Abstract

In view of the problem that it is difficult to measure the gas extraction of each coal seam alone by traditional device in the process of coal seam group gas combined extraction (CSGGCE), the calculation model of the mixing gas ratio is established and solved by using mathematical method, based on the definition of isotope value in gas isotope geochemistry and the ideal gas state equation. At the same time, the field test is selected in the Fengchun Coal Mine in Songzao Mining Area of China. The spatial distribution characteristics and differences of coal seam group are obtained, and the law of the CSGGCE mixing ratio is revealed with the variation of the extraction time, according to the discrete data of the separate and combined extraction gas components and isotope values. The results show that the coal seam gas has a thermal origin and a significant mantle-derived contribution. Compared with the traditional method, the CSGGCE mixing ratio obtained based on the isotope principle is dynamic. The mixing ratio is mainly controlled by the geochemical characteristics of the gas isotope in the initial stage of extraction and affected by gas deposit difference and physical space limitation as the extraction time increases, which is more in line with the actual situation of the CSGGCE in coal mines.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

As the intensity and depth of coal mining in China increase, reports of casualties from coal mine gas accidents continue to increase as well (Jiang et al. 2010; Yuan et al. 2015). In the decade from 2007 to 2017, gas accidents accounted for 64.4% of all major accidents in coal mines, and gas accident deaths accounted for 69.7% of all major accidental deaths (Cheng et al. 2018a, b; Wang et al. 2014). Therefore, the prevention and control of gas disasters is especially important to China’s coal industry.

As the most used technical measures for gas disaster prevention in coal mines, gas extraction has been widely used in most coal mines in China (Zhou et al. 2016). Gas extraction should be the standard of sampling evaluation because it would be difficult for the coal mine personnel to bury the safety hazards in follow-up mining operations when the extraction effect does not meet the standard (Cheng et al. 2018a, b). At present, most of China’s coal mines fall into the category of coal seam group mining. Most mines layout the layer drilling combined extraction of multiple coal seam gas in the bottom plate rock lane before they conduct rock cross-cut coal uncovering or coal lane excavation to improve the utilization rate of the extraction drilling and reduce the cost of gas treatment (Jiang et al. 2018). However, due to the differences in the characteristics of different coal seam gas deposits, coal seam group gas combined extraction (CSGGCE) is a three-dimensional spatial evolution process, so it is not possible to measure the actual gas drainage volume of each coal seam alone for a mixed coal seam gas using the existing single coal seam gas extraction measurement methods. It is also difficult to determine whether the gas extraction effect of each coal seam is up to the standard by calculating the residual gas content, the desorbed gas content, and the gas extraction rate of each coal seam. Thus, finding a way to quantify the CSGGCE is a key scientific problem that scholars all over the world are eager to solve.

The geochemical characteristics of stable carbon isotopes are commonly used to identify different sources of oil and gas, study the formation environment of oil and gas (Ju et al. 2014; Dai et al. 2009), and compare the deposit characteristics of coal seams and coal seam gas (Srivastava and Agnihotri 2013). One study found that the carbon isotopes of coal seam gas in German coal mines are proto zone (Teichmuller 1971). The range of carbon isotopes in different coal seams in the Huainan coalfields varies from 4−1 coal seam syllables to 11−2 coal seam syllables (Sun et al. 2013). The characteristics of the coal seam methane carbon isotopes in the Huaibei coalfields are typical of secondary biological cause gas, and the characteristics of the carbon dioxide carbon isotopes are typical of coal heat solution (Xu et al. 2017). The carbon isotope values of the coal seam gas in the Qin Shui Basin increase with increasing burial depth (Li et al. 2014a, b). There are also differences in the methane hydrogen isotopes, which are related to the positive correlation between the methane’s isotopes and the burial depth of the 3# coal seam. Moreover, the gas content and methane concentration of the Shanxi coal seam are generally higher than that of the Taiyuan coal seam (Meng et al. 2014, 2015). The methane carbon isotopes on the eastern edge of the Ordos Basin increase with increasing burial depth, forming a downward band of isotope fractionation (Li et al. 2014a, b). The methane carbon isotopes of the deep residual gas in the Jincheng region are heavy, while the methane carbon isotopes of the shallow coal seam gas are lighter (Duan et al. 2007). There is a primary band-transition zone between the methane carbon isotopes and the burial depth of the different coal seam gases (Duan et al. 2014; Qin et al. 2000). The above study found that there was a “vertical zone” between the coal seam methane carbon isotope and the burial depth, and there were significant differences in the methane carbon isotope values of the single and mixed gas in different coal seams.

