Abstract

The aim of the present study was to evaluate the occurrence of 23 mycotoxins in beer purchased in Mexico and to assess two exposure scenarios in the Mexican population through beer consumption. Multi-mycotoxin analysis of a total of 61 different beers (132 samples) was carried out using UHPLC-MS/MS equipment. Probability density functions were used to describe mycotoxins contamination. The daily intake of mycotoxins was estimated using a semi-probabilistic approach, applying the Monte Carlo method. Deoxynivalenol (DON) and its metabolites (deoxynivalenol-3-glucoside (DON3G) and 3-acetyl-deoxynivalenol (3ADON)) were the mycotoxins found in higher proportions in contaminated samples. None of the other mycotoxins overpassed the limit of quantification (LOQ) of the method. The combined intake of DON and its analogues ranged from 5.24 to 86.59 ng kg−1 bw day−1, which represent from 1.20 to 19.83% of the DON TDI. The results suggest that depending on the individual consumption of beer and depending on the type of beer, the intake of DON via beer could represent a significant percentage of the tolerable daily intake (TDI).

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Beer is the most consumed alcoholic beverage worldwide, with an annual per capita consumption greater than 100 L in some European countries (Euromonitor International 2014; Kirin 2016). Mexico, with a production of 10.5 billion litres, is the country with the highest export of beer worldwide. In 2016, Mexico beer exports reached $2.814 billion, followed by Netherlands (1.905 billion), Belgium (1.438 billion) and Germany (1.307 billion) (INEGI 2017). About 80% of Mexican beer is exported to the USA, the rest being distributed to more than 184 countries (Kantar Worldpanel Mexico 2015; INEGI 2017).

Cereals used in brewing are mainly barley, wheat and corn (Shetty and Jespersen 2006). These cereals can be subjected to contamination by different mycotoxins. Barley and wheat are mainly contaminated by ochratoxin A (OTA), trichothecenes (deoxynivalenol (DON), nivalenol (NIV), T-2 and HT-2 toxins and zearalenone (ZEN)). Corn is usually infested by fungi-producing fumonisins (FBs) and aflatoxins (AFs). All these mycotoxins have been associated with human and animal diseases (Zain 2011). Alternaria mycotoxins in cereals have been largely ignored both in Europe and overseas (Müller and Korn 2013). Alternaria species produces several mycotoxins, such as alternariol (AOH) and alternariol monomethyl ether (AME). Strong evidence suggests that they are genotoxic (Pfeiffer et al. 2007) and mutagenic (Schrader et al. 2001; Brugger et al. 2006).

The International Agency for Research on Cancer (IARC) classified AFs as a human carcinogen (class 1) and OTA and fumonisin B1 (FB1) as possible human carcinogens (class 2B), and DON, ZEN, NIV and T-2/HT-2 toxins were not classifiable as to their carcinogenicity to humans (class 3) (IARC 1993, 2002; FAO/WHO 2006; EFSA 2010b, 2014). The lack of regulation for Alternaria toxins worldwide is partially due to the limited toxicity data available for them. As a consequence, the European Food Safety Authority (EFSA) used the Threshold of Toxicological Concern (TTC) approach to evaluate the relative level of concern of Alternaria toxins for human health. The results demonstrated that dietary exposure to AOH and AME exceeded the TCC value of 2.5 ng/kg body weight per day, indicating the need for additional toxicity data (Arcella et al. 2016; Tralamazza et al. 2018).

The accumulation of mycotoxins in cereals, or derived foods and feeds, has been sporadically documented in Mexico, reaching concentrations higher than 1000 μg kg−1 for ZEN in wheat (Gonzalez-Osnaya and Farres 2011), 200 μg kg−1 for AFs in maize and maize products (Martínez-Flores et al. 2003; Castillo-Urueta et al. 2011), 5.8 μg kg−1 for OTA (Reyes-Velázquez et al. 2008) and 5600 μg kg−1 for FB1 (Robledo et al. 2001) in maize silage. In Mexico, there is no comprehensive food mycotoxins monitoring program carried out by the governmental agencies (Guzmán-de-Peña and Peña-Cabriales 2005).

AFs are the only mycotoxins legislated in Mexico, as described by the official Mexican norms number NOM-187-SSA1-2002 NOM-247-SSA1-2008 and NOM-243-SSA1-2010. The maximum allowed limit of AFs in cereals for human and animal consumption is 20 μg/kg. In the USA, AFs (20 μg/kg), DON (1000 μg/kg), FBs (2000–4000 μg/kg) and patulin (50 μg/kg) have been regulated (USDA 2015). European regulations on mycotoxin set maximum levels in foodstuff for 14 compounds (European Commission 2006b; European Commission 2013). Regulation 1881/2006 establishes a limit for fumonisin content in maize-based foods (applicable to beer) intended for human consumption to 1000 μg/kg. However, specific regulations for mycotoxins in beer do not exist in any of these countries.

Mycotoxin contamination can occur during cereal growth in the field, during post-harvest storage or during malting (Bertuzzi et al. 2011). Considering mycotoxins thermal stability (AFs, ZEN, and DON) and solubility in water (DON and FBs), they can be partially transferred from cereals to malt and then to beer (Rodríguez-Carrasco et al. 2015). Several authors have studied the occurrence of mycotoxins in industrial and craft beers sold in Argentina (Molto et al. 2000), Brazil (Piacentini et al. 2017), Spain (Torres et al. 1998; Rodríguez-Carrasco et al. 2015; Pascari et al. 2018b), Poland (Kuzdraliński et al. 2013), Belgium (Tangni et al. 2002) and other European countries (Papadopoulou-Bouraoui et al. 2004; Bertuzzi et al. 2011). There are no studies on the occurrence of mycotoxins in beer consumed in Mexico or in the USA; however, some of the surveys mentioned above included Mexican beers in their study detecting: OTA, AOH, DON and ZEN.

