Abstract

Alluvial deposits, which are mainly sediments with high void ratios, have not completed their geological formation. Since they contain organic matter, their bearing capacity and shear strength are low, and they are included in the class of problematic soils. The damage and financial losses that occur as a result of the frequent use of such soils as subgrade soils have made the idea of stabilizing their properties indispensable. Therefore, this study aims to perform an evaluation and assessment of the role of two common and distinct additives named lime and fly ash in the stabilization of alluvial subgrades. To better understand the effects of the grain size distribution of alluvial soils, the samples were distinguished as coarse grained (CG), medium grained (MG), and fine grained (FG) with three effective particle sizes. Since the evaluation of California Bearing Ratio (CBR) is the most significant indicator of strength in subgrade soils, the effect of 2, 4, 6, and 10% lime (L) and 10, 15, and 20% fly ash (FA) on the alluvial subgrades cured in several hours were investigated and further investigations were made for the most effective type of stabilization method, named as FA stabilization. Unconfined compressive strength (UCS) experiments were also carried out to establish correlations with CBR. Through great numbers of CBR tests, it was concluded that the few lime and fly ash significantly can affect the CBR value of alluvial soils in high degrees. While stabilizing FG and MG alluvial soils with 6%L increases the CBR value, 15% of FA is needed to increased the CBR value of MG and CG soils. Although FA additive should be used more, this method needs to be examined in more depth, since it is economical, provides more strength increase compared to lime, and is not adversely affected by the grain size effect as lime. That is why, in the current study, the main relations between CBR and compaction parameters for the quick application of FA stabilization with alluvial subgrades in the field were proposed. Since the compaction test is faster and more economical than the CBR tests, the use of correlations will be an effective study output.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

The creation of an adequate road network, especially in rural areas, is vital for the socio-economic development of each country (Sezer et al. 2006; Senol et al. 2006; Göktepe et al. 2008; Ghosh and Dey 2009; Clarke et al. 2010; Wilkinson et al. 2010). On the other hand, the construction through conventional means and techniques of a broad network of roads requires heavy financial investment (Tastan et al. 2011; Azadegan et al. 2012). To meet construction requirements, qualified subgrade soil materials are required for conventional construction activities and pavement design. The assessment of subgrade soil quality in many areas indicates poor soil properties with unwanted engineering characteristics such as low bearing capacity, shear resistance, high shrinkage and swell potentials, and high sensitivity to moisture (Liu and Pemberton 2010; Amiralian 2013; Chauhan and Sharma 2014). Qualified soils are scarce or in short supply in many parts of the world. On the other hand, the rapid increase in the transportation demand has led engineers to evaluate even the local lands with poor soil properties. In case of such soils are intended to use as underlying soil during the construction of a concrete or asphalt pavement, the pavement can be easily cracked. Because of these unfavorable circumstances, often, engineers are required to use under-standard materials, industrial construction aids, and creative design methods to pursue alternative designs (Amiralian et al. 2012a; Amiralian 2013; Yorulmaz et al. 2021).

Alluvial soils are one of the commonly encountered poor soil types in the construction of roads and embankments, which contain a wide particle size range both in terms of soil type and condition. These soils are formed by the deposition of a variety of facies at the cross-section and especially along the river’s course in the river valley system. In the process of their formation, with the growing distance from the head of the river, fine material is increasingly transported and deposited by rivers, often containing substantial organic fraction admixtures (Masaoud 2015; Kumar and Archana 2017; Do et al. 2018). Therefore, alluvial deposits are loose soils that do not fully complete the development of their geology when it is compared with the others. The erratic nature of these soils causes a high void ratio, low bearing capacity, and high compressibility potential (Semerci et al. 2017; Diab et al. 2018). Thus, in the case of the alluvial soils being encountered as a subgrade material, a detailed design procedure is required. Lack of studies in the literature about the characteristics of this type of soil causes mistaken designs, thereby, economic losses and even injuries (Itakura et al. 2005; Singh 2009). That is why further instigations are needed to evaluate the alluvial soil behavior and improve the weak properties.

To ensure proper design, enhance the mechanical and chemical characteristics of the soils’ engineering efficiency, techniques for soil stabilization have been applied, such as incorporating stabilizers. Furthermore, the use of stabilizing agents in roadwork and subgrades with poor soil conditions enhance other characteristics, such as cohesion, thus contributing to the stabilization of the road or embankment. This may potentially contribute to a major decrease in the cost of road construction. For this reason, various additives such as fly ash, lime, rice husk, silica fume, or other minerals such as cement and volcanic slag have been utilized (Amiralian et al. 2012b; Mukesh and Patel 2012; Kumar and Mishra 2005; Schanz and Elsawy 2015). In particular, lime and fly ash have been used in several engineering projects such as highways, foundation bases, and embankments as an effective additive in soil stabilization owing to their binding properties. Besides, the usage of fly ash makes the stabilization cheaper, since it is a type of waste material generated from thermal power plants.

In this paper, an effort was made to enhance the undesired properties of a subgrade material, namely alluvial soil, and assess the most suitable and cost-effective stabilization method. The study includes analysis, evaluation, and assessment of the role of lime and fly ash in the stabilization of alluvial subgrades in different particle sizes and curing periods effects. To systematically achieve this goal, firstly, by preparing fine (FG), medium (MG), and coarse-grained (CG) samples, the grain size effect on engineering properties of alluvial deposits was analyzed. To determine geotechnical index properties of each size group liquid limit, plastic limit, specific gravity, wet sieve analysis, and standard compaction tests were conducted. Furtherly, utilizing CBR and UCS tests, the effect of 2, 4, 6, and 10% L and 10, 15, and 20% FA on the CBR and UCS of each size group was investigated. To examine the curing time effect on CBR of alluvial subgrades, different periods as 24, 96, and 168 h were considered. At last, the acceptable stabilization parameters for alluvial soils were specified and proposed for the road constructions through a detailed analysis of the results. For each alluvial subgrade group and stabilizer combinations, empirical correlations were proposed as a function of OMC and MDD from the obtained set of data to a quick assessment of CBR value in-situ. The paper will be a useful tool for preventing the early failure of roads in projects consisting of alluvial soils by evaluating its versatile nature and proposing a convenient stabilization method for each size group.

Background of lime and fly ash stabilization

Lime stabilization

In 1924, lime was used for the first time on modern roads when hydrated lime was applied for the stabilization of short routes (Sezer et al. 2006; Clarke et al. 2010; Amiralian 2013). Since then, lime stabilization was used in many civil engineering projects such as highways, dams, routes, airports, slopes, foundation bases, and canal linings, all within certain economic limits (Wilkinson et al. 2010; Harichane et al. 2011a, b; Amiralian 2013). The quality, simplification, and related economic factors resulted in the lime being used extensively to change the engineering properties of soft soil as a stabilizer, and it is done by using different types of lime by performing several experiments including Atterberg’s limits, compaction, CBR, UCS, and CPT (Parsons and Kneebone 2005; Liu and Pemberton 2010; Amiralian 2013). Despite the variety of studies conducted on lime stabilization, the number of studies examining the unpredicted behavior of alluvial soils stabilized with lime has remained to a limited extent.