The Qin Shui Basin mining area realized the quantitative analysis of the sources of coal seam gas in the mining area and carried out engineering applications (Zhou et al. 2018). The Huainan mining area tested the value of a single and multiple coal seam mixed gas carbon isotopes and used mathematical methods to determine the source of gas on the mine’s recovery work surface (Gao et al. 2018). The above study discussed the geological indication significance of the gas origin type and carbon isotope in coal mine and the sources of coal seam gas in the coal mine recovery work surface mining area, which provided an important theoretical basis for the analysis of coal seam gas source and made great contribution to further perfecting the prediction theory of coal seam gas inflow.

The above research provided a new research idea for the stratification of the CSGGCE using the isotopic geochemical features of the gas. In this study, the coal seam group composed of the M6-3, M7-2, M8, and M11 coal seams in the Fengchun coal mine was studied. The spatial distribution was obtained by testing and analyzing the gas component contents and isotopic compositions of individual and combined extractions. A layered quantitative model for the CSGGCE was established using the mathematical calculation method, based on the isotopic geochemical characteristics. The proportion of each coal seam’s gas sources in the combined extraction mixing gas was determined, and a theoretical basis was provided for the evaluation of the standard of the CSGGCE effect in coal mines.

Model development and methods

Isotope value definition

Gas isotope geochemistry is mainly used to study the abundance of and variation in stable isotopes in gas (Tao 2015). Gas is defined as a mixture of hydrocarbons (CH4), non-hydrocarbons (CO2), and measuring gases (He). The gas is mainly included stable isotopes of carbon (CH4 and CO2) and rare gas isotopes of helium (He).

Carbon has two stable isotopes, 12C and 13C. Carbon isotope values are defined by Eqs. (1), (2), (3), (4). The standard sample is used PDB (Pee Dee Belemnite, a fossil of Cretaceous marine life in South Carolina, USA) (Zhang and Tao 2000).

The ideal gas state equation that describes the macro physical behavior of the ideal gas is defined by Eq. (5) (Gao 1997). Under the same pressure and temperature conditions, the volume of the gas and the amount of substance are related by Eqs. (6), (7), (8).

Model construction

Gas is regarded as an ideal gas at room temperature and normal pressure, and it is considered that there is no chemical reaction between the gas components after gas mixing. The relative abundance ratio and carbon isotope value of the mixed gas δ13Cmix can be expressed by Eqs. (9), (10), (11), (12). The percentage of gas for each group, in mixed gas, can be expressed by Eqs. (13), (14). Since the change of 12C relative abundance is \({x}_{{12}_{C}}=0.98853\sim 0.99037\approx 1\) (Zhang and Tao 2000), the Eq. (15) can be obtained from the Eqs. (12), (13), (14).

Similarly, helium has two stable isotopes, 3He and 4He, and helium isotope values are defined by a ratio of 3He4 He. The change of 4He relative abundance is \({x}_{{4}_{HE}}=0.999959\sim 1\approx 1\) (Zhang and Tao 2000). The Eq. (15) is derived from the definition of the carbon isotope value, so it is also possible to model the calculation of the mixing gas ratio according to the definition of the helium isotope value.

Test instruments and standards

The test instruments for component content and isotope values are shown in Fig. 1.