To estimate dietary exposure, it is necessary to combine data on food consumption and contamination levels in order to allow conclusions to be drawn about the amount of a substance being consumed by the population (FAO/WHO 2006). Monte Carlo simulation is a statistical method commonly used in probabilistic approach assessment. Monte Carlo simulation relies on a sequence of random numbers to carry out a simulation. This allows a probability distribution to be obtained and studied, instead of a single value to represent this risk (Landau and Binder 2015).

Among the studies of exposure to mycotoxin through beer intake that have been made so far, none has been conducted exclusively in Mexico. Therefore, the objective of this work was to assess two exposure scenarios to mycotoxins throughout beer consumption, focusing on data for the Mexican population (daily beer consumption, average body weight).

Materials and methods

Chemicals and reagents

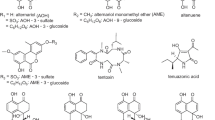

The standards of mycotoxins, aflatoxin B1 (AFB1), aflatoxin B2 (AFB2), aflatoxin G1 (AFG1), aflatoxin G2 (AFG2), sterigmatocystin (STE), OTA, roquefortine C (ROQ-C), AOH, AME, T-2 toxin (T-2), HT-2 toxin (HT-2), neosolaniol (NEO), diacetoxyscirpenol (DAS), DON, 3-acetyl-deoxynivalenol (3ADON), 15-acetyl-deoxynivalenol (15ADON), deoxynivalenol-3-glucoside (DON3G), NIV, fusarenon-X (F-X), ZEN, fumonisin B1 (FB1), fumonisin B2 (FB2), and fumonisin B3(FB3), were obtained from Sigma-Aldrich (Bornem, Belgium). An internal standard of deepoxy-deoxynivalenol (DOM-1) was obtained from Romer Labs (Getzersdorf, Austria). All mycotoxin solid standards were dissolved in methanol (1 mg/mL) and stored at − 18 °C.

Water was obtained from a Milli-Q® SP Reagent water system from Millipore Corp. (Brussels, Belgium). Disinfectol® (denaturated ethanol with 5% ether) was supplied by Chem-Lab (Zedelgem, Belgium). Methanol (LCMS grade) was purchased from BioSolve (Valkenswaard, the Netherlands), while acetonitrile (Analar Normapur) was obtained from VWR International (Zaventem, Belgium). Acetic acid (glacial, 100%) was supplied by Merck (Darmstadt, Germany). Magnesium sulphate (MgSO4) and sodium chloride (NaCl) were purchased from Fischer Scientific (NJ, USA).

Samples

Various types of bottled and canned beers (n = 61) were bought from supermarkets and beer stores of Veracruz city (Mexico) between July and October 2017. Every product was purchased by duplicate or triplicate (2 or 3 different lots of each beer) according to their availability at the time of buying (total of 132 samples). Twenty-five different beer-producing companies, originating from eight countries, Mexico (40), the USA (10), Belgium (4), Germany (3), Spain (1), Netherlands (1), Argentina (1) and Guatemala (1), were chosen for the analysis. To facilitate the interpretation and discussion of results, the samples were grouped as follows: according to their fermentation style—ale (31.1%) and lager (68.9%); their alcohol content—alcohol-free (3.3%), between 4 and 5% vol. (80.3%) and > 5.5% vol. (16.4%); their colour—golden (62.2%), amber (28.0%) and dark coloured (9.8%); and their production method—industrial (73.8%) and craft (26.2%).

Sample pre-treatment

Extraction of beer samples was carried out following a protocol modified from Monbaliu et al. (2009), validated by the Laboratory of Food Analysis from Ghent University, Belgium. Briefly, from each sample, a 100-mL aliquot was taken, degassed, sonicated for 15 min and stored at − 18 °C until analysis. Then, 18 mL of extraction solvent composed by acetonitrile:water:acetic acid (59:40:1, v/v/v) was added to 2 mL of degassed beer sample containing the internal standard (DOM-1) at a concentration of 10 μg L−1. The mixture was vigorously shaken for 30 s prior to the addition of premixed 4 g of MgSO4 and 1 g of NaCl, after which it was shaken again for 60 s and agitated during 30 min at 200 rpm in an orbital rotary shaker (Infors AG CH-4103, Bottmingen, Switzerland). The mixture was then centrifuged at 2336×g during 10 min with a Hettich Universal 320R centrifuge (Tuttlingen, Germany), and 7 mL of supernatant was collected and evaporated to dryness under a low nitrogen stream (40 °C). The dry extract was resuspended in 0.5 mL of methanol:water (95:5, v/v) and filtered (PTFE syringe filter, 0.22 μm) before injection in HPLC-MS/MS system.

Mycotoxin analysis

A Waters Acquity UHPLC system coupled to a Quattro XEVO TQ mass spectrometer (Waters, Milford, MA, USA) was used to analyse the samples. Data acquisition and processing were performed with MassLynx™ version 4.1 and QuanLynx® version 4.1 software (Waters, Manchester, UK). A Waters Acquity UPLC® HSS T3 2.1 × 100 mm, 1.8 μm column was applied (Milford, MA, USA).