The ability of lime to alter soil plasticity is one of the most noticeable advantages of lime as it has been stated by several scholars in the form of a decrease in the plasticity index of pure soil after stabilization (Parsons and Milburn 2003; Parsons and Kneebone 2005; Senol et al. 2006; Göktepe et al. 2008; Ghosh and Dey 2009; Clarke et al. 2010; Liu and Pemberton 2010; Wilkinson et al. 2010; Castro-Fresno et al. 2011; Seco et al. 2011; Amiralian 2013; Anggraini et al. 2014). A reduction in the plasticity index is directly related to the development of soil that is more workable and brittle (Jung and Bobet 2008). Furthermore, the plasticity index of the soil is directly related to the soil's swelling pressure and swelling potential. Lime can effectively restrict the swelling ability of soils through the chemical stabilization between the soil, lime, and water (Tastan et al. 2011; Pedarla et al. 2011; Jones and Jefferson 2012).

The chemical process between lime and soil is mainly based on the pozzolanic reactions, in which, aluminous and siliceous minerals in the soil and calcium hydroxide in the lime reacts. The main concept of these reactions relies on the development of cementitious compounds through the interchangeable nature of chemicals in the soil and lime. Since pozzolanic reactions are highly dependent on time, two main stages called immediate and long-term stages to dominate the outcomes obtained. The first stage, in other words, the immediate stage, includes the earlier phase of the reactions in which the exchange of free cations between soil and lime occurs (Sherwood 1993; Chittoori 2008; Khan et al. 2015; Firoozi et al. 2017). In cation exchange, the cations (Ca2+) in the lime replaces with the sodium and hydrogens in the soil at the exchangeable surfaces on the soil (Sherwood 1993). The interchange mechanism results in the reduction of repulsive forces in clay so that more compacted soil material with closer grains is obtained. As a result, the dispersed structure of the clay is destroyed and caused flocculation of the particles. This is the stage mainly responsible for the reduction in the plasticity of the soil and less water affinity in the soil. Furtherly, the structural transformation of the soil happens in the consequence of this stage from clayey type to more silty or sandy so that less plastic soil. These benefits are taken in hours or even days. The second and main stage can take days or even years to complete. This stage is responsible for the strength gaining process by the pozzolanic reactions. The reactions start with the increase in pH of the pore water reaches above 10.5 at which the clay particles are destroyed. At this moment, the silica and alumina in clay become free to react with the calcium in lime and make cementitious gels form (Eqs. 1 and 2).

The formed gels turn into cementitious materials in time by bonding the particles together and by behaving as the cohesion which leads strength to increase. The number of reactions depends on the number of minerals present in the soil and curing time. To boost soil strength, some scholars suggested different amounts of lime, and this may be linked to the number of clay minerals used in their soil modification tests. The availability of kaolinite, illite, and montmorillonite may help to increase the soil bearing capacity in this context (Göktepe et al. 2008). The influential parameters of the stabilization are detected from the past studies are mainly lime content, curing time, mineralogy, and engineering properties of the soil (Kassim and Chern 2004). Al-Kiki et al. (2011) increased the number of the factors related to the soil by supplementing the pore water pH, amount of free sodium, amount of organic matter, the number of silica and alumina, drainage conditions, etc. Moreover, lime stabilization can be successfully applied to fine- and medium-grained soils but there are still doubts about the coarse-grained ones. Therefore, in the current study, the effect of lime stabilization on the alluvial soils with different particle sizes such as fine-, medium-, and coarse-grained soils was evaluated.

Despite the advantages that come from lime stabilization, the situation can be reversed for some soils which contain sulfates and chloride (Puppala et al. 1999; Saussaye et al. 2015). Therefore, assessing the interaction of the lime with the different type of soils, particularly special ones like alluvial soils, become a critical point of the stabilization.

The evaluation of the success of the stabilization can be detected by using different laboratory tests, such as unconfined compressive strength (UCS), triaxial compression, and California bearing ratio (CBR). Extensive use of the CBR tests in transportation engineering and the empirical correlations obtained between this parameter and the bearing capacity of the soils over time makes the parameter a reference to be used in the studies related to stabilization. The past studies proved that the CBR of subgrade soil can be increased up to 86.85% of its initial value by stabilizing the soil with lime (Gidday and Mittal 2020). In the study, an optimum dosage of lime was inspected at about 7–9% at 7 days of curing.

Fly ash stabilization

Fly ash is one of the most plenteous and useful byproducts of power plants. This industrial gray powder includes incombustible, glass-like particles, and from thermal power plants creates residues from the combustion of powdered coal (Senol et al. 2006; Sezer et al. 2006; Amiralian et al. 2012b; Kavak and Baykal 2012). The application of fly ash as a stabilizer in the soil gives the opportunity of recycling and prevent environmental contamination. Due to the vast amount of its availability, utilizing fly ash in the soils cause an economical way of stabilization (Rifa et al. 2009; Dewangan et al. 2010; Vincent and Captain, 2011; Singhai et al. 2016). Therefore, in the current study, a sustainable stabilization method for the alluvial subgrade soils was intended to detect by fly ash contribution.

The stabilization of the soil is mainly caused by the pozzolanic reactivity of fly ash as in the case of lime. The contribution of fly ash to the strength is not only through the pozzolanic activity, but also its lime content and hydraulic properties (Kolias et al. 2005). The criterion of reactivity depends on the type of fly ash used. There are two kinds of fly ash produced in power plants such as class C and class F. Class C type fly ashes have self-cementitious property, whereas, Class F needs a cementitious activator to start pozzolanic reactions (Kumar and Sharma 2004; Arora and Aydilek 2005; Firoozi et al. 2015). The main outcomes from fly ash stabilization are the reduction in plasticity and increase in the bearing capacity, stiffness, and strength depending on the soil and fly ash-related parameters. The literature review has proven that both types of fly ashes can be effectively utilized in the subgrade soils since it causes significant increases in CBR indicating an enhancement in the strength (Qubain et al. 2000). In a study conducted by Kavak and Baykal (2012), the influence of self-cementing fly ashes for the stabilization of soft fine-grained soils was evaluated. Tests were performed on admixtures for CBR and modulus of resilient (Mr). The addition of fly ash improved the CBR and Mr of the inorganic soils dramatically. Probakar et al. (2013) studied the three different soil types and varying percentages of fly ash. The addition of fly ash decreased the dry density of the soil and the unit weight of the soil. With enhancing fly ash amount in soils, the void ratios and porosity have changed. By the addition of fly ash, the shear strength and CBR of the mixture were increased, and the increase was nonlinear. Umar et al. (2013) obtained improvement on the CBR of the soil up to 15–18% of fly ash content. Beyond these percentages of stabilizers, CBR has decreased. Based on the soil and fly ash type, the optimum content of the fly ash for gaining strength was found to be between 15 and 30% (Brooks 2009).