Noblesse

The CH4 and CO2 component contents were tested in accordance with National Standard of the People’s Republic of China. An Agilent 6890 N gas chromatograph was used with an SGE-60 column (50 mm × 0.25 mm × 0.25 mm). Each sample was tested 3 times and the average was taken as the content of each gas component. The CH4 and CO2 stable carbon isotope values were tested in accordance with Oil and Gas Industry Standard of the People’s Republic of China. A Delta Plus XP isotope-proportional mass spectrometer was used in conjunction with a GC-PAL liquid autosampler. The accuracy of the various sample analyses was assessed using laboratory working standards. The standard sample repeated analysis error was 0.2‰ (PDB). Each sample was tested 3 times, and the average was taken as the carbon isotope value of each gas component.

The instrument used to analyze the He component content and the rare gas isotope value was a Noblesse rare gas isotope mass spectrometer produced by NU Instruments in the UK (Wang et al. 2013). Based on the air standard of Lanzhou, Gansu Province, He was divided by low temperature pump, activated carbon furnace and liquid nitrogen, and then sent to a rare gas isotope mass spectrometer, measured the experimental value of 3He/4He isotopes in air samples. And compared with the internationally recognized values of 3He/4He isotopes in the air, the relative deviation and correction coefficients were obtained. Using the same analysis method and process as the air sample, the 3He/4He isotope experimental value of the gas sample was obtained, the experimental value is corrected by correction coefficient, and the actual value of 3He/4He isotope of the gas sample was obtained.

Methods for model parameters

For m-group gas, each group gas may obtain several discrete data on component content and isotope values in the test area, which are processed using interpolation and mean methods respectively to obtain calculated values that meet the needs of the mixing gas ratio calculation model.

The interpolation method is based on the relative coordinate origin O (0,0) and the relative coordinate (x, y) assumed in the test area, using the Kriging interpolation method, based on the theory of regionalized variables, with the variation function as the main tool, in ensuring that the estimate meets the non-biased and minimum variance conditions. Under the premise of using the gas component ratio and isotope value of several known points to obtain an estimate, the corresponding gas component content and isotope contour graph are plotted, and then according to the relative coordinates of the points sought in the test area, the gas component content and isotope approximation value of the desired point are obtained on the contour graph.

The mean method is based on several discrete data of the known gas component content and isotope value in the test area, the average of all discrete data is averaged, and the average value obtained in the test area is used as an approximation.

The solution method of the model

Based on the calculated values, the model created by Eq. (16) can be converted into a non-homogenous linear equation, with the construction coefficients A, x, and b making \(\mathbf{A}\mathbf{x}=\mathbf{b}\), build a broad matrix \(\overline{\mathbf{A} }=\left(\left.\mathbf{A}\right|\mathbf{b}\right)\) based on Eqs. (17), (18).

The broad matrix \(\overline{\mathbf{A} }\) is solved by using the Gaussian method commonly used in linear algebra, the primary transformation of the line is transformed into a step-by-line, the equation system is solved with the original equation, and the proportion of gas in each group in the mixed gas is solved. For \(\mathbf{A}\mathbf{x}=\mathbf{b}\) matrix operations, the construction matrix A and b can also be obtained by editing code from the MATLAB software, and the coefficient matrix x is obtained by dividing \(\mathbf{x}=\mathbf{A}\backslash \mathbf{b}\), which in turn obtains the proportion of the gas in each group of mixed gas. Since a non-homogenous linear equation can solve up to four unknowns, the model created by the Eq. (16) is suitable for the mixing gas ratio calculation of \(m\le 4\) group.

Field experimentation

Coal mine geology and conditions

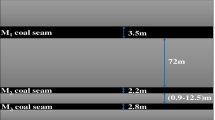

The Fengchun coal mine is in the Songzao mining area in southwestern China. The average inclination of the M6-3, M7-2, M8, and M11 coal seams in the mine is 48°, and the original gas content is much larger than 8 m3/t. The basic parameters of the coal seams are shown in Table 1.

To prevent gas disaster accidents, it is necessary to implement technical measures of protective layer mining and gas extraction (Cheng et al. 2018a, b). To enter the M6-3 coal seam, the M11, M8, M7-2, and M6-3 coal seams must be removed one by one using rock cross-cut coal formation measures. It is necessary to drill through the construction layer before the 7-m drop distance from the M11 coal seam and conduct coal seam gas combined extraction of all the coal seams.