The mobile phase consisted of a gradient with phase A: water:methanol (95:5, v/v) and phase B: methanol:water (95:5, v/v), both buffered with 10 mmol L−1 ammonium acetate and acidified with 0.3% of glacial acetic acid.

The phase gradient was adjusted with 5% of solvent B and the rest with solvent A. After 7 min, it was increased linearly at 65% of solvent B, and 4 min later, it was increased to 75% of B. Following that, the proportion dropped to 1% B within 2 min and increased to 99% B the next minute. After that, the proportion of solvent B again decreased to 5% and increased to 65% B and 75% B in the next 3.5 min and 1 min, respectively. In the following 1.2 min, the proportion of solvent B decreased to 1%, increasing to 5% after 1 min. Then, the solvent B proportion was increased linearly to 65% in 3.5 min to 75% in 1 min and to 99% in the next 1.6 min. In the last 2 min of the chromatogram, solvent proportion was kept at 5% B until the next injection. The flow rate was set at 0.3 mL min−1 through the entire analysis process.

The mass spectrometer was operated in positive electrospray ionisation mode (ESI+). The ESI parameters were set up as follows: capillary voltage 30 kV, and nitrogen applied as spray gas; source and dissolution temperatures 150 °C and 200 °C, respectively; argon collision gas pressure 9 × 10−6 bar; cone gas flow 50 L h−1; dissolution gas flow 4 mke h−1. Two selected reaction monitoring (SRM) transitions with a specific dwell time were chosen for each analyte, in order to increase the sensitivity and the selectivity of the mass spectrometric conditions.

LC-MS/MS method validation

The LC-MS/MS method for the simultaneous detection of 23 mycotoxins was successfully validated in-house based on European Commission 401/ 2006a. Validation data for each selected compound are presented in Table 1. Matrix-matched calibration plots were constructed for the determination of the analytes. Linearity and the homogeneity of variance were checked for each mycotoxin studied. The linearity was interpreted graphically using a scatter plot. The precision was represented in terms of relative standard deviation (RSD) and the bias of the method represented by measurement uncertainty (MU). The MU evaluation was performed according to European Regulation (European Commission 2002/657), which corresponded to a confidence interval of 95%. Limit of detection (LOD) and limit of quantification (LOQ) were calculated as three and six times the standard error of the intercept divided by the slope of the calibration curve, respectively. The calculated LOD and LOQ were verified by the signal-to-noise ratio (s/n), which should be more than 3 and 10, respectively, according to the IUPAC guidelines (IUPAC, prepared by Currie 1995). The results of the performance characteristics of the LC-MS/MS method were in good agreement with the criteria mentioned in European Commission 401/ 2006a.

The resulted detection and quantification limits are higher compared to the ones obtained in similar studies (Bertuzzi et al. 2011; Rodríguez-Carrasco et al. 2015; Bauer et al. 2016; Piacentini et al. 2017); however, none of them performed a simultaneous multi-analysis study of 23 mycotoxins with conversion rates close to 100%.

Treatment of left-censored data

Analytical methods are defined by LOD and LOQ; to express quantitatively the result below these limits, several techniques can be used. EFSA published a scientific report evaluating the accuracy of methods currently used and providing recommendations for more advanced alternative statistical approaches. WHO has proposed recommendations for replacing the non-detected samples by LOD/2 or 0 and LOD according to the percentage of non-detects in the samples; similar guidelines have been provided in the case of non-quantified values (EFSA 2010a).

In this study, taking into account that more than 60% but less than 80% of the samples were found to be below the detection limit (with < 25 results quantified), EFSA’s recommendations were applied: lower bound (LB) or best-case scenario, where the < LOD values were considered equal to zero and upper bound (UB) or worst-case scenario, where the < LOD values were equalled to LOD (EFSA 2010a).

Theoretical distribution of mycotoxin beer contamination

Using the Risk 7.5 (Palisade, Inc.) risk software, a comparison of different probability distribution functions was carried out. Considering the asymmetry of the histogram of mycotoxin contamination in beer, the data were adjusted to an exponential function. Probability density functions and descriptive statistics (the mean, median, standard deviation and the 95th percentile) of mycotoxin concentration in beer were also determined and analysed. The Monte Carlo method was applied with the iteration number (10,000) recommended by international agencies (US-EPA 1997).

Data used for body weight population and beer consumption

The high variability of alcohol consumption within the population makes it one of the most difficult food items for exposure assessment studies. According to the FAO/WHO (2014), in Mexico, alcohol consumption is six times higher in men (12.4 L of pure alcohol per year) than in women (2.6 L of pure alcohol per year) and 76% of the alcohol consumed comes from the intake of beer. Because there are no available studies describing the behaviour of beer consumption in groups of population, such as age, gender, region or socioeconomic level, the national average volume of 60 L of beer per year, equivalent to 164.38 mL/day, established by the Mexican Ministry of Economy (Secretaría de Economía 2015), will be applied in the present publication. To estimate the levels of intake in high drinkers, the beer consumption average of Czech Republic (143.3 L per year), the country with the highest consumption of beer in the world, was used.

The benchmark body weight used was that established by CANAIVE (2012) for an average Mexican (71.7 kg) (Cámara Nacional de la Industria del Vestido, (CANAIVE 2012).