Materials

Alluvial soil

Considering the importance and common usage of alluvial soils as a subgrade, the proposed study was carried out to evaluate and stabilization of their weak properties. The soil samples that are used in this study were taken from Çiğli – Balatçık region (İzmir, Turkey). In Fig. 1, a geological map of the coastal part of western Anatolia has been shown and the dominant soil type of the Balatçık region is alluvial soil according to the map. The samples were immediately coated with sealed bags to protect their natural properties and they were transferred to the soil mechanics laboratory and kept in airtight boxes.

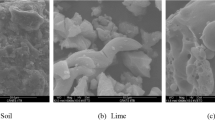

Since alluvial soils include a wide range of grain sizes in nature, in the current study, three distinct sizes of the samples were used. In this way, the engineering properties and the effect of particle size on the CBR of alluvial soils can be investigated and a general framework for the alluvial soils can be inspected. Figure 2 shows different particle sizes in alluvial soil samples prepared from these three groups of particle sizes in different combinations. Coarse (C) particle ranges between 4.75 and 2.00 mm, medium (M) particle varies between 2.00 and 0.425 mm, and fine (F) particle is below 0.425 mm. Table 1 shows the proportions of the prepared samples, respectively. Through laboratory investigations, the main index properties of each group were determined.

Thermal power plant fly ash

Different current evaluations have suggested that the use of fly ash is lower than the quantity produced, although potential use will increase (Sharma et al. 2012). Fly ash of about 500 million tons accounts for approximately 75–80% of the world’s total production, based on assessments (Fig. 3). Since the utilization of such huge amounts of byproduct would be advantageous both environmentally and economically in the projects where a large amount of stabilization material may be needed such as road projects, it was also evaluated as a stabilization method for alluvial soils in this study.

In this research, the thermal power plant fly ash used was received from Soma Power Plant, Manisa, Turkey. The maximum grain size of fly ash is 0.075 mm. The fly ash which is used in this research is shown in Fig. 4a. The chemical composition of fly ash was determined through X-ray fluorescence (XRF) analysis and results were presented as the percentage mass of each chemical in the material (Table 2). XRF provides qualitative information about the sample being measured. However, XRF is a quantitative technique. The X-rays emitted by the atoms in the sample are collected by a detector, then processed in the analysis section to create a spectrum showing the intensity points of the X-ray versus energy. The energy peak defines the element. The peak area or density is an indication of the amount of element in the sample. To classify the material, minimum conditions in Table 3 proposed by ASTM C618-12a and Manz (1999) were used. According to the composition requirements, the fly ash used in this study is considered in class C which is the product of lignite. The biggest advantage of using class C fly ash in stabilization is that an activator is not needed during stabilization due to the high lime content in it. Due to this feature of class C fly ash generally called self-cementitious material, by which, the additional budget allocated to stabilization in the projects becomes less.

Lime

Slaked lime which is the most common and easy to procure stabilizer, was also used in this study. Lime is a binder substance based on an inorganic basis obtained by evaporating the carbon dioxide in it as a result of heating limestone (calcium carbonate) at different degrees (850–1450 °C). The maximum grain size of the lime used in this study is 0.075 mm (Fig. 4b). The main chemicals of the lime which were determined by the XRF analysis are summarized in Table 4.

Methods

Index property tests

For the CG, MG, and FG sample groups, sieve analysis, specific gravity tests, standard compaction tests, and Atterberg limit tests were performed following the related ASTM standards in Table 5. On the other hand, for the stabilized soil samples, standard compaction tests and Atterberg limit tests were conducted to better correlate the values with the CBR. These laboratory tests were repeated for the samples with varying proportions of 10, 15, and 20% fly ash and 2, 4, 6, and 10% lime.

California bearing ratio test

California Bearing Ratio (CBR) is a mechanical parameter that can be related to the strength and bearing capacity of the subgrade soil in the road or pavement constructions. The parameter was first utilized by the California Division of Highways, then, it was introduced through many standards (ASTM, AASHTO, US, British) after the reliability and applicability of the method were satisfied from in situ and laboratory tests. Since the CBR has been used as a critical parameter in designing the roadworks (i.e., in assessing the thickness of the pavement systems), the evaluation of different stabilization methods in the current study was made through this parameter. CBR experiments were conducted on the soil samples at the maximum dry unit weight and optimum water content according to ASTM D2435. Firstly, tests were performed for unstabilized coarse-, medium-, and fine-grained soil samples. To examine the effect of lime on the CBR of these soils, 2, 4, 6, and 10% lime was thoroughly mixed by dry weight of soil and then experiments were performed. To examine the impact of fly ash on the CBR of these soils, 10, 15, and 20% fly ash was mixed by dry weight of soil and then tests were conducted.

The exact quantity of oven-dried (100–105 Co) soil was measured and properly mixed with water according to its optimum water content (OMC). The soil was then compacted to the maximum weight of the dry unit achieved by the Standard Proctor test. Since soaked CBR of the subgrade is usually preferred for designing flexible pavements which represents the worst scenario, soaked CBR tests were performed and molds were soaked in a water sink for 24, 96, and 168 h for curing. The samples prepared for CBR tests were labeled by using initials of influential parameters of the test as in Table 6.

Unconfined compressive strength test

The unconfined compressive strength (UCS) is the maximum axial compressive stress that a right-cylindrical sample of material can withstand under unconfined conditions—the confining stress is zero. UCS experiments were conducted on the soil samples at the maximum dry unit weight and optimum water content according to ASTM D4609. Firstly, tests were carried out for unstabilized CG, MG, and FG samples. To investigate the effect of lime on the UCS of these soils, 2, 4, 6, and 10% lime was thoroughly mixed by dry weight of soil and then tests were performed. To investigate the impact of fly ash on the UCS of these soils, 10, 15, and 20% fly ash was mixed by dry weight of soil and then tests were conducted.

The exact quantity of oven-dried (100–105 °C) soil was measured and properly mixed with water according to its optimum water content (OMC). The soil was then compacted to the maximum weight of the dry unit achieved by the Standard Proctor test. The sample was 5 cm in diameter and 10 cm in length.

Results and discussion

Index properties results

A summary of the geotechnical index results of the remolded CG, MG, and FG alluvial soil samples was presented in Table 7. The parameters in the table related to the granulometry of the samples were obtained from the grain size distribution curves illustrated in Fig. 5.

From the results, effective grain sizes confirm that the soil samples used in the study can be classified as coarse, medium, and fine. In addition, particle size coefficients illustrate that among the tested samples only CG can be classified as well-graded soil while the others not.

Since the compaction tests have a significant effect on the CBR test results, in addition to the compaction curves of the CG, MG, and FG natural (unstabilized) ones, the curves for the stabilized alluvial soils with 0, 10, 15, and 20% FA were also obtained as in Fig. 6.