Scheme design

The test area was selected the northern 2 mining area in the Fengchun coal mine. For a coordinate origin O (0,0), the horizontal coordinate x represents the horizontal direction (control range of 0 to 1400 m), and the vertical coordinate y represents the vertical direction (control range of 0 to 200 m). The sampling points of the gas samples in the testing area are shown in Fig. 2.

The gas samples of test group from the M6-3, M7-2, M8, and M11 coal seams were collected using sub-layer drilling (Φ42 mm and Φ94 mm), of which 32 samples were collected to test the conventional component content and carbon isotope values, and 8 samples were collected to test the rare gas components and isotope values. The CSGGCE samples of test group were collected using perforated drilling (Φ75 mm), of which 8 samples were collected to test the conventional component content and carbon isotope values, and 8 samples we collected to test the rare gas components and isotope values.

The test site of comparison group was selected at the cross roadway 300N2, using 16 (4 × 4) perforated drilling (Φ75 mm) combined extraction of gas, and all parameters measured negative pressure, velocity pressure, concentration, and so on each time every 10 days, thus calculating the extraction purity of all drilling. The sampling parameters are shown in Table 2 and Table 3.

Results and discussion

Law of the component contents and isotope distributions

By counting a total of 40 sets of discrete gas components and isotope values for a single coal seam in the Fengchun coal mine, a box diagram is drawn as shown in Fig. 3 and Fig. 4. On these plots, the upper and lower bounds of the box represent 75% and 25% of the data, respectively; the centerline of the box represents the average value of the data; the upper and lower vertical line boundaries of the box represent the maximum and minimum values of the data, respectively; and the scattered points outside the vertical line boundaries of the box represent the discrete values.

As can be seen from Fig. 3, the gas component contents of the different coal seams have significantly different characteristics. The CH4 component is the main component of the gas, with contents of 50% to 100%. From the M6-3 coal seam to the M11 coal seam, the CH4 content gradually decreased. The CO2 component is the secondary component of the gas, with contents of 0.4% to 4%. Although the average CO2 content of each coal seam is not high, it gradually decreases from the M7-2 coal seam to the M11 coal seam, and the CO2 content of the M6-3 coal seam is smaller than those of the other coal seams. The He component is the trace component of the gas, with contents of 2 to 4 ppm, and the He content of M7-2 coal seam is smaller than those of the other coal seams.

As can be seen from the Fig. 4, the CH4 carbon isotopes of the gas range from − 43 to -24‰, and the CO2 carbon isotopes of the gas range from − 20 to − 10‰. The gas has a thermal origin when the CO2 carbon isotopes are in the range of − 26 to − 5‰ and the CH4 carbon isotopes are greater than − 55‰ (Xu et al. 2017). Thus, the gas in the Fengchun coal mine has a thermal origin. Moreover, the 3He/4He ratio of the gas ranges from 1.5 × 10−6 to 2.5 × 10−6, which is standardized using the ratio of the atmosphere (Ra = 1.4 × 10−6). The R/Ra ratio of the gas ranges from 1.1 to 1.8 (R/Ra > 1), so the gas in the Fengchun coal mine has a significant source contribution.

Change law of the CSGGCE mixing ratio

A total of 16 group component content and isotope values of the CSGGCE are shown in Table 4.

According to the total of 40 sets of discrete data of gas component content and isotope values of a single coal seam in Fengchun Coal Mine, the data gridding using the Kriging interpolation method in Surfer 8.0 is obtained to obtain the regular mesh file, and then the contour chart is drawn separately, horizontal x intercept range is 650 to 950 m and vertically y intercept range is 0 to 200 m.

The contour charts based on relative coordinates are shown in Fig. 5, Fig. 6, and Fig. 7.

The gas component content and isotope values calculated by interpolation and mean method are shown in Table 5.

The component content and isotope values of the CSGGCE and each coal seam gas were replaced into the calculation model and solved, and the change law of the CSGGCE mixing ratio with the extraction time was shown in Fig. 8.

