 826:109–134. https://doi.org/10.1016/s0021-9673(98)00721-3

Gertler A, Weiss Y, Burstein Y (1977) Purification and characterization of porcine elastase II and investigation of its elastolytic specificity. Biochemistry 16:2709–2716

Greaves JP (1963) Protein digestibility and ingestion. Nature 197:499–500. https://doi.org/10.1038/197499a0

Hilmarsdottir GS, Ogmundarson Ó, Arason S, Gudjónsdóttir M (2020) The effects of varying heat treatments on lipid composition during pelagic fishmeal production. Processes 8:1142. https://doi.org/10.3390/pr8091142

Ji S-C, Takaoka O, Biswas AK, Seoka M, Ozaki K, Kohbara J, Ukawa M, Shimeno S, Hosokawa H, Takii K (2008) Dietary utility of enzyme-treated fish meal for juvenile Pacific bluefin tuna Thunnus orientalis. Fish Sci 74:54–61. https://doi.org/10.1111/j.1444-2906.2007.01475.x

Kawabata S-I, Miura T, Morita T, Kato H, Fujikawa K, Iwanaga S, Takada K, Kimura T, Sakakibara S (1988) Highly sensitive peptide-4-methylcoumaryl-7-amide substrates for blood-clotting proteases and trypsin. Eur J Biochem 172:17–25. https://doi.org/10.1111/j.1432-1033.1988.tb13849.x

Kitamikado M, Takahashi T, Noda H, Morishita T, Tachino S (1965) Digestibility of dietary components in young yellowtail. Bull Japan Soc Sci Fish 31:133–137. https://doi.org/10.2331/suisan.31.133

Kofuji PYM, Michihiro M, Hosokawa H, Masumoto T (2004) Comparisons of corn gluten meal and fish meal digestion in yellowtail (Seriola quinqueradiata) by in vivo and in vitro approaches. Aquaculture Sci 52:271–277

Lewis MJ, Francisa DS, Blythe D, Moyano FJ, Smullen RP, Turchinia GM, Boothd MA (2019) A comparison of in-vivo and in-vitro methods for assessing the digestibility of poultry by-product meals using barramundi (Lates calcarifer); impacts of cooking temperature and raw material freshness. Aquaculture 498:187–200. https://doi.org/10.1016/j.aquaculture.2018.08.032

Ljøkjel K, Harstad OM, Skrede A (2000) Effect of heat treatment of soybean meal and fish meal on amino acid digestibility in mink and dairy cows. Anim Feed Sci Tech 84:83–95. https://doi.org/10.1016/S0377-8401(00)00104-8

Maillard LC (1912) Action des acides amine’s sur les sucres; formation des melanoidines par voie methodigue. Comptes R Acad Sci 1912:66–68

Miyazaki R, Wang Y, Miyazaki K, Hirasaka K, Takeshita S, Tachibana K, Taniyama S (2018) Glycogen and lactic acid contents in muscle of Pacific mackerel Scomber japonicus immediately prior to killing and their relationship to its meat quality during storage. Japan J Food Chem Safety 25:139–144

Morioka K, Fujii SY, Itoh Y, Liu C, Obatake A (1999) Recovery of amino acid from the protein in the head and viscera of frigate mackerel by autolysis. Fish Sci 65:588–591

Mumford RA, Strauss AW, Powers JC, Pierzchala PA, Nishino N, Zimmerman M (1980) A zinc metalloendopeptidase associated with dog pancreatic membranes. J Biol Chem 255:2227–2230. https://doi.org/10.1016/S0021-9258(19)85874-X

Murray J, Burt JR (1969) The composition of fish. Tory Advisory Note No. 38, Ministry of Technology, Torry Research Station. http://megapesca.com/megashop/Torry%20Advisory%20Notes%20for%20website/Torry_Advisory_Note_No_38.htm

Myklestad O, Bjørnstad J, Njaa LR (1972) Effects of heat treatment on composition and nutritive value of herring meal. Fiskeridirektoratets Skrifter Serie Teknologiske Undersøkelser 5:1–15

Nygård H (2010) Standard norwegian fishmeal—and fishoil process. Heat treatment requirements. Nofima report 33/2010:1–25 https://proprotein.org/upload/private/information_items_property_120.pdf. Accessed 25 July 2023

Olsen JV, Ong SE, Mann M (2004) Trypsin cleaves exclusively c-terminal to arginine and lysine residues. Mol Cell Proteomics 3:608–614. https://doi.org/10.1074/mcp.T400003-MCP200

Opstvedt J, Nygård E, Samuelsen TA, Venturini G, Luzzana U, Mundheim H (2003) Effect on protein digestibility of different processing conditions in the production of fishmeal and fish feed. J Sci Agric 83:775–782

Ovissipour M, Rasco B, Tang J, Sablani S (2017) Kinetics of protein degradation and physical changes in thermally processed atlantic salmon (Salmo salar). Food Bioprocess Tech 10:1865–1882

Park JY, Back SS, Chun BS (2008) Protein properties of mackerel viscera extracted by supercritical carbon dioxide. J Environ Biol 29:443–448

Sakaguchi M, Murata M, Kawai A (1984) Changes in free amino acid contents in juvenile mackerel scomber japonicus muscle during ice storage. Nippon Suisan Gakkaishi 50:323–329. https://doi.org/10.2331/suisan.50.323