Estimation of mycotoxins daily intake and exposure risk

Daily intake was then calculated under a semi-probabilistic approach by Eq. (1):

where:

EDI= Probability density function of estimated daily intake (ng mycotoxin kg−1 bw day−1)

Mc= Probability function density of mycotoxin concentration in beer (ng L−1)

Bc= Beer consumption (L day−1)

bw= Body weight (kg)

In the case of mycotoxins that are not classified as genotoxic or carcinogenic, the exposure estimates were compared with the guidance values of tolerable daily intake (TDI). TDI used in the present study is summarised in Table 2.

Results and discussion

Occurrence of mycotoxin in beer

Mycotoxins were detected in 16 of the 61 analysed samples (26.2% positive samples); however, none overpassed the limits of quantification of the methodology used. Only one beer presented contamination in the two analysed replicates (different production batches).

The samples were purchased in supermarkets and beer stores in Veracruz city, so there is no information available on the traceability of the raw material or of the process; however, all the mycotoxins detected are produced by Fusarium fungi, which are characterised by invading cereals in the field (Gimeno and Martins 2003). Thus, the contamination probably originates in the field, with minimal possibility of contamination during storage or processing. From the analysed samples, nine presented contamination with DON, two with 3ADON, six with DON3G and three with FB1.

Similar results were reported by Pascari et al. (2018b) in beer purchased in Lleida, Spain, with 20.3% of samples contaminated by DON, DON3G, ZEN, HT2 and FB1. Kuzdraliński et al. (2013) and Rodríguez-Carrasco et al. (2015) reported contamination by DON in 100% of beers analysed; however, all samples showed contamination less than 48 μg L−1. This concentration is lower than the LOQ of our methodology, so decreasing the LOQ of our methodology, the proportion of positive samples would probably increase to a large extent.

The most frequent contaminants were DON and its metabolites, detected in 87.5% of the positive samples. In two samples, co-occurrence of DON and 3ADON was detected, which could have been due to their release from barley matrix during mashing and subsequent transfer to wort and beer because of their relatively high solubility in water (Samar et al. 2001; Kostelanska et al. 2011). Similarly, the presence of DON3G in five samples can be attributed to DON conversion during malting due to grain defence mechanisms against the presence of the contaminant, as reported by Lancova et al. (2008). ZEN was not detected in any of the samples. It would have been advisable to analyse α-zearalenone (α-ZEL) and β-zearalenone (β-ZEL) to discard contamination by ZEN metabolites (Karlovsky et al. 2016).

FB1 contamination was found in three analysed beers; this could be a consequence of the use of corn as an unmalted adjunct—corn grits are commonly used in order to achieve a greater degree of lightness in colour, clarity, calories and flavour (Bertuzzi et al. 2011). Corn has been proven susceptible to infestation by FB-producing Fusarium, which would explain the abovementioned finding (Robledo et al. 2001; Mendoza et al. 2017).

There are limited surveys that classify samples for data analysis (Rodríguez-Carrasco et al. 2015; Peters et al. 2017; Pascari et al. 2018a). In our study, beers with an alcohol content greater than 5.5% had mycotoxin contamination in 60% of the samples analysed, similar to the results reported by Pascari et al. (2018b). A possible explanation would be the necessity to use more grain in high-density malt wort to reach these alcohol levels, which could contribute to greater mycotoxin contamination. Light and non-alcoholic beers did not show contamination above LOD.

Craft beer presented a higher percentage of mycotoxin contamination (56.3%) than industrial beers (15.55%). In the same way, Peters et al. (2017) detected more mycotoxins (AFB1, OTA, ZEN, FBs, DON, T-2, and HT2) in craft beer than in industrial beer from 1000 beers analysed. It is recommended that small craft breweries consider the implementation of rapid analysis techniques for mycotoxins in cereals to control purchased malts and adjuncts as well as their final products.

The Mexican-brand or Mexican-made beers presented contamination in 27.5%. Although with a non-representative sample size (three positive samples from a total of seven analysed), the results agree with that reported by Bauer et al. (2016), who found a high frequency of mycotoxin contamination (75% for DON) although in low concentrations (2.2–20 μg L−1) in European beers. Regarding the colour classification, similar contamination was found, dark beers presented 33%, amber 26% and golden 23%. Finally, as for the fermentation style, ale beers had a higher percentage of contamination (42%) than lager (29%), which could be probably explained by different adsorptions of the toxins to the yeast cell during fermentation (Lancova et al. 2008); nonetheless, more investigation is needed to confirm this statement.

Estimation of the DON intake via beer consumption in various scenarios

Due to the limited number of positive samples contaminated with FB1 and other mycotoxins, only an assessment of the intake of DON through beer consumption was performed, considering the recommendations of EFSA (2013, 2014) to use the sum of DON and its modified forms (DON3G, 3ADON, and 15ADON) for calculation.

Table 3 shows the statistical parameters of the probability density function for mycotoxin contamination in beer for the two risk scenarios (LB and UB). It can be seen that even in the 99th percentile, the values are below the DON TDI of 1000 ng kg−1 bw day−1 (SCF 2000). Similar concentrations were presented by Bryła et al. (2018) (9.0 μg L−1), Kuzdraliński et al. (2013) (20.66 μg L−1) and Rodríguez-Carrasco et al. (2015) (28.9 μg L−1) in beer from different countries. The data on contamination by DON and its metabolites were adjusted to an exponential function. Figure 1a presents the probability density function of DON contamination in LB scenario.

a Probability density function fitted exponential distribution (solid line) for DON contamination in beer marketed in Mexico (lower bound values), obtained by the Monte Carlo method, showing contamination in the 5th and 95th percentiles (broken line). b Probability density function for estimated daily intake of DON (Lower bound values) though beer, obtained by Monte Carlo method, showing exposure in the 5th and 95th percentiles (broken line)