As can be seen from Fig. 8, for extraction times of 0 to 30 days, the CSGGCE of the m7 drilling was mainly from the M6-3 coal seam (40.16 to 56.79%), followed by the M7-2 and M8 coal seams (19.2 to 28.04% and 19.68 to 29.55%, respectively), and a small amount came from the M11 coal seam (2.26 to 4.38%). The mixing ratio of the M6-3 coal seam decreased significantly with increasing extraction time, whereas the mixing ratios of the M7-2 and M8 coal seams only increased slightly with increasing extraction time. Although the increases were basically the same, the mixing ratio of the M7-2 and M8 coal seams was less than the mixing ratio of the M6-3 coal seam, and the mixing ratio of the M11 coal seam remained basically unchanged.

For extraction times of 0 to 30 days, the CSGGCE of the m11 drilling was mainly from the M6-3 coal seam (22.39 to 61.38%), followed by the M7-2 and M8 coal seams (8.86 to 23.37% and 23.22 to 43.28%, respectively), and a small amount was from the M11 coal seam (6.54 to 10.95%). The mixing ratio of the M6-3 coal seam decreased significantly with increasing extraction time, whereas the mixing ratios of the M7-2 and M8 coal seams increased significantly with increasing extraction time. When the amount of increase was different, the mixing ratio of the M8 coal seam began to dominate. After an extraction time of 20 days, the mixing ratios of the M7-2 and M8 coal seams was comparable to that of the M6-3 coal seam, while the mixing ratio of the M11 coal seam remained basically unchanged.

Based on change in the mixing ratio of each coal seam in the m11 drilling, it can be inferred that the mixing ratios of the M7-2 and M8 coal seam in the m7 drilling, for a certain time node greater than 30 days, will exceed the mixing ratio of the M6-3 coal seam and while the mixing ratio of the M8 coal seam will dominate.

During the perforated extraction drilling through the M11, M8, M7-2, and M6-3 coal seam in the construction process, under the traction of the negative pressure at the bottom of the hole, the cylindrical exposure surface formed by the drilling in each coal seam initiate the gas absorption-seepage-diffusion process, at which time the isotopic geochemical characteristics of each coal seam’s gas determine the gas mixing ratio. As the extraction time increases, the gradual release of gas leads to the transfer of the impact range to the depth of the coal seam, significantly decreasing the coal seam solidification degree of the drill hole’s wall. Thus, small coal particles leave the coal seam body under the action of negative pressure traction, transfer from the M6-3 coal seam to the M11 coal seam and occupy the large drilling volume space. At this time, each coal seam gas’s isotopic geochemical characteristics, conservation differences, and physical space limitations will jointly determine the gas mix ratio.

Since parameters like the average thickness (3.07 m) and the original gas content (21.91 m3/t) of the M8 coal seam are much larger than those of the other three coal seams, we believe that as the extraction time increases, the M8 coal seam’s gas will dominate the CSGGCE.

Comparison of the CSGGCE mixing ratio

The process of calculating the CSGGCE ratio using the traditional methods is shown in Fig. 9.

For the comparison group of cross roadways 300N2, the seam length, original gas content, and bulk density of each coal seam were selected according to Table 1, and the total coal seam group (including surrounding rock) gas in the range of extraction was calculated; the CSGGCE rate in different extraction time was shown in Table 6.

As can be seen from the Table 6, within the scope of the extraction impact of the total reserves of the coal seam group’s (including the surrounding rock) gas, the CSGGCE rate and the total amount of the CSGGCE exhibit the same substantial increase. By assuming that the CSGGCE rate is equal to the coal seam gas extraction rate, the amount of gas extraction and the CSGGCE mixing ratio were obtained from each coal seam.

The contrast of gas mixing ratio between the conventional and isotope methods is shown in Fig. 10.

As can be seen from Fig. 10, the CSGGCE mixing ratio obtained by the traditional method was fixed, while the CSGGCE mixing ratio obtained by the isotope method was dynamically changing.