Sanz Y (2007) Aminopeptidase. In: Polaina J, MacCabe AP (eds) Industrial enzymes. Structure, function and applications. Springer, Dordrecht, pp 243–260

Satoh K, Hitaka E, Kimoto K (2000) Effect of water temperature on the protein digestibility of formula feed and mainly-raw-fish diet of young yellowtail. Nippon Suisan Gakkaishi 66:243–248. https://doi.org/10.2331/suisan.66.243

Satoh K, Maita M, Wakatsuki A, Matsuda S (2003) Growth and feed efficiency of adult yellowtail fed extruded pellet diets with two lipid levels and raw-fish diets. Suisanzoshoku 51:343–348

Sawada H, Yokosawa H, Hoshi M, Ishii S (1983) Ascidian sperm chymotrypsin-like enzyme; participation in fertilization. Experientia 39:377–378. https://doi.org/10.1007/BF01963132

Sevgili H, Kurtoğlu A, Oikawa M, Fedekar D, Emre Y, Takeno N (2015) Evaluation of nutritional values of selected commercial fish meal sources in turbot (Psetta maxima) diets. Aquaculture Res 46:2332–2343. https://doi.org/10.1111/are.12389

Sharp GJ (1934) Post-mortem breakdown of glycogen and accumulation of lactic acid in fish muscle—I. Proc R Soc B 114:506–512

Suyama M (1973) Free amino acid composition of the skeletal muscle of migratory fish. Bull J Soc Sci Fish 39:1339–1343. https://doi.org/10.2331/suisan.39.1339

Takakuwa F, Hayashi S, Yamada S, Biswas A, Tanaka H (2022) Effect of additional heating of fish meal on in vitro protein digestibility and growth performance of white trevally (Pseudocaranx dentex) juveniles. Aquacult Res 53:1254–1267. https://doi.org/10.1111/are.15659

Tsai CY, Kilberg MS, Husain SZ (2020) The role of asparagine synthetase on nutrient metabolism in pancreatic disease. Pancreatology 20:1029–1034. https://doi.org/10.1016/j.pan.2020.08.002

Vajda T, Szabo T (1976) Specificity of trypsin and alpha-chymotrypsin towards neutral substrates. Acta Biochim Biophys Acad Sci Hung 11:287–294

Villamil O, Váquiro H, Solanilla JF (2017) Fish viscera protein hydrolysates: production, potential applications and functional and bioactive properties. Food Chem 224:160–171. https://doi.org/10.1016/j.foodchem.2016.12.057

Wagner GP, Kin K, Lynch VJ (2012) Measurement of mRNA abundance using RNA-seq data: RPKM measure is inconsistent among samples. Theory Biosci 131:281–285. https://doi.org/10.1007/s12064-012-0162-3

Wang X, Parsons CM (1998) Effect of raw material source, processing systems, and processing temperatures on amino acid digestibility of meat and bone meals. Poultry Sci 77:834–841

Wiseman J, Jagger S, Cole DJA, Haresign W (1991) The digestion and utilization of amino acids of heat-treated fish meal by growing/finishing pigs. Animal Sci 53:215–225. https://doi.org/10.1017/S0003356100020158

Yasuike M, Iwasaki Y, Nishiki I, Nakamura Y, Matsuura A, Yoshida K, Noda T, Andoh T, Fujiwara A (2018) The yellowtail (Seriola quinqueradiata) genome and transcriptome atlas of the digestive tract. DNA Res 25:547–560. https://doi.org/10.1093/dnares/dsy024

Zajicek JL, Tillitt DE, Honeyfield DC, Brown SB, Fitzsimons JD (2005) A method for measuring total thiaminase activity in fish tissues. J Aquat Animal Health 17:82–94. https://doi.org/10.1577/H03-083.1

Zhao L, Budge SM, Ghaly AE, Brooks MS, Dave D (2011) Extraction, purification and characterization of fish pepsin: a critical review. J Food Process Technol 2:126

Zhao YM, de Alba M, Sun DW, Tiwari B (2019) Principles and recent applications of novel non-thermal processing technologies for the fish industry-a review. Crit Rev Food Sci Nutr 59:728–742. https://doi.org/10.1080/10408398.2018.1495613

Acknowledgements

Yellowtails were kindly provided by K. Yoshida, T. Noda and Y. Fujinami (Goto Station, Japan Fisheries Research and Education Agency, Japan). Ms. A. Ikimi and T. Yamawaki helped with sampling and measuring.

Funding

This work was supported by the Cabinet Office, Government of Japan, Moonshot Research and Development Program for Agriculture, Forestry and Fisheries (funding agency: Bio-oriented Technology Research Advancement Institution).

Author information

Authors and Affiliations

Contributions

TA designed the study. TA, MY, KI and AF conducted the experiments and acquired the data. TA, MY, KI and AF analyzed the data. TA, MY and KI wrote the manuscript.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Andoh, T., Yasuike, M., Ishihara, K. et al. Effects of heating duration on the digestibility of fish protein powders at 99 °C in vitro using yellowtail Seriola quinqueradiata digestive enzymes. Fish Sci 89, 671–685 (2023). https://doi.org/10.1007/s12562-023-01709-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12562-023-01709-2