Probability density function and probability density function parameters of the EDI calculated by the Monte Carlo method are shown in Fig. 1b and Table 4. The EDI average was 12.03 ng kg−1 bw day−1 (LB) and 198.31 ng kg−1 (UB) or 28.69 ng kg−1 bw day−1 (LB) and 473.64 ng kg−1 bw day−1 (UB) in the high consumption scenario. Those are lower than the recommendation of the JEFCA (2010) of 1000 ng kg−1 bw day−1. The percentage of TDI of DON mycotoxins that beer provides as a result of LB consumption is similar that reported by Pascari et al. (2018a) in Spain (1.6%) and lower that than obtained by Bauer et al. (2016) (5–10%) and Rodríguez-Carrasco et al. 2015 (10%) in beer consumers from Germany and Ireland respectively. Regarding other products, TDI in the LB scenario that beer provides for exposure to DON is similar to bread (5.3 ng kg−1 bw day−1) and cookies (5.7 ng kg−1 bw day−1) in the population of Brazil (Savi et al. 2016) and pasta (22 ng kg−1 bw day−1) in Spain. It is lower than corn flour (1600 ng kg−1 bw day−1) and greater than of oat flakes (0.07 ng kg−1 bw day−1) in China (Ji et al. 2018).

This is the first study with a large number of mycotoxins analysed in beer commercialised in Mexico, the country with the largest world export of beer. Mycotoxins were present in a greater proportion in craft beers than in commercial beers. DON and its modified forms (DON3G, 3ADON) were the most frequently occurring mycotoxins compared to other analized compounds. Although the contamination data obtained in the present study were not above the legal limits, DON intake through beer consumption should not be ignored (contribution to exposure from 1.20 to 19.83% of TDI). An even greater contribution may take place for the population consuming a daily amount of beer above the national average, such as the Mexican male population (according to WHO reports, men consume six times more alcohol than women).

References

Arcella D, Eskola M, Ruiz JAG (2016) Dietary exposure assessment to Alternaria toxins in the European population. EFSA J 14:4654. https://doi.org/10.2903/j.efsa.2016.4654

Bauer JI, Gross M, Gottschalk C, Usleber E (2016) Investigations on the occurrence of mycotoxins in beer. Food Control 63:135–139. https://doi.org/10.1016/j.foodcont.2015.11.040

Bertuzzi T, Rastelli S, Mulazzi A, Donadini G, Pietri A (2011) Mycotoxin occurrence in beer produced in several European countries. Food Control 22:2059–2064. https://doi.org/10.1016/j.foodcont.2011.06.002

Brugger EM, Wagner J, Schumacher DM, Koch K, Podlech J, Metzler M, Lehmann L (2006) Mutagenicity of the mycotoxin alternariol in cultured mammalian cells. Toxicol Lett 164(3):221–230. https://doi.org/10.1016/j.toxlet.2006.01.001

Bryła M, Ksieniewicz-Woźniak E, Waśkiewicz A, Szymczyk K, Jędrzejczak R (2018) Co-occurrence of nivalenol, deoxynivalenol and deoxynivalenol-3-glucoside in beer samples. Food Control 92:319–324. https://doi.org/10.1016/j.foodcont.2018.05.011

Cámara Nacional de la Industria del Vestido (CANAIVE) (2012) ¿Cuánto mide México? El tamaño sí importa. Cámara Nacional de la Industria del vestido. [How much does Mexico measure? size does matter]. Accessed 2018 June 13. México. www.canaive.com

Castillo-Urueta P, Carvajal M, Méndez I, Meza F. Gálvez A (2011) Survey of aflatoxins in maize tortillas from Mexico City. Food Addit Contam Part B 4:42–51. doi: https://doi.org/10.1080/19393210.2010.533390

Euromonitor International Beer in México, (2014) London. Retrieved from Euromonitor Passport database. Accessed 2018 Feb 11. http://www.euromonitor.com/beer

European Commission (2002) Commission Regulation (EC) 2002/657 of 12 of August 2002, concerning the performance of analytical methods and the interpretation of the results. Off J Eur Commun, L221eL232. Available from: https://publications.europa.eu/en/publication-detail/-/publication/ed928116-a955-4a84-b10a-cf7a82bad858/language-en. Accessed on 08/03/19

European Commission (2006a) Commission Regulation (EC) 401/2006 laying down the methods of sampling and analysis for the official control of the levels of mycotoxins in foodstuffs. Off J EU L70:12–34 Available from: https://fsvps.ru/fsvps-docs/ru/usefulinf/files/es401-2006.pdf. Accessed on 08/03/19

European Commission (2006b) Commission regulation (EC) no 1881/2006 of 19 December 2006 setting maximum levels for certain contaminants in foodstuffs. Off J Eur Communitites L364:5–24. https://doi.org/10.2203/dose-response.06-012.Hanekamp

European Commission (2013) Commission recommendation (EC) 2013/165 commission recommendation of March 27, 2013 on the presence of T-2 and HT-2 toxin in cereal and cereal products (2013/165/EU). Off J EU L91:12–11 Available from: http://extwprlegs1.fao.org/docs/pdf/eur122396.pdf

European Food Safety Authority (EFSA) (2010a) Management of left-censored data in dietary exposure assessment of chemical substances. EFSA J 8:1–96. https://doi.org/10.2903/j.efsa.2010.1557