The M6-3 coal seam’s mixing ratio (22.39 to 61.38%) decreased with increasing extraction time and gradually decreased to the traditional calculation value (11.94%). The M7-2 coal seam’s average mixing ratio (19.44%) is 31.48% higher than the traditional calculation value (13.32%). The M8 coal seam’s mixing ratio (19.68 to 43.28%) increased with increasing extraction time, and it gradually increased until it was closer to the traditional calculation value (64.96%). And the M11 coal seam’s average mixing ratio (6.03%) is 38.34% lower than the traditional calculation value (9.78%).

At present, the traditional method is mainly based on the assumption that the CSGGCE rate is equal to the gas extraction rate of each coal seam. Coal seams deposited in different geological ages are regarded as having a similar nature within the combination. However, when coal seam and gas parameters such as the seam length, extraction radius, original gas content, and unit weight are considered, the different depositional conditions of each coal bed will cause the structure and permeability of the coal body’s pores to differ, and the mixing ratio calculated using the theoretical hypothesis will not correspond to the actual situation of the CSGGCE.

The isotopic method was used to obtain the spatial distribution characteristics of the coal seam group through testing and analysis of the component contents and isotope values of individual coal seam extractions and the CSGGCE, which can achieve accurate dynamic analysis of the coal seam mixing ratio. Compared to those of the traditional method, the results of the isotope method are more in line with the actual situation of the CSGGCE in the coal mine. Therefore, determining a way to verify the conclusion of the isotope method and to effectively guide the coal seam gas extraction standard evaluation is a subject that requires further study.

Application of the method in other engineering projects

Based on the research results of the Fengchun Coal Mine in Songzao Mining Area, this method had been applied to the Xiaotun coal mine in Guizhou Province, China.

The rock roadway was arranged in the coal seam floor, and the perforated drilling of the rock roadway was constructed to jointly extract 6u, 6 m, and 6 l coal seam gas in Xiaotun coal mine. The basic parameters of the coal seams were showed in Table 7.

The experimental scheme designed two groups of layered measurement and isotope, of which four groups of drilling were arranged in the layered measurement group, and the gas flow was determined separately by each group of drilling. The carbon isotope group selected representative drilling to collect 6 l, 6 m, 6u coal seams and combined gas extraction samples. Drilling parameters were shown in Table 8.

Through sampling test, it was found that the carbon isotope values of 6 upper, 6 middle, and 6 lower coal seam gas also differ significantly in Xiaotun coal mine. The distribution of methane carbon isotope values was showed in Fig. 11.

The mean results of coal seam gas isotopes were replaced with the calculation model, the gas mixing ratio was calculated, and then the calculation results of the isotope method were compared with that of the layered measurement method in Xiaotun coal mine, as showed in Fig. 12.

As can be seen from Fig. 12, the results of these two methods are basically the same, and it also shows that the universality of isotope method can be proved wholly.

Conclusions

Based on the definition of carbon isotope, combined with the calculation model of CSGGCE mixing ratio, the coal seam gas mixing ratio of M6-3, M7-2, M8, and M11 coal seams in Fengchun coal mine was obtained and compared with the traditional calculation results, the conclusions are drawn as follows:

-

1)The calculation model of the mixing gas ratio is established and solved by using mathematical calculation method, based on the definition of isotope value in gas isotope geochemistry and the ideal gas state equation.

-

2)The spatial distribution characteristics and differences of coal seam group were obtained, according to the discrete data of the separate and combined extraction gas components and isotope values, it shows that the coal seam gas in the Fengchun coal mine has a thermal origin and a significant mantle-derived contribution.

-

3)Compared to the traditional method, the mixing ratio, obtained using the isotope method, was dynamic, it was mainly controlled by the gas isotopic geochemical characteristics at the beginning of the extraction, as the extraction time increased, it was also affected by the combined effects of the gas deposit differences and the physical space limitations. The calculation results of the isotope method are more in line with the actual situation of the CSGGCE in coal mine.