Figure 6 shows that there is an enhance in the maximum dry unit weight and reduction in the optimum moisture content for 10% FA stabilized soils, then there is a clear pattern that optimum moisture content increases while maximum dry unit weight decreases by 15% and 20% FA stabilized soils. The reason for the decrease of the optimum moisture content, especially in fine soils with 10% fly ash, can be discussed as follows: the ion exchange among chemicals and fine soil reduces the density of the electrical double layer and enhances flocculation. The flocculation of solid materials means that water-additive-soil mixtures could be compacted with lower moisture content and optimum water content can be decreased. The reduction in the optimum moisture content implies that alluvial soil can be stabilized by applying fly ash to soils with low moisture content. The reduction in the maximum dry unit weight via an increased percentage of fly ash is due to the decreased specific gravity of the fly ash as opposed to alluvial soil and the instant creation of cemented products which decrease the density of the stabilized soil (Dash and Hussain 2012; Kumar et al. 2007). This is also confirmed that behavior of expansive soil stabilized with fly ash was conducted by Ghosh (2010). Through standard Proctor experiments performed on the fly ash stabilized soils it is approved that via an increase in the content of fly ash, the maximum dry weight and optimum moisture content reduced. By rising the fly ash amount to 15%, optimum water content and maximum dry unit weight decreased 7% and 4.3% respectively.

CBR tests results

Unstabilized alluvial deposits

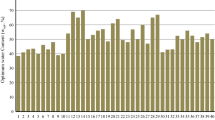

Figure 7 shows the CBR of FG, MG, and CG with different curing times. As it can be seen from Table 8, FG samples have the lowest CBR while CG specimen has the maximum. The coarser is the soil particle the higher CBR can be. In the literature, several empirical correlations were introduced to estimate CBR for different types of soils (Naveen and Santosh 2014; Rakaraddi and Gomarsi 2015; Siddhartha et al. 2015). Almost all equations derived demonstrated that CBR is dependent on the compaction properties of soil which are mainly maximum dry density (MDD) and optimum moisture content (OMC). It was proved by the equations that the soils with high MDD and low OMC exhibit more strength in CBR tests. In this study, the soils with different granulometry showed similar behavior in the literature. Coarse-grained samples exhibited higher CBRs than the fines. In addition to this, the CBRs demonstrated a different trend only in CG samples with the longest curing period.

Lime stabilized alluvial deposits

To examine the impact of lime on stabilization of alluvial deposits, 2, 4, 6, and 10% lime by dry weight of soil was mixed with CG, MG, FG alluvial soils. For curing time, 24, 96, and 168 h were considered. It is seen that lime treatment has a positive effect on the CBR results (Table 9). The maximum CBR for the FG sample was obtained in a 6% lime mixture at 168 h curing time as 27.8% which shows a significant increase in CBR. For MG samples the maximum CBR was obtained as 10.2% in 6% lime mixture at 168-h curing time. So, 6% of lime increased the CBR of the MG sample considerably. Since the CBR of the unstabilized CG sample was higher than FG and MG samples, the effect of lime on the CBR of CG samples was not as high as FG and MG samples. The maximum CBR for CG samples was 22.7% in a 2% mixture of lime (Fig. 8).

CBR test results for stabilized alluvial soil samples indicate that the application of lime can improve the CBR of FG and MG soils, whereas, this is not the general case for the CG samples. For the coarser samples, it is shown that less CBR for 10% lime stabilization than the unstabilized case was obtained. One of the most significant effects concerning the unstabilized form was obtained in FG samples. By introducing lime in the fine samples, the formation of cementitious gels is allowed over time due to the chemical reactions stated previously, soil gains strength and durability. The strength increase continues up to an optimum limit after which no chemical reactions can take place. In contrast, for CG, fewer reactions take place; however, due to the increase in fine content, less strength can be gained at low contents of the lime (Hamdani 2018). Regarding the obtained data, the curved plots such as CBR contours can be interpolated for each soil group concerning the increasing curing (IC) as in Fig. 9. The plots are indicative of the interactive nature of FG soils with lime, decreasing interaction for MG, and the worsening effect of CG. In addition, it can be seen that the optimum ratio of lime decreases with increasing grain size. This phenomenon was observed in almost all curing times.

The results are consistent with the literature studies researching this subject (Bose 2012). Noor and Uddin (2017) studied the impacts of lime stabilization on the modification of the mechanical characteristics of the cohesive soil, CBR experiments were carried out on soil samples with a normal composition and also with varying proportions of lime mixture. This can be stated that the CBR of natural composition has been achieved by 4.5%. CBRs are significantly increased up to 33% after stabilization with both 2 and 4% lime. Amadi and Okeiyi (2017) examined the use of quick and hydrated lime in the stabilization of lateritic soil, and a laboratory study was conducted to determine and compare the stabilization efficacy of various proportions of quick and hydrated lime (0, 2.5, 5, 7.5, 10%) by applying separately to regionally available lateritic soil. CBR experiment results indicate that the CBR of the natural specimen was 8 and 2% for unsoaked and soaked states, respectively. The addition of 6% hydrated lime strongly improved the CBR of the soaked sample by up to 43%.

Fly ash stabilized alluvial deposits

To examine the effect of fly ash on the stabilization of alluvial deposits, CBR experiments were performed on coarse-, medium-, and fine-grained alluvial deposits mixed with 10, 15, and 20% fly ash by dry weight of the soil. Twenty-four and 168 h were considered curing time to investigate only early and long-term stabilization for fly ash. In a general aspect, it was observed that the addition of fly ash significantly improved the CBR of FG, MG, and CG specimens. The mixture of 15% FA improved significantly the CBR of MG and CG samples. CBR of 15% mixture of FA of CG sample was determined as 41.7% which is the maximum CBR for CG specimens of this study. The maximum CBR for the MG sample is obtained as 38.3% in 15% FA admixture. 25.4% CBR was obtained in 20% of FA admixture as maximum CBR for FG sample. Figure 10 shows the comparison between the CBR of FG, MG, and CG alluvial deposits stabilized with 10, 15, and 20% fly ash in 24 and 168 h of curing time, respectively.

CBRs for FG, MG, and CG alluvial deposits stabilized with 10, 15, and 20% fly ash are listed in Table 10 and the interpolated CBR contours for fly ash stabilization are shown in Fig. 11. From these contours, it has been determined that the CBR increase continues for FG soils, while, the optimum values were achieved at 15% fly ash content for MG and CG samples. This situation indicates that a stabilizer amount should be higher for FG soils than the others. Besides this, as can be seen from the curves, fly ash, which is a more economical material than lime, provides stabilization at higher rates for all three different alluvial soil groups. Since the negative effect of lime on CG soils is not observed in the case of fly ash used, it makes this material more suitable for stabilization purposes for subgrade alluvial soils.