European Food Safety Authority (EFSA) (2010b) Opinion of the scientific panel on contaminants in the food chain related. Statement on recent scientific information on the toxicity of ochratoxin A. EFSA, Parma. https://doi.org/10.2903/j.efsa.2010.1626

European Food Safety Authority (EFSA) (2011a) Scientific opinion on the risks for animal and public health related to the presence of T-2 and HT-2 toxin in food and feed. EFSA J 9:1–187. https://doi.org/10.2903/j.efsa.2011.248

European Food Safety Authority (EFSA) (2011b) Scientific opinion on the risks for public health related to the presence of zearalenone in food. EFSA J 9:1–124. https://doi.org/10.2903/j.efsa.2011.2197

European Food Safety Authority (EFSA) (2013) Request for a scientific opinion on the risks for animal and public health related to the presence of deoxynivalenol, metabolites of deoxynivalenol and masked deoxynivalenol in food and feed. http://registerofquestions.efsa.europa.eu. Accessed on 08/03/19

European Food Safety Authority (EFSA) (2014) Scientific opinion on the risks for human and animal health related to the presence of modified forms of certain mycotoxins in food and feed. EFSA J 12:1–61. https://doi.org/10.2903/j.efsa.2014.3916

Food and Agriculture Organization and World Health Organization (FAO/WHO) (2006) The use of microbiological risk assessment outputs to develop practical risk management strategies: metrics to improve food safety. Report of a Joint FAO/WHO Meeting in collaboration with the German Federal Ministry of Food. Kiel, Germany. Accessed 2018 June 13. http://www.who.int/foodsafety/publications/micro/MRA_Outputs.pdf

Food and Agriculture Organization and World Health Organization (FAO/WHO) (2014) Global alcohol reports: Mexico. Report of a Joint FAO/WHO [Accessed 2018 June 14 http://www.who.int/substance_abuse/publications/global_alcohol_report/profiles/mex.pdf

Gimeno A, Martins M (2003) Micotoxinas y micotoxicosis en animales y humanos. Talleres gráficos del SRL, Buenos Aires

Gonzalez-Osnaya L, Farres A (2011) Deoxynivalenol and zearalenone in Fusarium-contaminated wheat in Mexico City. Food Addit Contam Part B 4:71–78. https://doi.org/10.1080/19393210.2011.551944

Guzmán-de-Peña D, Peña-Cabriales JJ (2005) Regulatory considerations of aflatoxin contamination of food in Mexico. Rev Latinoam Microbiol 47:160–164

Instituto Nacional de Estadística y Geografía (INEGI) (2017) Estadísticas a propósito de la actividad de elaboración de la cerveza [Statistics on the activity of brewing]. México. [Accessed 2018 [junio 01]. http://cervecerosdemexico.com/wp-content/uploads/2017/08/estadisticas-a-proposito-de-la-elaboracion-de-la-cerveza.pdf

International Agency for Research on Cancer (IARC) (1993) Some naturally occurring substances: food items and constituents, heterocyclic aromatic amines and mycotoxins IARC monographs on the evaluation of carcinogenic risk to humans, vol 56. IARC, World Health Organization, Lyon, France, pp 245–395

International Agency for Research on Cancer (IARC) (2002) Aflatoxins monograph on the evaluation of carcinogenic risks to humans, vol 82. IARC, World Health Organization, Lyon, France, pp 171–300

IUPAC, prepared by Currie L (1995) Commission or analytical nomenclature, recommendations in evaluation of analytical methods including detection and quantification capabilities. Pure Appl Chem 67:1699–1723. https://doi.org/10.1016/S0003-2670(99)00104-X

Ji X, Yang H, Wang J, Li R, Zhao H, Xu J, Xiao Y, Tang B, Qian M (2018) Occurrence of deoxynivalenol (DON) in cereal-based food products marketed through e-commerce stores and an assessment of dietary exposure of Chinese consumers to DON. Food Control 92:391–398. https://doi.org/10.1016/j.foodcont.2018.05.020

Joint FAO/WHO Expert Committee on food additives (JECFA) (2010) Summary and conclusions. In: Seventy-second meeting, Rome, 16–25 February 2010. FAO/WHO, Rome

Kantar Worldpanel México (2015) México 2° lugar en consumo de cerveza en Latinoamérica. [Mexico 2nd place in beer consumption in Latin America] [Accessed 2018 June 01]. https://www.kantarworldpanel.com/mx/Noticias-/Mexico-2-lugar-en-consumo-de-Cerveza-en-Latinoamerica

Karlovsky P, Suman M, Berthiller F, Meester J, Eisenbrand G, Perrin I, Oswald IP, Speijers G, Chiodini A, Recker T, Dussor P (2016) Impact of food processing and detoxification treatments on mycotoxin contamination. Mycotox Res 32:179–205. https://doi.org/10.1007/s12550-016-0257-7

Kirin Holding Company (2016) Global Beer Consumption by Country in 2015. Accessed 2018 June 01. https://www.kirinholdings.co.jp/english/news/2017/1221_01.html

Kostelanska M, Zachariasova M, Lacina O, et al (2011) The study of deoxynivalenol and its masked metabolites fate during the brewing process realised by UPLC-TOFMS method. Food Chem 126:1870–1876. https://doi.org/10.1016/j.foodchem.2010.12.008

Kuzdraliński A, Solarska E, Muszyńska M (2013) Deoxynivalenol and zearalenone occurrence in beers analysed by an enzyme-linked im munosorbent assay method. Food Control 29:22–24. https://doi.org/10.1016/j.foodcont.2012.06.003