Abbreviations

- K :

-

Relative abundance ratio, %

- x :

-

Relative abundance (mole fractions)

- n :

-

Amount of substance, mol

- p :

-

Pressure, Pa

- V :

-

Volume, m3

- T :

-

Thermodynamic temperature, K

- R :

-

Ideal gas constant

- w :

-

Component content, %

- a :

-

Proportion,

- δ :

-

Isotope value,

- sta :

-

Standard sample

- tot :

-

Total substances

- mix :

-

m-Group mixed gas

- i :

-

i-Group gas

References

Cheng L, Ge ZL, Chen JF, Ding H, Zou LS, Li K (2018a) A sequential approach for integrated coal and gas mining of closely-spaced outburst coal seams results from a case study including mine safety improvements and greenhouse gas reductions. Energy 11:3023. https://doi.org/10.3390/en11113023

Cheng L, Ge ZL, Xia BW, Li Q, Tang JR, Cheng YG, Zuo SJ (2018b) Research on hydraulic technology for seam permeability enhancement in underground coal mines in China. Energies 11:427. https://doi.org/10.3390/en11020427

Dai JX, Ni YY, Zou CN, Tao SZ, Hu GY, Hu AP, Yang C, Tao XW (2009) Carbon isotope features of alkane gases in the coal measures of the Xujiahe fomation in the Sichuan basin and their significance to gas-source correlation. Oil Gas Geol 30:519–529. https://doi.org/10.11743/ogg20090501

Duan LJ, Tang SH, Li HL, Li GZ, Wang B (2007) Carbon isotope characteristics and its origin of coalbed methane in Jincheng area. J China Coal Soc 32:1142–1146. https://doi.org/10.3321/j.issn:0253-9993.2007.11.005

Duan Y, Zhao Y, Cao XX, Xu L (2014) Carbon isotopic evolution and dynamic characteristics of pyrolysis methane. J China Univ Min Technol 43:64–71. https://doi.org/10.13247/j.cnki.jcumt.000003

Gao XZ (1997) Volume evaluation of the gas mixed with other gases using carbon isotopic compositions. Acta Sedimentol Sin 15:63–65 (in Chinese)

Gao H, Yang HW, Ci X (2018) Gas emission composition based on carbon-hydrogen isotope analysis technology. Safety Coal mines 49:16–19. https://doi.org/10.13347/j.cnki.mkaq.2018.11.004

Jiang B, Sun ZQ, Liu MQ, Jin HG, Zhang XL (2010) China’s energy development strategy under the low-carbon economy. Energy 35:4257–4264. https://doi.org/10.1016/j.energy.2009.12.040

Jiang XQ, Fan SW, Cheng ZH, Chen L, Li JP, Hou SY, Li QY (2018) Three region linkage comprehensive gas control model based on ground and underground gas joint drainage. Coal Sci Technol 46:107–113. https://doi.org/10.13199/j.cnki.cst.2018.06.018

Ju YW, Li QG, Yan ZF, Sun Y, Bao Y (2014) Origin types of CBM and their geochemical research progress. J China Coal Soc 39:806–815. https://doi.org/10.13225/j.cnki.jccs.2014.0086

Li JJ, Bai PK, Mao HP, Han WM, Wang XB, Li J, Zhang JL (2014) Analysis of geochemistry characteristics and its origin of CBM in Zhengzhuang and Hudi blocks. J China Coal Soc 39:1802–1811. https://doi.org/10.13225/j.cnki.jccs.2014.8004

Li Y, Tang DZ, Fang Y, Xu H, Meng YJ (2014b) Distribution of stable carbon isotope in coal bed methane from the east margin of Ordos basin. Sci China Earth Sci 44:1740–1747. https://doi.org/10.1007/s11430-014-4900-x

Meng ZP, Zhang JX, Liu H, Liu SS (2014) Relationship between the methane carbon isotope and gas-bearing properties of coal reservoir. J China Coal Soc 39:1683–1690. https://doi.org/10.13225/j.cnki.jccs.2014.9031

Meng SZ, Zhang WZ, Mo RH, Zhang H (2015) Difference characteristics in gas-bearing between multiple coal seams and coalbed methane accumulation models in Liulin Area. Coal Sci Technol 43(49–52):57. https://doi.org/10.13199/j.cnki.cst.2015.02.011