The findings obtained are in excellent accordance with those reported by Edil et al. (2006) and Firat et al. (2012). Edil et al. (2006) investigated the stabilization of FG soils with fly ash. The focus of this research was to assess the efficacy of self-cementing fly ash extracted from the combustion of sub-bituminous coal for FG soil stabilization at electric power plants. CBR and resilient modulus (Mr) experiments were performed on mixtures prepared with 7 soft FG soils and four fly ashes. As a result, the presence of fly ash resulted in a significant increase in CBR, and Mr. CBRs of the unstabilized soils varied between 1 and 5%. The implementation of 10% fly ash contributed in CBRs ranging from 8 to 17% and 18% fly ash contributed in CBRs ranging from 15 to 31%. Firat et al. (2012) examined the use of marble dust, fly ash, and waste sand (silt quartz) in highway sub-base filling materials. 0, 5, 10, 15, and 20% of fly ash, marble dust, and waste sand are supplemented by two types of natural soils. Experiments were run for normal compaction, permeability, and saturated CBR test. A soaked CBR test was conducted in this study to assess the soil's bearing ratio under severe situations. CBR of unstabilized soils ranged between 7 and 11%. After increasing fly ash content to 15%, the CBR value considerably improves, and it ranges between 25 and 51%.

UCS test results

The UCS test results for both unstabilized and stabilized samples have been shown in Fig. 12. In general, it was observed that the UCS value increased as the grain size increased for all samples. Khalid et al. (2015) were obtained that the UCS values increased as the sand content increased and clay content decreased. Optimum fly ash content and lime content were obtained as 15% and 4%, respectively. In addition, the UCS values of the fly ash stabilized samples were higher than the lime stabilized samples.

The correlation between OMC—MDD and CBR

As a result of the study, the relationship between compaction parameters and CBR for fly ash stabilization was investigated in more detail, due to the higher improvement property of fly ash compared to lime. Despite the vast number of empirical correlations available in the literature for the relation between CBR and compaction parameters, there is almost no relation obtained for the stabilized alluvial soils (Boltz et al. 1998; Kasim 2005; Singh 2009). Therefore, the analysis and interpretation of the results for the fly ash stabilized alluvial soils become an important part of the current study. Through the database obtained, statistical interpretations were made by plotting the relations. Among the geotechnical parameters, OMC and MDD were selected to relate CBR of stabilized samples, since CBRs are highly dependent on the compaction parameters. Figure 13(a) indicates the regression plot between CBR and OMC – MDD alluvial samples stabilized with fly ash, separately. In addition, Fig. 13(b) represents the same relation, but this time, it is generated by using the whole database. The obtained correlations are given on the graphs for the whole tested data.

While the R2 values of OMC – CBR and MDD – CBR curves are evaluated for each soil sample group, one can conclude that the soil groups with the most compatible results are FG and MG, respectively. The obtained relations for the CG soils became less significant by indicating a poor correlation. In addition to this, from the slope of the curves, it can be understood that changes in the compaction characteristics of FG soils tend to show sharper changes in the CBR. From the curves obtained by using the whole database, the equations between CBR and OMC – MDD were derived for the alluvial soil samples (Fig. 13b). The data showed that the decrease in OMC caused higher CBR for the alluvial soils, while, the situation for MDD is just the opposite. Similar relationships were also obtained in the study carried out by Singh (2009) on fine-grained alluvial soils. In addition, it was observed that this effect was only evident at low CBRs, and after a certain CBR, the OMC and MDD parameters remained independent of the CBR change. Since the highest CBRs could be obtained for CG soils, the horizontal portion of the curves belongs to that ones. This situation confirms the irrelevance of CBR of CG soils from the compaction parameters. Hence, in the case of the alluvial soil that meets the requirements of FG and MG soils, MDD & OMC becomes a significant parameter and can be correlated with CBR by giving good relation.

The correlation between UCS and CBR

Although there are many empirical correlations available in the literature for the relationship between UCS and geotechnical and mechanical, correlations between UCS and CBR are quite limited (Narendra et al. 2006; Xia 2014; Khalid et al. 2015). Therefore, the analysis and interpretation of the results for the relation between UCS and CBR become an important part of the current study. Through the database obtained, statistical interpretations were made by plotting the relations. Figure 14 indicates the regression plot between CBR and UCS for lime and fly ash stabilized alluvial samples, separately. From Fig. 14, R2 values were obtained very close 1 (0.839 ∼0.967). Equations obtained from UCS – CBR correlations for fly ash stabilized samples have been shown in Eqs. 3–5.

Equations obtained from UCS – CBR correlations for lime stabilized samples have been shown in Eqs. 6–8.

A limited number of researchers have studied the relation between UCS and CBR and have obtained different correlations. Yarbasi et al. (2007) have obtained equation as UCS = 0.2517CBR – 15.17. Saputra and Putra (2020) have obtained equation as UCS = 0.2416CBR – 1.24 and also Eme et al. (2016) have been derived the equation as CBR = -0.0113UCS + 286.35. When the correlations obtained in the literature were compared with the correlations obtained in the current study, it was observed that the UCS values in the current study were higher than the same CBR values. This is due to the correlations in the literature with unstabilized samples and the correlations in the current study with stabilized samples.

Conclusion

The stable and desired conditions for the construction of subgrades are high bearing capacity, low settlement, low void ratio, and low plasticity. Alluvial deposits are problematic soils because of their low bearing capacity, high organic matter content, high void ratio, so they do not meet the desired condition for the construction of as a subgrade, embankment material, or load-bearing soil underlying under a structure. Also, the modification of the engineering properties of alluvial soils is very important for geotechnical engineers in road construction, particularly in urban areas, as borrowing materials are becoming less and less available and very expensive for the foundation soils. The fact that alluvial soils are commonly encountered in nature and their engineering properties are insufficient under load has revealed the necessity of examining these soils and investigating their stabilization mechanisms. Therefore, in this study, the reactions of alluvial soils with different grain size distribution to lime and fly ash stabilization were investigated by comparing a significant parameter of pavements named CBR. Also to correlate the CBR results with the mechanical strength parameters, the UCS tests were conducted.

To accurately study the engineering properties, compaction properties, and CBR of composite alluvial soil samples, this research was carried out in two different stages. The first stage was to investigate the engineering index properties and compaction properties of three different grain size alluvial deposits. The second stage was to examine the effect of lime and fly ash on the CBR of FG, MG, and CG grain alluvial deposits.

The following can be inferred in conclusion:

-

1.

As was noted in several laboratory experiments, FG alluvial soil has got the minimum CBR; however, treating fine-grain alluvial soil with 6% lime improves the CBR of this soil significantly. While the increase in CBR at 6% of lime for FG samples was 27.8%, it remained about 10.2% in the case of MG samples. Interestingly, CG samples were not affected by the lime stabilization as the others owing to their insensitivity to the reactions with calcium-based stabilizers. Stabilization contours have proved that the addition of lime in high degrees can bring the situation even worse than the unstabilized case.

-

2.

CG and MG alluvial deposits have acceptable CBRs which make these grain size soils suitable for highway fillings. Treating CG and MG alluvial deposits with 6 and 4% lime improves the CBR of these soils.

-

3.