Lancova K, Hajslova J, Poustka J, Krplova A, Zachariasova M, Dostalek P, Sachambula L (2008) Transfer of Fusarium mycotoxins and “masked” deoxynivalenol (deoxynivalenol-3-glucoside) from field barley through malt to beer. Food Addit Contam - Part A 25:732–744. https://doi.org/10.1080/02652030701779625

Landau D, Binder K (2015) A guide to Monte Carlo simulations in statistical physics. Cambridge University Press, Cambridge

Martínez-Flores R, García-Aguirre G, Melgarejo-Hernández (2003) Inspección de aflatoxinas en maíz cultivado, almacenado y transportado en el estado de Tamaulipas, México en 1988. [Inspection of aflatoxins in corn grown, stored and transported in the state of Tamaulipas, Mexico in 1988] Instituto de Biología, UNAM, serie Botánica 74:313–321. Available from: http://www.ejournal.unam.mx/bot/072-02/BOT72205.pdf. Accessed on 08/03/19

Mendoza JR, Kok CR, Stratton J, Bianchini A, Hallen-Adams HE (2017) Understanding the mycobiota of maize from the highlands of Guatemala, and implications for maize quality and safety. Crop Prot 101:5–11. https://doi.org/10.1016/j.cropro.2017.07.009

Molto G, Samar M, Resnik S, Martínez EJ, Pacin A (2000) Occurrence of trichothecenes in Argentinean beer: a preliminary exposure assessment. Food Addit Contam 17:809–813. https://doi.org/10.1080/026520300415363

Monbaliu S, Van Poucke C, Van Peteghem C, Van Poucke K, Heungens K, De Saeger S (2009) Development of a multi-mycotoxin liquid chromatography/tandem mass spectrometry method for sweet pepper analysis. Rapid Commun. Mass Spectrom 21:3-11. doi.org/10.1002/rcm.3833

Müller MEH, Korn U (2013) Alternaria mycotoxins in wheat—a 10 years survey in the Northeast of Germany. Food Control 34:191–197. https://doi.org/10.1016/j.foodcont.2013.04.018

Norma Oficial Mexicana (2002) NOM-187-SSA1/SCFI-2002: Productos y servicios. Masa, tortillas, tostadas y harinas preparadas para su elaboración y establecimientos donde se procesan. Especificaciones sanitarias. Available from: http://www.salud.gob.mx/unidades/cdi/nom/187ssa1scfi02.html. Accessed on 08/03/19

Norma Oficial Mexicana (2008) NOM-247-SSA1–2008: Productos y servicios. Cereales y sus productos. Cereales, harinas de cereales, sémolas o semolinas. Alimentos a base de: cereales, semillas comestibles, de harinas, sémolas o semolinas o sus mezclas. Productos de panificación. Disposiciones y especificaciones sanitarias y nutrimentales. Métodos de prueba. Available from: http://dof.gob.mx/nota_detalle.php?codigo=5100356&fecha=27/07/2009. Accessed on 08/03/19

Norma Oficial Mexicana (2010) NOM-243-SSA1–2010: Productos y servicios. Leche, fórmula láctea, producto lácteo combinado y derivados lácteos. Disposiciones y especificaciones sanitarias. Métodos de prueba. Available from: http://dof.gob.mx/normasOficiales/4156/salud2a/salud2a.htm. Accessed on 08/03/19

Papadopoulou-Bouraoui A, Vrabcheva T, Valzacchi S, Stroka J, Anklam E (2004) Screening survey of deoxynivalenol in beer from the European market by an enzyme-linked immunosorbent assay. Food Addit Contam 21:607–617. https://doi.org/10.1080/02652030410001677745

Pascari X, Ortiz-Solá J, Marín S, Ramos AJ, Sanchis V (2018a) Survey of mycotoxins in beer and exposure assessment through the consumption of commercially available beer in Lleida, Spain. LWT Food Sci Technol 92:87–91. https://doi.org/10.1016/j.lwt.2018.02.021

Pascari X, Ramos AJ, Marín S, Sanchis V (2018b) Mycotoxins and beer. Impact of beer production process on mycotoxin contamination. A review. Food Res Int 103:121–129. https://doi.org/10.1016/j.foodres.2017.07.038

Peters J, Van Dam R, Van Doorn R, Katerere D, Berthiller F, Haasnoot W, Nielen MWF (2017) Mycotoxin profiling of 1000 beer samples with a special focus on craft beer. PLoS One 12:1–27. https://doi.org/10.1371/journal.pone.0185887

Pfeiffer E, Eschbach S, Metzler M (2007) Alternaria toxins: DNA strand-breaking activity in mammalian cells in vitro. Mycotoxin Res 23(3):152–157. https://doi.org/10.1007/BF02951512

Piacentini KC, Rocha LO, Fontes LC, Carnielli L, Reis TA, Corrêa B (2017) Mycotoxin analysis of industrial beers from Brazil: the influence of fumonisin B1 and deoxynivalenol in beer quality. Food Chem 218:64–69. https://doi.org/10.1016/j.foodchem.2016.09.062

Reyes-Velázquez WP, Isaías-Espinoza VH, Rojo F, Jiménez-Plascencia C, de Lucas-Palacios E, Hernández-Góbora J, Ramírez-Álvarez A (2008) Occurrence of fungi and mycotoxins in corn silage, Jalisco State, México. Rev Iberoam Micol 25:182–185