Qin Y, Tang XY, Ye JP, Jiao SH (2000) Characteristics and origins of stable carbon isotope in coalbed methane of China. J China Univ Min Technol 29:113–119. https://doi.org/10.3321/j.issn:1000-1964.2000.02.001

Srivastava AK, Agnihotri D (2013) Coal seam correlation of an Indian Gondwana coalfield: a palaeobotanical perspective. Int J Coal Geol 113:88–96. https://doi.org/10.1016/j.coal.2012.06.009

Sun XH, Chen J, Wu D, Liu GJ (2013) Coal seam stable organic carbon isotope distribution characteristics in Zhangji coalmine, Huainan coalfield. Coal Geol China 25:7–9. https://doi.org/10.3969/j.issn.1674-1803.2013.04.02

Tao MX (2015) Preliminary study of geochemistry of coal seam gas isotopes in China. Acta Geol Sinica 89:185–186 (in Chinese)

Teichmuller M (1971) Anwendung kohlenpetrographischer Methoden bei der Erdol-und Erdgasprospektion. Erdol Kohle 24:69–76

Wang XB, Li ZS, Li J, Wang DL, Chen JF, Xie ZY, Sun ML, Wang YF, Li J, Wang R (2013) Techniques for total composition and isotope analyses of noble gases. Acta Petrolei Sinica 34:70–77. https://doi.org/10.7623/syxb2013S1008

Wang L, Cheng YP, Liu HY (2014) An analysis of fatal gas accidents in Chinese coal mines. Saf Sci 62:107–113. https://doi.org/10.1016/j.ssci.2013.08.010

Xu C, Chen BY, Wu D, Ding DS, Xia YY, Liu GJ (2017) Distribution characteristics of isotope carbon and its geological origin in coal gas carbon of Qidong coal mine, Huaibei coalfield. Coal Geol Explor 45:54–58. https://doi.org/10.3969/j.issn.1001-1986.2017.03.010

Yuan L, Lin BQ, Yang W (2015) Research progress and development direction of gas control with mine hydraulic technology in China coal mine. Coal Sci Technol 43:45–49. https://doi.org/10.13199/j.cnki.cst.2015.01.011

Zhang JB, Tao MX (2000) Geological significances of coal bed methane carbon isotope in coal bed methane exploration. Acta Sedimentol Sinica 18:611–614. https://doi.org/10.14027/j.cnki.cjxb.2000.04.023

Zhou FB, Xia TQ, Wang XX, Zhang YE, Sun YN, Liu JS (2016) Recent developments in coal mine methane extraction and utilization in China: a review. J Nat Gas Sci Eng 31:437–458. https://doi.org/10.1016/j.jngse.2016.03.027

Zhou W, Yuan L, Zhang GL, Du HL, Xue S, He GH, Han YC (2018) A new method for determining the individual sources of goaf gas emissions: a case study in Sihe Coal Mine. J China Coal Soc 43:1016–1023. https://doi.org/10.13225/j.cnki.jccs.2017.1136

Acknowledgements

The authors wish to thank the reviewers for careful and constructive suggestions. The authors also wish to thank LetPub (www.letpub.com) for its linguistic assistance during the preparation of this manuscript.

Funding

This research was funded by the National Natural Science Foundation of China (NSFC) (Grant No. 51774234 and No. 51974358), the Natural Science Foundation of Chongqing, China (Grant No. cstc2020jcyj-msxmX1013), and the Science and Technology Innovation and Venture Capital Special Projects of TIANDI Science Technology Co. Ltd (Grant No. 2019-TD-QN032).

Author information

Authors and Affiliations

Corresponding author

Additional information

Responsible Editor: Domenico M. Doronzo

Rights and permissions

About this article

Cite this article

Zhang, T., Wu, J., Ding, H. et al. Isotope geochemical features and layered quantitative method of coal seam group gas combined extraction. Arab J Geosci 14, 2718 (2021). https://doi.org/10.1007/s12517-021-09122-8

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s12517-021-09122-8