FA is more effective than lime for improving the CBR of MG and CG alluvial deposits. MG and CG samples stabilized with 15% FA were improved significantly, whereas 20% FA maximized the CBR of FG alluvial soil. CG samples were stabilized up to 41.7% of its initial CBR, and this value was found as 38.3% for the MG sample is obtained as 38.3%. The minimum degree of stabilization for FA was encountered in the case of FG soils being tested. It was determined that the CG samples that could not be cured with lime were significantly compatible with fly ash, and as a result, it was suggested to use fly ash instead of lime for stabilization as the grain size increased in alluvial soils.

-

4.

The fact that fly ash provides better results and is economical has allowed its use in alluvial soils to be examined in more detail. In the study, correlations between compaction parameters and CBRs of fly ash stabilized alluvial soils showed that OMC and MDD values were proportional to CBR to some degree. In addition, from the exponential equations obtained for alluvial soils, it has been shown that there is a negative relationship between OMC and CBR while a positive relationship is obtained between MDD and CBR. As a general state, it can be said that particle size has a significant effect on the CBR and lime stabilization method of alluvial soils. CG and MG samples have much higher CBRs than FG soils. However, when it comes to stabilization, one should pay attention to the type of additive used.

-

5.

UCS test results showed that the UCS value increased as the grain size increased for all samples. Optimum fly ash content and lime content were obtained as 15% and 4%, respectively. The UCS values of the fly ash stabilized samples were higher than the lime stabilized samples. Different correlation equations have been obtained from the relationship between UCS – CBR and these obtained correlations were almost linear.

The use of chemical stabilization as an economical and environmentally sustainable technique in geotechnical projects will continue. The financial aspects and possible environmental side effects of building projects could be minimized by understanding the key chemical components of stabilizers used to boost the geotechnical efficiency of the soil.

Data availability statement

All data, models, and code generated or used during the study appear in the published article.

References

Al-Kiki IM, Al-Atalla MA, Al-Zubaydi AH (2011) Long term strength and durability of clayey soil stabilized with lime. Eng Tech J 29(4):725–735

Amadi AA, Okeiyi A (2017) Use of quick and hydrated lime in stabilization of lateritic soil: comparative analysis of laboratory data. Int J Geo-Eng 8(3):1–13. https://doi.org/10.1186/s40703-017-0041-3

Amiralian S (2013) Study on soil stabilisation technique using lime & fly ash. Bentley, Australia. https://espace.curtin.edu.au/handle/20.500.11937/892.

Amiralian S, Chegenizadeh A, Nikraz H (2012a) Investigation on the effect of lime and fly ash on hydraulic conductivity of soil. Int J Biol Ecol Environ Sci 1(3):120–123. http://hdl.handle.net/20.500.11937/23693.

Amiralian S, Chegenizadeh A, Nikraz H (2012b) Laboratory investigation on the compaction properties of lime and fly ash composite. Proc Int Conf Civ Archit Appl. Phuket, Thailand, pp 79–83

Anggraini V, Huat BBK, Asadi A, Nahazanan H (2014) Effect of coir fibre and lime on geotechnical properties of marine clay soil. In: 7th International congress on environmental geotechnics: iceg2014, engineers, Australia. 143022.

Arora S, Aydilek AH (2005) Class F Fly-ash-amended soils as highway base materials. J Mater Civ Eng 17(6):640–649

ASTM (American Society for Testing and Materials). 2004. Standard test methods for specific gravity of soil solids by water pycnometer. ASTM D854–02. West Conshohocken, PA: ASTM.

ASTM (American Society for Testing and Materials). 2008. Standard guide for evaluating effectiveness of admixtures for soil stabilization (Withdrawn 2017). ASTM D4609–02. West Conshohocken, PA: ASTM.

ASTM (American Society for Testing and Materials). 2012a. Standard test methods for laboratory compaction characteristics of soil using standard effort (12,400 ft-lbf/ft3 (600 kN-m/m3). ASTM D698. West Conshohocken, PA: ASTM.

ASTM (American Society for Testing and Materials). 2012b. Standard test methods for liquid limit, plastic limit, and plasticity ındex of soils. ASTM D4318–10. West Conshohocken, PA: ASTM.

ASTM (American Society for Testing and Materials). 2012c. Standard test method for CBR (California Bearing Ratio) of laboratory-compacted soils. ASTM D2425/D2435M-11. West Conshohocken, PA: ASTM.

ASTM (American Society for Testing and Materials). 2012d. Standard specification for coal fly ash and raw or calcined natural pozzolan for use in concrete. ASTM C618–12a. West Conshohocken, PA: ASTM.

ASTM (American Society for Testing and Materials). 2014. Standard test methods for particle-size distribution (gradation) of soils using sieve analysis. ASTM D6913–14. West Conshohocken, PA: ASTM.

ASTM (American Society for Testing and Materials). 2017. Standard test methods for amount of material in soils finer than the no . 200 ( 75-µm ). ASTM D1140–17. West Conshohocken, PA: ASTM.

Azadegan O, Hadi Jafari S, Li J (2012) Compaction characteristics and mechanical properties of lime/cement treated granular soils. Electron J Geotech Eng 17:2275–2284. http://www.ejge.com/2012/Ppr12.191alr.pdf.

Boltz LR, Benson CH, Boutwell GP (1998) Estimating optimum water content and maximum dry unit weight for compacted clays. Journal of Geotechnical and Geoenvironmental Engineering ASCE 124(9):907–912

Bose B (2012) Geo-engineering properties of expansive soil stabilized with fly ash. Electron J Geotech Eng 17:1339–1353. http://www.ejge.com/2012/Ppr12.109alr.pdf.

Brooks MR (2009) Soil stabilization with fly ash and rice husk ash. Int J Res Rev Appl Sci 1(3):209–217

Castro-Fresno D, Movilla-Quesada D, Vega-Zamanillo Á, Calzada-Pérez M (2011) Lime stabilization of bentonite sludge from tunnel boring. Appl Clay Sci 51(3):250–257. https://doi.org/10.1016/j.clay.2010.11.028

Chauhan R, Sharma R (2014) An experimental investigation on CBR improvement of sand-flyash mix using geogrid layers. J Civ Eng 4(3):10–14. https://doi.org/10.26634/jce.4.3.3021

Chittoori BCS (2008) Clay mineralogy effects on long-term performance of chemically treated expansive clays, Doctoral dissertation, The University of Texas at Arlington.

Clarke BO, Porter NA, Symons RK, Marriott PJ, Stevenson GJ, Blackbeard JR (2010) Investigating the distribution of polybrominated diphenyl ethers through an Australian wastewater treatment plant. Sci Total Environ 408(7):1604–1611. https://doi.org/10.1016/j.scitotenv.2009.11.059

Dash SK, Hussain M (2012) Lime Stabilization of Soils: Reappraisal. J Mater Civ Eng 24(6):707–714

Degirmenci N, Okucu A, Turabi A (2007) Application of phosphogypsum in soil stabilization. Build Environ 42(9):3393–3398. https://doi.org/10.1016/j.buildenv.2006.08.010

Dewangan P, Pradhan M, Kishore N (2010) Utilisation of fly ash as a structural fill material for safe and sustainable development: need of the hour. IME J 134–139.