Robledo M, Marín S, Ramos AJ (2001) Contaminación natural con micotoxinas en maíz forrajero y granos de café verde en el Estado de Nayarit (México) [Natural contamination with mycotoxins in fodder corn and green coffee beans in the State of Nayarit (Mexico)]. Rev Iberoam Micol 18:141–144

Rodríguez-Carrasco Y, Fattore M, Albrizio S, Berrada H, Mañes J (2015) Occurrence of Fusarium mycotoxins and their dietary intake through beer consumption by the European population. Food Chem 178:149–155. https://doi.org/10.1016/j.foodchem.2015.01.092

Samar MM, Neira MS, Resnik SL, Pacin A (2001) Effect of fermentation on naturally occurring deoxynivalenol (DON) in Argentinean bread processing technology. Food Addit Contam 18:1004–1010. https://doi.org/10.1080/02652030110051284

Savi GD, Piacentini KC, Tibola CS, Santos K, Maria GS, Scussel VM (2016) Deoxynivalenol in the wheat milling process and wheat-based products and daily intake estimates for the Southern Brazilian population. Food Control 62:231–236. https://doi.org/10.1016/j.foodcont.2015.10.029

Schrader TJ, Cherry W, Soper K, Langlois I, Vijay HM (2001) Examination of Alternaria alternata mutagenicity and effects of nitrosylation using the Ames Salmonella test. Teratog Carcinog Mutagen 21(4):261–274. https://doi.org/10.1002/tcm.1014

Scientific Committee for Food (SCF) (2000) Opinion of the scientific committee on food on Fusarium toxins. Part 2: Zearalenone (ZEA). Available from https://ec.europa.eu/food/sites/food/files/safety/docs/cs_contaminants_catalogue_out65_en.pdf. Accessed on 08/03/19

Scientific Committee for Food (SCF) (2003) Updated opinion of the scientific committee on food on fumonisin B1, B2 and B3. European Commission, Health and consumer protection directorate-general, document number SCF/CS/CNTM/MYC/28 Final of 4 April 2003. Available from: https://ec.europa.eu/food/sites/food/files/safety/docs/cs_contaminants_catalogue_fusarium_out185_en.pdf. Accessed on 08/03/19

Scientific Committee on Food (SCF) (2002) Opinion of the Scientific Committee on Food on Fusarium toxins. Part 6: group evaluation of T-2 toxin, HT-2 toxin, nivalenol and deoxynivalenol. Scientific Committee on Food SCF/CS/CNTM/ MYC/27 Final. Available from: http://ec.europa.eu/food/fs/sc/scf/out123_en.pdf. Accessed on 08/03/19

Secretaría de Economía (SE) (2015) Industria de la Cerveza en México [Beer industry in Mexico]. Subsecretaría de Industria y Comercio. Catálogo de Publicaciones de la Administración General del Estado: http://publicacionesociales.boe.es/NIPO:280-16-007-6 Deposito legal: M-25254-2016

Shetty PH, Jespersen L (2006) Saccharomyces cerevisiae and lactic acid bacteria as potential mycotoxin decontaminating agents. Trends Food Sci Technol 17:48–55. https://doi.org/10.1016/j.tifs.2005.10.004

Tangni EK, Ponchaut S, Maudoux M, Rozenberg R, Larondelle Y (2002) Ochratoxin A in domestic and imported beers in Belgium: occurrence and exposure assessment. Food Add Contam 12:1169–1179. https://doi.org/10.1080/02652030210007859

Torres MR, Sanchis V, Ramos AJ (1998) Occurrence of fumonisins in Spanish beers analyzed by an enzyme-linked immunosorbent assay method. Int J Microbiol 39:139–143. https://doi.org/10.1016/S0168-1605(97)00113-X

Tralamazza SM, Piacentini KC, Iwase CHT, Rocha L de O (2018) Toxigenic Alternaria species: impact in cereals worldwide. Curr Opin Food Sci 23:57–63. doi: https://doi.org/10.1016/J.COFS.2018.05.002

U.S. Environmental Protection Agency (US EPA) (1997) Exposure factors handbook. US EPA/600/P-95/002Fb, Volume II, Food ingestion factors, Office of Research and Development, Washington, DC. Available from: https://www.epa.gov/risk/risk-assessment-guidelines. Accessed on 08/03/19

Unites States Department of Agriculture (USDA) (2015) Mycotoxin handbook. Grain Inspection Packers and Stockyards Administration, Washington, D.C. https://www.gipsa.usda.gov/fgis/handbook/MycotoxinHB/MycotoxinHandbook_2016-07-12.pdf. Accessed on 08/03/19

Zain ME (2011) Impact of mycotoxins on humans and animals. J Saudi Chem Soc 15:129–144. https://doi.org/10.1016/j.jscs.2010.06.006

Funding

This work received financial support from the University of Lleida (grant JADE Plus 218/2016), the Spanish Ministry of Economy, Competitiveness (MINECO, Project AGL2014-55379-P) and Consejo Nacional de Ciencia y Tecnología (CONACyT) by the scholarship assigned to Wall-Martínez HA.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that there are no conflicts of interest.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Electronic supplementary material

ESM 1

(DOCX 14 kb)

Rights and permissions

About this article

Cite this article

Wall-Martínez, H.A., Pascari, X., Ramos, A.J. et al. Frequency and levels of mycotoxins in beer from the Mexican market and exposure estimate for deoxynivalenol mycotoxins. Mycotoxin Res 35, 207–216 (2019). https://doi.org/10.1007/s12550-019-00347-x

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12550-019-00347-x