Diab AA, Najjar SS, Sadek S, Taha H, Jaffal H, Alahmad M (2018) Effect of compaction method on the undrained strength of fiber-reinforced clay. Soil Found 58:462–480. https://doi.org/10.1016/j.sandf.2018.02.013

Do J, Heo O, Yoon YW, Chang I (2018) Geotechnical design parameter evaluation using the alluvial plain characteristics in southeastern Iraq. Arab J Geosci 11(20):1–14. https://doi.org/10.1007/s12517-018-4019-z

Edil TB, Acosta HA, Benson CH (2006) Stabilizing soft fine-grained soils with fly ash.” J Mater Civ Eng 18.https://doi.org/10.1061/(ASCE)0899-1561(2006)18:2(283)

Eme DB, Nwofor TC, Sule S (2016) Correlation between the California Bearing Ratio (CBR) and unconfined compressive strength (UCS) of stabilized sand-cement of the Niger delta. SSRG Int J Civ Eng 3(3):7–13. https://doi.org/10.14445/23488352/IJCE-V3I3P103

Firat S, Yilmaz G, Cömert AT, Sümer M (2012) Utilization of marble dust, fly ash and waste sand (silt-quartz) in road subbase filling materials. KSCE J Civ Eng 16(7):1143–1151. https://doi.org/10.1007/s12205-012-1526-4

Firoozi AA, Taha MR, Firoozi AA, Khan TA (2015) The influence of freeze-thaw cycles on unconfined compressive strength of clay soils treated with lime. J Teknol 76(1):107–113

Firoozi AA, Firoozi AA, Baghini MS (2017) A review of physical and chemical clayey. J Civ Eng Urban 6(4):64–71

Ghosh A (2010) Compaction characteristics and bearing ratio of pond ash stabilized with lime and phosphogypsum. J Mater Civ Eng 22(4):343–351. https://doi.org/10.1061/(asce)mt.1943-5533.0000028

Ghosh A, Dey U (2009) Bearing ratio of reinforced fly ash overlying soft soil and deformation modulus of fly ash. Geotext Geomembr 27(4):313–320. https://doi.org/10.1016/j.geotexmem.2008.12.002

Gidday BG, Mittal S (2020) Improving the characteristics of dispersive subgrade soils using lime. Heliyon no.6 p.e03384.

Göktepe AB, Sezer A, Sezer GI, Ramyar K (2008) Classification of time-dependent unconfined strength of fly ash treated clay. Constr Build Mater 22(4):675–683. https://doi.org/10.1016/j.conbuildmat.2006.10.008

Hamdani DA (2018) Correlation of CBR value with particle size and compaction characteristics of cohesionless soil. Kufa J Eng 9(1):158–174. https://doi.org/10.30572/2018/KJE/090111

Harichane K, Ghrici M, Missoum H (2011a) Influence of natural pozzolana and lime additives on the temporal variation of soil compaction and shear strength. Front Earth Sci 5(2):162–169. https://doi.org/10.1007/s11707-011-0166-1

Harichane K, Ghrici M, Kenai S, Grine K (2011b) Use of natural pozzolana and lime for stabilization of cohesive soils. Geotech Geol Eng 29(5):759–769. https://doi.org/10.1007/s10706-011-9415-z

Itakura T, Airey DW, Dobrolot JYM (2005) Geotechnical characterisation of alluvial soils used to contain industrial liquid wastes. Bull of Eng Geol and Environ 64(3):273–285. https://doi.org/10.1007/s10064-004-0243-8

Jones LD, Jefferson I (2012) Expansive soils. ICE Publishing, London, pp 413–441

Jung C, Bobet A (2008). Post-Construction Evaluation of Lime-Treated Soils. https://doi.org/10.5703/1288284313443

Kasim, PFB. (2005) Estimation of soil compaction parameters based on Atterberg’s limits. Thesis (MS) Universiti Teknologi Malaysia.

Kassim KA, Chern KK (2004) Lime stabilized Malaysian cohesive soils. Malays J Civil Eng 16(1):13–23

Kavak A, Akyarli A (2007) A field application for lime stabilization. Environ Geol 51(6):987–997. https://doi.org/10.1007/s00254-006-0368-0

Kavak A, Baykal G (2012) Long-term behavior of lime-stabilized kaolinite clay. Environ Earth Sci 66(7):1943–1955. https://doi.org/10.1007/s12665-011-1419-8

Khalid U, Rehman Zia-ur, Farooq K, Muftaba H (2015) Prediction of unconfined compressive strength from index properties of soils. Sci Int (Lahore) 27(5): 4071–4075. http://www.sci-int.com/pdf/636341814172612556.pdf.

Khan TA, Taha MR, Firoozi AA, Firoozi AA (2015) Strength tests of enzyme-treated illite and black soil mixtures. In: Proceedings of the institution of civil engineers-engineering sustainability, vol. 169, no. 5. Thomas Telford Ltd, Westminster. pp 214–222

Kolias S, Kasselouri-Rigopoulou V, Karahalios A (2005) Stabilisation of clayey soils with high calcium fly ash and cement. Cem Concr Compos 27(2):301–313. https://doi.org/10.1016/j.cemconcomp.2004.02.019

Kumar PR, Archana P (2017) Experimental studies on strength characteristics of expansive soil treated with Zycobond. Imp J Int Res 3(2):979–983. https://doi.org/10.15680/IJIRSET.2017.0601101

Kumar H, Mishra MK (2005) Optimization and evaluation of fly ash composite properties for geotechnical application. Arab J Geosci 8(6):3713–3726. https://doi.org/10.1007/s12517-014-1502-z

Kumar B, Ghosh A, Ghosh A (2007) Compaction Characteristics of Pond Ash. J Mater Civ Eng 19(4):349–357. https://doi.org/10.1061/(asce)0899-1561(2007)19:4(349)

Kumar B, Sharma R (2004) Effect of fly ash on engineering properties of expansive soils. Journal of Geotech Geoenviron Eng 130(7):764. 130. https://doi.org/10.1061/(ASCE)1090-0241(2004)130:7(764).

Liu MD, Pemberton S (2010) A study of the strength of lime treated soft clays, In Proc Int Symp Exhib Geotech Geosynth Eng Challenges Oppor Clim Chang 245–251. Bangkok, Thailand.

Manz OE (1999) Coal fly ash: a retrospective and future look. Fuel 78(2):133–136. https://doi.org/10.1016/s0016-2361(98)00148-3

Masaoud AA (2015) Geotechnical evaluation of the alluvial soils for urban land management zonation in Gharbiya governorate. Egypt J Afr Earht Sci 101:360–374. https://doi.org/10.1016/j.jafrearsci.2014.10.009

Mukesh AP, Patel HS (2012) A review on the effects of stabilizing agents for stabilization of weak soil. Civ Environ Res 2(6):1–7. www.iiste.org.

Narendra BS, Sivapullah PV, Suresh S, Omkar SN (2006) Prediction of unconfined compressive strength of soft grounds using computational intelligence techniques: a comparative study. Comp Geotech 33(3):196–208. https://doi.org/10.1016/j.compgeo.2006.03.006

Naveen BS, Santosh GH (2014) Establishing relationship between CBR value and physical properties of soil. J Mech Civ Eng 11(5):26–30. https://doi.org/10.9790/1684-11512630

Noor ST, Uddin R (2017) Effect of Lime Stabilization on the Alteration of Engineering Properties of Cohesive Soil. In Proc Glob Civ Eng Conf 1257-1264.https://doi.org/10.1007/978-981-10-8016-6_88

Parsons RL, Kneebone E (2005) Field performance of fly ash stabilised subgrades. Ground Improv 9(1):33–38. https://doi.org/10.1680/grim.9.1.33.58543

Parsons R, Milburn J (2003) Engineering behavior of stabilized soils. Transp Res Rec J Transp Res Board 1837:20–29

Pedarla A, Chittoori S, Puppala A (2011) Influence of mineralogy and plasticity index on the stabilization effectiveness of expansive clays. Transp Res Rec J Transp Res Board 2212:91–99

Probakar J, Dendorkar N, Morchhale RK (2013) Influence of fly ash on strength behavior of typical soils. Const Build Mater 18(2004):263–267. https://doi.org/10.1016/j.conbuildmat.2003.11.003

Puppala AJ, Hanchanloet S, Jadeja M, Burkart B (1999) Sulfate induced heave distress: a case study. In: Proc Transport Res Board Annual Meeting Washington DC.

Qubain BS, Seksisnky EJ, Li J (2000) Incorporating subgrade lime stabilization into pavement design. Proc 79th Annual Meeting CD ROM Transport Res Board Washington DC.

Rakaraddi PG, Gomarsi V (2015) Establishing relationship between CBR with different soil properties. Int Daily J 4(2):182–188. Corpus ID: 14272428.

Rifa A, Yasufuku N, Omine K, Tsuji K (2009) Experimental study of coal ash utilization for road application on soft soil. Paper presented at the international joint symposium on geodisaster prevention and geoenvironment in Asia JSFukuoka.

Saputra NA, Putra R (2020) The correlation between CBR (California Bearing Ratio) and UCS (unconfined compression strength) laterite soils in Palangka Raya as heap material. Int Conf Environ Tech: Earth Environ Sci 469:1–8. https://doi.org/10.1088/1755-1315/469/1/012093

Saussaye L, Boutouil M, Baraud F, Leleyter L (2015) Influence of sulfate and chloride ions on the geotechnical and microstructural properties of soils treated with hydraulic binders: individual and coupling effects. Eng Geol 189:98–103

Schanz T, Elsawy M (2015) Swelling characteristics and shear strength of highly expansive clay-lime mixtures: a comparative study. Arab J Geosci 8(10):7919–7927. https://doi.org/10.1007/s12517-014-1703-5

Seco A, Ramírez F, Miqueleiz L, Garci B, Prieto E (2011) The use of non-conventional additives in Marls stabilization. Appl Clay Sci 51(4):419–423. https://doi.org/10.1016/j.clay.2010.12.032

Semerci B, Develioglu I, Pulat HF (2017) Geotechnical characterization of alluvial soil in Çiğli-Balatçık Region. Eurasian J Civ Eng Archit 2(2):44–50. https://dergipark.org.tr/tr/pub/ejcar/issue/39134/433456.

Senol A, Edil TB, Bin-Shafique MS, Acosta HA, Benson CH (2006) Soft subgrades’ stabilization by using various fly ashes. Resour Conserv Recycl 46(4):365–376. https://doi.org/10.1016/j.resconrec.2005.08.005

Sezer A, Inan G, Yilmaz HR, Ramyar K (2006) Utilization of a very high lime fly ash for improvement of Izmir clay. Build Environ 41(2):150–155. https://doi.org/10.1016/j.buildenv.2004.12.009

Sharma NK, Swain SK, Sahoo UC (2012) Stabilization of a clayey soil with fly ash and lime: a micro level investigation. Geotech Geol Eng 30(5):1197–1205. https://doi.org/10.1007/s10706-012-9532-3

Sherwood P (1993) Soil stabilization with cement and lime. Transport Research Laboratory, College Park.

Siddhartha M, Ghosh P, Das T (2015) A correlative study of different geotechnical parameters of the local soil of West Bengal with varying percentage of sand. The Int Daily J 40(184):260–266

Singh VP (2009) Alluvial soils as subgrade material: laboratory and statistical evaluation. Georisk 3(4):232–239. https://doi.org/10.1080/17499510902937440

Singhai AK, Singh SS, MP (2016) Laboratory study on soil stabilization using fly ash. vol 12.

Tastan EO, Edil TB, Benson CH, Aydilek AH (2011) Stabilization of organic soils with fly ash. J Geotech Geoenvironmental Eng 137(9):819–833. https://doi.org/10.1061/(asce)gt.1943-5606.0000502

Umar M et al (2013) Beneficial use of class-C fly ash in improving marginal lateritic soils for road construction. Electr J Geotech Eng EJGE 18:2815–2822

Vincent RD, Captain (2011) Variation in pozzolanic behaviour of fly ashes, vol. 10.

Wilkinson A, Haque A, Kodikara J, Adamson J, Christie D (2010) Improvement of problematic soils by lime slurry pressure injection: case study. J Geotech Geoenvironmental Eng 136(10):1459–1468. https://doi.org/10.1061/(asce)gt.1943-5606.0000359

Xia Z (2014) Study of correlation on unconfined compressive strength between different soil. Advan Mater Res 838–841:926–929. https://doi.org/10.4028/www.scientific.net/AMR.838-841.926

Yarbasi N, Kalkan E, Akbulut S (2007) Modification of the geotechnical properties, as influenced by freese-thaw, of granular soils with waste additives. Cold Reg Sci Tech 48(1):44–54. https://doi.org/10.1016/j.coldregions.2006.09.009

Yorulmaz A, Sivrikaya O, Uysal F (2021) Evaluation of the bearing capacity of poor subgrade soils stabilized with waste marble powder according to curing time and freeze-thaw cycles. Arab J Geoscie 14(5):1–10. https://doi.org/10.1007/s12517-021-06749-5

Acknowledgements

The authors gratefully acknowledge the financial support by the Scientific Research Project (BAP) of Izmir Katip Celebi University (2019-GAP-MÜMF-0004).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no competing interests.

Additional information

Responsible Editor: Zeynal Abiddin Erguler

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Malikzada, A., Arslan, E., Develioglu, I. et al. Determination of strength characteristics of natural and stabilized alluvial subgrades. Arab J Geosci 15, 535 (2022). https://doi.org/10.1007/s12517-022-09829-2

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s12517-022-09829-2